Shearing-force increase and filtrate loss reduction agent for drilling fluid and preparation method thereof

A technology of fluid loss reducer and drilling fluid, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of drilling fluid maintenance difficulties, achieve high plastic viscosity and yield value, and improve the effect of apparent viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

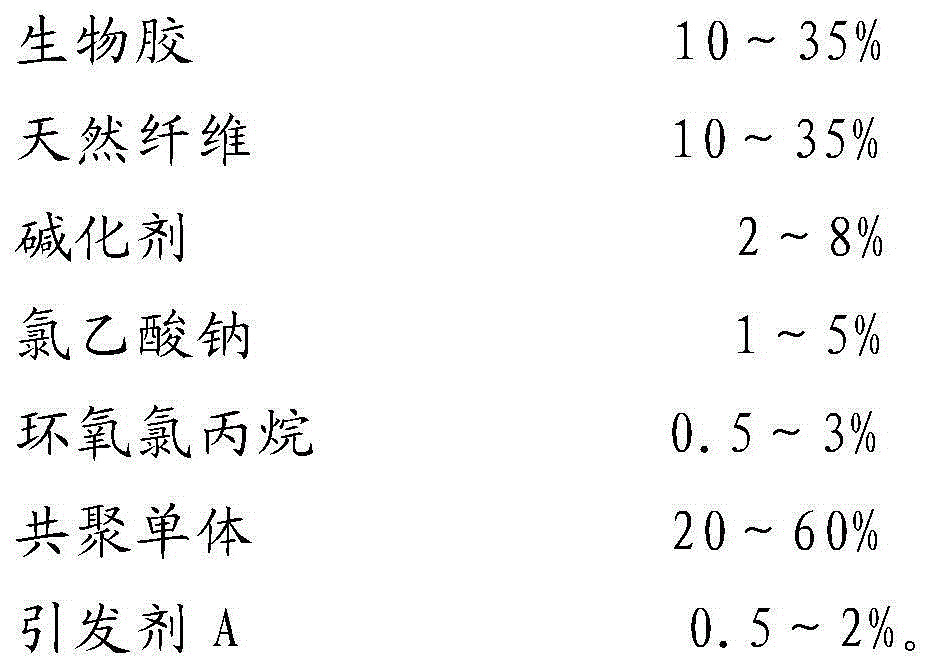

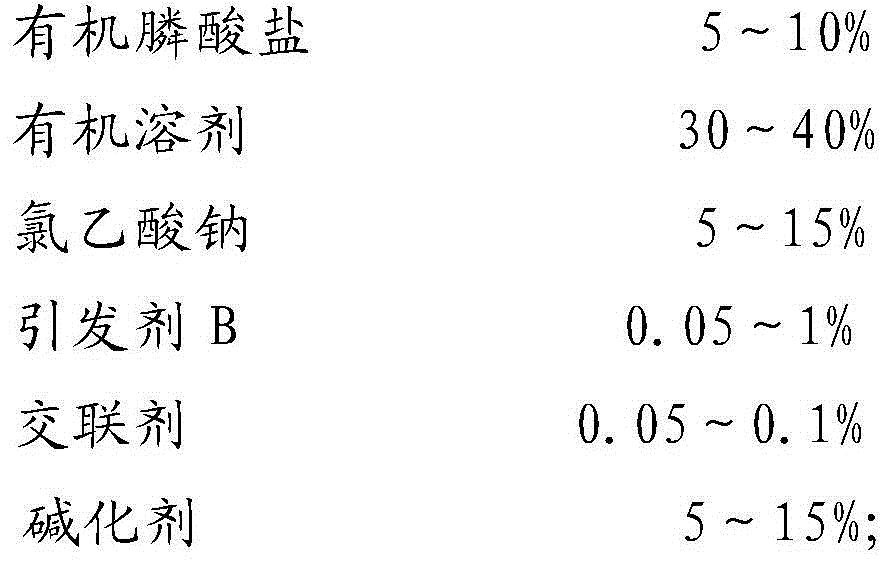

Method used

Image

Examples

Embodiment 1

[0039] This example is used to illustrate the preparation method of crosslinked starch in the present invention.

