Patents

Literature

283 results about "Plastisol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

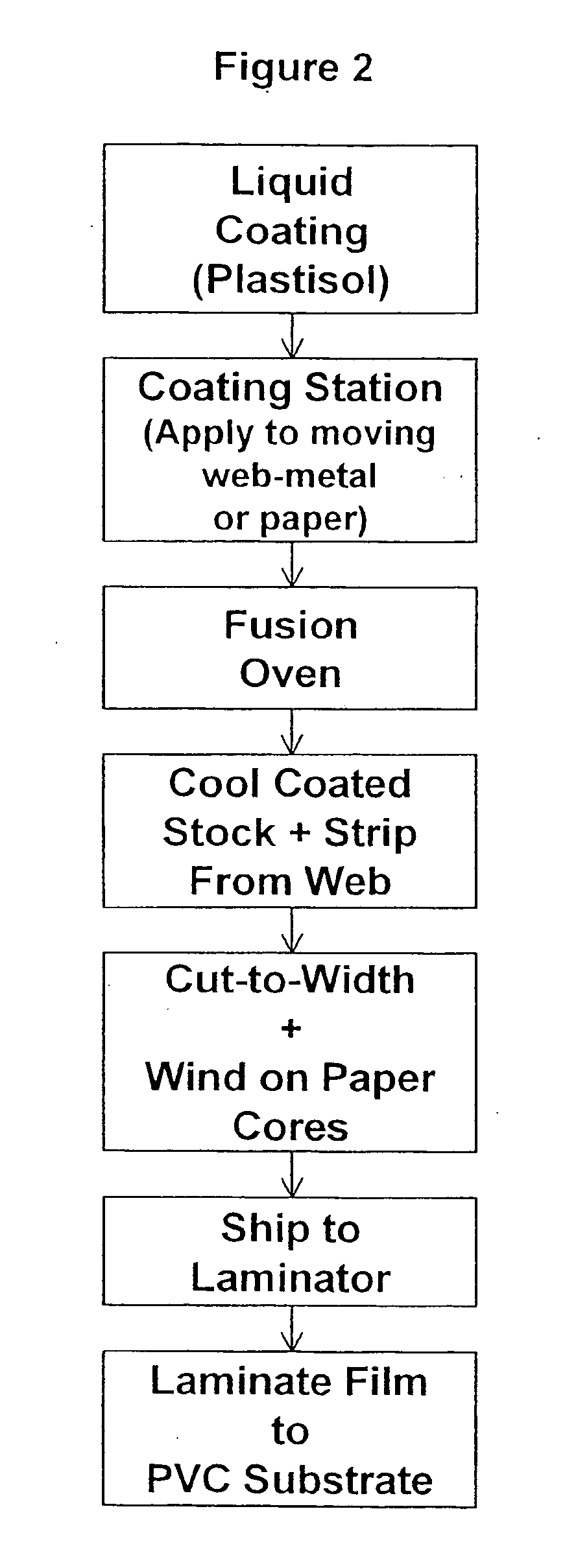

Plastisol is a suspension of PVC or other polymer particles in a liquid plasticizer; it flows as a liquid and can be poured into a heated mold. When heated to around 177 degrees Celsius, the plastic particles dissolve and the mixture turns into a gel of high viscosity that usually cannot be poured anymore. On cooling below 60 degrees C, a flexible, permanently plasticized solid product results. Aside from molding, plastisol is commonly used as a textile ink for screen-printing and as a coating, particularly in outdoor applications (roofs, furniture) and dip-coating.

