High-yield-value and high-transparency suspension stabilizer as well as preparation process and application thereof

A suspension stabilizer, high-transparency technology, used in transportation and packaging, chemical instruments and methods, dissolution, etc., can solve the problems of poor product experience, inability to distribute evenly, sink or float, etc., and achieve high yield value, increase Sensory effect, good suspension stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

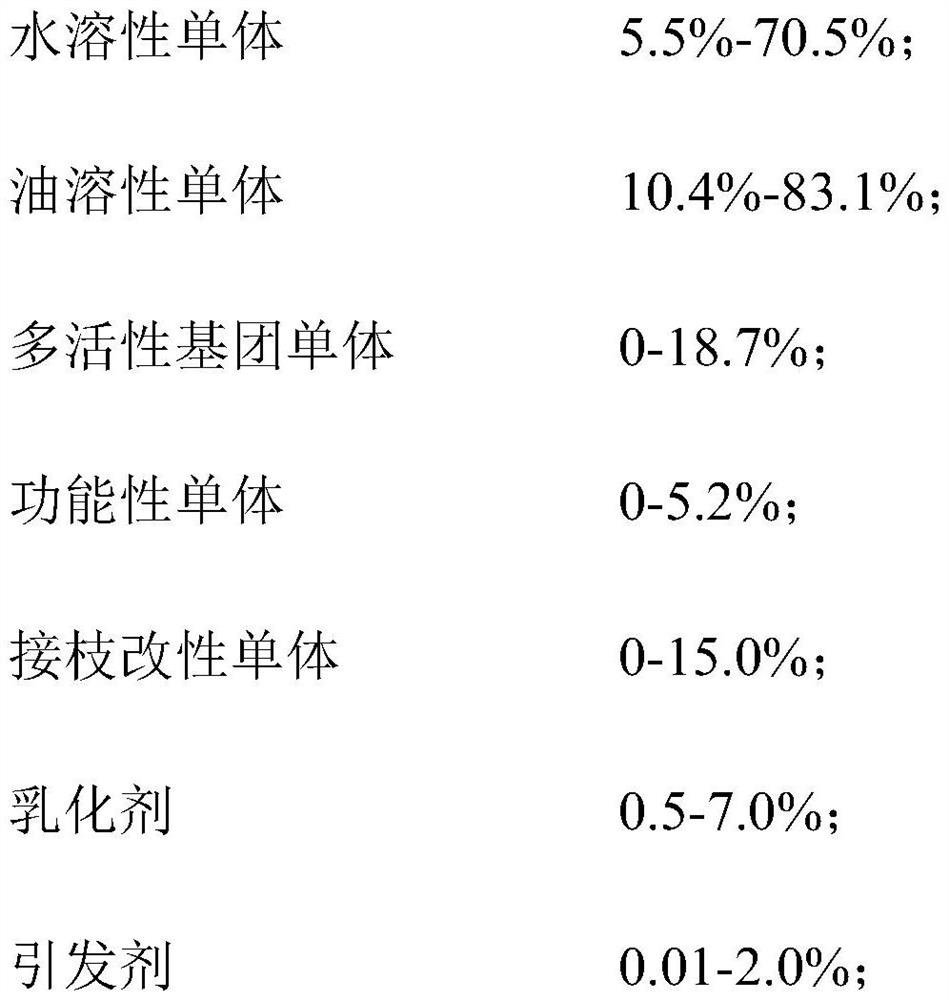

[0068] A suspension stabilizer with high yield value and high transparency, comprising the following ingredients:

[0069]

[0070] The preparation technology of this suspension stabilizer is:

[0071] (1) Add 423g deionized water to a 1L stirred flask, add 1.7gTX-10, 2.2g AES-Na at the same time, stir well, rotate at 400-600 rpm, then add 171g of acrylic acid and 105g of ethyl acrylate , isooctyl acrylate 49g, diallyl phthalate 2.2g, keep stirring at a high speed, and prepare an emulsion for later use.

