Patents

Literature

140 results about "Design styles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

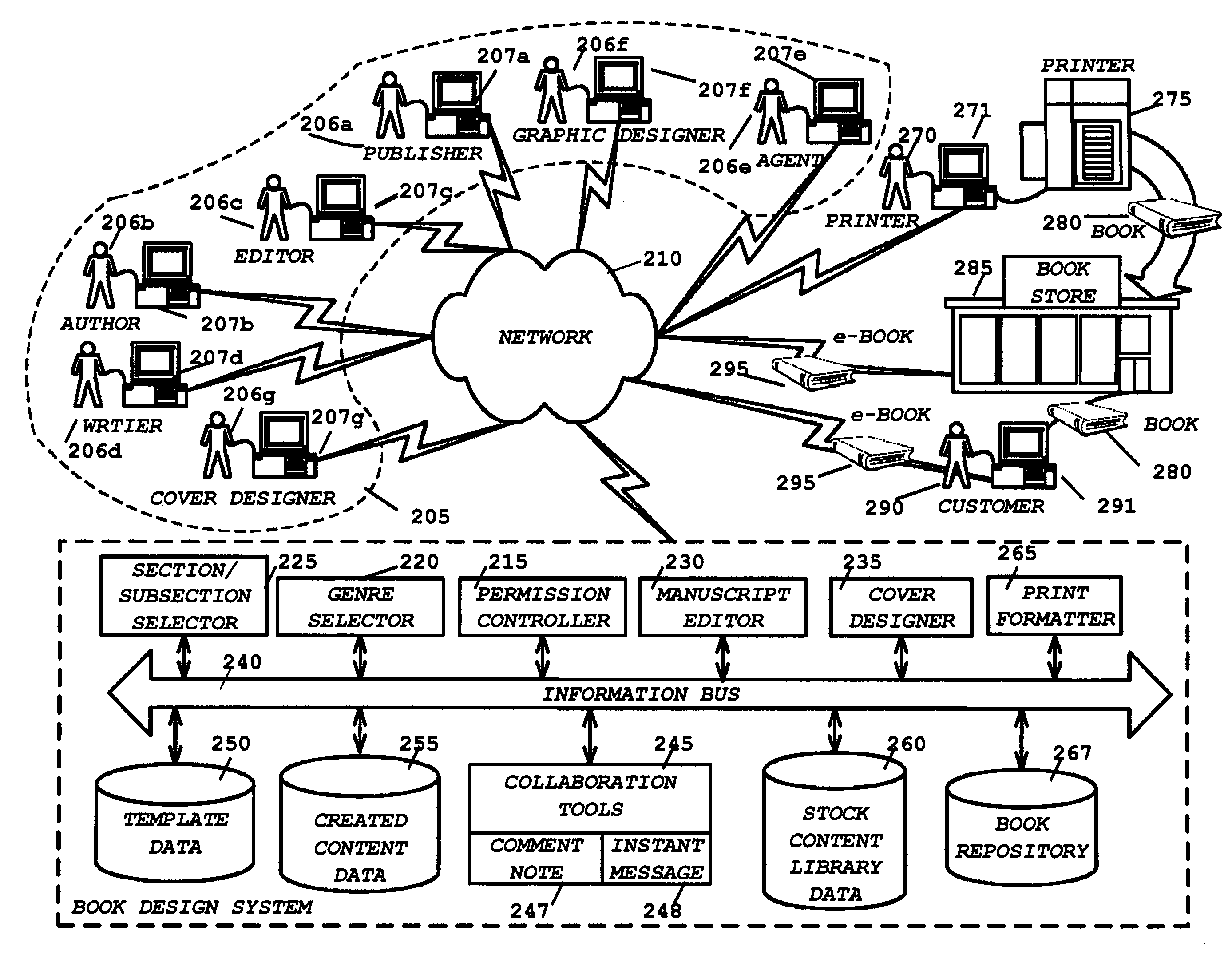

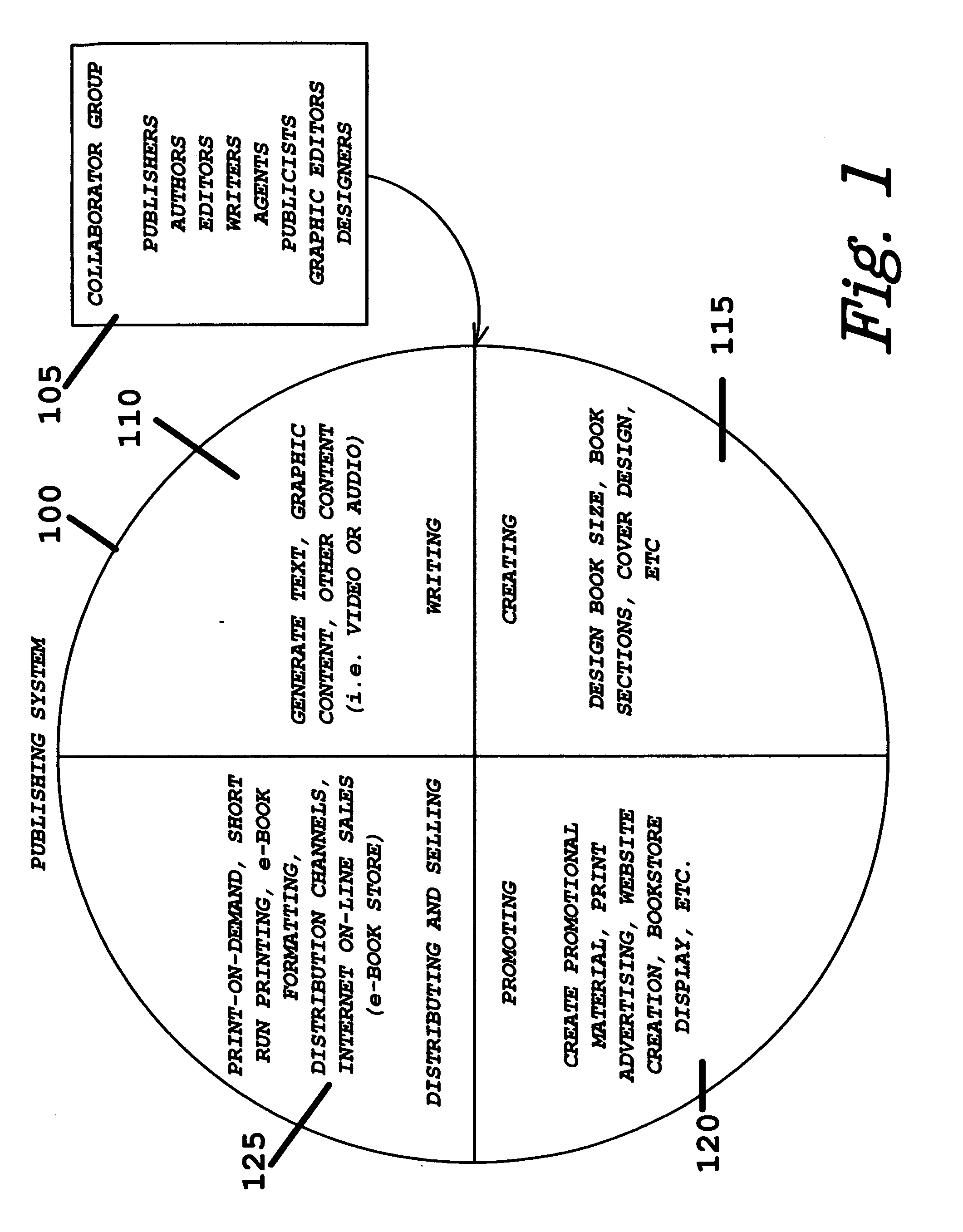

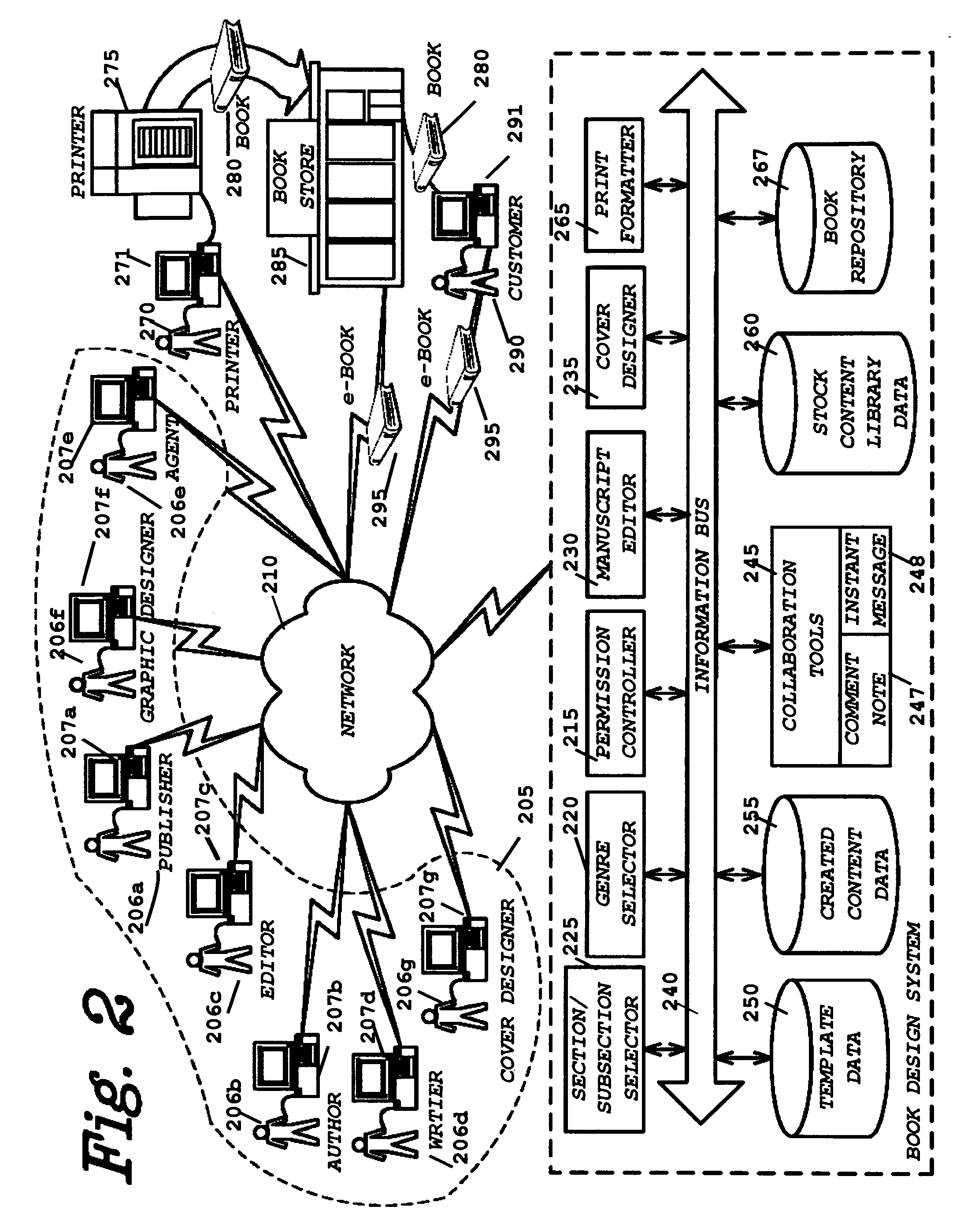

Publishing system and method that enables users to collaboratively create, professional appearing digital publications for "On-Demand" distribution in a variety of media that includes digital printing

InactiveUS20090254802A1Low costEasily assumeNatural language data processingMultiple digital computer combinationsGraphicsDigital printing

Apparatus and methods are provided for providing publishers and authors with the organizational and creative tools to professionally create books inclusive of writing, graphics and multi-media. The apparatus and methods further enable users to design and format their publication with minimal effort. A text editor is used to manipulate the input in a “What-You-See-Is-What-You-Get” (W.Y.S.I.W.Y.G.) environment. The user is able to professionally design a publication. The publication is previewed with images of the “print-ready” publication. Publishing resource tools are provided that allow the publisher, author and other collaborators to create and edit content. The publisher and authors can select from provided design styles and images or upload their own images to create professional looking publications. The publication is converted to a “print-ready file” and or an e-book and stored in a database. A bookstore associated with the apparatus and methods allow books to be viewed and purchased.

Owner:PRINT ASSET MANAGEMENT

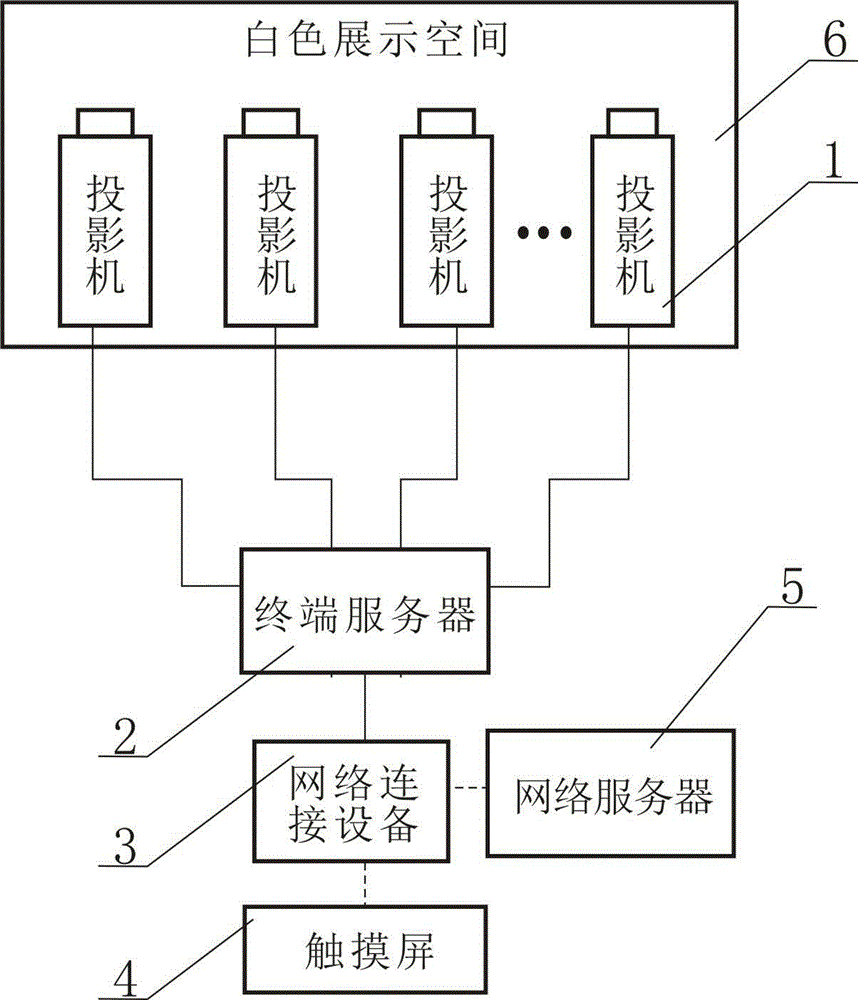

Virtual decoration combination system for physical space

InactiveCN105139213AReproduce reasonable choices in real timeReasonable choice of convenienceAdvertisingDisplay meansCollocationPhysical space

The invention discloses a virtual decoration combination system for a physical space. The system comprises hardware and software, wherein the hardware mainly comprises a white display space, a plurality of projectors and a terminal server, wherein the plurality of projectors are connected with a multi-path display output interface of the terminal server; and the terminal server is projected to a wall, a floor and furniture within a white display space through the projectors according to the preset picture or video image, so that the wall, the floor, the furniture and the like within the white display space are changed into a plurality of collocation effects. By the virtual decoration combination system, the selected decorative materials can be displayed in real time; and the collocation effects with other materials can be represented in real time. Therefore, great convenience is provided for reasonable selection of decorative materials for consumers. The system can be applied to the places such as fairs and trade shows, is input once, and can be used for a plurality of times, so that the decoration cost of the places is greatly reduced; and different design styles can be represented according to different requirements.