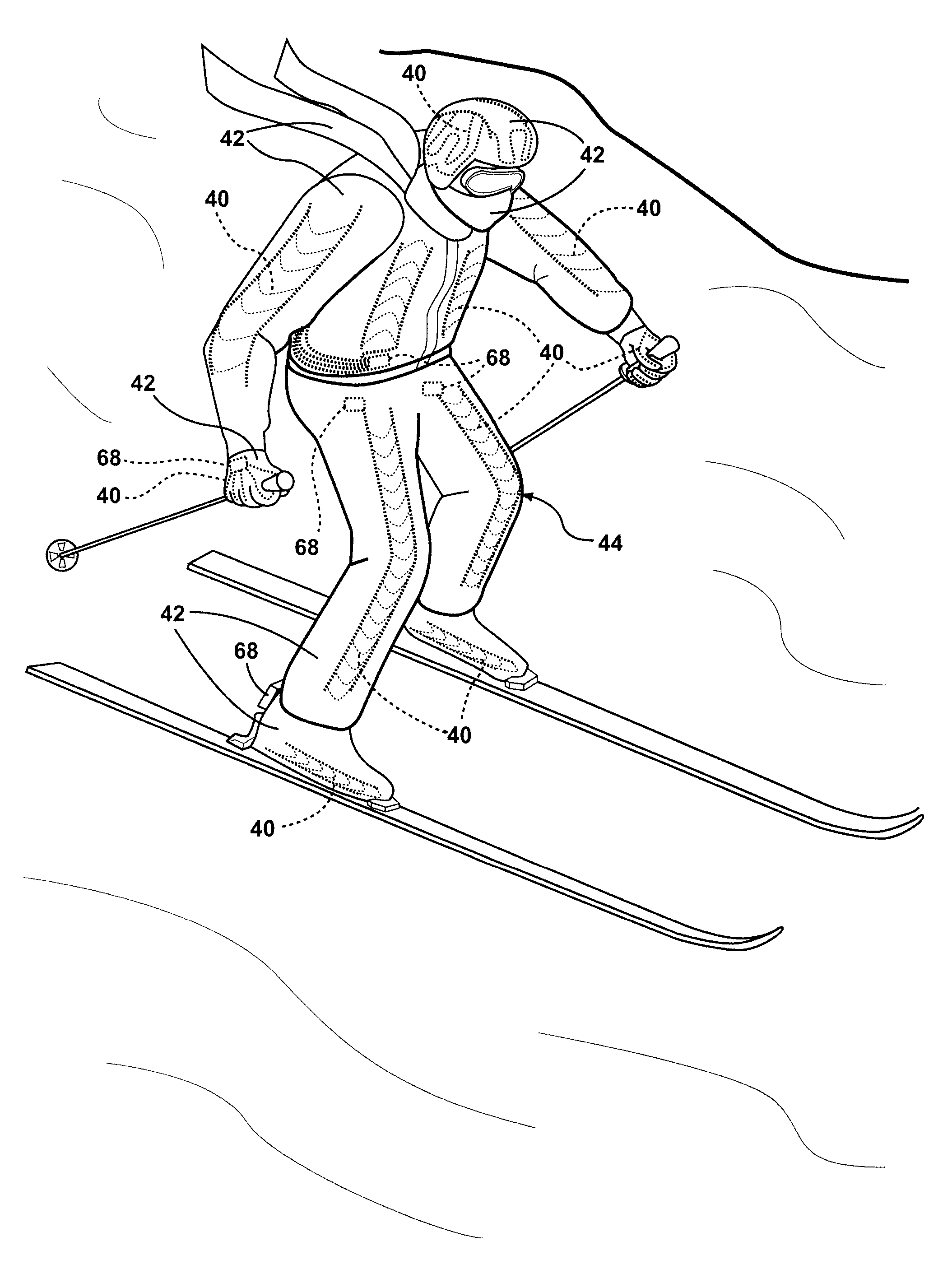

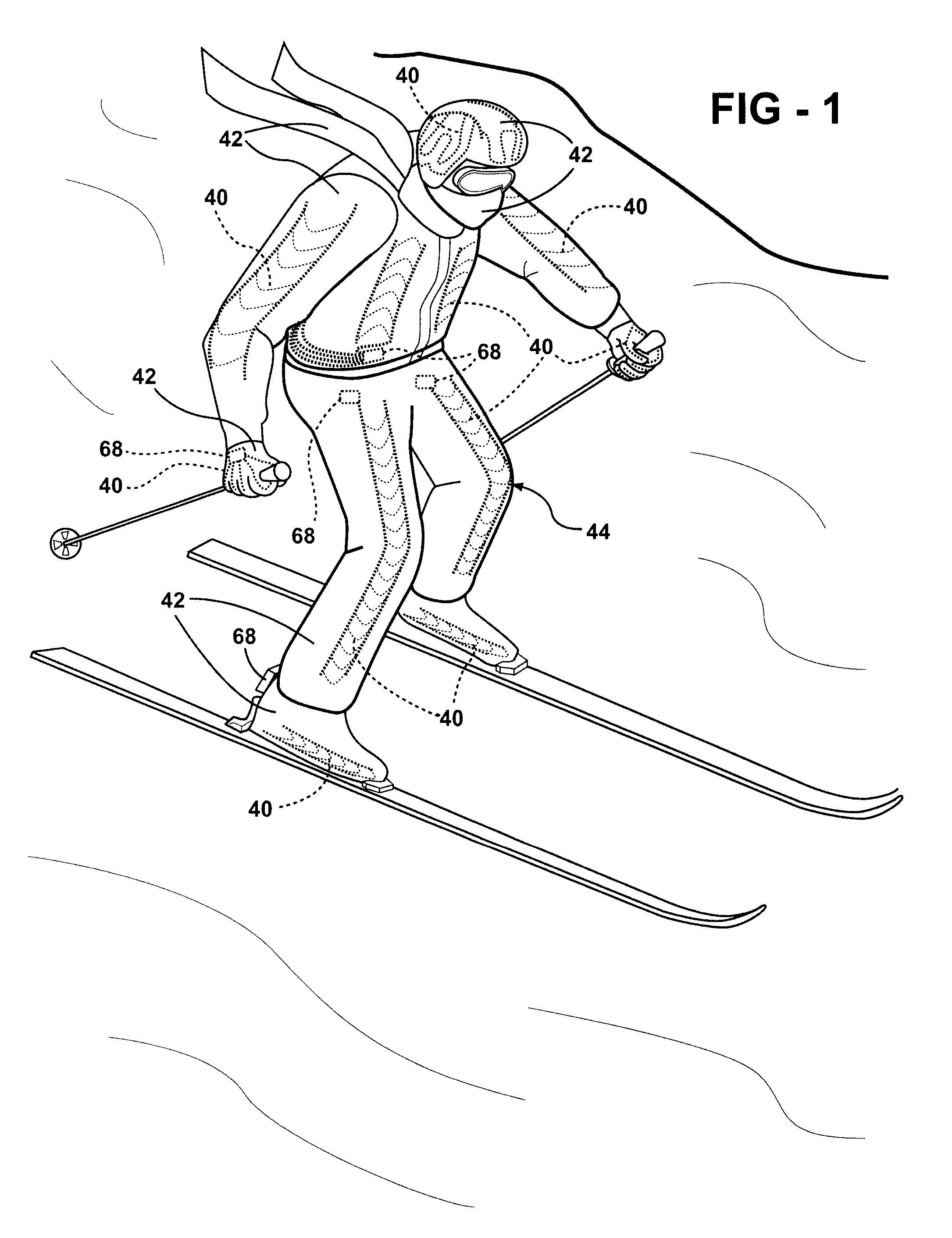

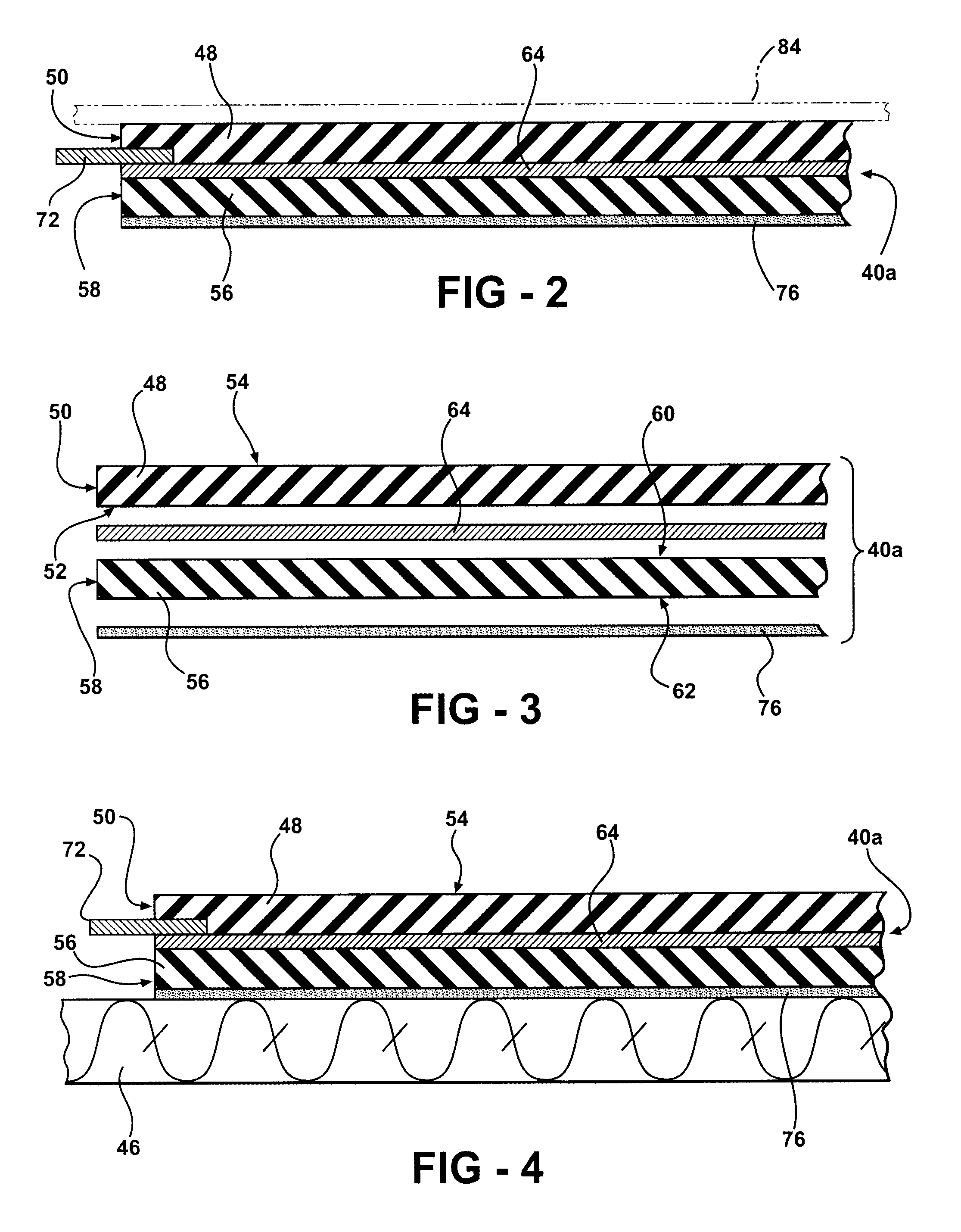

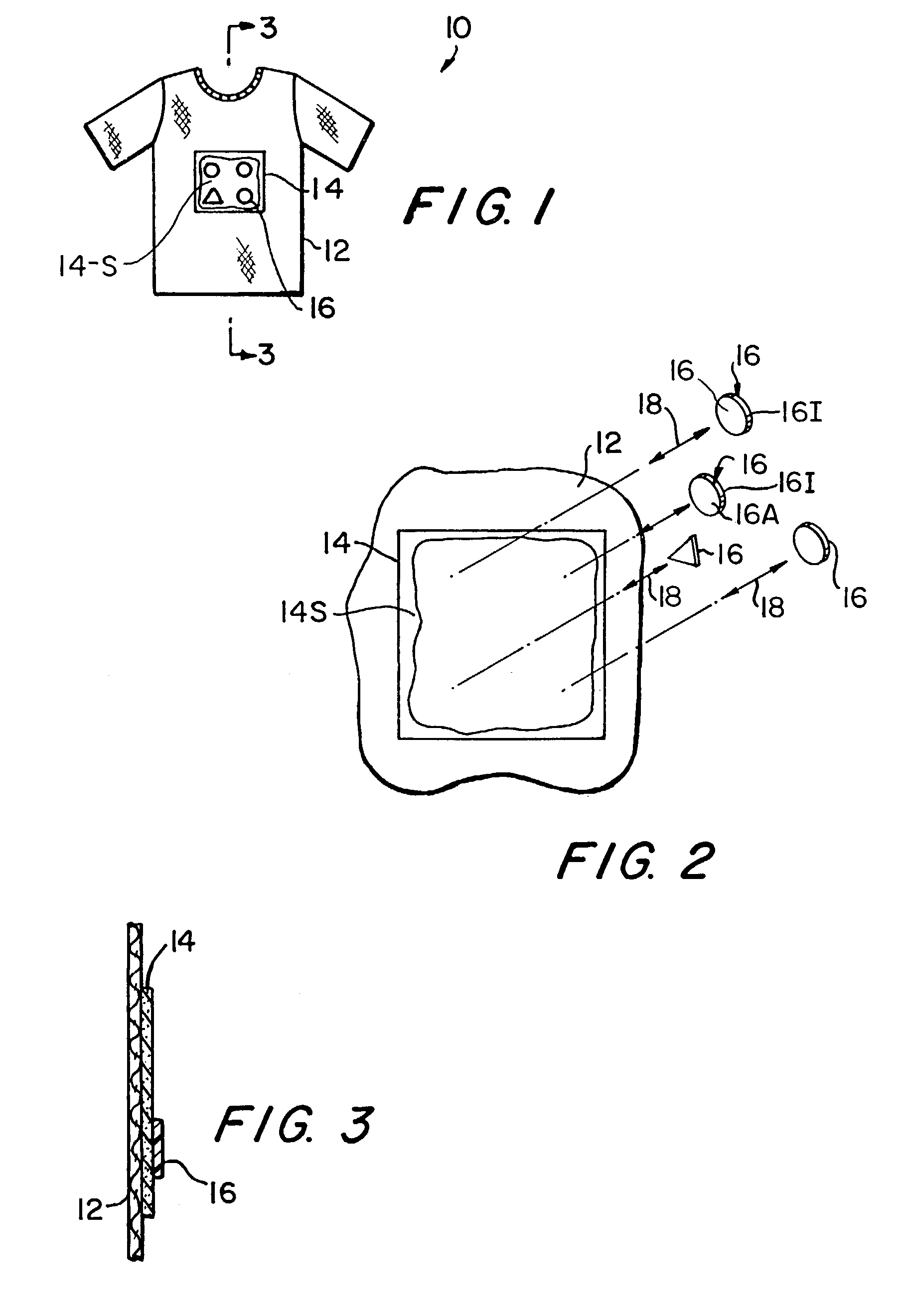

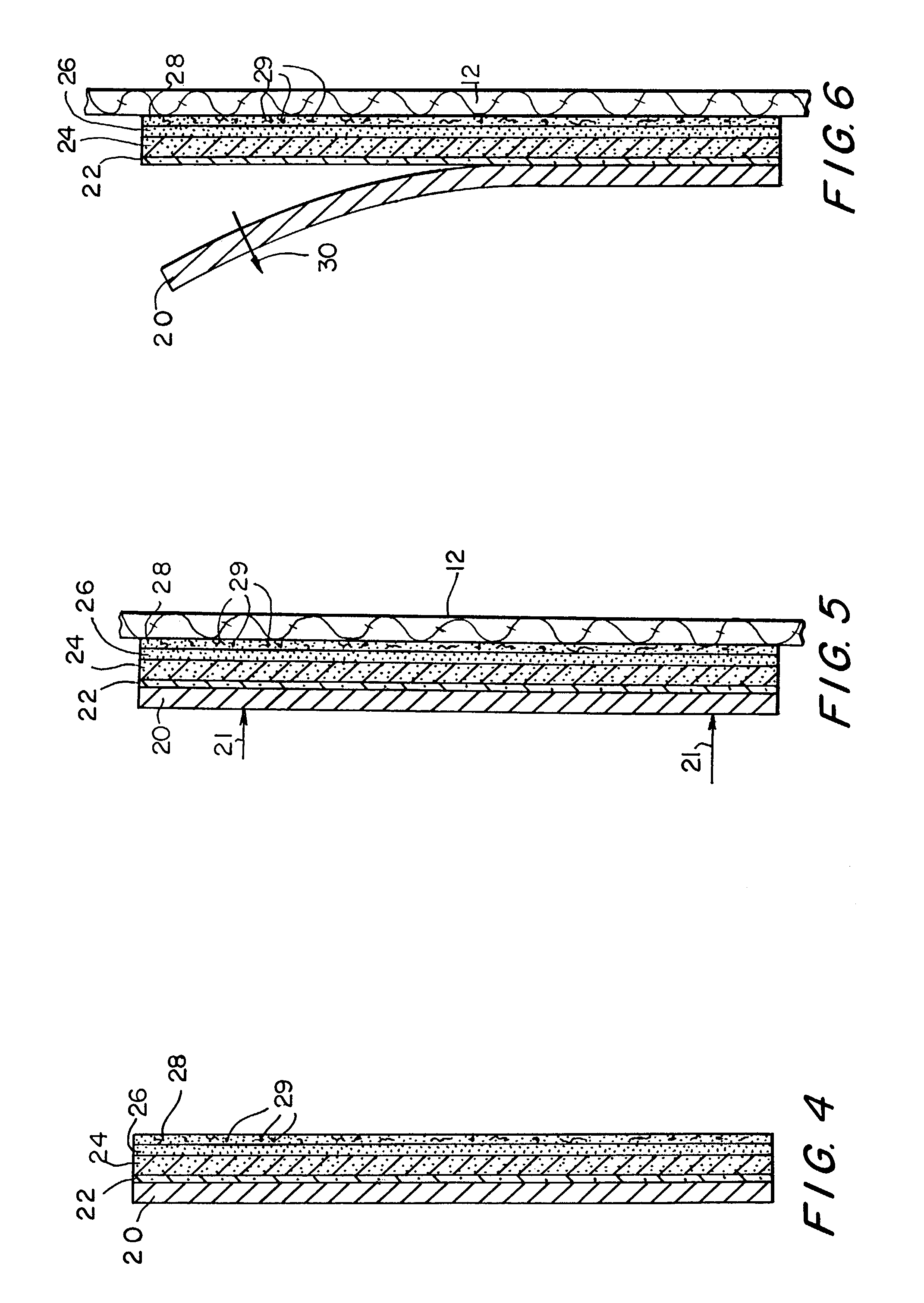

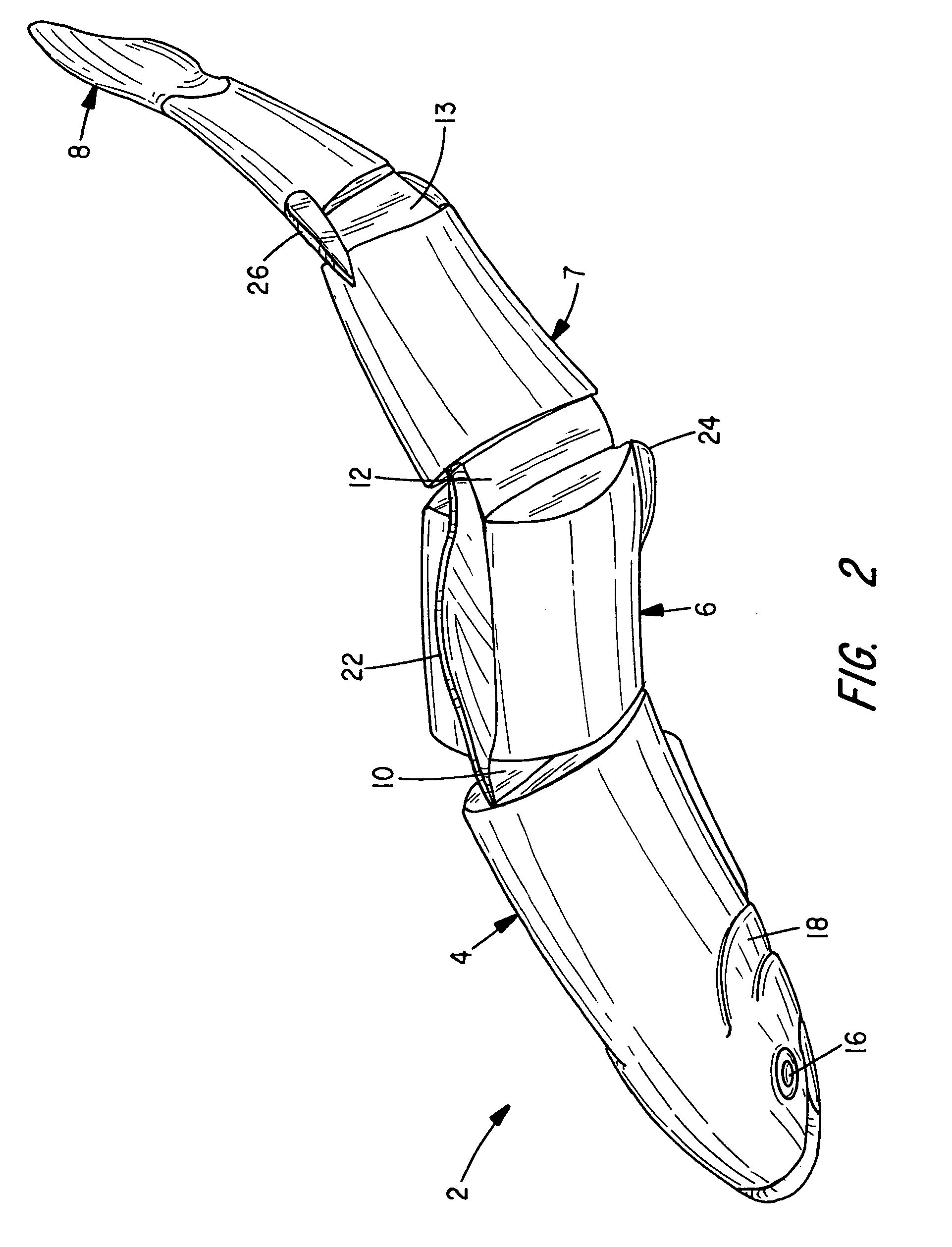

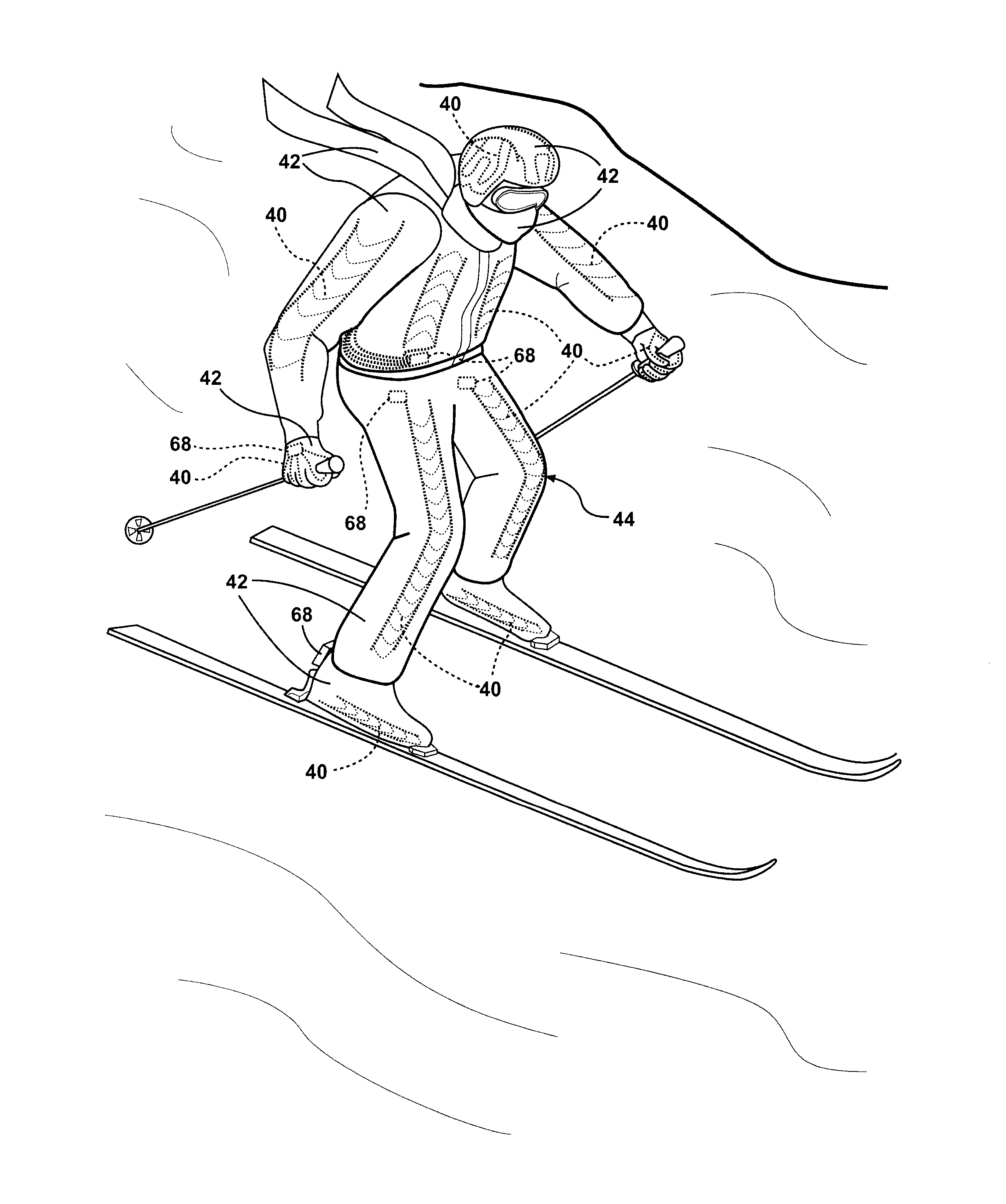

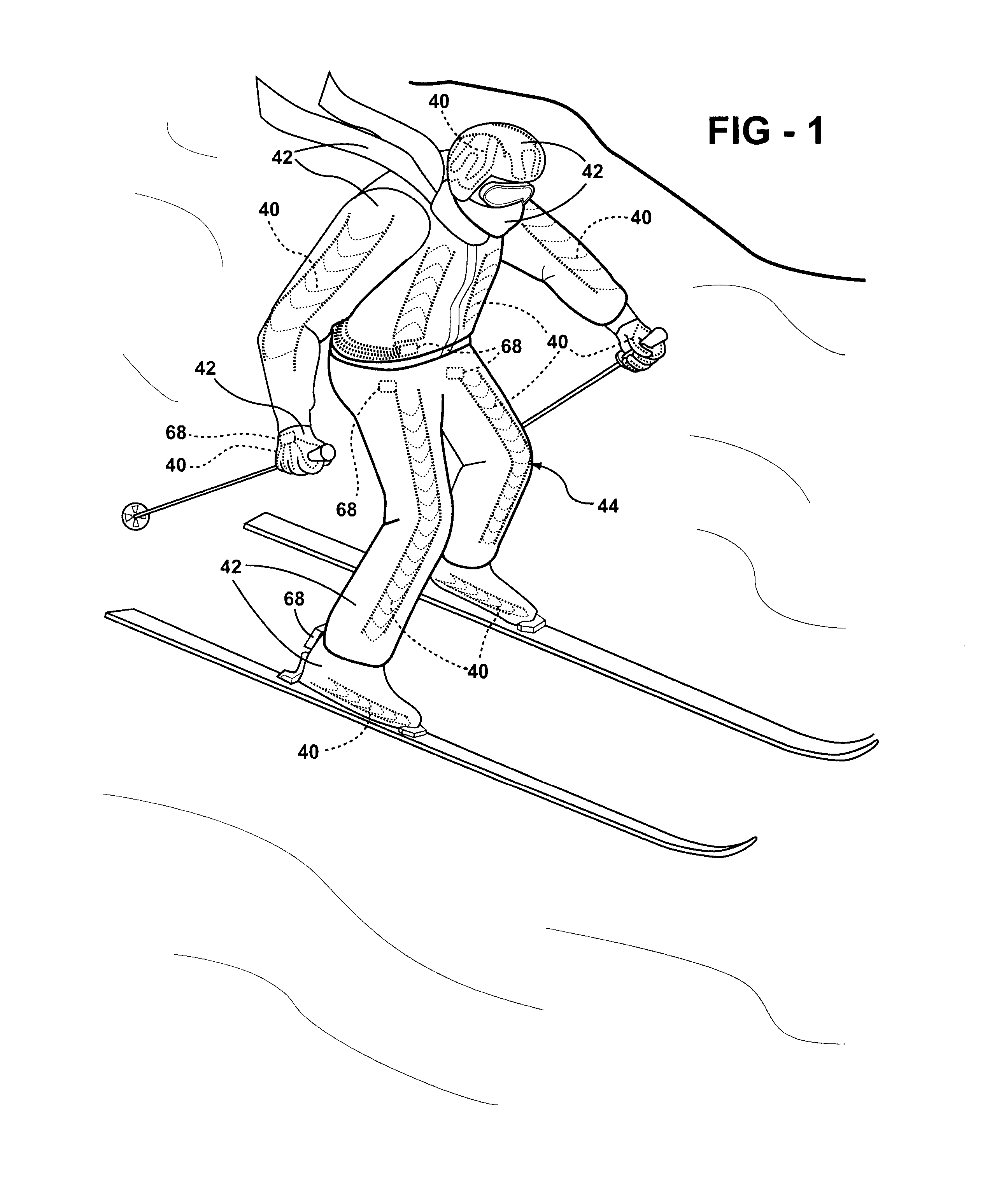

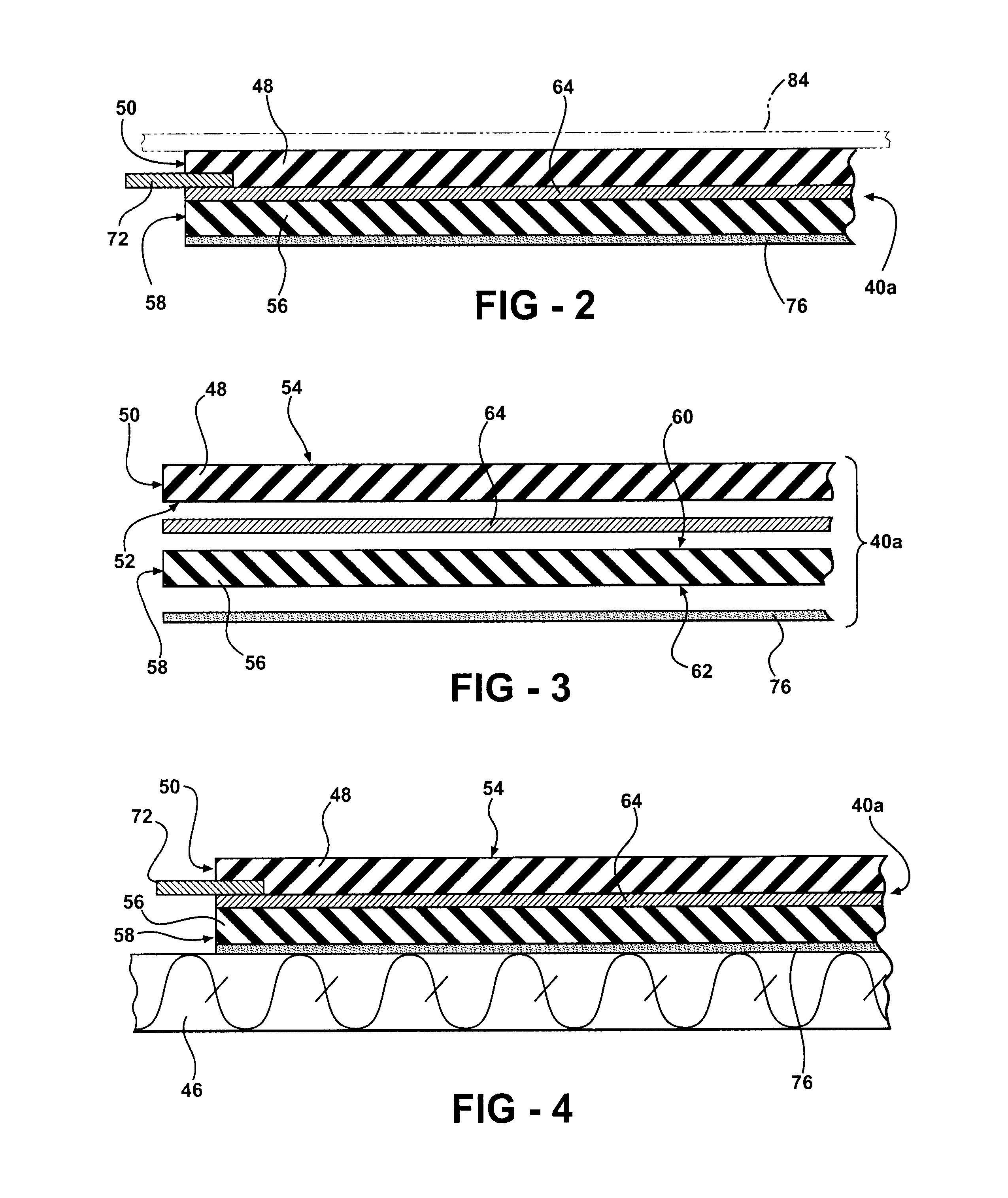

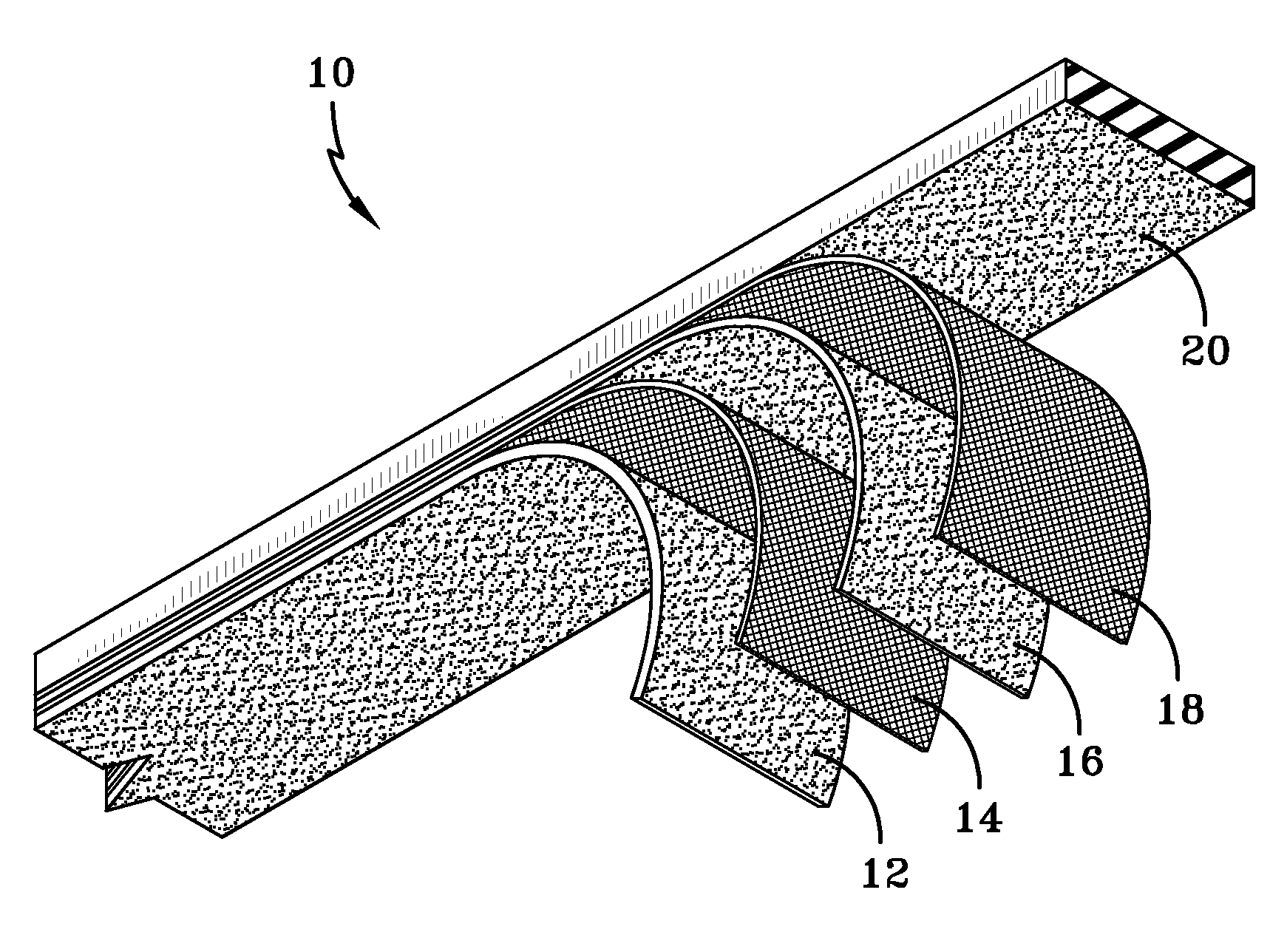

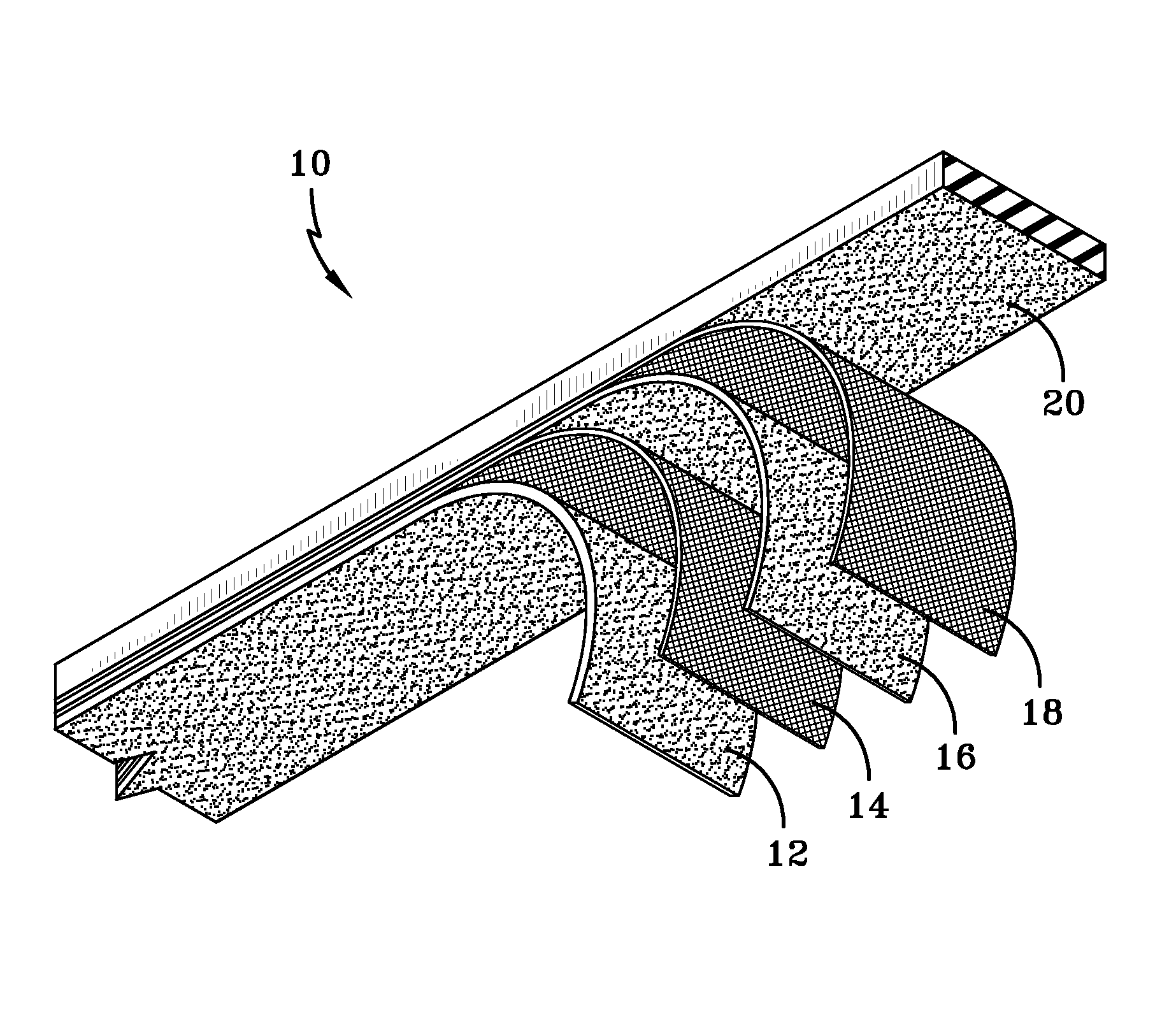

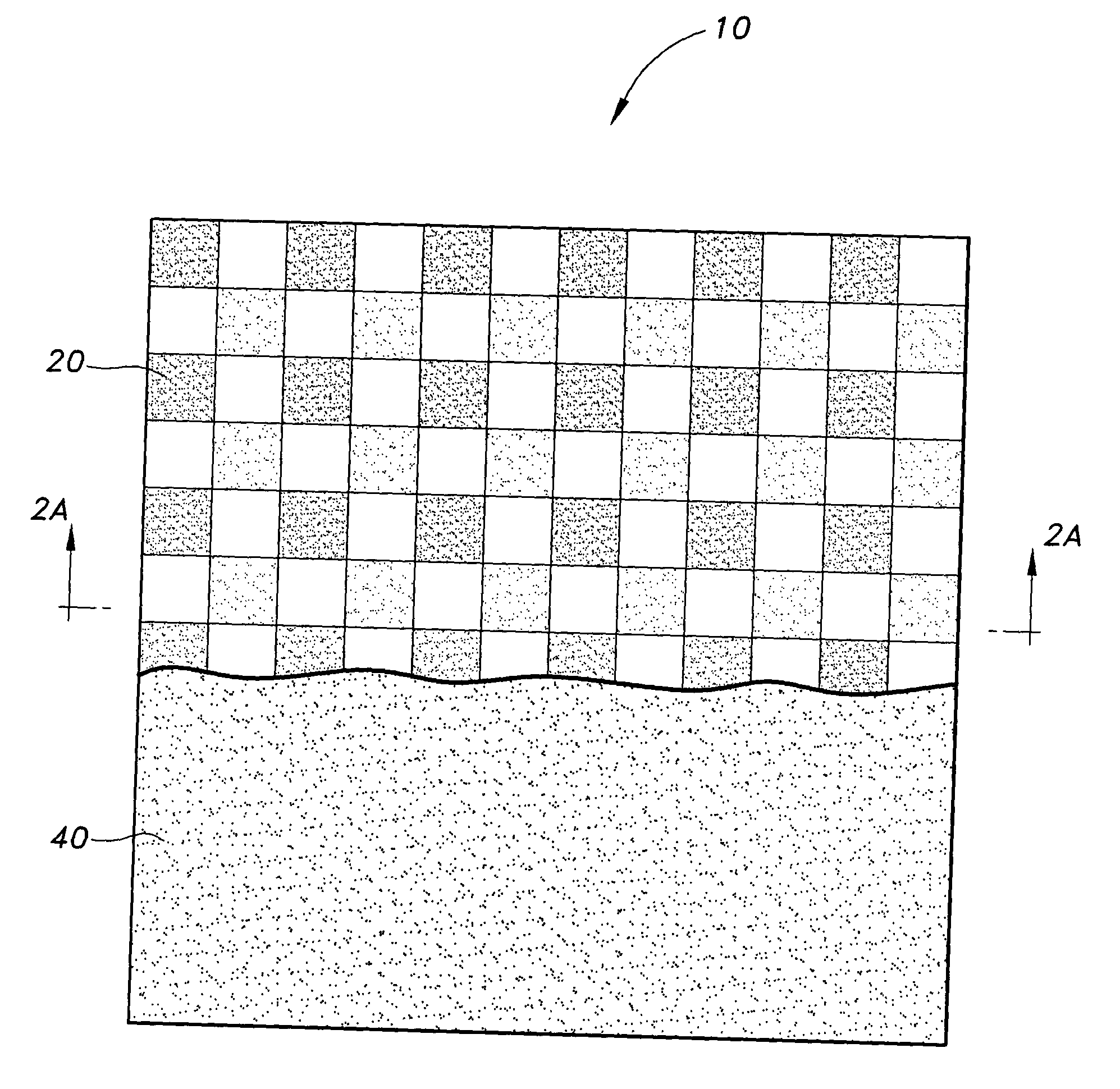

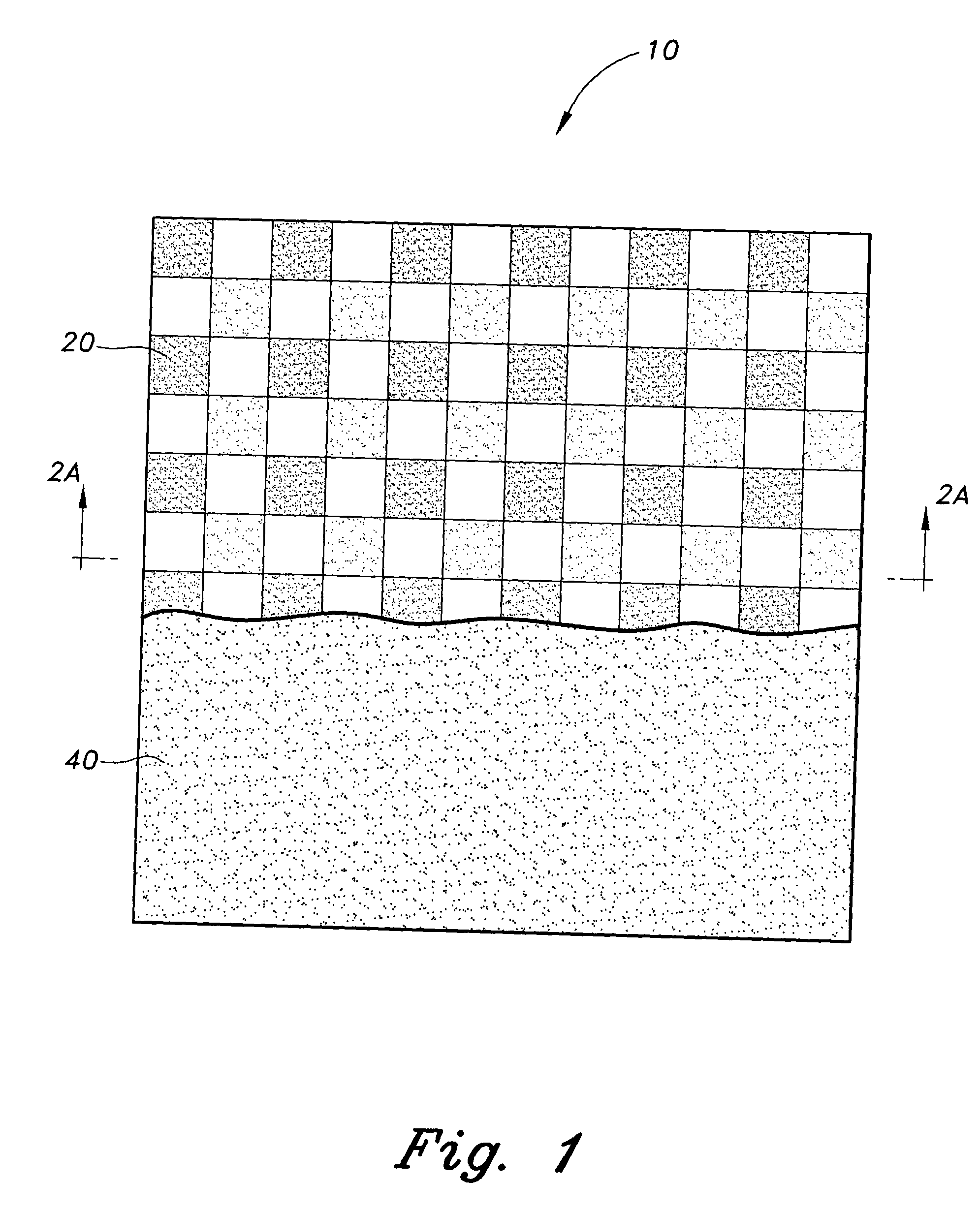

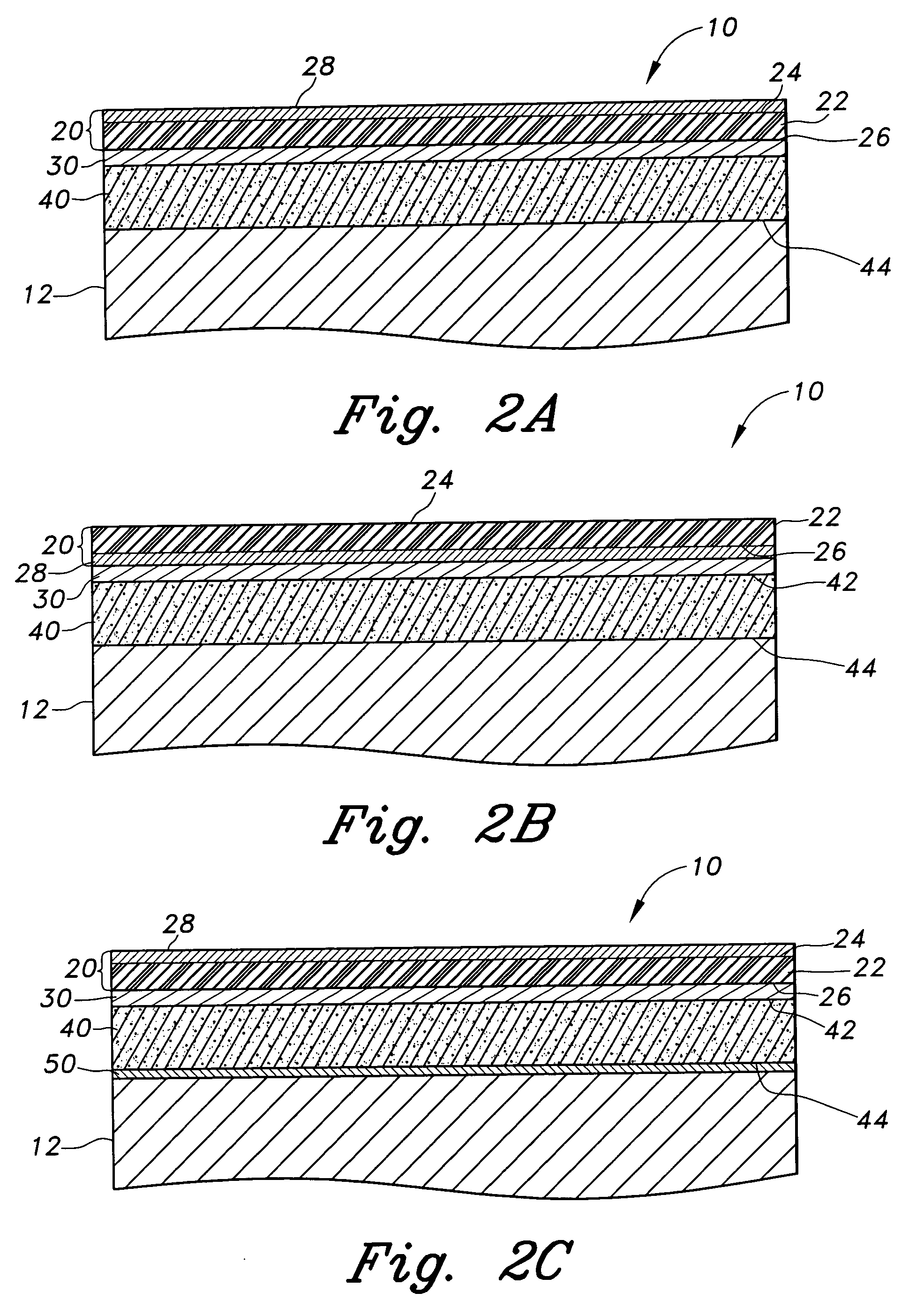

Heated textiles and methods of making the same

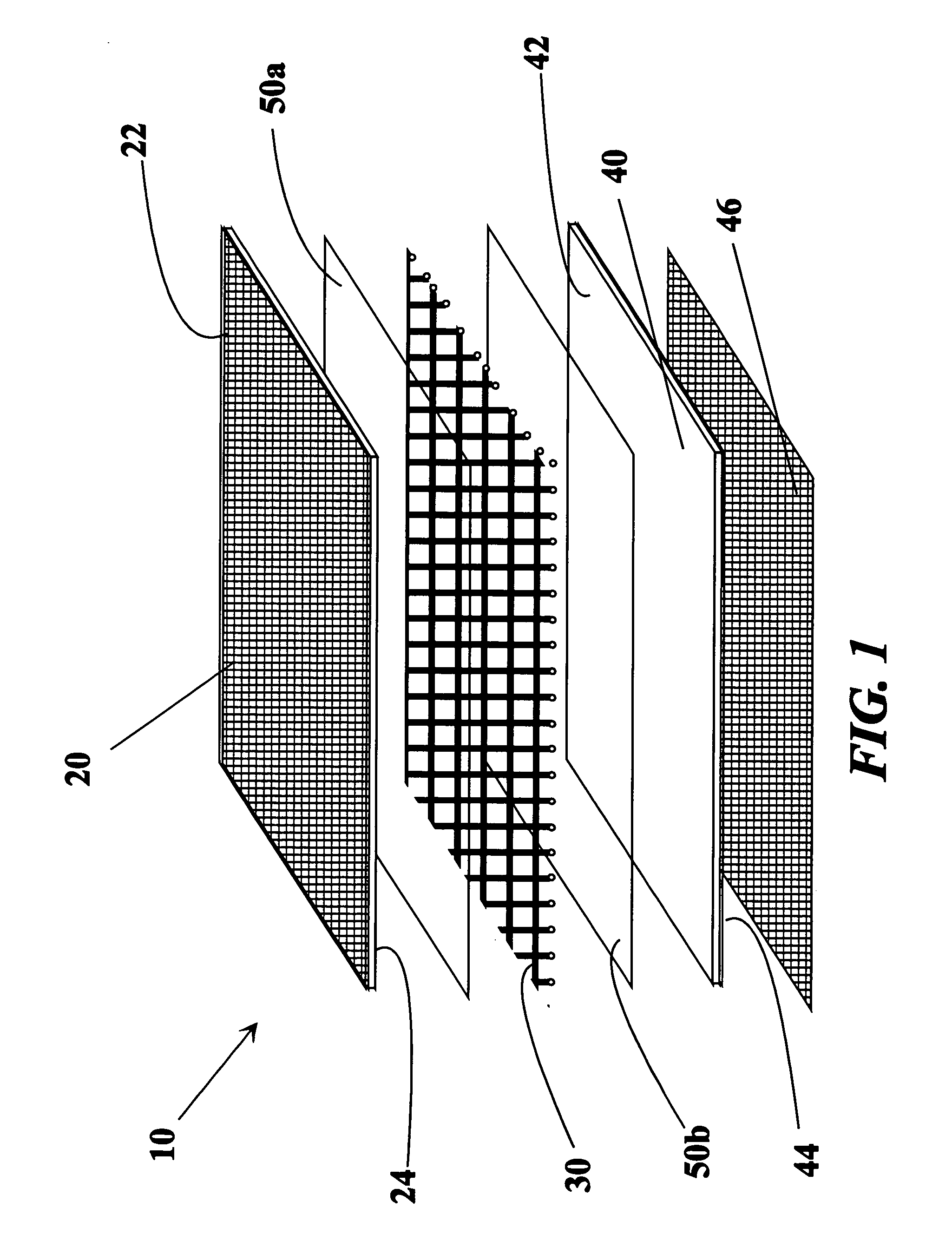

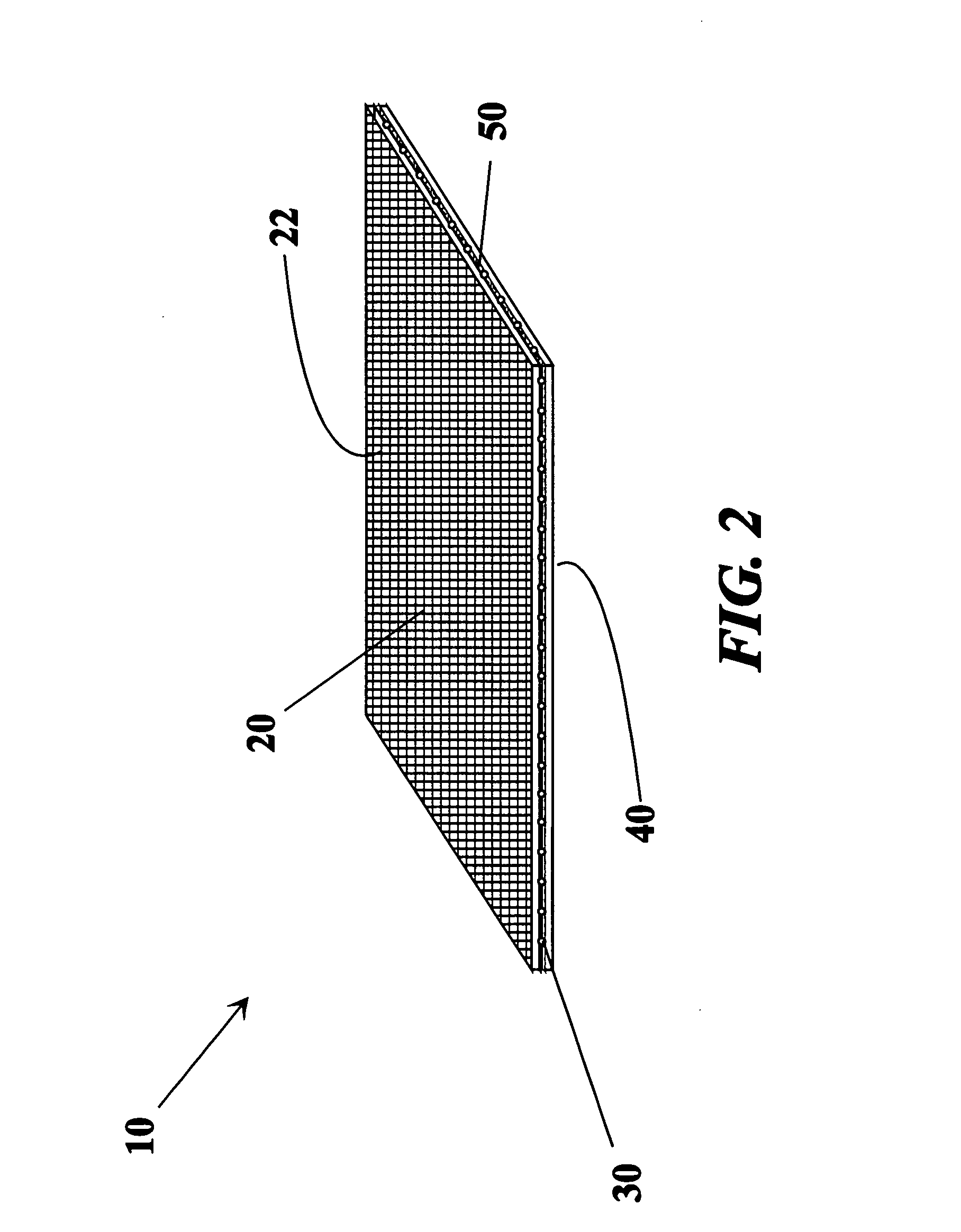

InactiveUS20080083721A1Improve washabilitySave battery powerOhmic-resistance heating detailsFootwearDielectric layerMaterials science

The present invention provides a composite heating element suitable for heating an article when activated by a power source. The composite heating element comprises first and second dielectric layers each having an inner surface and an outer surface. The composite heating element further comprises a conductive layer formed from at least one conductive ink composition comprising a plastisol component and a conductive component. The conductive layer is disposed between the inner surfaces of the first and second dielectric layers and defines a circuit. The composite heating element further comprises an adhesive layer coupled at least one of the outer surfaces of the first and second dielectric layers opposite the conductive layer.

Owner:T INK INC

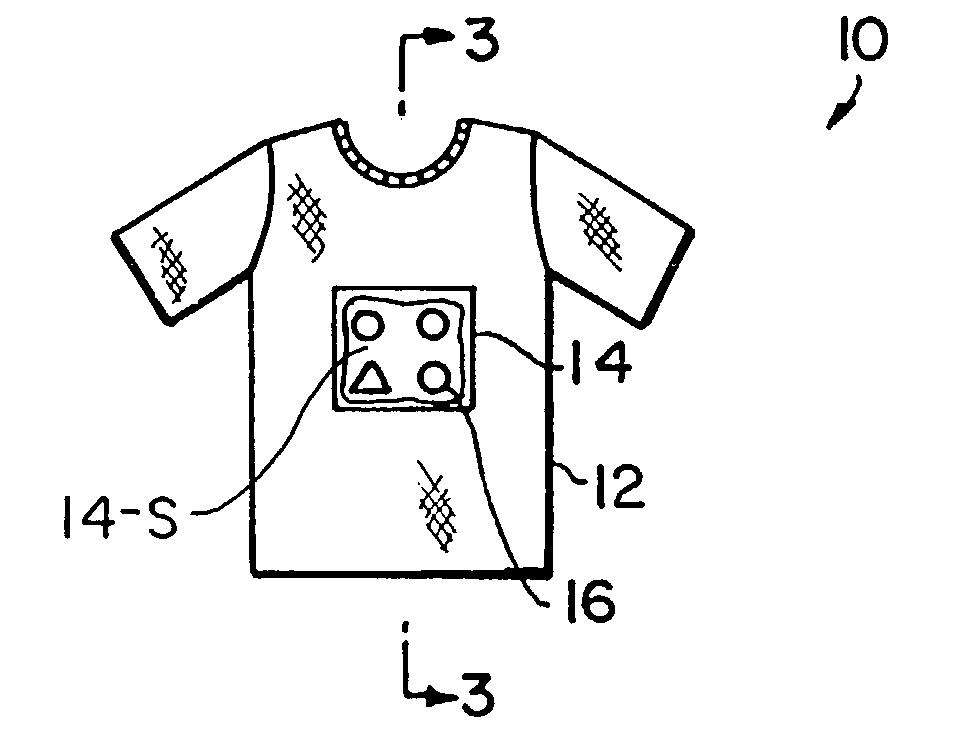

Interactive-design garment where the wearer can create and alter the graphic decoration on the garment and method of manufacturing same

InactiveUS6982115B2Maximum thinnessGood artworkDecorative surface effectsLayered productsGraphicsInteractive design

An interactive-design garment which has heat-affixed thereto a flexible substrate formed of a laminate including a layer of plastisol ink which includes a primary graphic image therein of a particular theme and a plurality of flexible PVC sheet appliques which have secondary graphic images thereon and are positionable onto the substrate by a user to cooperate artistically with the graphic theme of said substrate on the garment.

Owner:POULOS HARRY K +1

Plastic floor covering and method for obtaining same

InactiveUS20040102120A1Retention characteristicImprove featuresClosuresLayered productsThermoplasticEngineering

