Patents

Literature

40results about How to "Avoid incomplete cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

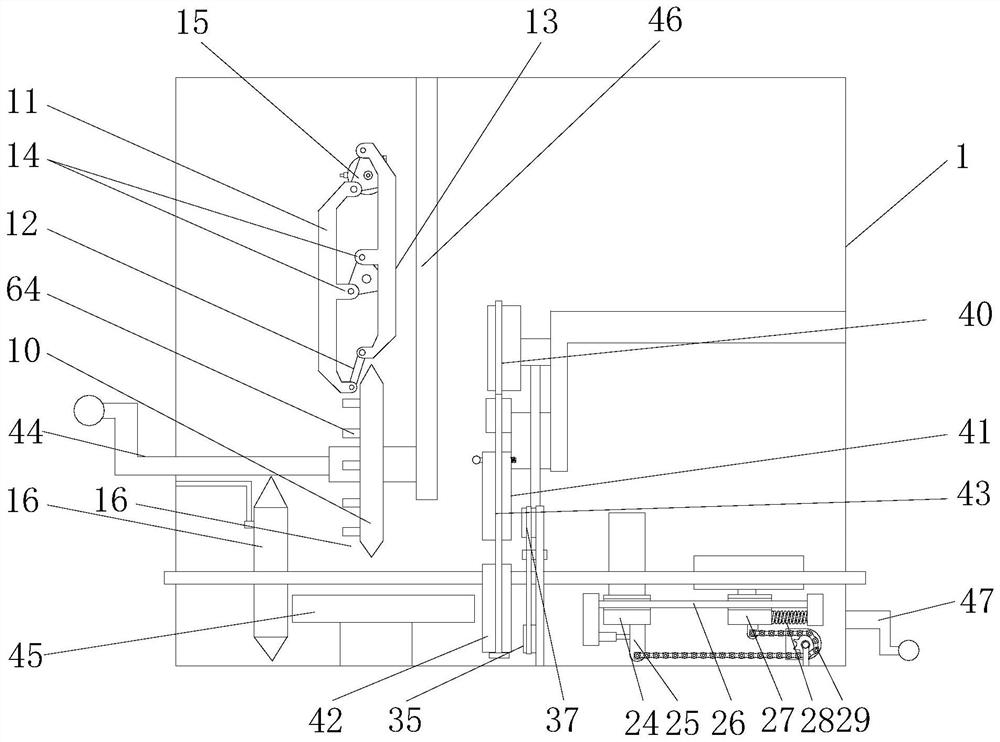

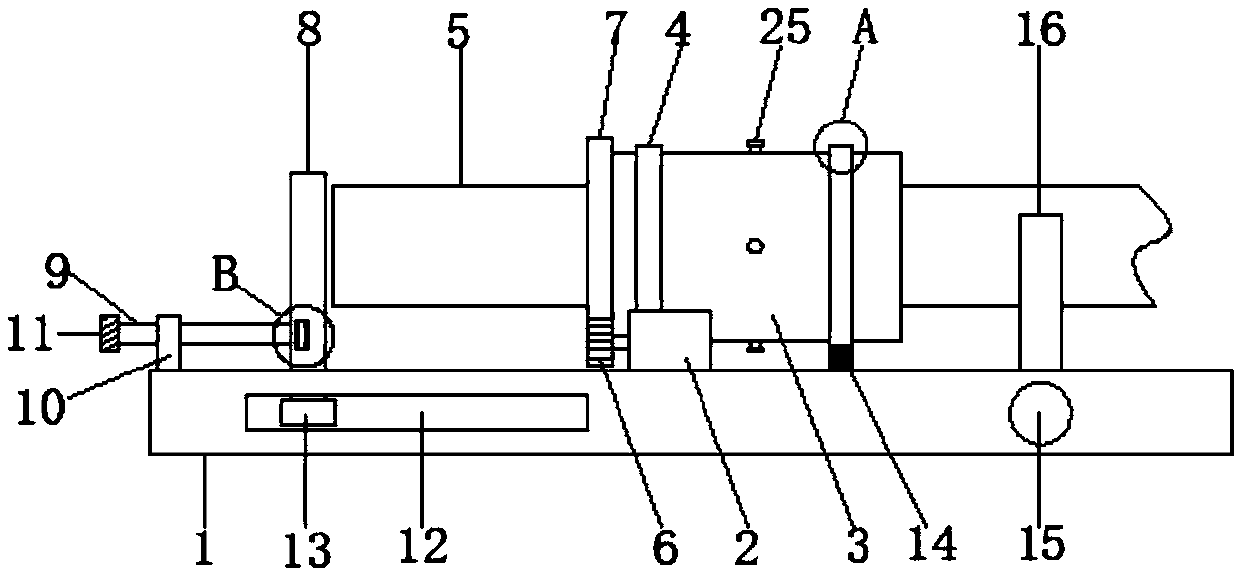

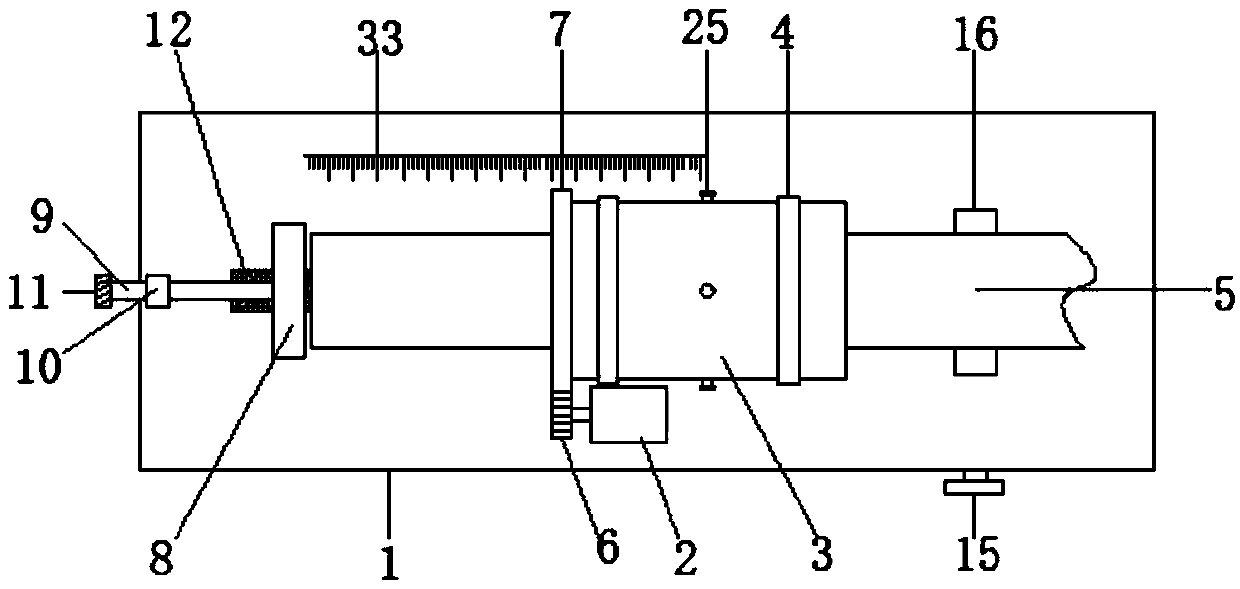

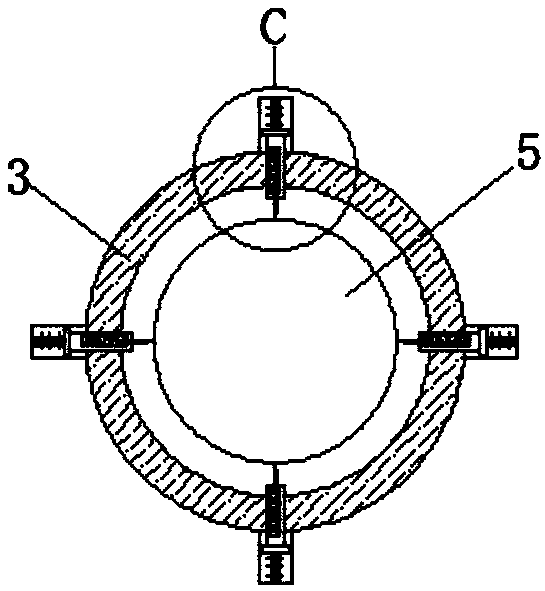

Live pig hanging automatic processing system

ActiveCN109452341APlay a role in the separationAvoid incomplete cuttingSplitting instrumentsSlaughterhouse arrangementsThoracic structureEngineering

The present invention relates to a live pig hanging automatic processing system. The live pig hanging automatic processing system comprises a supporting bottom plate, a cutting plate, a guiding plateand a stablizing device, the cutting plate is arranged on a top part of a right end of the supporting bottom plate, the fixing device is arranged on a top part of the cutting plate, a left end of thecutting plate is connected with a right end of the guiding plate, and a left end of the guiding plate is arranged on a top part of a left end of the supporting bottom plate; and the stablizing devicecomprises a stabilizing bracket, a positioning telescopic body, a positioning spring, positioning push rods, a positioning connecting plate, positioning wheels, an external support mechanism, an extrusion mechanism and a separation guide block. The live pig hanging automatic processing system can solve problems that during live pig half cutting, many people are needed to assist cutting of the livepigs, the live pig half cutting has risks, the live pig half cutting is uneven, the live pig half cutting cuts thoracic cavity of the live pigs and causes waste, the live pig cutting is incomplete, and can achieve functions of positioning conveying and pressing cutting of the live pigs.