Owner:广州市博源数码科技有限公司

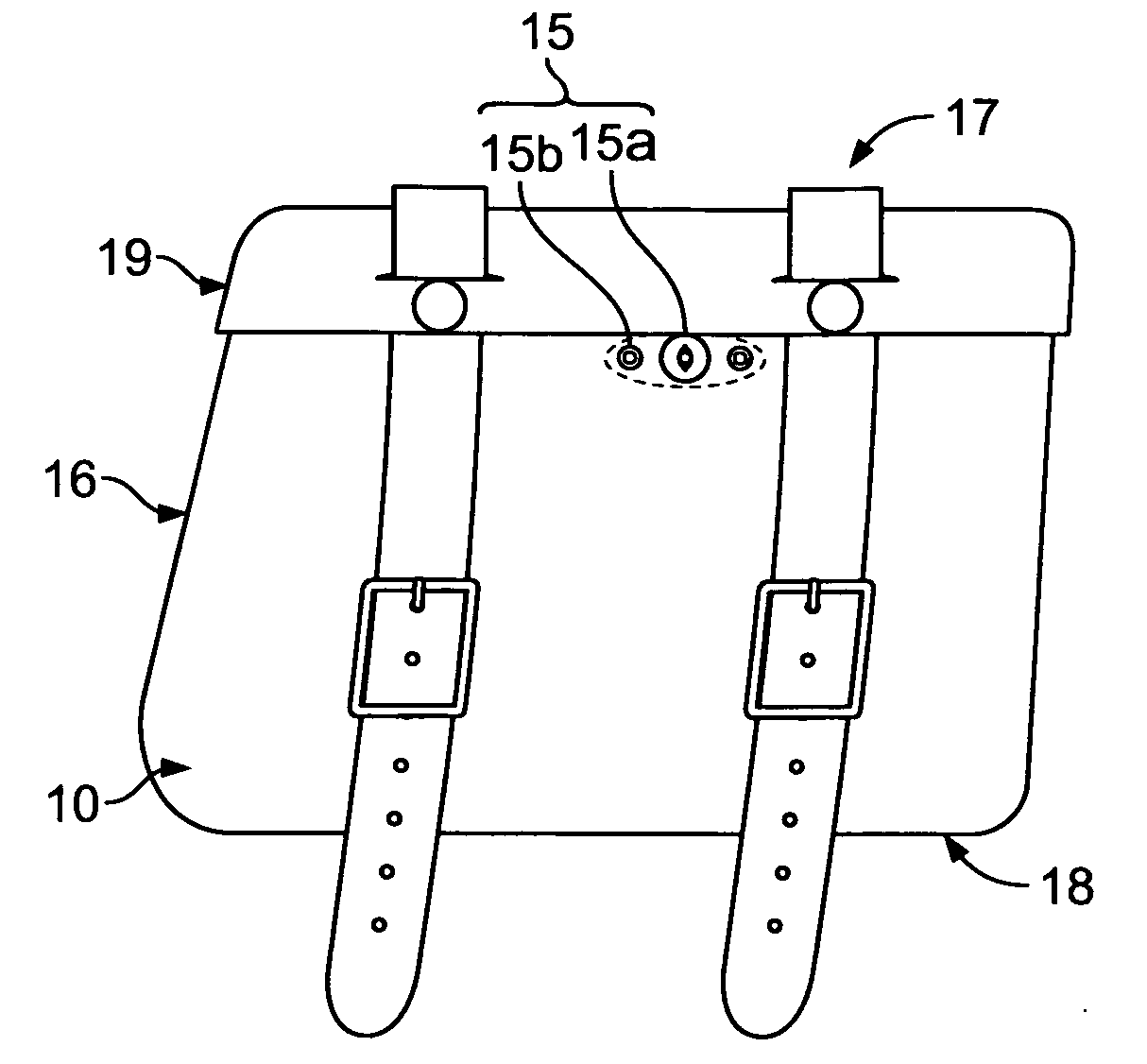

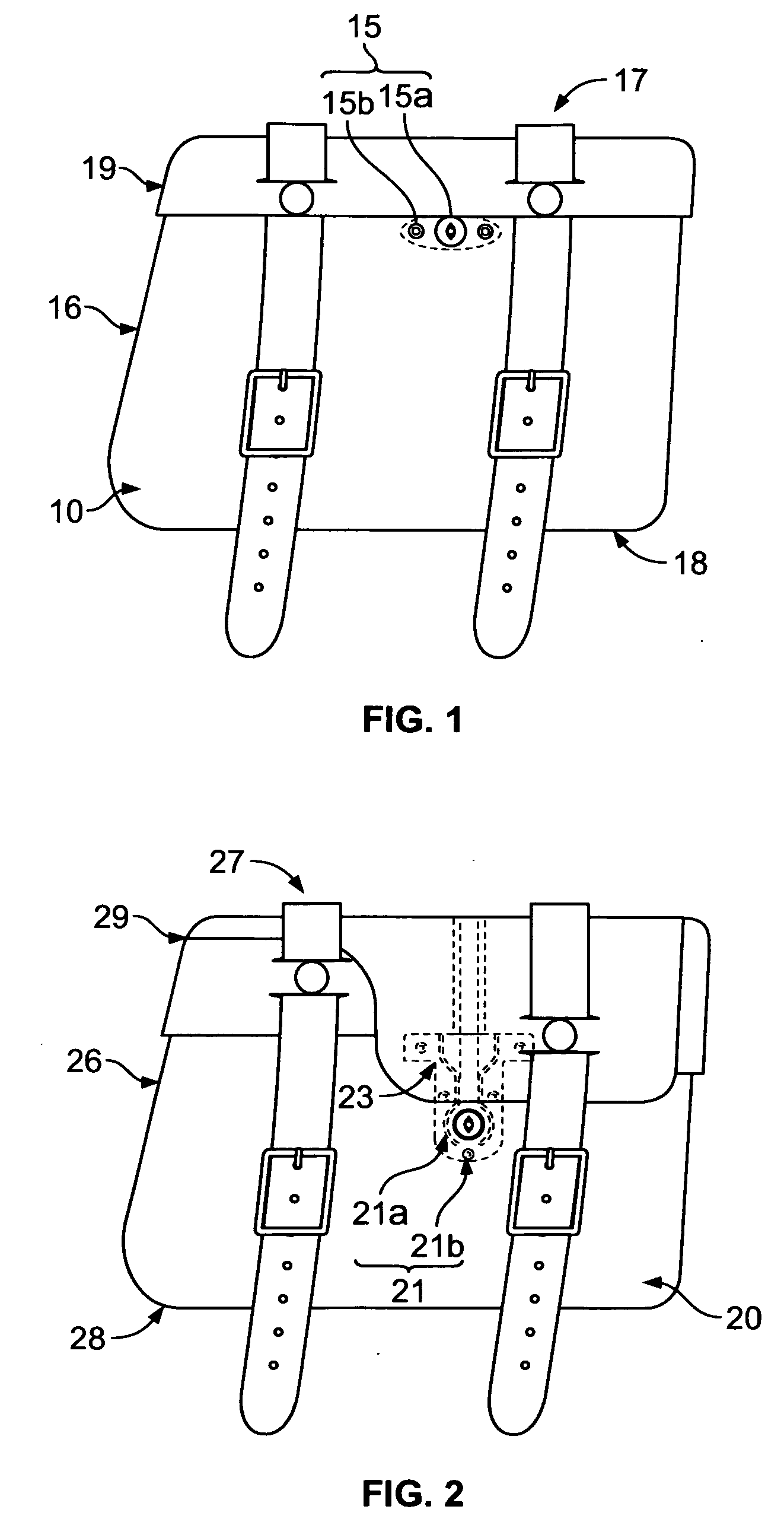

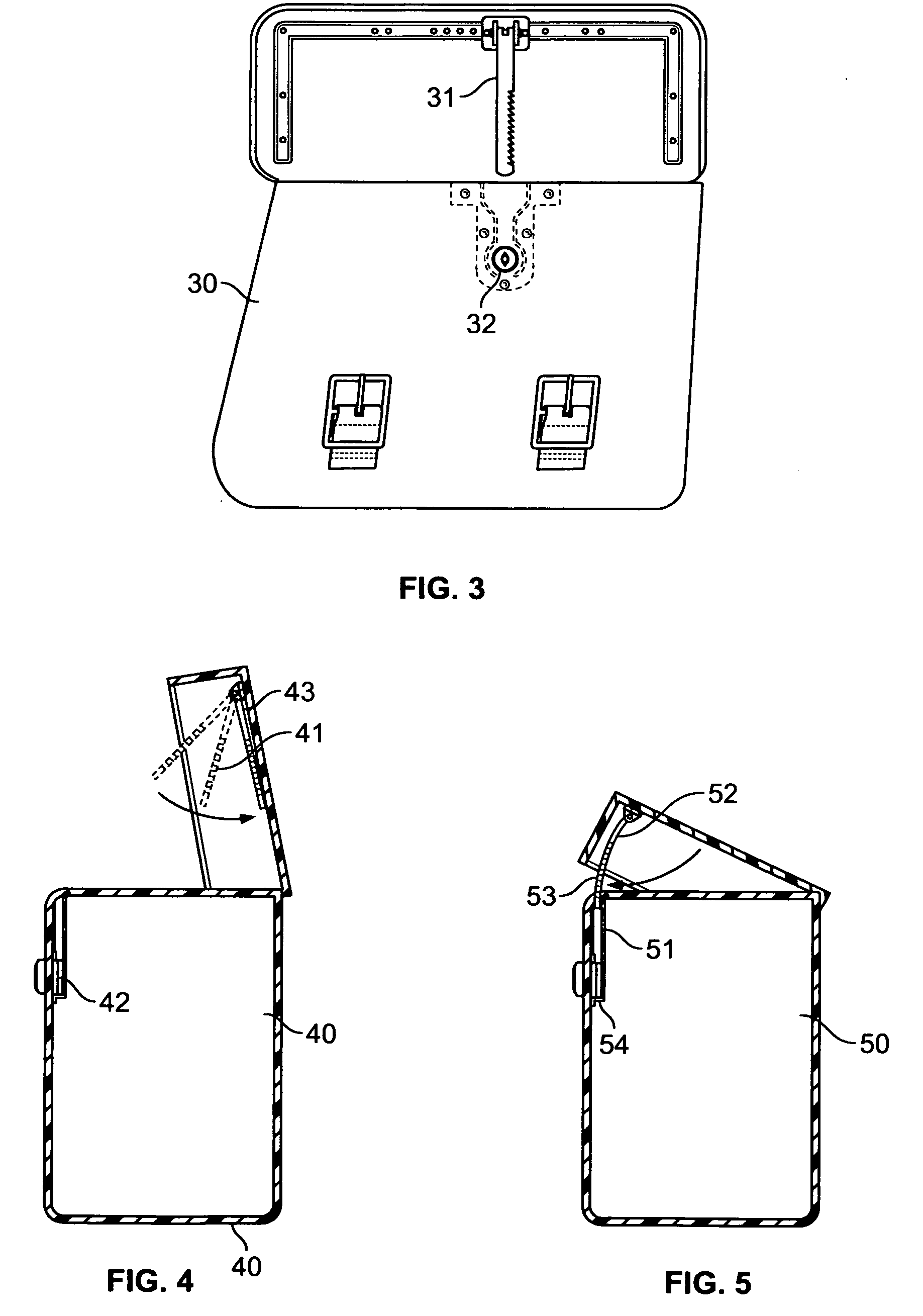

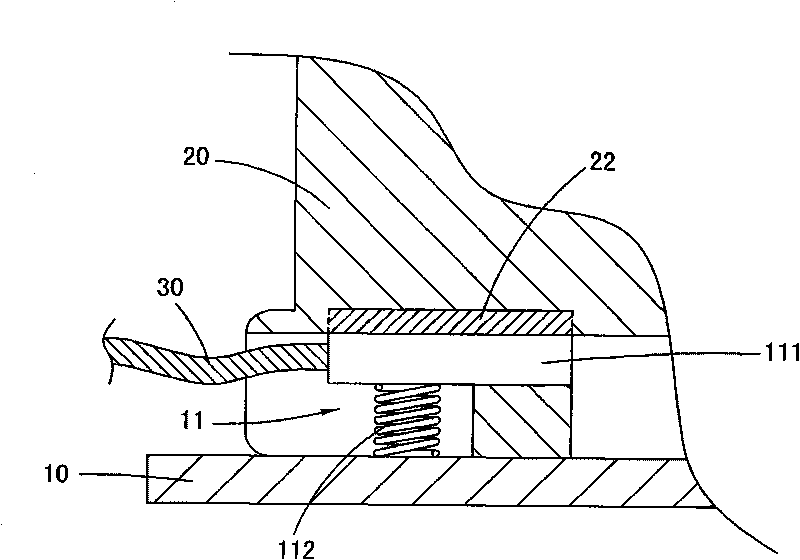

Semirigid motorcycle saddlebag universal lock assemby

A road saddlebag universal, self-aligning locking latch and receptacle assembly mechanism for a semi-rigid saddlebag assembly for a variety of road bike, motorcycle styles. It provides a toothed pawl, lock and receiver, self-aligning latch and keyed lock mechanism to provide secure, tamper proof locking functionality to the semi-rigid saddlebag high security motorcycle and rider gear stowage. It also provides a method for providing universal, self-aligning locking latch and receptacle assembly mechanism for a semi-rigid saddlebag assembly for a variety of road bike, motorcycle styles. It also provides a spring loaded pawl receiver, self-aligning mechanism with toothed pawl latch functionality guided into a lower pawl engagement receiver providing a full encapsulation of traveling pawl receiver. It can be easily adapted to various designs of the road bike, motorcycle saddlebag, gear stowage compartments. The security locking system is not dependent upon a particular design style. It provides tamperproof lock and latch mechanism apparatus security by utilizing the traveling toothed latch fully encapsulating the toothed pawl within the self-aligning receptacle and tamper restricting lock guard cover of the lock mechanism. It provides resistance to the collapse and / or deformation of the semi-rigid leather saddlebag in order to defeat the integrity of the locking mechanism.

Owner:SANDERS DEAN

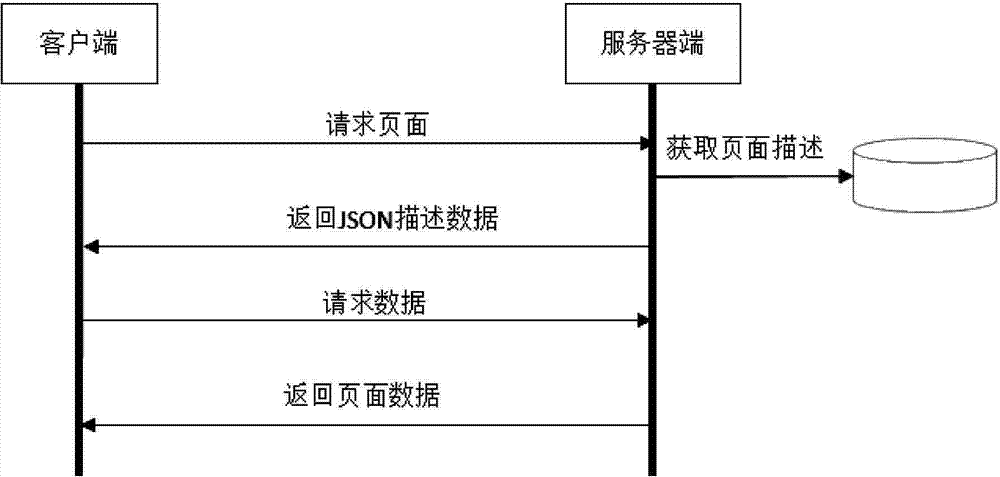

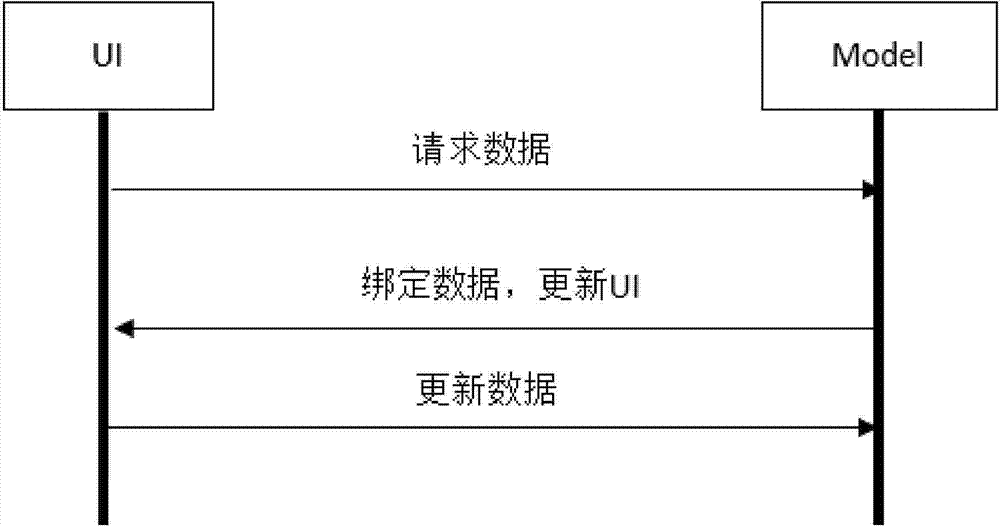

Method for displaying runtime customized page based on Bootstrap

InactiveCN104731594APracticalSpecific program execution arrangementsClient-side scriptingAdaboost algorithm

The invention discloses a method for displaying a runtime customized page based on Bootstrap. The method specifically comprises the steps that page initialization is conducted firstly, wherein a user on the client side sends a page browsing request to the server side, and the server side acquires a page description file according to the ID of the requested page and analyzes the page description file, so that JSON-format data are formed and fed back to the client side; page linkage operation is conducted; a client script calls the JSON data which are fed back to describe a UI page, generates a data Model example, and binds the acquired data to the page, so that linkage between the UI page and the data is achieved. Compared with the prior art, the method has the advantages that after iteration is conducted multiple times with the AdaBoost algorithm, various elements, overall arrangement and functions of the page can be defined according to service requirements, final content display is conducted according to a designed style, practicality is high, and popularization is easy.

Owner:INSPUR GROUP CO LTD

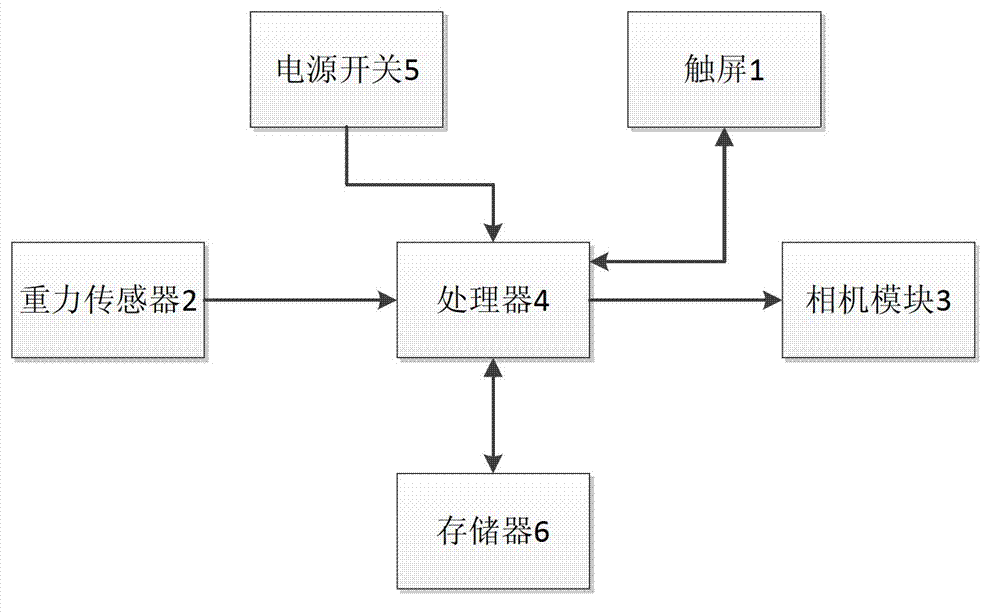

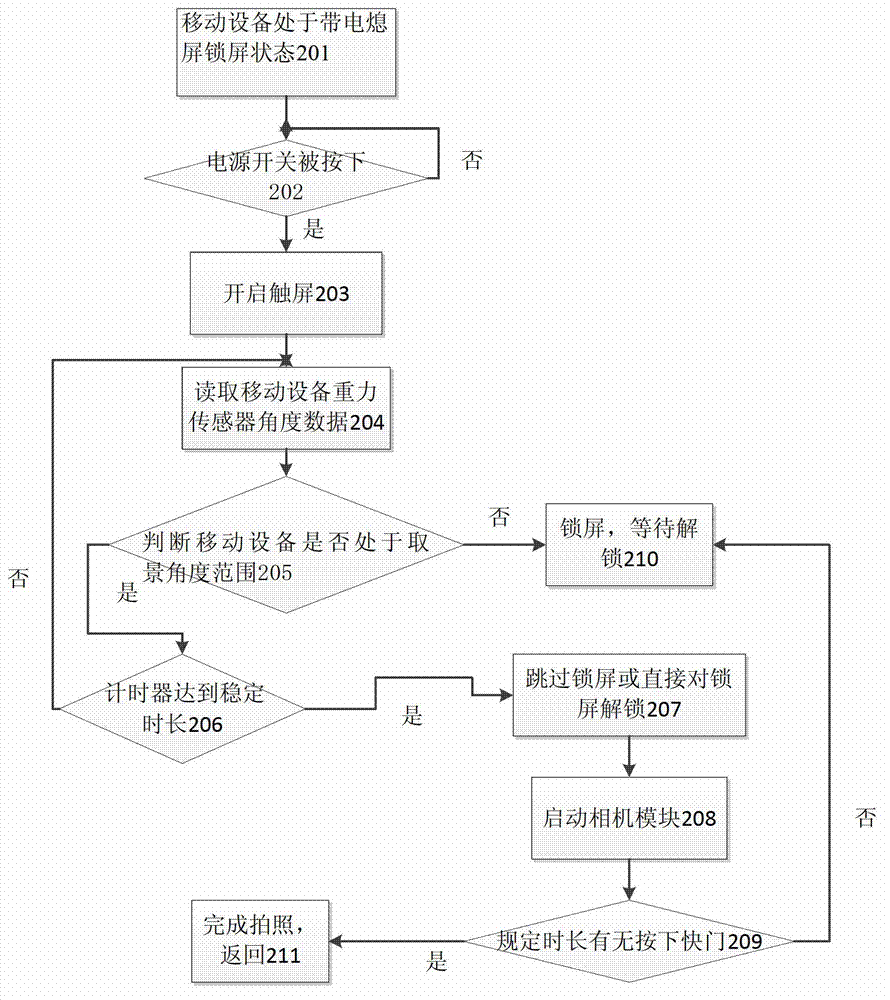

Method of starting camera by mobile device

ActiveCN103037103ASimple to extreme design styleWill not affect operating proceduresSubstation equipmentCamera moduleSmart technology

The invention relates to the mobile device technology, in particular to a method of starting a camera by a mobile device. When a key of the mobile device is pressed down, the method includes a first step of opening a touch screen (1) to transfer into a bright screen, a second step of reading angle data of the mobile device in a gravity sensor (2) of the mobile device and a third step of starting a camera module (3) when the angle data of a device body of the mobile device are in the range of viewing angle and predetermined stable length of time is kept. The method of starting the camera by the mobile device has the advantages of reducing operating steps required by a user who uses the mobile device to the minimum when a photographed function is started, and not influencing other operating procedures when the user uses other functions of the mobile device and initially guaranteeing photographing effect of tacking pictures due to the design of a function of straightening movement starting the camera. The method of starting the camera by the mobile device adopts humanized intellectual technology and enables the user to experience the simplest design style of the mobile device.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Fine remote clothing customization system

InactiveCN103854190AImprove wearing effectMeets requirementsCommerceClothes making applicancesPersonalizationComputer module

The invention relates to a fine remote clothing customization system. The fine remote clothing customization system is connected with a computer terminal through the internet. The fine remote clothing customization system comprises a user login module, a customization selection module, a format generating module and an order receiving and sending module. An element selection database comprises a display area, a fabric selection module, a color selection module and a style selection module, the style selection module is divided into a design style template and a depth design template, the element selection database is also communicated with an error correction module, and the error correction module is used for correcting apparent errors existing in design element selection. The clothing customization selection module which is finer and more personalized is used, so that a consumer can participate in clothing design at a greater degree, the customer can select all elements of clothing according to the preference of himself or herself, and therefore the clothing produced finally can better meet the requirements of the customer.

Owner:青岛酷特智能股份有限公司

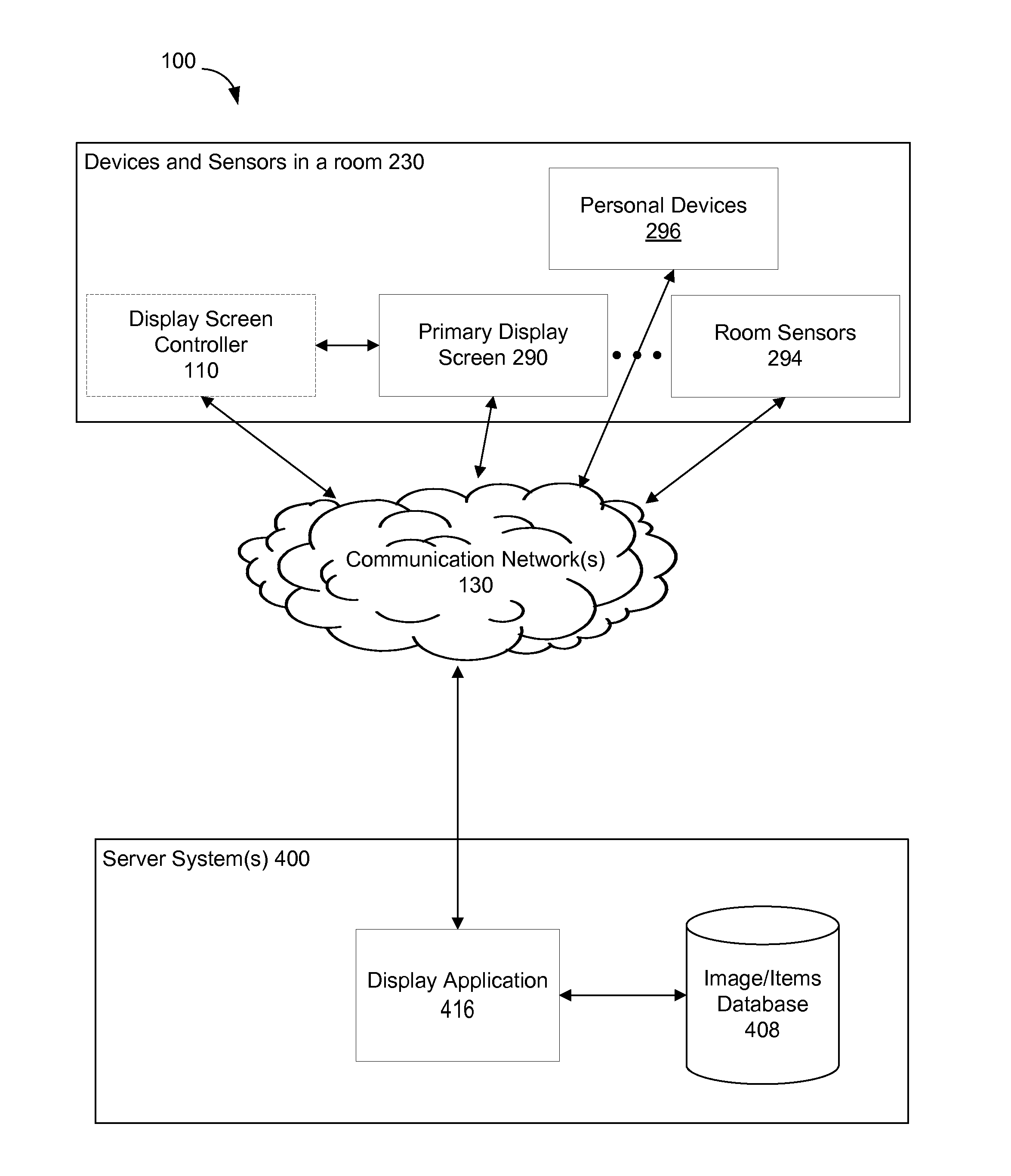

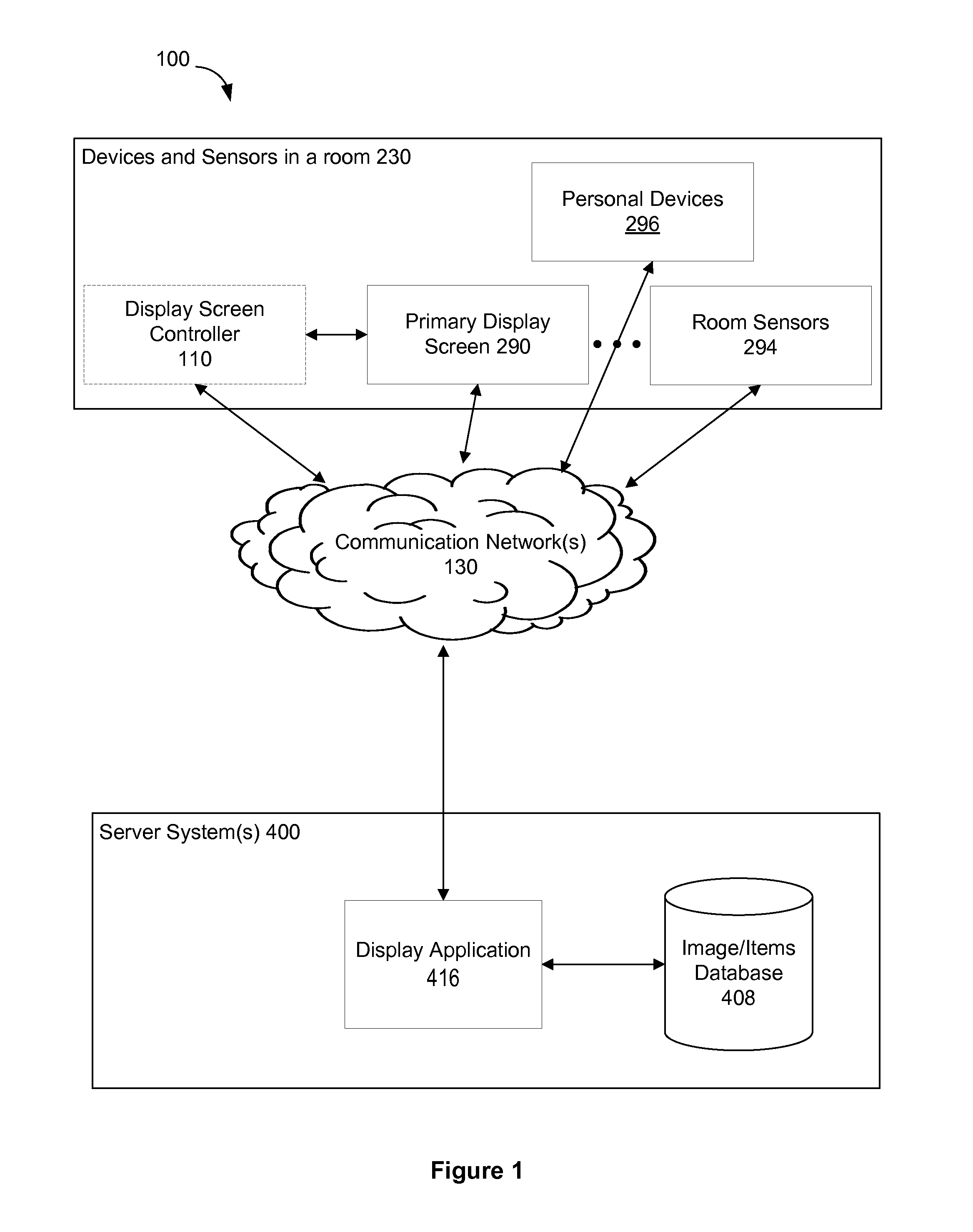

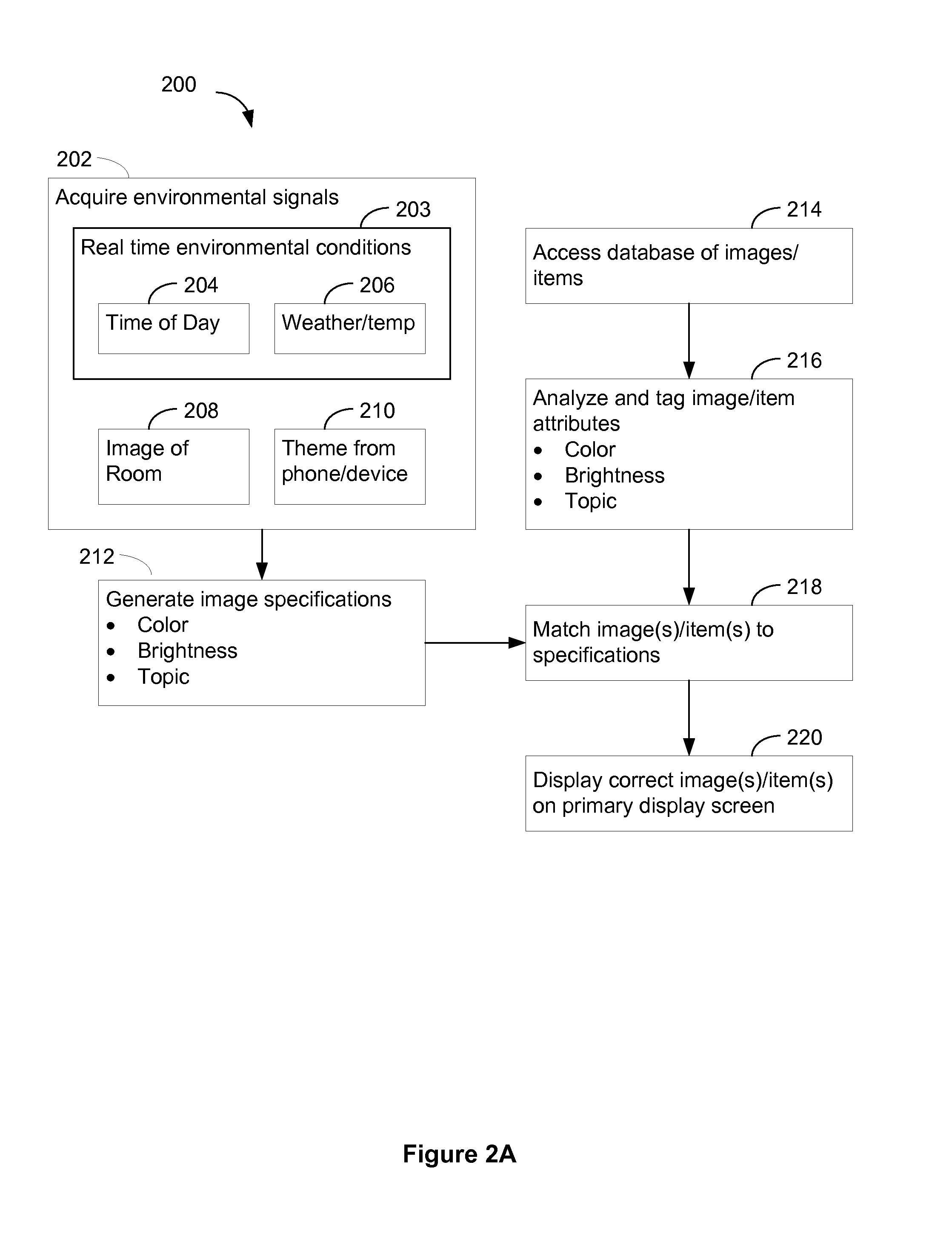

Automatic Theme and Color Matching of Images on an Ambient Screen to the Surrounding Environment

InactiveUS20150332622A1Cathode-ray tube indicatorsMarketingComputer graphics (images)Computerized system

Systems, methods, and computer readable storage mediums are provided for automatically matching the theme of an image on an ambient screen to its surroundings. In some implementations, one or more real time environmental conditions of a room in which a primary display screen is located are evaluated. The primary display screen is controllable by computer system via a network or a client device coupled to it. The environmental conditions include the current time, the current date, the current season, the geographic location, the ambient light level and color temperature, and / or the ambient sound level. A design style associated with the room is identified. Then a media content item having visual characteristics based on the design style and the environmental conditions is sent to the primary display screen for display.