The invention concerns a floor covering produced by coating and comprising a thermoplastic-based structure, in particular plasticized PVC, reinforced with a textile reinforcement, optionally combined with a foam backing and whereof the visible surface consists of a surface coating providing decoration and wear resistance to the product. The invention is characterised in that the back surface designed to be in contact with the floor, consists of a textile web, the bonding between the textile structure and the supporting back surface being produced by means of an additional plastisol layer, which penetrates over a minor part the thickness of the textile structure and which, after gelling, bonds said textile to the thermoplastic substrate back surface.

Owner:GERFLOR

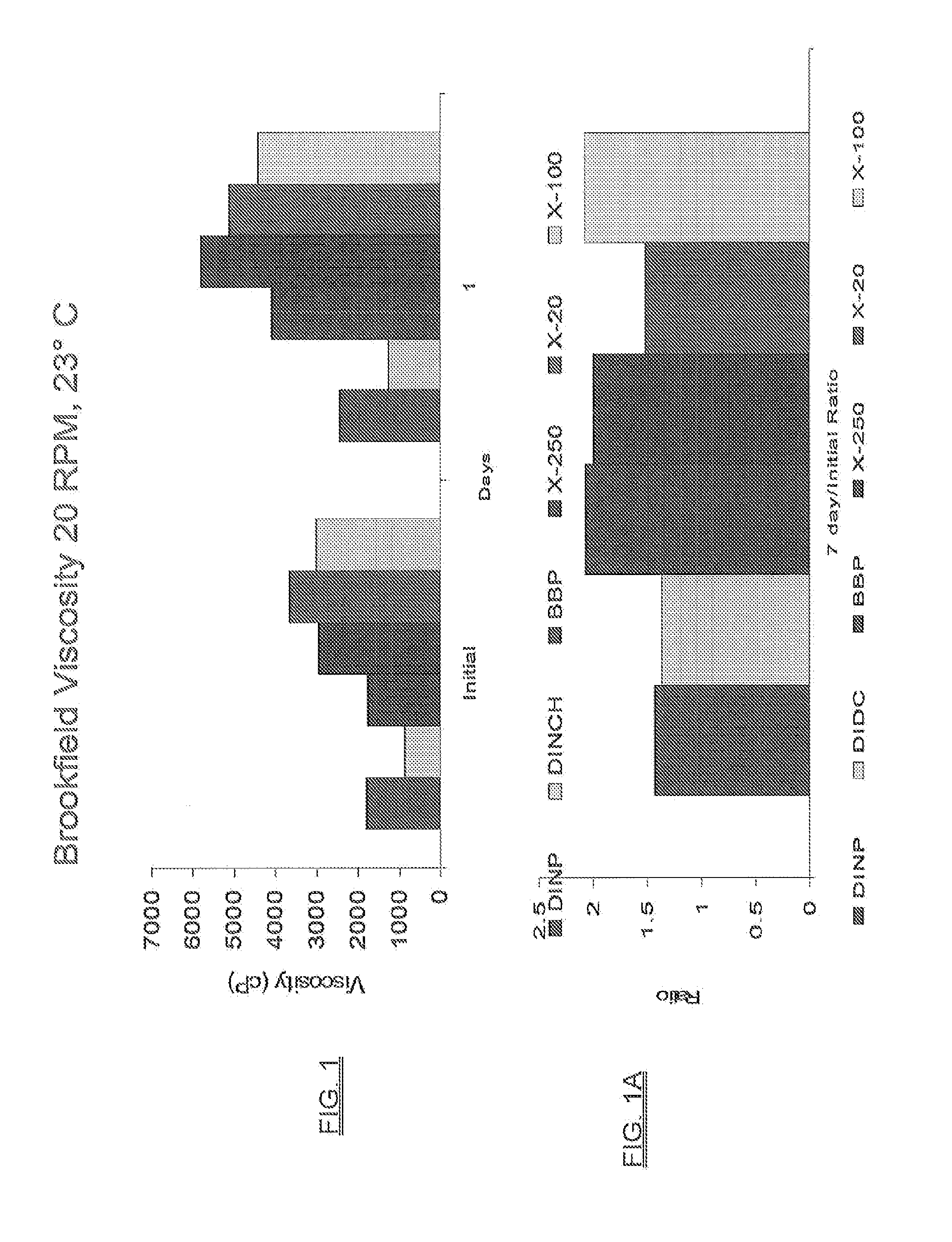

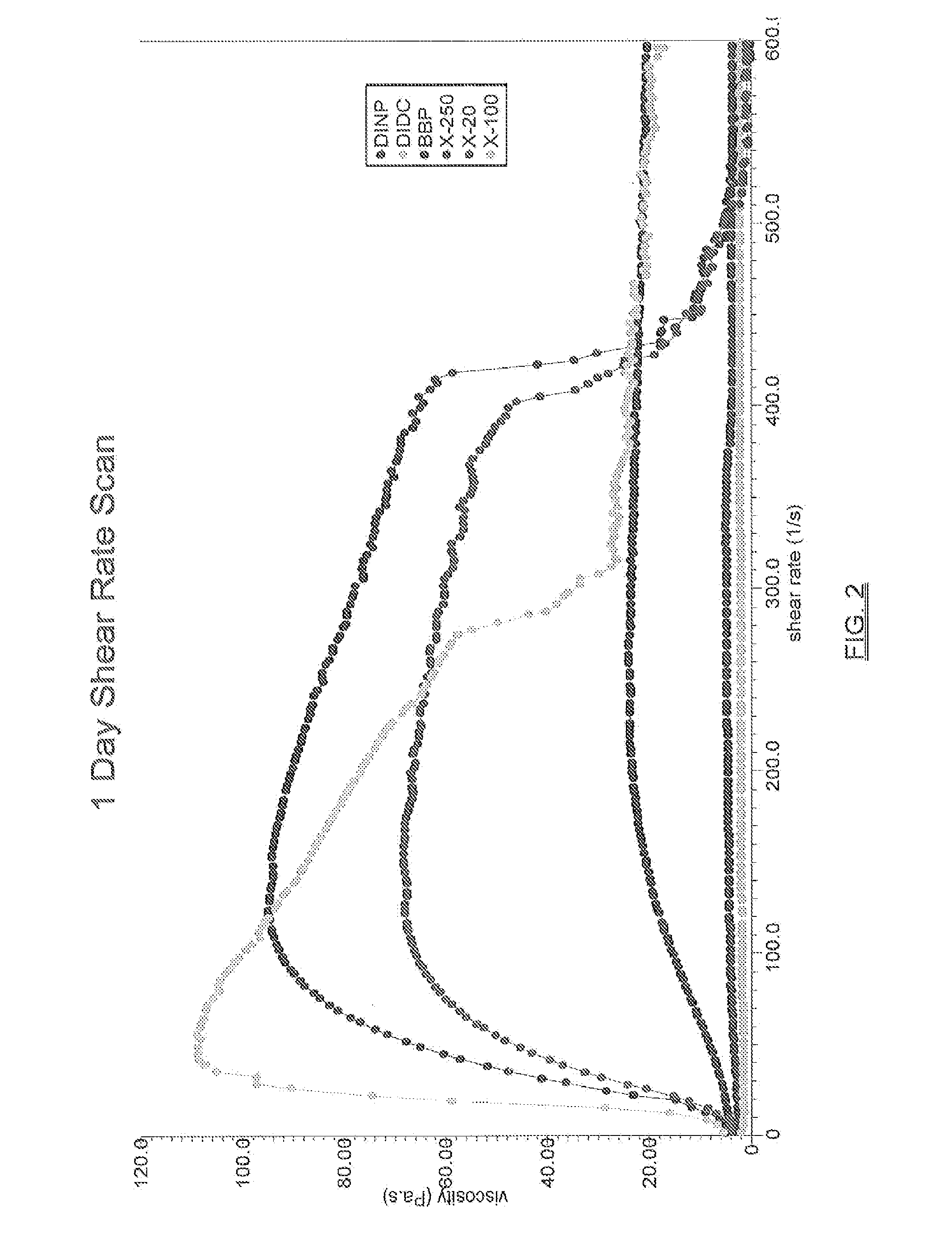

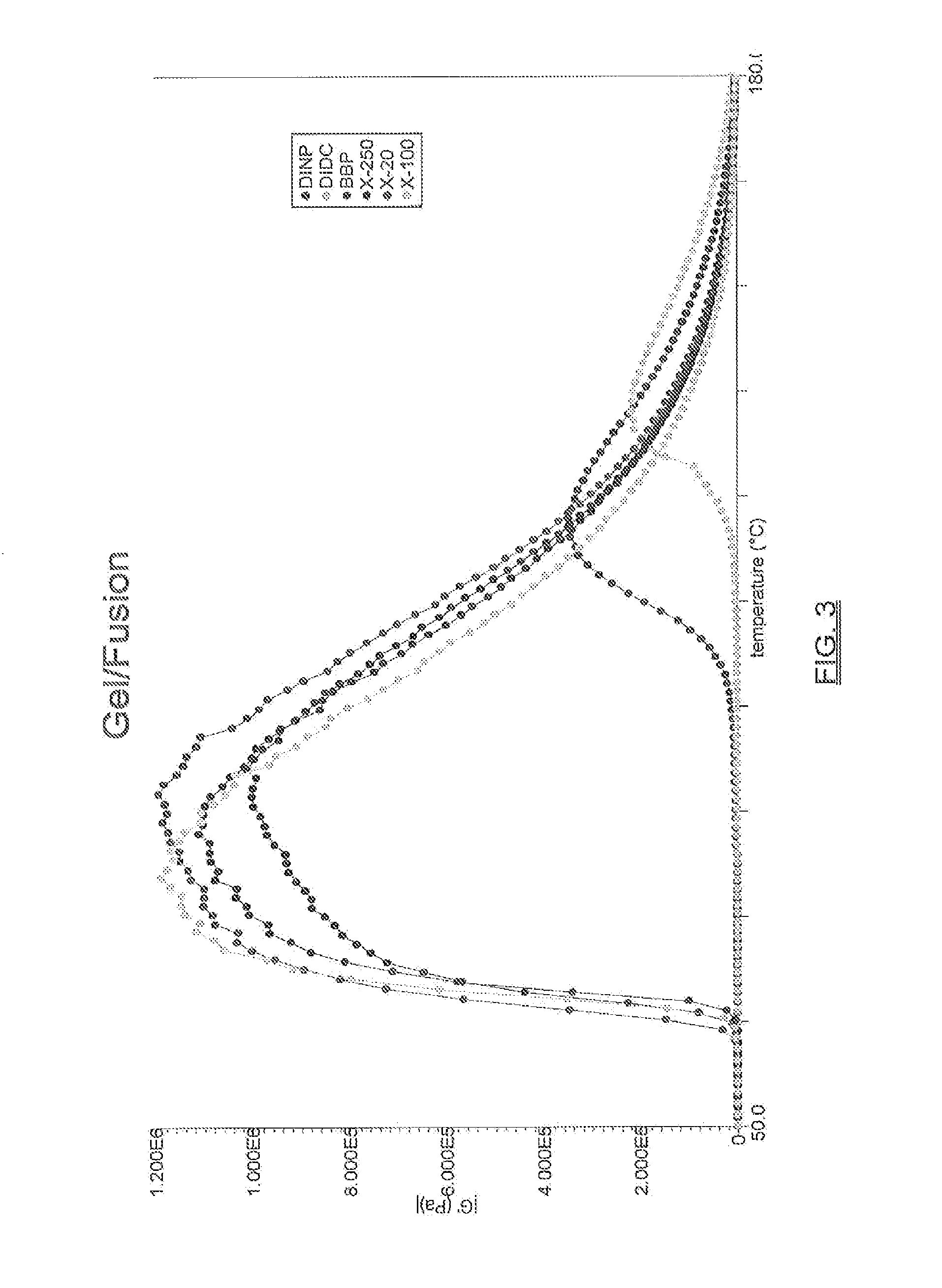

Blends of dibenzoate plasticizers

ActiveUS20130274396A1Efficient Tg suppressionFaster processing timeNon-macromolecular adhesive additivesInksElastomerAdhesive

Plasticizer blends comprise a triblend of diethylene glycol dibenzoate, dipropylene glycol dibenzoate, and 1,2-propylene glycol dibenzoate, in specified ratios, useful in combination with a multitude of thermoplastic polymers, thermosetting polymers, and elastomeric polymers and numerous applications, including but not limited to plastisols, adhesives, sealants, caulks, architectural coatings, industrial coatings, OEM coatings, inks, overprint varnishes, polishes, and the like. The advantages rendered by the use of the triblend depend on the type of polymer and application in which it is utilized and include among other advantages higher solvating power and lower processing time, low VOC's, reduced plasticizer freeze point, improved gelation and fusion characteristics, higher tensile strength, superior stain and extraction resistance, and improved rheology over traditional diblends of diethylene glycol dibenzoate and dipropylene glycol dibenzoate.

Owner:EMERALD KALAMA CHEM

Method for synthesis of spray-dried poly(METH)acrylate polymers, use of same as polymer components for plastisols, and plastisols produced therewith

InactiveUS6989409B2Improve featuresExcellent abrasion resistanceOrganic chemistryEmulsion paintsPolymer scienceMeth-

A plastisol formulation which can be used for coatings of metal sheets, the coatings having high abrasion resistance, contains a) a plasticizer or mixture of plasticizers; and b) a mixture of polymer particles containing at least two components A and B; c) at least one member selected from the group consisting of fillers, coupling agents, stabilizers, desiccants, rheological additives, hollow bodies and mixtures thereof; wherein the polymer particles containing at least two components A and B have one of the following structures ba) a 2-stage structure, a 3-stage structure or multi-stage structure, or bb) a gradient polymer structure.

