Patents

Literature

48results about How to "High yield value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pumpable epoxy paste adhesives resistant to wash-off

ActiveUS20110036497A1Low viscositySimplify the assembly processNanostructure manufactureNon-macromolecular adhesive additivesEpoxyAdhesive

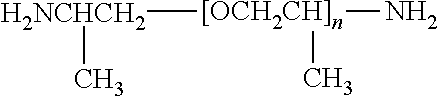

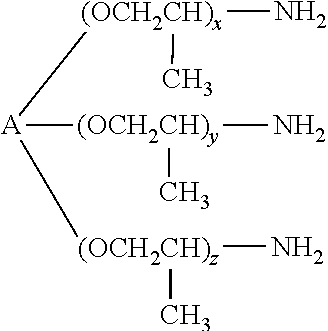

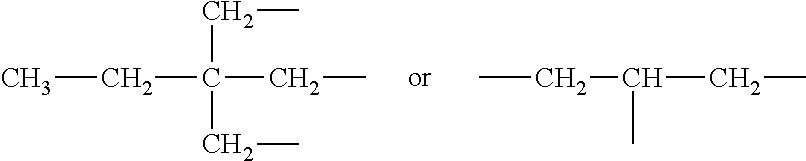

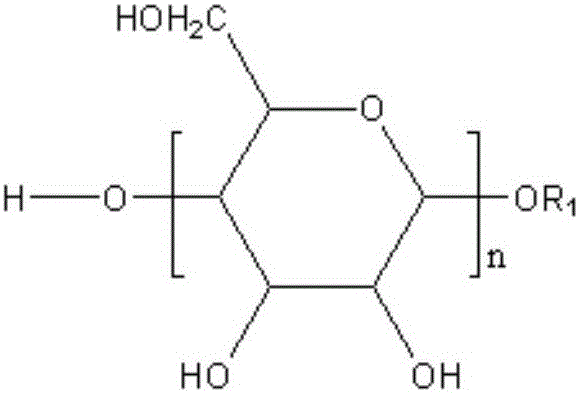

This invention relates to compositions useful as adhesives and more particularly to the preparation of heat-curable epoxy-based adhesive compositions that are capable of being easily pumped under high shear at temperatures around room temperature but are resistant to being washed off substrate surfaces prior to being cured.

Owner:HENKEL KGAA

Kitchen wet-tissue immersion liquid as well as preparation method and application thereof

ActiveCN106148030APrevents wet wipe contents from settlingImprove stabilityCationic surface-active compoundsOrganic detergent compounding agentsChemistryOxide

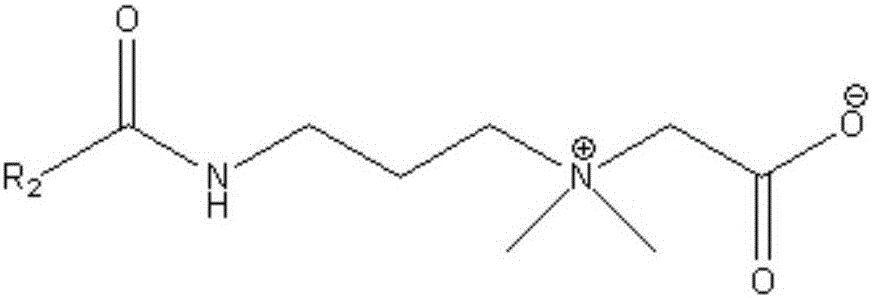

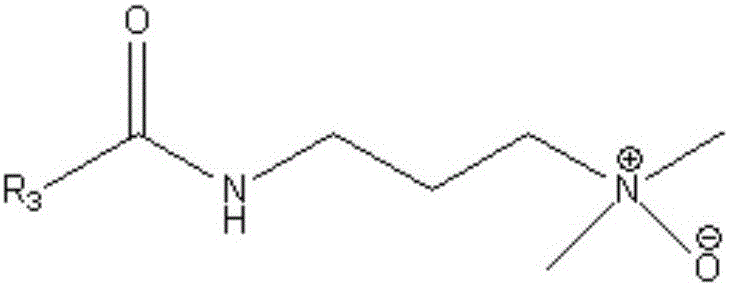

The invention relates to kitchen wet-tissue immersion liquid as well as a preparation method and application thereof. The kitchen wet-tissue immersion liquid is prepared from the following raw material components in percentage by mass: 0.01-0.2% of a rheology control agent, 1-10% of a surfactant composition, 0-1.5% of a fungicidal preservative, 0-5% of a chelating agent, 0-0.1% of an antifoaming agent, 0-0.2% of essence and the balance of water, wherein the rheology control agent is an acrylate crosslinking copolymer with molecular weight of 1.0*10<8>-1.0*10<10> Daltons; the surfactant composition is a mixture composed of alkyl glycoside, alkyl amidopropyl betaine and alkenamides propylamine oxide according to a mass ratio of (10-1):(5-1):1. According to the kitchen wet-tissue immersion liquid disclosed by the invention, the problem that content of the wet-tissue is easy to settle is solved, the product stability is improved, and the immersion liquid is efficient in decontamination, safe and mild and has good application prospect.

Owner:广州超威生物科技有限公司

Magnetic block printing ink

Owner:CHINA BANKNOTE PRINTING & MINTING

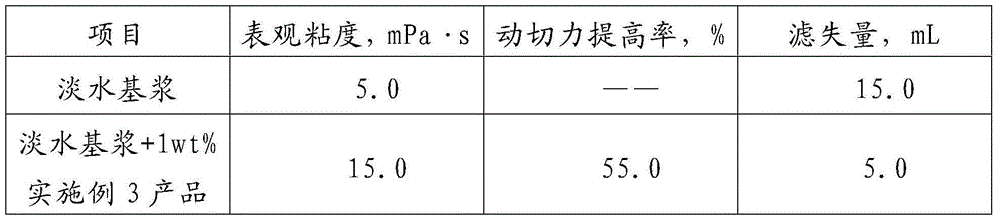

Shearing-force increase and filtrate loss reduction agent for drilling fluid and preparation method thereof

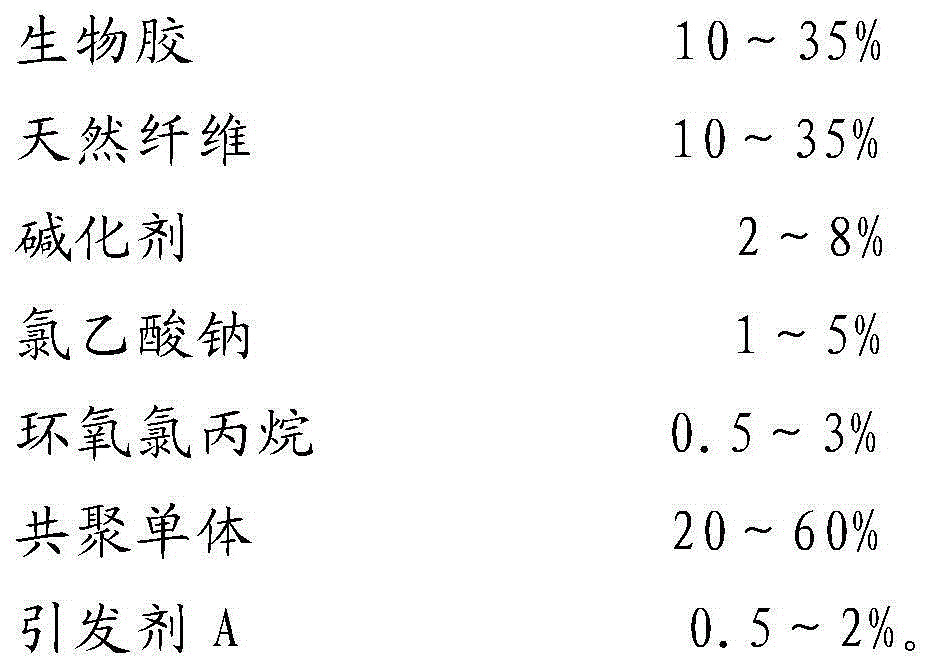

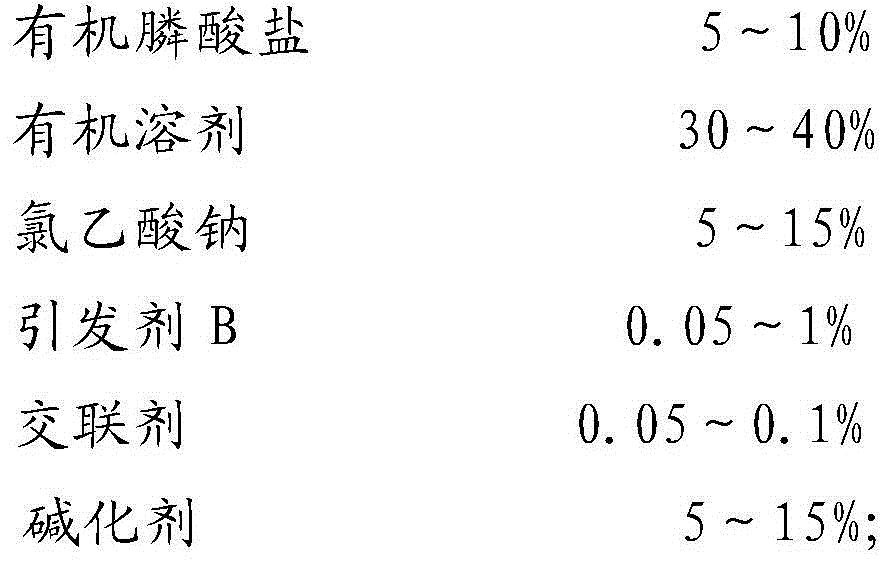

ActiveCN104559964AStrong stretch abilityNo significant increase in apparent viscosityDrilling compositionCross-linkSodium chloroacetate

The invention relates to a shearing-force increase and filtrate loss reduction agent for drilling fluid and a preparation method thereof. The shearing-force increase and filtrate loss reduction agent for drilling fluid is prepared with a method as follows: cross-linked starch, modified natural fiber and biological glue are subjected to graft copolymerization with comonomer under the action of an initiating agent A, wherein with the weight of the cross-linked starch as a reference, the weight fraction of other raw materials is as follows: biological glue accounts for 10-35%, natural fiber accounts for 10-35%, a basifier accounts for 2-8%, sodium chloroacetate accounts for 1-5%, epoxy chloropropane accounts for 0.5-3%, comonomer account for 20-60%, and the initiating agent accounts for 0.5-2%. The shearing-force increase and filtrate loss reduction agent for the drilling fluid can scientifically adjust apparent viscosity and static shearing force of the drilling fluid, has good filtrate loss reduction performance and shearing-force increase performance and is good in salt-resistant and temperature-resistant effect.

Owner:北京中科日升科技有限公司

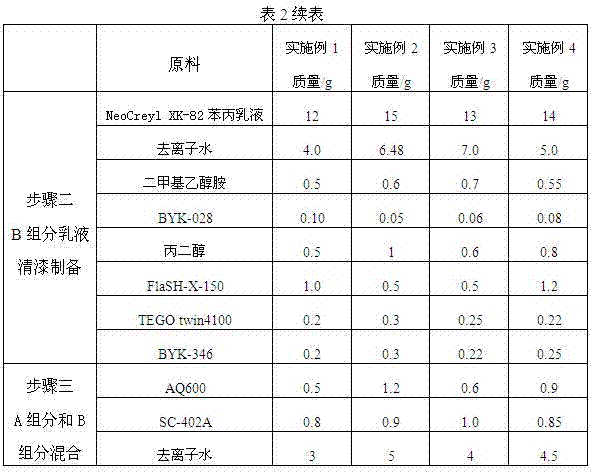

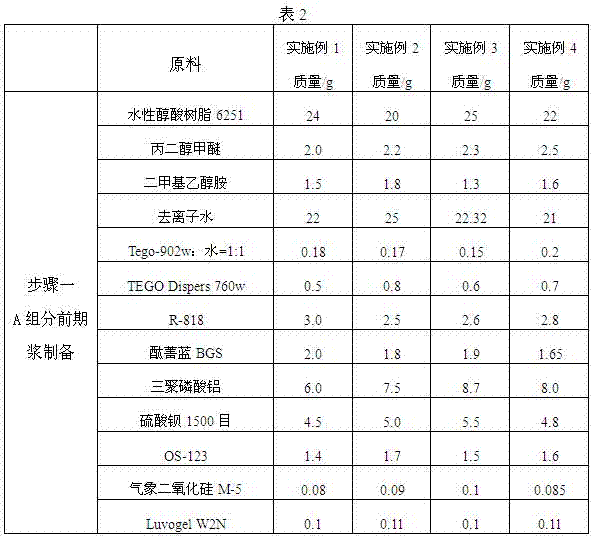

Environment-friendly water-based paint for living container and preparation method thereof

ActiveCN106883739AGood environmental friendlinessProtect physical and mental healthAnti-corrosive paintsPolyester coatingsSolventChemistry

The invention discloses environment-friendly water-based paint for a living container and a preparation method thereof, and relates to the technical field of water-based paint. The environment-friendly water-based paint is prepared from the following raw materials in parts by weight: 20 to 25 parts of waterborne alkyd resin, 12 to 15 parts of waterborne styrene-acrylic emulsion, 28 to 37 parts of deionized water, 2 to 2.5 parts of environment-friendly cosolvents, 1.8 to 2.5 parts of neutralizers, 0.2 to 0.3 part of antifoaming agents, 0.2 to 0.3 parts of flatting agents, 0.2 to 0.3 part of substrate wetting agents, 0.8 to 1.0 part of adhesion promoters, 0.5 to 1 part of coalescing agents, 1.4 to 1.7 parts of waterborne driers, 0.5 to 1.2 parts of flash-rust inhibitors, 0.5 to 1.2 parts of rheological agents, 0.18 to 0.2 part of anti-settling agents, 0.5 to 0.8 part of dispersing agents, 1.65 to 2.0 parts of phthalocyanine blue, 2.5 to 3.0 parts of rutile titanium dioxide, 6 to 8.7 parts of aluminum triphosphate and 4.5 to 5.5 parts of barium sulfate. The environment-friendly water-based paint has the advantages that the environment is protected; the impact resistant, water resistant, weather resistant and salt spray resistant effects are achieved; the indexes such as the adhesive force meet the national standard requirements.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