Owner:XIAMEN YINXIANG GROUP

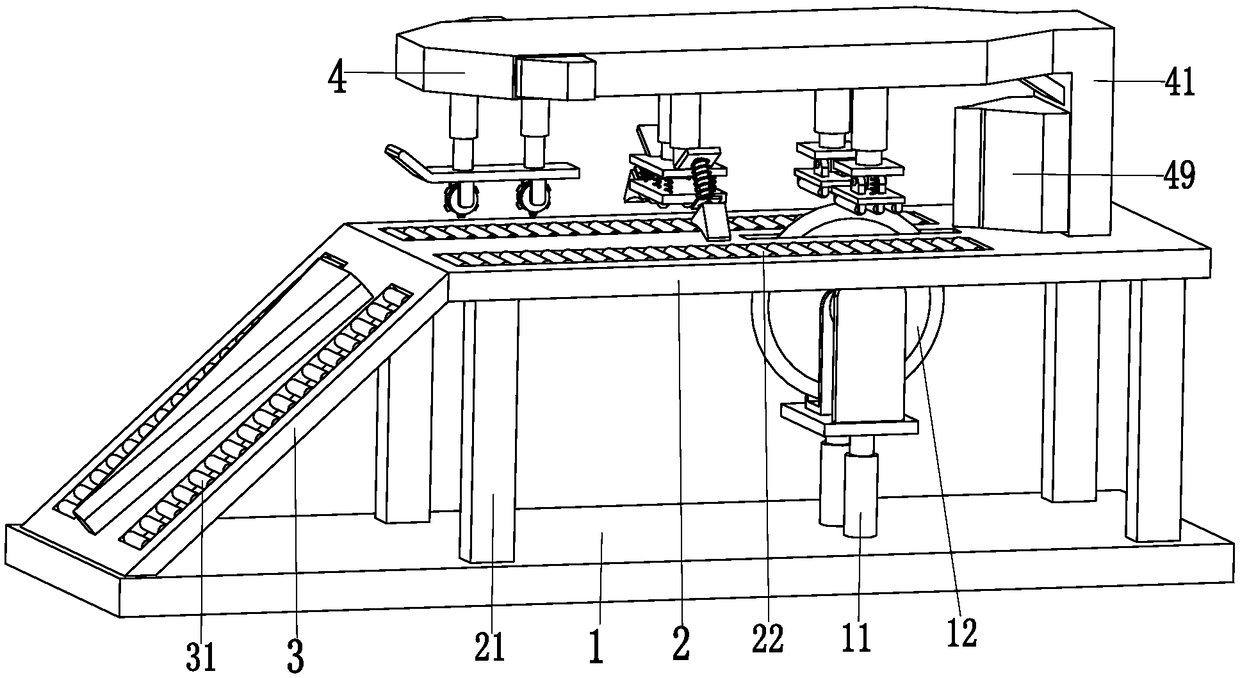

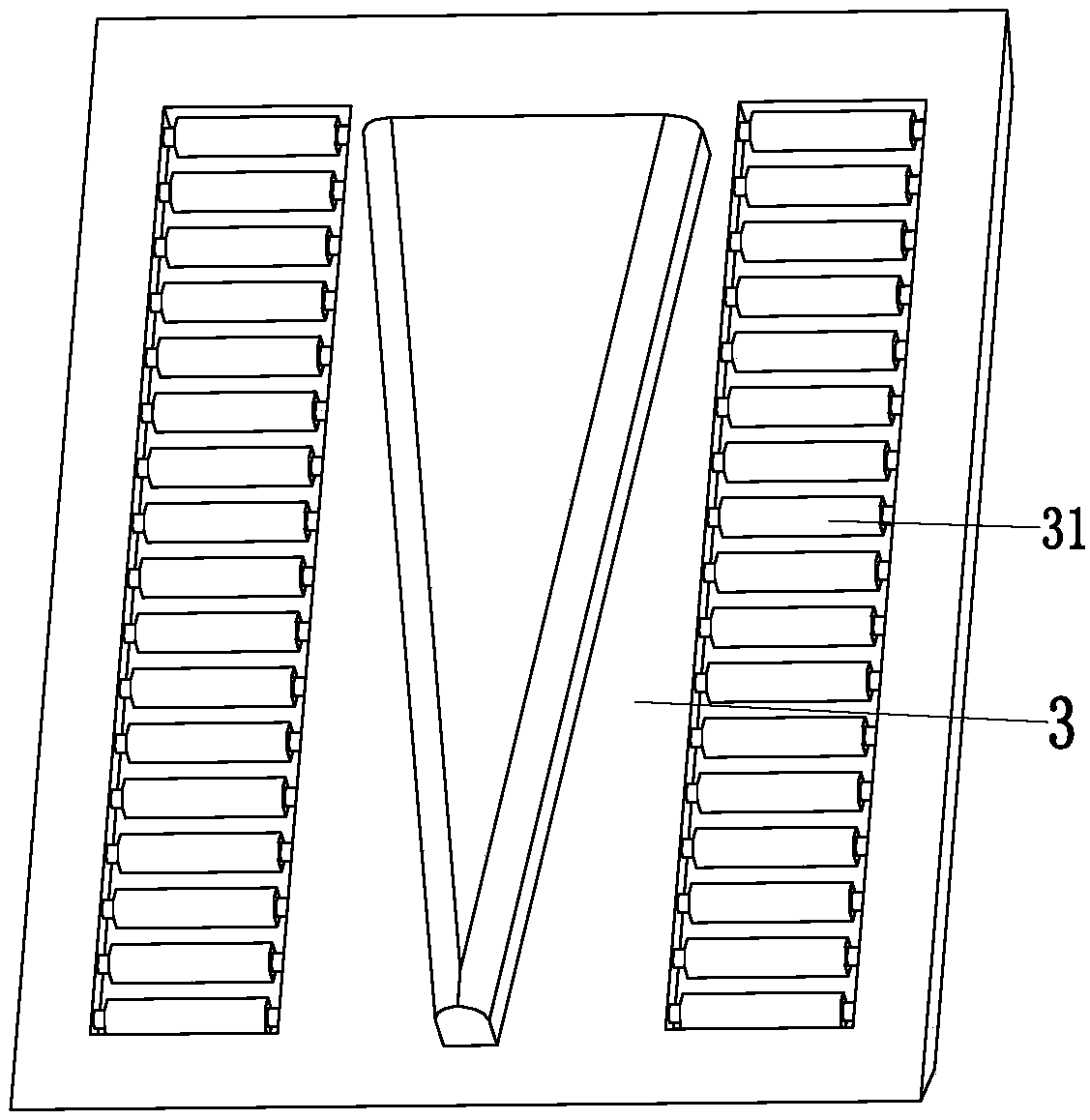

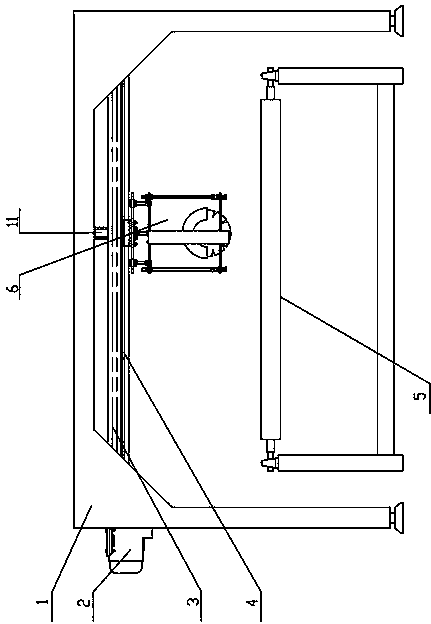

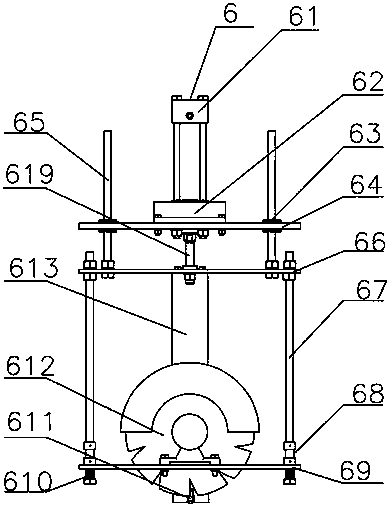

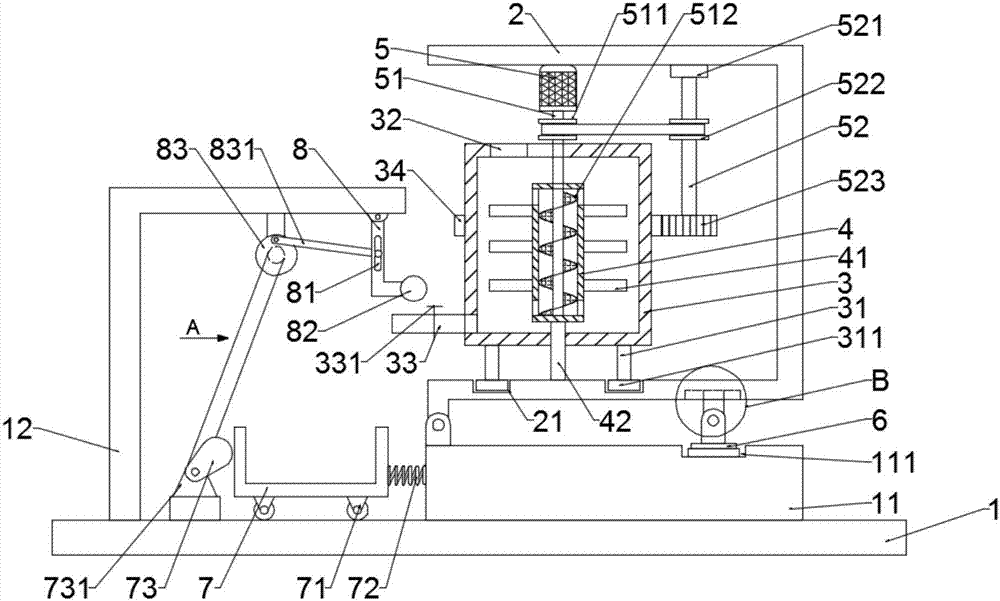

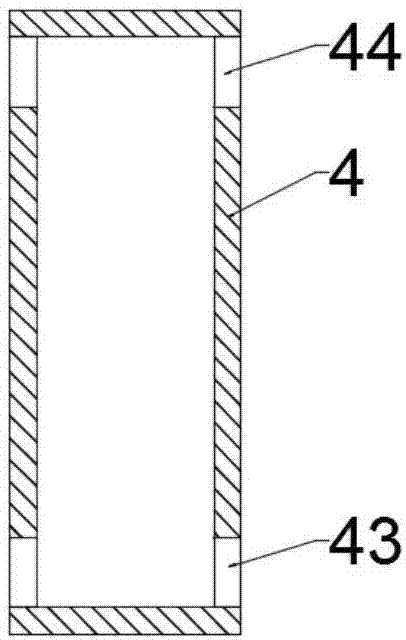

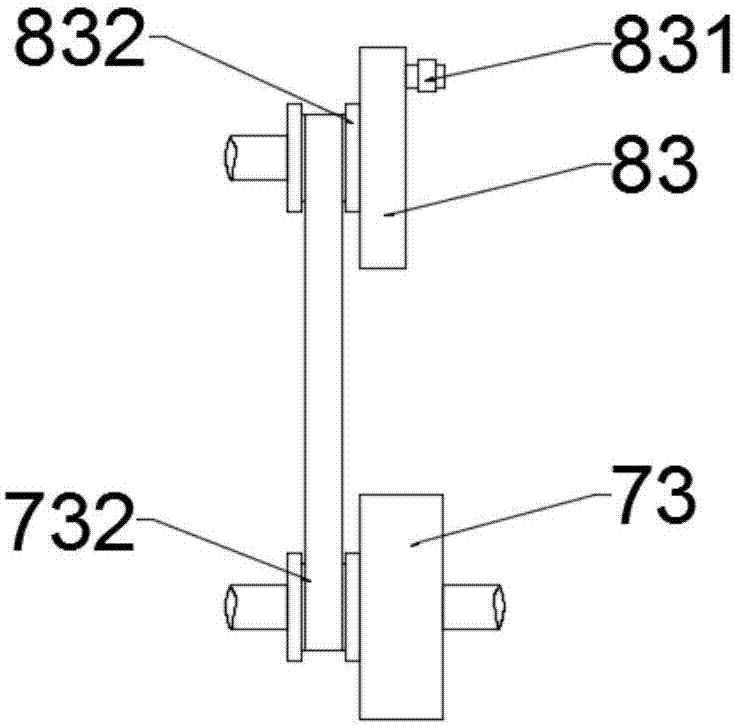

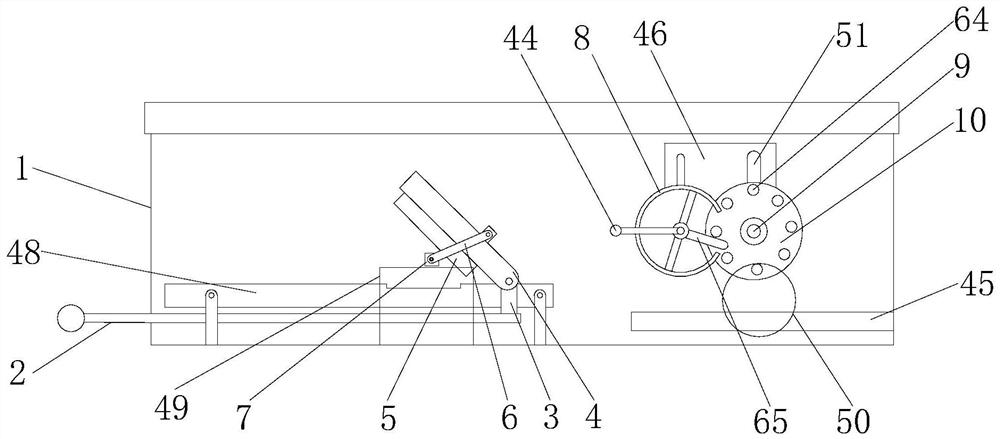

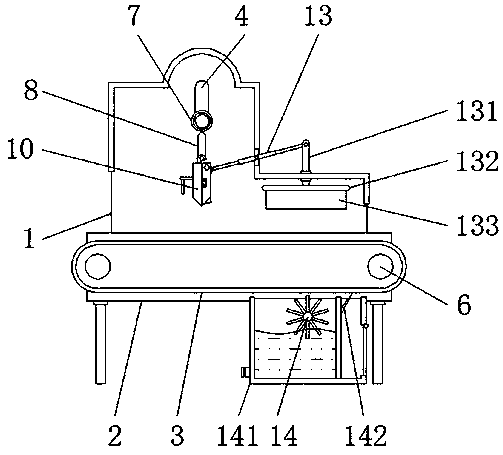

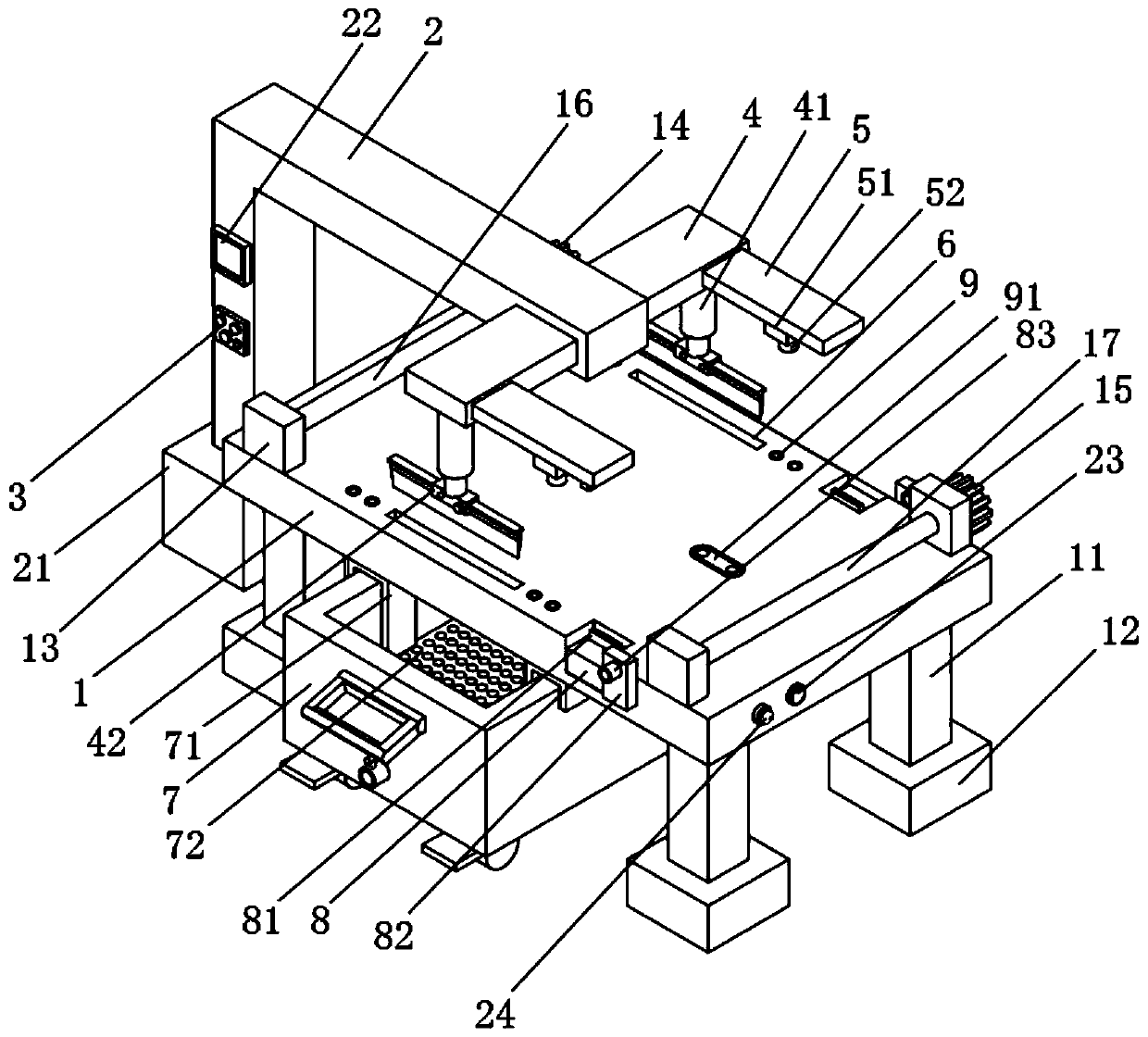

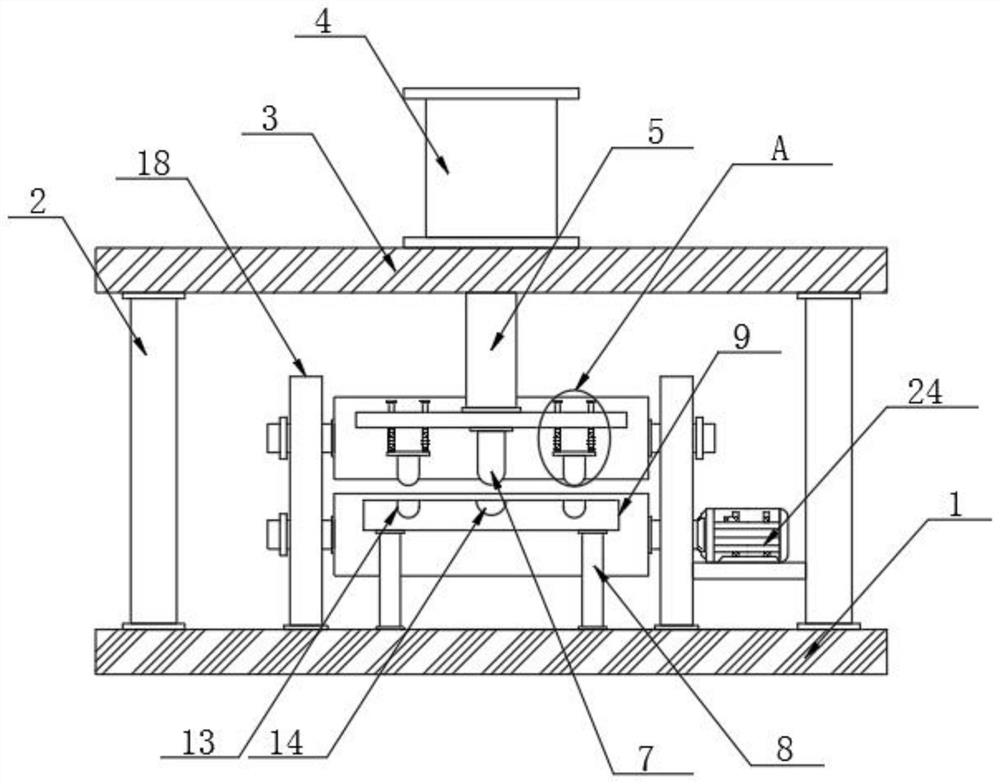

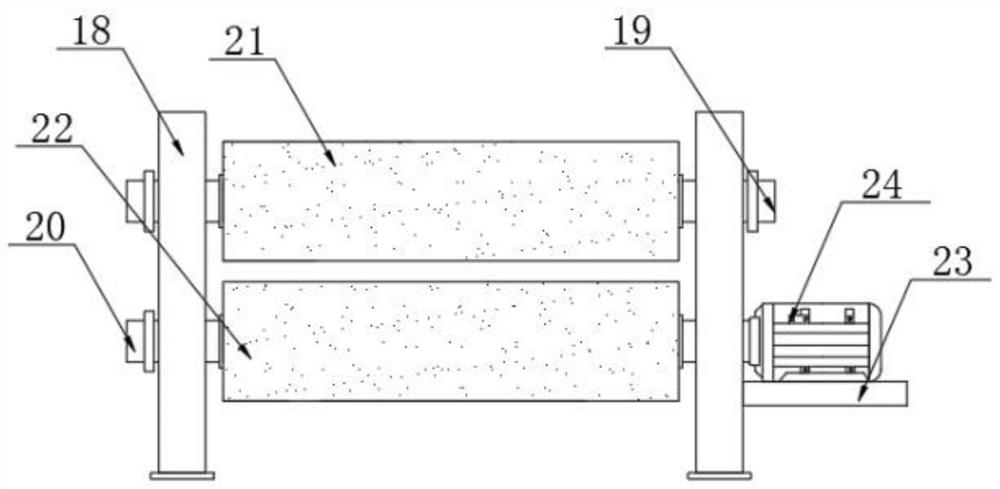

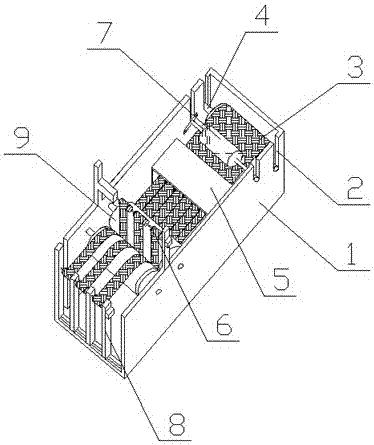

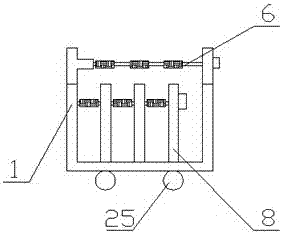

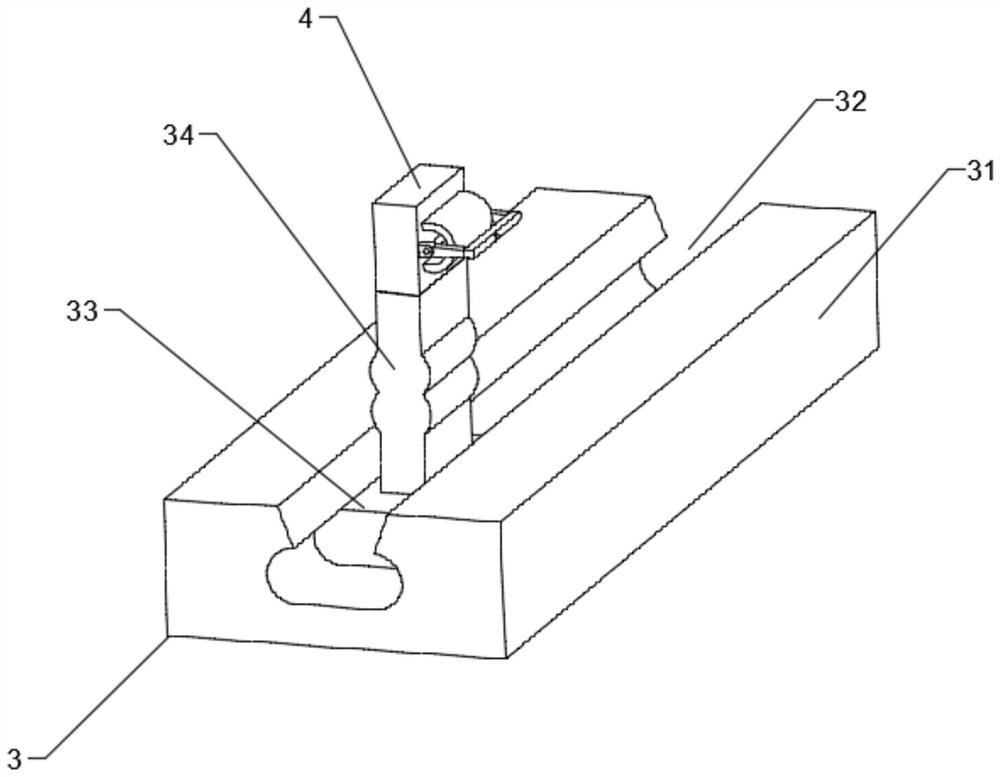

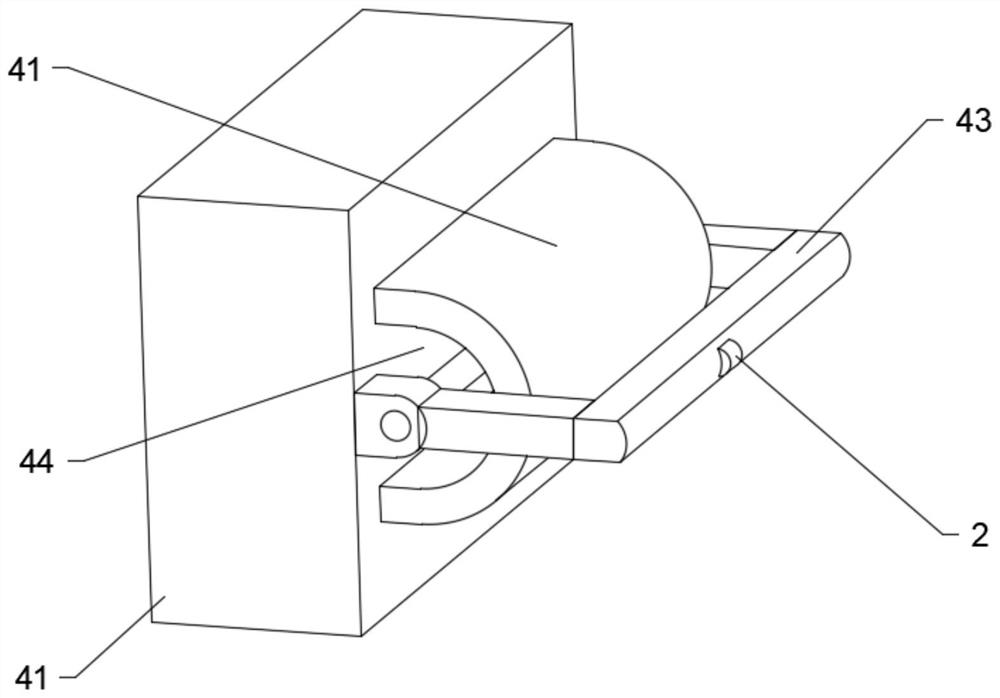

Full-automatic machine for cutting plates

InactiveCN103786263ASmall sizeFast and smooth cuttingStone-like material working toolsEngineeringActuator

The invention discloses a full-automatic machine for cutting plates. The full-automatic machine for cutting plates comprises a machine body, a feeding device, a cutting device, a detecting and adjusting device and a conveying belt, wherein the feeding device, the cutting device, the detecting and adjusting device and the conveying belt are all arranged in the machine body. The feeding device is arranged on the top of the machine body, the cutting