Owner:EVONIK ROEHM GMBH

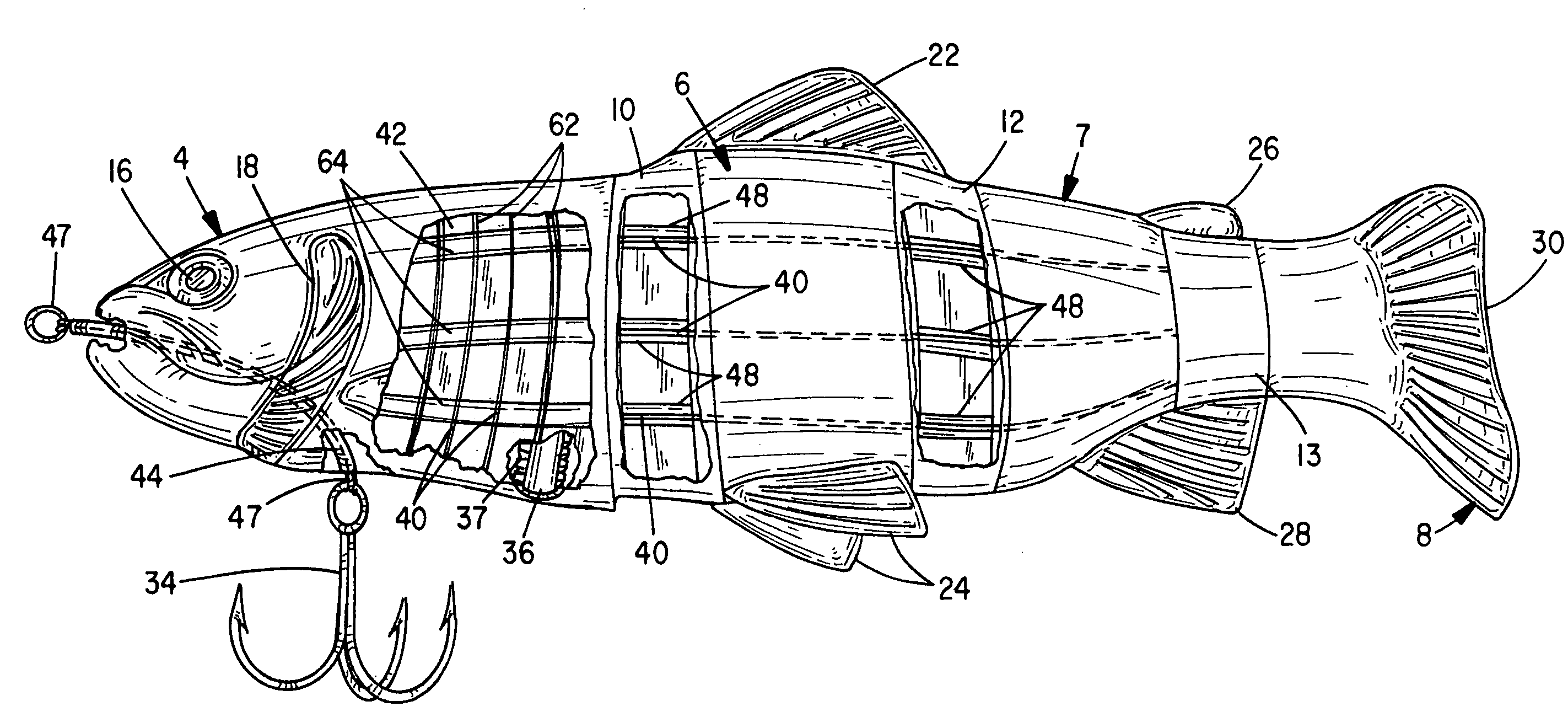

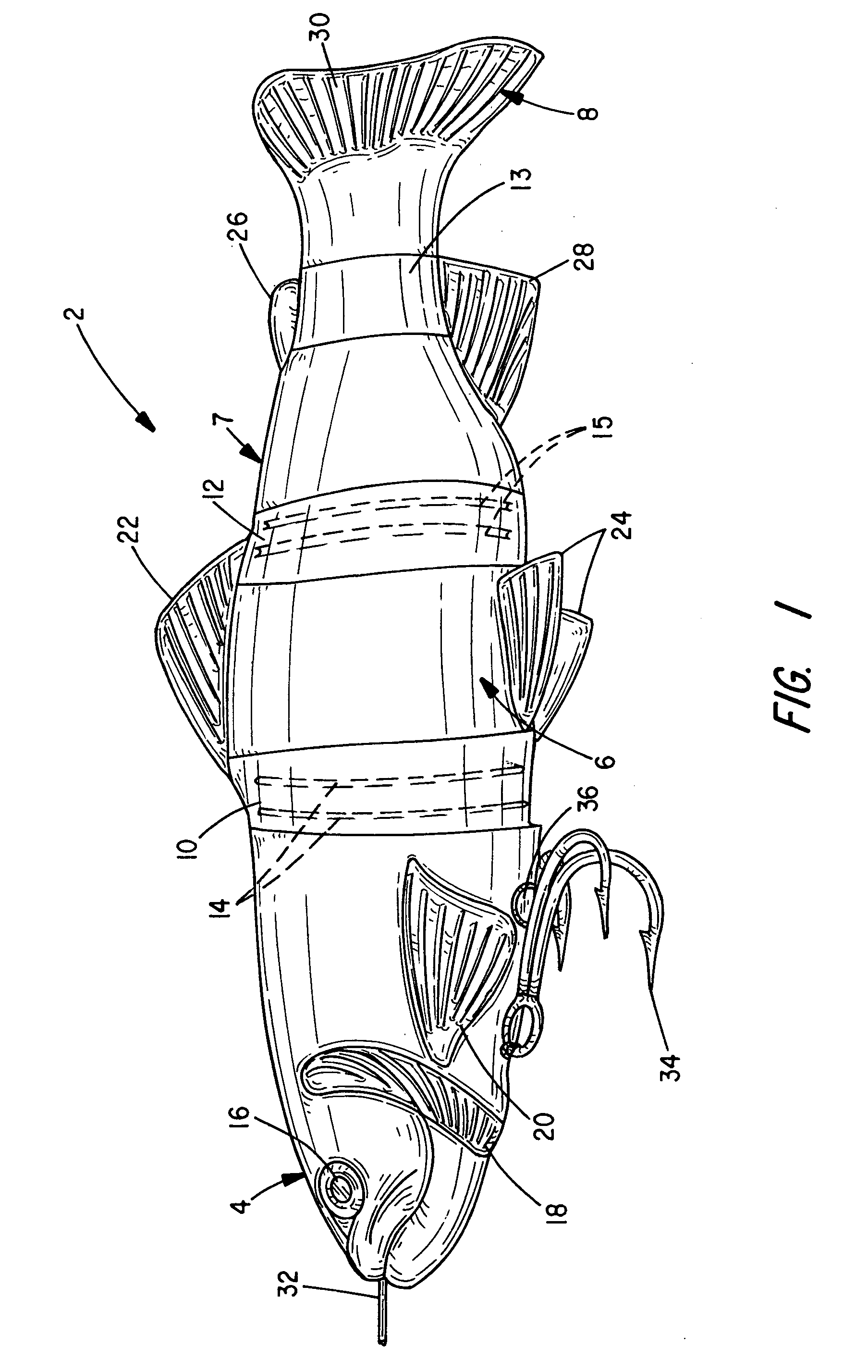

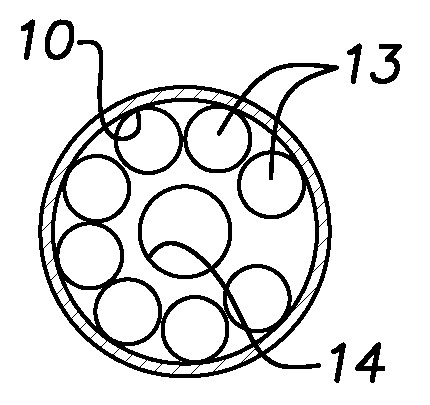

Fiber reinforced fishing lure

Fishing lures constructed with internal strands of high tensile strength fibers (e.g. aramid) bonded to body pieces independent of any associated hooks. The strands are trained in appropriate alignments (e.g. longitudinally, transverse and / or radially) at high wear areas to enhance flexion and minimize tearing, especially at spanned joints. The fibers can be bonded into the body materials or anchored to the body pieces. Several soft plastic (e.g. plastisol and pvc) lures molded with resilient, durable stranded and webbed fibers enhancing durability and defining flexible joints, appendages etc. are disclosed.

Owner:NATURE VISION

C7-C12 Secondary Alcohol Esters of Cyclohexanoic Acid

InactiveUS20100305250A1Easy to processGood low temperature flexibilityAlcoholCyclohexanecarboxylic acid

C7-C12 secondary alcohol esters of cyclohexanecarboxylic acids are especially useful as plasticizers for PVC and other plasticizable polymers. In embodiments, these plasticizers are useful in plastisol formulations to help improved processability of flexiblePVC material. In other embodiments these same plasticizers can be used in blends with other plasticizers to improve processability. In preferred embodiments these same plasticizers can be used to prepare flexible PVC compounds with enhanced low temperature flexibility, low toxicity, and improved resistance to outdoor aging.

Owner:EXXONMOBIL CHEM PAT INC

Aroma-releasing polymeric gel matrix

A translucent-to-clear, plasticized PVC thermoplastic polymeric matrix gel composition comprising (i) a high loading of fragrance composition and / or odor counteractant(s)—preferably greater than about 85%; (ii) from about 4% to about 25% of a plastisol with a Shore hardness of from about 60 to about 95 that is liquid at room temperature; and, optionally, (iii) an evaporation / firmness controlling agent. The high loading of fragrance and / or odor counteractants in the polymeric matrix gel composition of the invention provides a desired aroma to an environment in a persistent manner over an extended period of time.

Owner:WHITEHEAD KENNETH R +1

Plastisol compositions comprising vinyl chloride polymers and mixtures of aromatic and aliphatic esters of diols as plasticizers

InactiveUS6933337B2Improve solubilityReduce the temperatureOrganic compound preparationCarboxylic acid esters preparationCarboxylic acidDiol

Mixtures of esters produced by reacting a mixture of aromatic and aliphatic monocarboxylic acids with a diol containing from 2 to 12 carbon atoms are effective plasticizers for plastisols containing dispersion grade polymers of vinyl chloride. The freezing point of the present ester mixtures and their efficacy as plasticizers can be varied by adjusting the type and relative concentration of the aliphatic acid used to prepare the plasticizer. The ester mixtures can also be used as plasticizers for other organic polymers.

Owner:EASTMAN SPECIALITIES HLDG CORP

Textured and printed membrane that simulates fabric

InactiveUS20060270298A1Easy to cleanImprove the immunitySynthetic resin layered productsPaper/cardboard layered productsEngineeringAntimony trioxide

A textured and printed membrane has an embossed top layer with a protective coating, a fabric layer, a printed bottom layer with a protective coating, where the layers are adhered with a PVC plastisol. The printing pattern matches the embossing, such that the membrane has the appearance of cloth on both sides. The textured vinyl membrane composite has a thickness of from 10 to 35 mils. The membrane can be fitted on an awning to display illuminated (white / opaque) graphics (lettering or design). The top layer is preferably compounded PVC formulated with a colorant. The bottom layer is also PVC, typically formulated with a flame retardant package, such as antimony trioxide or brominated compounds, aluminum trihydrate, magnesium hydroxide, and the like to suppress the spread of an ignited flame. Both top and bottom layers can have heat stabilizers and lubricants to improve processing of the PVC.

Owner:COOLEY

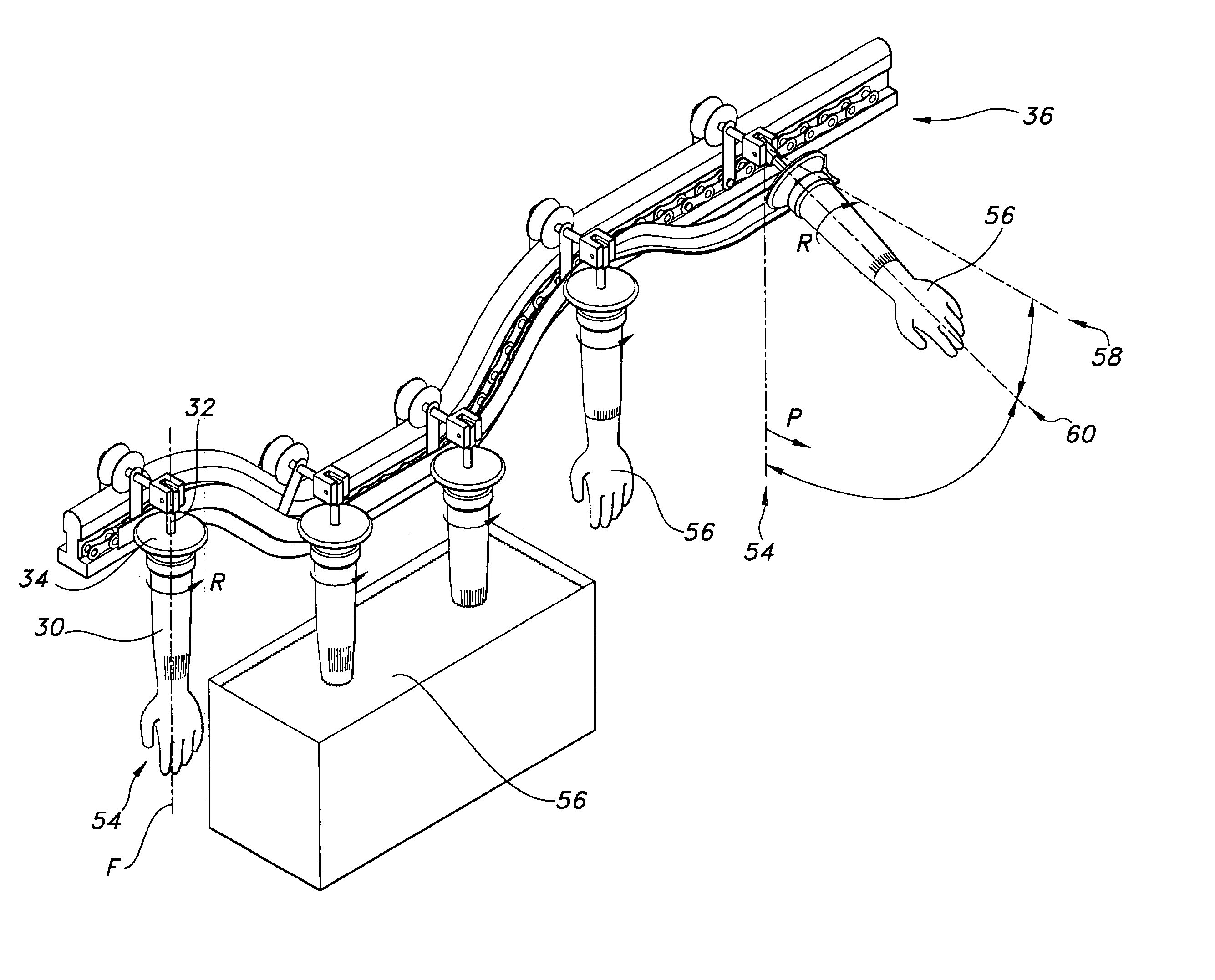

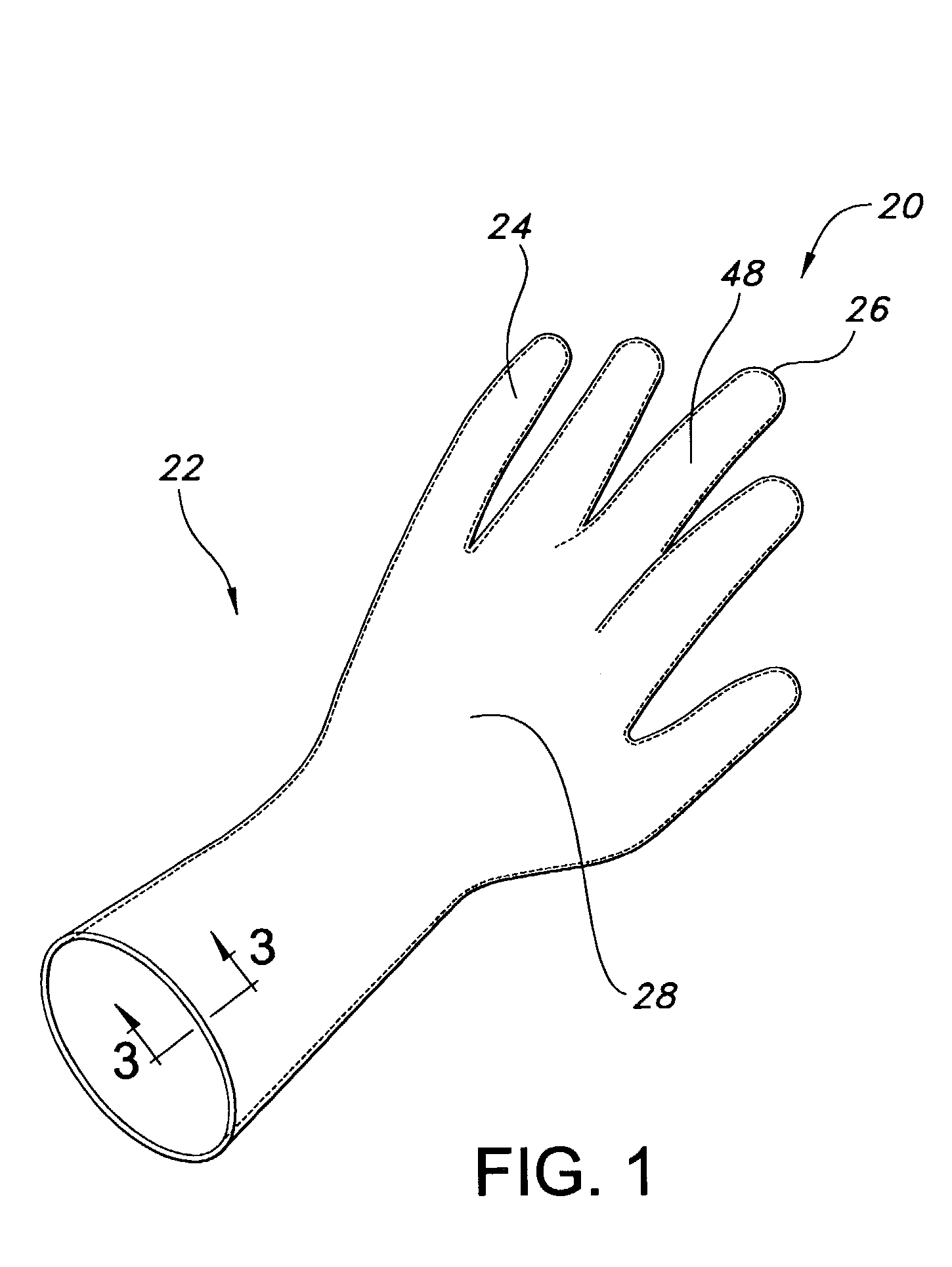

Polyvinyl chloride article having improved durability

InactiveUS20050015846A1Improved fingertip puncture resistanceGlovesEye treatmentPolyvinyl chloridePuncture resistance

A method of forming a glove having improved fingertip puncture resistance is disclosed. The method includes providing a glove former, the former pivotably attached to a chain assembly, dipping the former into a plastisol in a first position, the position being substantially vertical, removing the former from the plastisol, pivoting the former to a second position, the second position forming an angle less than 90 degrees with respect to the first position, and maintaining the former at the second position until the plastisol forms a gel on the former.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Acrylic polymer fine particles and plastisol using the same

InactiveUS20010016612A1Satisfactory in retainabilitySatisfactory in storage stabilityOrganic chemistryDyeing processMethacrylatePolymer science

Acrylic polymer fine particles which comprise primary particles P of 250 nm or more in average particle diameter having a core shell structure and plastisols prepared using the same. In the fine particles, a core polymer C and a shell polymer S are copolymers of the following monomer mixtures Mc and Ms, respectively, and the weight ratio of Mc and Ms is 10 / 90-90 / 10: Mc: methyl methacrylate 20-85 mol % (meth)acrylic ester of C2-C8 aliphatic alcohol and / or aromatic alcohol 15-80 mol % other copolymerizable monomers not more than 30 mol %; , when the total amount of these monomers is 100 mol %; Ms: methyl methacrylate 20-79.5 mol % (meth)acrylic ester of C2-C8 aliphatic alcohol and / or aromatic alcohol 5-40 mol % a monomer containing carboxyl group or sulfonic acid group 0.5-10 mol % other copolymerizable monomers not more than 30 mol %.

Owner:MITSUBISHI CHEM CORP

Plasticizer compositions for non-aqueous plastisols

Monoesters derived from a dihydric alcohol and a carboxylic acid such as benzoic acid are secondary plasticizers for non-aqueous and solventless plastisols containing primary plasticizers that do not contain unreacted alkanol groups.

Owner:EASTMAN SPECIALITIES HLDG CORP

Method for preparing full biodegradable environment protection hot melt adhesive

InactiveCN101250385AGood compatibilityHigh initial bond strengthStarch derivtive adhesivesPolymer scienceCarton

The invention belongs to the technical field of polymer materials processing, which particularly relates to a method for producing biological fully-degradable environmental-friendly hot melt adhesive. Biological fully-degradable environmental-friendly hot melt adhesive is manufactured through modifying cornstarch and a process technique which is squeezed through blending. The method comprises the following steps: mixing and adding cornstarch and plasticizing agent, obstructing agent, reinforcing agent, lubricating agent and filling material in a stirrer according to proportion, stirring under 80 DEG C and 1000-3000rpm, preparing modified fecula, utilizing a double screw extrusion machine to blend and extrude after modified fecula, biodegradable polyester, plastisol, viscosity modifier, plasticizing agent, antioxidant and filling material are mixed, wherein the temperature of an extrusion machine is 100-180 DEG C, and number of revolution of a screw bolt is 40-200rpm, wherein modified fecula is 40-60%, biodegradable polyester is 0-30%, plastisol is 20-30%, viscosity modifier is 5-10%, plasticizing agent is 0-10%, antioxidant is 0.5-1%, and filling material is 0-10%. Hot melt adhesive which is got by the invention has the advantages of excellent compatibility, uniform products, low production cost, excellent initial viscosity and fully-degradable biology, which can be widely used in the fields such as cartons, unsewn binding of books, nonwoven manufacture and the like.