[0072] (2) Add 0.4 g of potassium persulfate into 100 g of deionized water and dissolve to prepare an aqueous initiator solution.

[0073] (3) Add 244g of deionized water, 0.7g of TX-10 and 0.9g of AES-Na to another four-necked flask, and start stirring at 400-600 rpm. After 10 minutes, add 40g of the emulsion in the first step, and slowly Heat up and adjust the speed to 20-40 rpm. When the temperature rises to 75°C, add the aqueous initiator solution dropwise, and star...

Embodiment 2

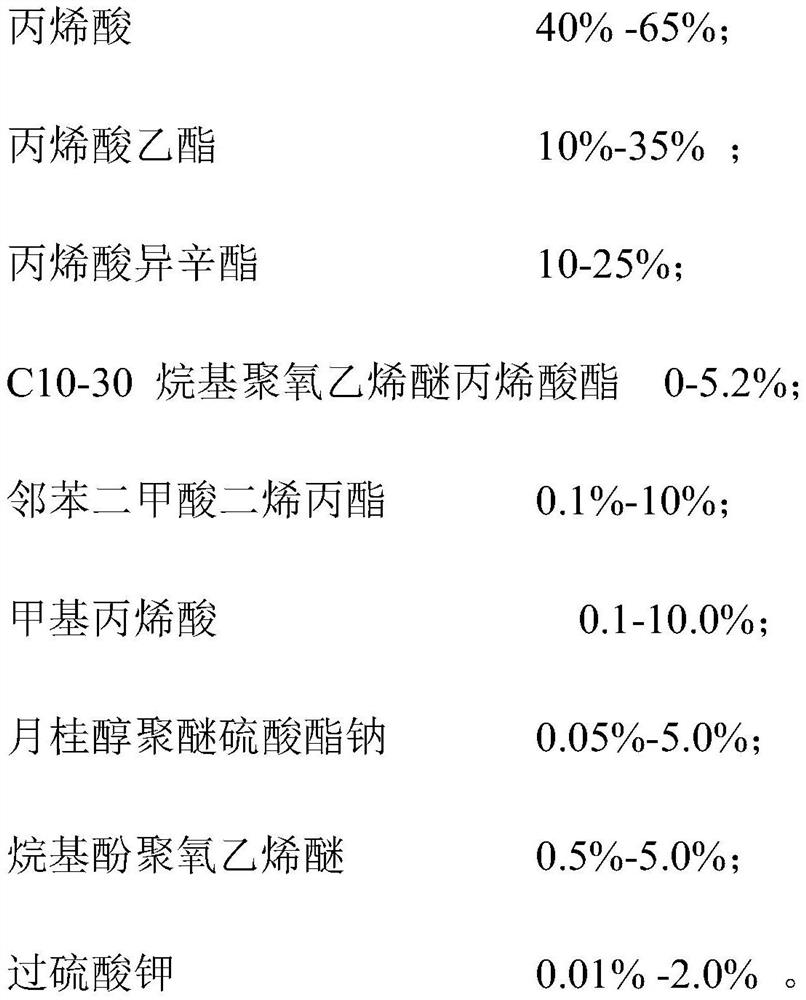

[0084] A suspension stabilizer with high yield value and high transparency, comprising the following ingredients:

[0085]

[0086] The preparation technology of this suspension stabilizer is:

[0087] (1) Add 423g deionized water to a 1L stirred flask, add 1.7gTX-10, 2.2g AES-Na at the same time, stir well, rotate at 400-600 rpm, then add 171g of acrylic acid and 105g of ethyl acrylate , 49g of isooctyl acrylate, 2.2g of diallyl phthalate, 1.07g of C10-30 alkyl polyoxyethylene ether acrylate, kept stirring at high speed, and prepared into an emulsion for later use.

[0088] (2) Add 0.4 g of potassium persulfate into 100 g of deionized water and dissolve to prepare an aqueous initiator solution.

[0089] (3) Add 244g of deionized water, 0.7g of TX-10 and 0.9g of AES-Na to another four-necked flask, and start stirring at 400-600 rpm. After 10 minutes, add 40g of the emulsion in the first step, and slowly Heat up and adjust the speed to 20-40 rpm. When the temperature rise...