Owner:GOOGLE LLC

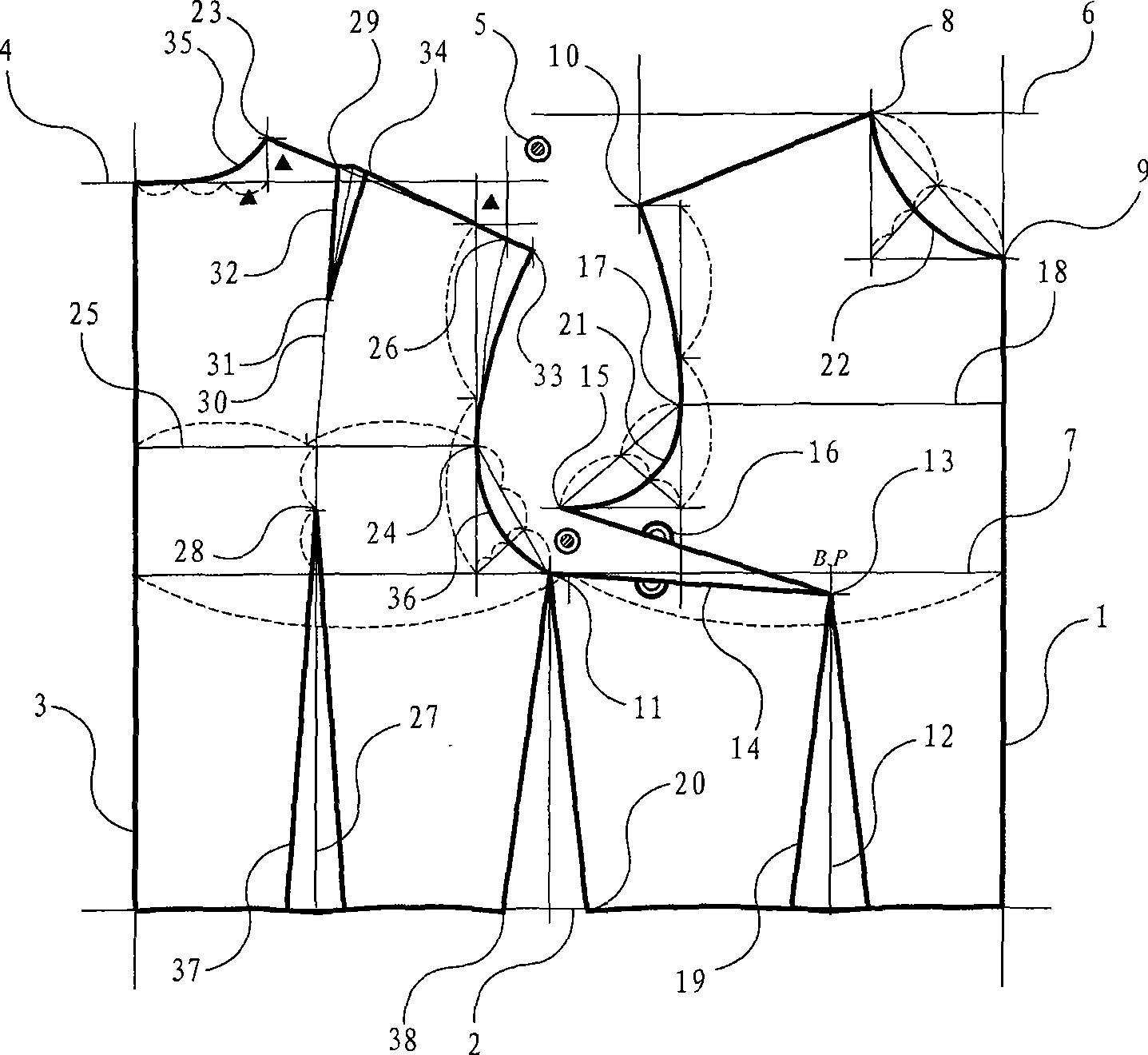

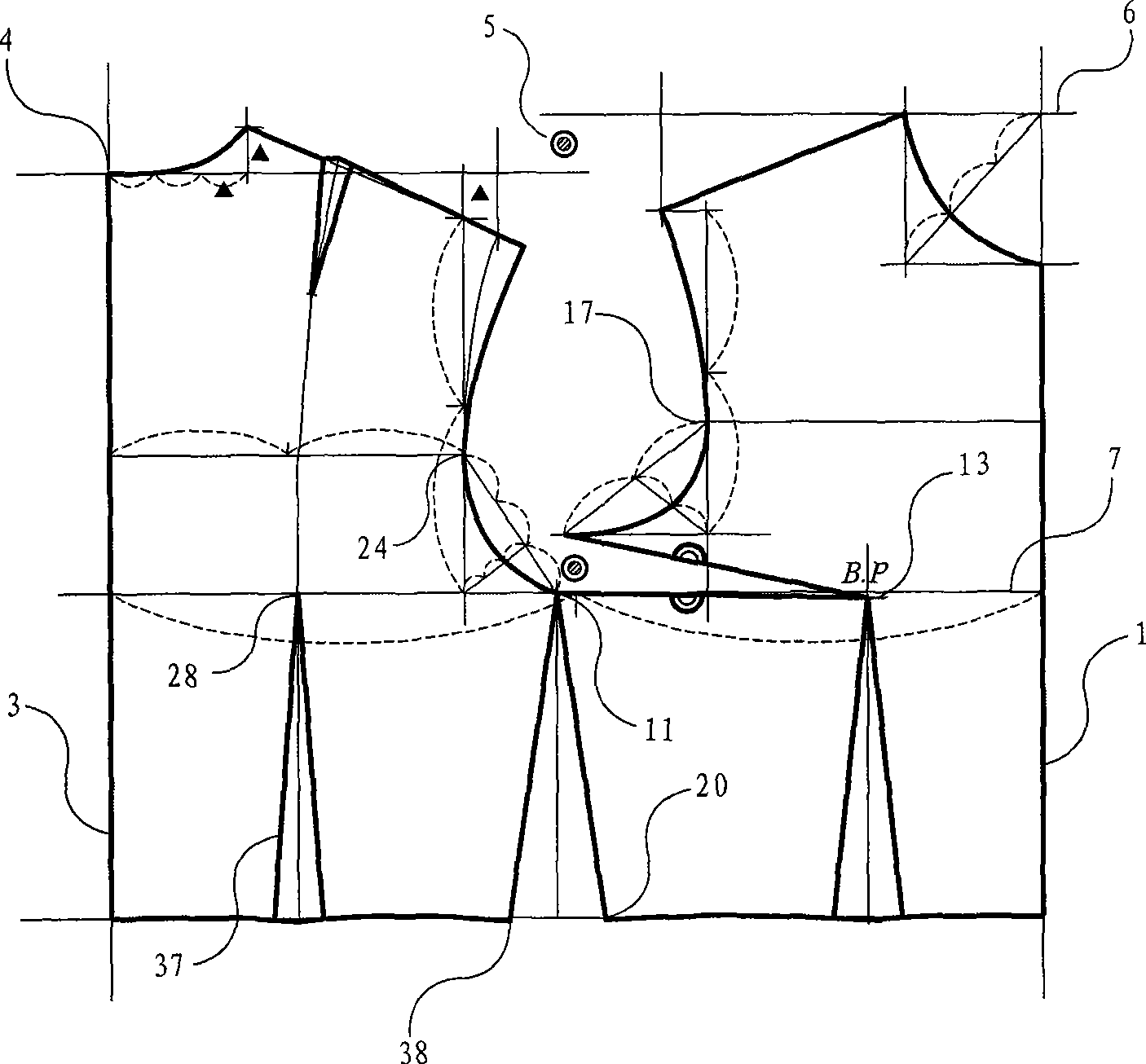

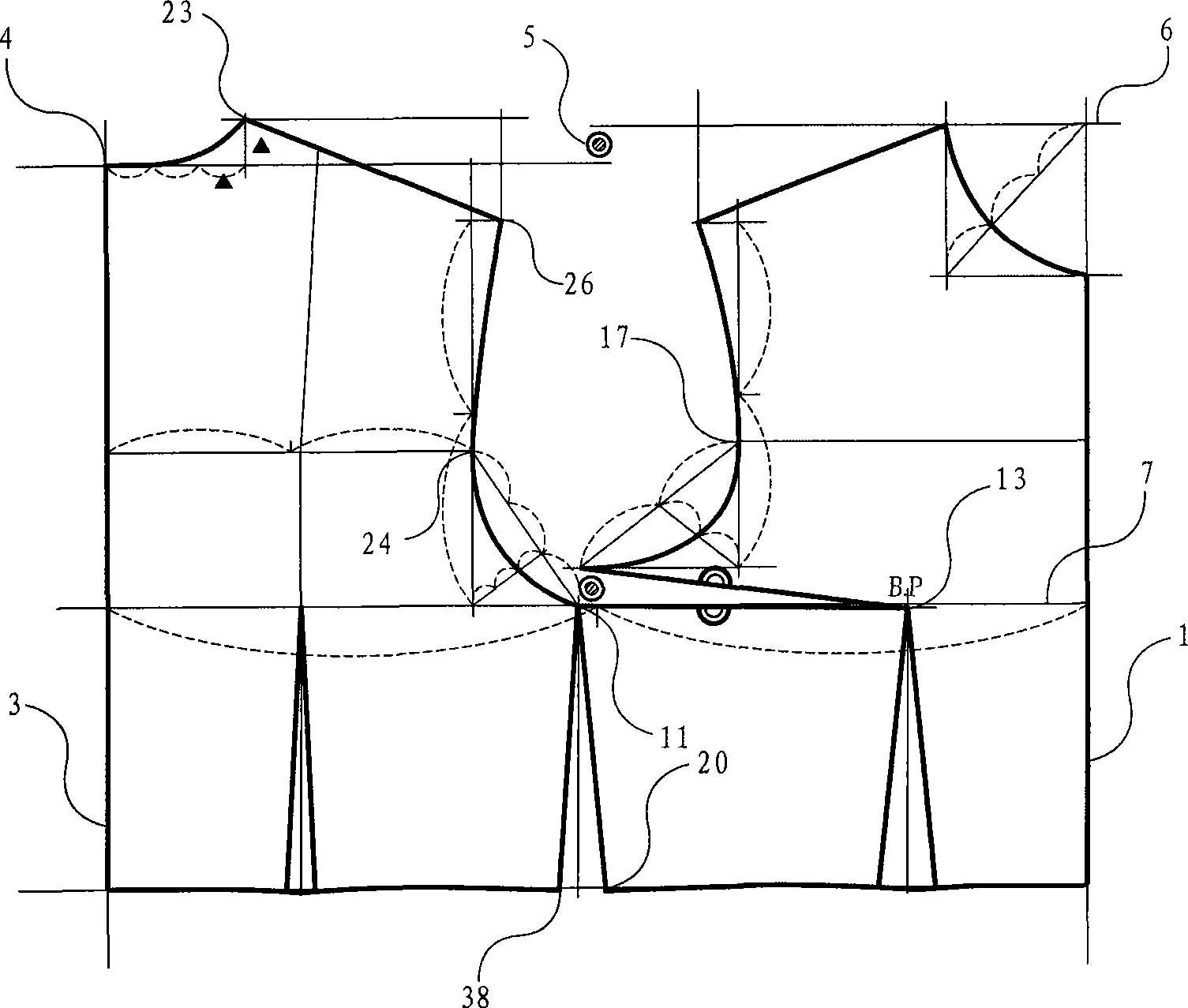

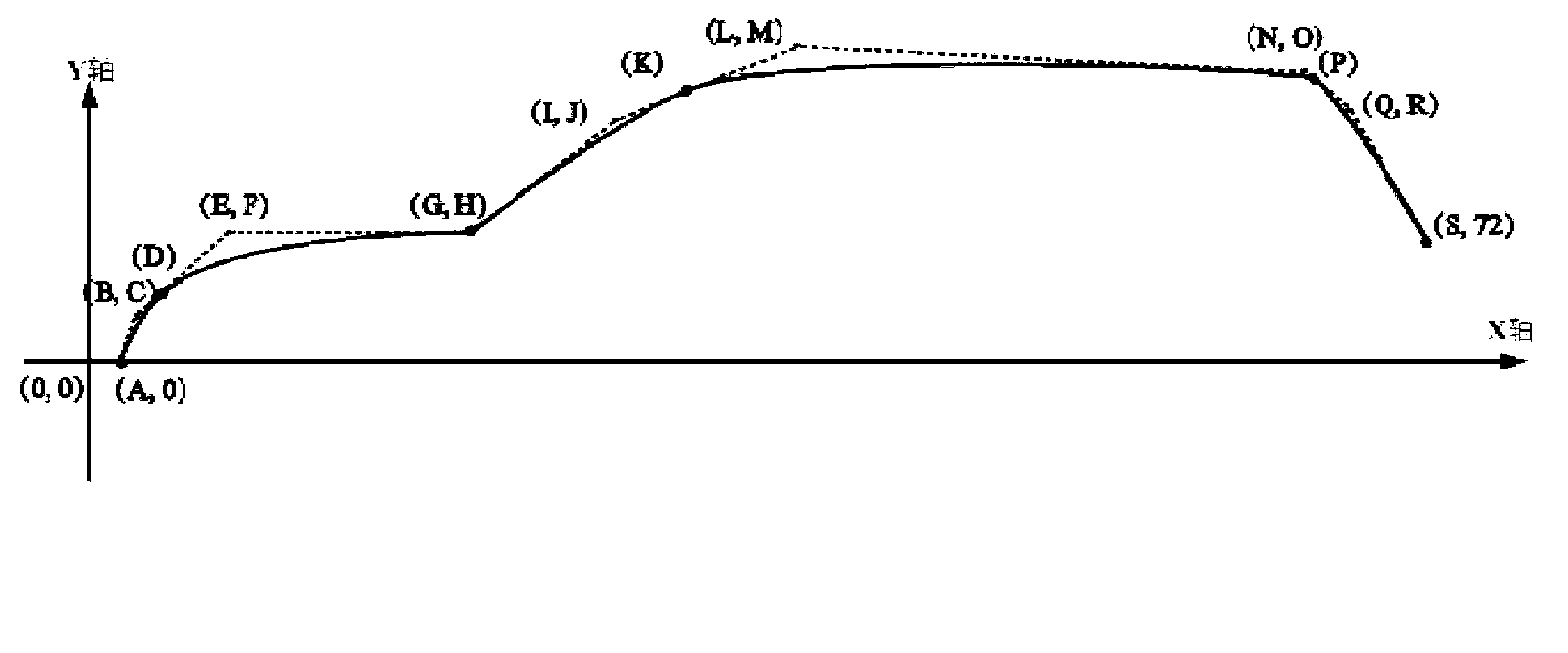

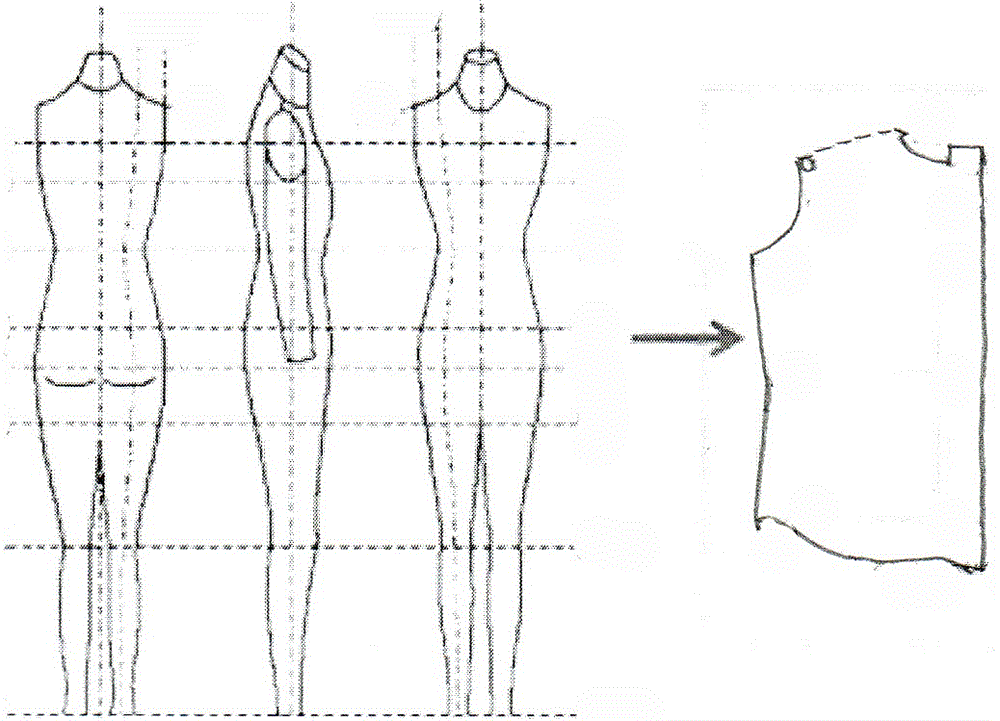

Structure design method for suit-dress pattern

InactiveCN101485500ASimple designScientific and reasonable designClothes making applicancesEngineeringDesign space

The invention provides a method for designing a suit-dress structure, in particular a structure designing method for a series of women coat pattern. The method is a novel proportion method which is different from the prior garment pattern designing method. The method has the advantages of scientific and reasonable proportion formula design, simple calculation and easy learning; and the setting of adjusting the numerical value can provide a variational design space for a designer and can better reflect the relation between the human body and the suit-dress structure. The novel proportion formula forming method is adopted to design the calculation formula of all the structural points of the suit-dress pattern, and the specification changes of all the positions of the formed pattern structure are in accordance with the level rule of garment uniform size. Thus, the method completely solves the problem of pattern modeling structural distortion caused by the size specification changes so as to ensure the pattern stability and the style duration. The series of suit-dress pattern is taken as the basis of the structural design of the suit-dress style; the structural design change is flexible and accurate and can keep the pattern style characteristics steady and create conditions for forming the brand designing style, and the design efficiency is very obvious. The method not only deepens the theoretical study of the suit-dress structure, but also further expands the thought and the method of the suit-dress structural design, and has good practicability and economic value potential.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

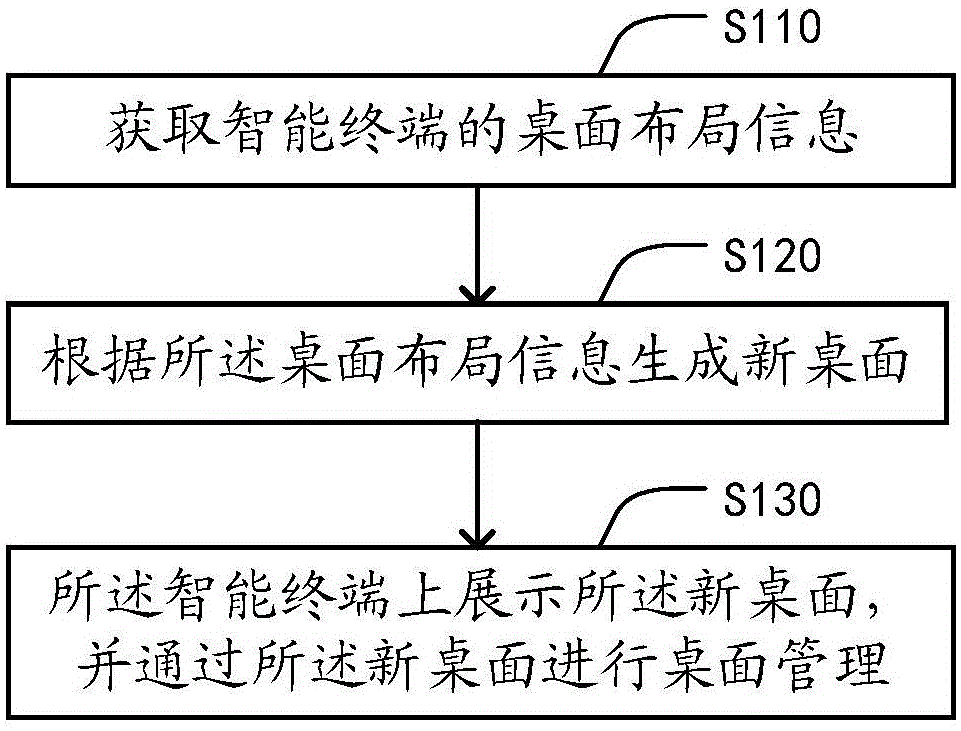

Desktop management method and device for intelligent terminal

ActiveCN105138226AMeet usage habitsPreserve layout stateSubstation equipmentInput/output processes for data processingHabitOperating system

The invention discloses a desktop management method and device for an intelligent terminal. The method includes the steps that desktop layout information of the intelligent terminal is obtained, a new desktop is generated according to the desktop layout information, the new desktop is displayed on the intelligent terminal, and desktop management is conducted through the new desktop. Due to the fact that the existing desktop layout information of the intelligent terminal of a user is obtained, the use habits of the user can be completely reserved, the existing layout state, not needing to be changed, of the user is reserved while the design style of the new desktop is provided for the user, and better user experience is provided.