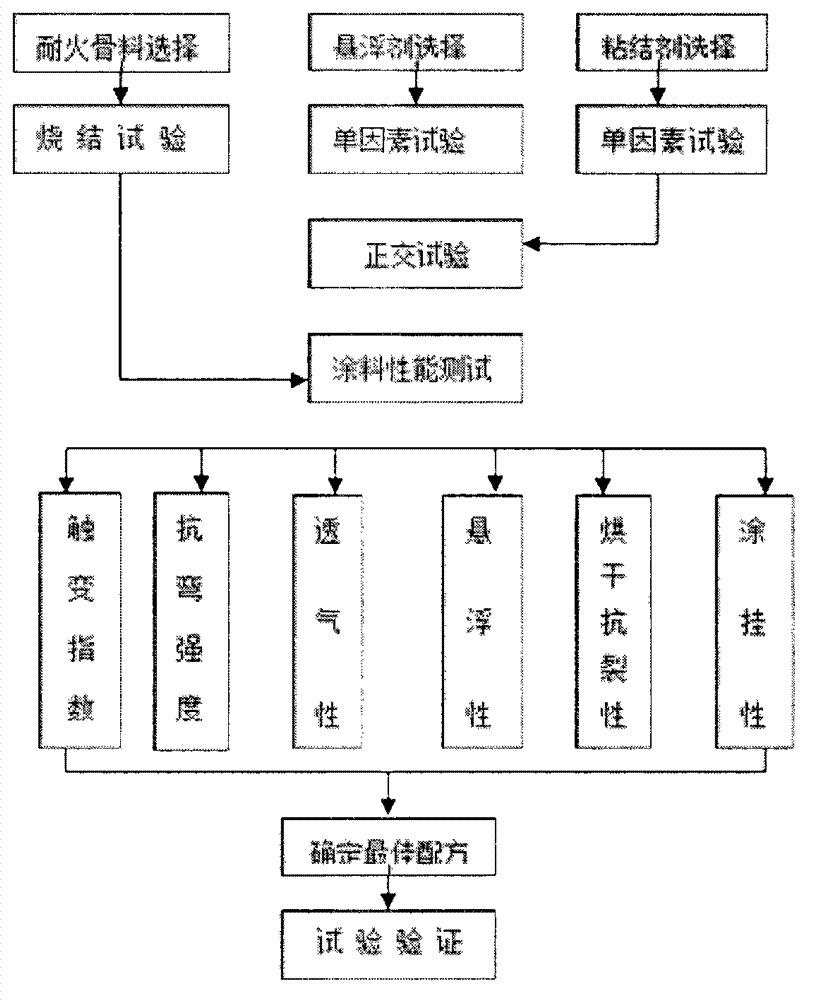

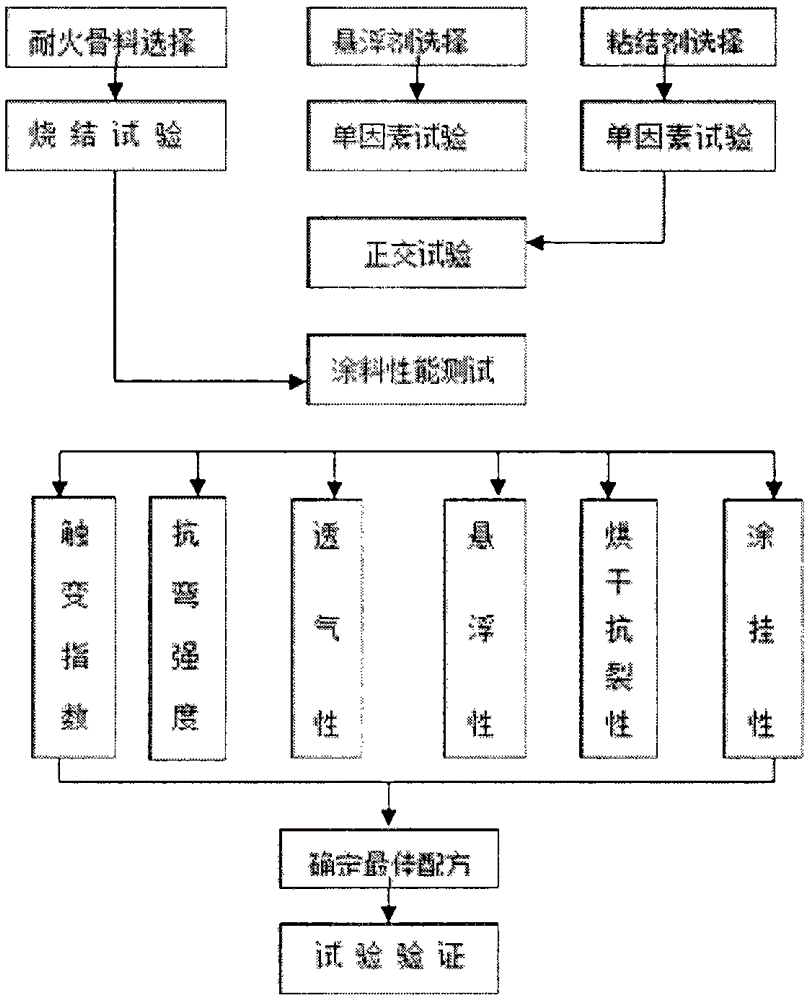

High-precision evanescent mode cast steel coating

InactiveCN104275435APromote sinteringHigh refractorinessFoundry mouldsFoundry coresSodium BentoniteSuspending Agents

The invention discloses a high-precision evanescent mode cast steel coating which consists of the following components in parts by weight: 90-120 parts of fireproof aggregates, 10 parts of auxiliaries, 3 parts of silica sol and 10-50 parts of water, wherein the water serves as a carrier; the fireproof aggregates are a combination of one or several of aluminum-silicon powder, quartz powder and bauxite clinker; the auxiliaries comprise the following internal components in percentage by mass: 15 percent of potato modified starch serving as a binder, 30 percent of Ca-based bentonite serving as a suspending agent, 50 percent of ground calcium carbonate serving as mineral adjustment powder and 5 percent of a surfactant which is FC-4430 fluorine surfactant; the fireproof aggregates are screened by a 200-300-mesh sieve. According to the coating, the surface roughness value of a casting can be reduced, casting defects are prevented, the sand falling and cleaning efficiency of the casting can be effectively improved, and gas generated by pyrolysis of a foam pattern can be effectively discharged out of a casting mold; meanwhile, permeation of metal liquid can be prevented, the strength and the rigidity of the foam pattern can be improved, and deformation of and damage to the pattern are prevented; the high-precision evanescent mode cast steel coating has good heat preservation and insulation effects.

Owner:渠县金城合金铸业有限公司

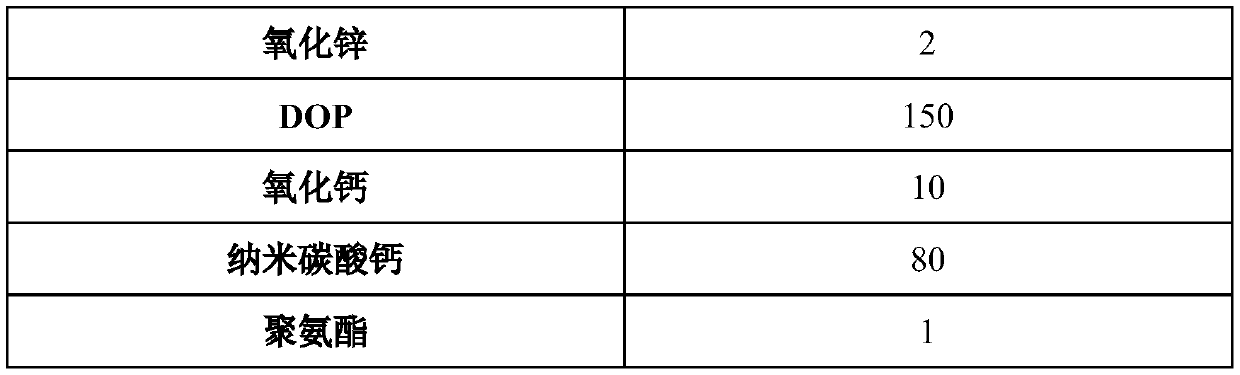

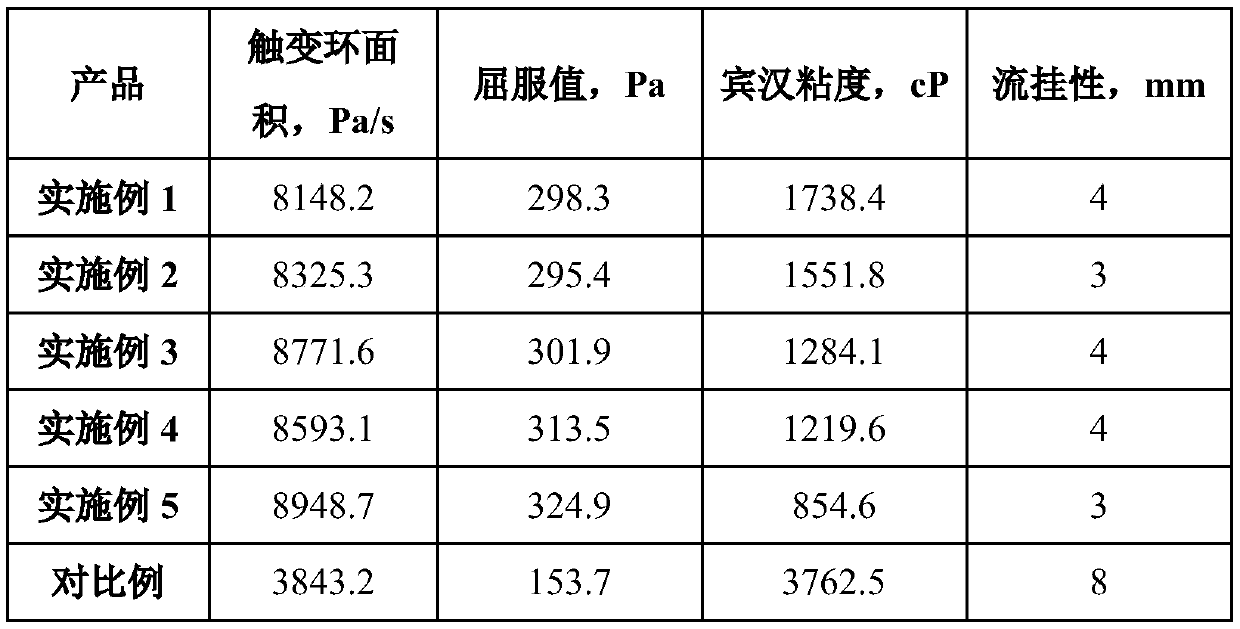

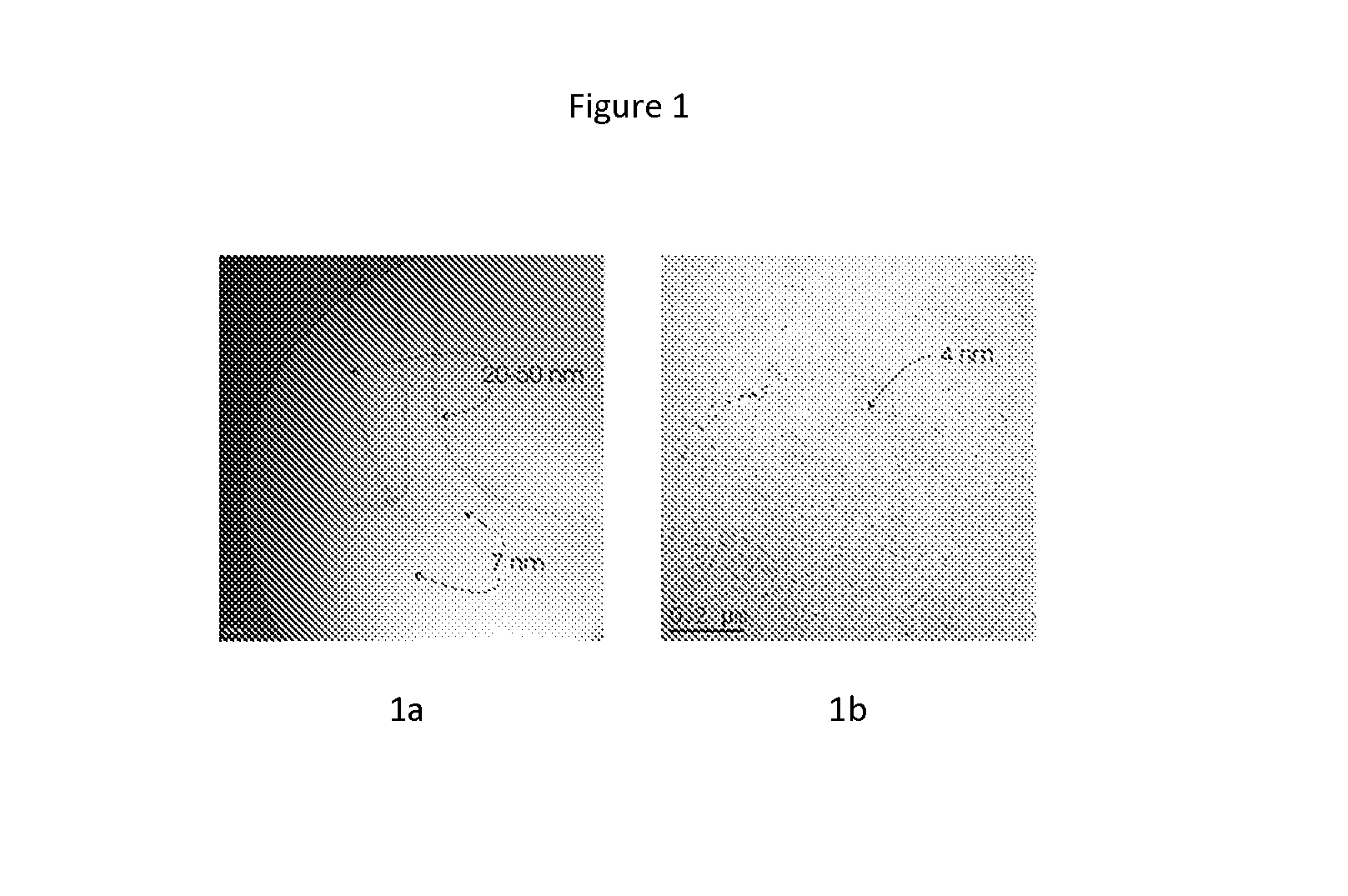

Preparation method of nanometer calcium carbonate for automobile primer

ActiveCN110499045AGood dispersionHigh yield valuePigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsHigh sodiumFiltration

The invention discloses a preparation method of nanometer calcium carbonate for an automobile primer. The preparation method comprises the following steps: adjusting the specific gravity of refined lime milk to 1.055-1.080, controlling the temperature at a certain value, adding a metal salt crystal form control agent, performing uniform mixing, then introducing the obtained mixture into a bubblingcarbonation reaction kettle, performing a carbonation reaction, stopping the reaction when the pH value of the obtained slurry is less than or equal to 7 in order to obtain a calcium carbonate suspension, heating the calcium carbonate suspension to 55-75 DEG C, adding an agent composed of higher sodium aliphatate, a modified imide cyclosilane coupling agent and epoxidized cyclohexane dioctyl phthalate under the stirring of an emulsifying machine, and performing compounding to obtain a surface treating agent; performing continuous stirring for 30-90 min to finish surface modification treatmentin order to obtain a modified nano calcium carbonate suspension; and carrying out press filtration, drying, crushing and sieving to obtain the nanometer calcium carbonate for the automobile primer. The automobile primer obtained by filling with the prepared nanometer calcium carbonate filled has excellent thixotropy, remarkably reduced shear viscosity and improved anti-sagging performance, well meets the performance requirement of the automobile primer, and has a very broad market prospect.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