device is arranged at the lower end of the feeding device, the detecting and adjusting device is arranged on the cutting device, and the conveying belt is arranged at the bottom of the machine body; the feeding device comprises a transverse nut screw rod moving pair, a longitudinal nut screw rod moving pair, a transverse driving motor, a longitudinal driving motor, a moving support and two guide rails; the cutting device comprises an upper support for cutting, a plurality of air cylinders, two sliders, a lower support for cutting, a mounting plate for cutting, an electric saw and an electric saw driving motor; the detecting and adjusting device comprises a cantilever support, an industrial camera and a plurality of micro-displacement actuators. With the full-automatic machine for cutting plates, plates with any size can be cut at a time, the full-automatic machine for cutting plates is convenient to operate and high in efficiency, and the abrasion loss of the electric saw can be compensated for in real time.

Owner:JIANGSU UNIV OF SCI & TECH

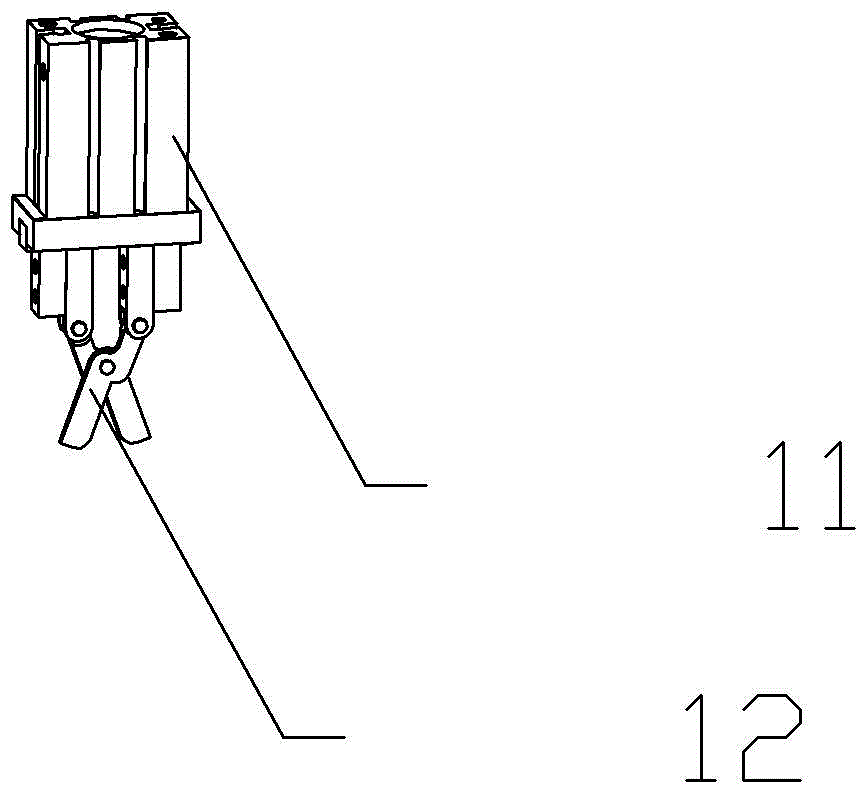

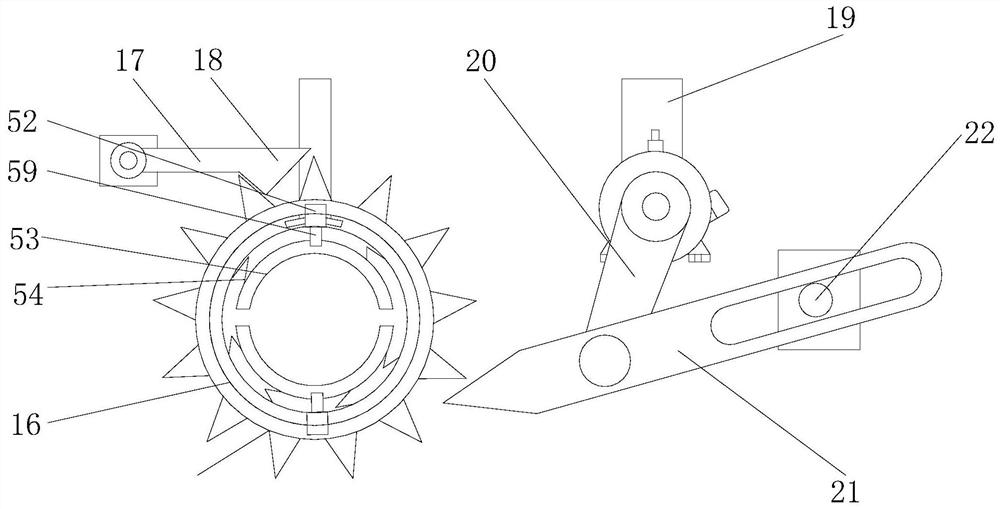

Mechanical hand for harvesting tea

ActiveCN105210556AIncrease tea productionPossess practical promotionPicking devicesManipulatorAerospace engineering