Owner:BEIJING QIHOO TECH CO LTD

Dyeing technique of true silk-tencel/cotton interwoven cloth

The invention provides a dyeing technique of true silk-tencel / cotton interwoven cloth, which comprises the steps of pretreating, dyeing and finishing. The dye liquor used in the dyeing technique comprises 0-5% (owf.) of Lanasol dye, 0-5% (owf.) of Novacron, 1-5 g / L of leveling agent, 15-45 g / L of glauber salt and 5-15 g / L of sodium carbonate. By adopting reactive dyes in different structures, theinvention solves the problem of interaction between true silk and tencel / cotton in the apposition dyeing treatment, and prevents the true silk and tencel / cotton from dyeing each other. In addition, by using the invention, the dyeing technique and color are easy to control and implement, thereby sufficiently displaying the design style, color and pattern effects of the fabric, highlighting the multicolor stereoscopic effect of the high-grade true silk-tencel / cotton interwoven cloth, enhancing the novelty, and satisfying the dyeing and finishing matched technique demands and market demands for novel shell fabric.

Owner:江苏欧化纺织有限公司

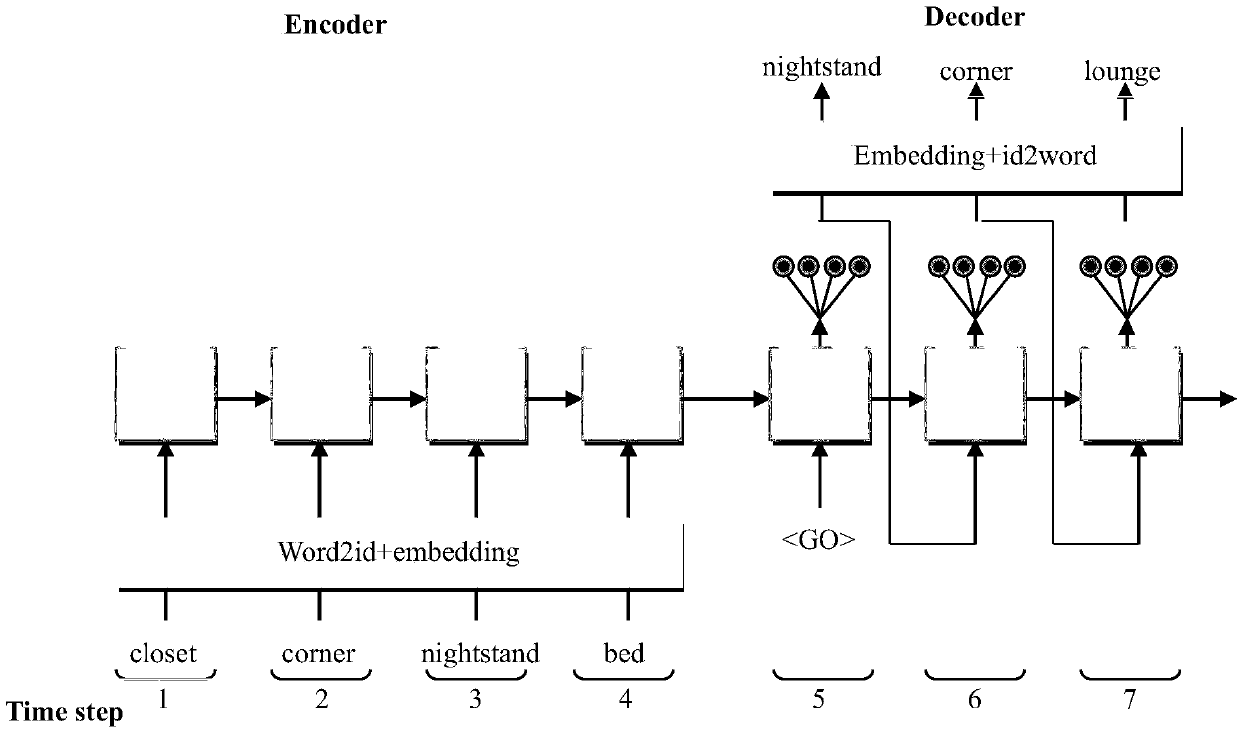

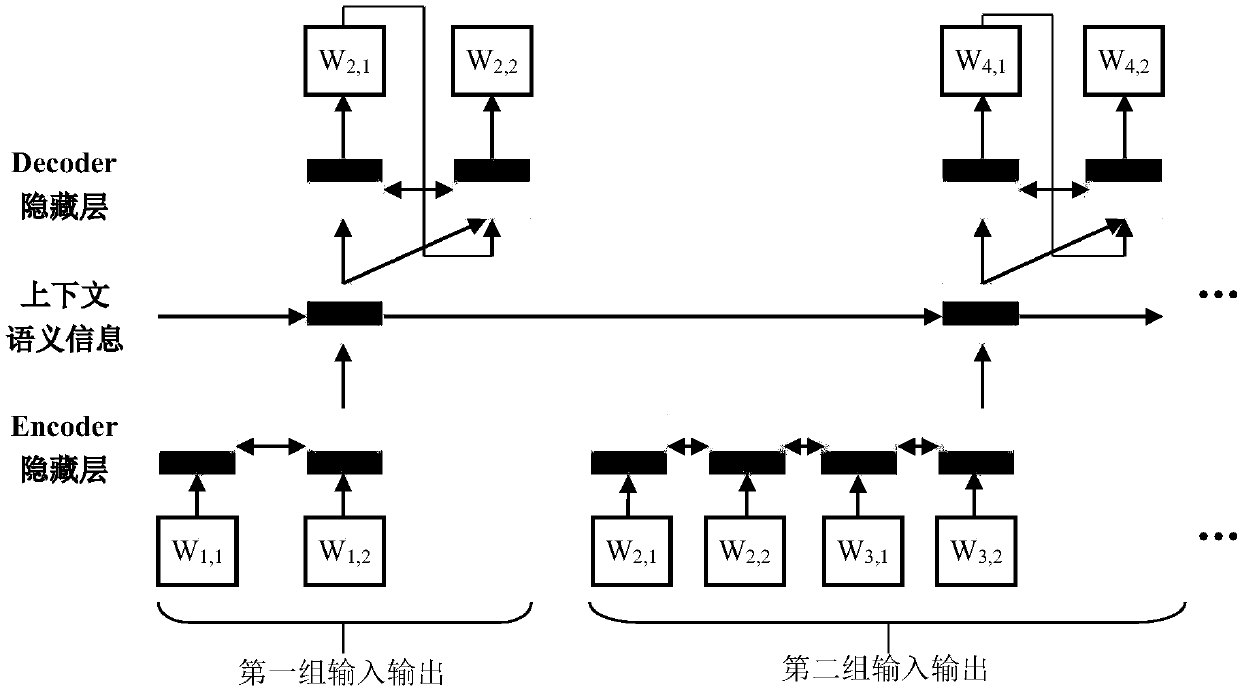

A home design method based on deep neural network

ActiveCN108984904APredictive structurePredicted sizeGeometric CADNeural architecturesBusiness forecastingComputer science

The invention relates to a home design method based on a deep neural network, belonging to the technical field of the deep neural network and the home design. At first, the household design display iscollected to mark the household, and then the serial data is generated based on the labeled household placement sequence. Secondly, the prediction model of home furnishings is designed. Based on theprediction model, the structural features between characters of furniture are extracted, the sequence data are learned and the order of home furnishings is predicted. Based on the parameter constraintof the relative size of household objects, a bi-directional hierarchical household prediction model is designed, and then hierarchical recursive multi-round prediction is carried out, so that the multi-round prediction results are more in line with the actual situation of household design. Finally, according to the requirements of different design styles in practical application, the home forecasting model is designed for specific style. The method utilizes a three-dimensional engine to perform three-dimensional household scene rendering, and intuitively proves the effectiveness of the modeland the style learning advantage in a three-dimensional manner.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Material formula of 18K gold bullet and gold bracelet and preparation process of 18K gold bullet and gold bracelet

The invention discloses a material formula of a 18K gold bullet and gold bracelet and a preparation process of the 18K gold bullet and gold bracelet. The material formula of the 18K gold bullet and gold bracelet includes the following components in parts by weight: 75.2% of gold, 0.00496% of silver, 13.69208% of copper, 7.44248% of nickel, and 3.66048% of zinc, or 75.2% of gold, 0.00992% of silver, 7.27384% of copper, 12.66536% of nickel, and 4.85088% of zinc. The preparation process of the 18K gold bullet and gold bracelet comprises the steps of cutting, heating die and polishing. By means of the invention, the bracelet has high hardness,certain elasticity, flexibility, extensibility and a wider space for designing styles, can be bent, and is convenient to wear.

Owner:深圳市星光达珠宝首饰实业有限公司

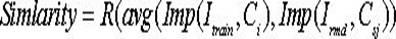

Method for mining and recommending style elements based on clothing graph group

ActiveCN102663092ASummarize the design styleMeet the noveltySpecial data processing applicationsFeature extractionStatistical analysis

The invention provides a method for mining and recommending style elements based on a clothing graph group. The method includes that a user selects or inputs clothing sample images and recommendation requirements for a recommending system; the recommending system preprocesses the inputted clothing sample images, and the specified clothing graph group is built; the recommending system extracts specific features of the clothing images in the specified clothing graph group according to the recommendation requirements; the recommending system performs specific clothing visual element mining for the clothing images; and styles of the clothing images in a database are analyzed according to required and mined clothing visual elements, and various types of clothing are rated. The clothing visual elements of the clothing images are mined by the aid of a feature expression and statistic analysis method, accordingly, design styles of the clothing images are summarized, and the clothing images are retrieved and recommended according to the clothing styles. By the aid of the method, the requirement on novelty when consumers purchase clothing can be met.

Owner:哈尔滨工业大学人工智能研究院有限公司

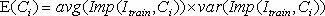

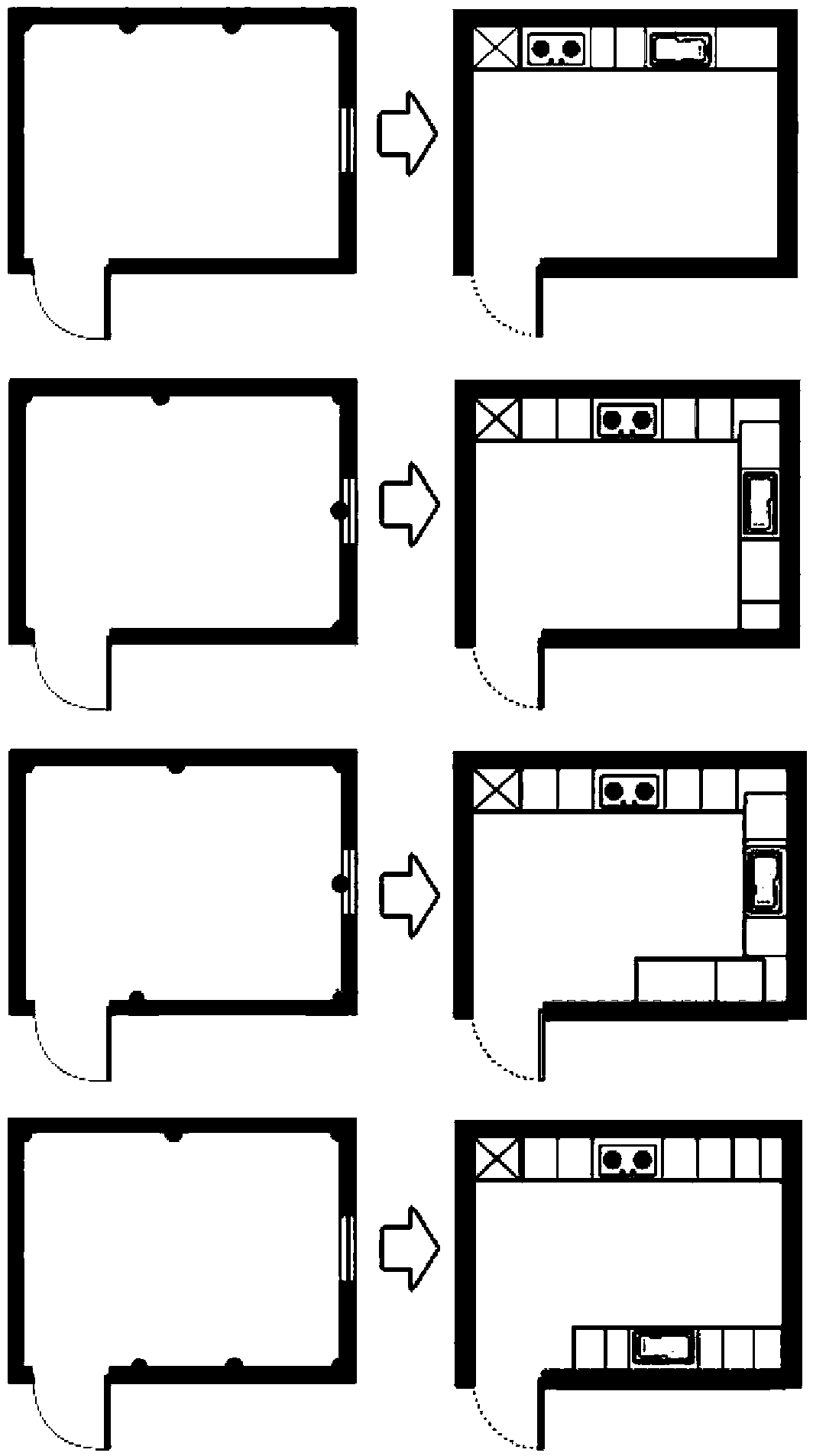

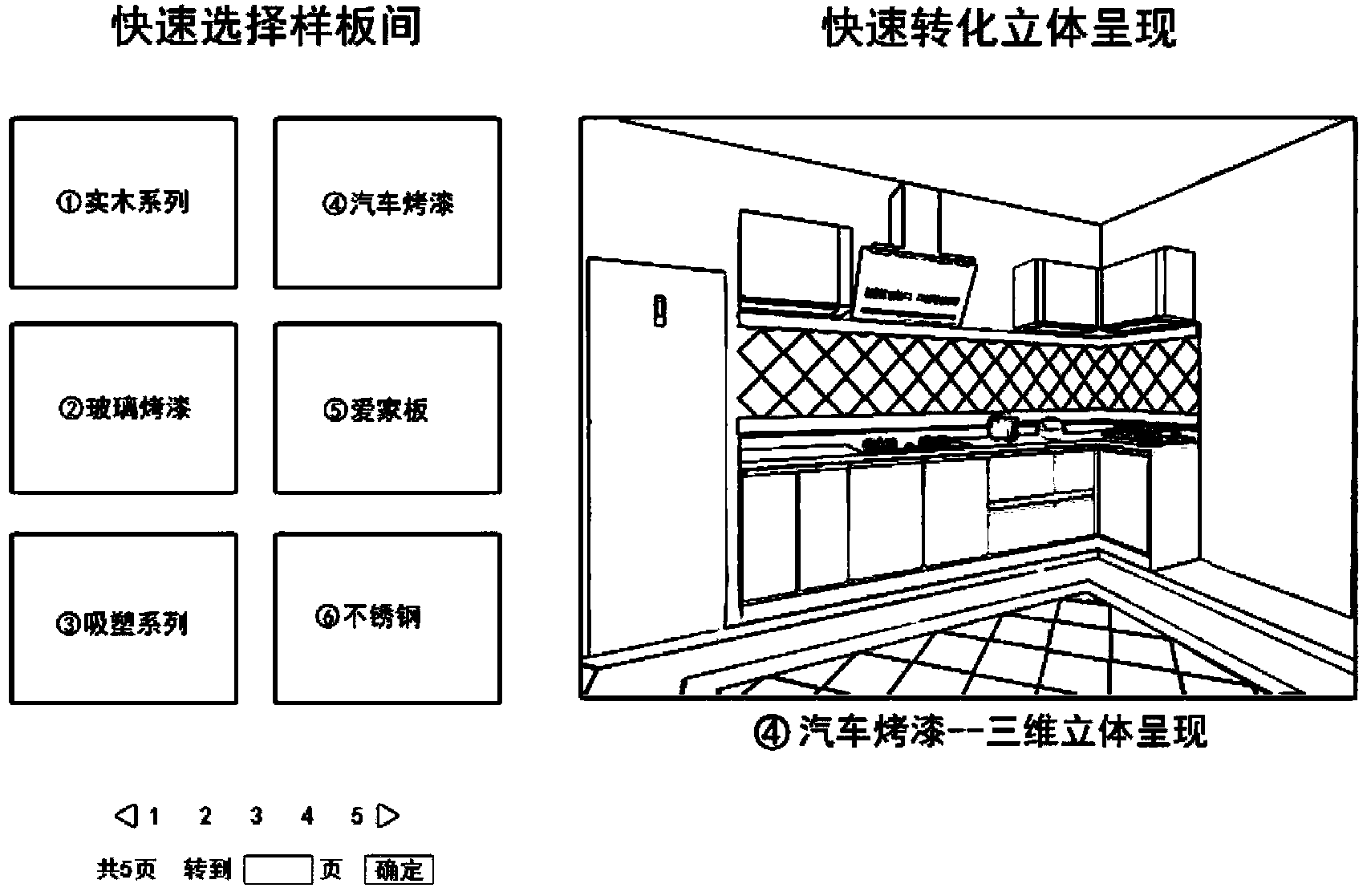

Kitchen design scheme generating method

ActiveCN104252562ASolve the problem that the settings may be biasedTimely and accurate three-dimensional effectGeometric CADConfiguration CADSoftware engineeringCupboard

The invention discloses a kitchen design scheme generating method. The method includes step 1), leading data like combined data of each series, type, size, plate type, door plate style and accessories of each brand and each cabinet and 3D models into databases of the corresponding brands of easy-to-do software according to easy-to-do rules; step 2), converting cupboard design of each type and using needs on placement into description language and function formula of a computer; step 3), determining starting points, corner points, finishing points of a to-be-placed cupboard and position points of a range hood and a water tank in a guest kitchen, determining an area where the cupboard is placed, and determining placement starting points and placement finishing points of an island shelf and a bar counter. By the kitchen design scheme generating method, optimal design placement schemes of each series can be calculated in an easy-to-do system immediately according to design needs of users and can be presented in a 2D interface. The method is relatively small in stored data quantity, so that the design schemes can be conveniently transmitted to each computer having easy-to-do cupboard software in the world. Various updated cupboard series and various updated design styles can be conveniently transmitted to anywhere.

Owner:BEIJING ERYIJU TECH

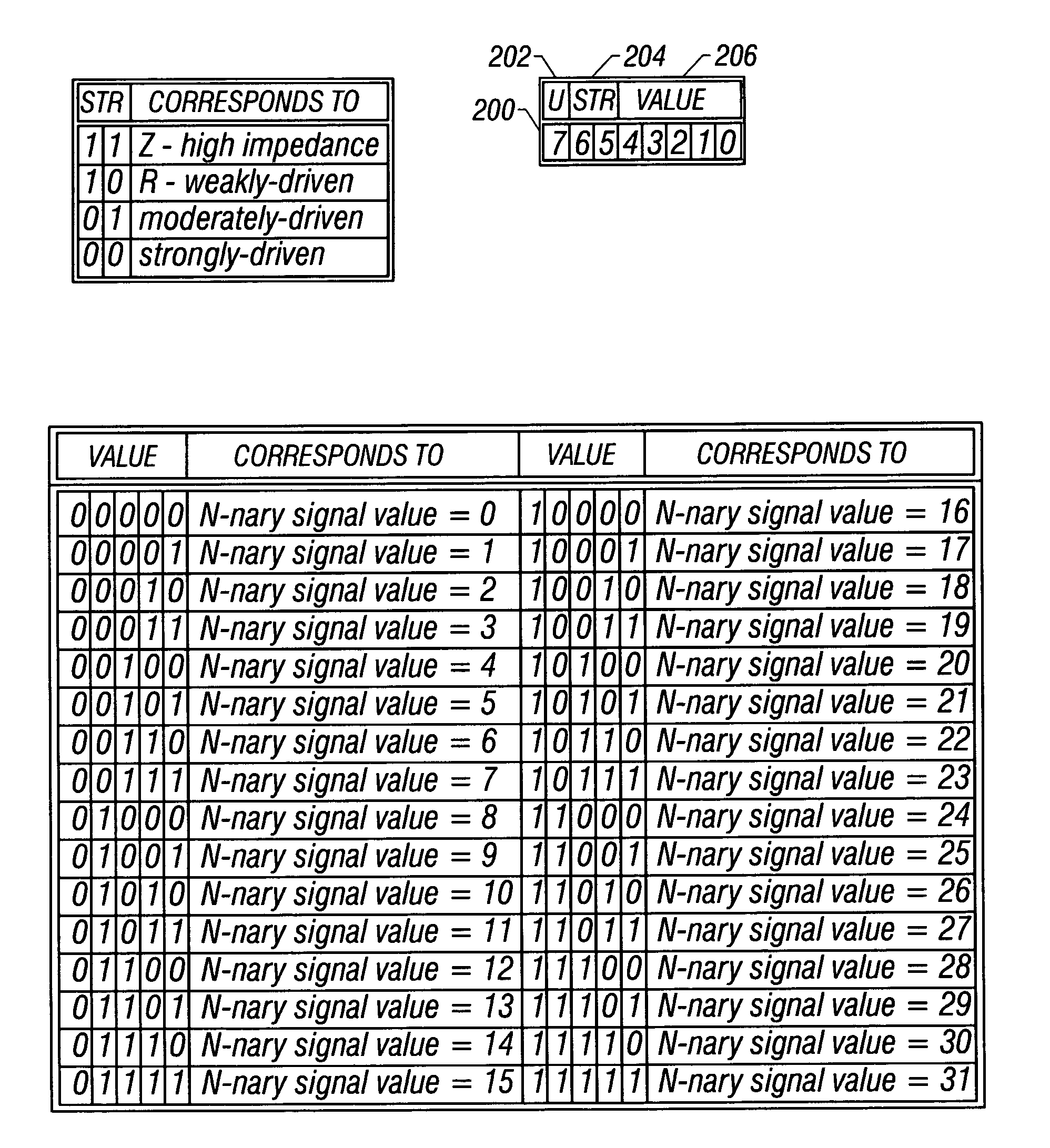

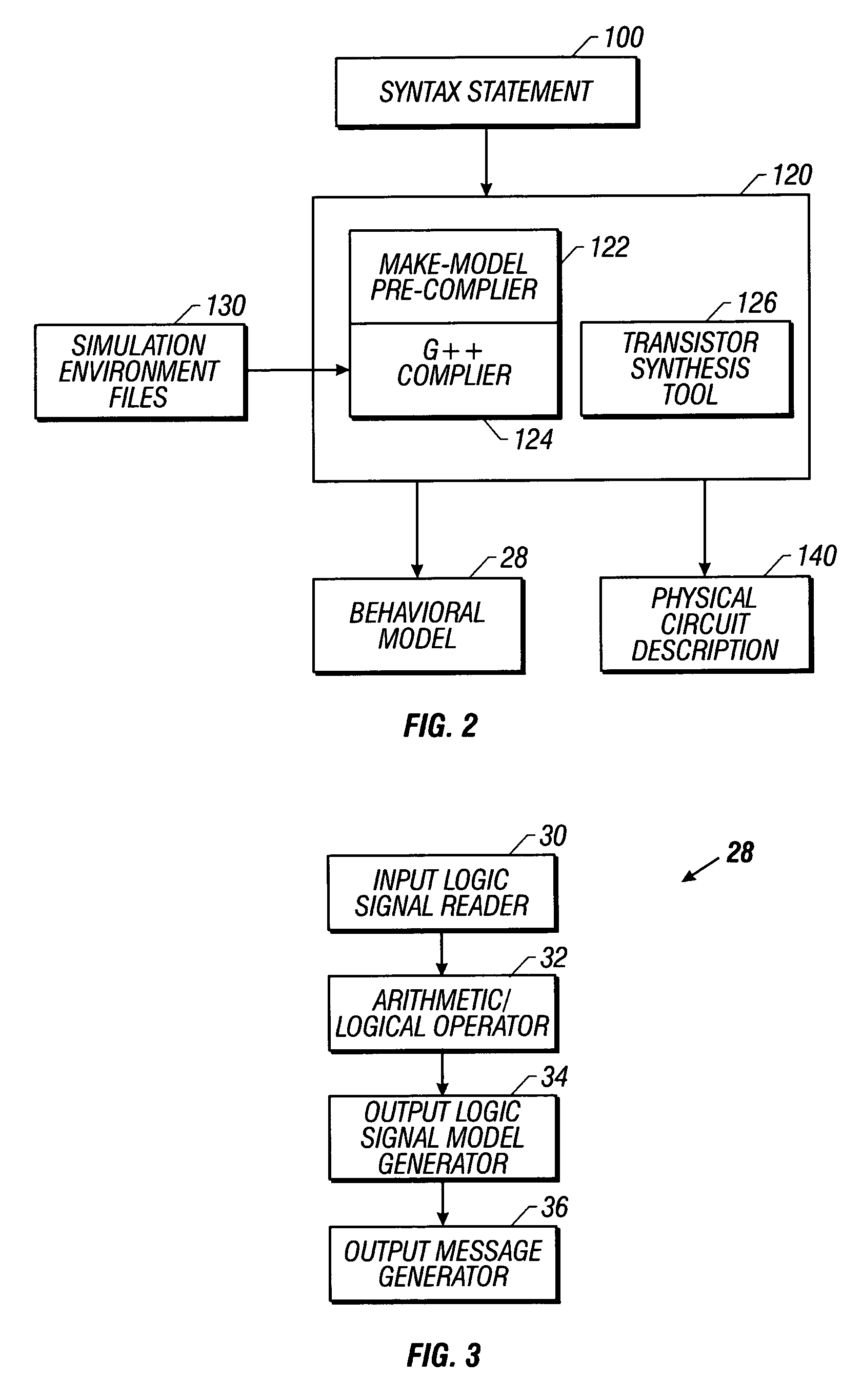

Software modeling of logic signals capable of holding more than two values

InactiveUS7031897B1Effective simulationAnalogue computers for electric apparatusMultiple digital computer combinationsMultiplexerTheoretical computer science

A method of efficiently simulating logic designs comprising signals that are capable of having more than two unique decimal values and one or more unique drive states, such as designs based upon the new N-nary logic design style, is disclosed. The present invention includes a signal model that models N-nary signal value, drive strength, and signal definition information in a specific format that supports the ability of the simulator to simulate the operation of the N-nary logic gates such as adders, buffers, and multiplexers by arithmetically and logically manipulating the unique decimal values of the N-nary signals. The simulator comprises an input logic signal model reader, an arithmetic / logical operator, an output logic signal model generator, and an output message generator that generates one or more output- or input-signal-specific output messages that pack relevant simulation data into a format optimized to the architecture of the simulation host.