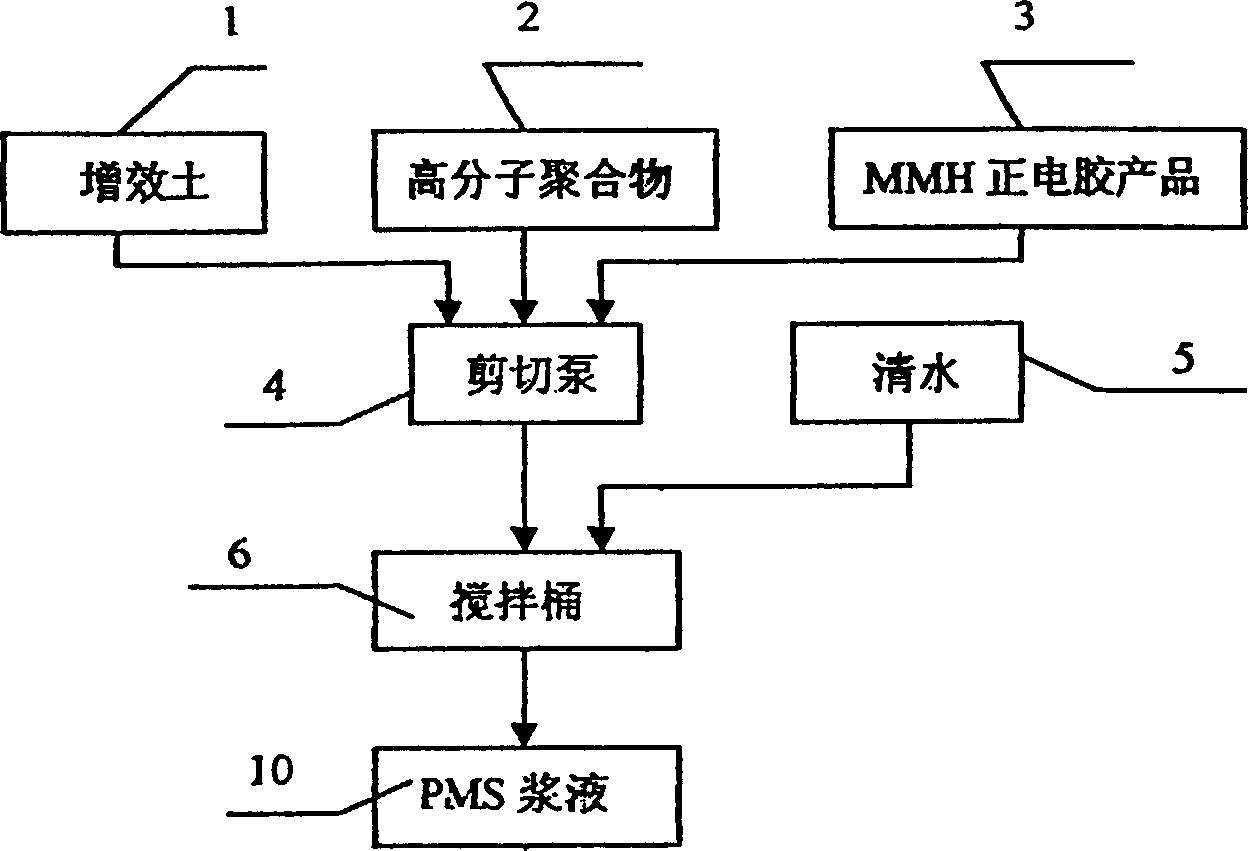

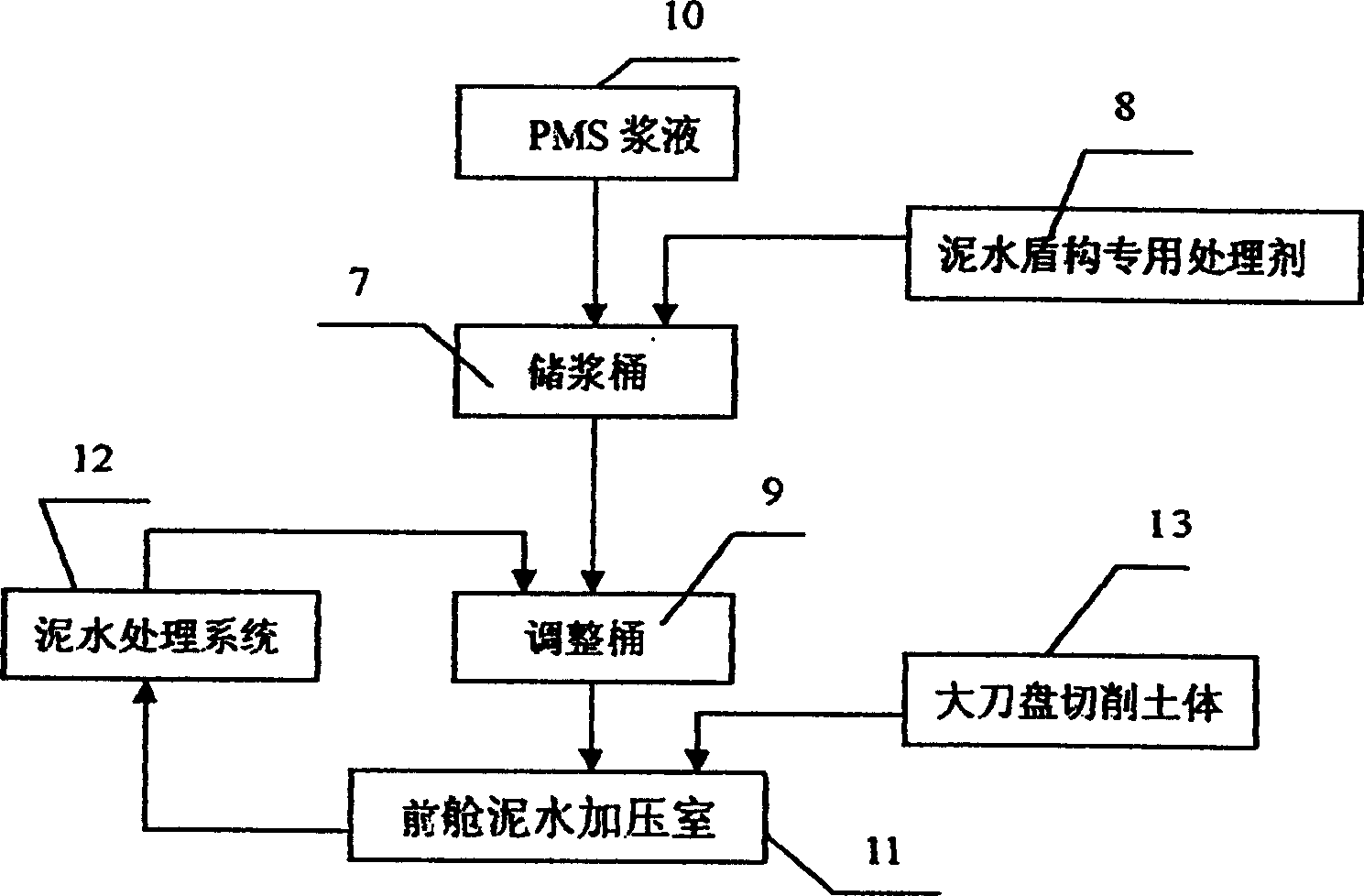

PMS sludge prepn. method and its application in construction of sludge balance shield and pipe-jacking

This is a preparing method of PMS mud and water paste and its application on the working of supporting pipe. Its features are: Use high polymer and positron glue to prepare PMS mud and water paste liquid. During this procession, to use soil mortar liquid separated grade by grade, in the mud paste mix PMS paste liquid and its assistant materials in proper time, and advance the six steps on the application.

Owner:上海第二市政工程有限公司

Production method for attapulgite ceramic plastic mass

The invention discloses a production method for an attapulgite ceramic plastic mass. The key point of the technical scheme is that the production method comprises the following steps of: crushing ingredients of the attapulgite ceramic plastic mass, performing sodium treatment on the crushed mixture into a moist mixture, pressing the moist mixture into a sheet, extruding into a strip, airing the strip, grinding, removing iron from powder, adding water into the powder, extruding into a cylindrical strip, and packaging into the finished product of the attapulgite ceramic plastic mass. The attapulgite ceramic plastic mass consists of attapulgite clay, white bentonite, sepiolite, calcined clay, sodium metasilicate and sodium carbonate. The attapulgite ceramic plastic mass has uniform water content and consistent structure, and has the characteristics of good cohesiveness, plasticity, high yield value and large extension deformation; ceramic products prepared from the attapulgite ceramic plastic mass have the characteristics of small shrinkage, no deformation, high strength, and uniform texture; and the attapulgite ceramic plastic mass is suitable for producing the ceramic products.

Owner:XUYI KEYUAN NEW MATERIALS FACTORY

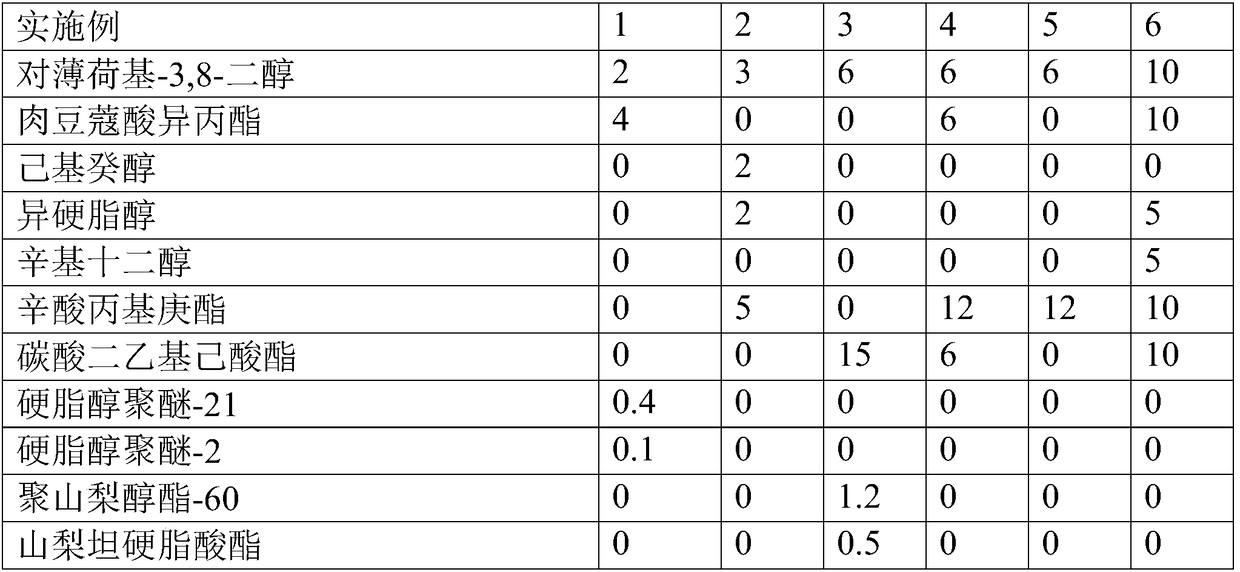

Ethanol-free anti-mosquito composition capable of improving effects of p-menthyl-3,8-diol

ActiveCN108771640AReduce the impactImprove solubilityCosmetic preparationsToilet preparationsSkin surfaceChemical products

The invention relates to the technical field of daily chemical product type mosquito repellents applied to the surface of skin of a human body and particularly relates to an ethanol-free anti-mosquitocomposition capable of improving the effects of p-menthyl-3,8-diol. Selected grease is capable of well dissolving p-menthyl-3,8-diol at the normal temperature, has certain dissolving capacity at a low temperature and can be uniformly spread on the surface of the skin, an added water-resistant film forming agent is capable of generating a synergetic spreading effect and prolonging the standing time of p-menthyl-3,8-diol on the surface of the skin, so that the influences caused by external moisture and moisture in sweat to an anti-mosquito film formed on the surface are reduced, and the anti-mosquito effect is improved; and besides, by adding butanediol, the solubilizing of p-menthyl-3,8-diol can be assisted, so that the separation of crystals is prevented. By conditioning the proportion ofgrease to other components in the composition, the product with a stable system and good skin feel experience can be acquired.

Owner:广州超威生物科技有限公司

High-suspension sand mold coating and preparation method thereof

InactiveCN103658509AHigh yield valueImprove adhesionFoundry mouldsFoundry coresCarboxymethyl celluloseSodium Bentonite

The invention discloses a high-suspension sand mold coating which comprises the following components in parts by weight: 100 parts of water, 20-40 parts of crystalline graphite powder, 60-80 parts of amorphous graphite powder, 0.3-0.6 part of sodium carboxymethyl cellulose, 4-5.5 parts of bentonite, 0.36 part of soda, 0 .3 part of alkylphenol ethoxylates and 0.05 part of Tween 80. According to the sand mold coating, all components are uniformly mixed, and can be uniformly suspended in a solution without generating sediment for 12 months; the infiltration effect is good, so that processes such as flow coating, spray coating and brush coating can be adopted to coat the sand mold coating on the surface of a sand mold. The sand mold coating is simple to prepare and low in cost, can improve the sand mold strength when coated on the surface of the sand mold, and has greatly improved corrosion resistance, high-temperature resistance, and fire resistance.