Owner:TONGJI UNIV

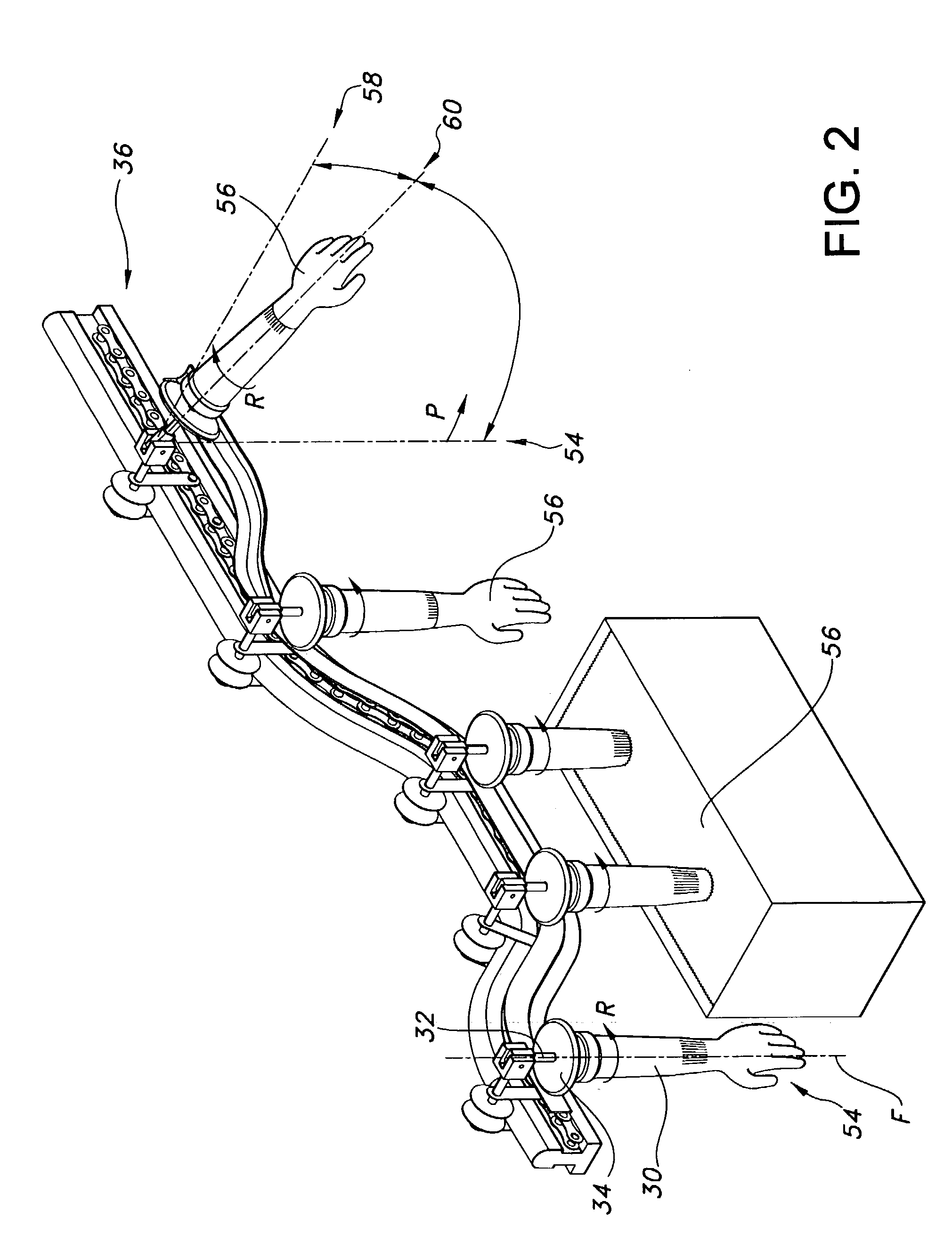

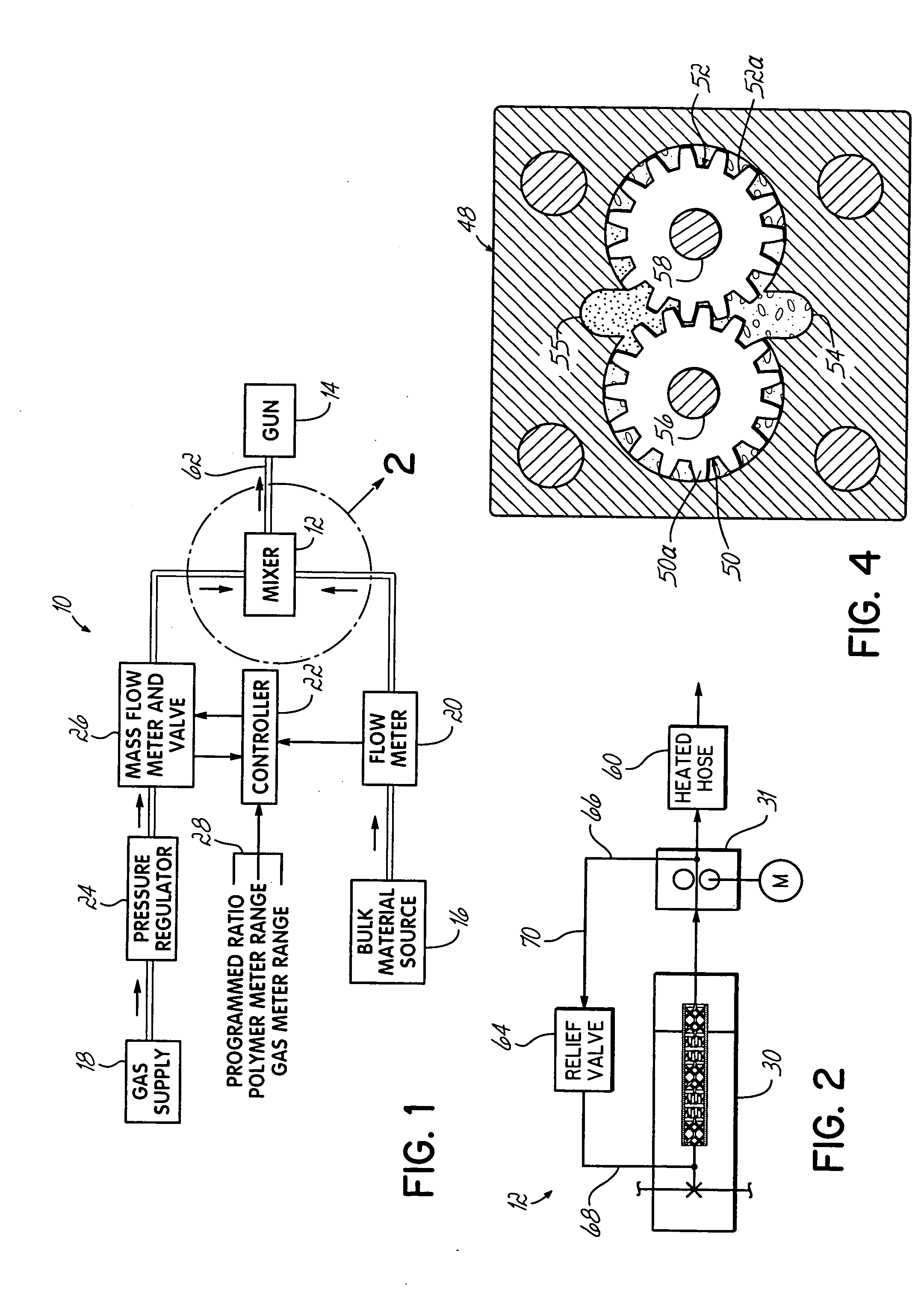

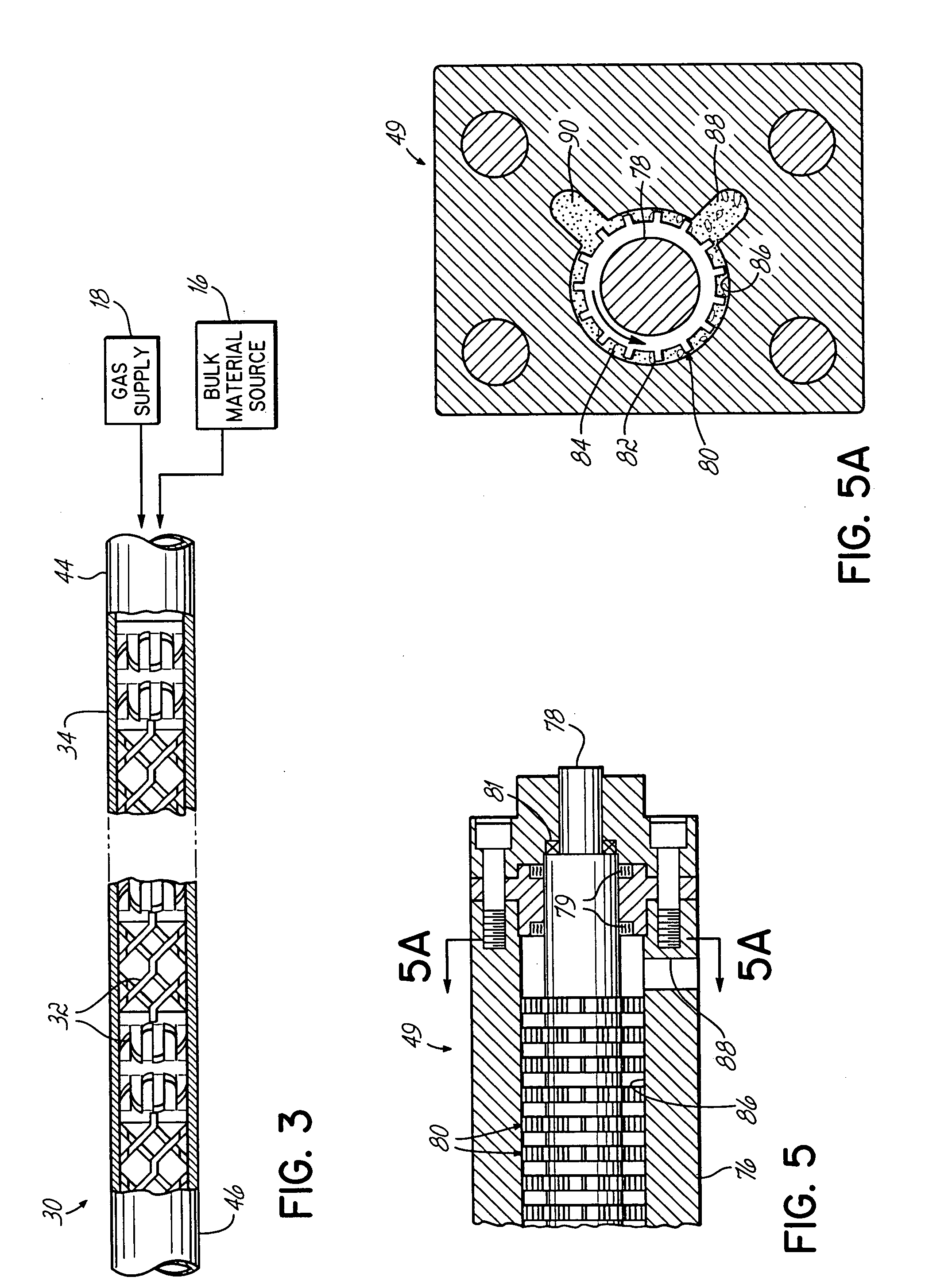

Method and apparatus for producing closed cell foam

InactiveUS20050094482A1Simple designEasy to operateFlow mixersRotary stirring mixersViscous liquidEngineering

Methods and apparatus for producing high quality closed cell foams for use in applications such as coatings, sealant beads, seam filling and gaskets is provided. A two-stage mixing unit, having a static mixing stage comprising a static mixer having a plurality of mixing elements followed immediately by a second dynamic stage such as a dynamic gear pump or disc mixer is used to homogeneously disperse a gas throughout a highly viscous liquid polymeric material such as a plastisol, silicone, butyl or urethane based materials.

Owner:NORDSON CORP

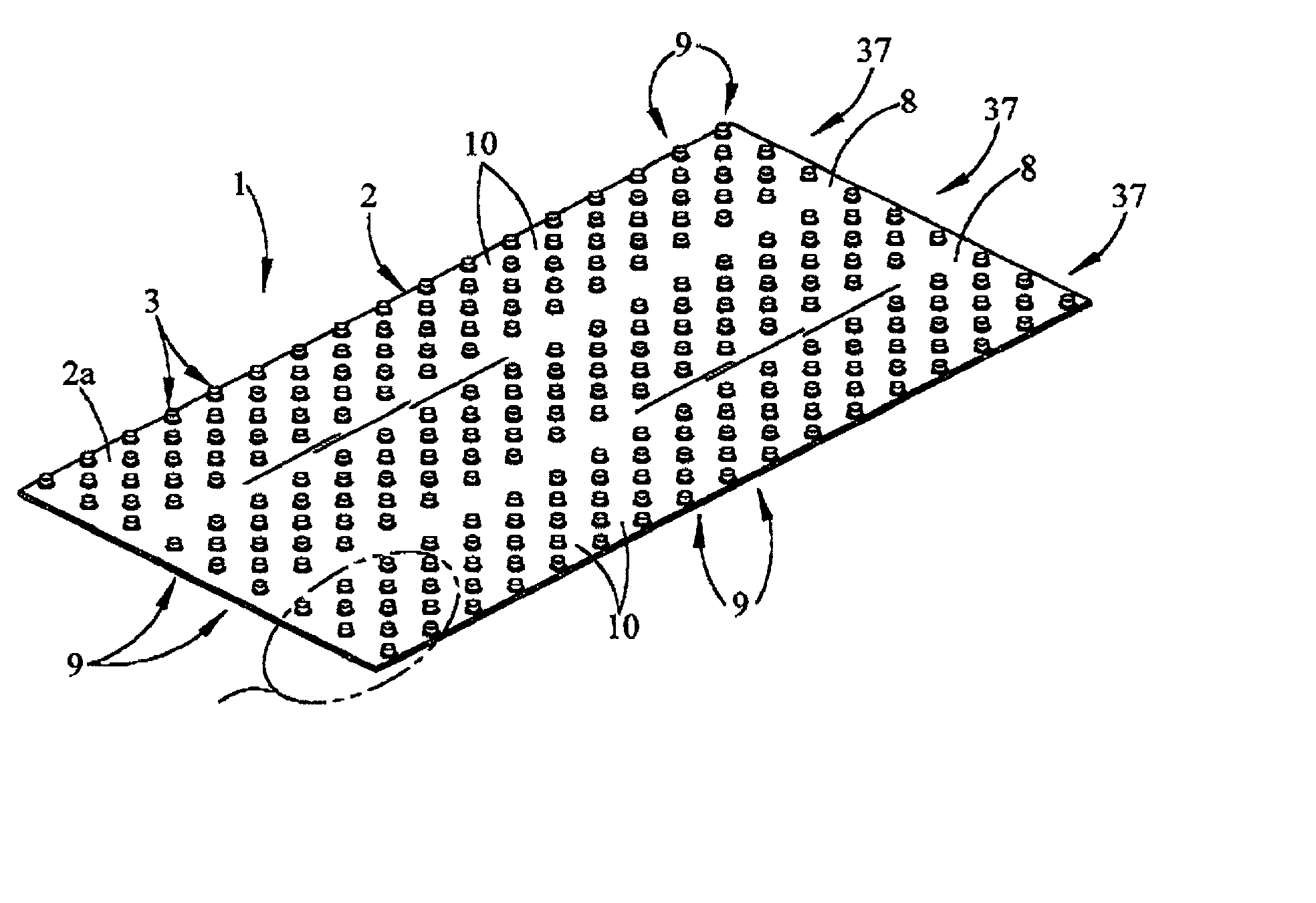

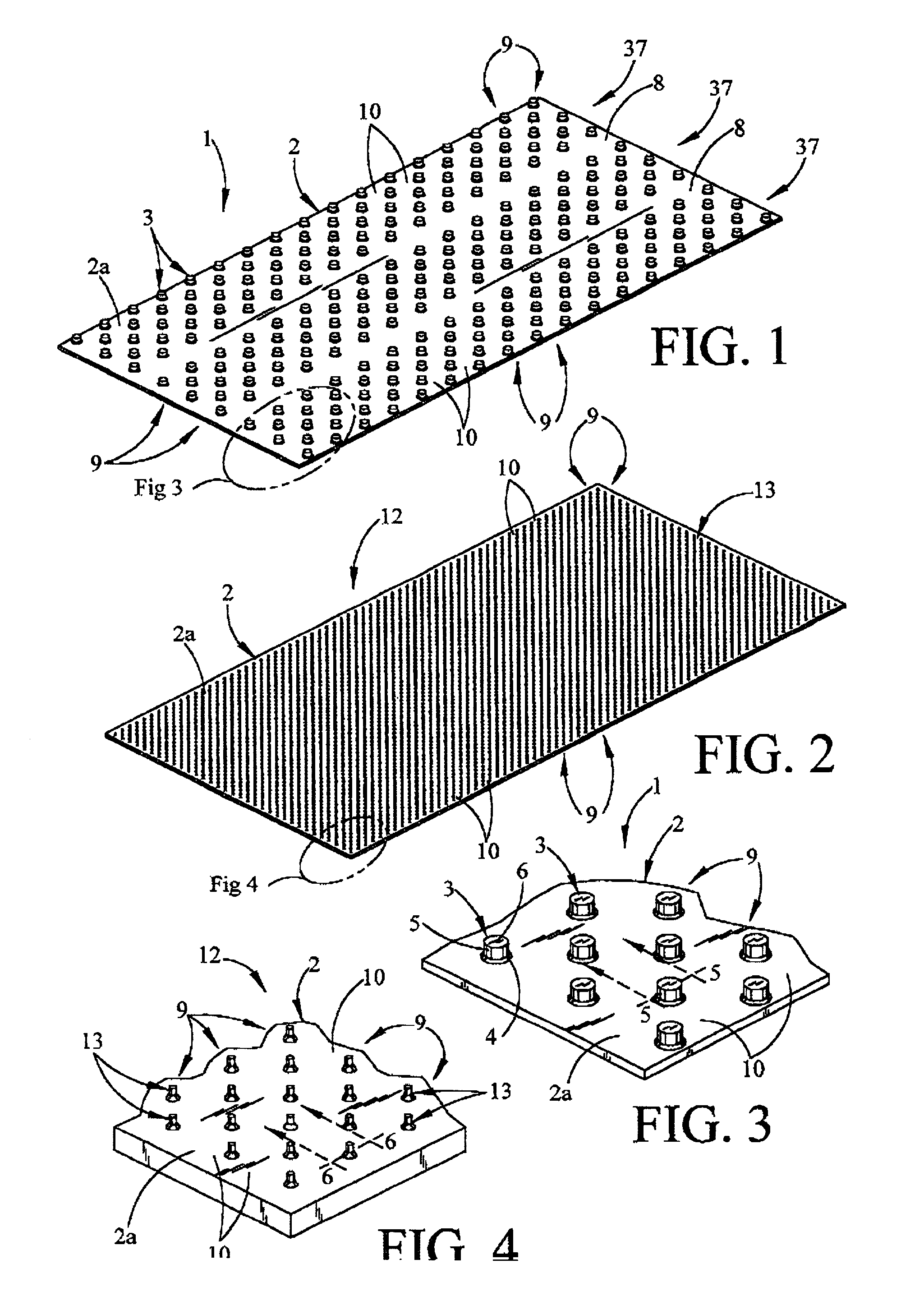

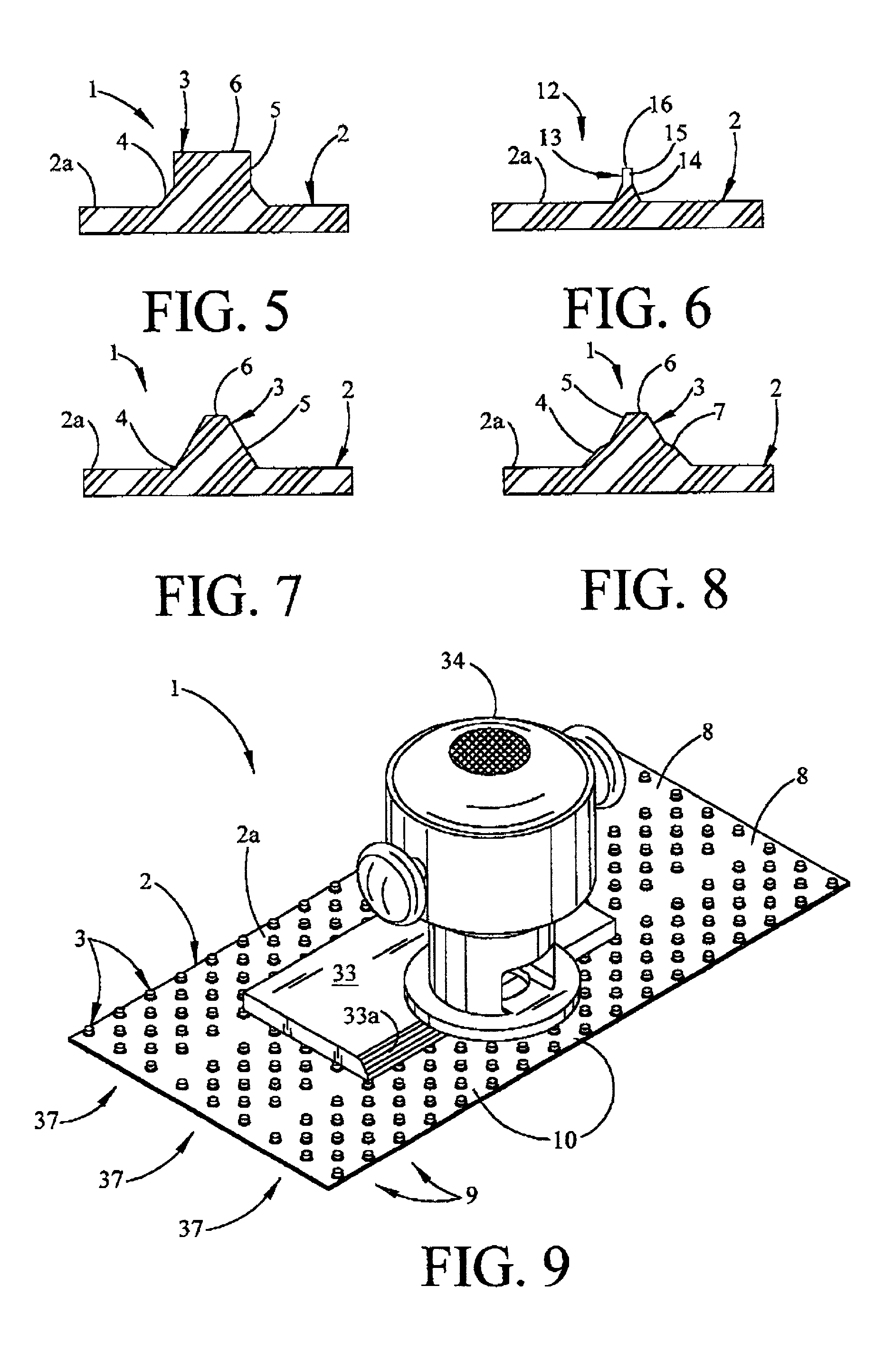

Reduced motion and anti slip pad

InactiveUS20020018877A1Preventing inadvertent slippage and motionReduce relative motionLayered productsLarge fixed membersDiagonalContinuous field

A multi-purpose reduced motion and anti-slip pad which is particularly suitable for substantially immobilizing a workstock as a tool is applied to the workstock. In a preferred embodiment the pad is constructed of vinyl plastisol and is characterized by a flexible, durable sheet having multiple, resilient, spaced-apart nodules of selected size and cross-sectional configuration extending from the sheet typically in multiple parallel, diagonal rows. Each of the nodules typically has a flat top surface, and multiple nodules contact and substantially immobilize the workstock as the workstock rests on the pad. In one embodiment, the parallel diagonal rows of the nodules are arranged in columns, with adjacent, parallel columns of nodules separated by a clear lane characterized by an absence of nodules on the sheet and on which a cylindrical workstock can be placed and immobilized. In another embodiment, the diagonal rows of nodules define a continuous field of the nodules on the sheet. In still another embodiment, the nodules are smaller and more numerous to facilitate immobilizing smaller workstocks on the pad.