Owner:APPLE INC

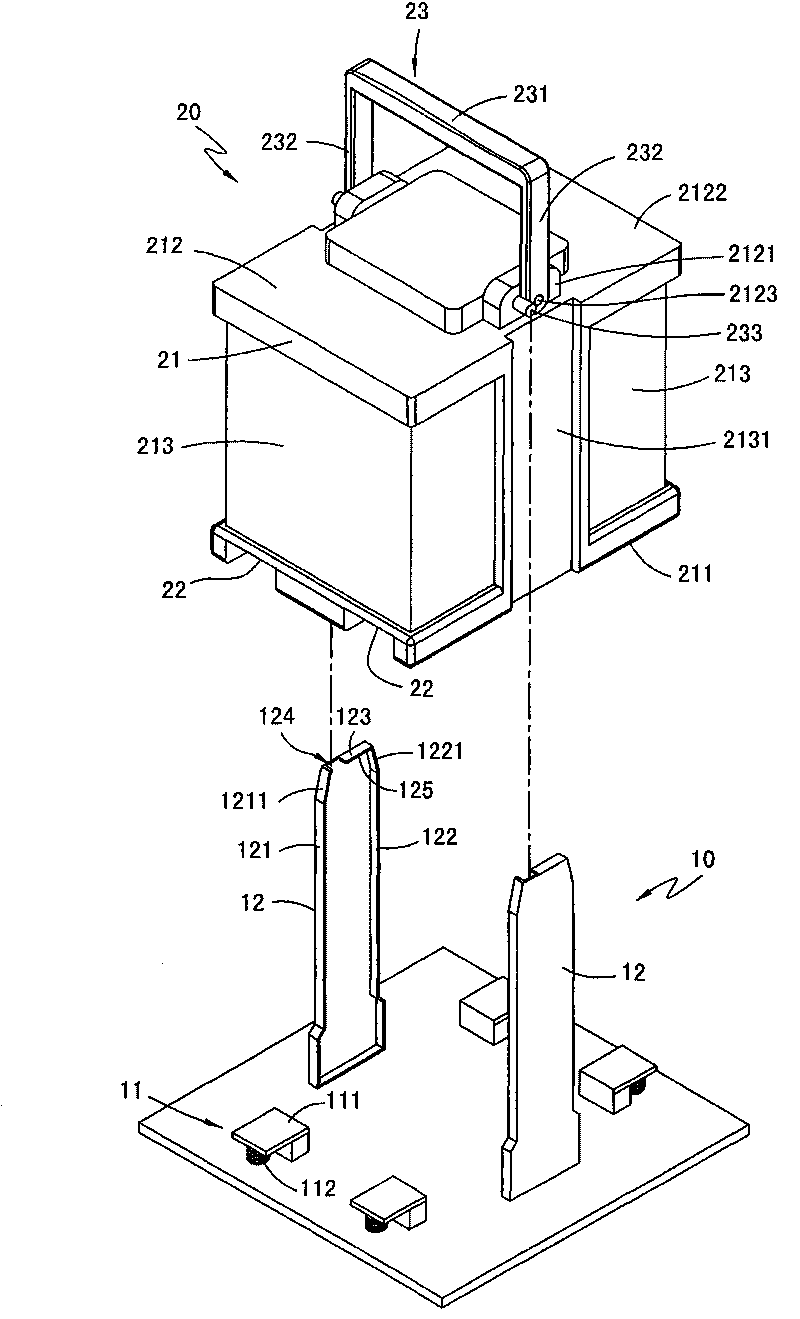

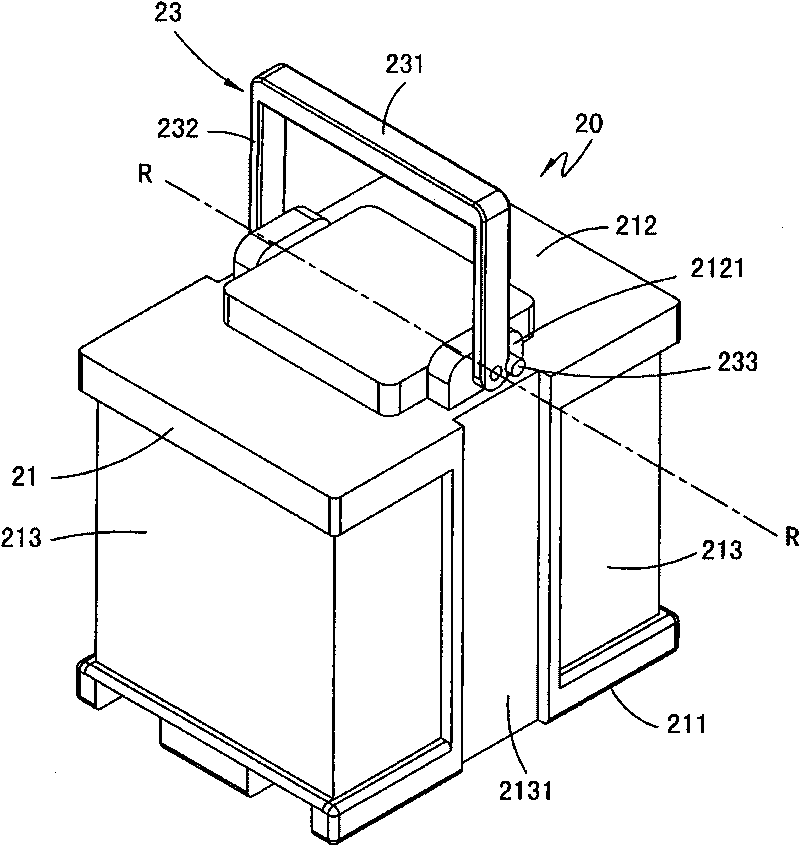

Fast removable battery structure

InactiveCN101752598AEnsure electrical connectionEasy to disassembleFinal product manufactureSecondary cells manufactureElectrical and Electronics engineeringComposite structure

The invention relates to a fast removable battery structure which is applied to a battery module with the electric energy being supplied by an electric device. The battery module is pivoted with a rotatable handle; the handle is provided with a clamping piece in parallel; a fixed structure is vertically arranged on a base of a battery composite structure; a resisting part and a releasing port are arranged at the top edge of the fixed structure; the handle is screwed to a holding position so as to lift the battery module, so that the battery module can be arranged on the base along the fixed structure; and then the handle is screwed to a retraction position, so that the clamping piece moves to the resisting part. Therefore, due to the designing style of the battery structure, the battery module is combined and fixed on the base, so as to ensure the electric connection of the battery module and the electric device.

Owner:IND TECH RES INST

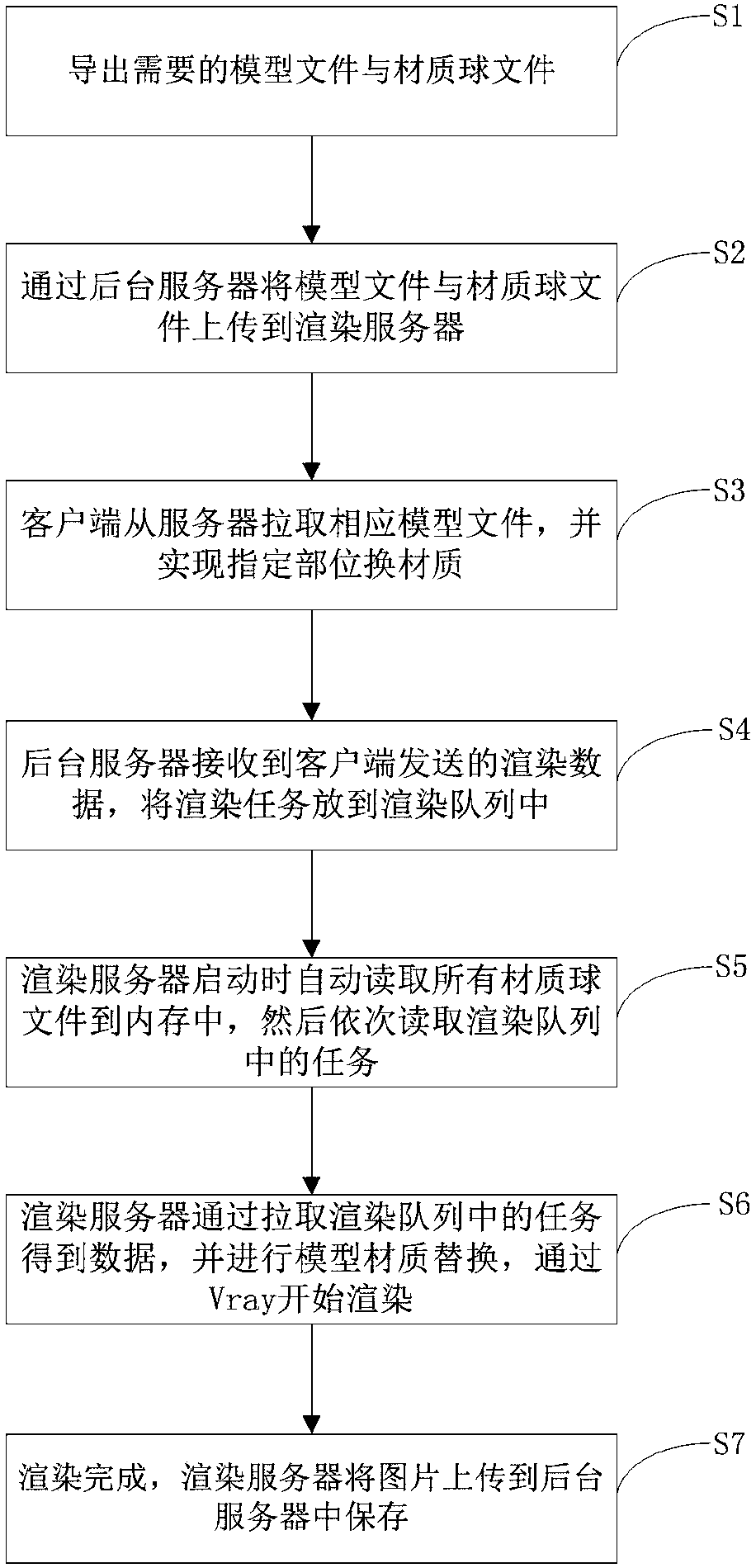

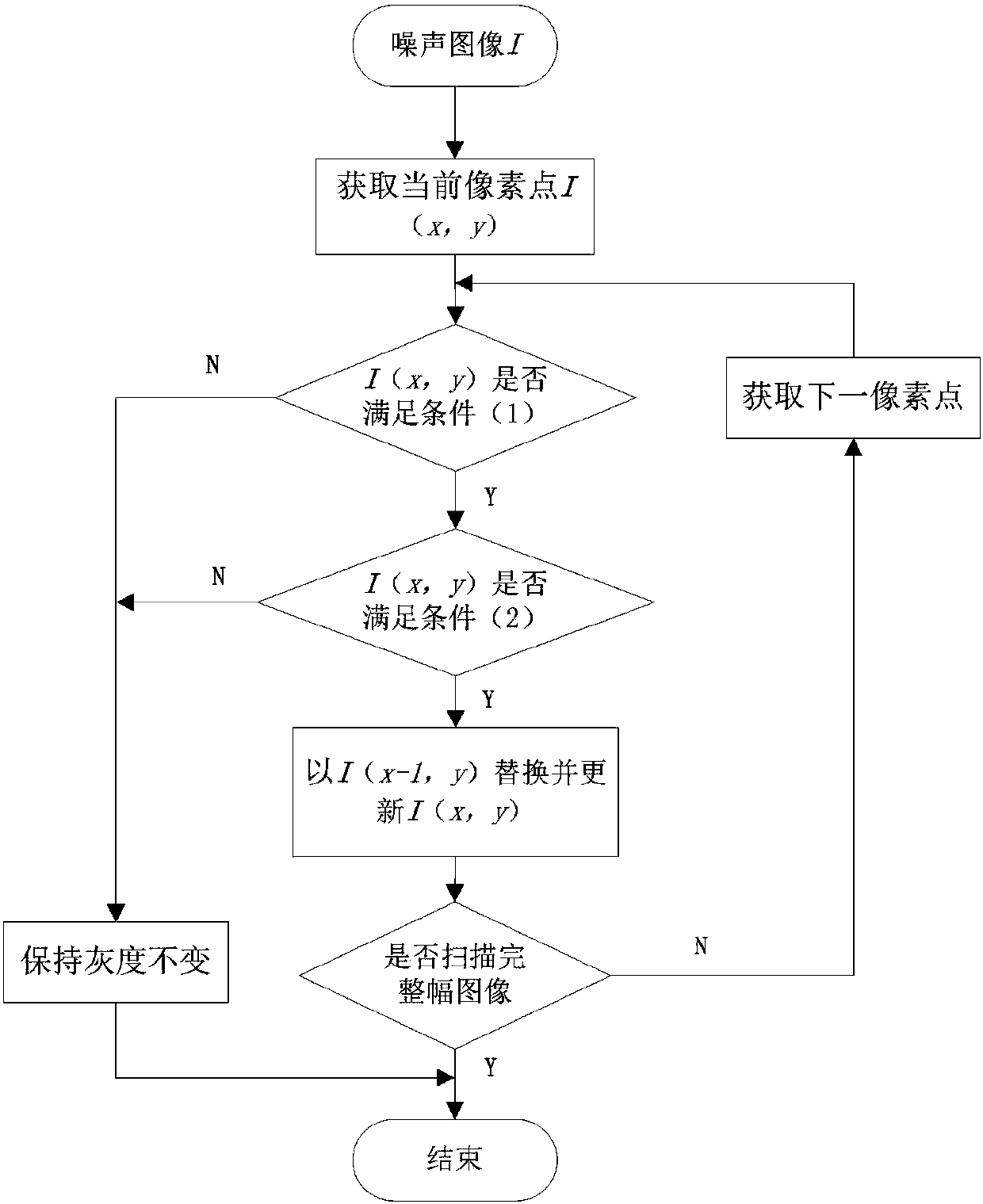

Rendering plotting method for replacing specific part material based on three-dimensional model

ActiveCN107680153AFor quick replacementUnity controlImage enhancement3D-image renderingGraphicsDimensional modeling

The invention discloses a rendering plotting method for replacing a specific part material based on a three-dimensional model, and relates to the field of computer graphic image rendering. The methodcomprises the steps: exporting needed model files and material ball files; uploading the model files and the material ball files to a rendering server through a background server; enabling a client toextract the corresponding model file from the server, and achieving the replacement of the material of a specific part; enabling the background server to receive the rendering data transmitted by theclient, and inputting a rendering task into a rendering queue; enabling the rendering server to automatically read all material ball files into a memory when the rendering server is started; sequentially reading the tasks in the rendering queue, and enabling the server to obtain the data through extracting the tasks in the rendering task, and carrying out the replacement of the material of a model; starting rendering through Vray, and completing the rendering; enabling the rendering server to upload an image to the background server for storage. The method can achieve the replacement of any material with any part, is more flexible in rendering, and enables the uniformity of a design style to be easier to control.