Owner:FUZHOU WENTAI MACHINERY CASTING

Additive for cementitious materials

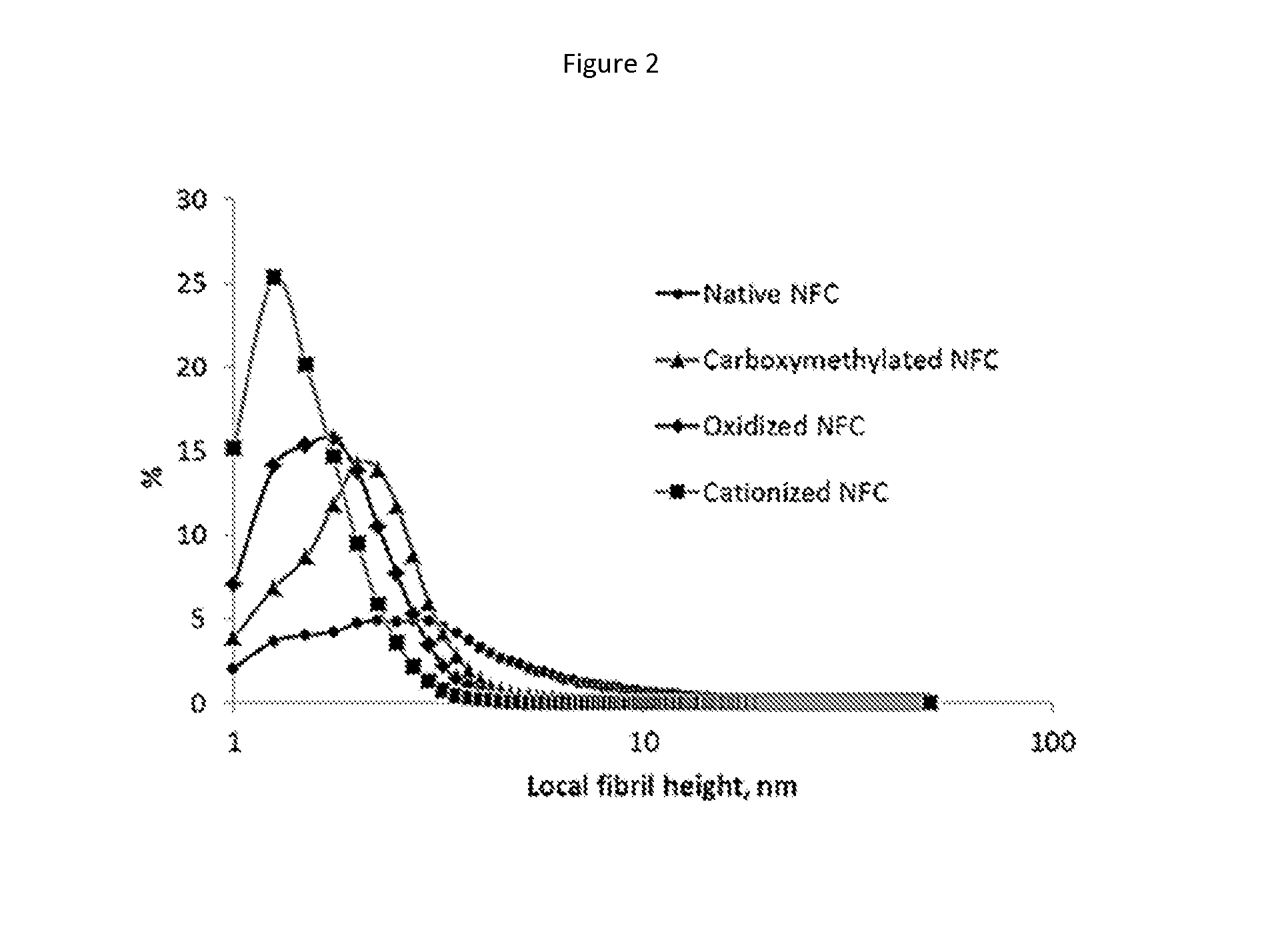

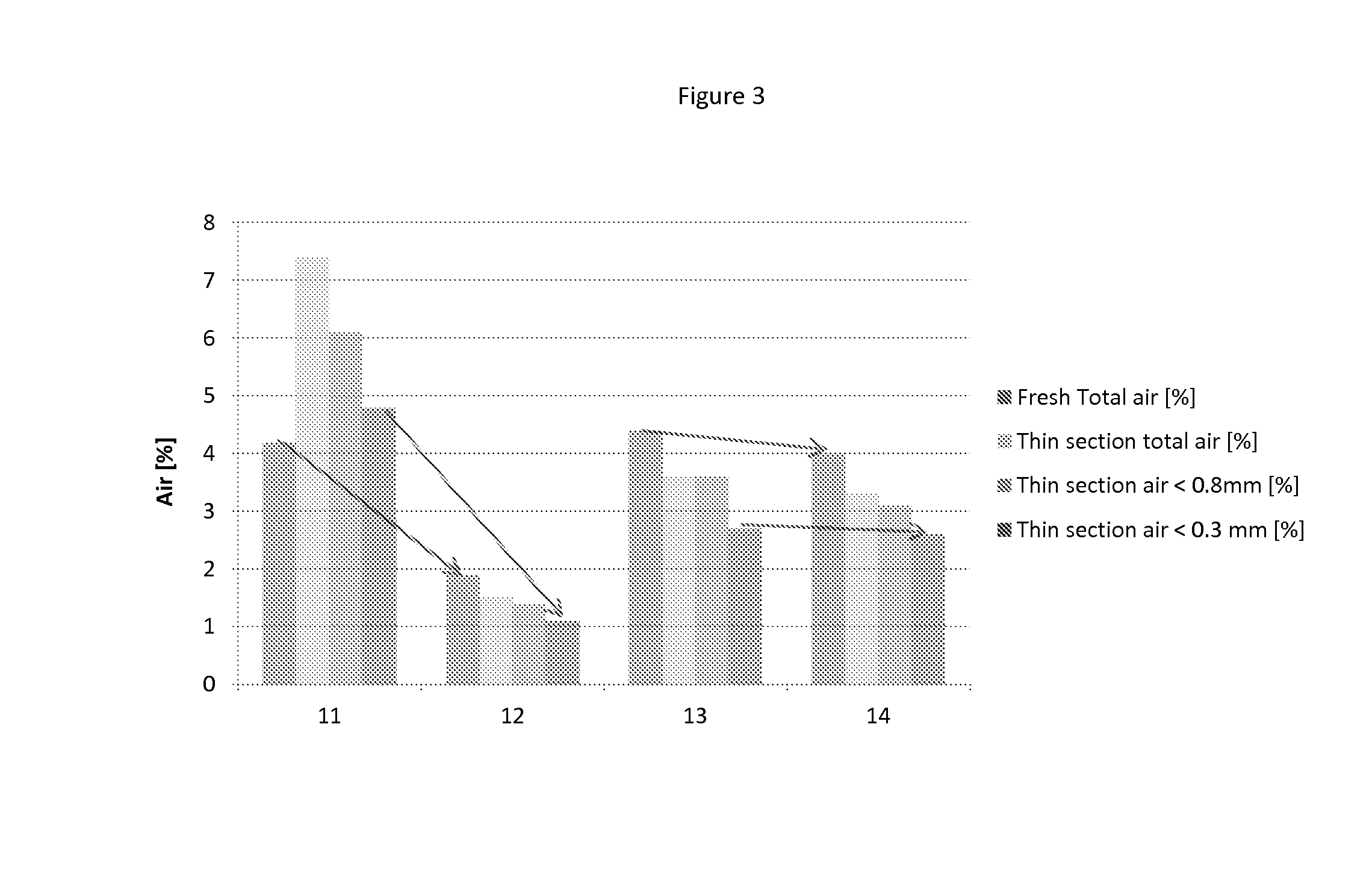

ActiveUS20160257614A1Improve stabilityQuality improvementSolid waste managementCeramicwareCelluloseWater content

The invention relates to use of nano-fibrillar cellulose as an gas-entrainment stabilizer, which when used in cementitious materials, provides improved gas pore structure quality and / or stability and / or robustness with regard to water content variation. The invention further relates to a method for stabilizing gasentrainment of cementitious materials and to a method for providing cementitious material with improved air pore structure quality and / or stability and / or robustness with regard to water content variation.

Owner:UPM-KYMMENE OYJ

Quick-drying paint for metal

Quick-drying paint for metal is prepared from components in parts by mass as follows: 30-40 parts of deionized water, 15-40 parts of methyl ethyl ketone, 15-20 parts of maleic anhydride (P.R57:1), 0.8-1 part of dimethylethanolamine, 4-10 parts of styrene, 2.0-5 parts of triethylamine, 3-5 parts of ethanol, 1-4 parts of butanol and 1.0-3 parts of polyethylene wax. According to the quick-drying paint for the metal and a preparation method thereof, the quick-drying paint is hard, short in silk and excellent in leveling property, has the viscosity value of 8-14 at 400 rmp, is anti-set-off, is dried completely within 0.8 s, has the large yield value, can be widely applied and continuously replace existing products.

Owner:叶青

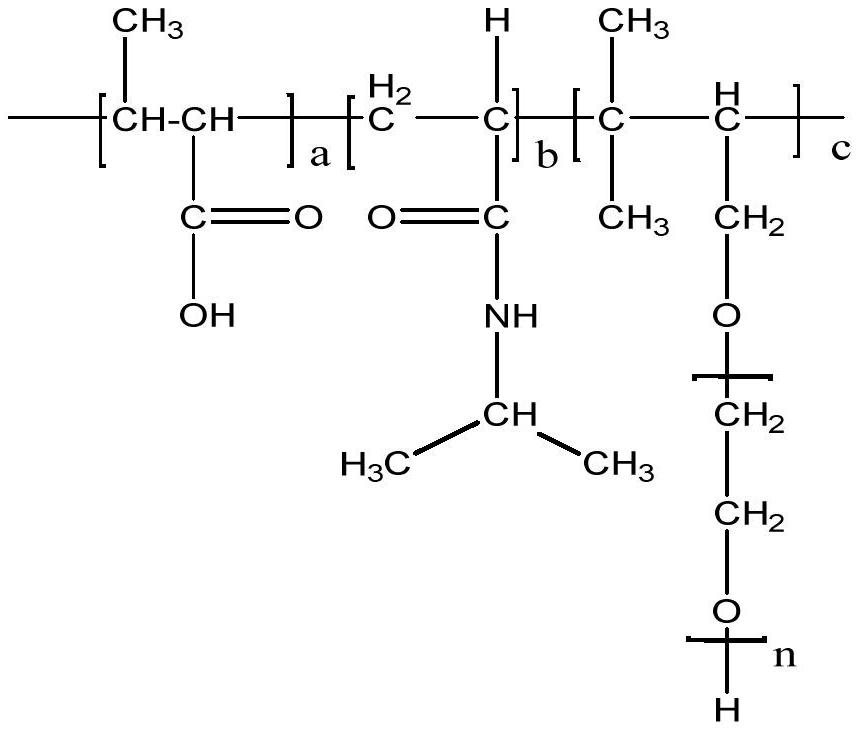

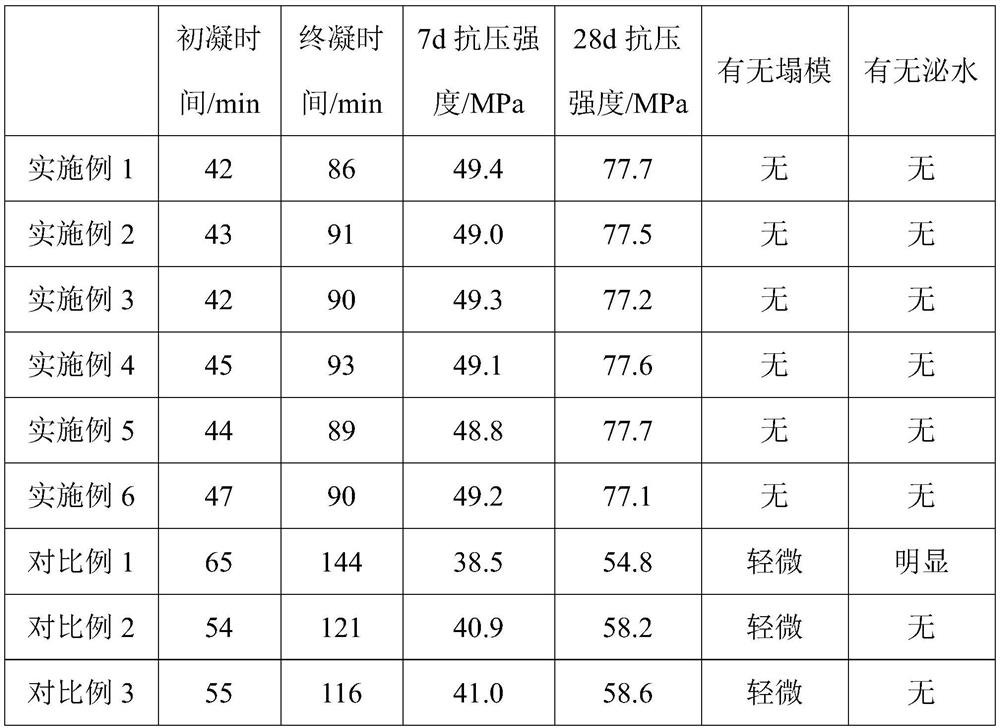

Special anti-sloughing liquid coagulant for foam concrete cast-in-place wall

The invention relates to the field of concrete auxiliary agents, in particular to a special anti-sloughing liquid coagulant for foam concrete cast-in-place wall. The special anti-sloughing liquid coagulant is prepared from the following components in parts by weight: 30-55 parts of polyaluminum sulfate, 5-10 parts of magnesium sulfate, 0.1-5 parts of tertiary amine, 1-5 parts of magnesium fluosilicate, 0.1-0.5 part of an amide modified polycarboxylate superplasticizer, 1-4 parts of mixed acid, 0.1-0.5 part of sodium bicarbonate, 0.1-0.5 part of hydroxypropyl methyl cellulose, 0.1-0.5 part of carboxymethyl starch ether, 1-3 parts of sodium tripolyphosphate and 400-500 parts of water. The early setting agent can shorten the initial setting time and the final setting time of the foam concrete, prevents a foam concrete wall from collapsing, avoids the bleeding phenomenon, and improves the mechanical property of the foam concrete to a certain extent.

Owner:SHANDONG JIAOTONG UNIV +1

Wear-resistant offset printing ink and preparation method thereof

The invention provides a wear-resistant offset printing ink prepared from the following raw materials in parts by weight: 6-8 parts of propylene glycol methyl ether acetate, 2-2.5 parts of nano zinc oxide, 2-3 parts of polytetrafluoroethylene micropowder, 30-35 parts of rosin modified phenol-formaldehyde resin, 0.1-0.2 part of oxo-2-ethylhexanoato-o aluminum homopolymer, an appropriate amount of mineral oil, 50-55 parts of soybean oil, 0.1-0.2 part of tert-butyl hydrogen peroxide, 20-30 parts of a colorant, 1-2 parts of lanthanum ethylhexanoate, 1-1.5 parts of pentaerythritol ester, 1.3-1.6 parts of methyl methacrylate, 2-3 parts of acrylic acid, 1-2 parts of lac and 1-2 parts of polymeric castor oil. According to the offset printing ink provided by the invention, the soybean oil is used for replacing most of petroleum solvents in the traditional ink to ensure that the VOC (volatile organic compound) is reduced to be less than 15%, and nano zinc oxide is added to catalyze oxidation reaction and promote drying, so that the glossiness and toughness of the ink are improved. The ink is quick to oxidize and dry and cannot cause 'skin formation' in an ink fountain of an offset printing machine, and a film is quick to form.

Owner:安徽雅美油墨有限公司

Parking lot parking reservation management method and system

InactiveCN106327917AHigh yield valueHigh yieldIndication of parksing free spacesTime informationElectronic communication

The invention relates to the technical field of electronic communication, and specifically relates to a parking lot parking reservation management method and system. The parking lot parking reservation management method includes following steps: according to obtained information of a parking reservation request sent by a mobile terminal, the reservation request is accepted when parking time information of the reservation request is allowed; and from parking reservation historical data whose reservation time is later than that of a current reservation time within an operation period, a parking reservation request quantity P is taken, a parking reservation request quantity Q whose predicted parking fee is not more than F is taken, E=P / Q is then calculated, and when the expected reservation value E is higher than a preset value, the parking space is reserved for the parking reservation request. The expected reservation value E is related to the predicted parking fee Fi of which is later than the parking reservation request in a historical database, the parking reservation request can be assessed, and when the expected reservation value E is higher than the preset value, the parking reservation request can obtain high earning rate.

