Formaldehyde-free board adhesive and preparing method

An adhesive and sheet technology, applied in the directions of adhesives, adhesive types, cellulose adhesives, etc., can solve problems such as formaldehyde pollution and harm to health, increase water retention, improve flow performance, and simple preparation equipment workable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

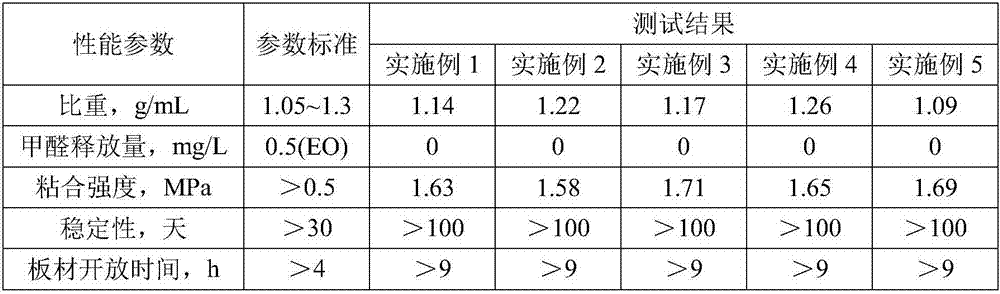

Examples

Embodiment 1

[0025] This embodiment provides a formaldehyde-free sheet adhesive, comprising the following components by mass: 30 parts of deionized water, 15 parts of ethyl acrylate, 5 parts of starch ether, 3 parts of methyl cellulose ether, and 1 part of polyvinyl alcohol , 1 part of MDI-50 curing agent, 0.5 part of water-based polyurethane associative thickener, 0.1 part of polyether modified silicone defoamer, and 0.1 part of trishydroxymethylaminomethane.

[0026] The preparation method of the formaldehyde-free sheet adhesive of the present embodiment comprises the following steps:

[0027] Step 1: Add ethyl acrylate, starch ether, and methyl cellulose ether into the reaction kettle in sequence, raise the temperature to 55°C, and stir evenly;

[0028] Step 2: Add polyvinyl alcohol, water-based polyurethane associative thickener and polyether modified silicone defoamer to the obtained product in Step 1, continue to heat up to 72°C, and keep warm for 2.5 hours;

[0029] Step 3: Add dei...

Embodiment 2

[0033] This embodiment provides a formaldehyde-free sheet adhesive, comprising the following components by mass: 50 parts of deionized water, 30 parts of ethyl acrylate, 15 parts of starch ether, 10 parts of methyl cellulose ether, and 5 parts of polyvinyl alcohol , 10 parts of HMDI curing agent, 2 parts of water-based polyurethane associative thickener, 1 part of mineral oil mixture defoamer, 0.5 parts of potassium methyl silicate.

[0034] The preparation method of the formaldehyde-free sheet adhesive of the present embodiment comprises the following steps:

[0035] Step 1: Add ethyl acrylate, starch ether, and methyl cellulose ether into the reaction kettle in sequence, raise the temperature to 60°C, and stir evenly;

[0036] Step 2: Add polyvinyl alcohol, water-based polyurethane associative thickener and mineral oil mixture defoamer to the obtained product in Step 1, continue to heat up to 78°C, and keep warm for 2.5 hours;

[0037] Step 3: Add deionized water to the obt...

Embodiment 3

[0041] This embodiment provides a formaldehyde-free sheet adhesive, comprising the following components by mass: 40 parts of deionized water, 20 parts of ethyl acrylate, 10 parts of starch ether, 6 parts of methyl cellulose ether, and 3 parts of polyvinyl alcohol , a total of 5 parts of IPDI curing agent and HDI curing agent, 1 part of aqueous alkali-swellable acrylic thickener, 0.5 part of modified polysiloxane emulsion defoamer, and 0.3 part of ammonia water.

[0042] The preparation method of the formaldehyde-free sheet adhesive of the present embodiment comprises the following steps:

[0043] Step 1: Add ethyl acrylate, starch ether, and methyl cellulose ether into the reaction kettle in sequence, raise the temperature to 58°C, and stir evenly;

[0044] Step 2: Add polyvinyl alcohol, water-based alkali-swellable acrylic thickener and modified polysiloxane emulsion defoamer to the obtained product in Step 1, continue to heat up to 75°C, and keep warm for 2.5 hours;

[0045...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com