Owner:重庆市乾丰茶业有限责任公司

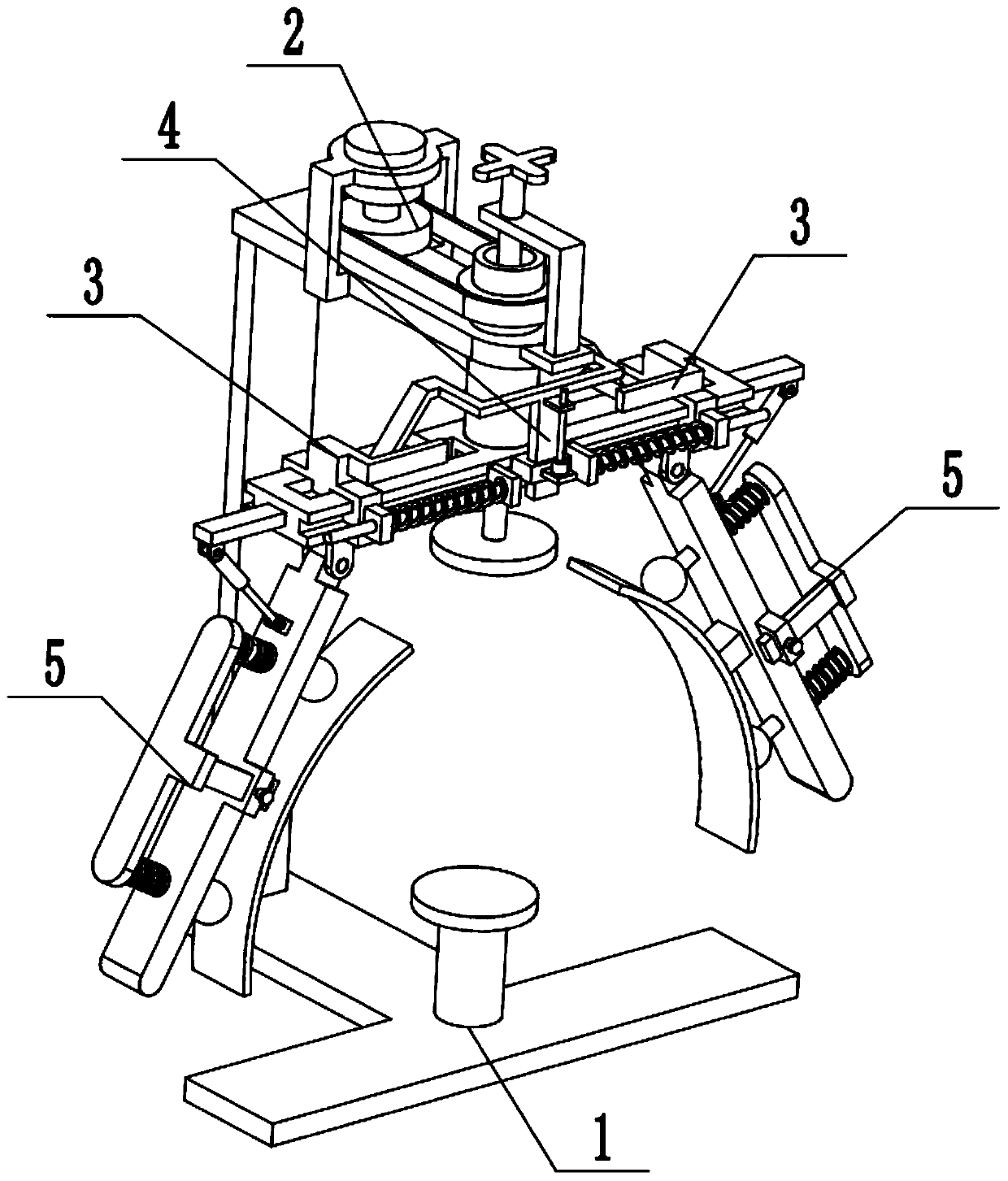

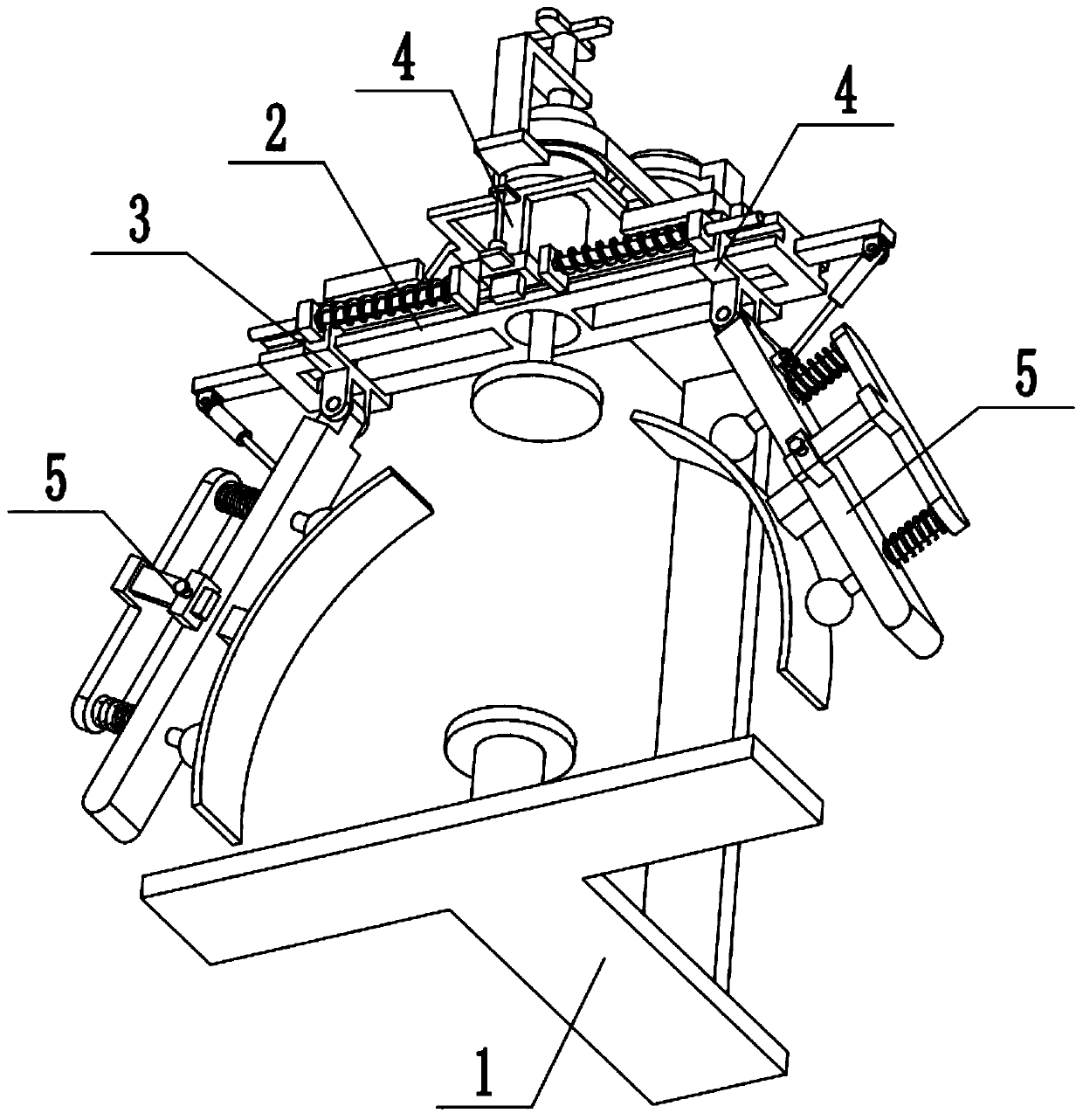

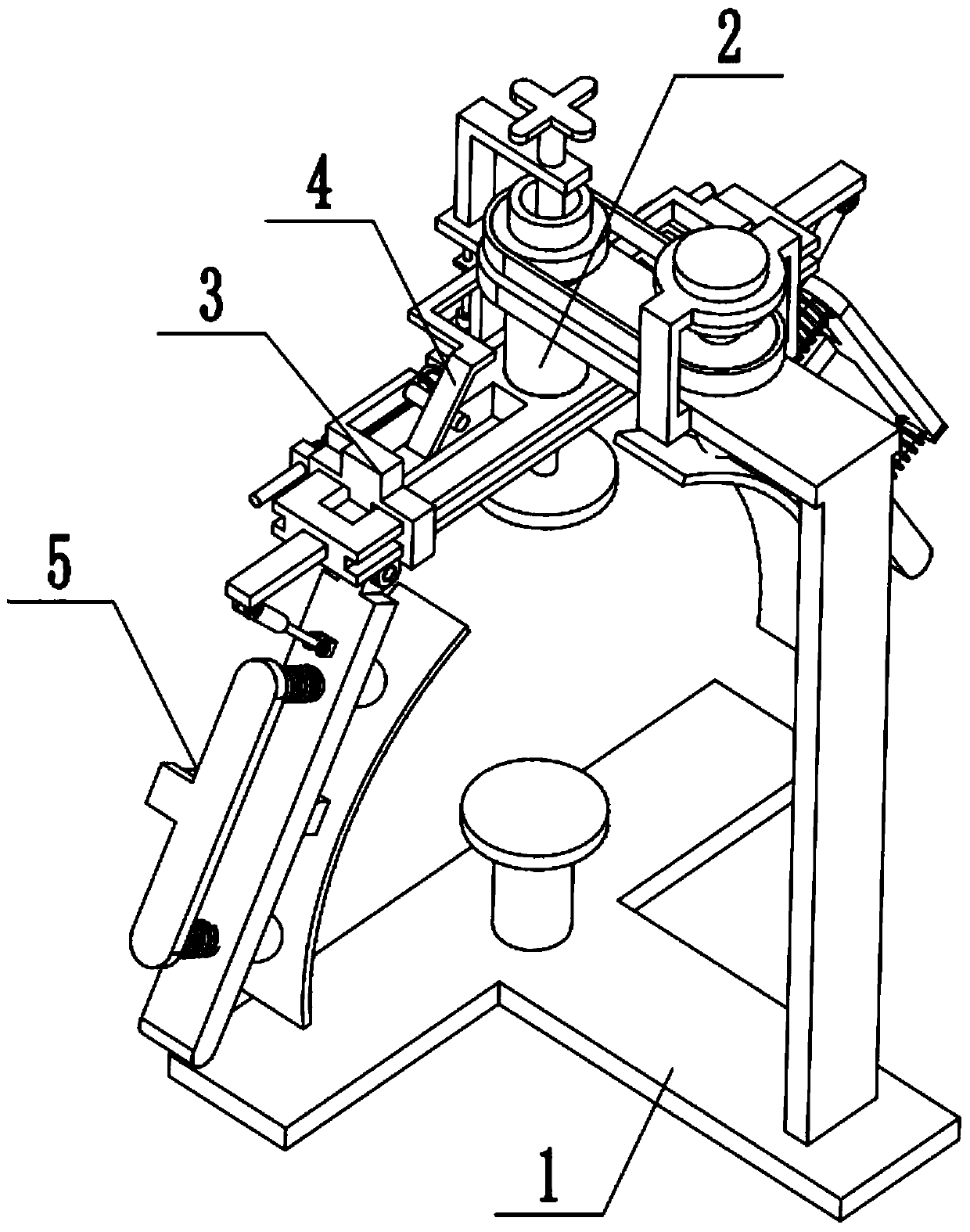

Fruit peeling device

The invention discloses a fruit peeling device and relates to the field of fruit processing. The fruit peeling device comprises a fruit fixing frame, a rotary driving mechanism, a cutter angle adjusting mechanism, a cutting depth adjusting mechanism and a cutting mechanism. The fruit peeling device has the beneficial technical effects that peels with different thicknesses can be peeled, the peel cutting thickness can be adjusted, the radian of the cutter can be adjusted according to the radian of the surface of a fruit, and therefore the cutter better fits the surface of the fruit, and incomplete cutting is avoided. The rotary driving mechanism is connected to the fruit fixing frame in a matched mode. Two adjusting mechanisms are arranged, and the two adjusting mechanisms are symmetricallyconnected to the rotary driving mechanism in a matched mode. The cutting depth adjusting mechanism is arranged on the rotary driving mechanism and is connected with the two adjusting mechanisms in amatched mode. There are two cutting mechanisms symmetrically arranged on the two adjusting mechanisms, the two adjusting mechanisms drive the two cutting mechanisms to fit the surface of a fruit, andthe rotary driving mechanism drives the two cutting mechanisms to rotate to peel the fruit.

Owner:王盼盼

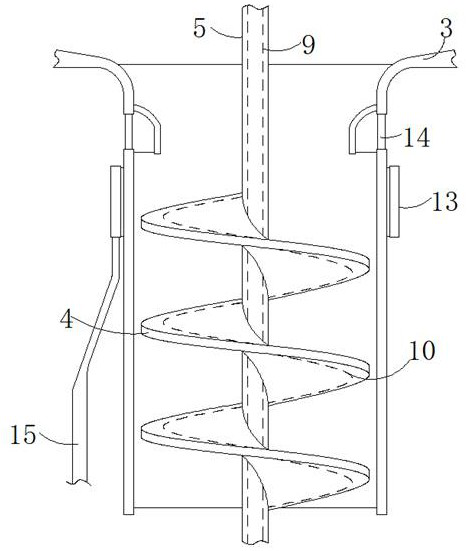

Efficient and easy-unloading feed mixing device

The invention discloses a high-efficiency and easy-to-cut feed mixing device, which includes a base, a mixing cylinder, an inner cylinder, a mixing drive mechanism, a lifting device and a material receiving frame; a chassis is fixed on the top right side of the base, and A support frame is provided; the mixing cylinder is rotated and set in the support frame, and the outer bottom of the mixing cylinder is connected with a discharge pipe; the inner cylinder is relatively static and is set at the center of the inner cavity of the mixing cylinder, and the inner cylinder is provided with a helical blade, which is driven by mixing. The mechanism drives the mixing cylinder and the spiral blade to rotate; the support frame rotates and connects to the chassis, and its tilt is controlled by the lifting device; the top left side of the base is movable with a material receiving frame; the left side of the material receiving frame is also equipped with an auxiliary unloading mechanism. The feed mixing device of the invention can effectively prevent the feed from sinking to the bottom, has good feed mixing effect, and is easy to feed; meanwhile, it has a reasonable structure and convenient operation, and is worthy of popularization and use.

Owner:桐乡市搏腾贸易有限公司

Fixing mechanism for cutting sugarcane

InactiveCN106550654AGuaranteed stabilityGuaranteed fixed effectHarvestersSeedlingMechanical engineering

Owner:GUANGXI UNIV

Stripping device for cable wiring

InactiveCN111934246AGuaranteed stabilityGuaranteed uniformityLine/current collector detailsApparatus for removing/armouring cablesHydraulic cylinderGear wheel

The invention discloses a stripping device for cable wiring, which is characterized in that one side of a mounting plate is provided with a fixed shaft, the fixed shaft is provided with a cutting knife, and one side of the cutting knife is provided with a rotating wheel cooperating with the cutting knife; a plurality of blocking rods are arranged on one side of the cutting knife, and shifting rodscorresponding to the blocking rods are arranged on one side of the rotating wheel; a first sliding block is arranged on one side of the supporting table, an L-shaped clamping block is movably connected to the upper portion of the first sliding block through a sliding block, a cylindrical cam is connected to one side of a second motor, a swing arm is arranged on the lower portion of the cylindrical cam, a sector gear is connected to the lower end of the swing arm, and a rack meshed with the sector gear is arranged on the lower portion of the clamping block; and a hydraulic cylinder is arrangedon one side of the third connecting rod. According to the invention, the cutting knife is arranged in the shell, the first sliding block and the clamping block are arranged on one side of the cuttingknife, a cable is inserted into the shell through a cable stripping hole, a cable sheath is cut off under the cutting action of the cutting knife, then the cut cable sheath is pulled out under the action of the clamping block and the first sliding block, and the stability and uniformity of cable stripping are guaranteed.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO PINGYUAN POWER SUPPLY CO

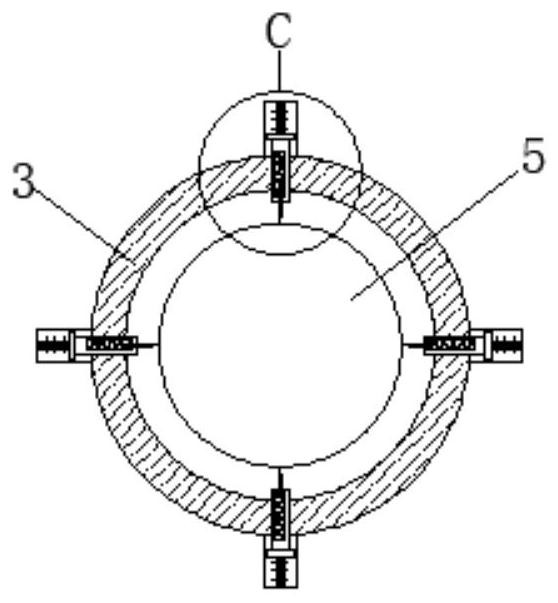

Cutting device for communication wire and cable shielding layer

ActiveCN110661207AAvoid shakingAvoid uneven cutsApparatus for removing/armouring cablesElectric machineGear wheel

The invention discloses a cutting device for a communication wire and cable shielding layer. The device comprises a bottom plate, and a motor and a sleeve are mounted on the top wall of the bottom plate, wherein the motor is located at the outer side of the sleeve; two annular groove plates are arranged on the symmetrical outer side walls of the sleeve, and supporting plates are mounted on the bottom walls of the two annular groove plates; the bottom ends of the two supporting plates are mounted on the top wall of the bottom plate; a gear is installed at the driving end of the motor, a ring gear meshed with the gear is installed on the side wall of one end of the sleeve, a cable is arranged in the sleeve in a penetrating mode, four cutting devices are symmetrically installed on the outer side wall of the sleeve, and a positioning groove is formed in the top wall of the bottom plate. Through the mutual cooperation of all the structures, a shielding layer and an insulating layer of the cable can be cut, and the cutting length of the cable and the depth of a notch can be simply and effectively adjusted; the device has the beneficial effects that the cutting speed is high, the notch isneat, and a cable core cannot be damaged.

Owner:四川越洋电子科技有限责任公司

Novel intelligent telescopic pipeline cutting machine

InactiveCN106975843AWide range of cuttingMove away quicklyWelding/cutting auxillary devicesAuxillary welding devicesDrive wheelGear wheel

The invention discloses a novel intelligent telescopic pipe cutting machine, which includes a body frame, a control panel, a transmission motor, a transmission wheel, a driven wheel, a pipe pulley and a laser cutting knife, and a sliding lifting bracket is arranged on the right side of the body frame. A laser generator is arranged on the sliding lifting bracket, the laser cutting knife is installed under the laser generator, an infrared sensing device is arranged on the laser generator, the control panel is installed on the left side of the body frame, and the A track is arranged on the right side of the bottom of the body frame, a transmission platform is arranged above the track, the transmission motor is installed on the transmission platform, and the transmission wheel is installed on the bottom of the transmission platform. The invention has a scientific and reasonable structure, safe and convenient operation, the cut pipe can be quickly removed through the transmission platform, and the cutting can be quickly completed through the pipe rotating motor, so as to avoid incomplete pipe cutting or pipe damage caused by the movement of the laser cutting knife.

Owner:王连福

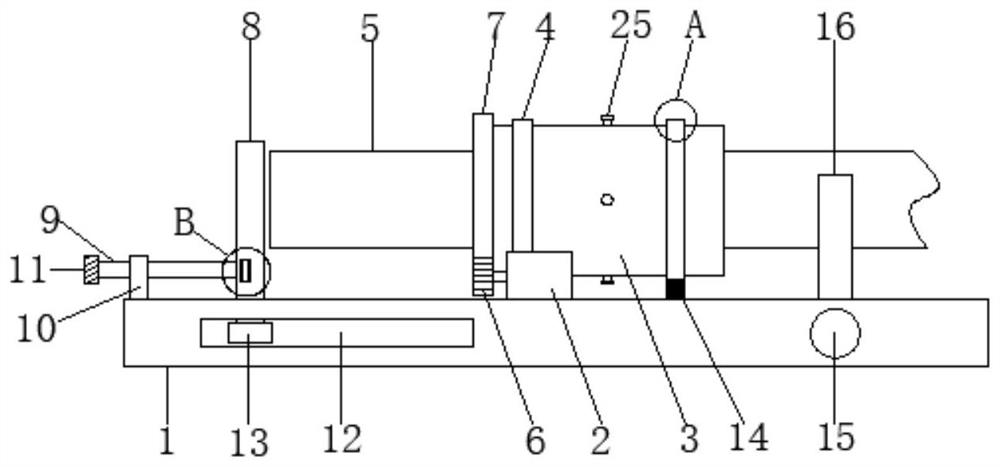

Cutting device for processing insulation layer of cable

InactiveCN110948545AAvoid dangling stateAvoid incomplete cuttingMetal working apparatusInsulation layerStructural engineering

The invention relates to a cutting device for processing an insulation layer of a cable. The cutting device comprises a workbench. A pulling rod is fixedly connected to the left side of the top of theworkbench, the right side of the pulling rod is provided with a supporting rod and a cutting table, the supporting rod and the cutting table are fixed to the top of the workbench, and a limit rolleris rotatably connected to the inner wall of the supporting rod. The cutting table is located on the right side of the supporting rod, and a supporting arm is fixedly connected to the top of the workbench. A cable protection sheath fits the cutting table, the situation that the cable protection sheath is hung in the air during cutting is avoided, and accordingly the situation that the protection sheath cannot be completely cut under the effect of drawing force is avoided. The cable protection sheath is fixed, the situation that the cable protection sheath shifts during cutting is avoided, the cutting quality is improved, a blade cuts the cable protection sheath pressed on the cutting table, the trouble of manually cutting the cable protection sheath is avoided, the time and labor are saved,and accordingly the production efficiency is improved.