Owner:GUANGZHOU INST OF GEOGRAPHY GUANGDONG ACAD OF SCI +2

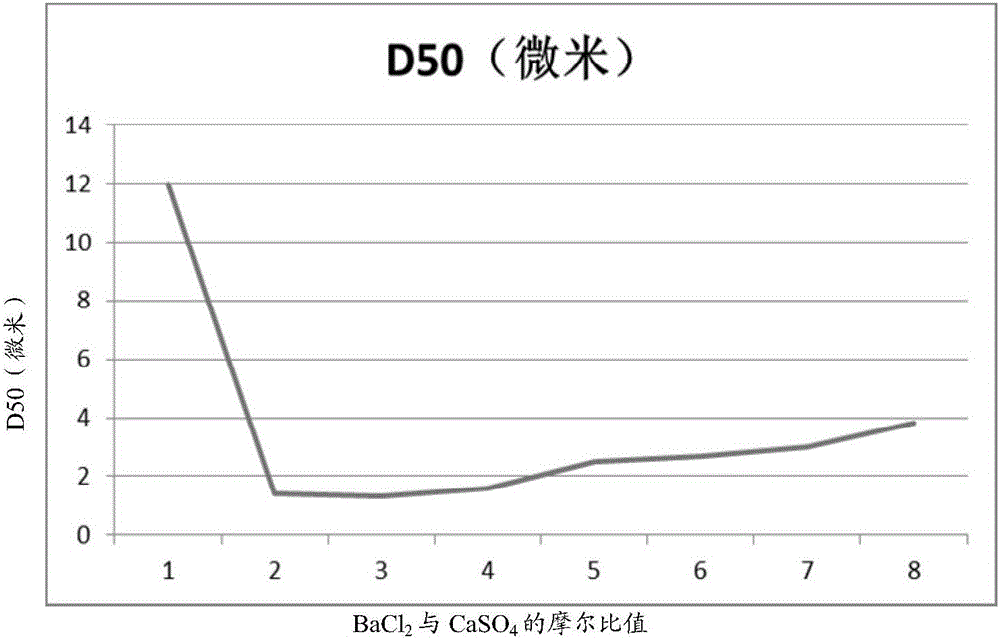

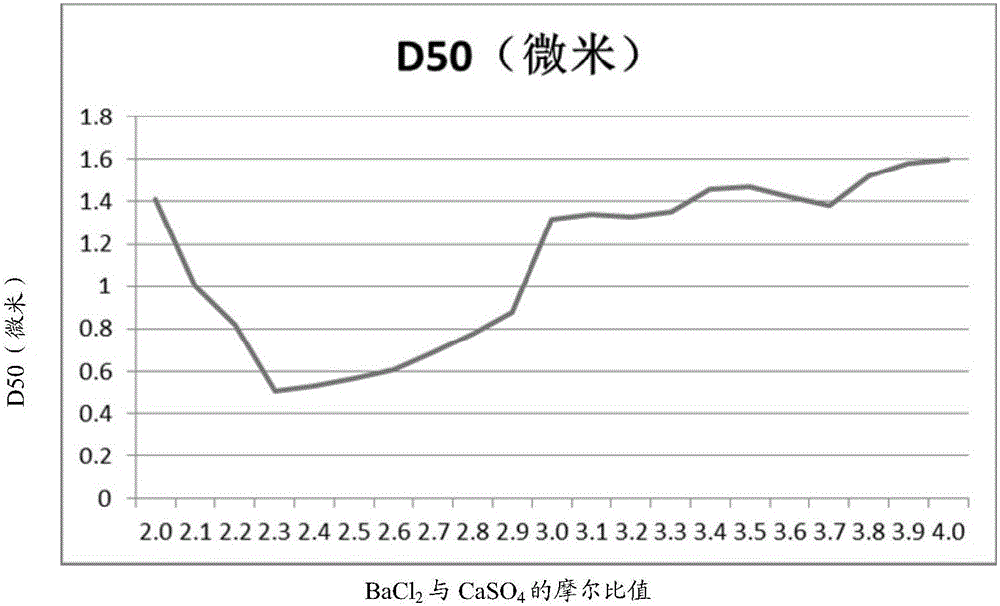

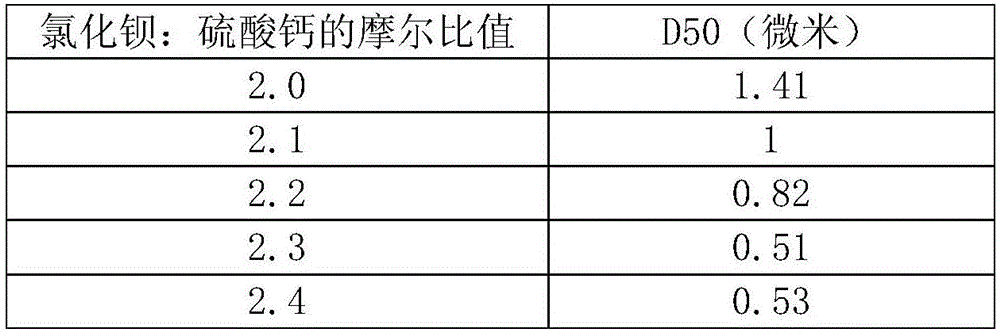

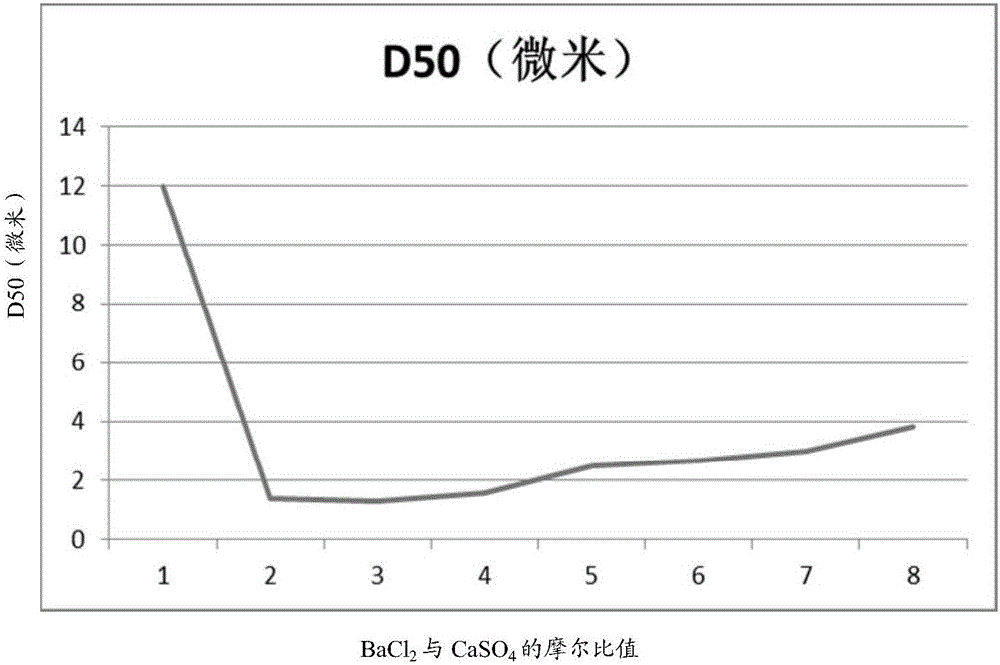

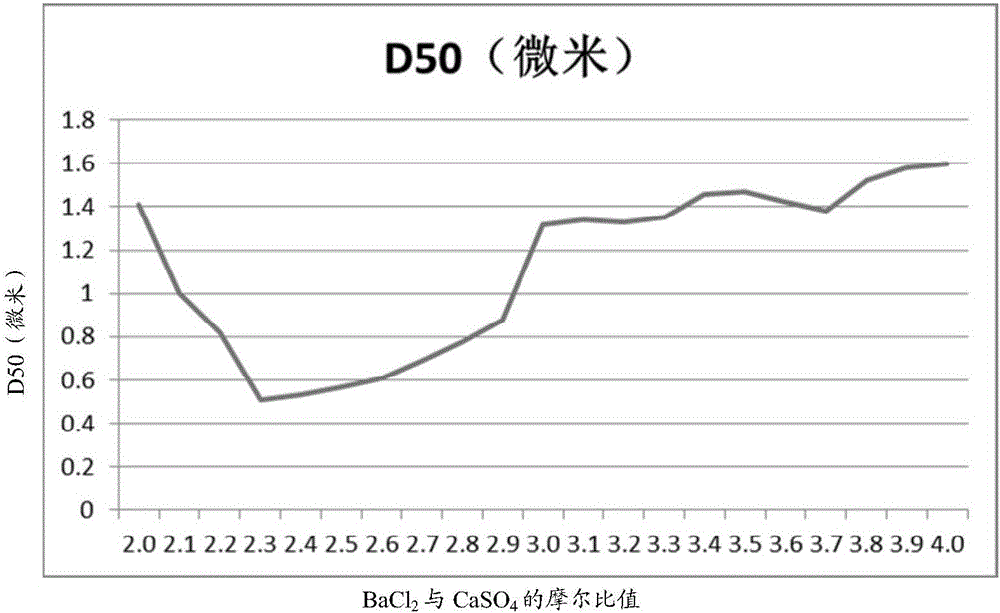

Preparation method for magnesium oxide raw material and magnesium hydroxide with low particle size by using low-grade magnesite

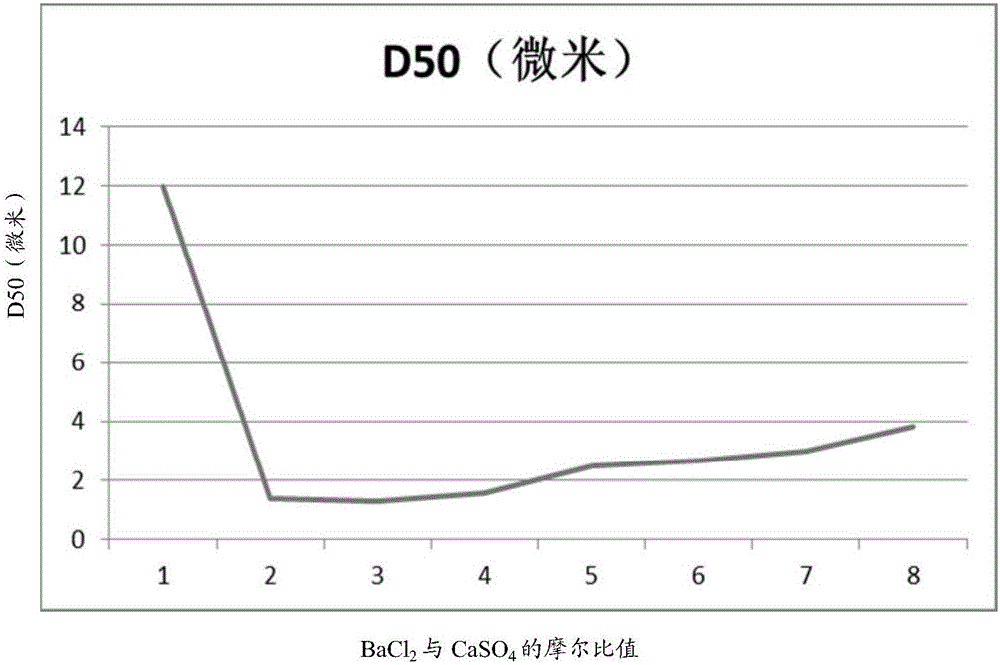

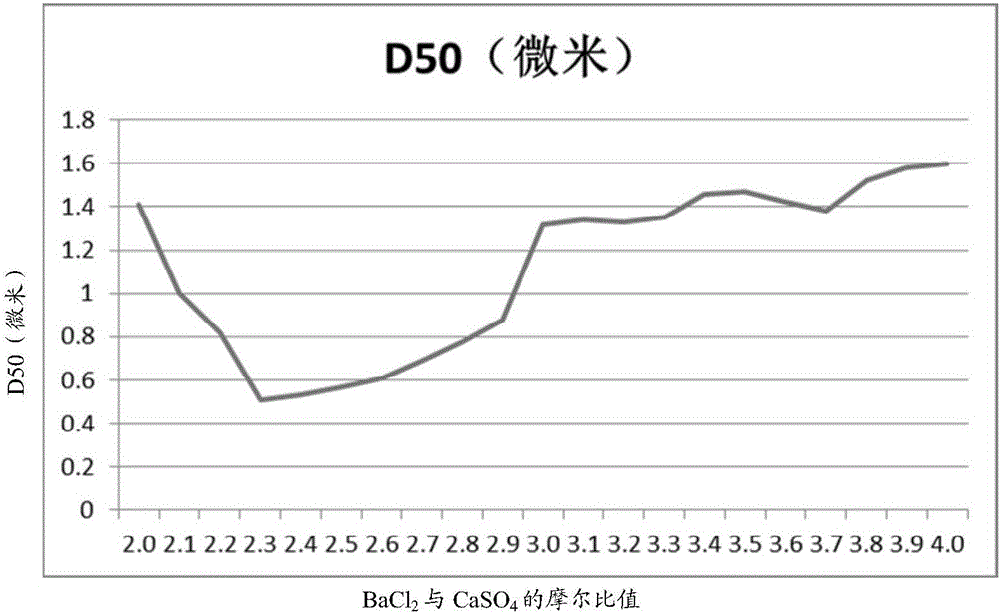

The invention provides a preparation method for a magnesium oxide raw material and magnesium hydroxide with low particle size by using low-grade magnesite. Specifically, the invention provides a preparation method for a magnesium oxide raw material used for producing magnesium hydroxide by using low-grade magnesite. The method comprises the following steps: subjecting magnesite to calcining so as to obtain light calcined ore, and recycling carbon dioxide; crushing the light calcined ore, and preparing the crushed light calcined ore into a slurry with a concentration of 35%; subjecting the slurry and an ammonium chloride solution to reaction, then filtering the reacted slurry, and recycling ammonia gas; subjecting obtained filtrate, ammonia water and carbon dioxide to reaction, and carrying out filtering; subjecting the filtrate and excess ammonia water to reaction, then carrying out filtering, washing filter residue, and carrying out drying so as to obtain crude magnesium oxide; and detecting the content of calcium sulfate, and adding barium chloride so as to obtain the magnesium oxide raw material. The invention also provides a preparation method for magnesium hydroxide by using the magnesium oxide raw material. According to the invention, the low-grade magnesite can be utilized to prepare magnesium hydroxide with high hydration rate and D50 less than 1.0 micron.

Owner:刘昕

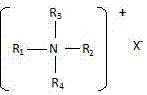

An organic soil for preparing high yield value oil-based drilling fluid and its preparation method

The invention relates to organic soil for oil base drilling fluids with a high yield value. The organic soil is formed by reacting montmorillonite, an alkyl quaternary ammonium salt surfactant, a quaternary ammonium salt cationic surfactant with a strong polar group and an anionic surfactant with a long chain alkyl group, wherein the input amount of the alkyl quaternary ammonium salt surfactant is 0.6-1.5 times of a sodium-based montmorillonite cation exchange capacity; the input amount of the quaternary ammonium salt cationic surfactant with the strong polar group is 0.01-0.5 times of the sodium-based montmorillonite cation exchange capacity; the molar ratio of the anionic surfactant with the long chain alkyl group to the quaternary ammonium salt cationic surfactant with the strong polar group is 1 to 1. According to the organic soil for oil base drilling fluids, the drilling fluids prepared by mineral oil has high yield value and can keep stable after being aged at high temperature.

Owner:ZHEJIANG FENGHONG NEW MATERIAL

Method for preparing magnesium hydroxide by using magnesium oxide

ActiveCN105776258AHigh yield valueSmall particle sizeMagnesium hydroxideBarium dichlorideDistilled water

The invention provides a method for preparing magnesium hydroxide by using magnesium oxide. The method comprises the following steps: obtaining magnesium oxide and determining the content of calcium sulphate in the magnesium oxide; preparing paste with magnesium oxide by using distilled water, adding barium chloride to the paste, and performing stirring under the temperature of 45-55 DEG C at the speed of 400-500r / m for 6-7 hours so as to enable the magnesium oxide and the distilled water to be subjected to a reaction; then filtering out liquid so as to prepare crude magnesium hydroxide; drying the crude magnesium hydroxide under 45-55 DEG C until the water content is lower than 1wt%, so as to prepare dried magnesium hydroxide; sieving the dried magnesium hydroxide with a mesh screen of which the bore diameter is 200 microns or below, and removing coarse particles, so as to prepare the magnesium hydroxide with small particle diameters. Through the adoption of the method, the magnesium oxide can be directly used for preparing the magnesium hydroxide which is high in yield and of which D50 is smaller than 1.0 micron without any post treatment.

Owner:刘昕

A High-Precision Lost Foam Cast Steel Coating

InactiveCN104275435BPromote sinteringHigh refractorinessFoundry mouldsFoundry coresSodium BentoniteSuspending Agents

The invention discloses a high-precision evanescent mode cast steel coating which consists of the following components in parts by weight: 90-120 parts of fireproof aggregates, 10 parts of auxiliaries, 3 parts of silica sol and 10-50 parts of water, wherein the water serves as a carrier; the fireproof aggregates are a combination of one or several of aluminum-silicon powder, quartz powder and bauxite clinker; the auxiliaries comprise the following internal components in percentage by mass: 15 percent of potato modified starch serving as a binder, 30 percent of Ca-based bentonite serving as a suspending agent, 50 percent of ground calcium carbonate serving as mineral adjustment powder and 5 percent of a surfactant which is FC-4430 fluorine surfactant; the fireproof aggregates are screened by a 200-300-mesh sieve. According to the coating, the surface roughness value of a casting can be reduced, casting defects are prevented, the sand falling and cleaning efficiency of the casting can be effectively improved, and gas generated by pyrolysis of a foam pattern can be effectively discharged out of a casting mold; meanwhile, permeation of metal liquid can be prevented, the strength and the rigidity of the foam pattern can be improved, and deformation of and damage to the pattern are prevented; the high-precision evanescent mode cast steel coating has good heat preservation and insulation effects.

Owner:渠县金城合金铸业有限公司

Spray flow gel and preparation method thereof

The invention relates to the technical field of hydrogel preparation, in particular to spray flow gel and a preparation method thereof.The preparation method includes the following steps of (1) addingfood natural macromolecules into deionized water and stirring at a certain temperature until the food natural macromolecules are completely swollen into a uniform solution; (2) enabling the swollen solution to form spray under the action of compressed air with certain pressure, and controlling the aperture of an outlet of a spray head to be 0.2-0.8 mm to form micron-scale liquid drops; (3) blowing with cold air with a certain temperature within the range of liquid drops to ensure that the liquid drops complete sol-gel conversion in the air; and collecting liquid drops after gel transformationby using a container with a certain temperature to obtain the spray flowing gel. The preparation method of the spray flow gel is different from a rotary shearing mode, the micron-scale small liquid drops are subjected to a gelling effect at the temperature far lower than a gel dissolving transition point through an air shearing mode, the preparation efficiency is high, and the industrial production is facilitated.

Owner:HUBEI UNIV OF TECH

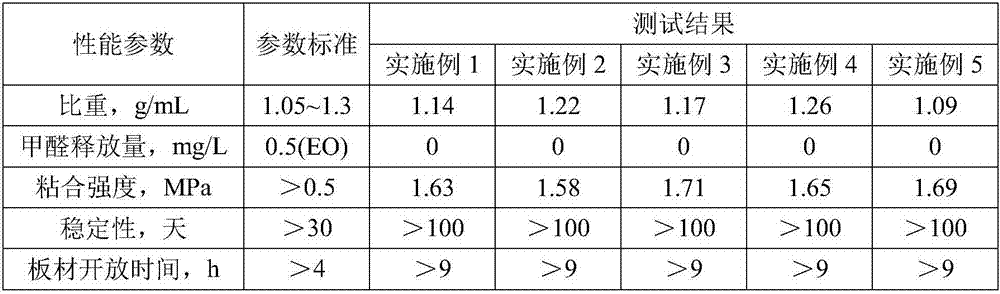

Formaldehyde-free board adhesive and preparing method

InactiveCN107474767ACompatibility is reasonableExcellent adhesionStarch derivtive adhesivesEster polymer adhesivesMethyl celluloseEther

The invention belongs to the technical field of adhesives, and particularly relates to a formaldehyde-free board adhesive. The adhesive is prepared from, by weight, 30-50 parts of deionized water, 15-30 parts of ethyl acrylate, 5-15 parts of starch ether, 3-10 parts of methyl cellulose ether, 1-5 parts of polyving akohol, 1- 10 parts of curing agent, 0.5-2 parts of thickener, 0.1-1 part of antifoaming agent, and 0.1-0.5 part of pH regulator. Compared with the existing technology, the prepared environment-friendly adhesive has the advantages of reasonable compatibility of raw materials, no pollution to environment, no formaldehyde and other harmful substances, and good adhesion and stability performances. In addition, the invention further provides a preparing method for the formaldehyde-free board adhesive, the preparation process and preparation equipment are simple and feasible, so that the adhesive is suitable for large-scale industrial production and has a good prospect.

