Functional PVC plastic colloidal sols for non-powder PVC gloves and uses thereof

A plastisol, functional technology, applied in the field of PVC plastisol, can solve the problems of glove allergy, waste of coating agent, and reduced production efficiency, and achieves the improvement of anti-self-adhesion performance, good smooth wearing performance, and avoidance of pinholes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Add 800 parts by mass of deionized water into a reactor with a condensation reflux device, add 6 parts by mass of polymer suspending agent polyvinyl alcohol, add 1 part by mass of sodium polyacrylate as a dispersant, and add 2 parts by mass of magnesium hydroxide , stir to disperse evenly. 5 parts by mass of methyl acrylate, 40 parts by mass of methyl methacrylate, 50 parts by mass of styrene, 5 parts by mass of bisacryloyl-terminated polydimethylsiloxane and 0.5 parts by mass of dibenzoyl peroxide were pre-mixed uniform, and added to the above aqueous medium. Under strong stirring, polymerize at 80-90°C for 6 hours, then raise the temperature to 100°C and keep it warm for 5 hours to fully react the monomers. After polymerization, cool to room temperature, filter, pickle to remove inorganic salts, then wash with water and air-dry, and finally sieve and classify. Polysiloxane-modified styrene-acrylic resin microparticles with a particle diameter of 2 μm to 10 μm are ob...