[0040]Add 100Kg of cornstarch and 30Kg of alcohol (85% v / v) into reactor R2, and add 30wt% sodium salicylate phosphonate aqueous solution made by dissolving 6Kg of sodium salicylate phosphate in water into reactor R2 In, the solution prepared by dissolving 0.3Kg sodium dihydrogen phosphate in 1.5Kg water and the solution prepared by dissolving 1.8Kg sodium monohydrogen phosphate in 9Kg water are mixed to obtain a buffer solution (pH is 7-9), and the buffer solution is added to In the reactor R2, after stirring evenly, heat up rapidly, and keep the temperature at about 50°C for 30 minutes; slowly add 50wt% aqueous sodium hydroxide solution made of 8Kg of sodium hydroxide solution into the reactor R2, and keep the temperature at 70°C, after fully stirring for 20 minutes, make 10Kg sodium chloroacetate into a 30wt% sodium chloroacetate aqueous solution, and add it to...

Embodiment 2

[0042] This example is used to illustrate the preparation method of the cutting fluid loss control agent for drilling fluid provided by the present invention.

[0043] Weigh 10Kg of guar gum, 8Kg of xanthan gum and 10Kg of cotton fiber respectively, and add them to the reaction kettle R1; weigh 3Kg of sodium hydroxide to prepare an aqueous solution with a mass fraction of 30%, add it to the reaction kettle R1, and stir at a constant speed for 10 minutes ; Take 2Kg sodium chloroacetate and mix it into a 40wt% aqueous solution and add it to the reactor R1, stir at a constant speed for 35 minutes, and keep the temperature at about 60°C; weigh 1Kg epichlorohydrin and add it to the reactor R1, stir at a constant speed, At the same time, keep the temperature at about 60°C, and the reaction time is 35 minutes; weigh 100Kg of the cross-linked starch prepared in Example 1 and slowly add it to the reaction kettle R1 under stirring conditions, continue to keep the temperature at 60°C, and...

Embodiment 3

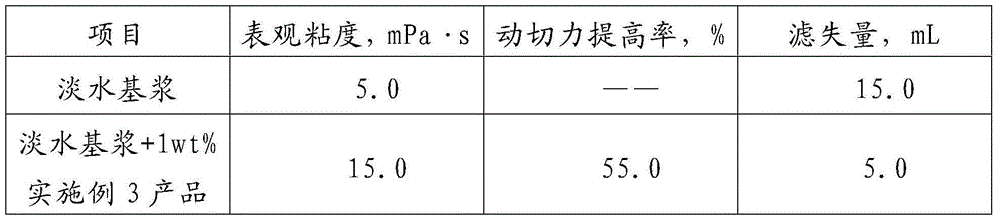

[0045] This example is used to illustrate the preparation method of the cutting fluid loss control agent for drilling fluid provided by the present invention.

[0046] Take by weighing guar gum 35Kg, hemp fiber 25Kg and fruit shell 10Kg respectively, join in the reactor R1, take by weighing potassium hydroxide 8Kg and be mixed with the aqueous solution that concentration is 40wt% to join in the reactor R1, stir at a constant speed for 15 minutes; Take 5Kg of sodium chloroacetate to prepare an aqueous solution with a concentration of 40wt%, add it to the reactor R1, stir at a constant speed for 50 minutes, and keep the temperature at about 80°C; weigh 3Kg of epichlorohydrin and add it to the reactor R1, stir at a constant speed, and keep The temperature is around 80°C, and the reaction time is 50 minutes. Weigh 100Kg of the cross-linked starch prepared in Example 1 and slowly add it into the reaction kettle R1 under stirring conditions, continue to keep the temperature between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com