Owner:湖州立新电缆有限公司

A device for cutting fabric

InactiveCN104924340BSteady throughUniform sizeSevering textilesMetal working apparatusEngineeringMechanical engineering

Owner:瓮安县雅韵服饰有限公司

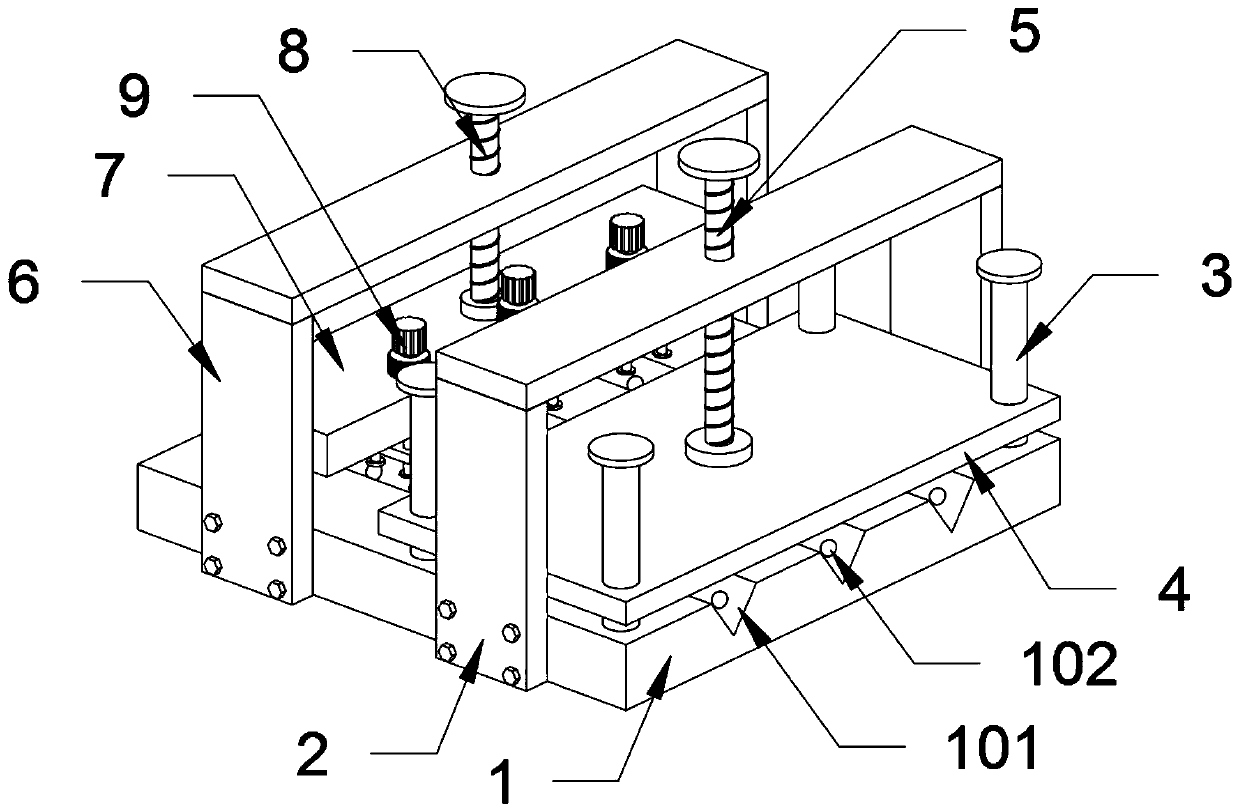

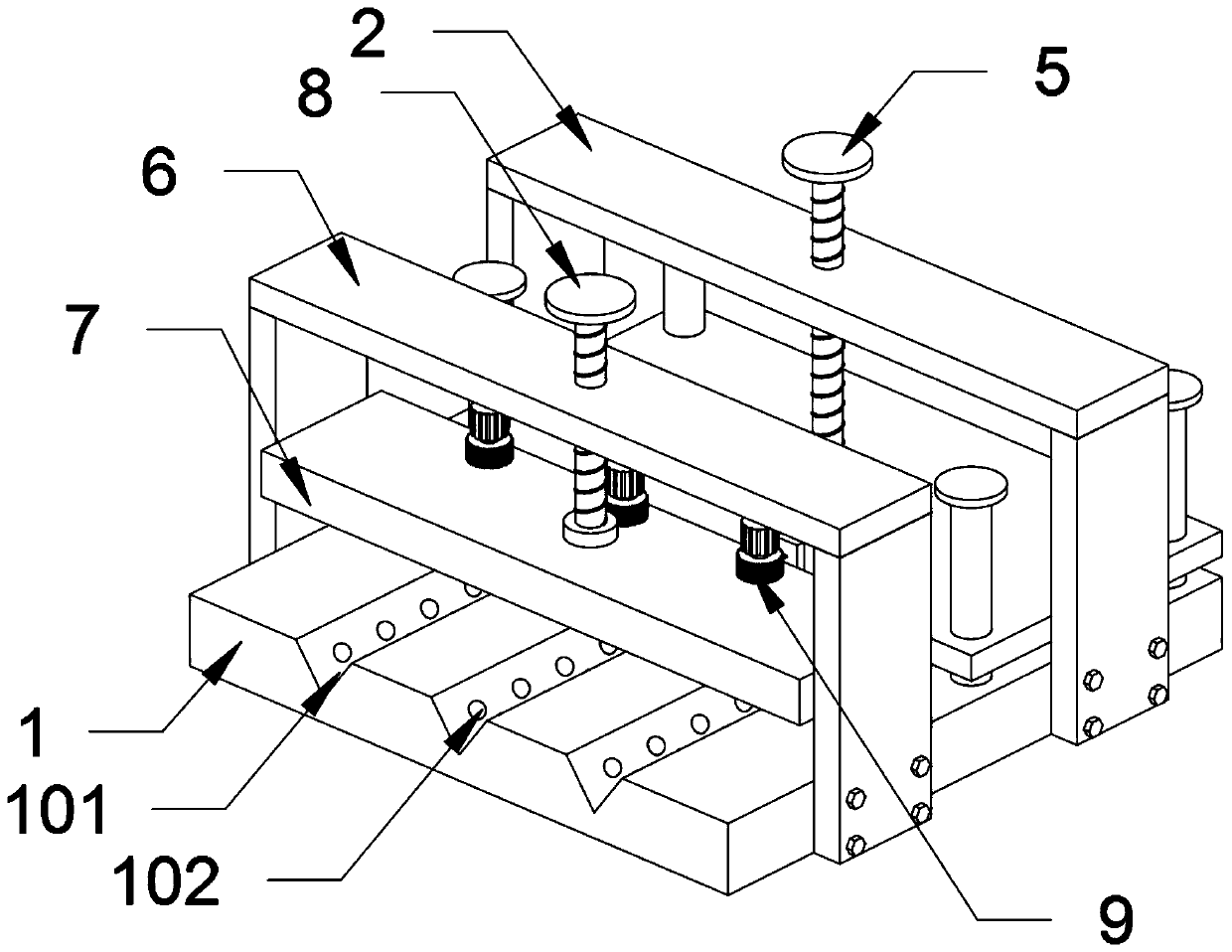

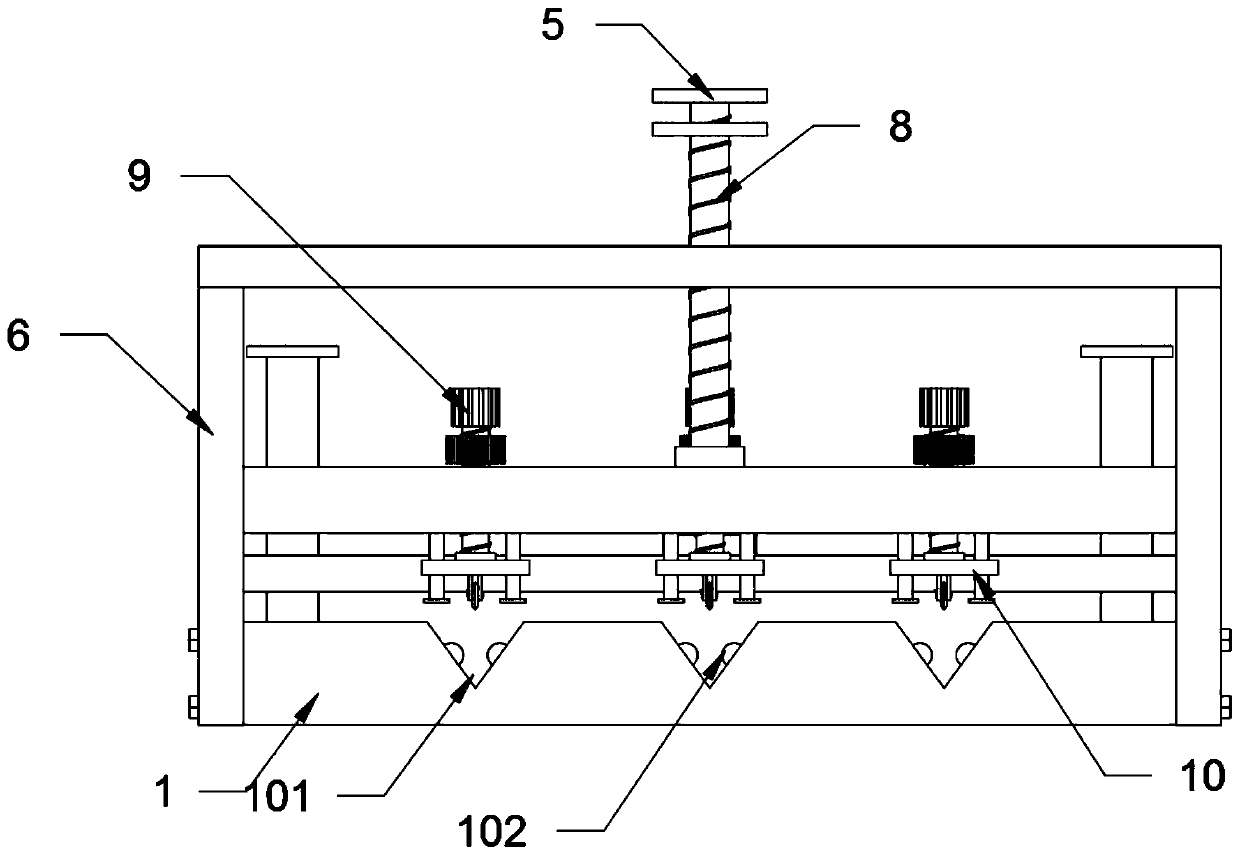

Cutting machine

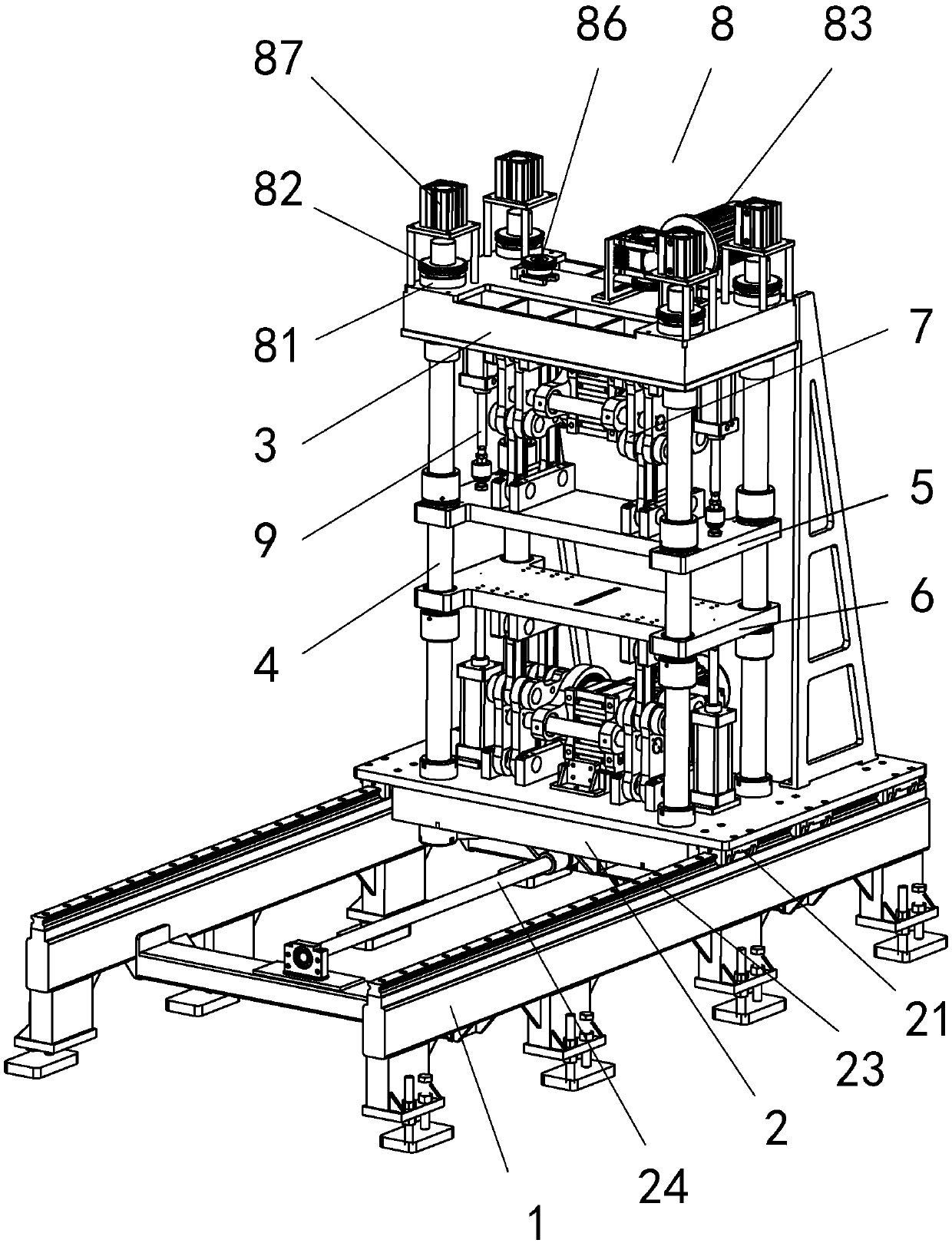

PendingCN107825516AImprove general performanceCan work continuouslyMetal working apparatusPunchingStructural engineering

The invention discloses a cutting machine. The cutting machine comprises a base, a lower base plate, an upper fixing plate, and guide vertical columns, wherein an upper pressing plate and a lower pressing plate are mounted between the lower base plate and the upper fixing plate; an opening regulating component connected with the guide vertical columns is arranged at the top end of the upper fixingplate; the base is connected with the lower base plate through a horizontal movement mechanism; the upper pressing plate and the lower pressing plate are closed and opened at a time to complete primary punching operation, the cutting machine moves forwards horizontally through the horizontal movement mechanism to a next work station to carry out the punching operation again, the cutting machine further moves forwards horizontally through the horizontal movement mechanism to a work station, so that the repeated cycle operation is completed, and when the cutting machine moves forwards horizontally for the maximum stroke, the punching operation is completed continuously; meanwhile, the height of the upper fixing plate is reduced through the opening regulating mechanism, the height of the upper pressing plate connected with the upper fixing plate is reduced, the opening distance between the upper pressing plate and the lower pressing plate is changed, the cutting machine can be adapted tomaterials and cutting dies with different dimensions, and the cutting machine has the advantages of strong universality and continuous punching capability.