Owner:WOODALL CALVIN L +1

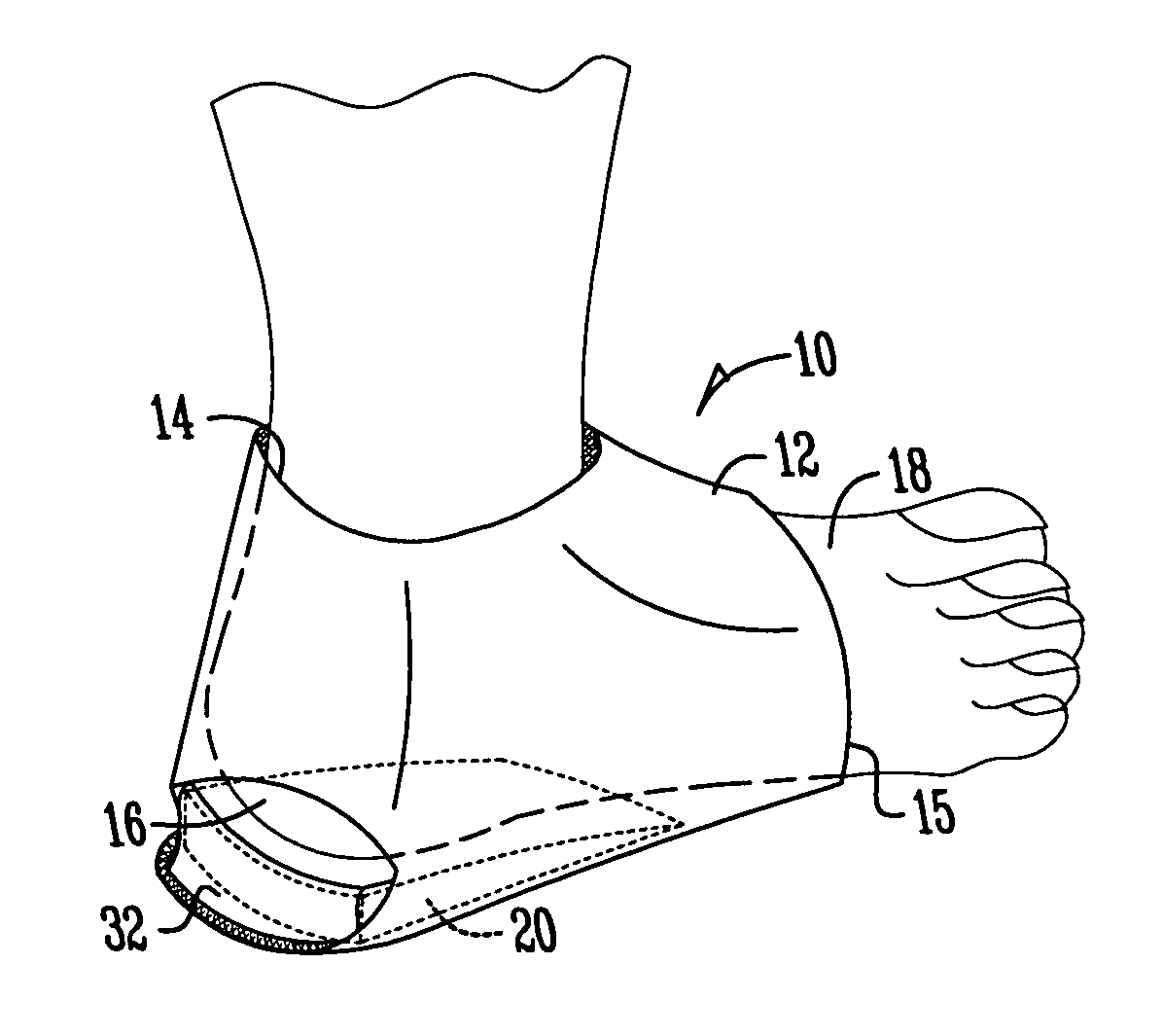

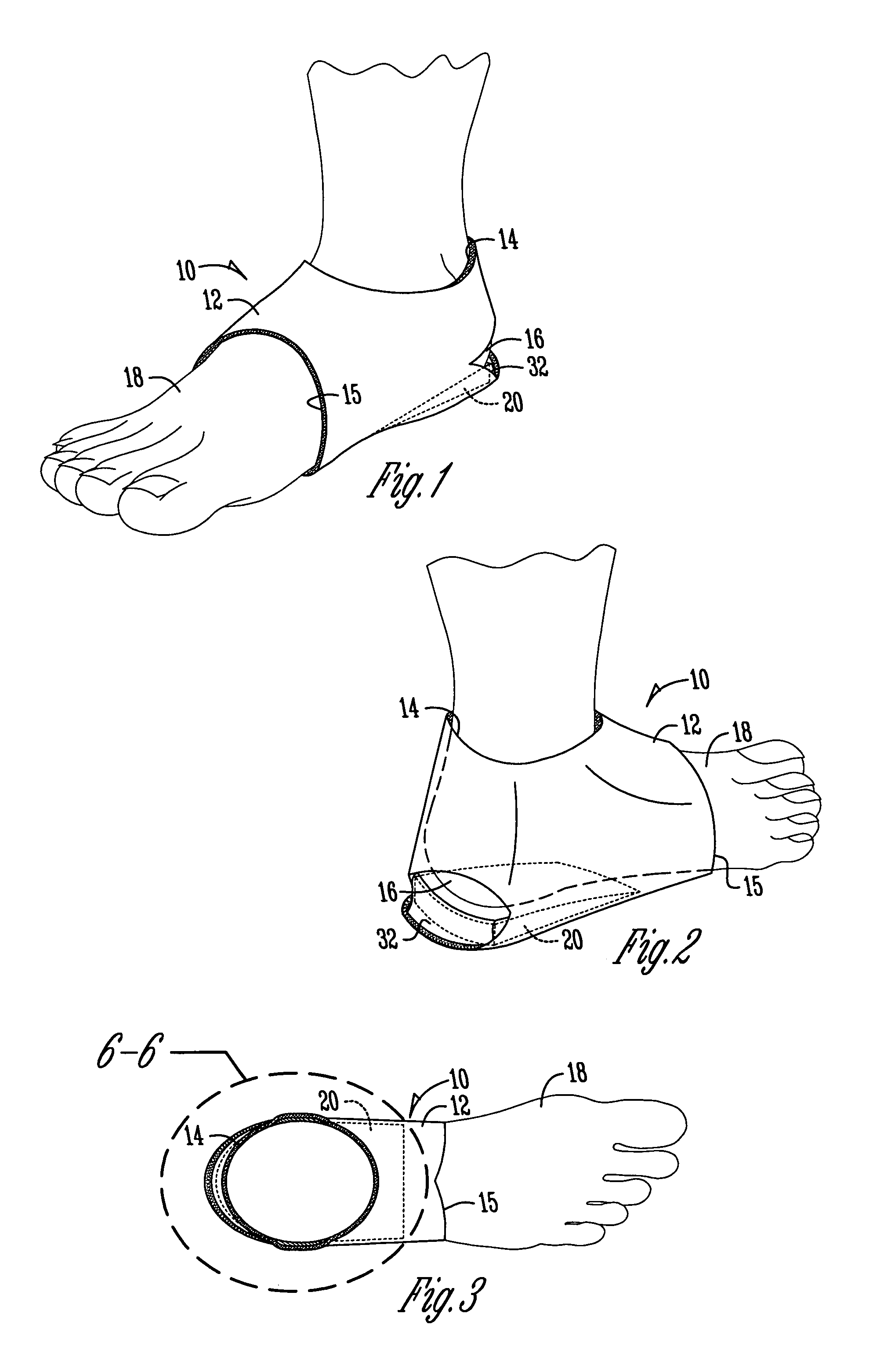

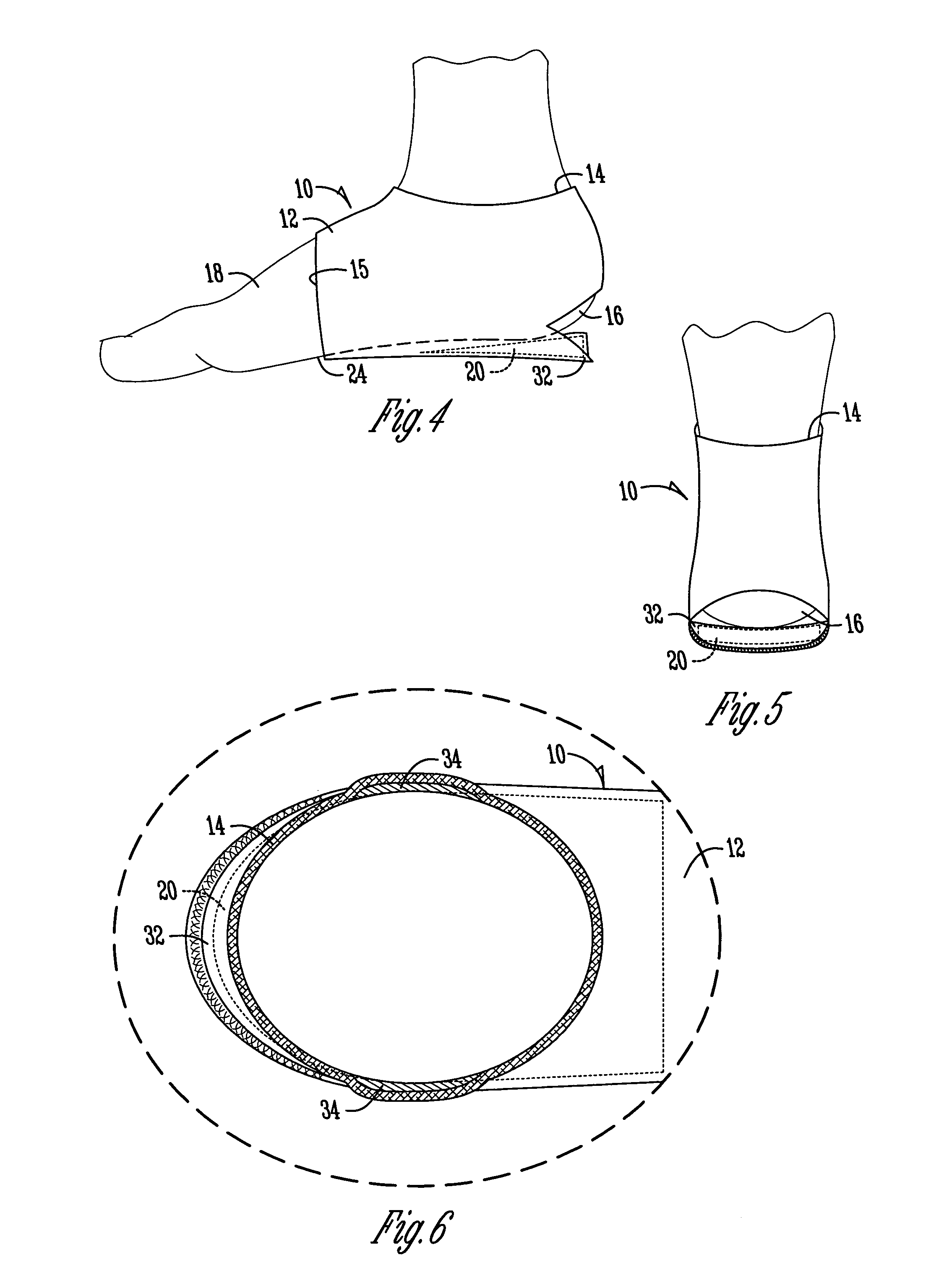

Device for heel shock absorption, swelling, and pain treatment

ActiveUS7056299B2Relieve painShock absorptionFeet bandagesNon-surgical orthopedic devicesCushioningOrthotic device

An orthotic device for absorption of heel shock, treating edema and swelling and for lessening pain. It is comprised of an elastic sleeve adapted to fit over the foot and heel of a person. The sleeve includes a shock absorbing heel pad inside of the sleeve in a position to be disposed under the heel when the sleeve is worn around the heel. The sleeve is of elastomeric material providing compression to treat edema and swelling. The pad may be a polymeric plastisol material which can be cooled to provide cold therapy and positioned under the heel to provide cushioning and shock absorption.

Owner:BROWNMED

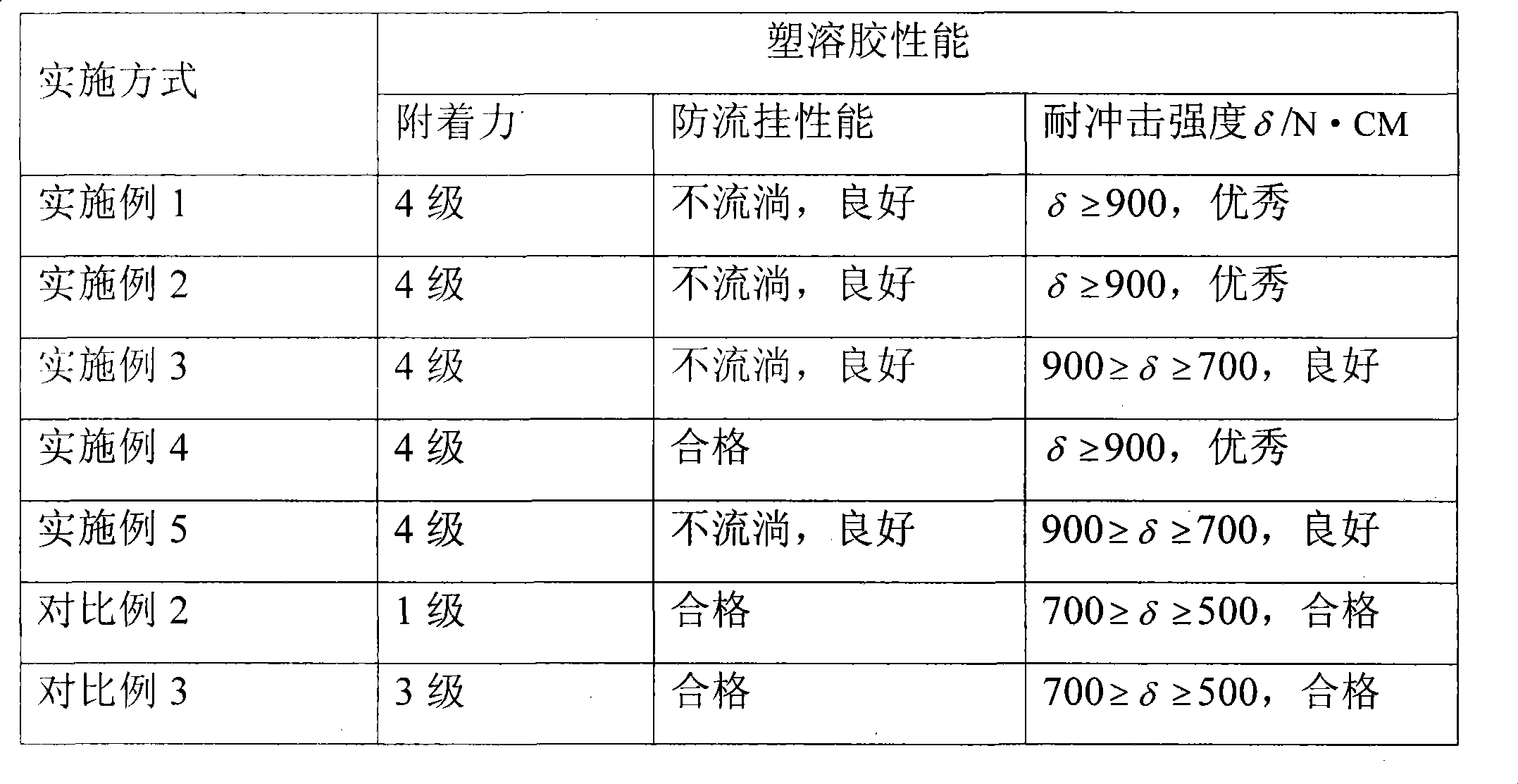

Low-temperature plasticizing type PVC plastic colloidal sols and method of producing the same

InactiveCN101402772AReduce plasticizing temperatureReduce the temperaturePolyurea/polyurethane coatingsEnd-groupPolyamide

The invention relates to a low-temperature plasticization PVC plastisol which can effectively reduce the plasticization temperature of PVC plastisol and ensure the adhesive force of the PVC plastisol on an electrophoretic paint plate; the components of the low-temperature plasticization PVC plastisol comprise a plasticizer, PVC resin paste, chloride vinyl acetate copolymer, a heat stabilizer, nano activated calcium carbonate, a thixotropic agent, a low molecular polyamide resin, a viscosity depressant and a pigment; the PVC plastisol is characterized in that: the components of the PVC plastisol also comprise a closed polyurethane prepolymer, wherein, polymethylene polyisocyanate and polyol are polymerized to obtain quasi-prepolymer with an end group of -NCO, and the end of the quasi-prepolymer is sealed by a sealing agent to obtain the closed polyurethane prepolymer. The preparation method of the low-temperature plasticization PVC plastisol comprises the steps: the closed polyurethane prepolymer and the low molecular polyamide resin are added into the plasticizer and evenly dispersed in the plasticizer, and then other components are added into the plasticizer and evenly dispersed in the plasticizer to obtain an evenly-dispersed material which is put into a double shaft agitator and agitated for 30min; vacuumizing is carried out while blending the material until the degree of vacuum is degree of vacuum, and then the material is placed for 24h at a normal temperature for the curing of the PVC plastisol and finally filtered.

Owner:匡建钢

Compositions Based on C4-C7 Secondary Aliphatic Alcohol Esters of Cyclohexanecarboxylic Acids

InactiveUS20100310891A1Easy to processReduce solubilitySynthetic resin layered productsThin material handlingCyclohexanecarboxylic acidCarboxylic acid

C4-C7 secondary aliphatic alcohol esters of cyclohexanediacid are especially useful as plasticizers for PVC. In embodiments, these fast fusing plasticizers are useful in plastisol formulations to help improve the processability of flexible PVC material. In preferred embodiments these same plasticizers can be used in blends with other plasticizers, especially slower fusing plasticizers or plasticizers with reduced solvency, such as di-2-propylheptyl phthalate or di-isononyl cyclohexanedicarboxylic acid, to improve processability.

Owner:EXXONMOBIL CHEM PAT INC

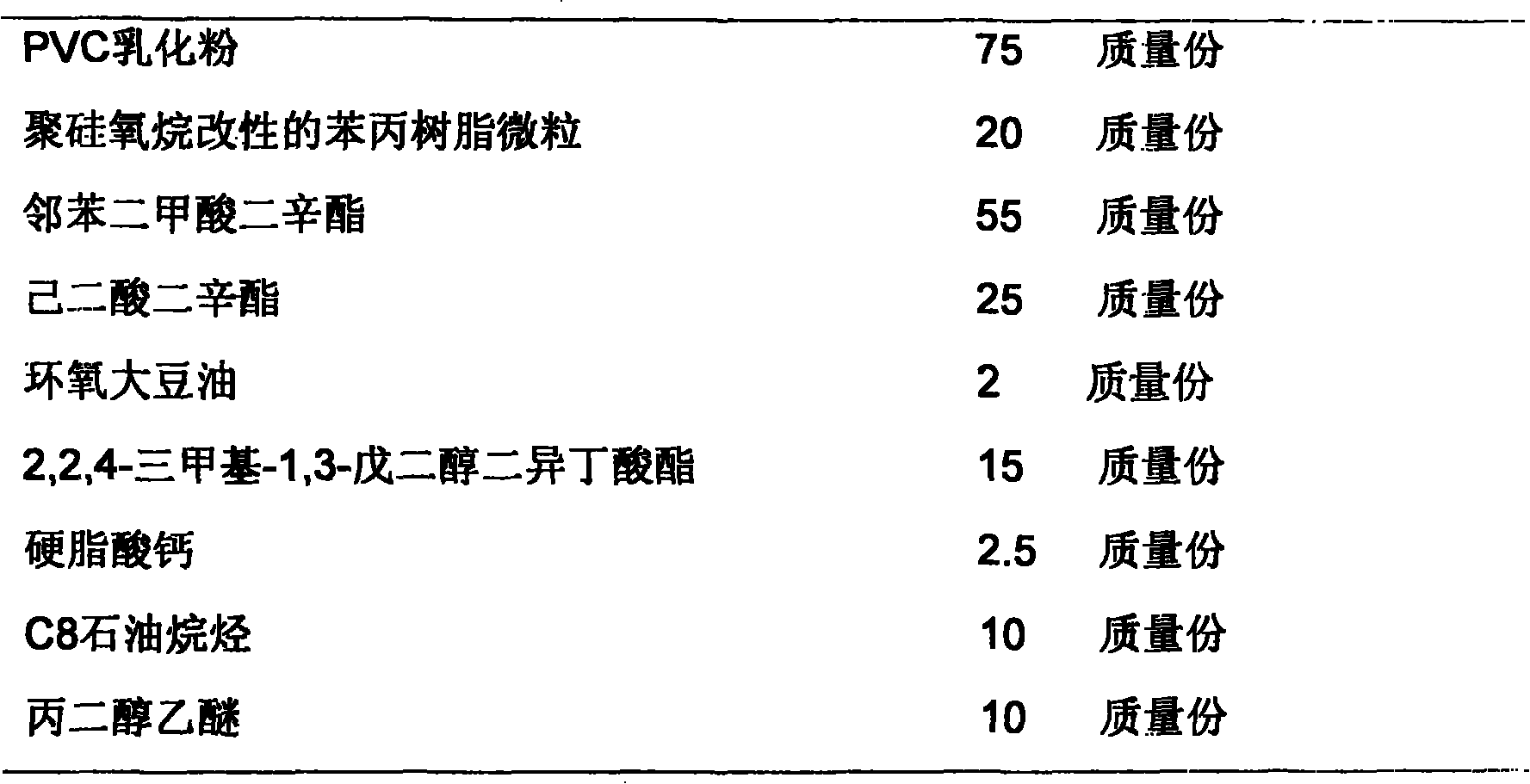

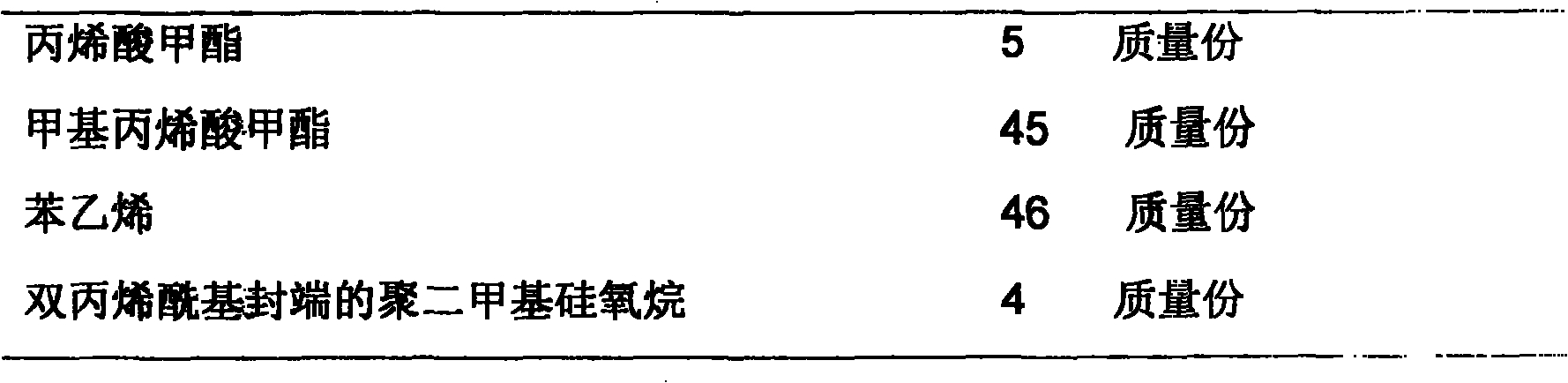

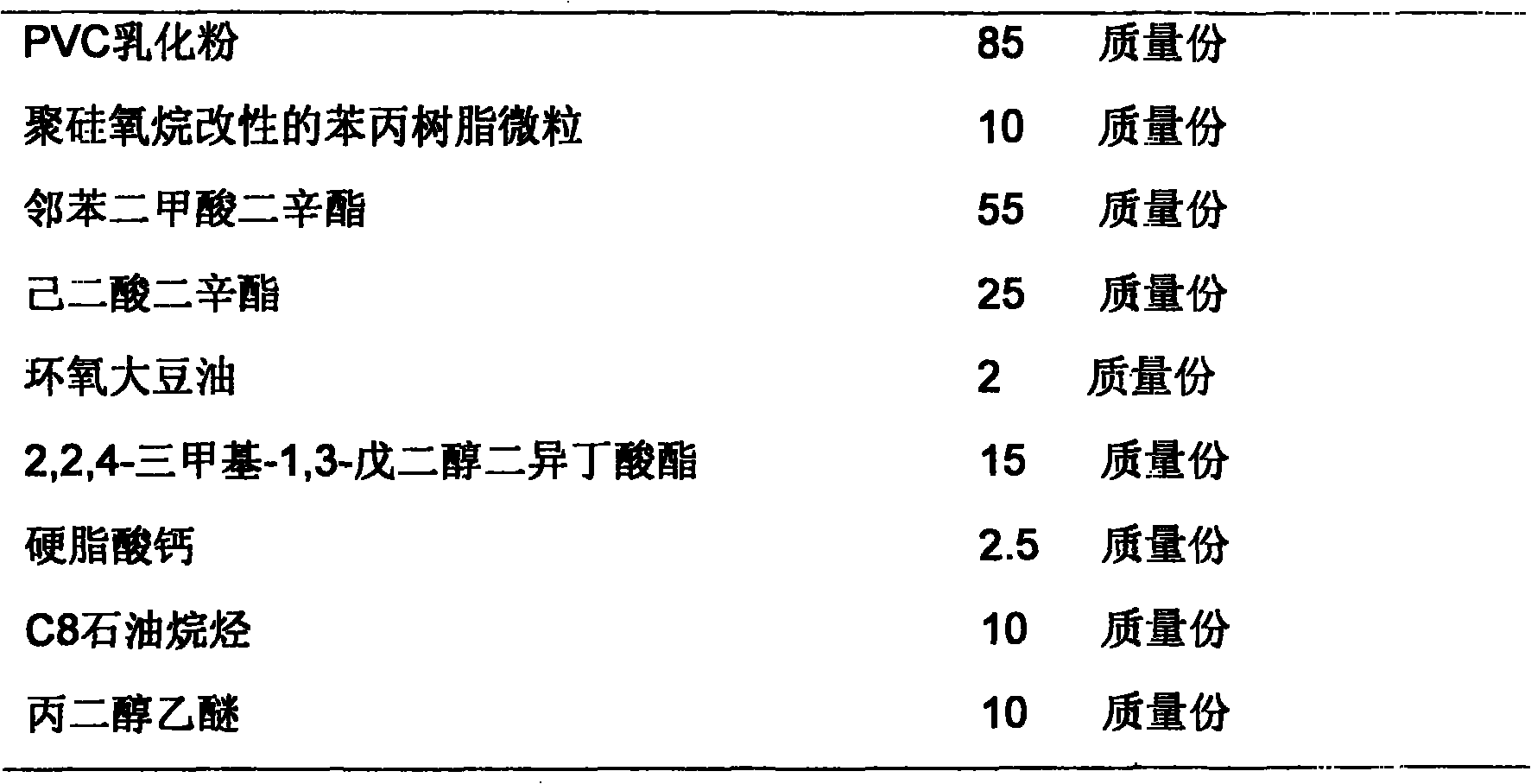

Functional PVC plastic colloidal sols for non-powder PVC gloves and uses thereof

The invention discloses a functional PVC plastisol used by powderless PVC gloves and the application of the plastisol, belonging to the technical field of the PVC gloves; to solve the problems of low production efficiency and bad dressing effect of present powderless PVC gloves, the functional PVC plastisol is made from benzene inner resin particles which are modified by PVC emulsification powder, primary plasticizers, secondary plasticizers, viscosity depressants, stabilizing agents and polysiloxane, uniformly mixed and treated with vacuum defoamation; a preheated hand die is gelled to form a film after going through digestion and roast in the ordinary PVC plastisol, then is gelled to form a film by digestion and roast in the functional PVC plastisol of the invention and then the powderless gloves with good dressing effect and no self conglutination are obtained by edge turning and parting.

