Dedusting, desulfurization and denitrification integrated treatment process for industrial smoke

A technology for industrial flue gas, desulfurization and denitrification, which is applied in the direction of air quality improvement, the use of liquid separating agents, chemical instruments and methods, etc., can solve the problems of wasting water resources, high industrial energy consumption, complex processes, etc., and reduce industrial energy consumption. , The effect of low investment cost and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

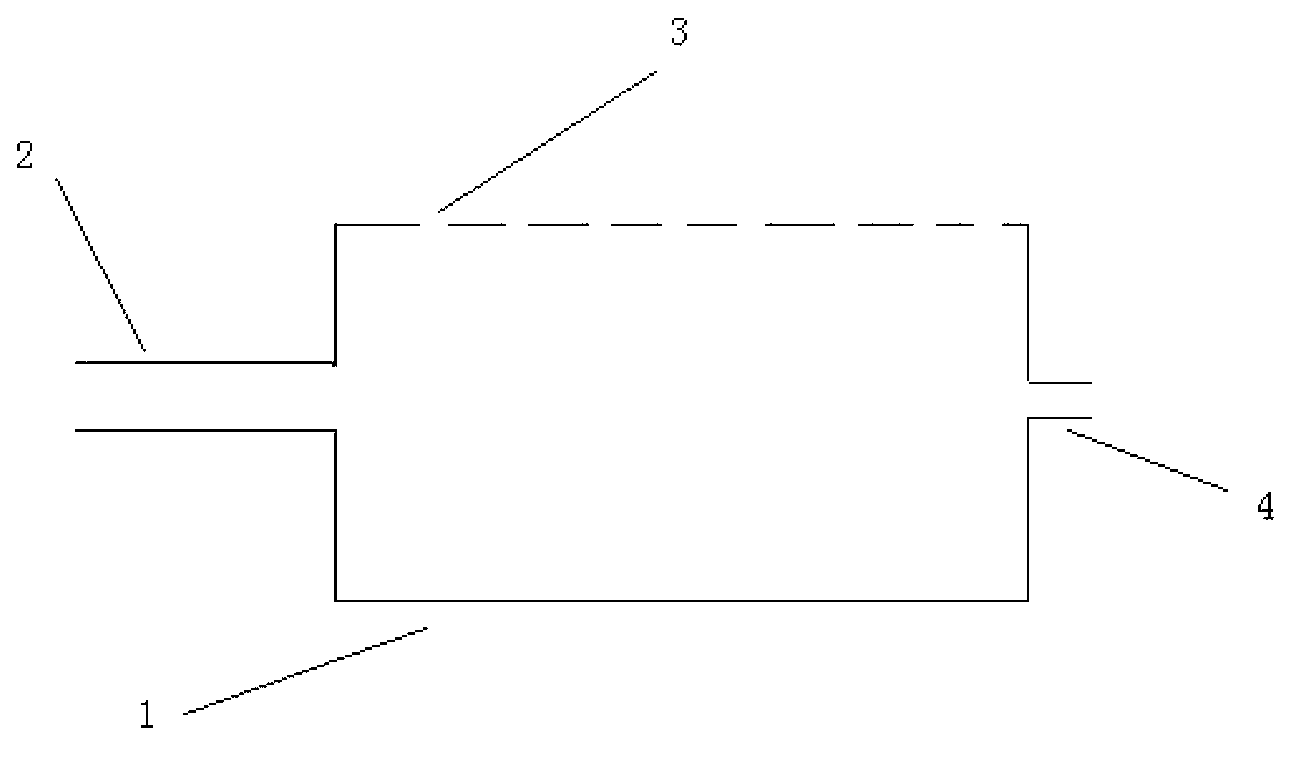

Image

Examples

Embodiment 1

[0036]An integrated dust removal, desulfurization and denitrification treatment process for controlling industrial flue gas, which includes the following steps: industrial flue gas enters the cooling pipe from the chimney for refrigeration treatment, so that the temperature of the flue gas is controlled at 25°C, and then enters the biological reaction chamber, and the biological reaction The upper nozzle hole of the device sprays out the composite bacterial liquid, and performs dust removal, desulfurization and denitrification purification treatment on the industrial flue gas. The treatment time is 3 days, and the purified industrial flue gas is finally discharged through the gas outlet;

[0037] The composite bacteria solution is mixed with the following raw material bacteria in weight fractions: 30% Thiobacillus denitrificans, 20% Pseudomonas aeruginosa, 15% Acidophilus Thiobacillus ferrooxidans, 15% Bacillus subtilis, waxy Bacillus 10%, Alcaligenes faecalis 10%.

[0038] Se...

Embodiment 2

[0041] An integrated dust removal, desulfurization and denitrification treatment process for controlling industrial flue gas, which includes the following steps: industrial flue gas enters the cooling pipe from the chimney for refrigeration treatment, so that the temperature of the flue gas is controlled at 30°C, and then enters the biological reaction chamber, and the biological reaction The upper nozzle hole of the device sprays out the composite bacterial liquid, and performs dust removal, desulfurization and denitrification purification treatment on the industrial flue gas. The treatment time is 3 days, and the purified industrial flue gas is finally discharged through the gas outlet;

[0042] The composite bacteria solution is mixed with the following raw material bacteria in weight fractions: 30% Thiobacillus denitrificans, 20% Pseudomonas aeruginosa, 15% Acidophilus Thiobacillus ferrooxidans, 15% Bacillus subtilis, waxy Bacillus 10%, Alcaligenes faecalis 10%.

[0043] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com