Owner:广东鸿钢智能装备有限公司

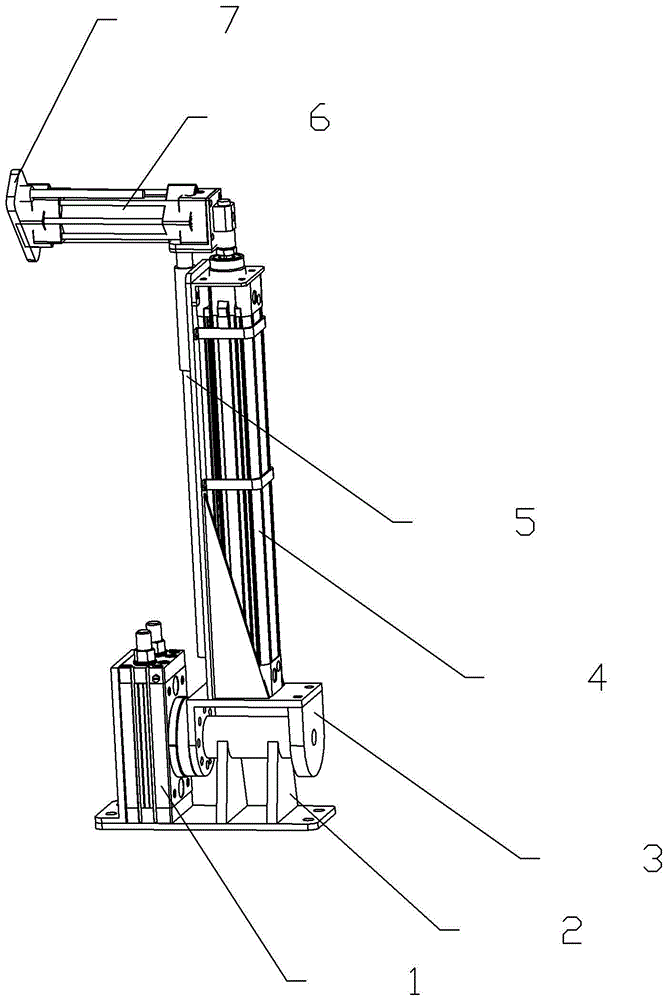

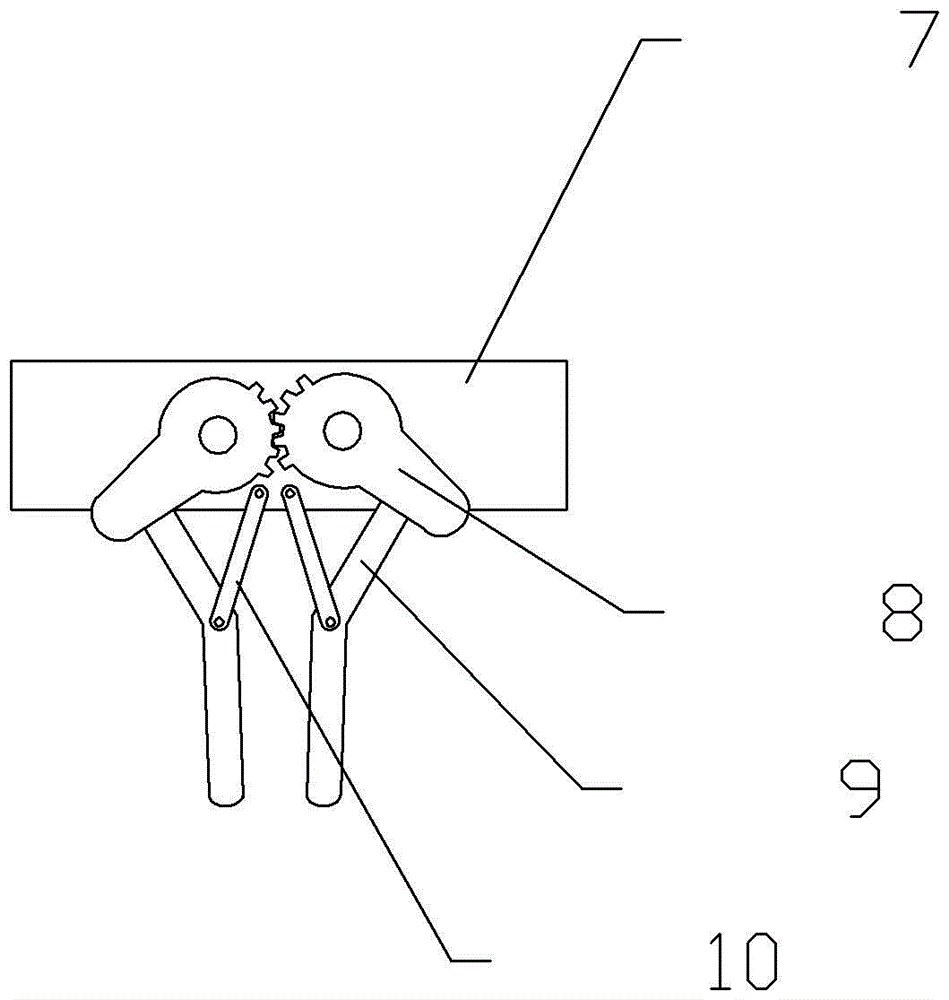

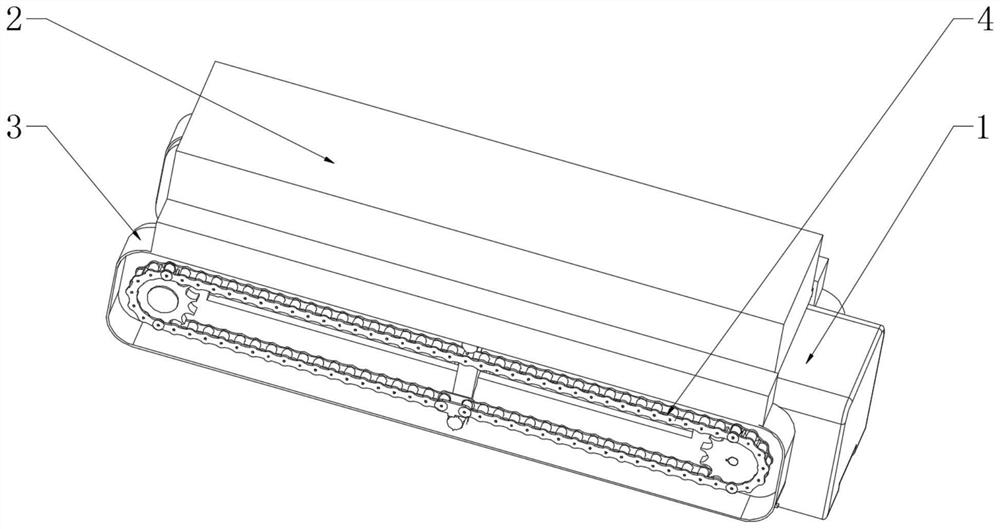

Tea plucking machine

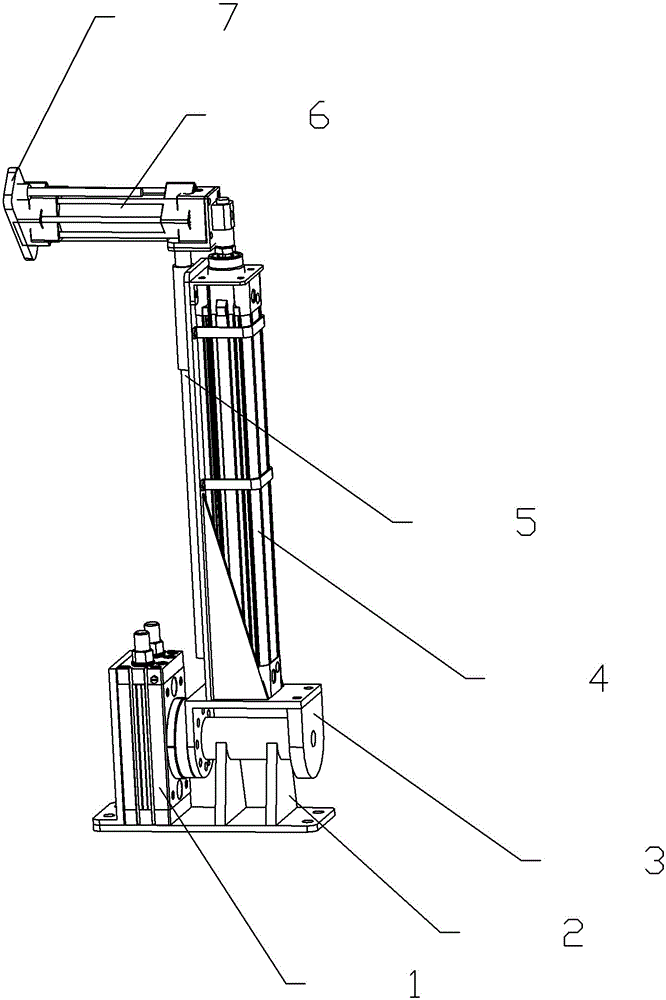

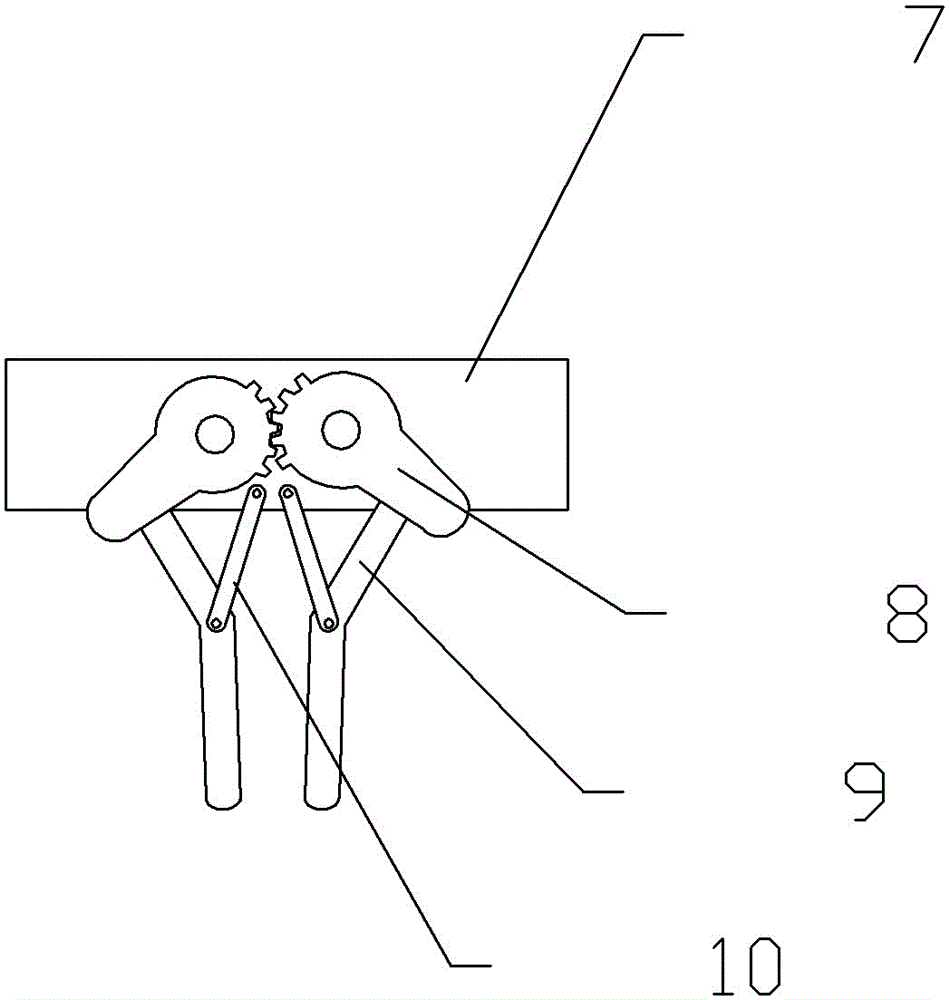

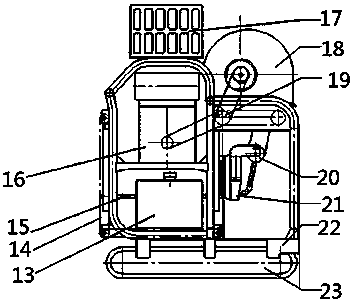

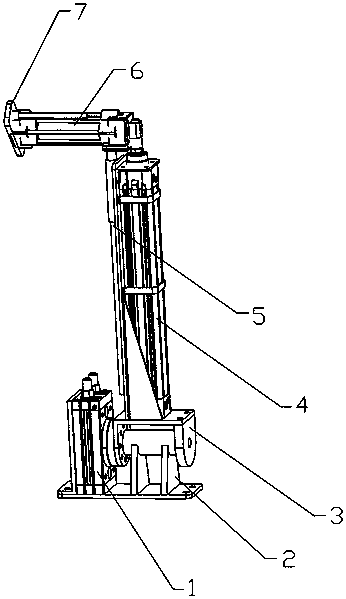

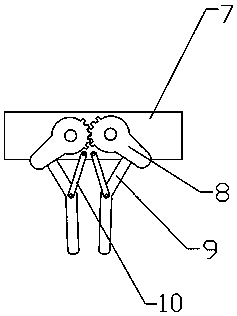

ActiveCN105123121AIncrease tea productionPossess practical promotionPicking devicesControl engineeringManipulator

The invention discloses a tea plucking machine which can lift, stretch, retract and rotate in a small space. The tea plucking machine comprises a rack assembly. Caterpillar band assemblies are installed on the two sides of the rack assembly. The upper portion of the rack assembly is provided with a gasoline tank, a power mechanism, a rotating and lifting mechanism and a tea leaf collecting box. The rotating and lifting mechanism is provided with a rotating and lifting platform. The upper portion of the rotating and lifting platform is provided with a tea plucking mechanical arm. The tea plucking machine is characterized in that the tea plucking mechanical arm comprises a first vertical installation plate, a vertical rotating air cylinder is arranged on the first vertical installation plate, a rotating shaft of the rotating air cylinder stretches out of the rotating air cylinder and is horizontally arranged, the rotating shaft is fixedly provided with a U-shaped connecting seat, a second vertical installation plate is fixed to the side face of the U-shaped connecting seat, a vertical telescopic air cylinder is arranged on the second vertical installation plate, a horizontal clamping seat is fixed to the end of the vertical telescopic rod of the vertical telescopic air cylinder, a horizontal telescopic air cylinder is installed on the clamping seat, a vertical connecting disc is fixed to the end of a horizontal telescopic rod of the horizontal telescopic air cylinder, and a plucking jaw is installed on the connecting disc.

Owner:重庆市乾丰茶业有限责任公司

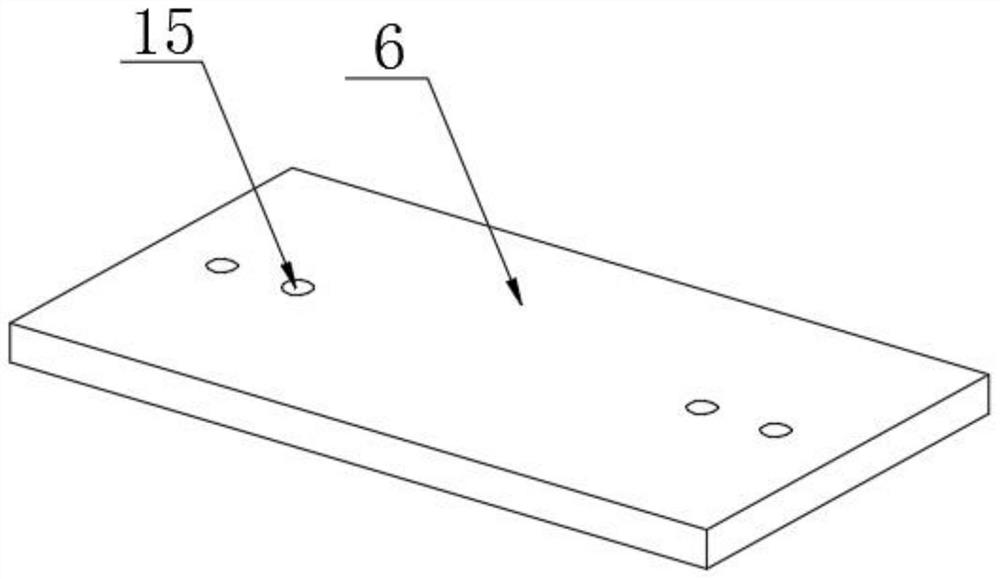

Recoverable cable stripping equipment for safety explosion-proof cable for instrument

InactiveCN110265195AReduce frictionFunctionalBasic electric elementsElectronic waste recyclingThreaded rodPetroleum engineering

The invention provides recoverable cable stripping equipment for a safety explosion-proof cable for an instrument. The recoverable cable stripping equipment comprises a bottom plate, a plug pin and a spring. The bottom plate has a rectangular plate structure, and the top surface of the bottom plate is provided with three guide grooves in a rectangular array shape. The rectangular plate is slidably connected on a guide shaft B, and a cutter holder is welded on the bottom end surface of the guide shaft B. A cutter is rotatably connected on the cutter holder. An adjusting frame B, a mounting plate, a threaded rod B, an adjusting rod structure, a stripping structure and a fixing structure are arranged, firstly the threaded rod B can be adjusted according to the thickness of the cable; secondly, the adjusting rod structure is rotated to adjust the height of the cutter so as to perform simultaneous stripping of the cables with different diameters; thirdly, the tooth disc and the fixing structure can limit the position of the rotation adjusting rod structure to prevent the rotation of the adjusting rod structure from causing incomplete cutting in the use process; and fourthly, the cutter has a circular cutter structure so that the stagnation phenomenon can be effectively avoided in the use process.

Owner:国网宁夏电力有限公司中卫供电公司

Wall sticker manufacturing process

ActiveCN110216864AIncrease contact areaReduce waste generationFilm/foil adhesivesMetal working apparatusThree dimensional shapeEngineering

The invention discloses a wall sticker manufacturing process. The wall sticker manufacturing process comprises the following steps: (a) substrates are treated; (b) arrangement of decoration layers: the decoration layers are bonded on the upper surfaces of main material layers; and the color batch feeding, the printing, the printing or the heat transfer are performed on the decoration layers; (c) arrangement of bonding layers: bonding agents are fully coated on release surfaces of secondary material layers by using a coating machine to form the bonding layers; (d) bonding of main and secondarylayers: under a certain pressure, the products in the step (b) and the products in the step (c) are bonded, and the bonding layers are successfully transferred to the lower surfaces of aluminum foil layers; (e) high-temperature baking: the products in the step (d) are fed in a high-temperature oven for baking at a certain temperature by a certain time; (f) mold hot pressing: the products in the step (e) are shifted out from the oven to cover the upper surfaces of molds with corresponding shapes; and a press is used for applying pressure to form concave-convex and three-dimensional shapes; and(g) cutting of finished products: the products in the step (f) are placed in a slitting machine for cutting according to the machining demands to remove redundant leftovers of the products to obtain the finished products.