Owner:BEIJING COMENS NEW MATERIALS

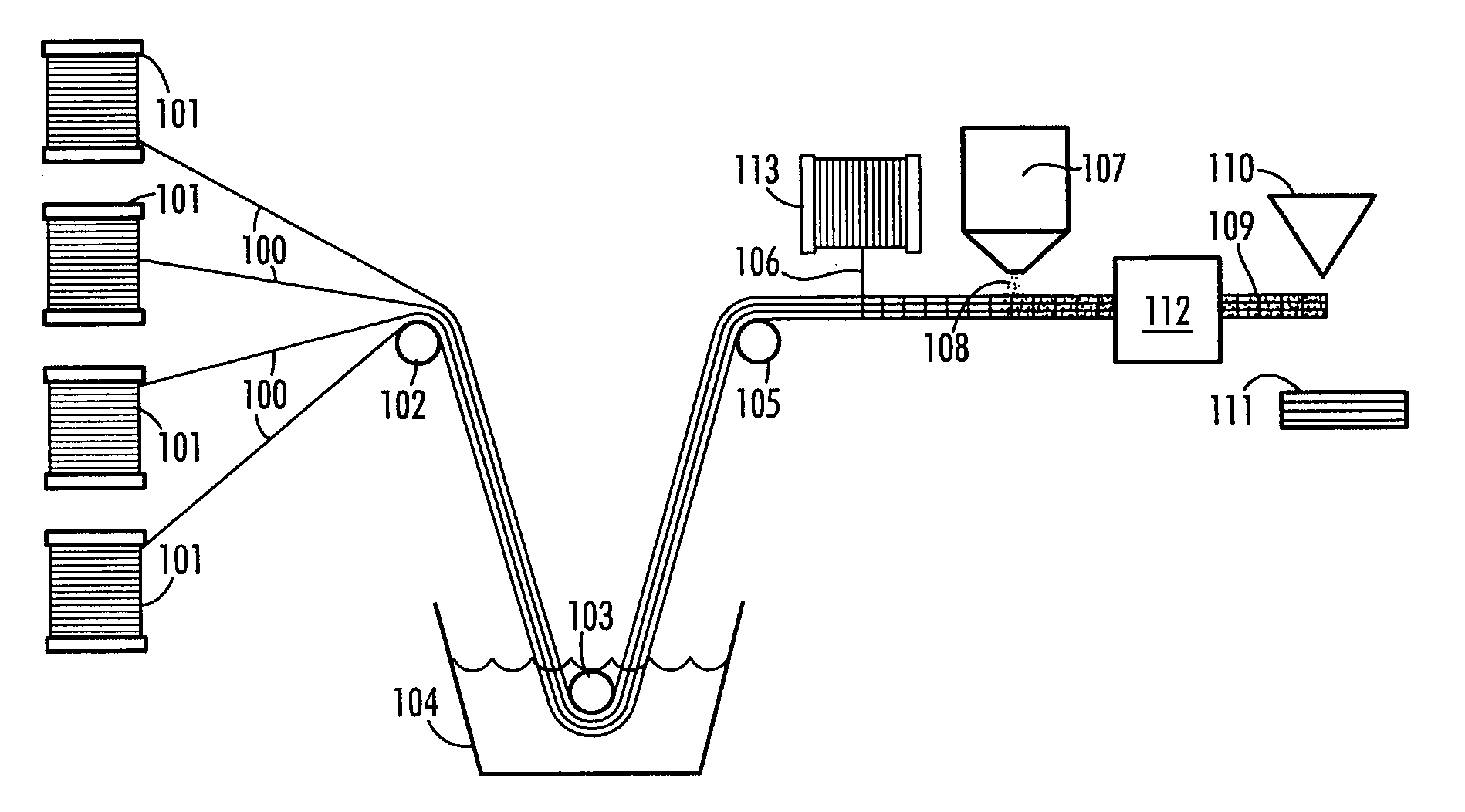

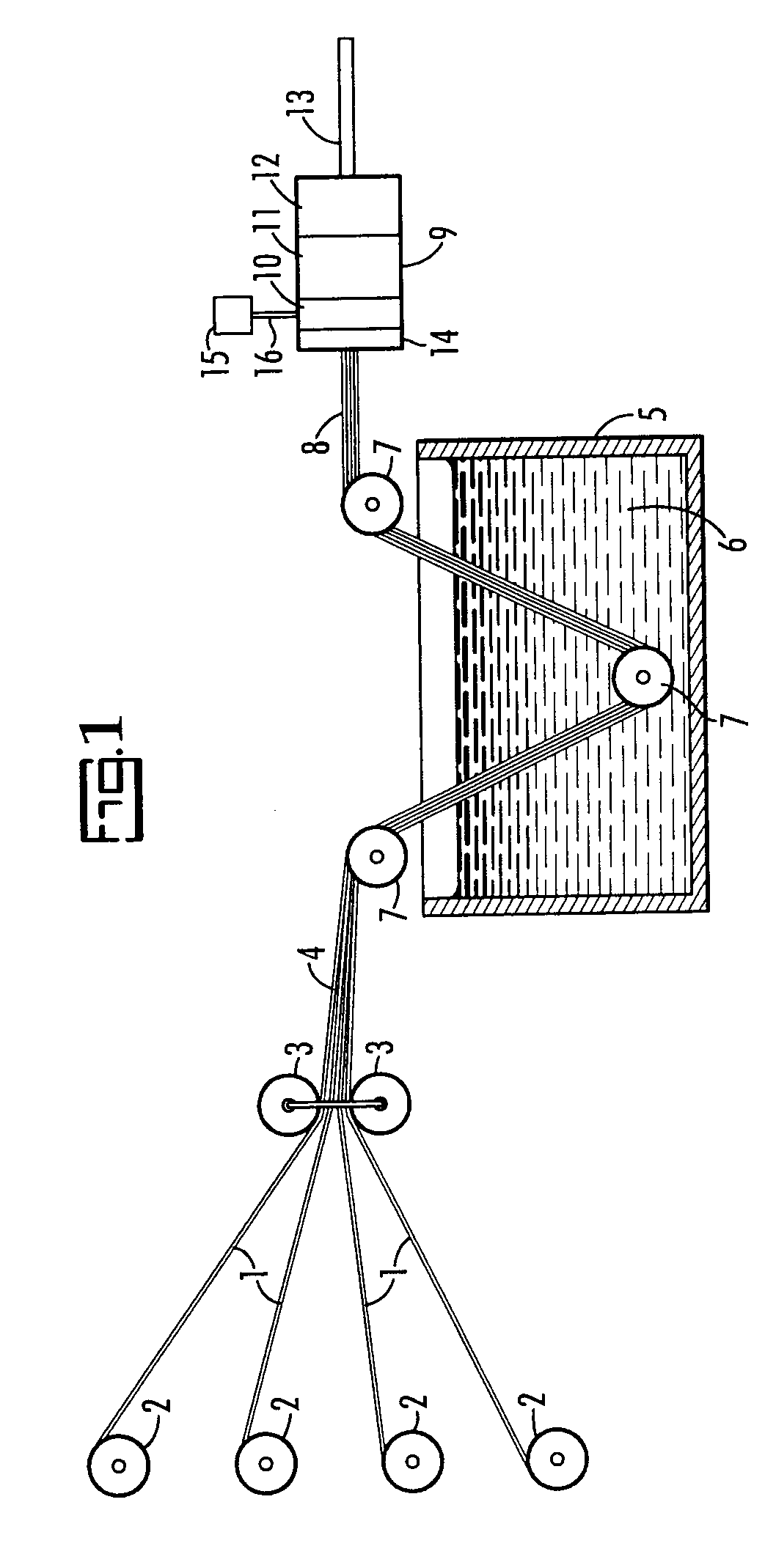

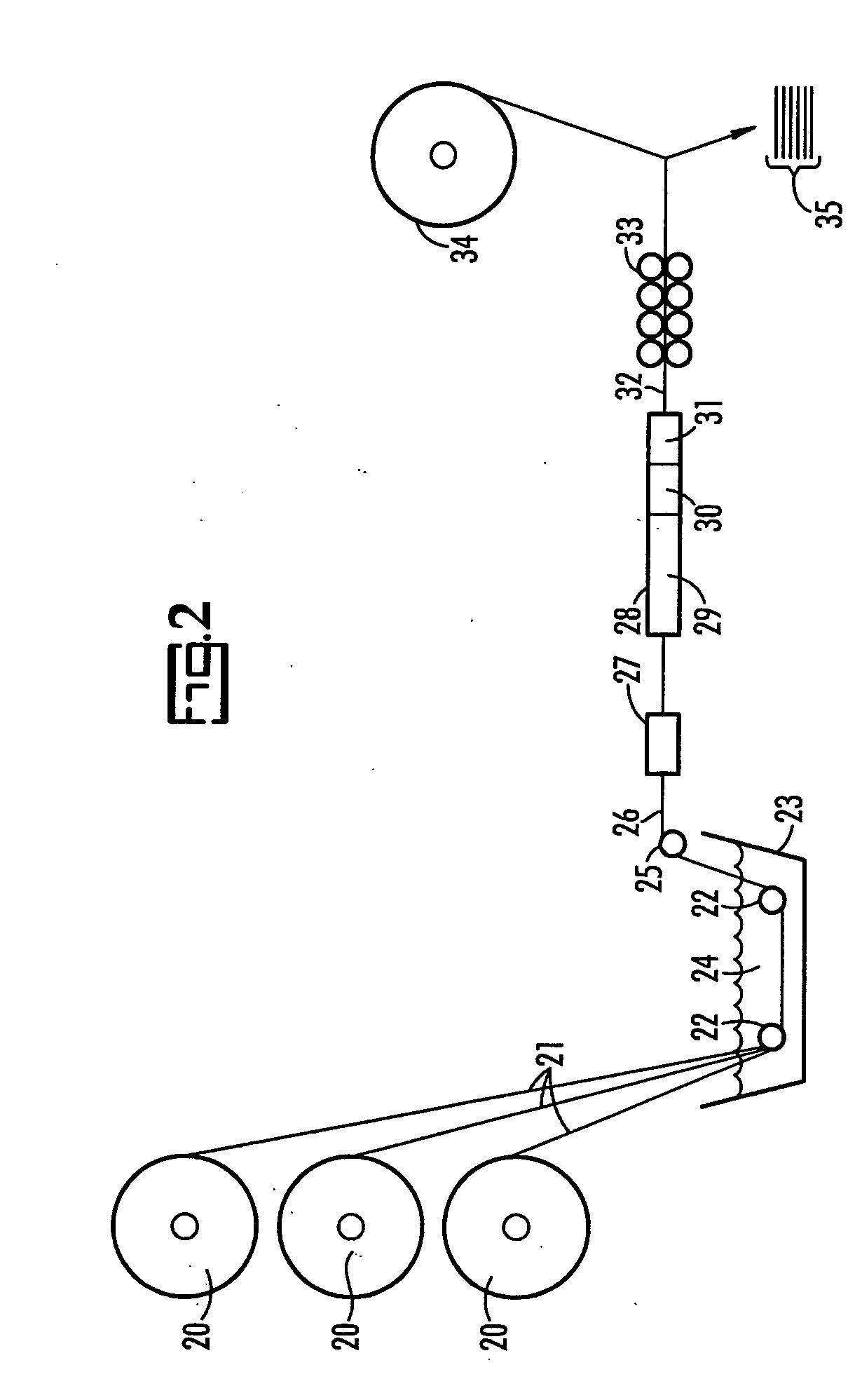

Method of making reinforced PVC plastisol resin and products prepared therewith

InactiveUS20080318042A1Readily availableLow costLayered productsDomestic articlesMechanical engineeringLaminated composites

A pultrusion machine for forming a laminated composite with a predetermined profile and the product obtained. The apparatus comprises at least two spools for supplying elongated reinforcements. A collator receives the elongated reinforcements and arranges the reinforcements in layered relationship to form a layered elongated bundle. A supply member wets the layered elongated bundle with plastisol to form a wetted elongated bundle. The wetted elongated bundle is transported through a pultrusion die wherein the wetted layered bundle is molded into the predetermined profile. A converting apparatus cures, or converts, the wetted layered bundle into the layered composite. A particularly preferred embodiment is an extrusion comprising a reinforcing material wherein said reinforcing material comprises a fiber reinforced plastisol.

Owner:KUSEK WALTER W

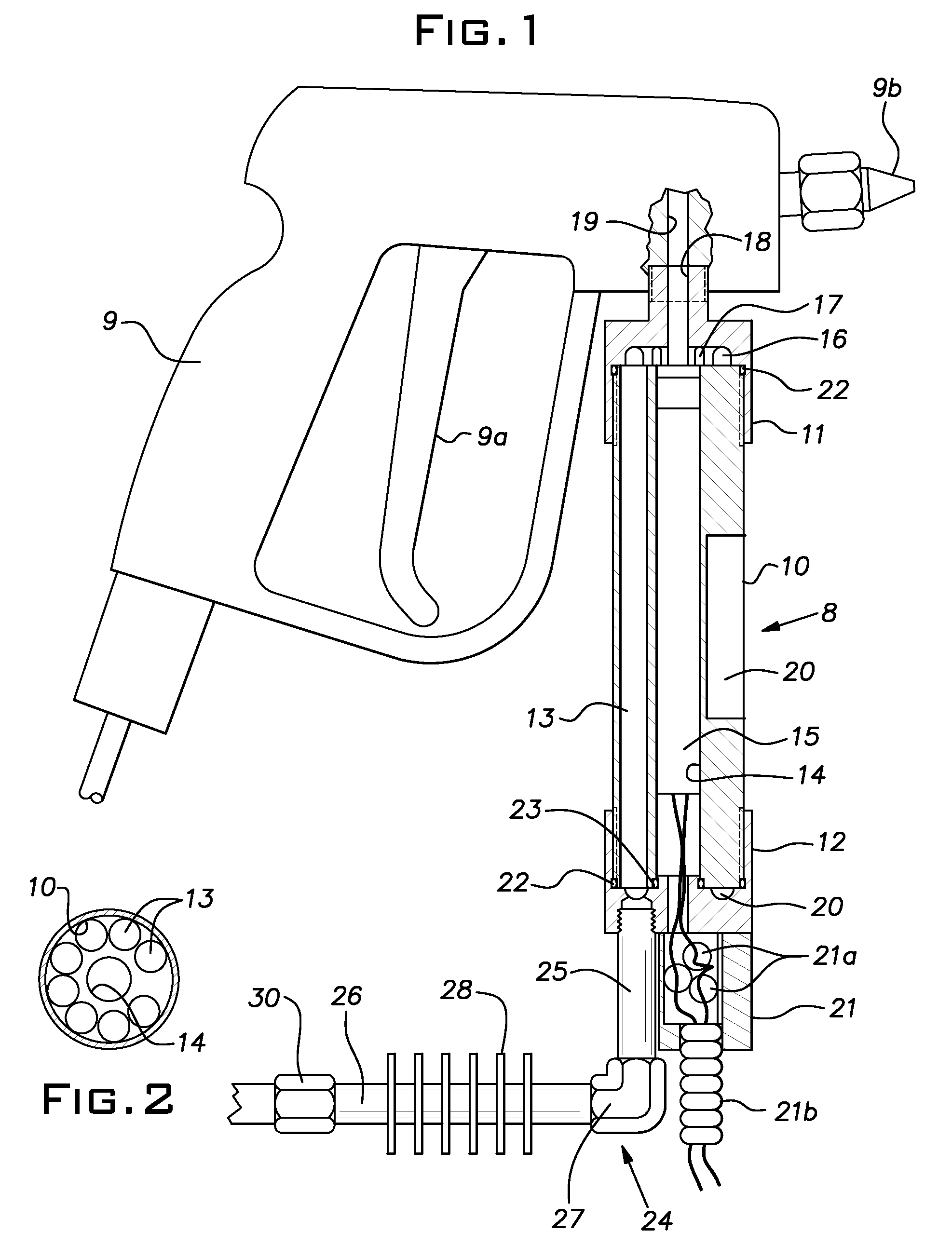

Heated textiles and methods of making the same

InactiveUS9161393B2Reduce resistanceImprove washabilityHeater elementsFootwearDielectric layerMaterials science

The present invention provides a composite heating element suitable for heating an article when activated by a power source. The composite heating element comprises first and second dielectric layers each having an inner surface and an outer surface. The composite heating element further comprises a conductive layer formed from at least one conductive ink composition comprising a plastisol component and a conductive component. The conductive layer is disposed between the inner surfaces of the first and second dielectric layers and defines a circuit. The composite heating element further comprises an adhesive layer coupled at least one of the outer surfaces of the first and second dielectric layers opposite the conductive layer.

Owner:T INK INC

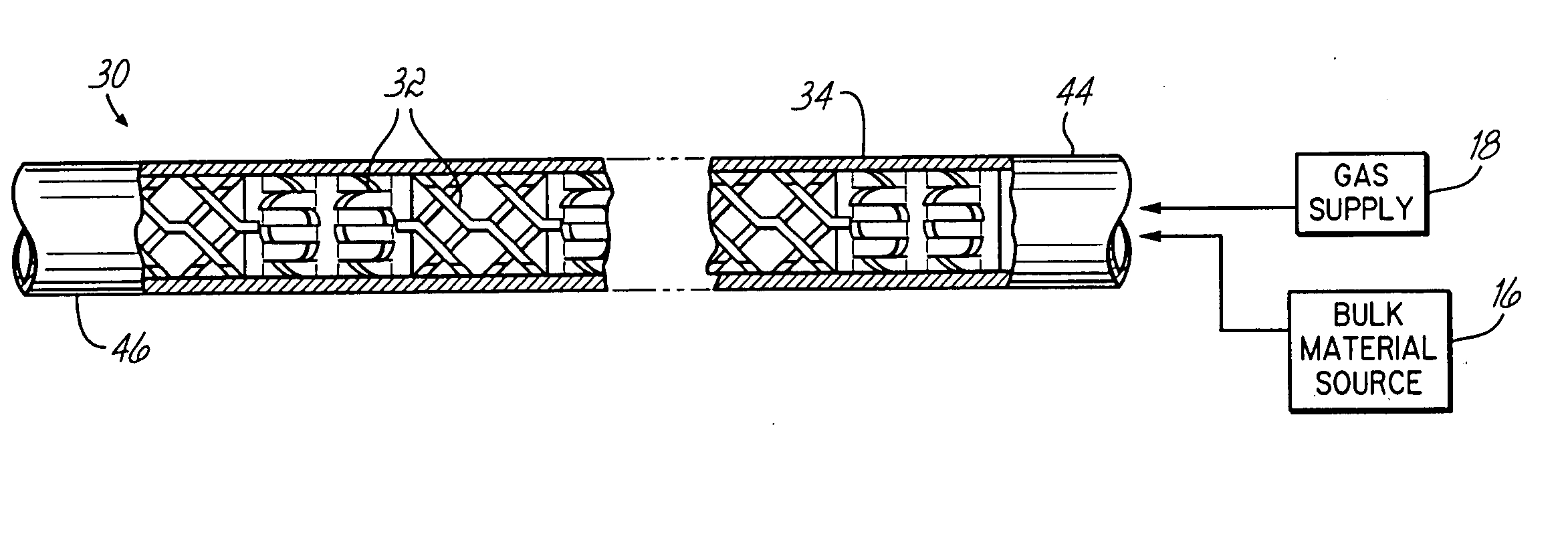

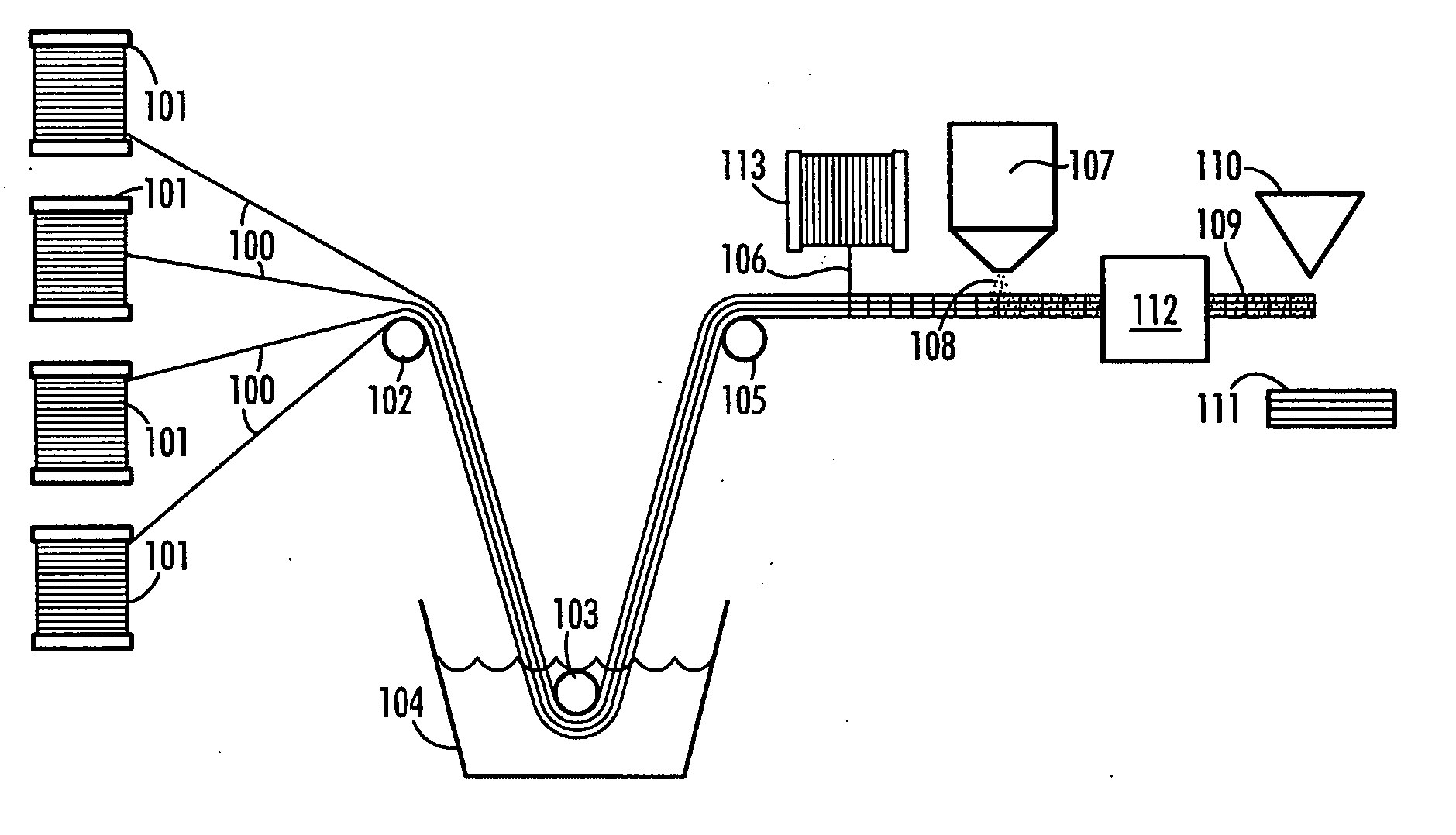

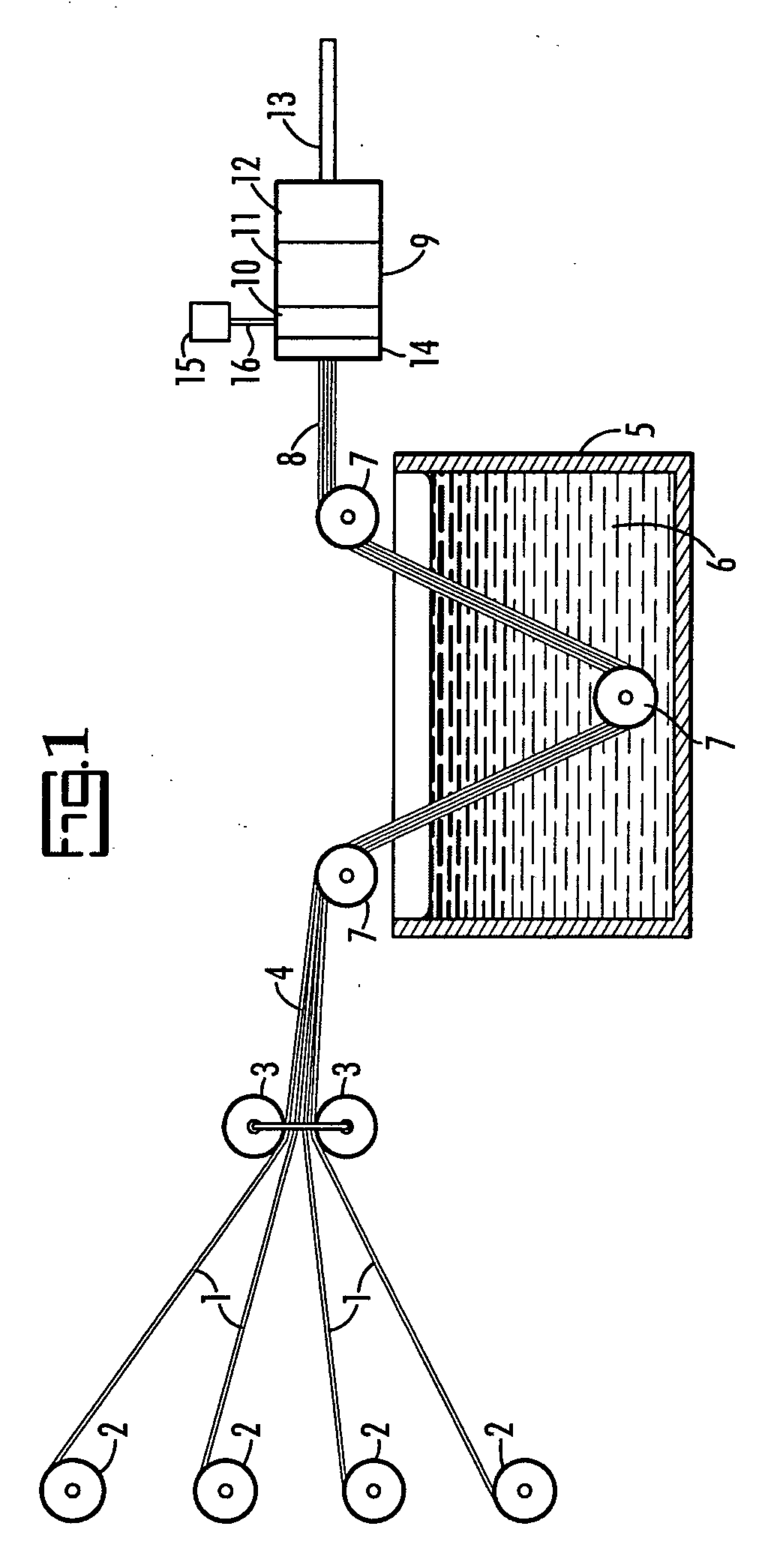

Method of making reinforced PVC plastisol resin and products prepared therewith

InactiveUS20070006961A1Readily availableLow costLiquid surface applicatorsDomestic articlesRebarBiomedical engineering

A pultrusion machine for forming a laminated composite with a predetermined profile and the product obtained. The apparatus comprises at least two spools for supplying elongated reinforcements. A collator receives the elongated reinforcements and arranges the reinforcements in layered relationship to form a layered elongated bundle. A supply member wets the layered elongated bundle with plastisol to form a wetted elongated bundle. The wetted elongated bundle is transported through a pultrusion die wherein the wetted layered bundle is molded into the predetermined profile. A converting apparatus cures, or converts, the wetted layered bundle into the layered composite. A particularly preferred embodiment is an extrusion comprising a reinforcing material wherein said reinforcing material comprises a fiber reinforced plastisol.