Owner:东莞市冠力胶业有限公司

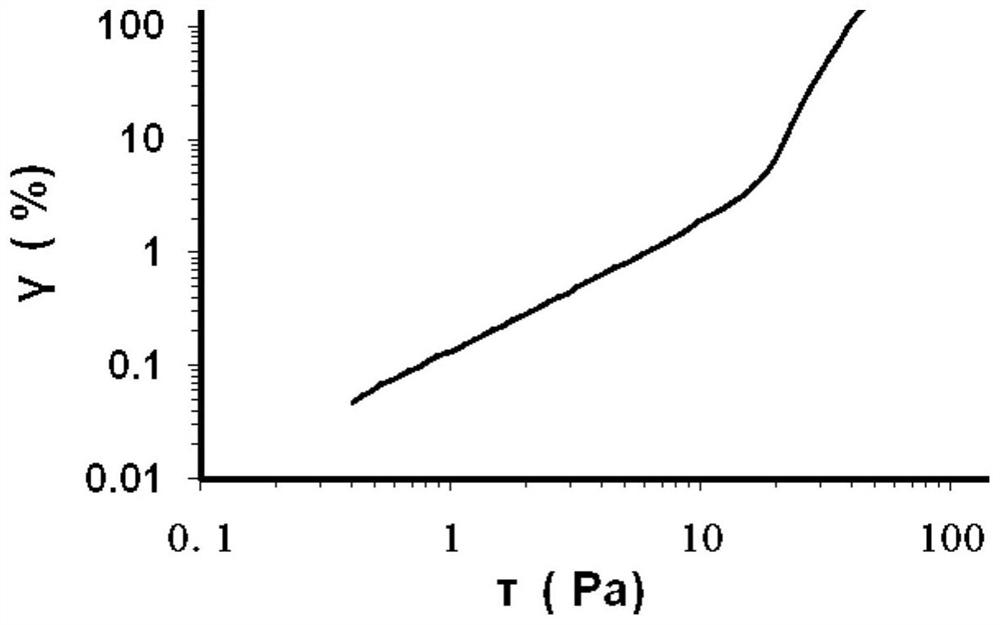

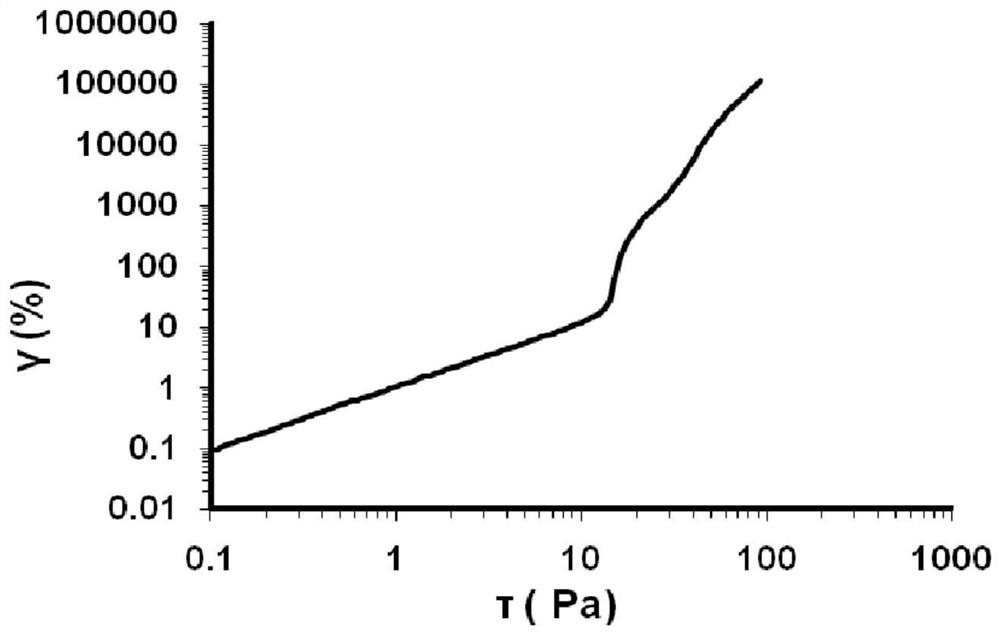

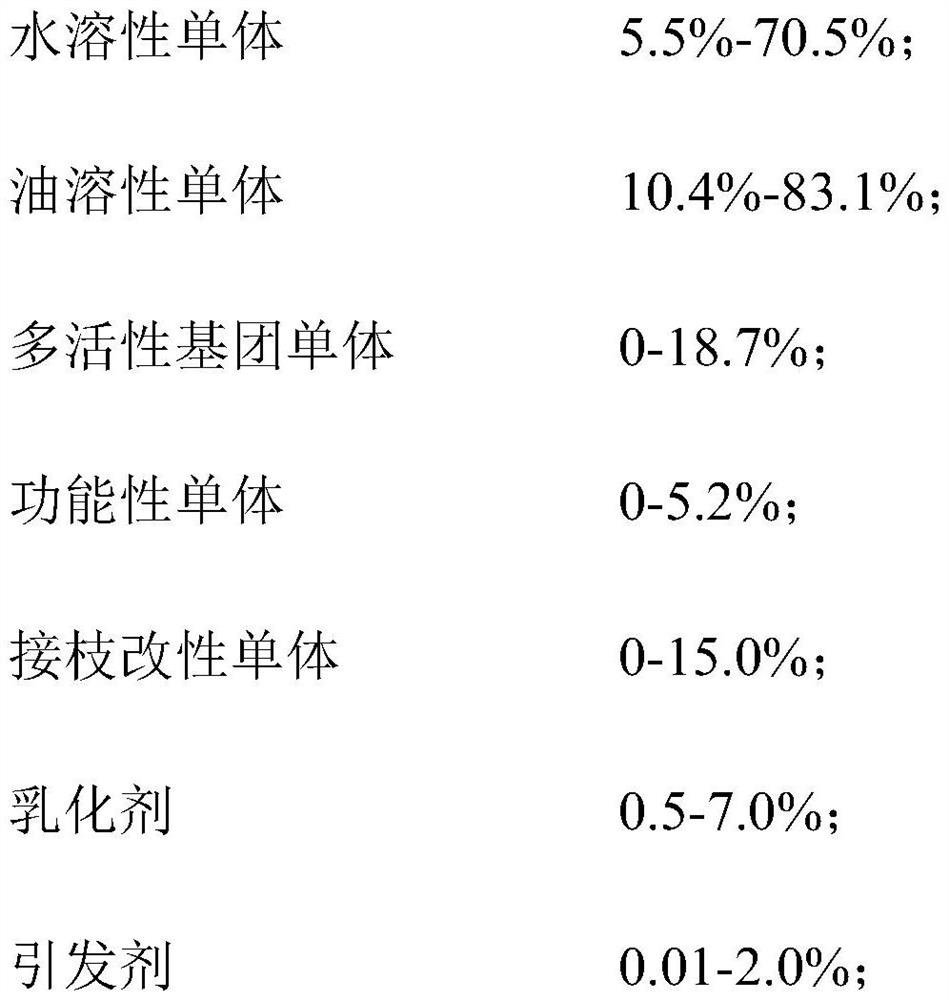

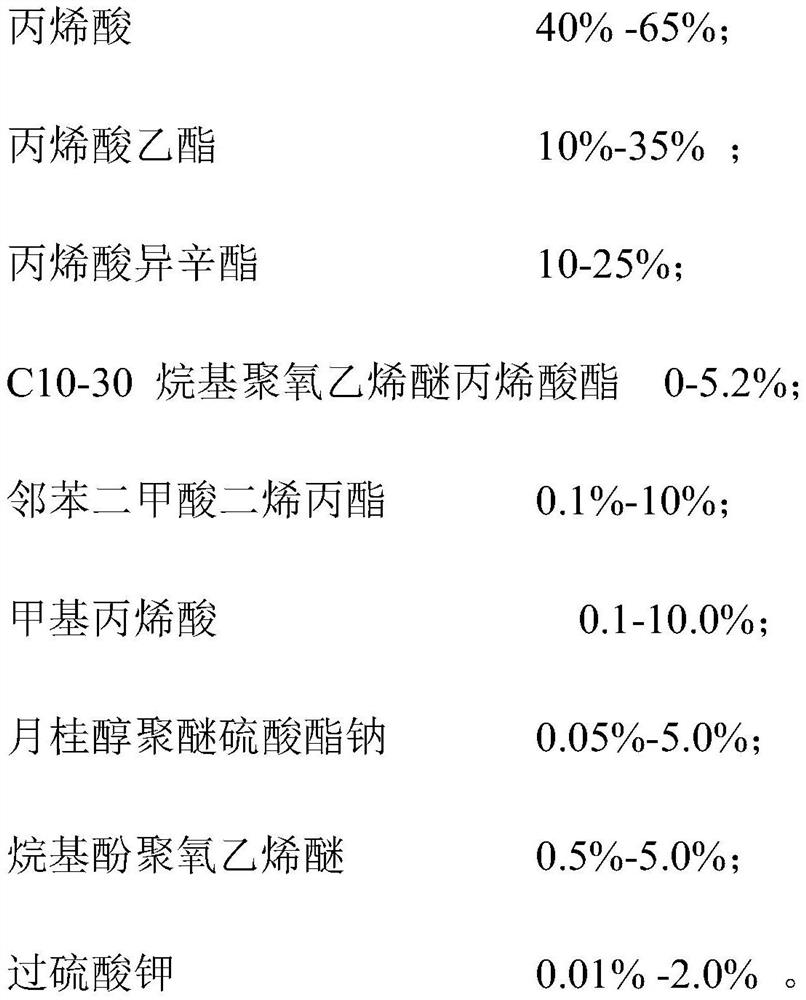

High-yield-value and high-transparency suspension stabilizer as well as preparation process and application thereof

ActiveCN112225846AHigh yield valueImprove suspension stabilityTransportation and packagingMixingHydrophilic monomerPolymer science

The invention relates to the field of suspension stabilizers, in particular to a high-yield-value and high-transparency suspension stabilizer and a preparation process and application thereof, and relates to the field of suspension stabilizers. The suspension stabilizer comprises the following components in percentage by mass: 5.5%-70.5% of a water-soluble monomer; 10.4%-83.1% of an oil-soluble monomer; 0-18.7% of a multi-active group monomer; 0-5.2% of a functional monomer; 0-15.0% of a graft modified monomer; 0.5-7.0% of an emulsifier; and 0.01-2.0% of an initiator. The graft modified monomer is a hydrophilic monomer and / or a hydrophilic group graft modified monomer. Compared with the prior art at home and abroad, a later grafting modification process is added, the yield value of the product is 1-5 times that of similar products on the market, the suspension capacity is higher, and the dosage of the suspension stabilizer in the same formula can be reduced by 20-50%. Meanwhile, the compound light transmittance reaches 97% or above, the suspension stabilizer is basically completely transparent and is suitable for suspended petals, frosted particles and the like of high-transparencyproducts, and the color and sensory effects of the products are improved.

Owner:GUANGZHOU DX CHEM

Sunscreen lotion and preparation method thereof

PendingCN112336646ALess irritatingHigh yield valueCosmetic preparationsToilet preparationsSunscreen agentsSunscreen Effect

The invention discloses a sunscreen lotion, and relates to the technical field of daily cosmetics. The sunscreen lotion comprises 12-22 parts of a sunscreen agent, 4-7 parts of a sunscreen solvent, 8-15 parts of a humectant, 0.5-1 part of a thickening suspending agent and 1-5 parts of an auxiliary agent, wherein the sunscreen agent comprises a liquid sunscreen agent and a solid sunscreen agent; and the auxiliary agent comprises a lubricant, a chelating agent and a skin conditioner. The sunscreen lotion prepared by the formula has a good sunscreen effect and antibacterial and anti-inflammatoryeffects, is relatively good in skin feeling, refreshing, non-greasy and relatively good in stability, and is suitable for long-term storage.

