Preparation method of nanometer calcium carbonate for automobile primer

A technology of nano-calcium carbonate and calcium carbonate, applied in primers, chemical instruments and methods, fibrous fillers, etc., can solve the problems of reduced molecular force, long time of nano-calcium carbonate, and increased cost, and achieve high shear Reduced viscosity, enhanced anti-sag performance, and improved anti-sag performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

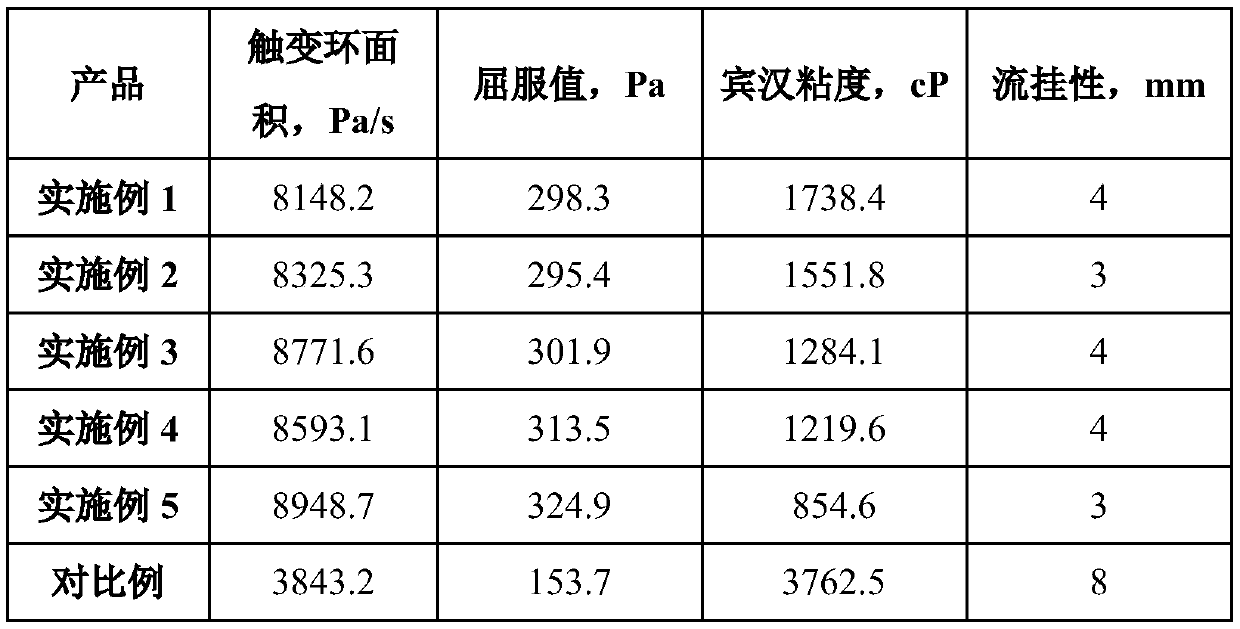

Embodiment 1

[0033] A kind of preparation method of nanometer calcium carbonate for automobile primer, comprises the following steps:

[0034] (1) Adjust the specific gravity of the refined milk of lime to 1.060, control the temperature of the milk of lime to 23°C, add 0.6% zinc sulfate crystal form control agent on a dry basis of calcium carbonate and mix evenly, then introduce the bubbling carbonation reaction kettle, and feed the volume Carbon dioxide mixed gas with a concentration of 30% is used for carbonation reaction. When the pH value of the slurry is ≤7, the reaction is stopped, and the specific surface area is selected as 25m 2 / g of calcium carbonate suspension, for subsequent use;

[0035] (2) Calcium carbonate suspension is heated to 60 ℃, and the emulsifier rotating speed is adjusted to 2500r / min, adds the surface treatment agent that is calcium carbonate dry basis mass 3.5% under stirring, and described composite surface treatment agent is by mass percentage: 68% sodium ste...

Embodiment 2

[0038] A kind of preparation method of nanometer calcium carbonate for automobile primer, comprises the following steps:

[0039] (1) Adjust the specific gravity of the refined milk of lime to 1.065, control the temperature of the milk of lime to 25°C, add 0.8% aluminum sulfate crystal form control agent on a dry basis of calcium carbonate and mix evenly, then introduce the bubbling carbonation reaction kettle, and feed the volume Carbon dioxide mixed gas with a concentration of 33% is used for carbonation reaction. When the pH value of the slurry is less than or equal to 7, the reaction is stopped, and the specific surface area is selected as 26m 2 / g of calcium carbonate suspension, for subsequent use;

[0040] (2) Calcium carbonate suspension is heated to 60 ℃, and the emulsifier rotating speed is adjusted to 2000r / min, adds the surface treatment agent that is calcium carbonate dry basis mass 3.7% under stirring, and described composite surface treatment agent is by mass pe...

Embodiment 3

[0043] A kind of preparation method of nanometer calcium carbonate for automobile primer, comprises the following steps:

[0044] (1) Adjust the specific gravity of refined milk of lime to 1.070, control the temperature of milk of lime to 24°C, add 0.3% zinc sulfate and 0.5% aluminum sulfate crystal form control agent on a dry basis of calcium carbonate and mix evenly, and then introduce bubbling carbonation reaction The kettle is fed with carbon dioxide mixed gas with a volume concentration of 33% for carbonation reaction. When the pH value of the slurry is less than or equal to 7, the reaction is stopped, and the specific surface area is selected as 24m 2 / g of calcium carbonate suspension, for subsequent use;

[0045] (2) Calcium carbonate suspension is heated to 70 ℃, and the emulsifying machine rotating speed is adjusted to 2000r / min, adds the surface treatment agent that is calcium carbonate dry basis mass 4.0% under stirring, and described composite surface treatment ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com