Owner:KUSEK WALTER

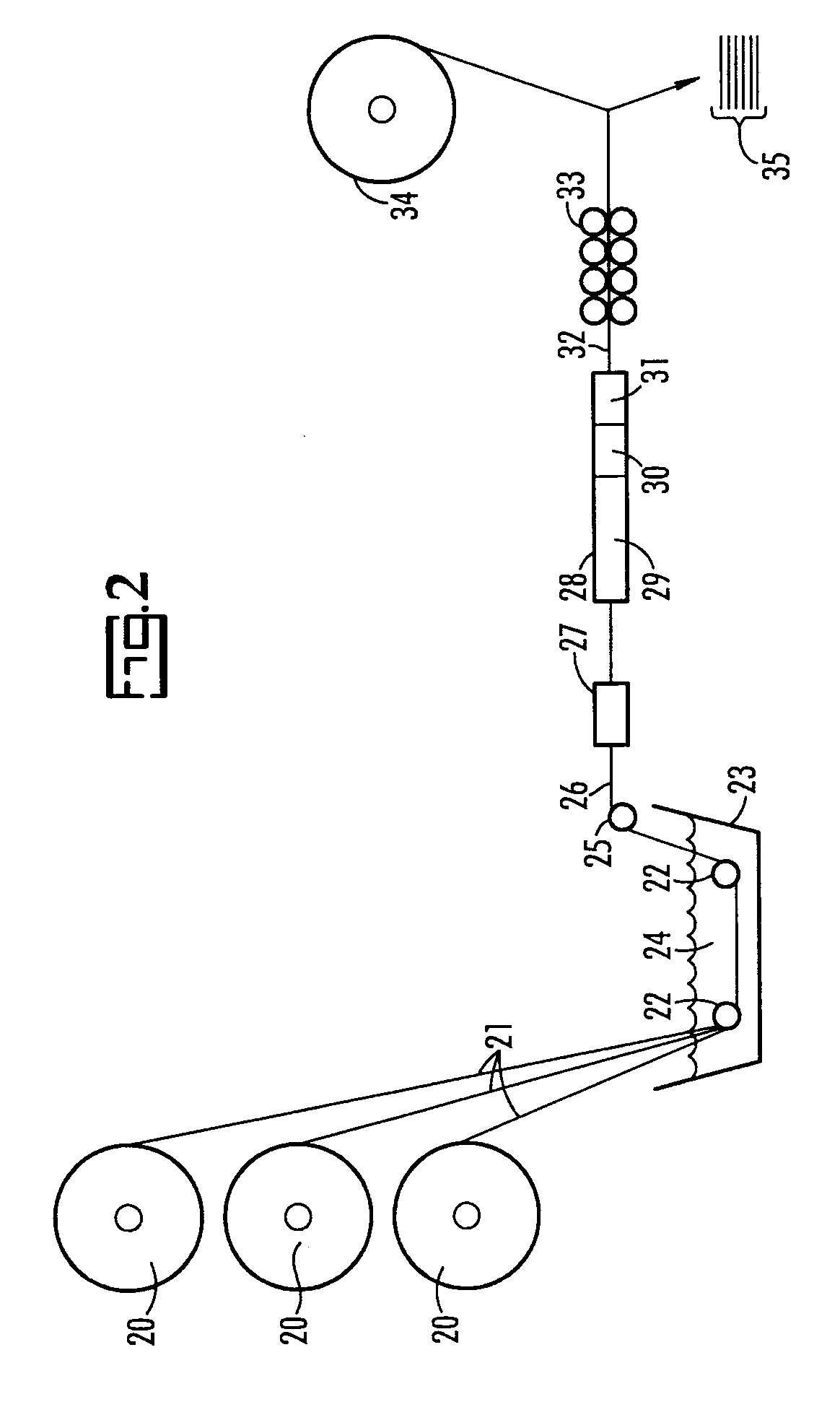

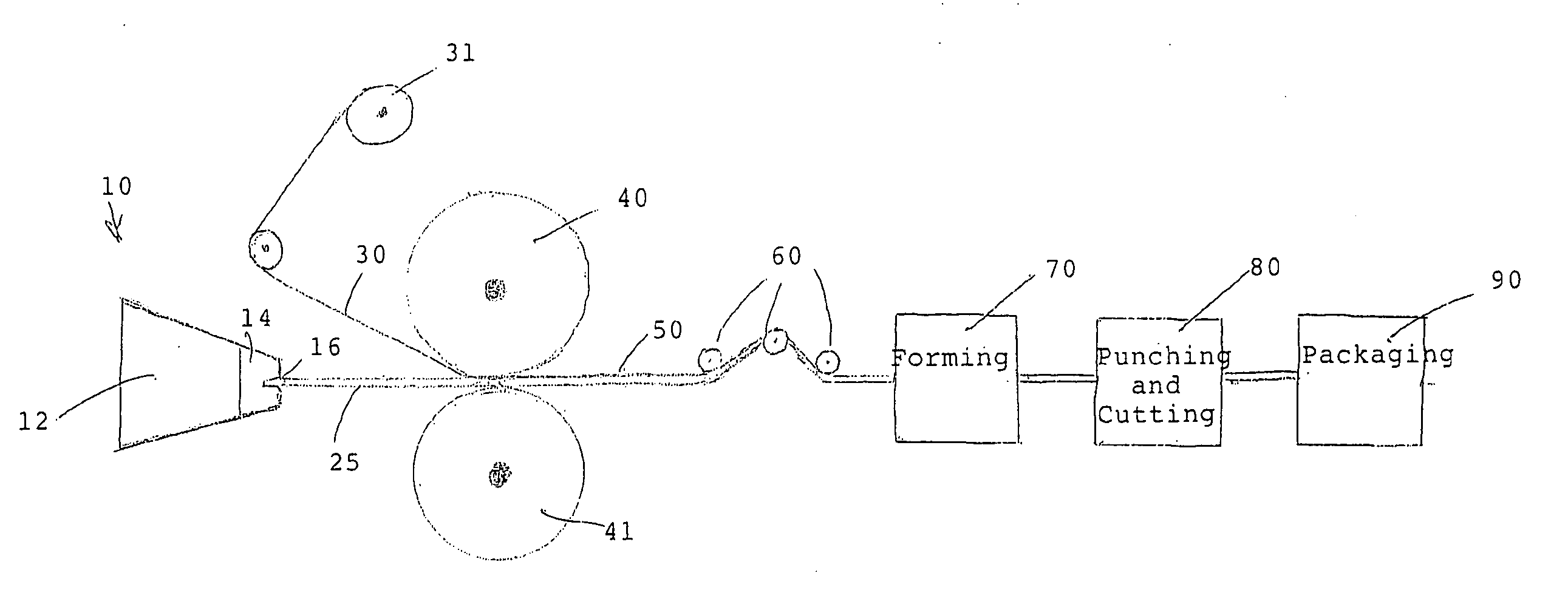

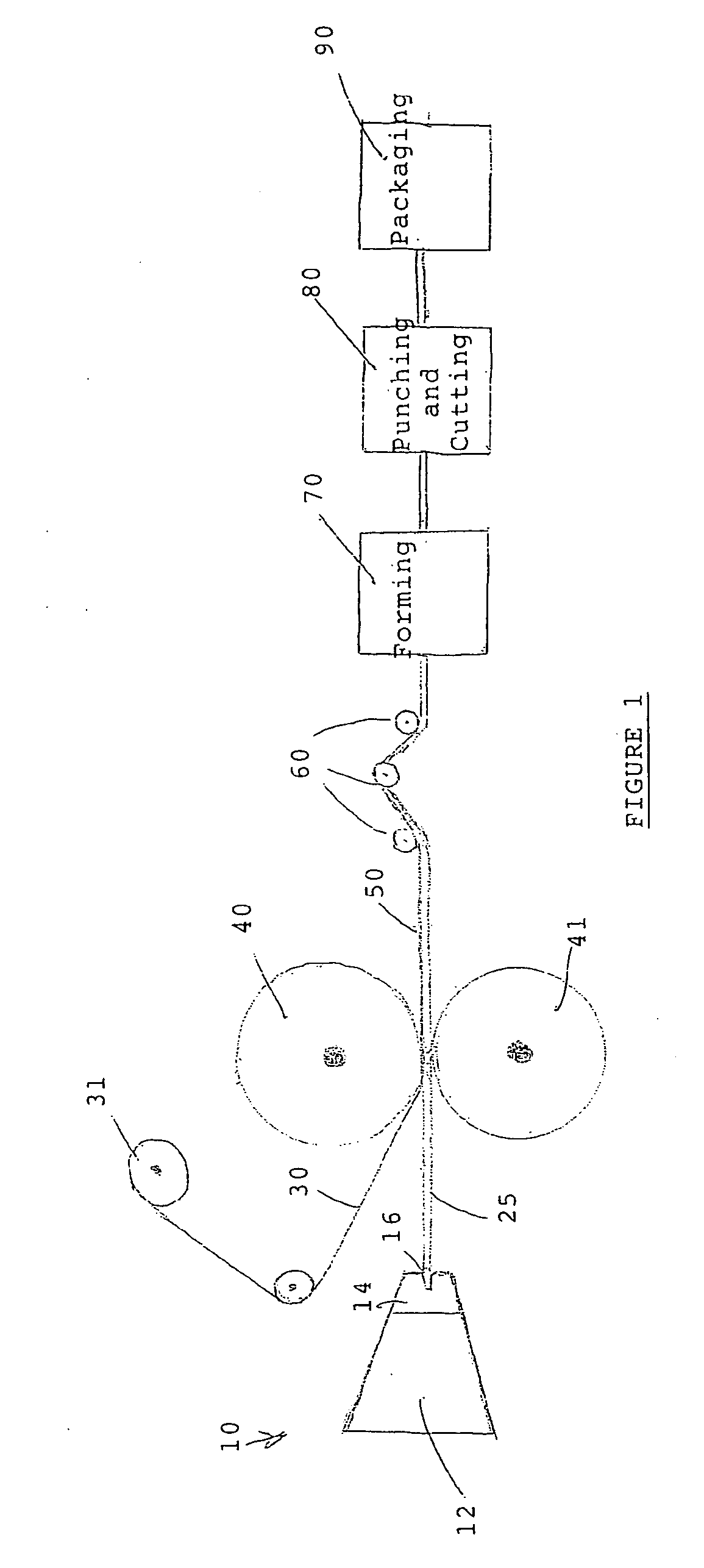

Conveyor belt

ActiveUS8910780B2Low costReduce labor requirementsConveyorsLamination ancillary operationsEngineeringConveyor belt

The present invention reveals a method of manufacturing a fabric reinforcement having improved peel adhesion characteristics which is of particular value in reinforcing endless belts, wherein at least two layers of fabric material are embedded in the fabric reinforcement, said process comprising (1) impregnating a fabric material with a bonding agent in a plastisol to form coated fabric material, (2) applying a plastisol layer between two or more layers of coated fabric thereby creating a belt carcass, (3) continuously feeding the belt carcass into a double belt press which presses the impregnated fabric materials together with the plastisol layer(s) at a pressure of at least 5 psi to produce a preformed fabric carcass while (4) heating the preformed fabric carcass to a temperature which is within the range of 360° F. to 450° F. for a period of at least 6 minutes, and (5) continuously withdrawing the fabric carcass from the press.

Owner:CONTITECH USA INC

Surface modified nano calcium carbonate and polychloroethylene plastisol thereof

InactiveCN101451023AStrong adhesionImprove adhesionPigment treatment with macromolecular organic compoundsEnd-groupPolyamide

The invention provides nano calcium carbonate with surface modification and polyvinyl chloride plastic sol thereof. Calcium oxide and carbon dioxide gas are used as raw material to synthesize the nano calcium carbonate; and after carbonizing reaction, the nano calcium carbonate is further subjected to surface modification treatment by taking carboxyl end group amilan polyamide resin as surface modifier, wherein the resin is prepared by condensation of fatty group polyprotic acid and fatty group polybasic amine, and the acid value is controlled between 50 and 500mgKOH / g. The invention also provides the polyvinyl chloride plastic sol added with the nano calcium carbonate, which comprises the following components by weight percentage: 10 to 25 percent of polyvinyl chloride resin, 0.2 to 5 percent of stabilizer, 20 to 45 percent of plasticizer, 0.2 to 8 percent of drying agent, 20 to 50 percent of common calcium carbonate filler, and 10 to 40 percent of nano calcium carbonate. Compared with the prior plastic sol, the polyvinyl chloride plastic sol, after solidification by a coating film, greatly improves impact resistance, and has good, anti-sag performance and adhesive force to electrophoresis of the polyvinyl chloride plastic sol.

Owner:海宁市盐官工业投资有限公司

Shelf liner

InactiveUS20050037190A1Enhances fused bonding of layerConsistent thicknessLamination ancillary operationsSynthetic resin layered productsPolyvinyl chlorideEngineering

The shelf liner is a multi-layered thermoplastic composite sheet of consistent thickness, with a non-slip bottom side and a decorative top side. A decorative top sheet is fused to a top surface of a substrate layer. The substrate layer comprises a nonwoven fabric or material that is coated on both sides, and can be fully impregnated, with a foamed plasticized polyvinyl chloride. The foamed plasticized polyvinyl chloride coating on the bottom side of the substrate layer gives the shelf liner a non-slip characteristic. An interlayer of polyvinyl chloride plastisol is disposed between the top sheet and the substrate to enhance the fused bonding of the layers. A bottom surface of the substrate layer may be fully or partly covered with a bottom coating to modify the non-slip nature of the shelf liner.

Owner:MARKETING & SALES MANAGEMENT CORP

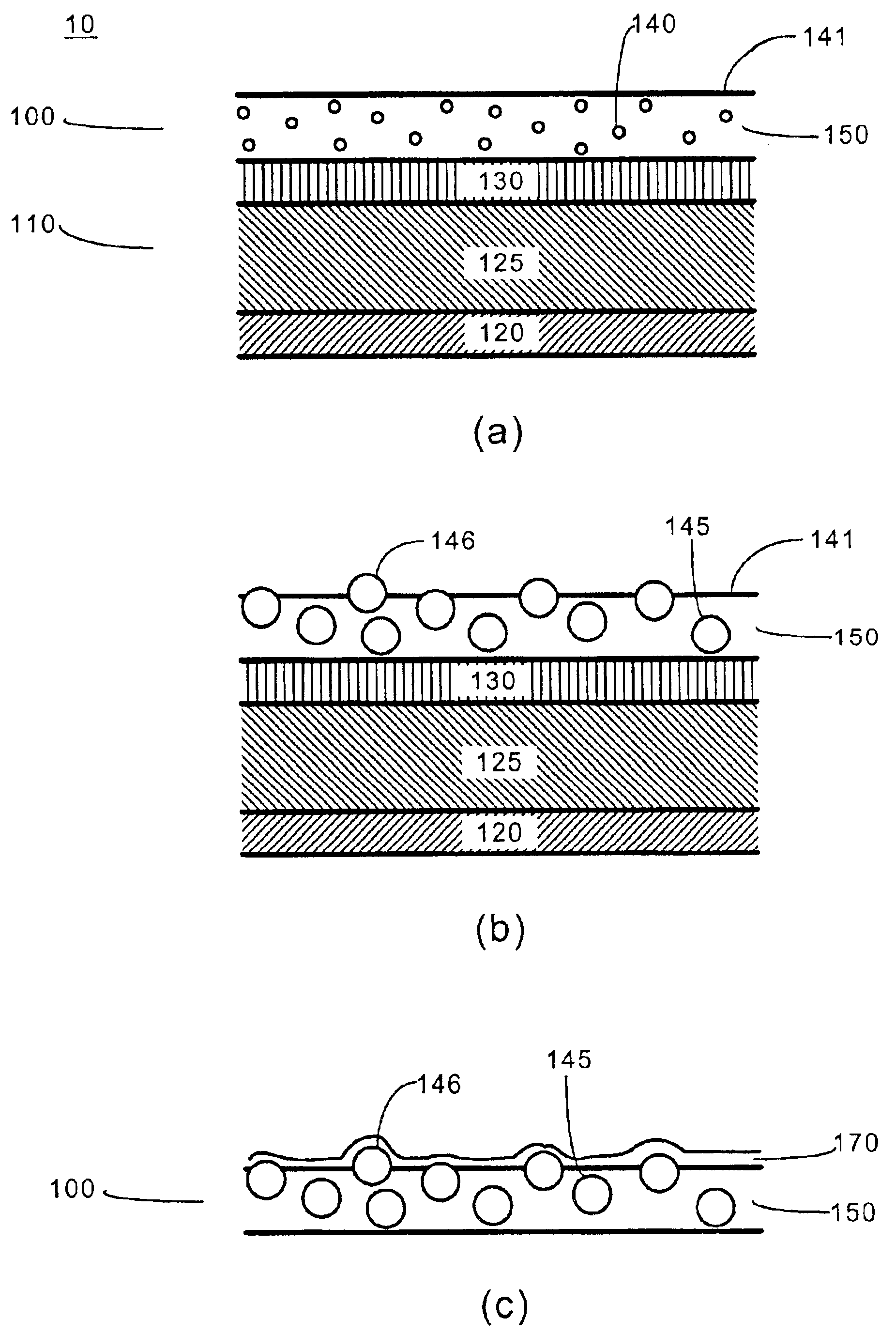

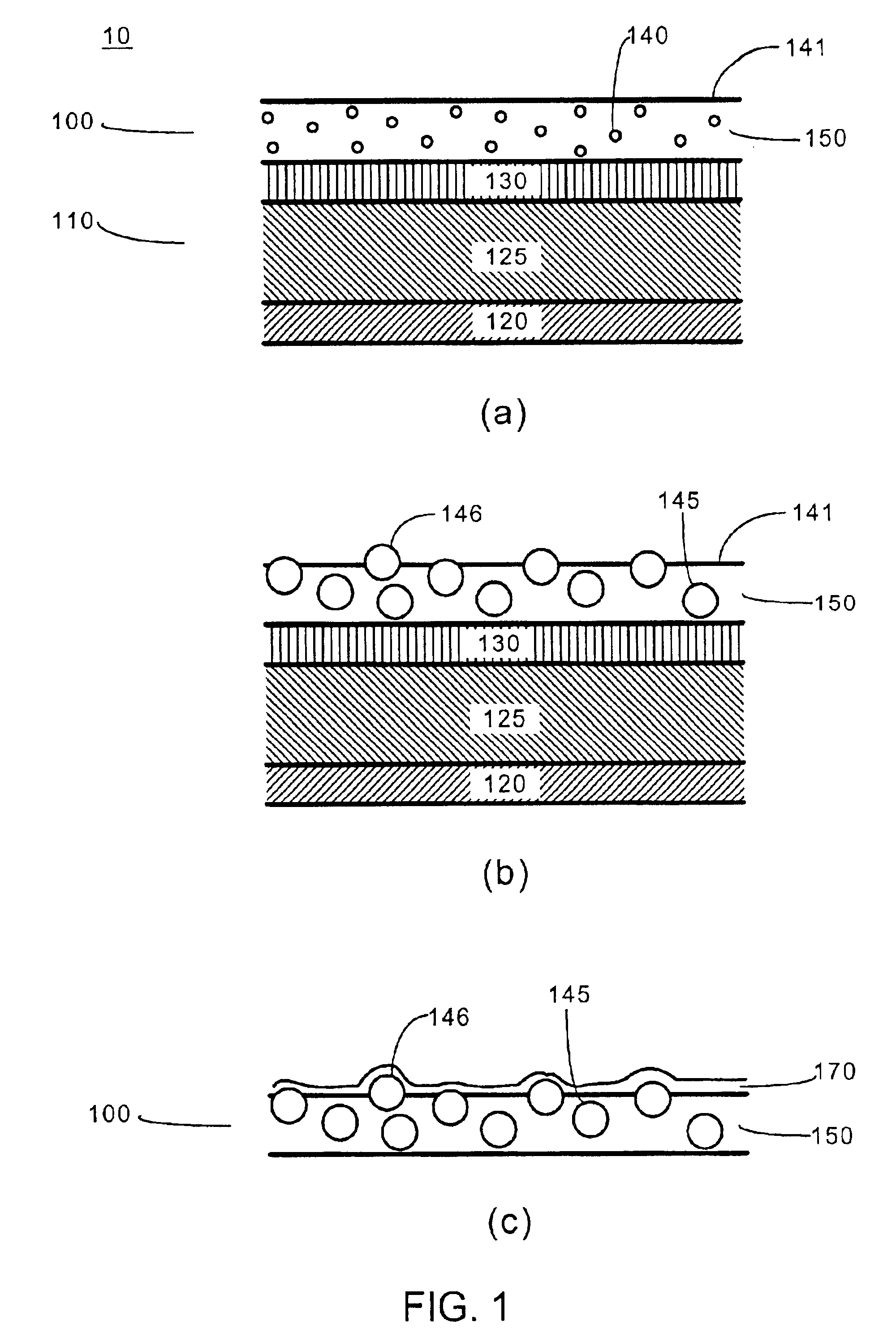

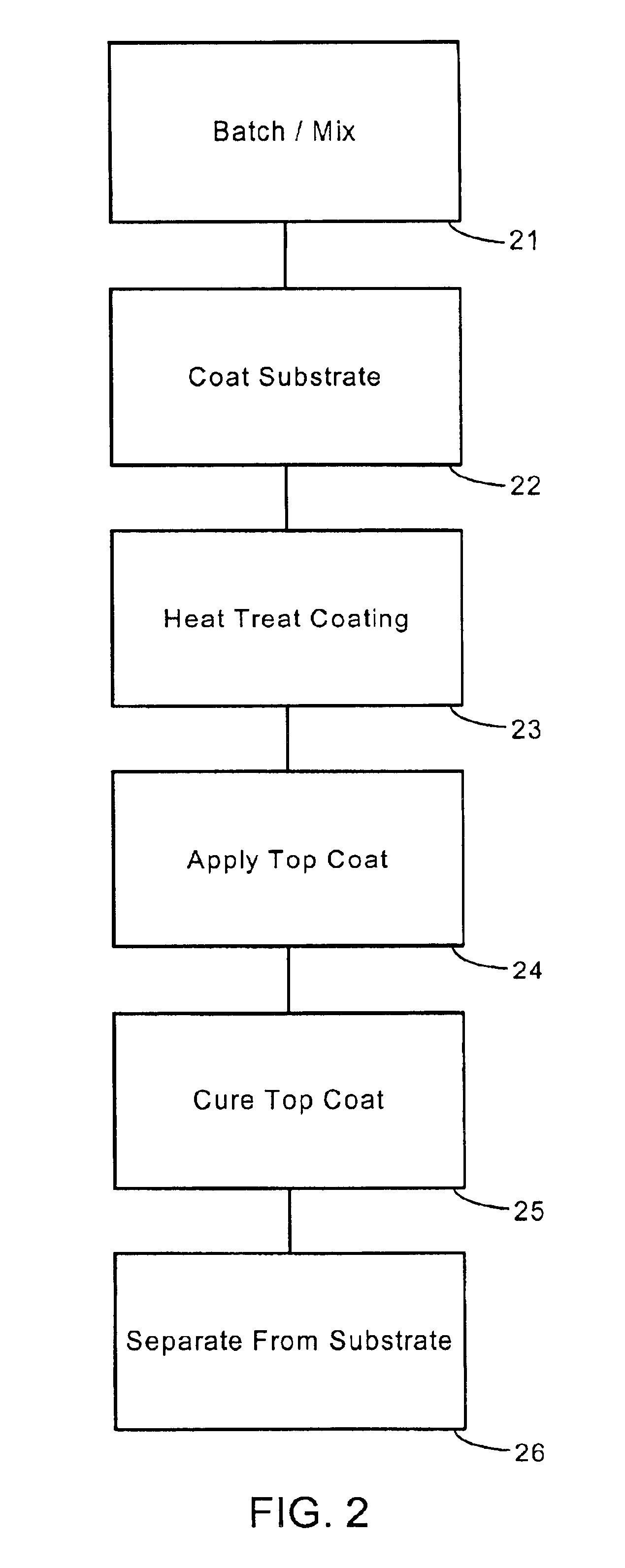

Heat activated coating texture

A process for making a textured coating on a substrate and compositions for such coatings are disclosed wherein coating mixtures comprising un-expanded micro-capsules and a plastisol or other suitable resins are applied to the substrate and subsequently heat treated to expand the micro-capsules within the coating. The expanded micro-capsules create an aesthetically pleasing surface texture in the coating while retaining the desired wear-resistant properties of the coating.

Owner:LAW DEBENTURE TRUST COMPANY OF NEW YORK

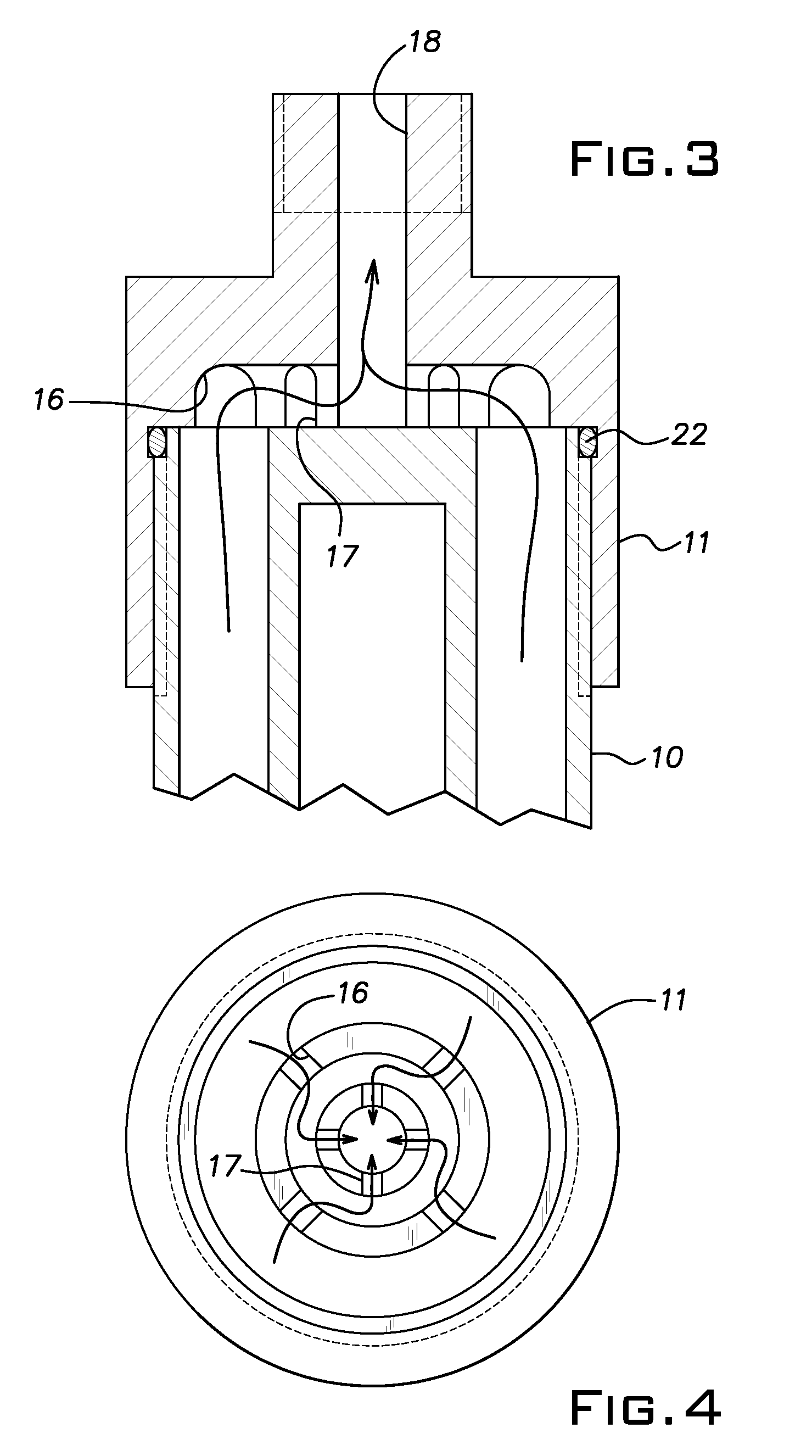

Multi-function heat exchanger

A multi-function heat exchanger for use with a dispensing gun for dispensing hybrid plastisol hot melt material, the heat exchanger having an elongated tubular high temperature heater assembly having a front end hydraulically connected to an inlet port of a dispensing gun and a rear end connected to a heat dissipating assembly which in turn is connected to the outlet end of a supply hose for providing hybrid plastisol material which is liquid at room temperature and under sufficient hydraulic pressure to move the plastisol material through the heat dissipating assembly and the high temperature heater assembly into the dispensing gun when the gun is operated. The heater assembly has a heat source providing sufficient heat to turn the plastisol into a molten liquid as it passes into the dispensing gun. The heat dissipating assembly prevents heat from the high temperature heater assembly from migrating back into the plastisol supply hose.

Owner:HB FULLER CO

Surface treatment method of nano-calcium carbonate used for polyvinyl chloride plastisol

ActiveCN102492310AGood surface modificationRaw materials are cheap and easy to getPigment treatment with non-polymer organic compoundsPolyvinyl chlorideSlurry

The invention discloses a surface treatment method of nano-calcium carbonate used for polyvinyl chloride plastisol. The surface treatment method comprises the following steps: adding nano-calcium carbonate serous fluid into a reaction kettle, wherein the specific surface area (BET) of nano-calcium carbonate in the serous fluid is 18.0-60.0m<2> / g and the pH of the nano-calcium carbonate serous fluid is 8.5-9.5; heating to 70-95 DEG C, stirring, adding a mixed modifier accounting for 1.8-6.0% of the mass of the nano-calcium carbonate in the serous fluid, continuing stirring for 30-180 minutes, thus completing surface treatment. The mixed modifier is a mixture of stearic acid alkali metal saponified matter and calcium stearate, the mass ratio of fatty acid to calcium stearate in the complex modifier is 20-70%, and the proportion of the using quantity of the fatty acid to a saponifier is 1: 1. According to the method, the fatty acid is saponified by a strong base, so that the shortcoming that the fatty acid is difficult to react with the surface of calcium carbonate in water to generate the calcium stearate during wet process surface modification of the nano-calcium carbonate can be overcome; and the calcium stearate is directly introduced through fatty acid saponification liquor, so that a significant surface modification effect is obtained. The method has the advantages that raw materials are low in price and easy to obtain, the processes are simple and feasible, and the quality of a product is state. The method has significant economic benefits and social benefits.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

Laminated building panels having preselected colors

InactiveUS20050003154A1Improve work performanceCovering/liningsRecord information storagePolyvinyl chlorideEngineering

Plastic building panels for exterior use on buildings are made by forming a plastic sheet at an elevated temperature, overlaying an exterior surface portion of the formed sheet with a coloring sheet having a preselected color, and thermally bonding the coloring sheet to the formed sheet. The coloring sheet may comprise a vinyl resin plastisol and pigment particles. Both the formed sheet and the vinyl resin in the plastisol may comprise polyvinyl chloride (PVC). The coloring sheet can be configured with a matte surface substantially without the use of flattening agents, and an adhesion system can be used to augment the lamination between the coloring sheet and the plastic sheet. The coloring sheet can also be configured to have a predetermined pattern, such as may be provided with a plurality of coloring materials having multiple colors.

Owner:ALCOA HOME EXTERIORS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com