Owner:SHENZHEN BINCENT TECH

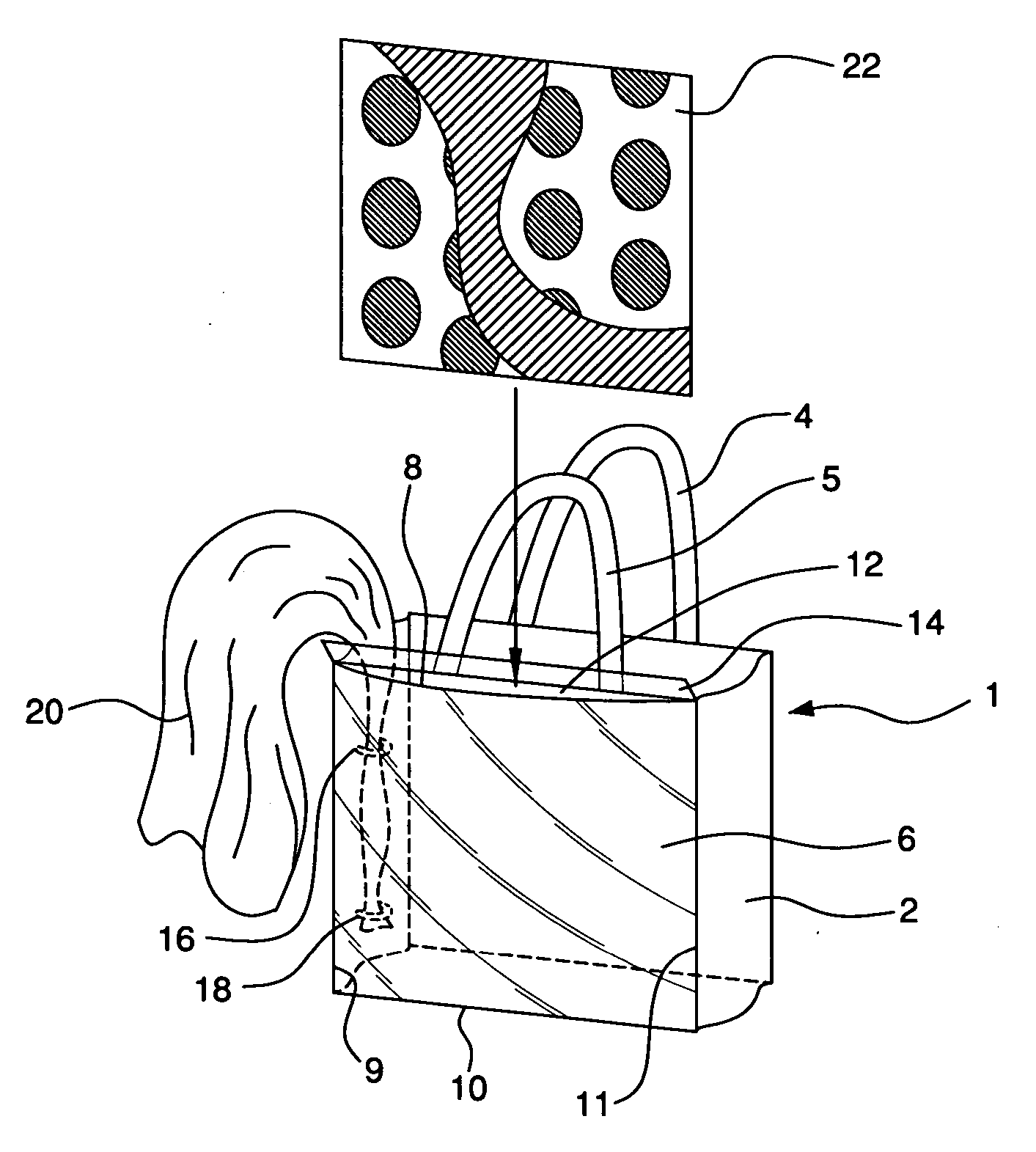

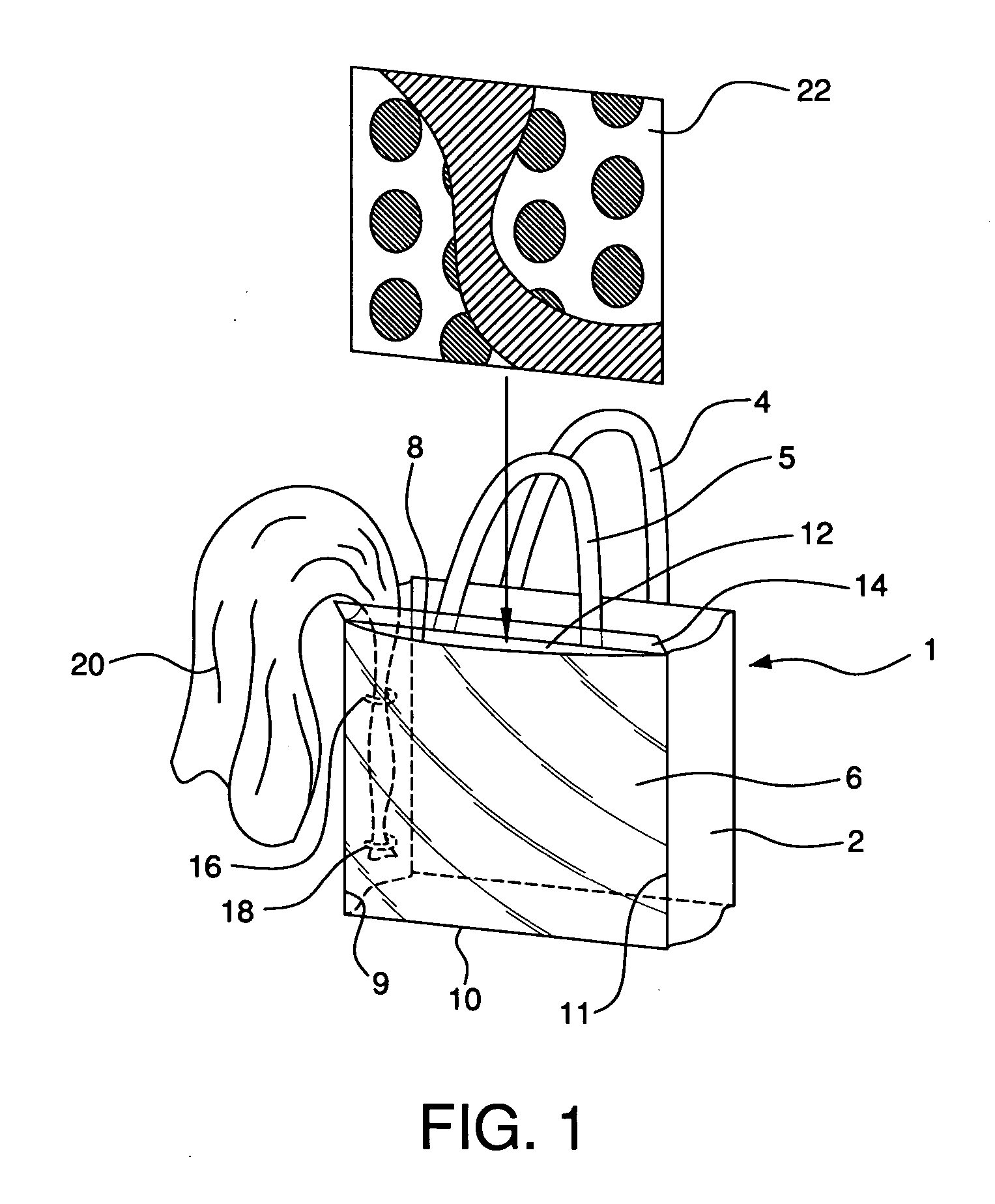

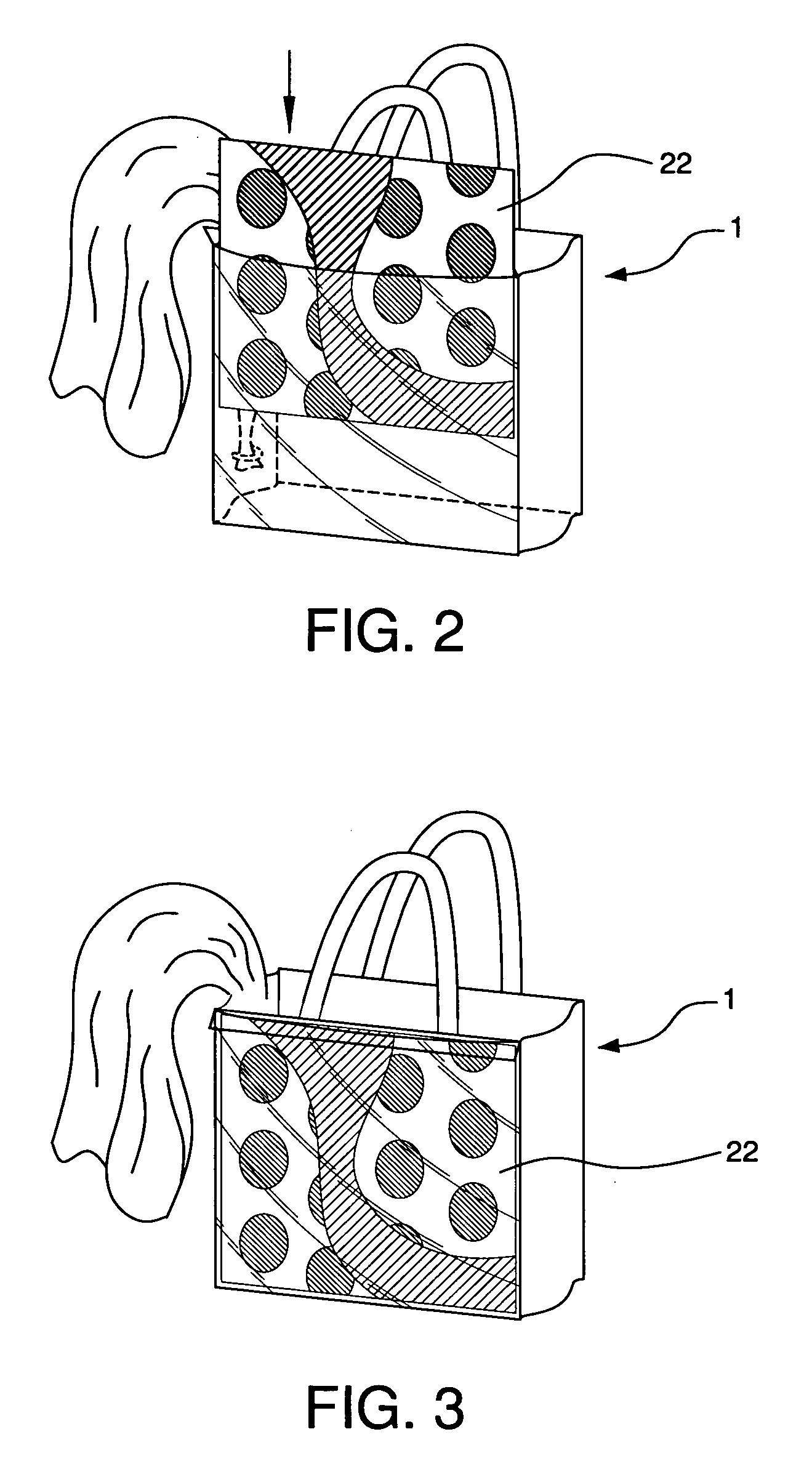

Interchangeable handbag design method

A method is disclosed for varying the design appearance of a manually carried handbag using a handbag with an exterior pocket formed between the handbag's outer surface and a transparent outer sheet. Any number of display sheet inserts, custom designed by the individual user, can be generated by, for example, computer and printed out for insertion into the pocket. By means of these interchangeable, display sheet inserts, the design, color and design style of a single handbag can be easily and simply changed, based on the individual taste and preference of the user. Matching display sheet inserts can also be used with other accessories like bracelets and purses.

Owner:PERSIC TIFFANY

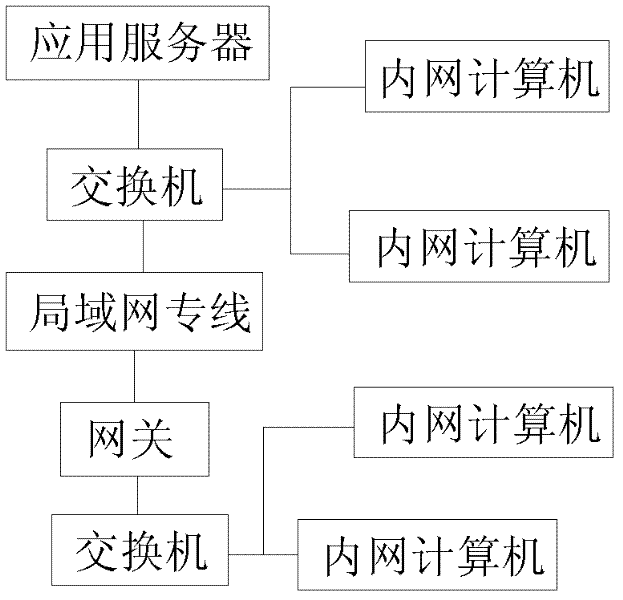

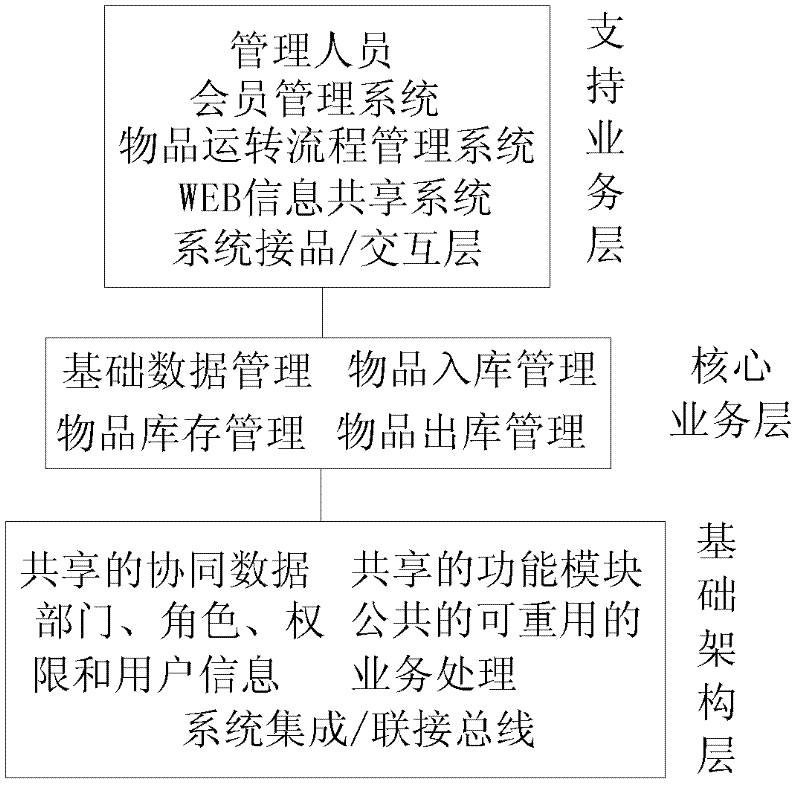

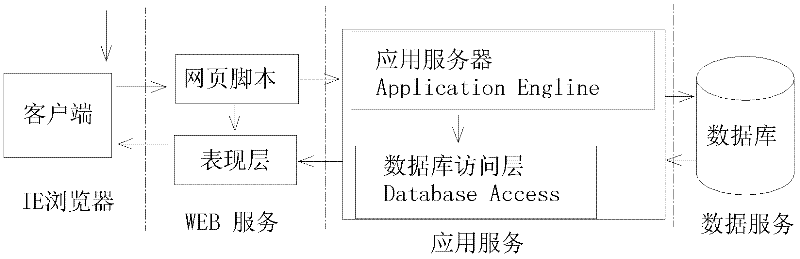

Management system for spare parts of transformer substation

InactiveCN102521721ARealize whole process real-time monitoringPay attention to practicalityLogisticsInformation technology support systemService flowOperational system

The invention discloses a management system for spare parts of a transformer substation. A B / S architecture is used in the system, an own browse of an operating system is used as a client, from the view of practical applications, the actual users are centered, and the design of the whole system is integrated with the humanized design concept, particularly, the practicability of function application and the simplicity of operation are emphasized. With intelligent platform management, integrated operation, simple design style and clear and smooth service flows, the problem of conflict between the functions of the system is solved fundamentally, and the modern enterprise informationized management concept of full real-time monitoring, real-time summarization of data, intelligent management and integrated operation on the spare parts is really realized.

Owner:CHUZHOU POWER SUPPLY CO OF STATE GRID ANHUI ELECTRIC POWER CORP +1

Method for SUV (Sport Utility Vehicle) product family gene evolution based on genetic algorithm

InactiveCN103295063AAchieve two-way conversionStrong market significanceGenetic modelsPersonalizationBuilding product

The invention discloses a method for SUV (Sport Utility Vehicle) product family gene evolution based on genetic algorithm. The method includes: through abstracting and expressing SUV appearance individualized genes and SUV appearance successional genes, building SUV product lines with differential SUV designed styles and consumer-preference-driven evolution function according to different consumer preferences, generating optimal individualized gene progenies in Matlab based on the genetic algorithm, realizing evolution of the SUV appearance individualized genes, adding SUV appearance inheritance genes to the evolutional genes, realizing overall application of SUV product family appearance genes, generating a series of product design schemes, and building product family images with continuation and differentiation.

Owner:ZHEJIANG UNIV

Production method of tape-casting glazed ceramic vase

The invention discloses a production method of a tape-casting glazed ceramic vase. The production method is characterized by comprising the following production steps of: (1) taking and putting triphane, quartz, feldspar, calcium carbonate, steatite and kaolin in a ball mill, and then, adding clear water to carry out ball milling and sieving to prepare a ceramic glaze for later use; (2) producing a ceramic vase biscuit with a height of 60-120 cm; and (3) uniformly coating the ceramic glaze for later use on a surface in a spray coating way from a vase neck of the ceramic vase biscuit to the middle part of a vase body within 20-30 seconds to form a glaze layer which has a thickness of 1-2 mm, then placing the ceramic vase biscuit in a kiln, firstly carrying out low-temperature sintering for 10-15 minutes at 120-140 DEG C, and then, heating to 1100-1120 DEG C for sintering for 4-5 hours so as to prepare a finished product. The tape-casting glaze is formed on the surface of the vase produced by the invention; the vase has natural and random appearance; a unique and novel aesthetic feeling is generated; and the design style of the conventional product is broken through.

Owner:李永强

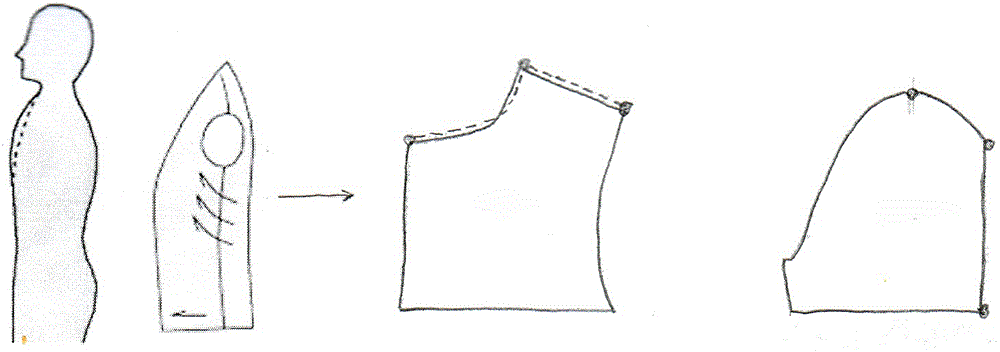

3D cutting method

InactiveCN106758110ARealize acquisitionRealize smart fittingSevering textilesMetal working apparatusThree Dimensional SizePattern generation

The invention relates to a 3D cutting method and belongs to the technical field of fabric processing and forming. The 3D cutting method includes measurement, style design, pattern generation, coding, automatic cutting and precision cutting, and specifically includes measuring in a photographing or scanning manner, feeding measured three-dimensional sizes back in a data form, and selecting specifications, fabric and accessories according to data to complete style design; converting a designed style into a pattern, composing and determining materials; generating signals from material, pattern making and composing data, coding the signals and transmitting the coded signals to an automatic cutting system to complete cutting. The 3D cutting method is applied to business suit and garment making and is capable of achieving both standardized making and large-scale personalized customization.

Owner:SHAOXING BOYA FASHION CO LTD

Manufacturing process of decoration for jade mounted gold

InactiveCN104621876AAchieve diversificationKeep using gradeJewelleryPulp and paper industrySilica gel

The invention discloses a manufacturing process of a decoration for jade mounted gold. The manufacturing method comprises the following steps: processing a wood base material, namely, selecting a health-care wood material, cutting the health-care wood material into corresponding wood blocks; after 3D modeling by virtue of a three-dimensional wood carving machine, carving and grinding according to a model, processing a groove profile or hole used for embedding a jade in each wood block; processing a jade material, namely, grinding the jade by using a jade carving machine, cutting into a jade blank body contour, and cutting the formed blank body into jade pieces of 2-8mm according to a design style; making edges of the jade pieces flat, and flatting the surfaces of the jade pieces; then performing surface accurate grinding to obtain the jade material; and finger-joining wood and jade, namely, coating organic silica gel on the surface, which is in contact with the jade material, of the groove profile or hole of the wood base material, and embedding the wood base material with the jade material, finger-joining at a temperature of 500-650 DEG C, and integrally polishing and grinding to obtain a finished decoration. The jade decoration is diversified by adopting a health-care wood material, and the use grade of the jade decoration is kept, a health-care function is obtained, and the use value is improved.

Owner:HUACHANG JEWELRY

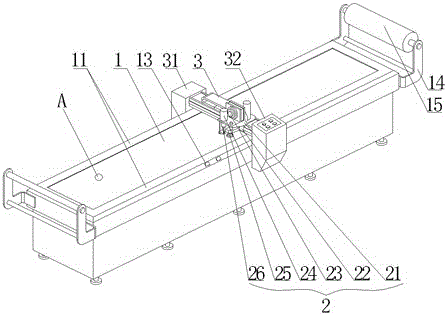

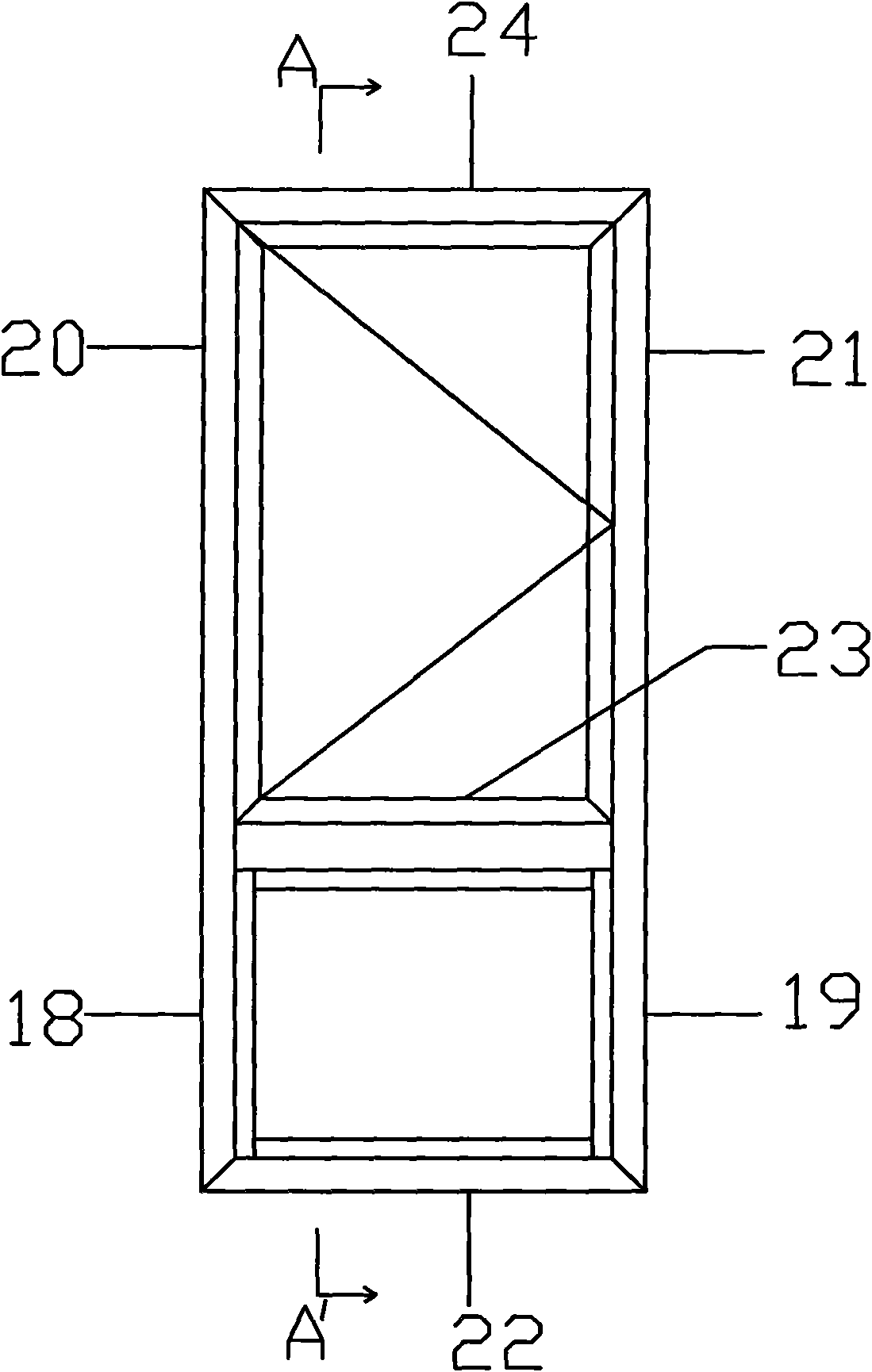

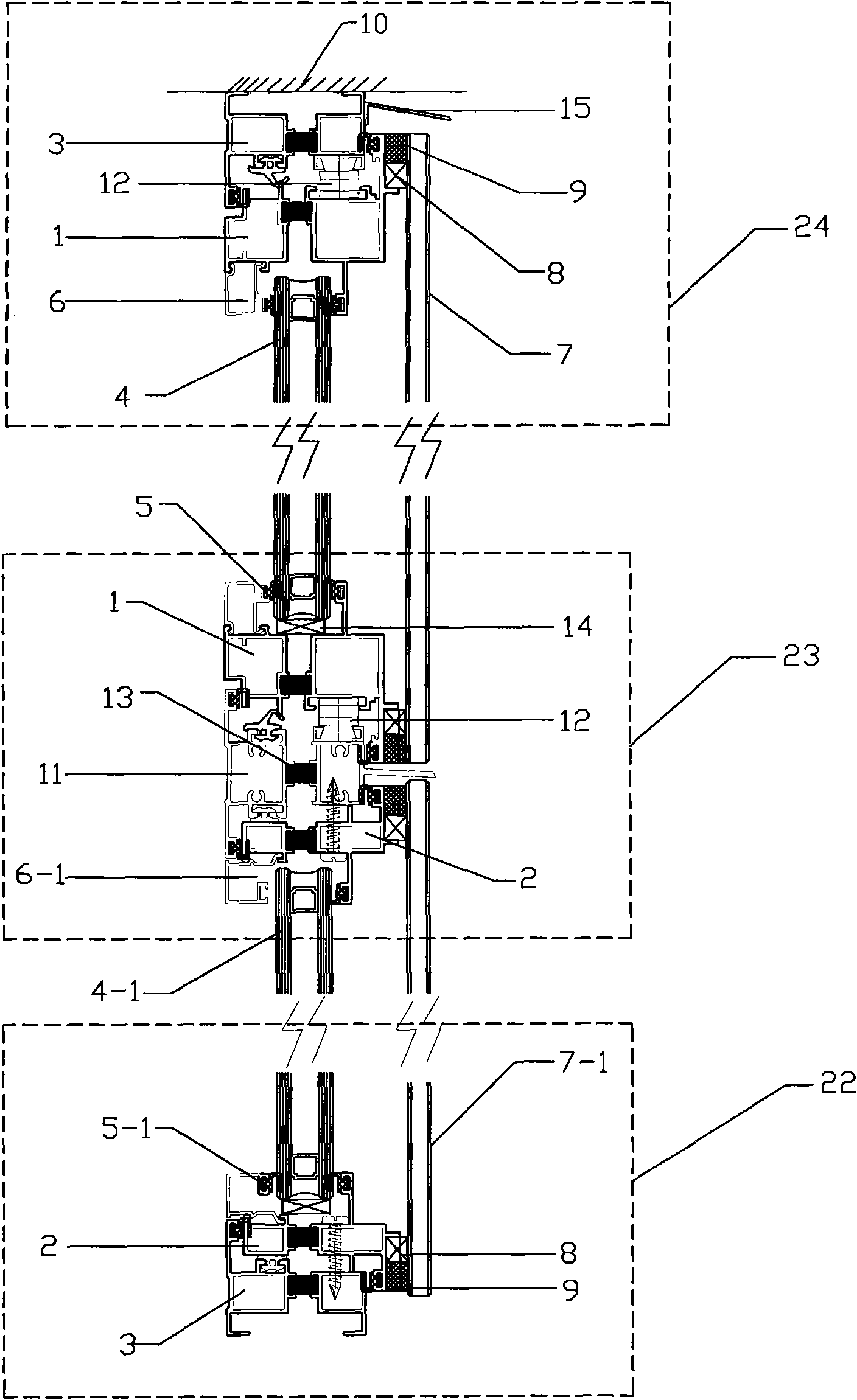

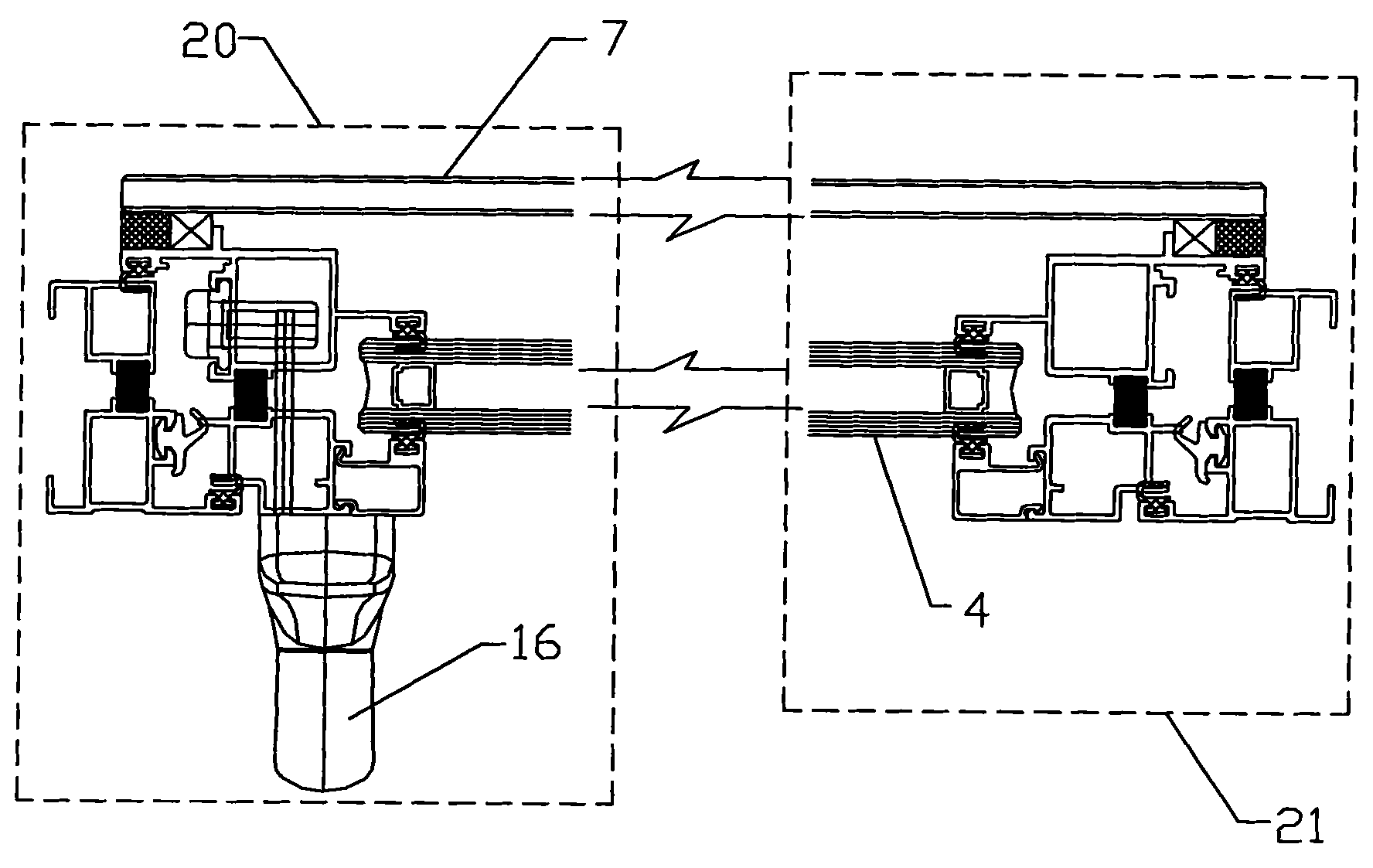

Frame-hiding three-glass energy-saving sound insulating window and manufacture method thereof

ActiveCN102052045AStable and mature processImprove tensile propertiesNoise insulation doors/windowsSealing arrangementsFoaming agentAdhesive

The invention relates to a frame-hiding three-glass energy-saving sound insulating window and a manufacture method thereof. The sound insulating window is characterized by comprising a flat opening window sash (1) consisting of a hollow glass inner layer and a single glass outer layer, a fixed window sash (2) and a window outer frame (3), wherein a muntin (11) needs to be arranged between the flat opening window sash (1) and the fixed window sash (2) according to design style; the hollow glass (4) is fixedly connected with the flat opening window sash (1) by a seal adhesive tape (5) and a flat opening window sash press strip (6); the single glass (7) is fixedly connected with the outer side of the flat opening window sash (1) by a double-side adhesive tape (8) and silicone structure adhesive (9); the top surface of the window outer frame (3) is in flexible embedded seal connection with a wall body (10) by a polyurethane foaming agent; and the top surface of the flat opening window sash (1) is connected with a window frame by a stainless steel sliding support (12). The invention has the advantages of firm and durable structure, tensile resistance, high shearing strength, stable quality, high noise reducing and sound insulating performance, air tightness, high watertight performance, high heat preserving performance and attractive appearance.