Owner:广东柏俐臣生物科技有限公司

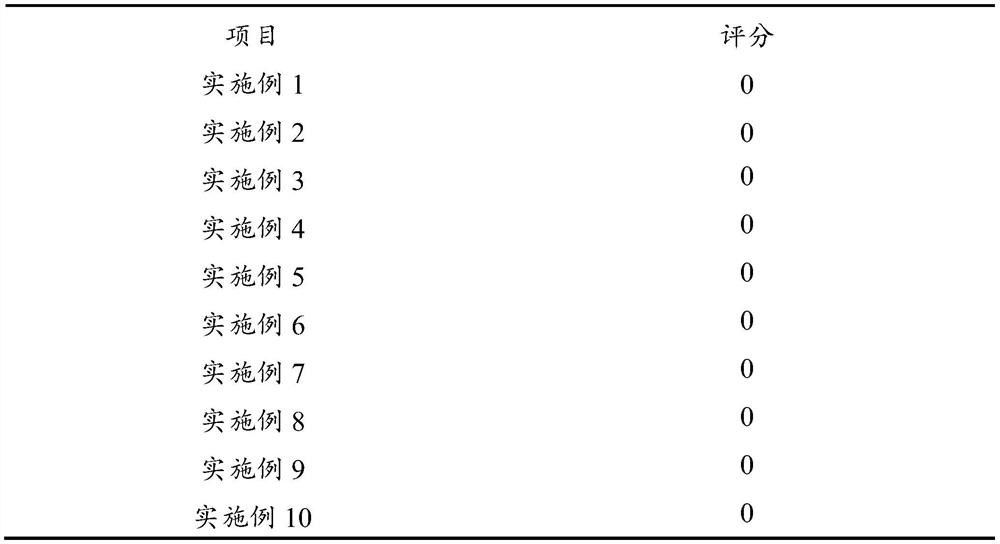

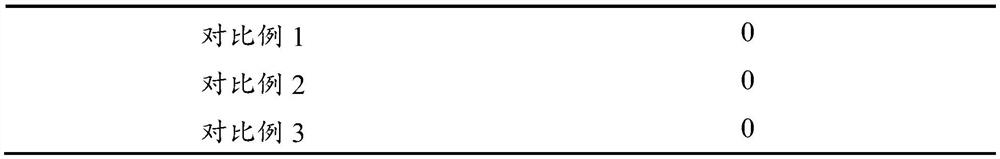

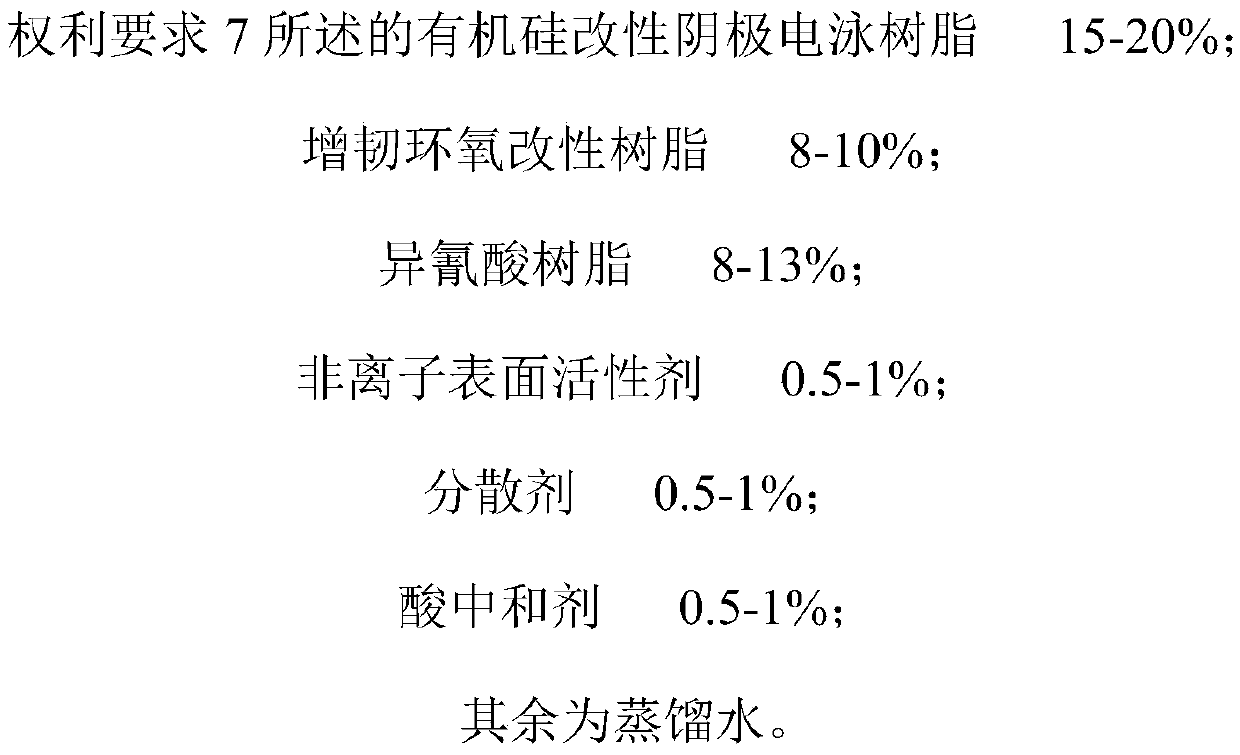

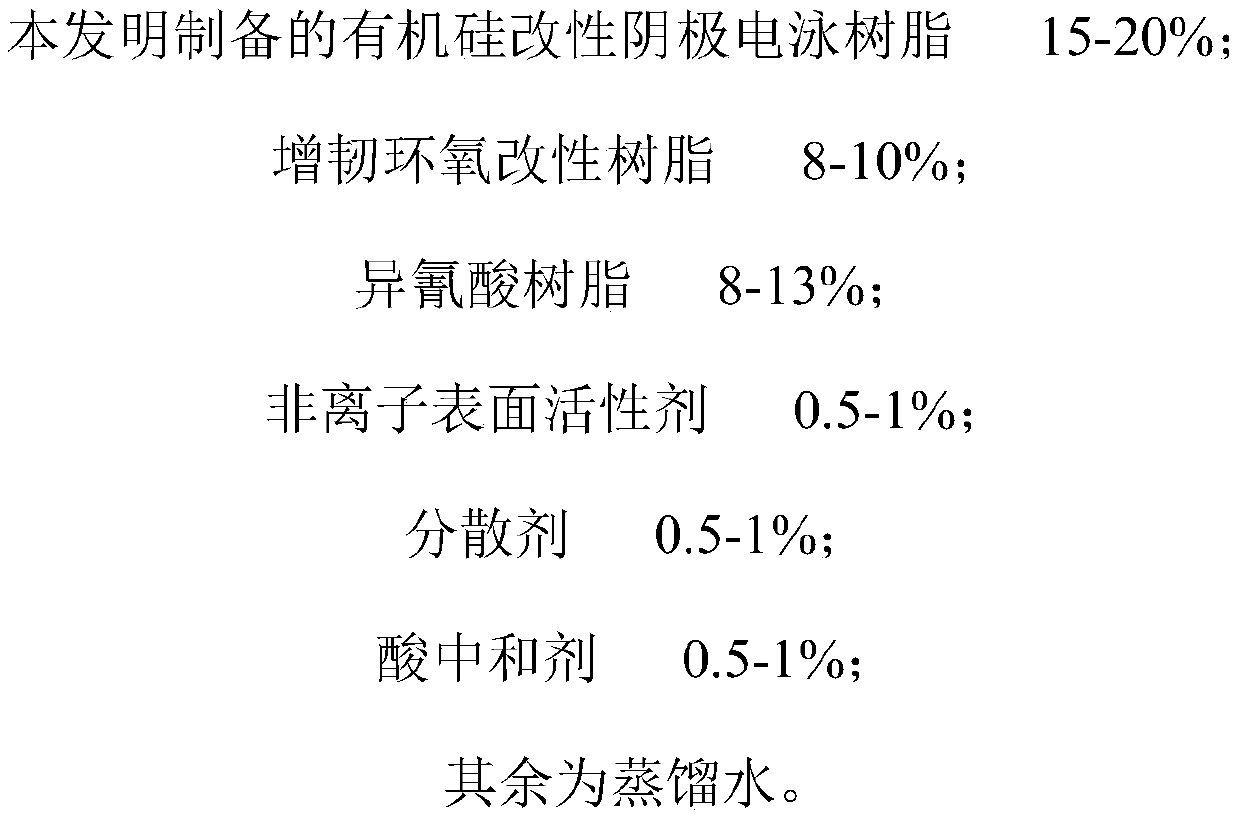

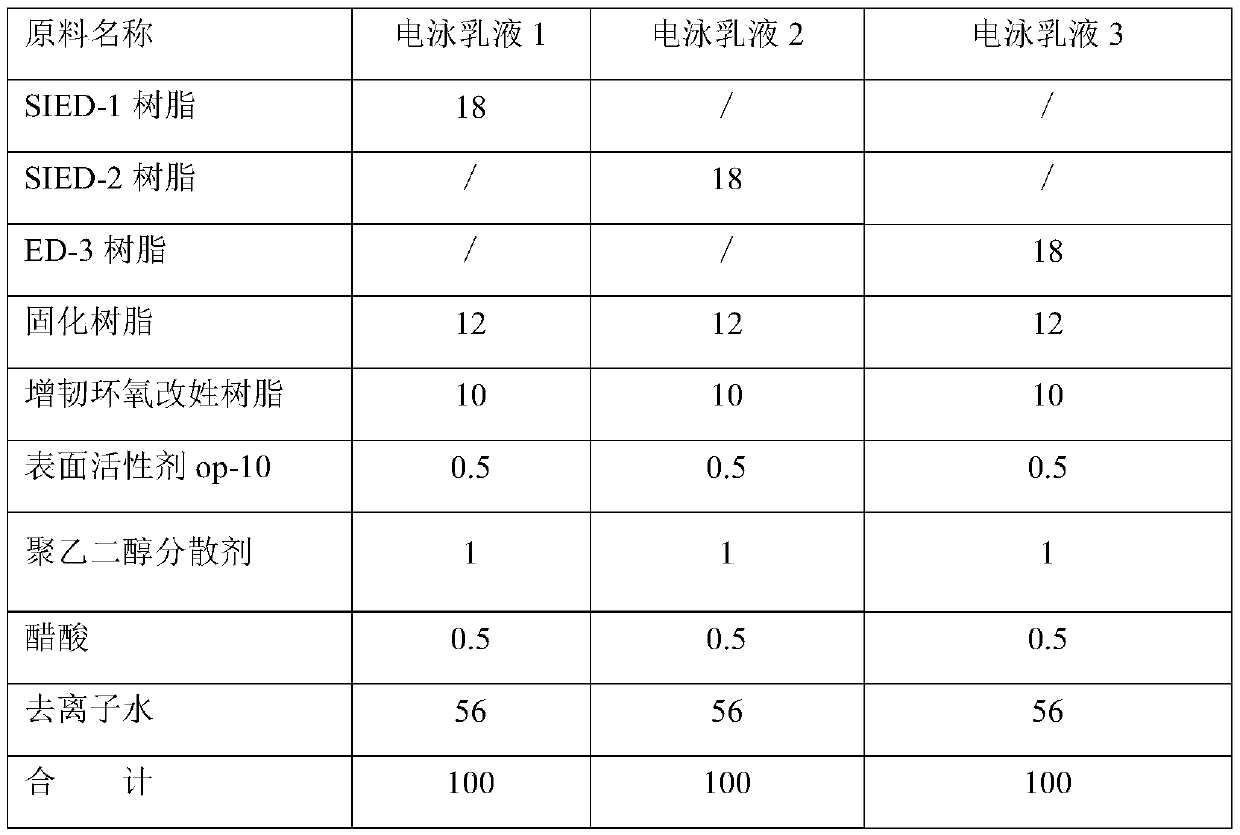

Preparation method of organic silicon modified cathode electrophoresis resin and cathode electrophoresis emulsion prepared by preparation method

PendingCN111019092AIncrease film thicknessImproved sharp edge corrosion performanceAnti-corrosive paintsPolyurea/polyurethane coatingsOrganosiliconMethyl isobutyl ketone

The invention discloses a preparation method of organic silicon modified cathode electrophoresis resin and a cathode electrophoresis emulsion prepared by preparation method. The preparation method comprises the steps: mixing epoxy resin E-51, bisphenol A, diethanol amine and methyl isobutyl ketone, carrying out a reaction at the temperature of 115-125 DEG C for 1 h, continuously adding an organicsilicon monomer, and carrying out a reaction for 2-2.5 h; adding methyl isobutyl ketone, controlling the reaction temperature to 90 DEG C, adding diethanol amine, heating to 140 DEG C, and carrying out a reaction for 3 h; and supplementing methyl isobutyl ketone, uniformly mixing and stirring, cooling and discharging to obtain the organic silicon modified cathode electrophoresis resin. The cathodeelectrophoresis emulsion and a bath solution are prepared by taking the organic silicon modified cathode electrophoresis resin as a raw material, the obtained cathode electrophoresis emulsion is stable in storage, and a paint film of a sample plate obtained by bath solution electrophoresis plate making is relatively good in salt spray resistance, sharp edge corrosion resistance and cup drawing performance.

Owner:WUHU CHUNFENG NEW MATERIAL

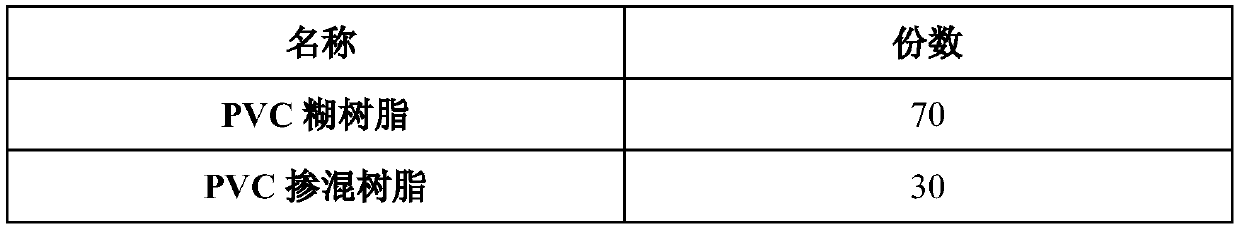

Preparation method of nano calcium carbonate for PVC automobile bottom gluing yield enhancement

ActiveCN109399683AGood dispersionHigh yield valueCalcium/strontium/barium carbonatesNanotechnologyEmulsionMicro bubble

The invention relates to a preparation method of nano calcium carbonate for PVC automobile bottom gluing yield enhancement, which comprises the following steps of: (1) calcining and crushing limestoneinto fine particles; adding hot water for digestion; (2) sieving to prepare emulsion; (3) after being diluted through adding water, placing the mixture in a micro-bubble type ultra-fine calcium carbonate synthesis reactor at the temperature of less than or equal to 30 DEG C; (4) introducing mixed gas during stirring; adding a crystal touch change modifier when the conductivity rises after firstlydropping to the bottom of a valley; standing when the conductivity rises to the initial value; introducing air until the pH value is 7 when the mixture is stirred again; (5) placing the mixture in areaction kettle for heating and heat preservation. Adding a surface touch change modifier and uniformly stirring; (6) filtering, drying and crushing. The obtained product can effectively improve the yield value of a rubber product under the condition of the same viscosity.