Owner:ZHEJIANG SUOFAN ADHESIVE PROD

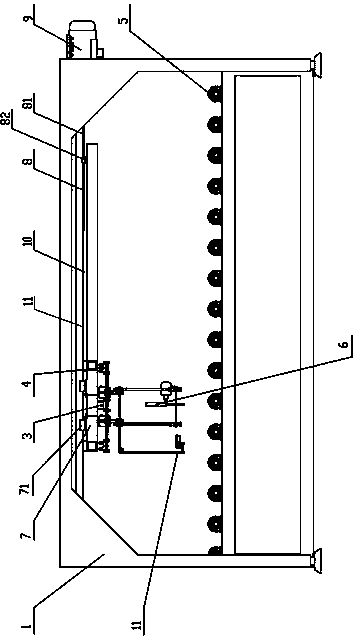

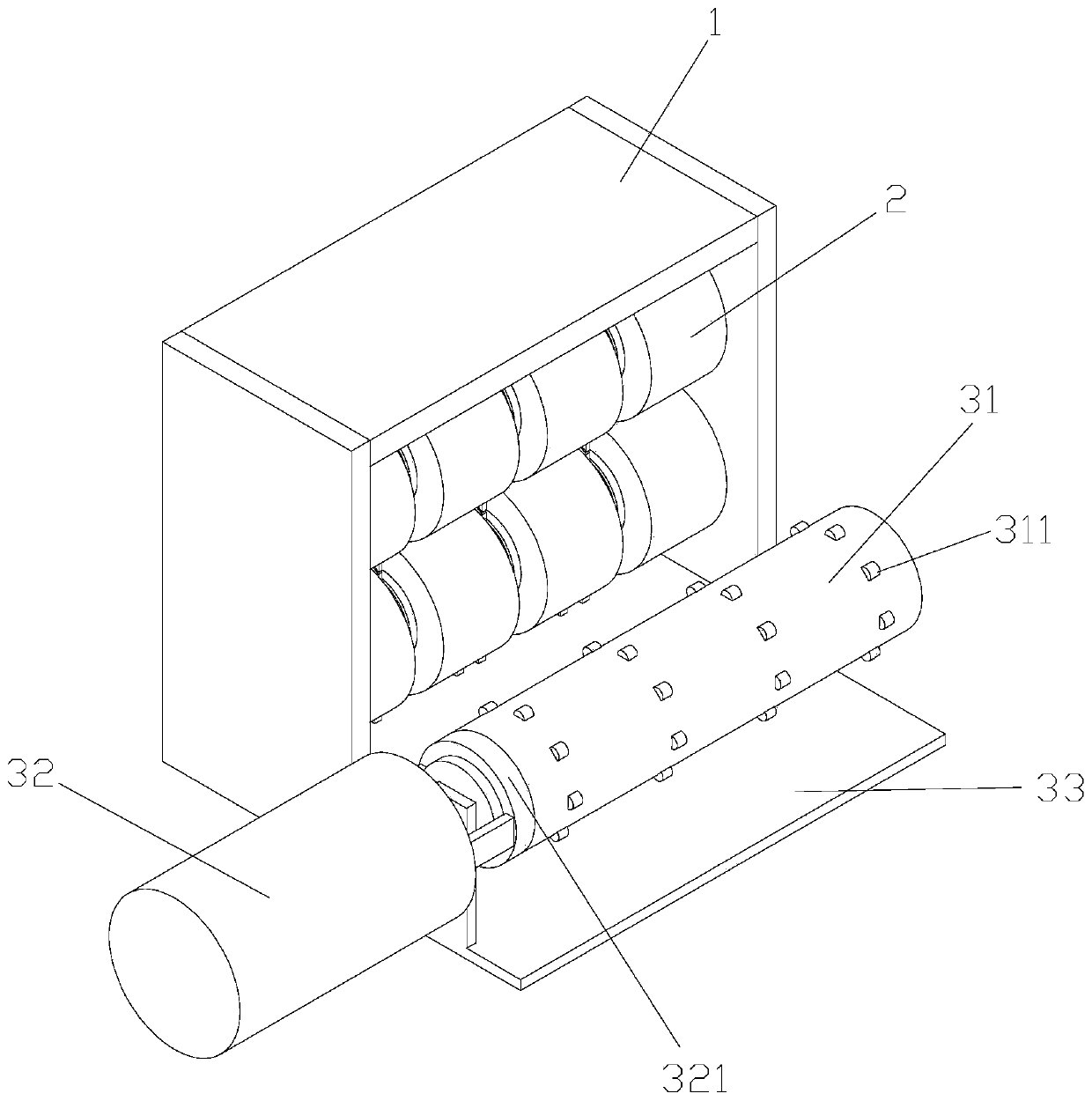

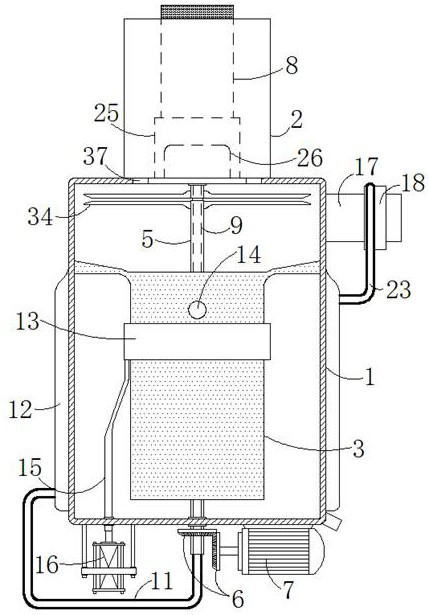

Slicing and melting integrated processing system for mask non-woven fabrics

ActiveCN113771370AIncrease heatRealize active exportDispersed particle filtrationMetal working apparatusProcess engineeringNonwoven fabric

The invention discloses a slicing and melting integrated processing system for mask non-woven fabrics. The slicing and melting integrated processing system comprises a shell, a feeding opening, an auger plate and a material hole, the feeding opening is formed in the top end of the shell, a molten material discharging opening is formed in the bottom end of the shell, a circulating barrel is fixedly installed in the shell, the auger plate rotatably conveys materials in the circulating barrel downwards, and a material hole is formed in the top end of the shell. According to the slicing and melting integrated processing system for the mask non-woven fabrics, the conduction effect of each cavity structure is utilized, so that hot oil can synchronously flow in materials accumulated on the outer wall of the shell and in the center of the interior, it is ensured that the outer side and the center area of the materials can be well heated, and the hot melting efficiency is improved; and meanwhile, double-blade opposite slicing and active guiding-out of waste gas in the melting process can be achieved through flowing of the hot oil, the structure is reasonable, and more energy saving and environmental protection are achieved.

Owner:徐州市康农消毒技术研究院有限公司

Efficient cutting and forming equipment for woven bag production

InactiveCN110641079AEasy to cutAvoid incomplete cuttingBag making operationsPaper-makingStructural engineeringKnife blades

The invention discloses efficient cutting and forming equipment for woven bag production. The equipment comprises a rack I, a rack II and a material collecting roller, wherein a material cutting bin is formed between the rack I and the rack II, the two ends of the material collecting roller are connected with fixing frames, the lower ends of the fixing frames are fixedly connected with the rack Iand the rack II correspondingly, and a fixing mechanism is arranged on the right side wall of the rack I; a material cutting mechanism comprises a fixing block I, clamping plates I and a blade, wherein a mounting groove is formed in the middle of the left side wall of the fixing block I, a blade fixing frame is horizontally fixed in the mounting groove, the blade is fixedly connected with the blade fixing frame through a bolt, and the two clamping plates I are arranged at two sides of the mounting groove in a symmetric mode; and the fixing mechanism comprises a fixing block II, clamping platesII and a cutting block. According to the equipment, in the cutting process, the woven bag is tightened and fixed through the two groups of clamping plates, then cutting is carried out through the blade, the cutting effect is good, the phenomenon of incomplete cutting is avoided, and the rework rate is reduced.