Owner:武汉鸿和岗科技有限公司

Ceramic tile with dispersed shimmering powder and manufacturing method thereof

The ceramic tile with dispersed shimmering powder comprises a ceramic brick blank, a color glaze layer, a shimmering powder layer and a clear frit layer, wherein the color glaze layer comprises the following components in percentage by mass: screen printing glaze, glaze pigment, kaolin, methyl cellulose and sodium tripolyphosphate; and the shimmering powder layer comprises the following components in percentage by mass: mica sheet, oily stamp-pad ink and screen printing glaze. The manufacturing method comprises the following steps: manufacturing a flower screen, preparing the color glaze, preparing the shimmering powder, pushing the screen printing glaze and the shimmering powder, pushing the printing frit granules, firing, and sanding and polishing. The ceramic tile is hard, durable and beautiful; the shimmering powder mainly composed of mica sheet is suspended in the clear frit, and the shimmering powder is naturally dispersed to some extent; and the manufacturing method is simple and quick, can implement mass mechanical production under the condition of not greatly changing the existing equipment, is very simple to operate, and can be used for flexibly producing different design styles of ceramic tiles.

Owner:FOSHAN MAY ROSE CERAMIC

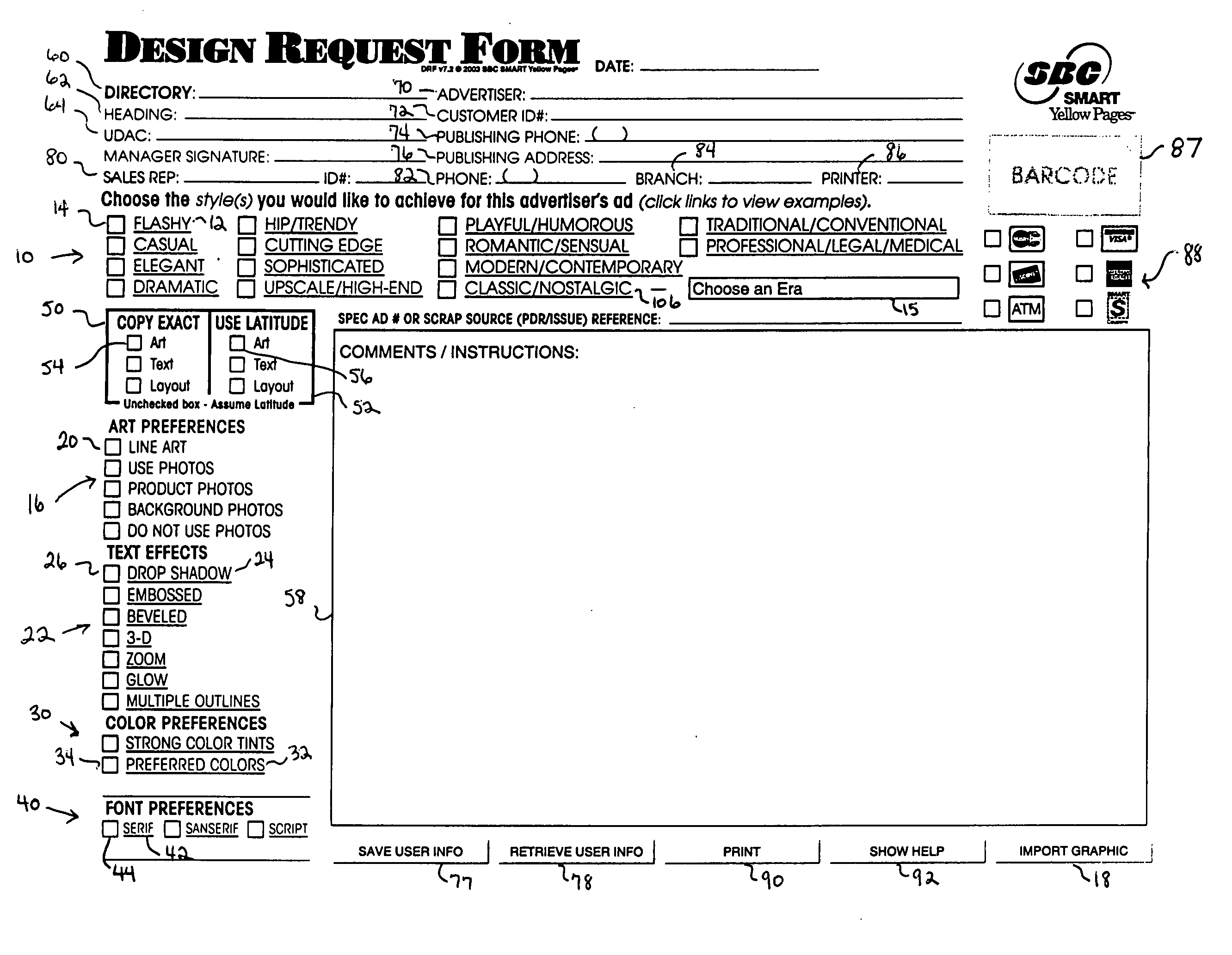

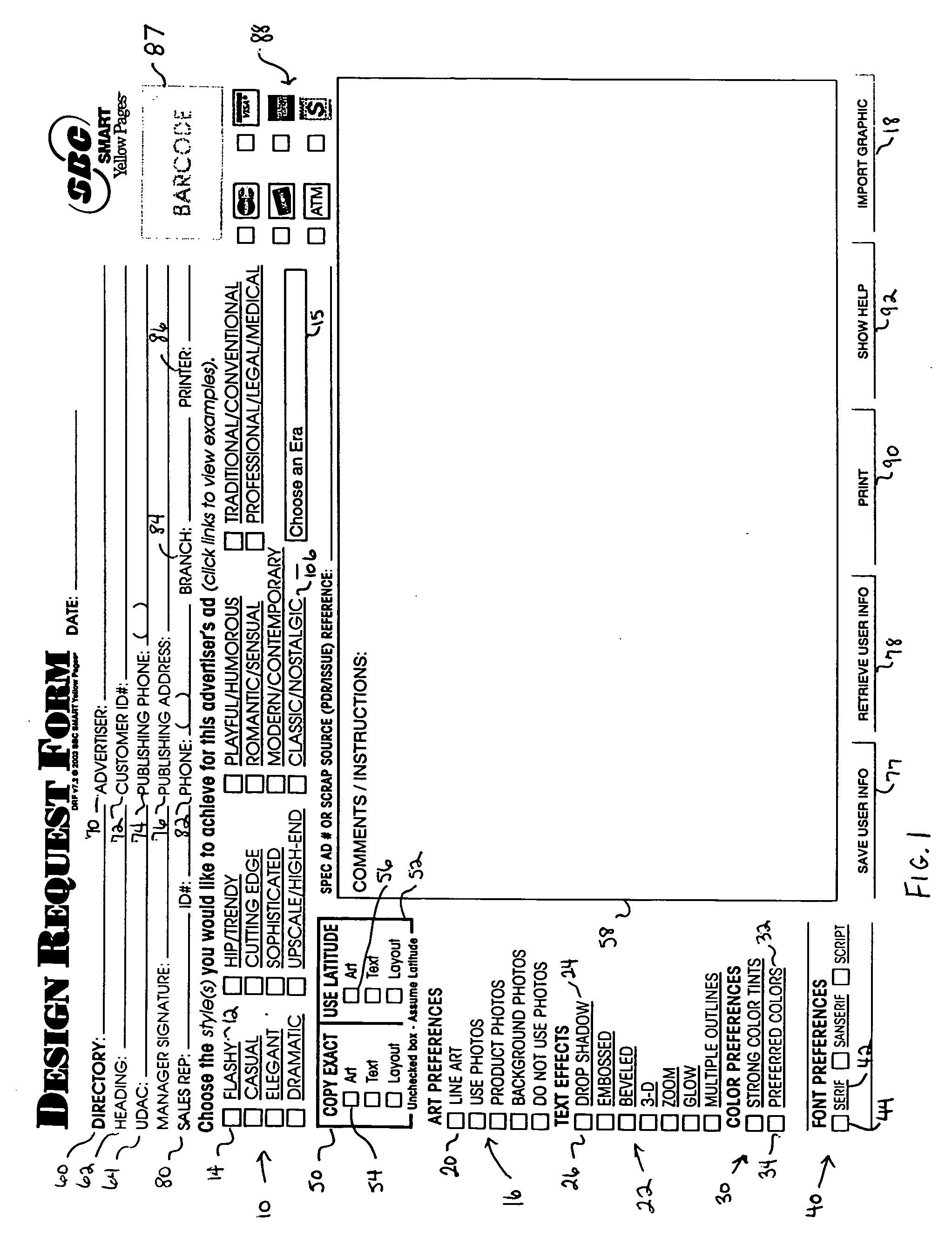

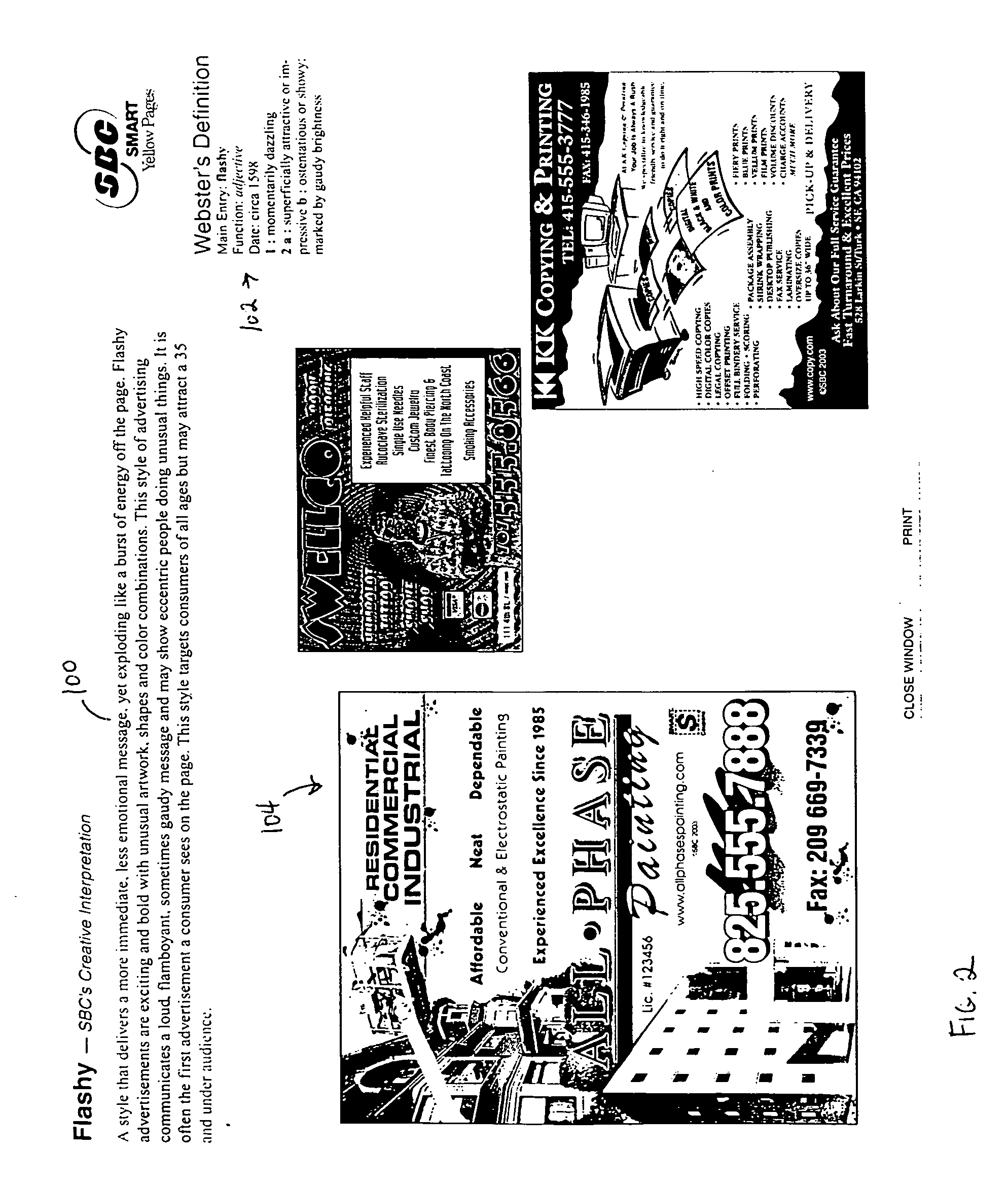

Design request form

A design request form comprises a style selection portion having a plurality of user-selectable design styles from which one or more design styles suited to a product, business or service of a potential advertiser in a telephone directory are selectable by a sales representative. The style selection portion provides a plurality of user-selectable links to a plurality of style pages for the design styles. The style pages provide visual representations of sample telephone directory advertisements having the design styles and creative interpretations of the design styles. The samples and creative interpretations are usable by a designer to design a telephone directory advertisement for the potential advertiser based on which one or more of the design styles are selected.