Embodiment 2

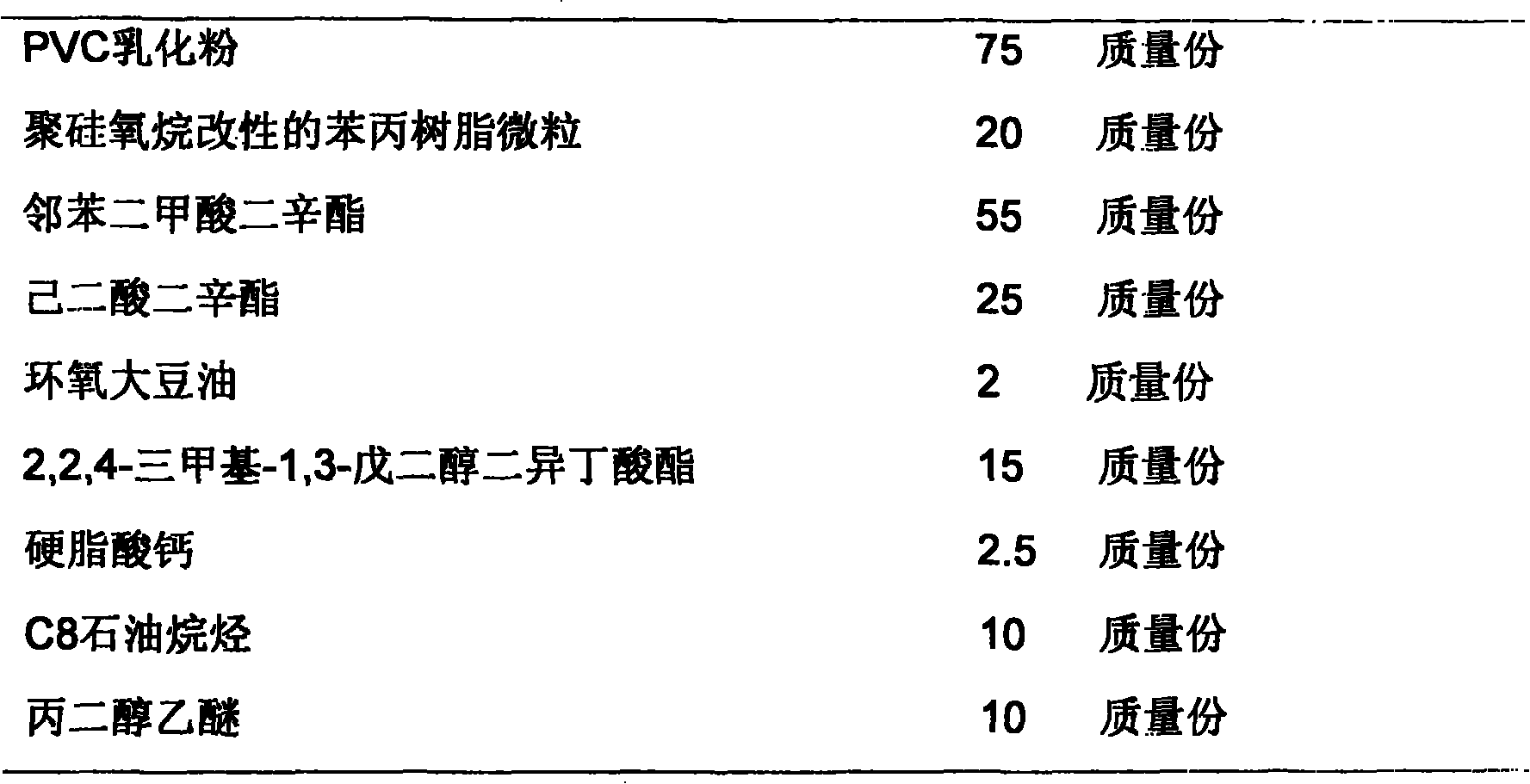

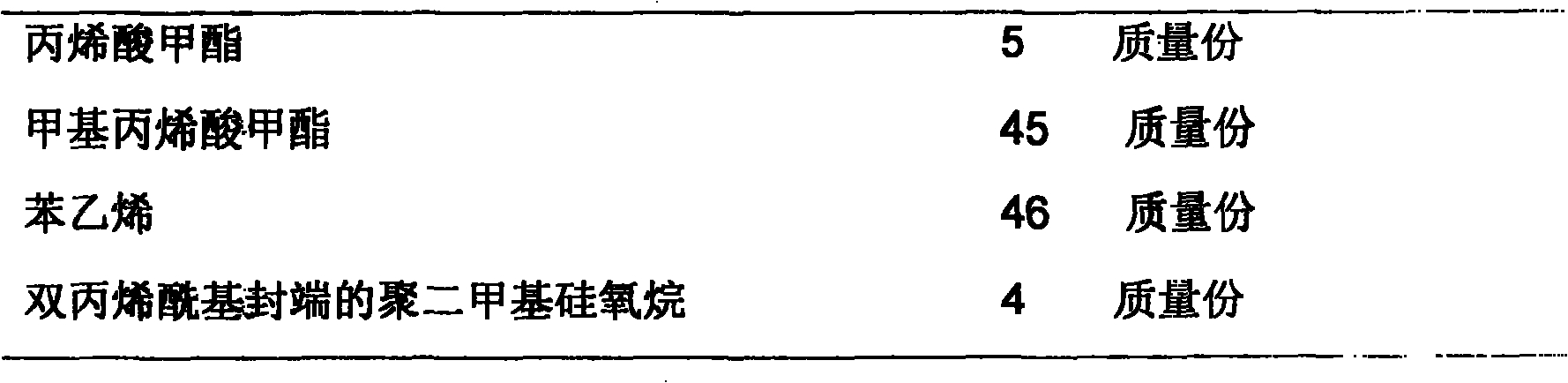

[0042] Add 800 parts by mass of deionized water into a reactor with a condensation reflux device, add 6 parts by mass of polymer suspending agent polyvinyl alcohol, add 1 part by mass of sodium polyacrylate as a dispersant, add 2 parts by mass of calcium phosphate, Stir to disperse evenly. 5 parts by mass of methyl acrylate, 45 parts by mass of methyl methacrylate, 46 parts by mass of styrene, 4 parts by mass of bisacryloyl-terminated polydimethylsiloxane and 0.5 parts by mass of dibenzoyl peroxide were pre-mixed uniform, and added to the above aqueous medium. Under strong stirring, polymerize at 80-90°C for 6 hours, then raise the temperature to 100°C and keep it warm for 5 hours to fully react the monomers. After polymerization, cool to room temperature, filter, pickle to remove inorganic salts, then wash with water and air-dry, and finally sieve and classify. Polysiloxane-modified styrene-acrylic resin microparticles with a particle diameter of 2 μm to 10 μm are obtained....