Owner:NORTHEASTERN UNIV

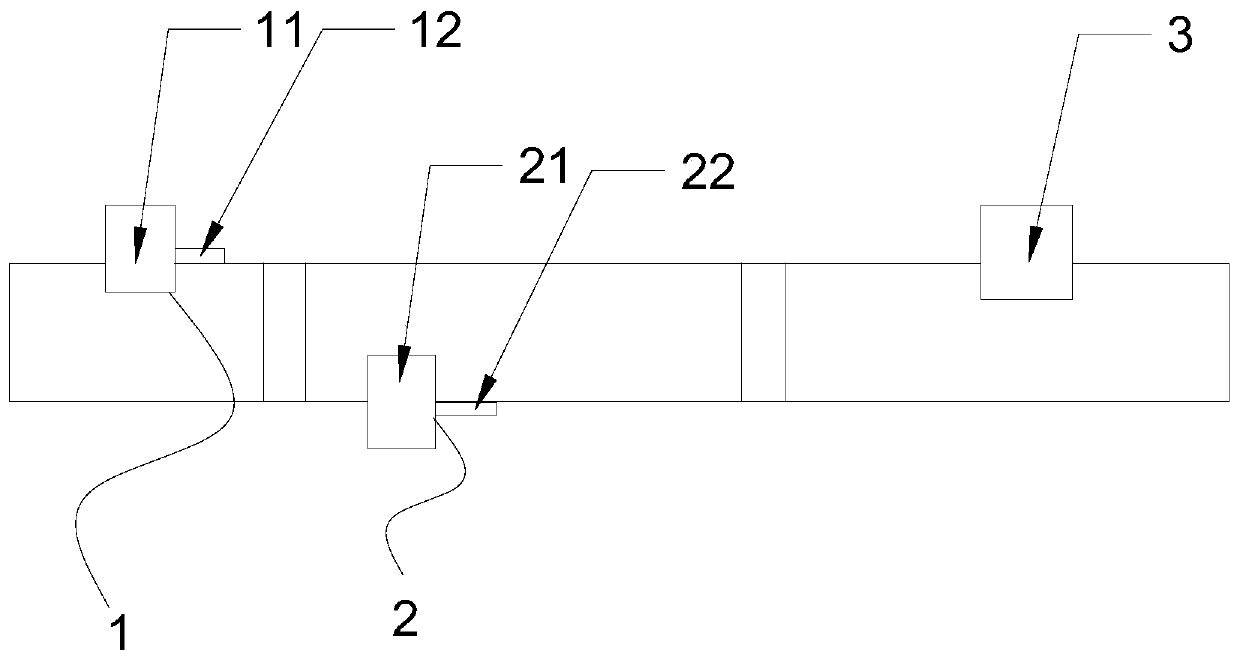

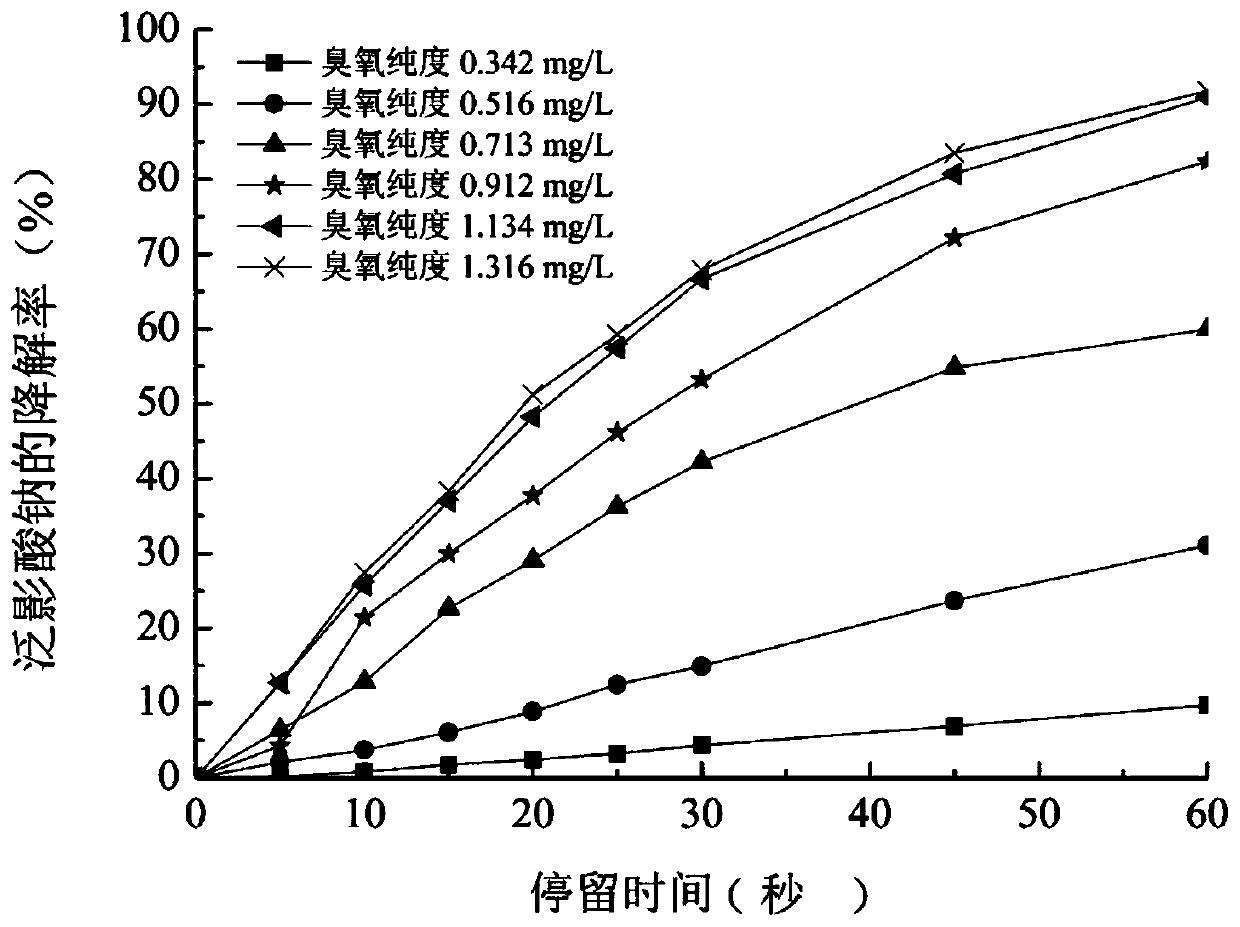

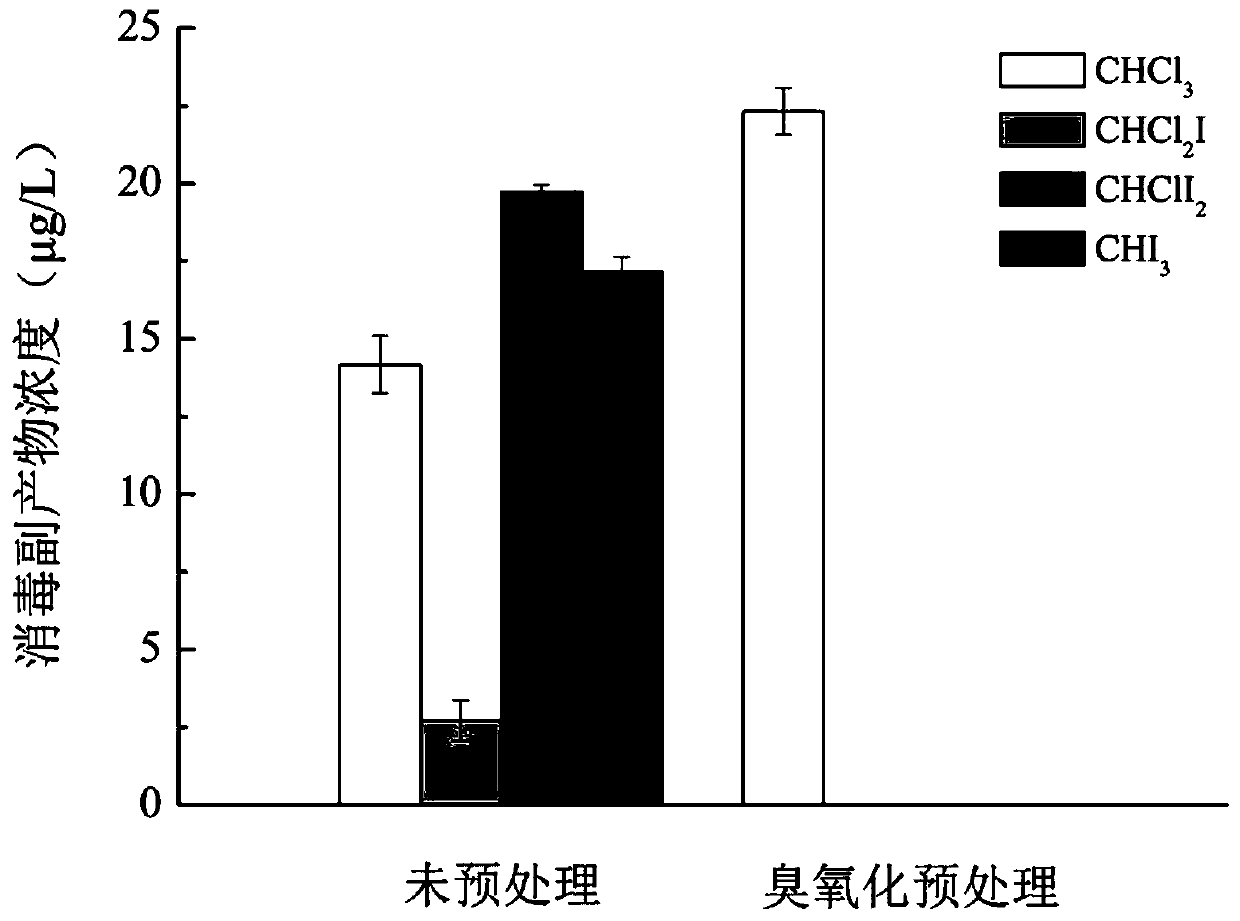

Device for removing iodo-X-ray contrast agent in water

InactiveCN110204090AImprove processing efficiencyMaintain stabilityWater contaminantsMultistage water/sewage treatmentOzone generatorX-ray

The invention relates to a device for removing an iodo-X-ray contrast agent in water. The device comprises a three-segment-type pipe, a pretreatment assembly, an ozone oxidization assembly and a post-oxidization assembly which are in series connection in sequence; the pretreatment assembly is arranged on a first pipe segment and comprises a PH meter and an acid / alkaline liquid addition module; theozone oxidization assembly is arranged on a second pipe segment and comprises an ozone generator and an ozone concentration detector; the post-oxidization assembly is arranged on a third pipe segmentand comprises a chloracid addition device used for introducing a chloracid solution into water flowing through the ozone generation assembly. Compared with the prior art, the efficiency of treating the iodo-X-ray contrast agent by the device can reach 90% or above, the stable removal effect is achieved, and the practical application prospect is good; the PH is adjusted in the front segment, ozoneis introduced in the middle segment, chlorine is adopted for treatment in the back segment, and the treatment capacity per unit time is significantly increased.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

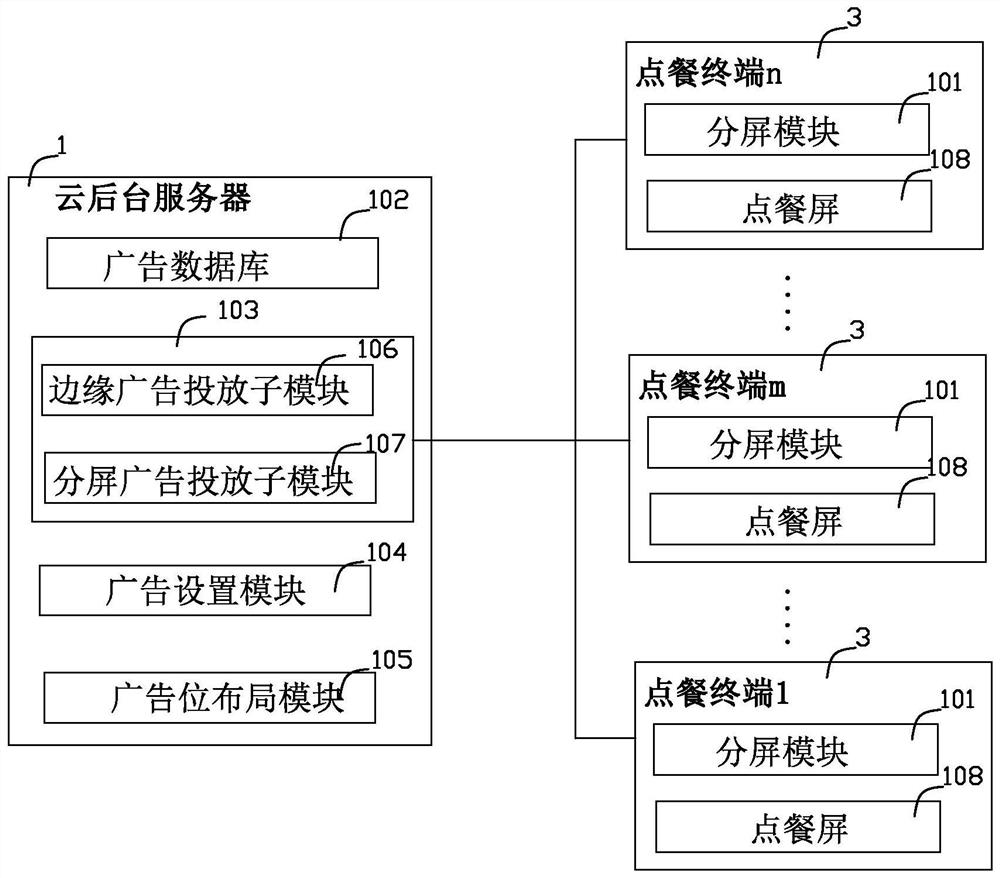

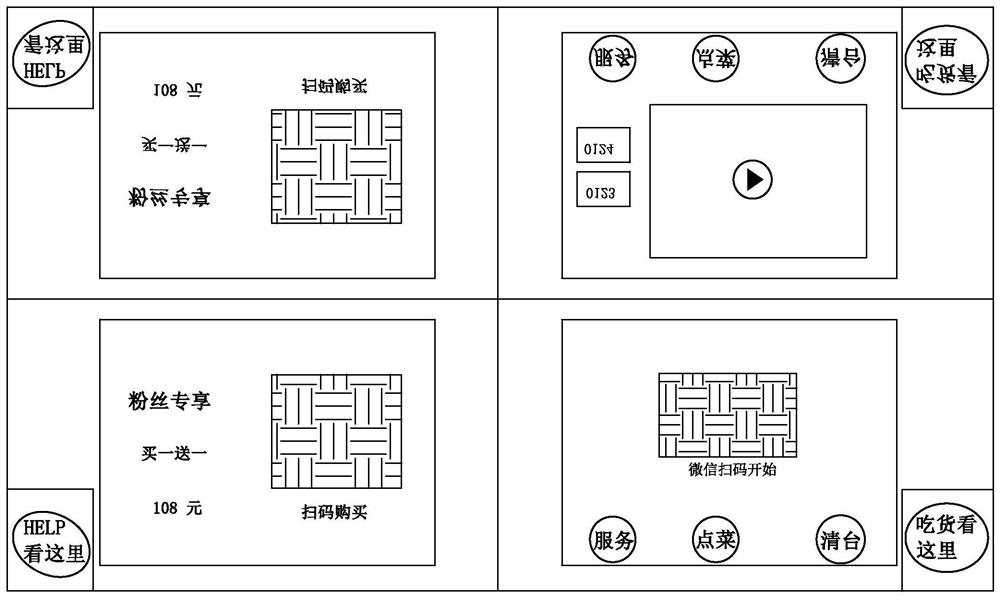

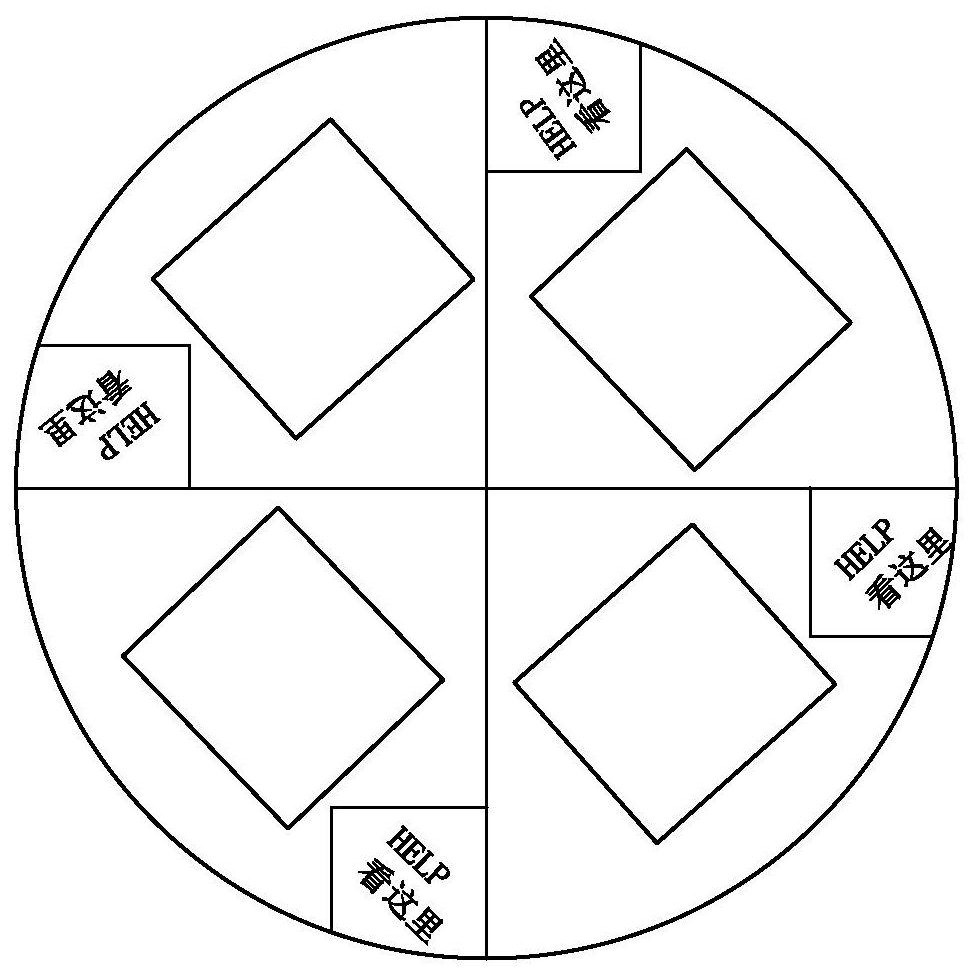

A system for displaying commercial advertisements using large restaurant traffic data

ActiveCN107967623BLarge playback volumePrecise deliveryAdvertisementsArticle advertisingEngineeringTouchscreen

The invention relates to a system for displaying commercial advertisements by using large-flow data in a restaurant, including a cloud background server and a device terminal with ID information communicating with the cloud background server. The device terminal includes a meal ordering terminal, and each meal ordering terminal includes settings A touch screen point table, split screen module and more than one table ID; cloud background server package advertisement database, advertisement delivery module, advertisement setting module and advertisement space layout module; system provided by the present invention includes the intelligent Dining table, set up different partitions according to the number of seats to form a diversified display interface, and then rationally arrange different advertising spaces according to the characteristics of the table and dining; it can support the configuration of advertisements, support videos, pictures, QR codes, etc. Advertisement supports precise advertisement delivery for different merchants, business districts, advertising spaces and groups of people, so as to achieve the effect with the highest revenue value.

Owner:北京新弘宝科技有限公司

A kind of method that uses low-grade magnesite to prepare magnesium oxide raw material and low particle size magnesium hydroxide

ActiveCN105924023BLow yield valueSmall particle sizeMagnesium hydroxideLime productionBarium dichlorideSulfate

Owner:刘昕

Production method for attapulgite ceramic plastic mass

The invention discloses a production method for an attapulgite ceramic plastic mass. The key point of the technical scheme is that the production method comprises the following steps of: crushing ingredients of the attapulgite ceramic plastic mass, performing sodium treatment on the crushed mixture into a moist mixture, pressing the moist mixture into a sheet, extruding into a strip, airing the strip, grinding, removing iron from powder, adding water into the powder, extruding into a cylindrical strip, and packaging into the finished product of the attapulgite ceramic plastic mass. The attapulgite ceramic plastic mass consists of attapulgite clay, white bentonite, sepiolite, calcined clay, sodium metasilicate and sodium carbonate. The attapulgite ceramic plastic mass has uniform water content and consistent structure, and has the characteristics of good cohesiveness, plasticity, high yield value and large extension deformation; ceramic products prepared from the attapulgite ceramic plastic mass have the characteristics of small shrinkage, no deformation, high strength, and uniform texture; and the attapulgite ceramic plastic mass is suitable for producing the ceramic products.

Owner:XUYI KEYUAN NEW MATERIALS FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com