Owner:SBC KNOWLEDGE VENTURES LP

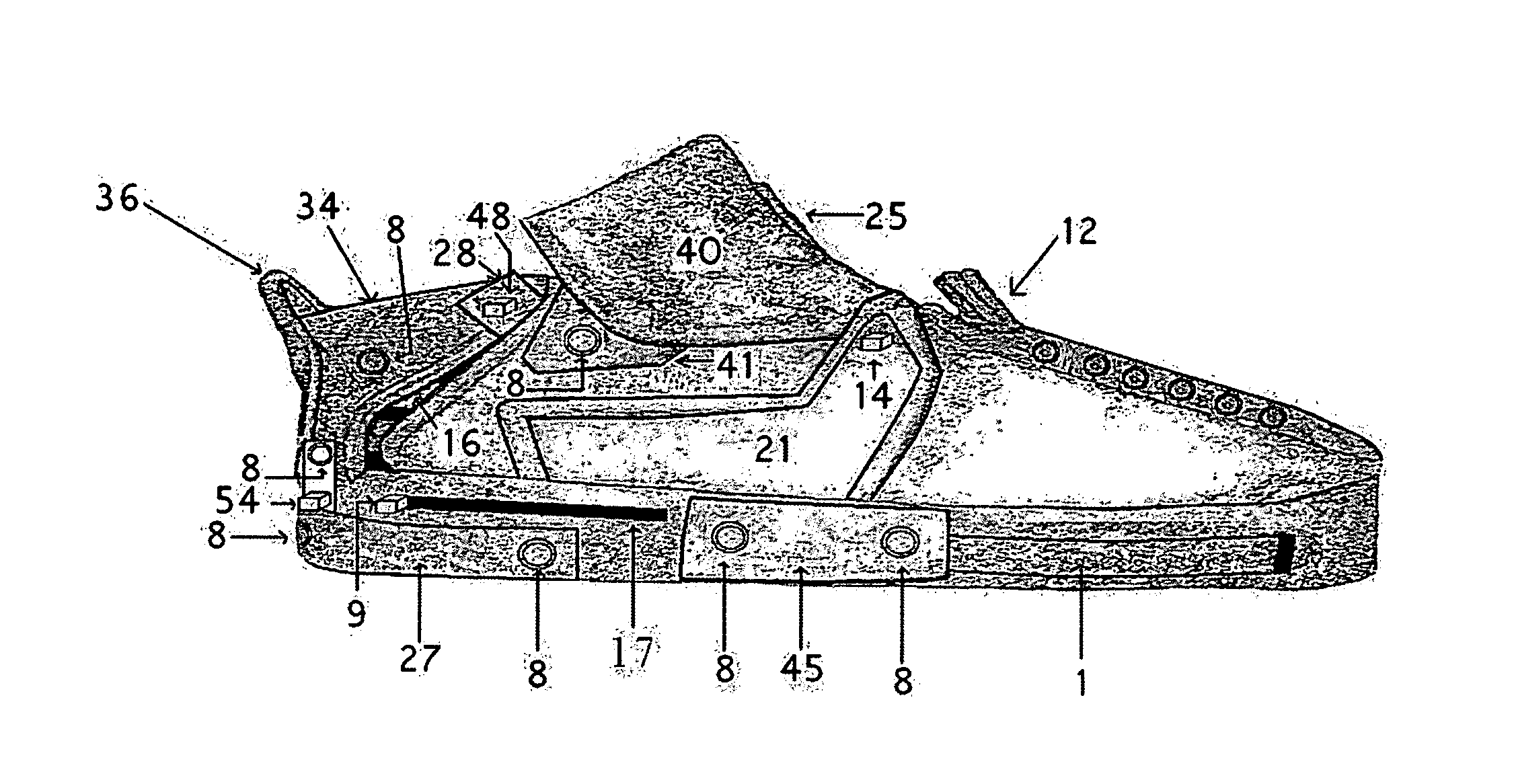

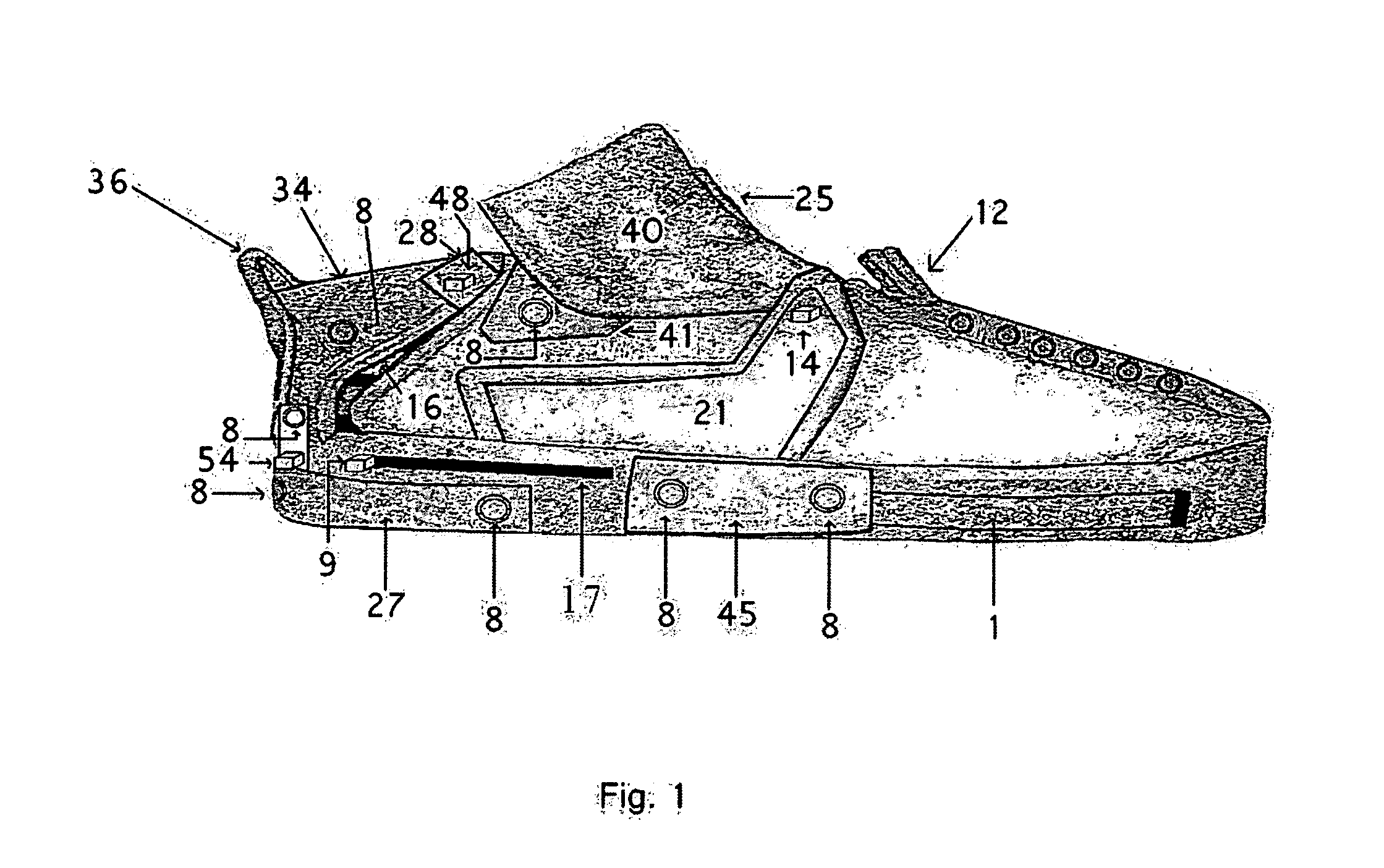

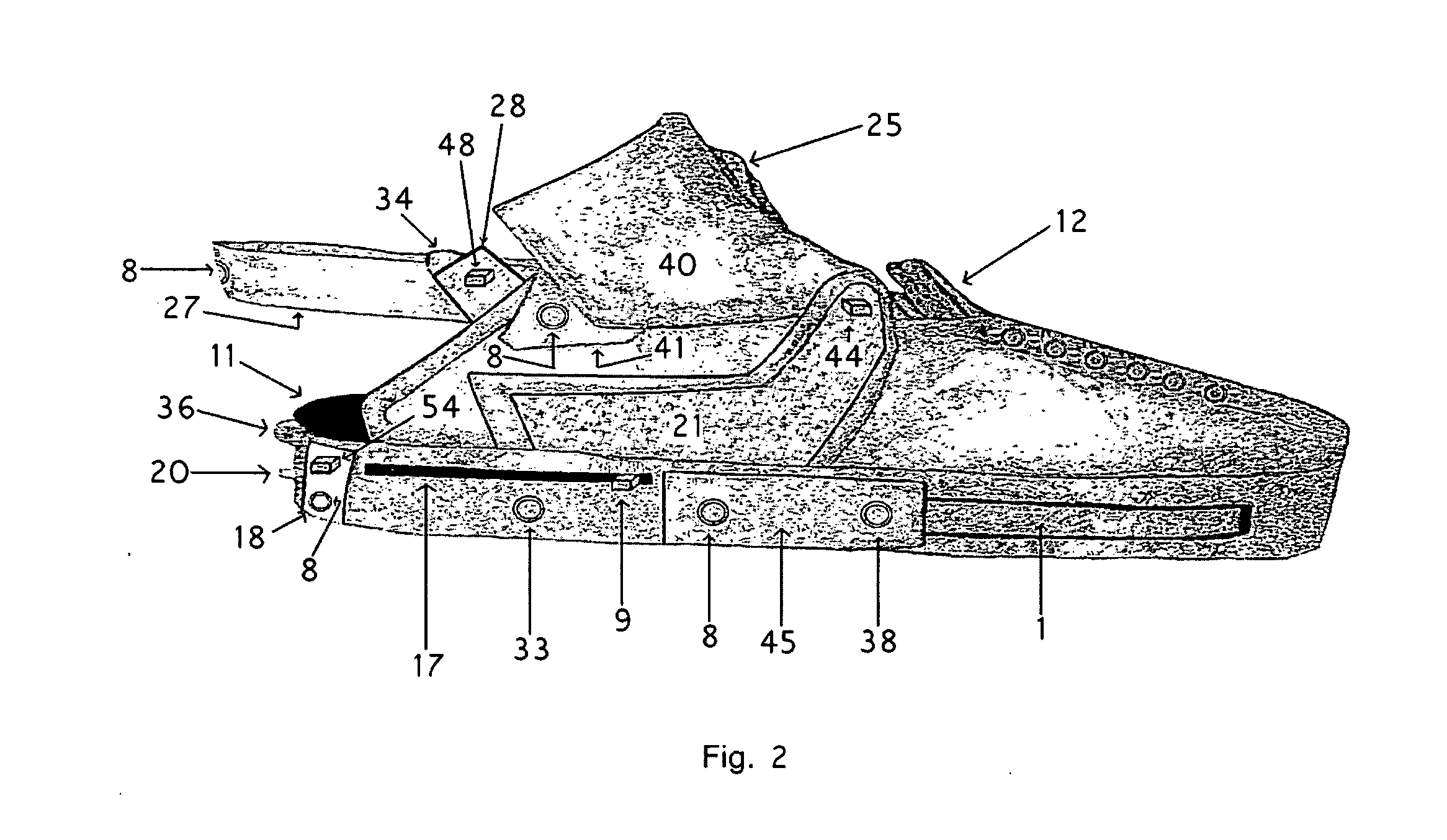

Transforming shoe with rotating, sliding; and pivoting panels

A transforming shoe that can be taken apart and reassembled to function as a multi-functional design of choice possibilities to include the arrangements of a high-top shoe; low-top shoe; panel off the back of the shoe; option of back shoe scrap to secure shoe on back; and projecting heel of shoe pivot drawers. These transforming designs are achieved by the included: (a) two rotating high top side panels that snaps to the outside of the shoe on both sides; (b) a sliding back tongue of shoe that slides along an open rectangular opening in heel of shoe with and end piece stopper attachment; for which, also have the included attachment means to attach to complimentary snap member components on the rotating posterior panels; (c) two rotating posterior panels (d) attachment means such as velcro, snaps, and rods with circular, snap, and square end-pieces. The assembly of the different shoe attachments allows the user to attach one portion of the shoe to another to achieve a multiple of arrangements of shoe design style. This transforming shoe allows the user to switch from one style to another.

Owner:CAMPBELL SHIRLENE ANDREA

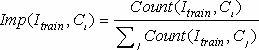

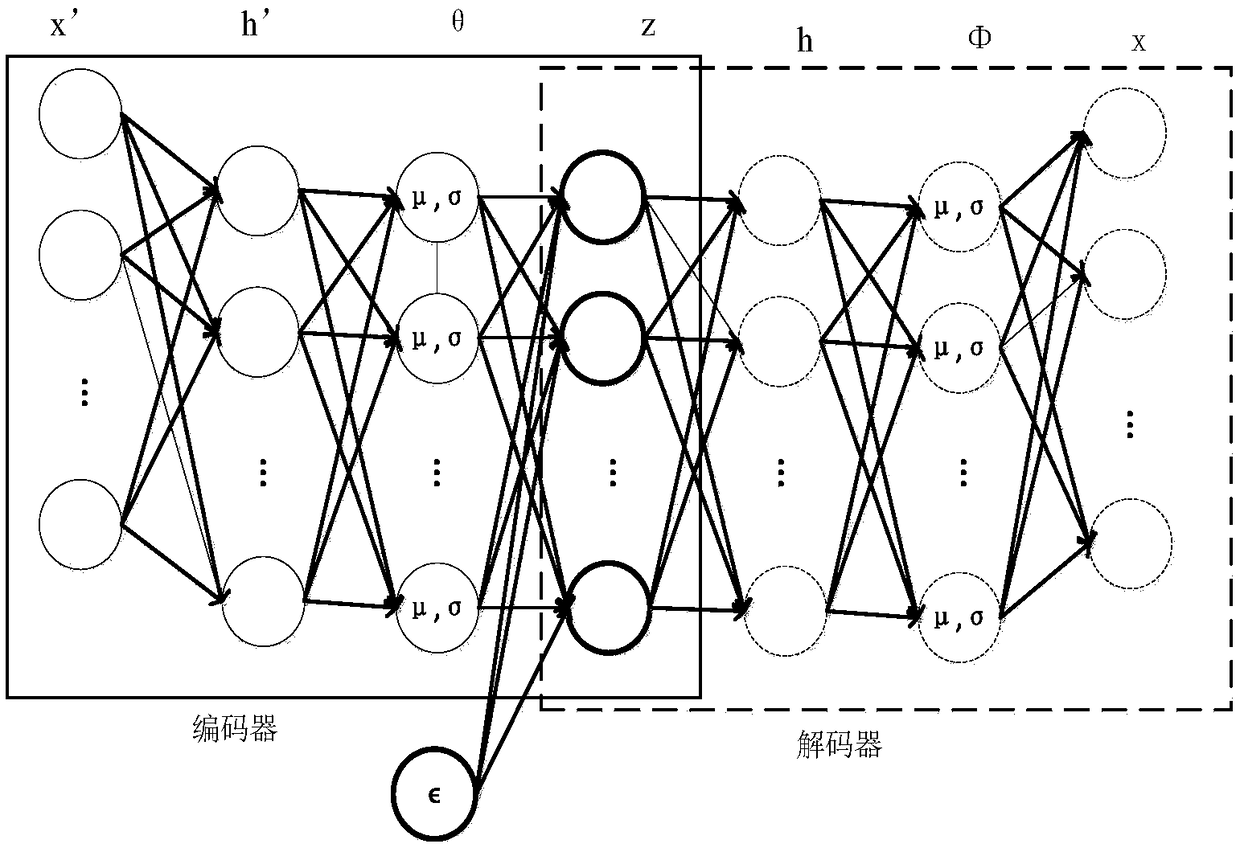

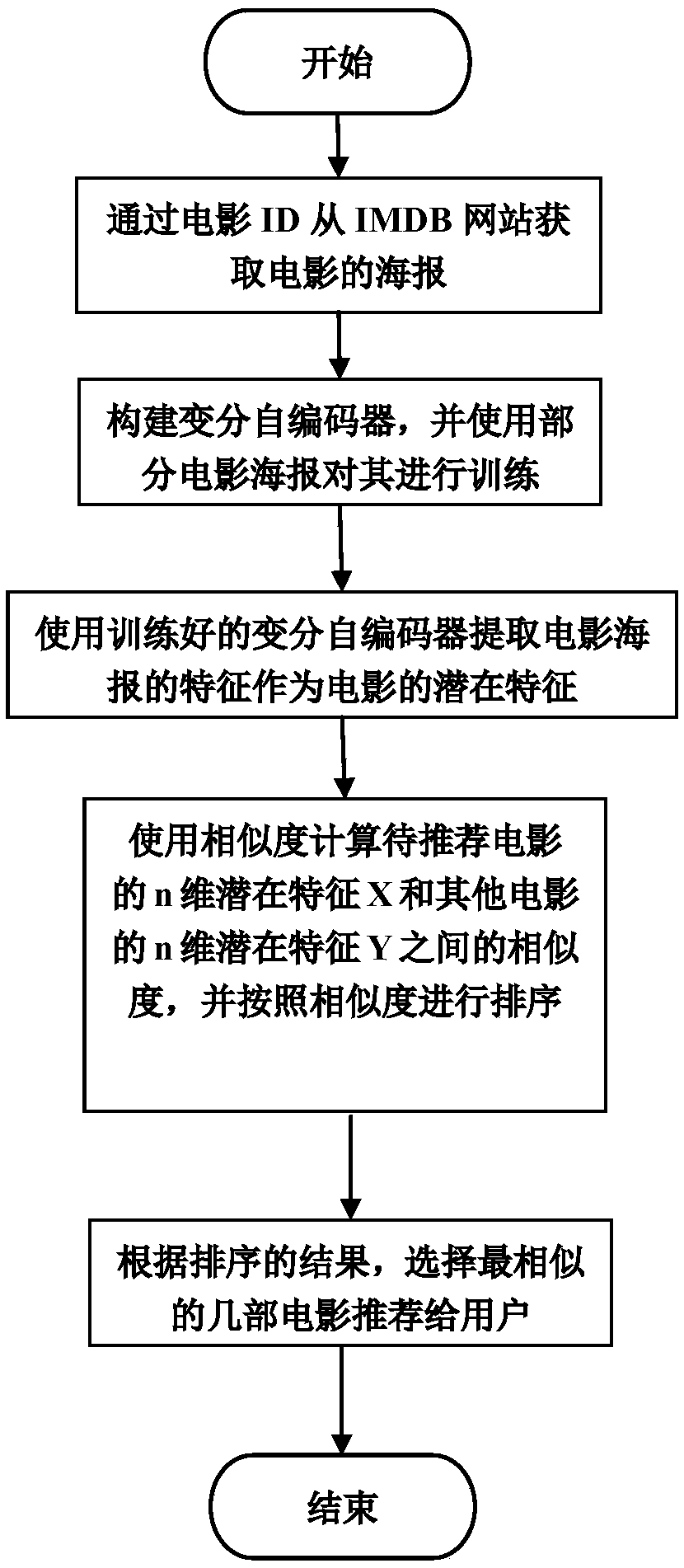

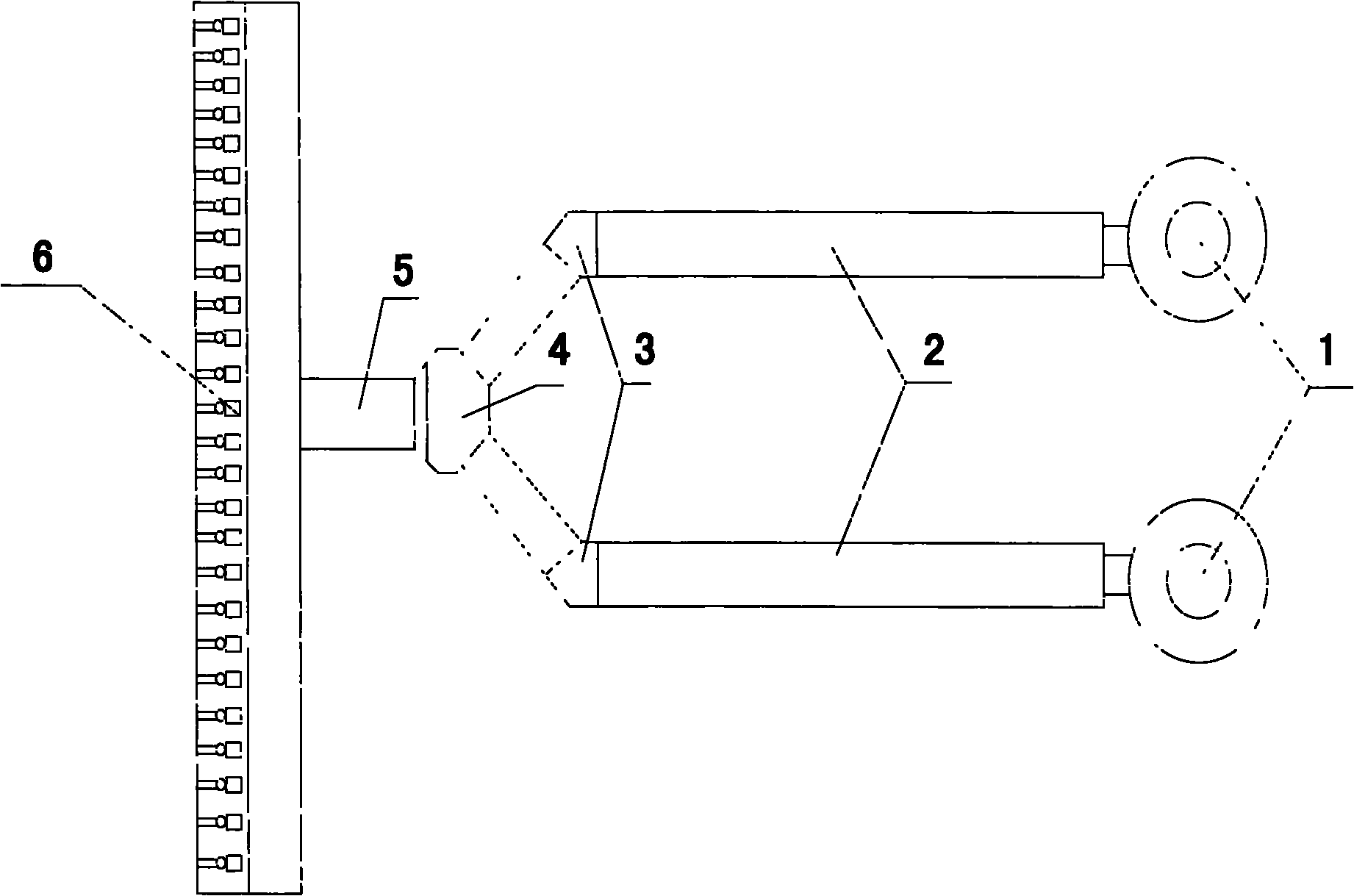

Film recommendation method

ActiveCN109034953ARecommended fastSolve the cold start problemBuying/selling/leasing transactionsNeural architecturesFeature vectorCosine similarity

The invention discloses a film recommendation method, belonging to the technical field of recommendation systems. First of all, the same type of films have similar characteristics in poster design style; therefore, it is necessary to obtain the information of the film-related posters; in the process of feature extraction of these movie posters by variational self-coding, the extracted posters areused as the potential feature vector of the movie, and the similarity between films is calculated by the cosine similarity according to the potential feature vector of the movie, and then the films are ranked according to the similarity, and finally the most similar films are selected as the recommendation results to the users. This method has low complexity and has no disadvantages of sparse andcold start in traditional collaborative filtering recommendation method. The method is mainly used in movie recommendation.

Owner:SOUTHWEST JIAOTONG UNIV

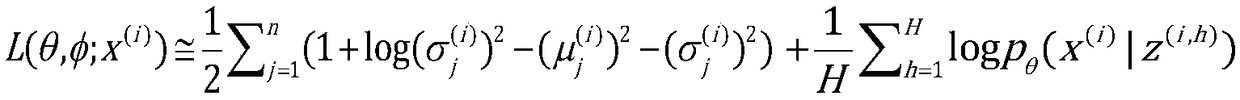

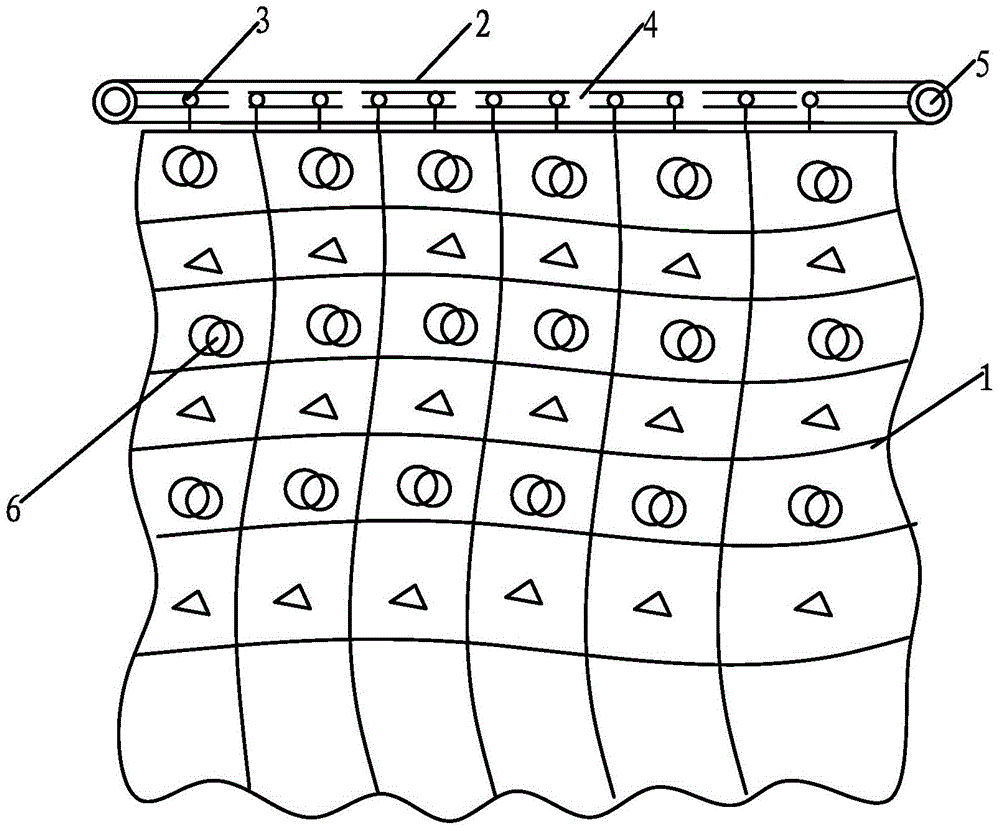

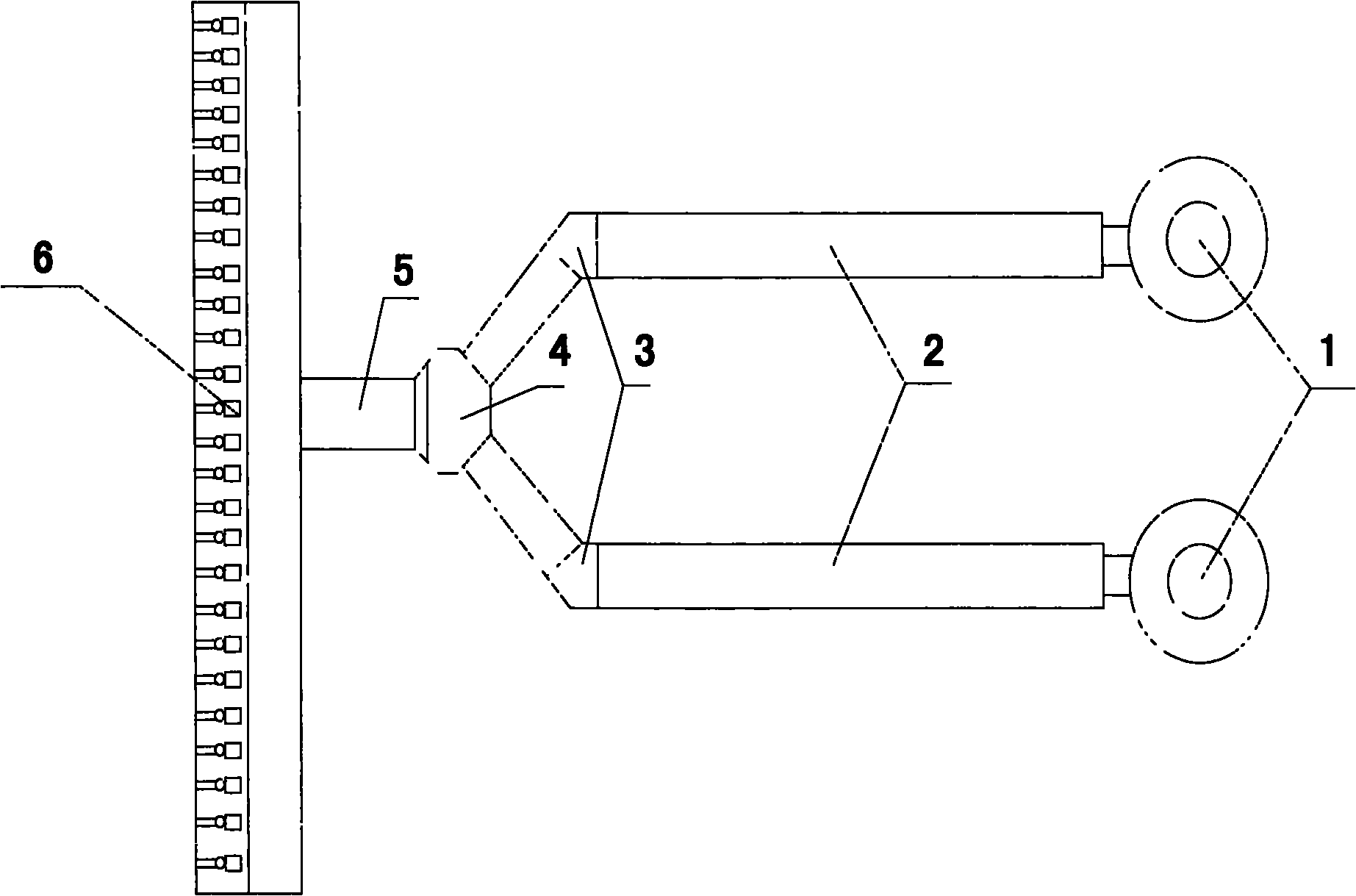

Digital technology based weaving and printing combined design style curtain and manufacturing method thereof

InactiveCN104921580ASoft textureHigh glossSynthetic resin layered productsCurtain rodsPolyesterEngineering

The invention provides a digital technology based weaving and printing combined design style curtain and a manufacturing method thereof and belongs to the technical field of the light and textile industry. The problem that the existing curtain is limited to materials, low in stereoscopic impression, unclear in layer, unobvious in jacquard effect and the like is solved. The digital technology based weaving and printing combined design style curtain comprises a curtain body and a fixing pole located at the top of the curtain body, the top of the curtain body is connected with sliding rings, a guide rail is arranged in the fixing pole, the sliding rings are embedded in the guide rail to form sliding connection, fixing holes are arranged in two ends of the fixing rod, the curtain body comprises a jacquard layer, a shade layer and a support layer, the jacquard layer is a jacquard fabric formed by interweaving of warps and wefts, concave-convex patterns made by digital jacquard and digital positioning printing technologies are distributed on the jacquard fabric, the shade layer is polyester shade cloth, and the support layer is a cellular adhesive layer.

Owner:ZHEJIANG HEXIN TEXTILE

Method for preparing ultra-wide aluminium-plastic composite panel and special devices thereof

The invention discloses a method for preparing an ultra-wide aluminium-plastic composite panel and special devices thereof. The method comprises the followings steps: adopting at least two single screw extrusion machines to simultaneously provide uniform materials for a T-shaped die head; extruding plastic panels in the T-shaped die head; and under the conditions of heating and pressurizing, compositing the plastic panels with upper and lower aluminium coils, thus obtaining the ultra-wide aluminium-plastic composite panel. The special devices comprise at least two single screw extrusion machines, the material outlets of the single screw extrusion machines are converged in the same charging barrel, and the charging barrel is communicated with the T-shaped die head. The ultra-wide aluminium-plastic composite panel (with a width of 1600 to 2000mm) produced by the method of meets the design requirements for large span and large breadth, and embodies an unique design style; meanwhile, the method provided by the invention has the advantages of facilitating the cutting of the panels in various specifications, reducing the waste of odd bits, saving the auxiliary materials such as keels and the like, saving the installation costs, and greatly reducing the possibility of water seepage between the panels.

Owner:JIANGSU PIVOT NEW DECORATIVE MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com