Embodiment 3

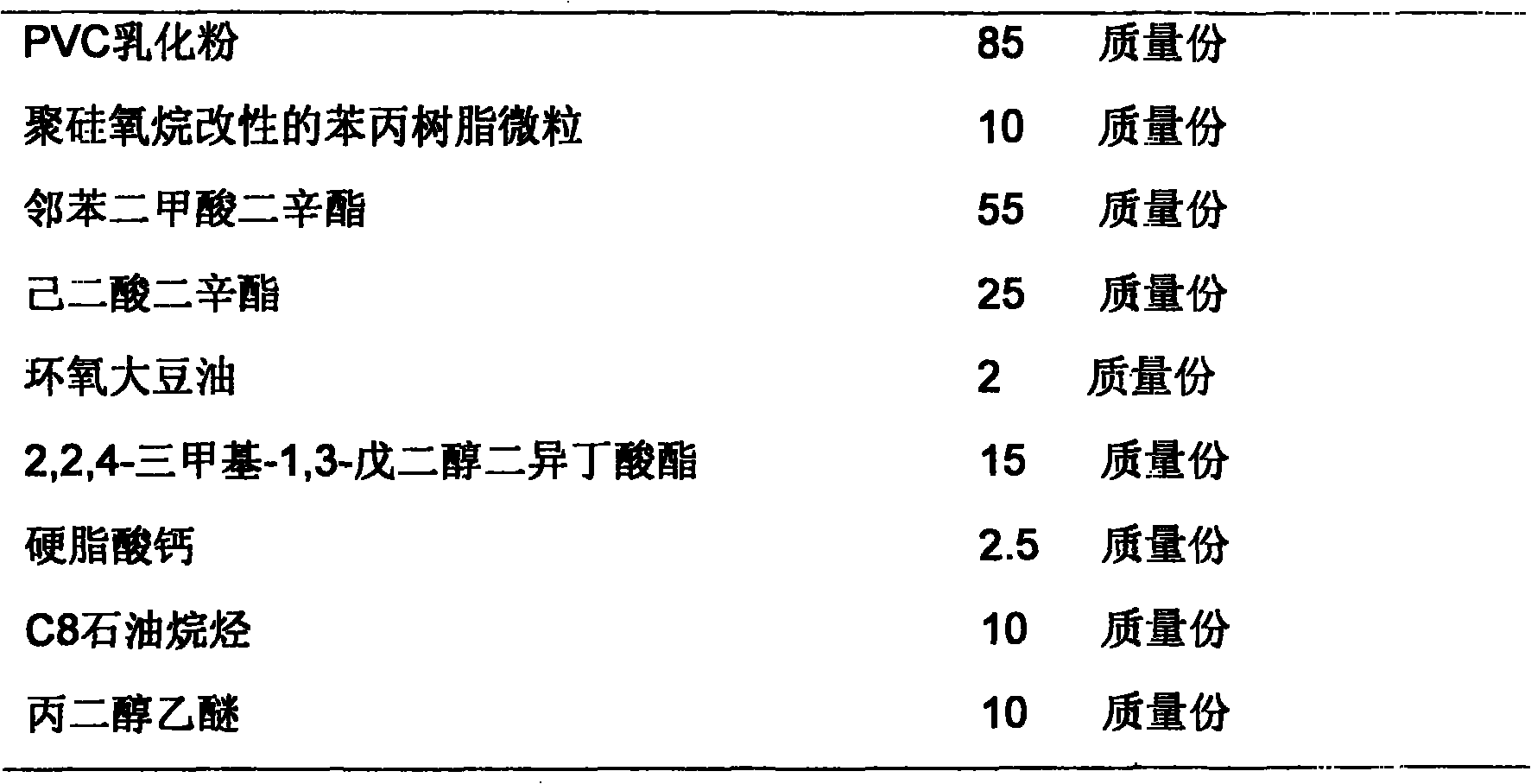

[0050] Add 800 parts by mass of deionized water into a reactor with a condensation reflux device, add 6 parts by mass of polymer suspending agent polyvinyl alcohol, add 1 part by mass of sodium polyacrylate as a dispersant, and add 2 parts by mass of magnesium hydroxide , stir to disperse evenly. Mix 2 parts by mass of methyl acrylate, 45.5 parts by mass of methyl methacrylate, 50 parts by mass of styrene, 2.5 parts by mass of divinyl-terminated polymethylsiloxane and 0.6 parts by mass of dibenzoyl peroxide , and added to the above aqueous medium. Under strong stirring, polymerize at 80-90°C for 6 hours, then raise the temperature to 100°C and keep it warm for 5 hours to fully react the monomers. After polymerization, cool to room temperature, filter, pickle to remove inorganic salts, then wash with water and air-dry, and finally sieve and classify. Polysiloxane-modified styrene-acrylic resin microparticles with a particle diameter of 2 μm to 10 μm are obtained.

[0051] Mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com