3D cutting method

A 3D and 1.3D technology, applied in the field of fabric processing and forming, can solve problems such as poor product quality stability, lack of standardized standards, and long production time, so as to avoid incomplete cutting and facilitate accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

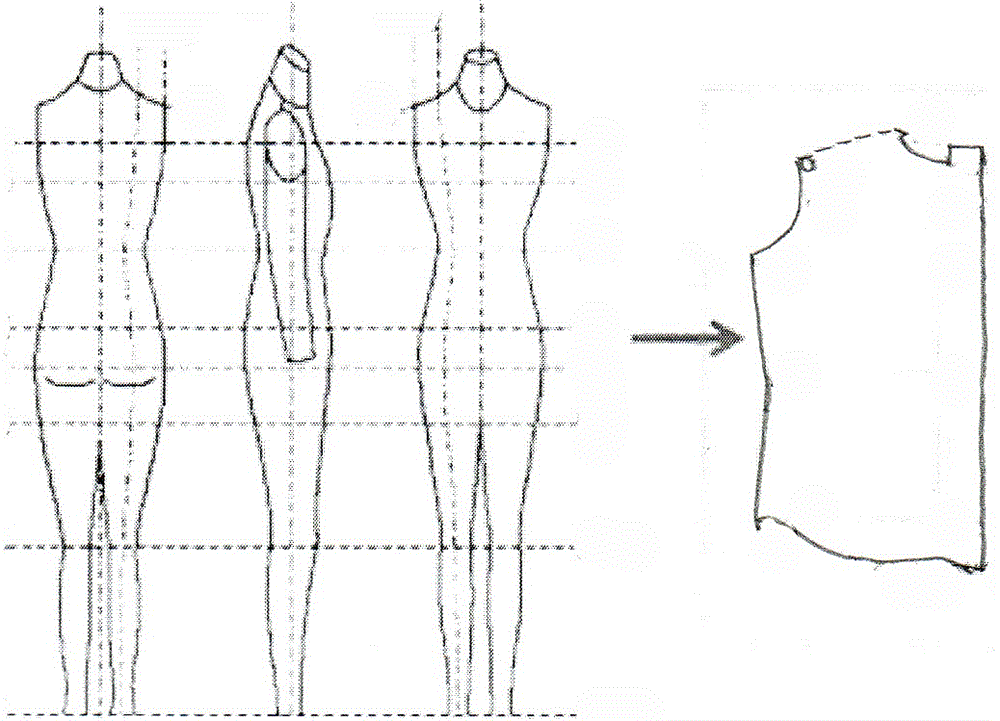

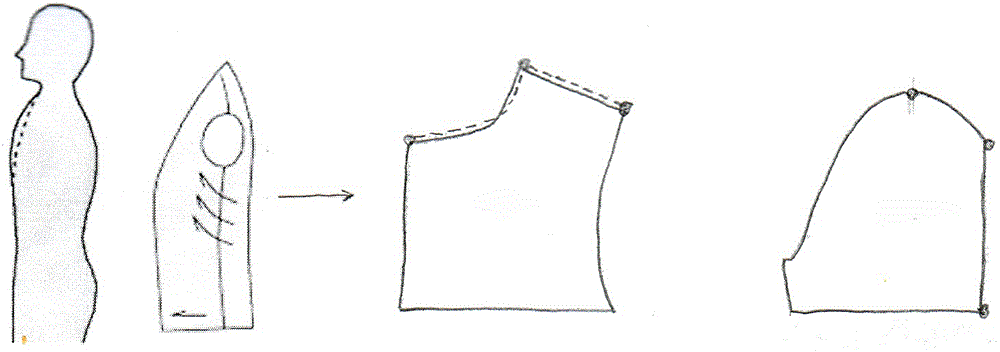

[0037] In this embodiment, a 3D cutting method is composed of measurement, style design, plate shape generation, coding, automatic cutting, and fine cutting. The measurement is in the form of photographing or scanning, and the measured three-dimensional size is fed back in the form of data. According to the data, the size, fabric and accessories are selected to complete the style design; the designed style is transformed into a pattern, typesetting and determining the materials used; the materials, pattern making and typesetting data are generated and coded, and sent to the automatic Cutting is done at the cutting system.

[0038] Among them, the measurement is carried out by using a 3D scanner to obtain a complete 1:1 3D model of the human body, and complete the automatic extraction of several key dimensions of the human body, and output the anthropometric data. Compared with traditional manual measurement, it has unparalleled advantages in data integrity and reusability, and...

Embodiment 2

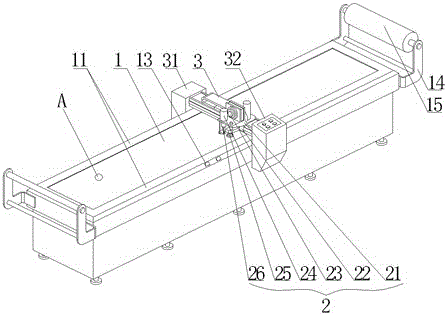

[0049] The setting and working principle of this embodiment and embodiment 1 are the same, the difference is that in the automatic cutting system, a side beam 11 is arranged on the periphery of the workbench 1, and the track frame 31 is erected on the side beam 11 in its length direction, and is controlled by the controller. Under the drive of 32, move back and forth along side beam 11; Side beam 11 two ends are provided with support 14, and support 14 is provided with film roll 15, is used for laying film for workbench 1. The laying of the film separates the workbench 2 from the fabric to be treated, especially when the workbench 1 is a flexible workbench, when the blade 26 of the cutting head 2 cuts downward, the film is cut open, and the cut part The pressure difference is formed between the gaps between the columns 12 and other positions, and the film is absorbed and compacted instantly. The setting of the film not only increases the friction between the fabric and the work...

Embodiment 3

[0051] The setting and working principle of this embodiment are the same as that of Embodiment 1, the difference is that in the automatic cutting system, a flattening sheet 27 is set on the blade 26, which is used to flatten the cutting position and avoid miscutting caused by uneven fabric surface or wrong cutting; the knife rest 21 is provided with a smoothing piece 28 for pre-leveling the fabric; the card slot 22 is provided with a load-bearing piece 29, which is used to balance the force of the entire knife Unilateral emphasis. Wherein, flattening sheet 27, smoothing sheet 28, load-bearing sheet 29 all can adopt iron sheet, stainless steel sheet etc., especially flattening sheet 27, smoothing sheet 28, its lower bottom surface is flat and smooth structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com