Embodiment 3

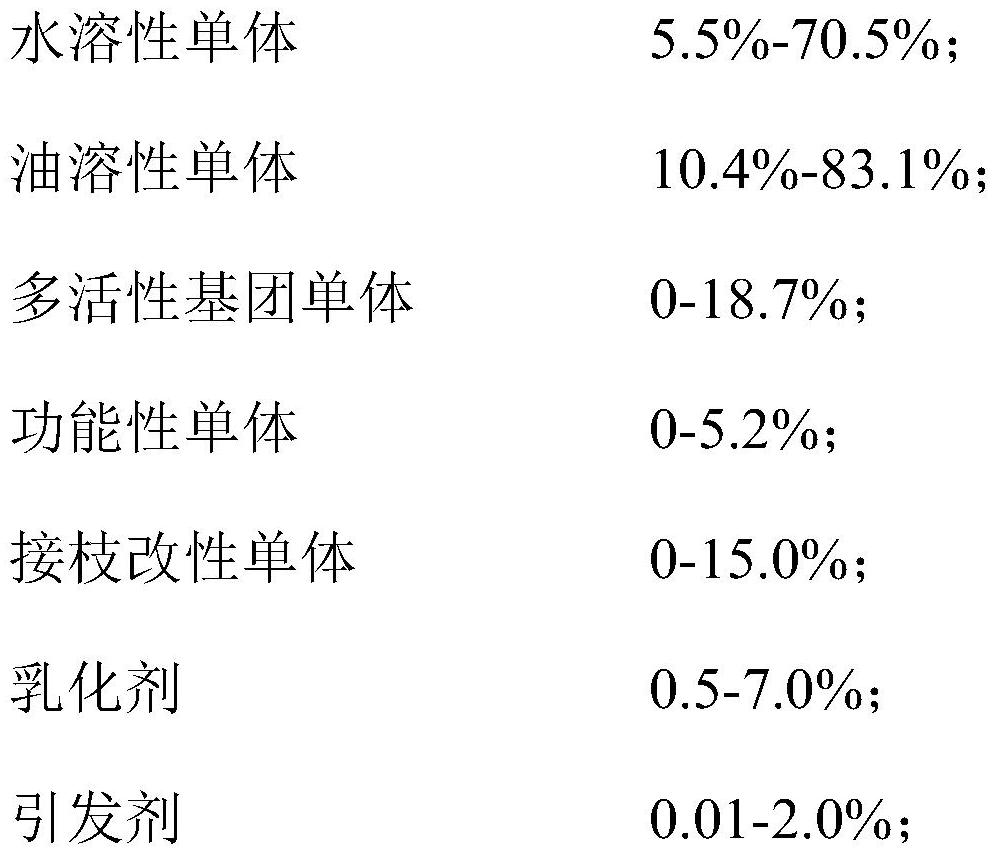

[0100] A suspension stabilizer with high yield value and high transparency, comprising the following ingredients:

[0101]

[0102]

[0103] The preparation technology of this suspension stabilizer is:

[0104] (1) Add 425g of deionized water to a 1L stirred flask, add 1.0g of sodium dodecylbenzenesulfonate and 3.4g of Tween-80 at the same time, stir well, and rotate at 400-600 rpm, then add methyl Acrylic acid 177g, ethyl acrylate 120g, N,N'-methylenebisacrylamide 4.4g, alkyl polyoxyethylene ether acrylate 5.2g, C10-30 alkyl polyoxyethylene ether acrylate 3.55g, keep stirring at high speed , prepared into an emulsion for later use.

[0105] (2) Add 0.5 g of ammonium persulfate into 100 g of deionized water and dissolve to prepare an aqueous initiator solution.

[0106](3) Add 240g of deionized water, 1.01g of sodium dodecylbenzenesulfonate and 2.4g of Tween-80 to another four-necked flask, start stirring at 400-600 rpm, and add the emulsification of the first step aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com