Owner:泗县东方塑料有限责任公司

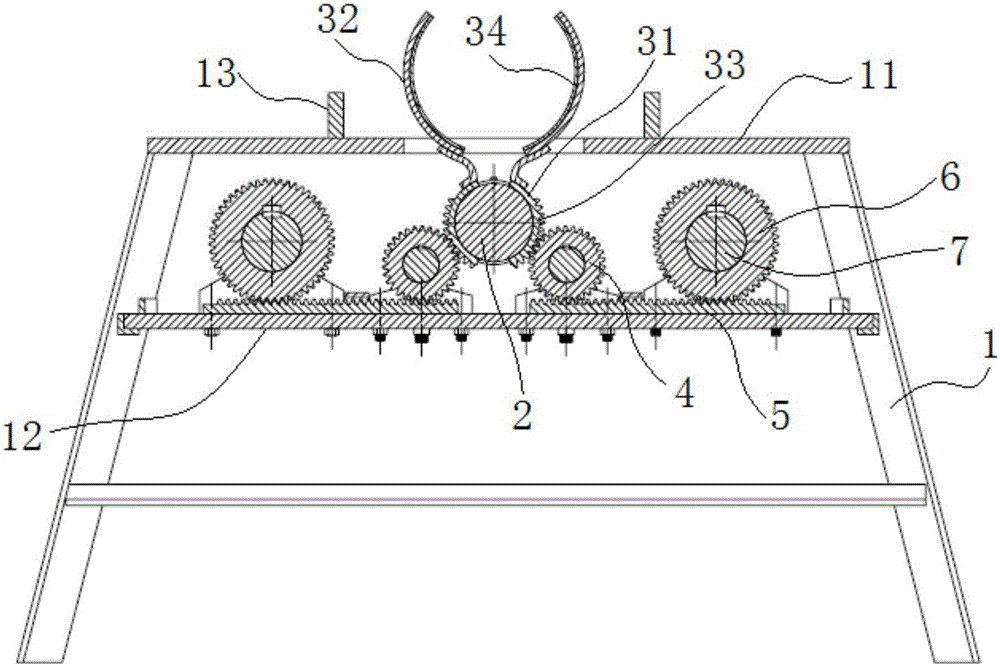

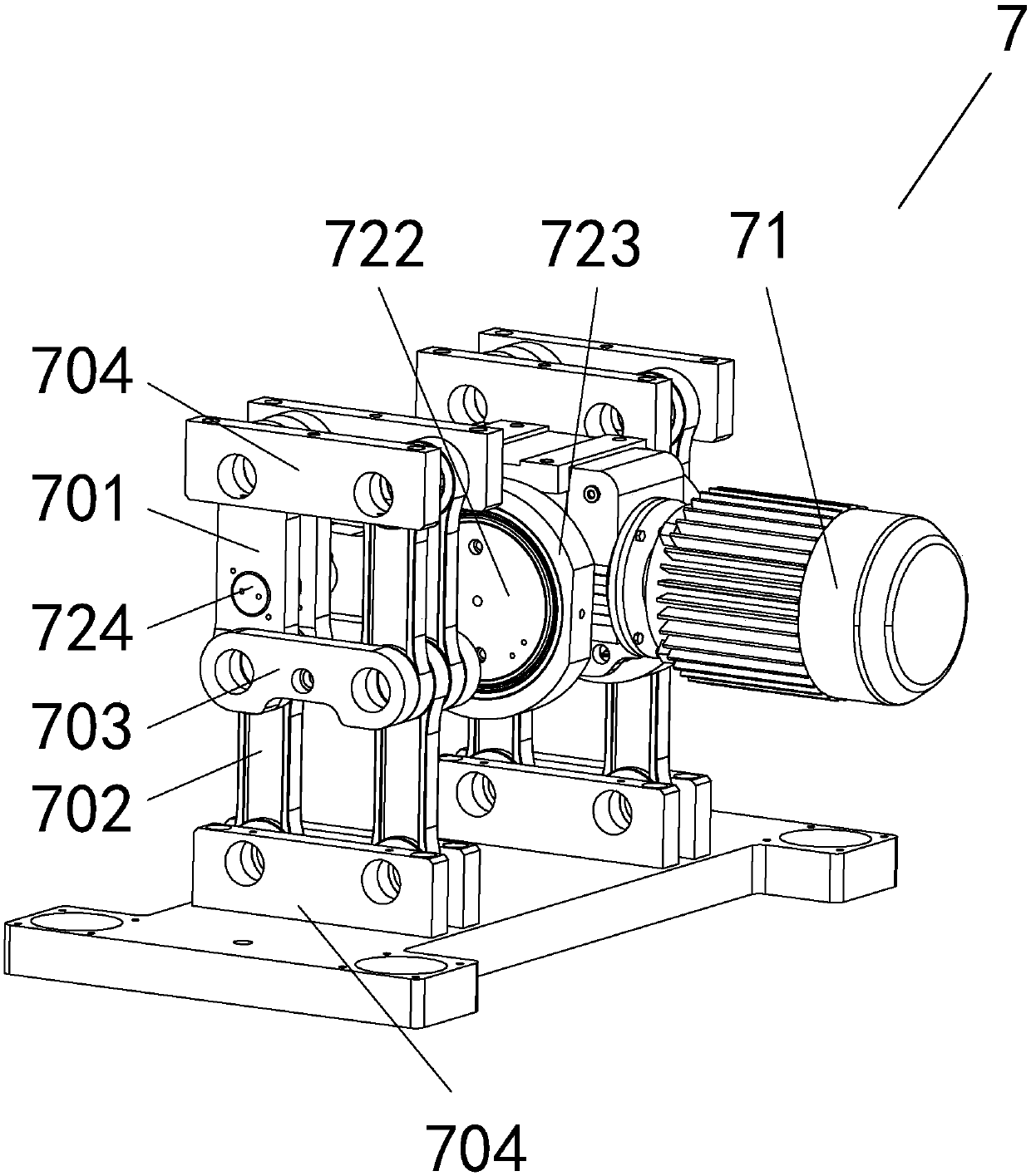

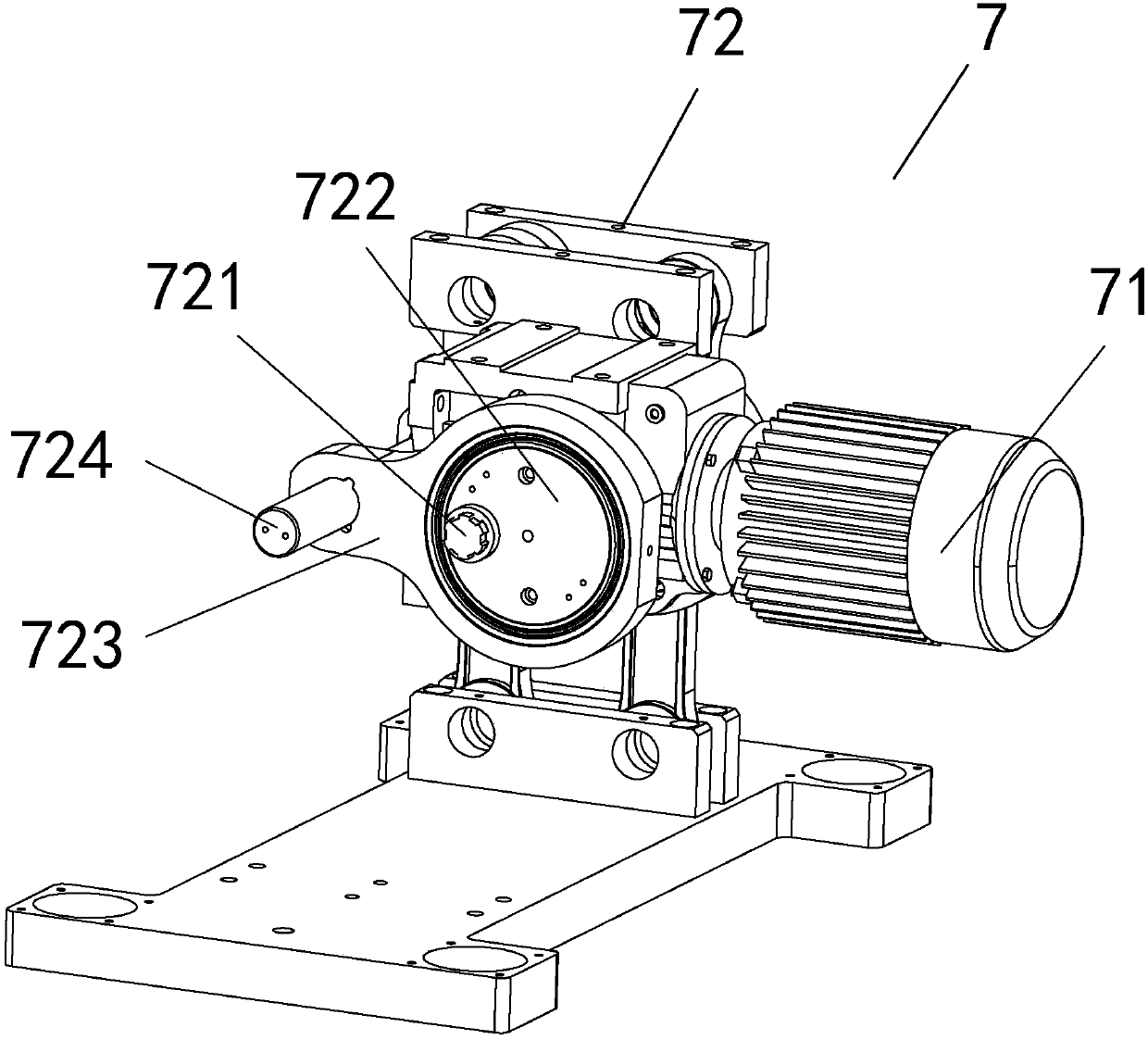

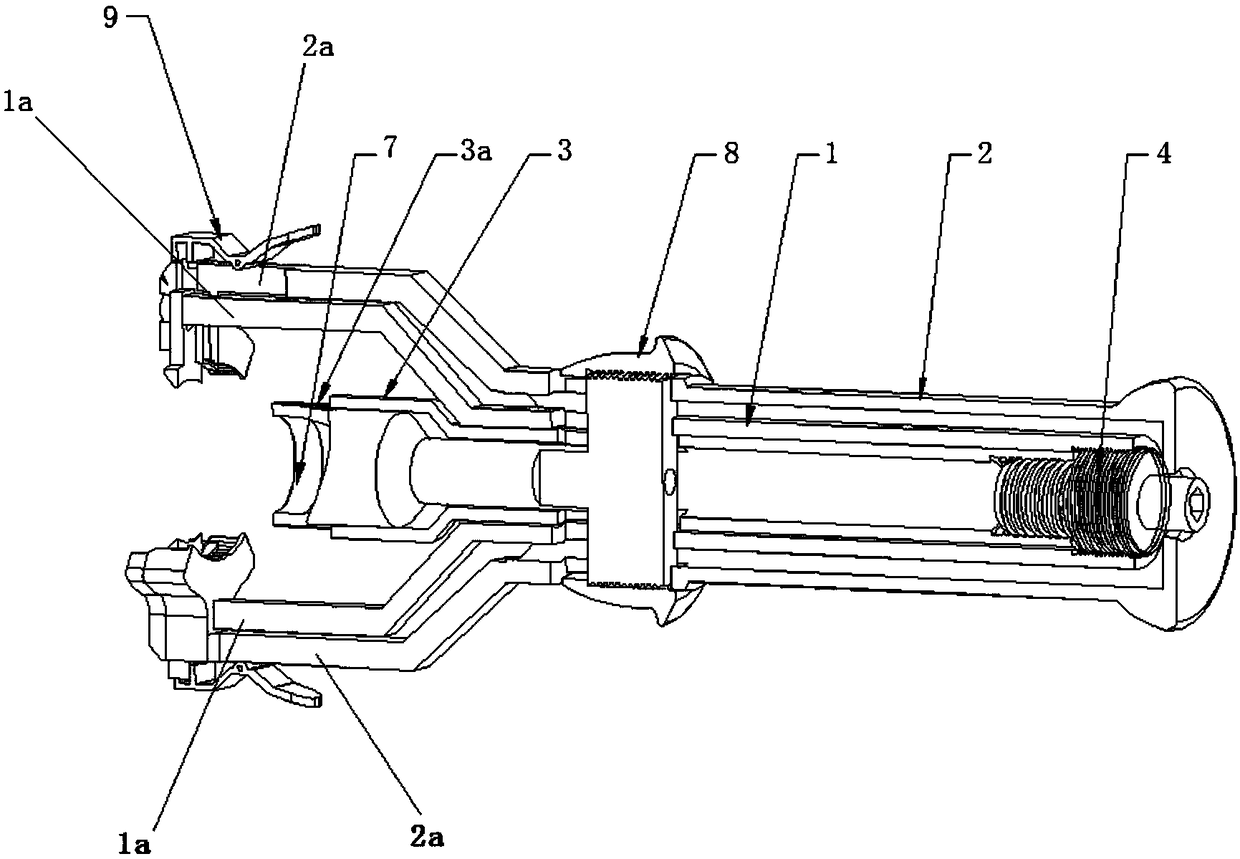

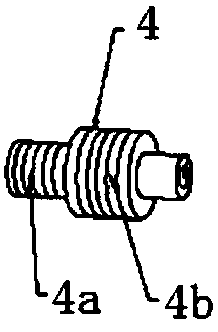

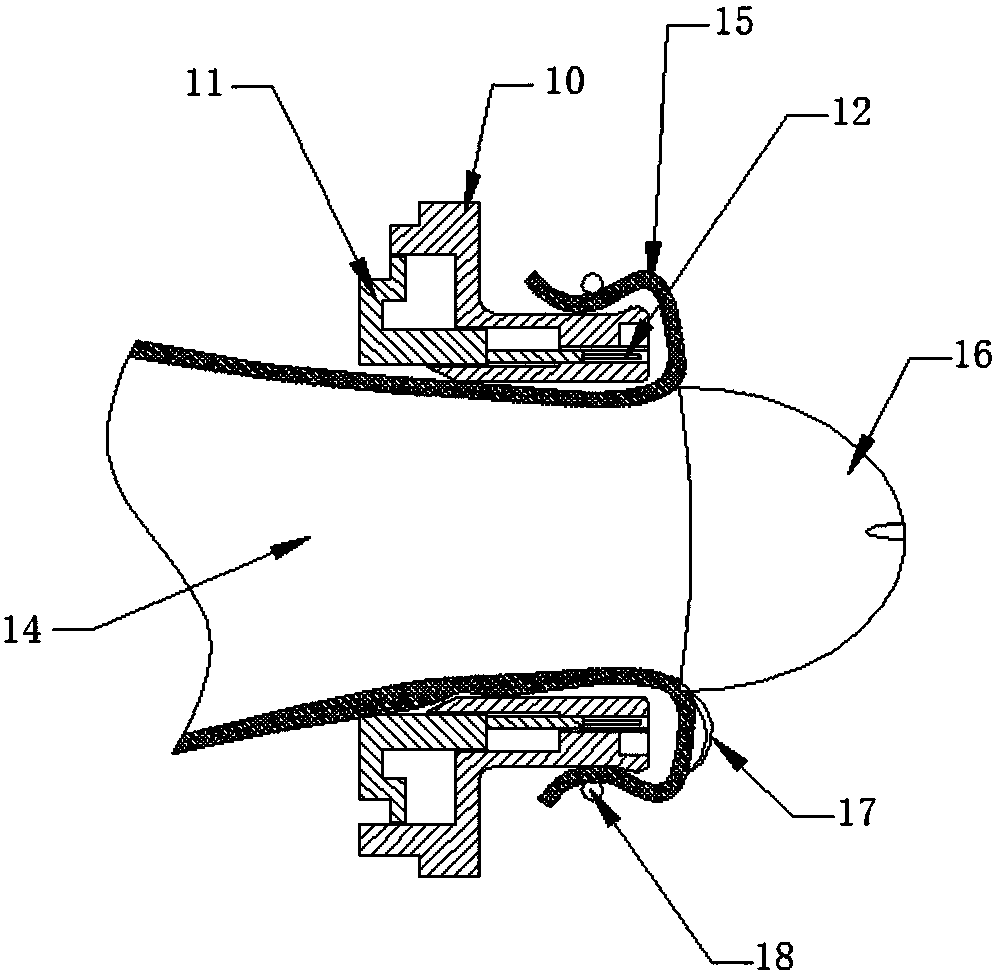

Electric drive circumcision mechanism and foreskin suture ring cutter

PendingCN108451598AReduce bleedingReduced hand strength requirementsSurgical staplesForeskinDrive shaft

The invention provides an electric drive circumcision mechanism and a foreskin suture ring cutter and belongs to the technical field of medical instruments. The electric drive circumcision mechanism and the foreskin suture ring cutter solves various technical problems such as that circumcision in the prior art needs manually operation to complete the suturing and cutting steps during the operation. The electric drive foreskin suture ring cutter comprising a suture ring cutter is characterized in that the electric drive foreskin suture ring cutter also comprises a driving piece, a soft drive shaft and a drive module, wherein the drive module comprises a motor and a control module; the control module is electrically connected with the motor; the drive soft shaft is connected with the drivingpiece; the electric drive foreskin suture ring cutter only needs the motor and the control module to transmit mechanical energy torque to the driving piece through the soft drive shaft and automatically completes the steps of stitching and cutting.

Owner:GUANGZHOU DEEMINE MEDICAL APP & INSTR CO LTD

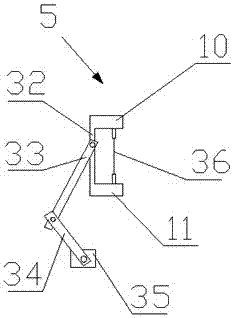

Semifinished cutting device for aquatic products

ActiveCN109588464AWon't slip awayAvoid incomplete cuttingCleaningFish cuttingAquatic productWork in process

The invention discloses a semifinished cutting device for aquatic products. The semifinished cutting device comprises a device casing, a conveying belt, an abnormal shaft and bush rollers, wherein thedevice casing is arranged on an outer frame of the conveying belt; the conveying belt is arranged in the outer frame of the conveying belt; the abnormal shaft is arranged on the upper-half section ofthe device casing; a revolving ring is rotationally arranged on a middle abnormal section of the abnormal shaft; in addition, the lower end face of the revolving ring is fixedly arranged at the top end of the rotating rod; a cross bar is arranged on a first cutting knife; the device casing is internally provided with a horizontally-distributed connecting rod; in addition, the middle section of the connecting rod is rotationally connected with one end of a telescopic lever; the brush rollers are positioned at the bottom end of the conveying belt. According to the semifinished cutting device for the aquatic products, by redesign of a cutting knife structure, a fish body is prevented from slipping at the cutting end and further the processing efficiency is improved; in addition, the conditions that the fish body is cut incompletely and fish flesh is still connected with fish skin are avoided; meanwhile, the conveying belt can be effectively cleaned in real time, and greater convenience in use is realized.

Owner:江苏溯源食品有限公司

Stainless steel plate plasma cutting processing method

InactiveCN113000999AAvoid incomplete cuttingAvoid forcePlasma welding apparatusCutting forcePlasma cutting

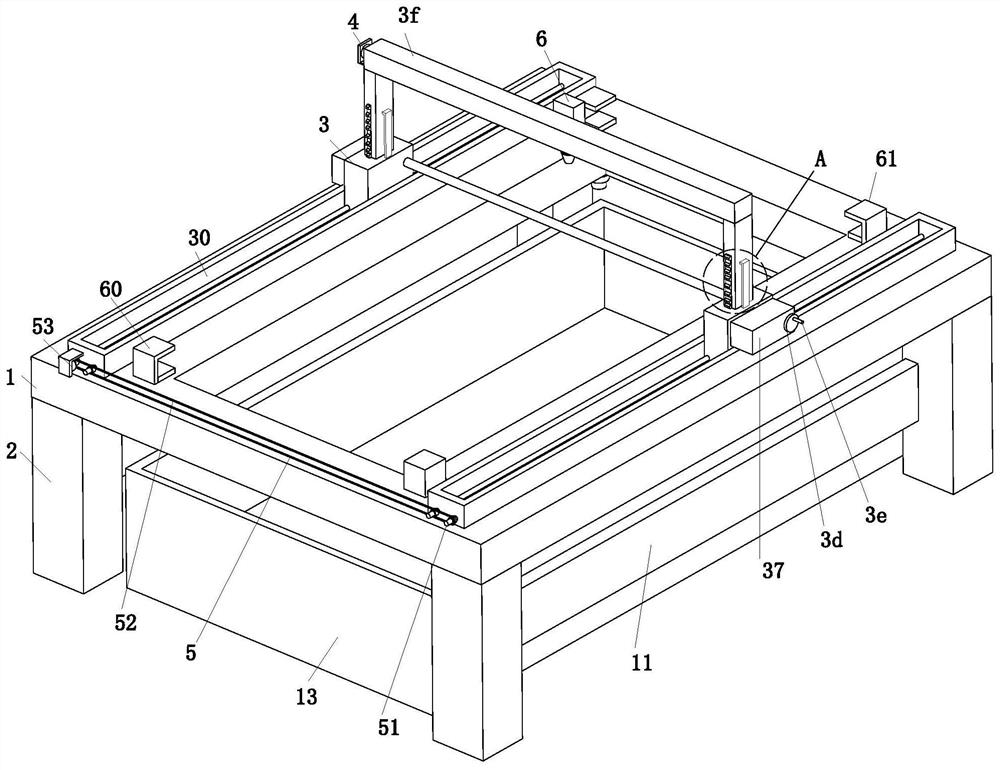

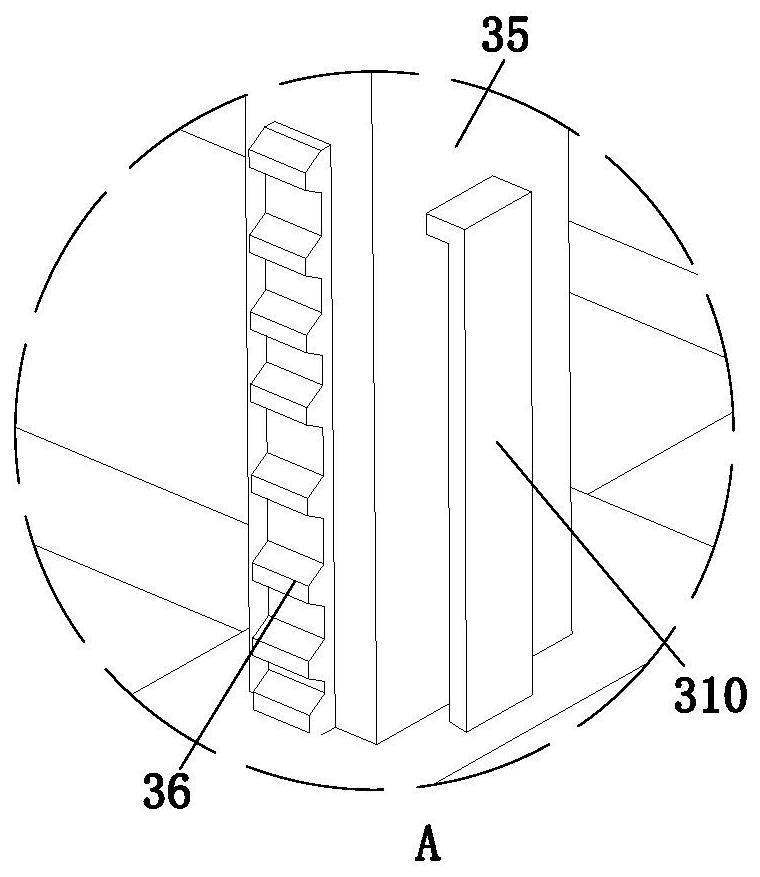

The invention relates to a stainless steel plate plasma cutting processing method. The stainless steel plate plasma cutting processing method uses a stainless steel plate plasma cutting processing device, the stainless steel plate plasma cutting processing device comprises a cutting table, supporting legs, a height adjusting mechanism, a left-right moving mechanism, a front-back moving mechanism and a clamping mechanism. According to the stainless steel plate plasma cutting processing method, the height adjusting mechanism can adjust the distance between a plasma cutting head and a stainless steel plate, therefore, the phenomenon that when the plasma cutting head cuts a thick or thin stainless steel plate, cutting is not thorough or cutting force is large, and waste is caused is avoided, meanwhile, the cutting quality of the plasma cutting head on the stainless steel plate is guaranteed, the stainless steel plate is fixed and limited through the clamping mechanism, and the phenomenon that cutting is inaccurate due to the fact that the stainless steel plate moves in the cutting process is avoided.

Owner:南京健昌机电科技有限公司

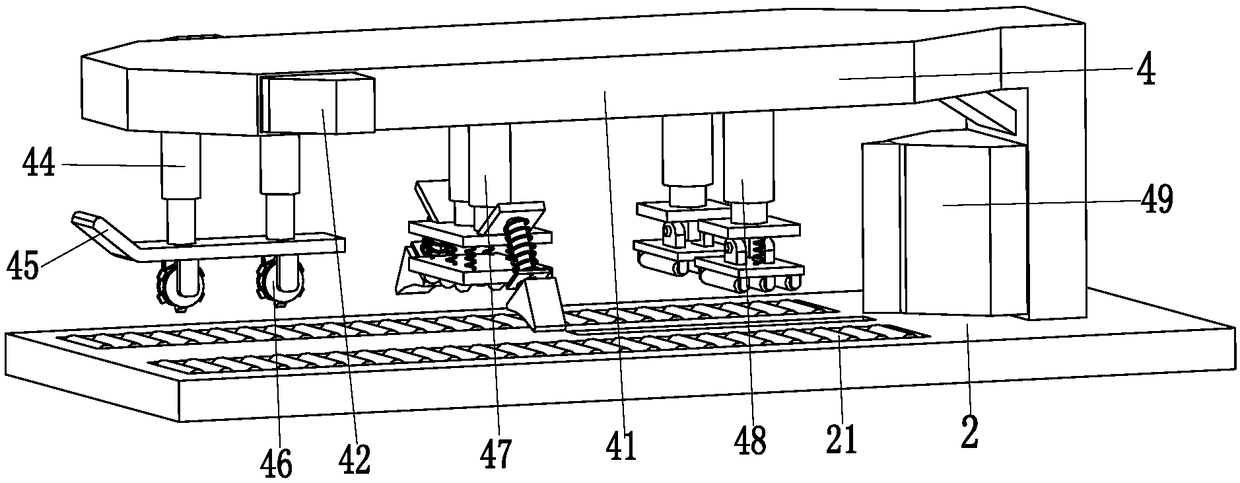

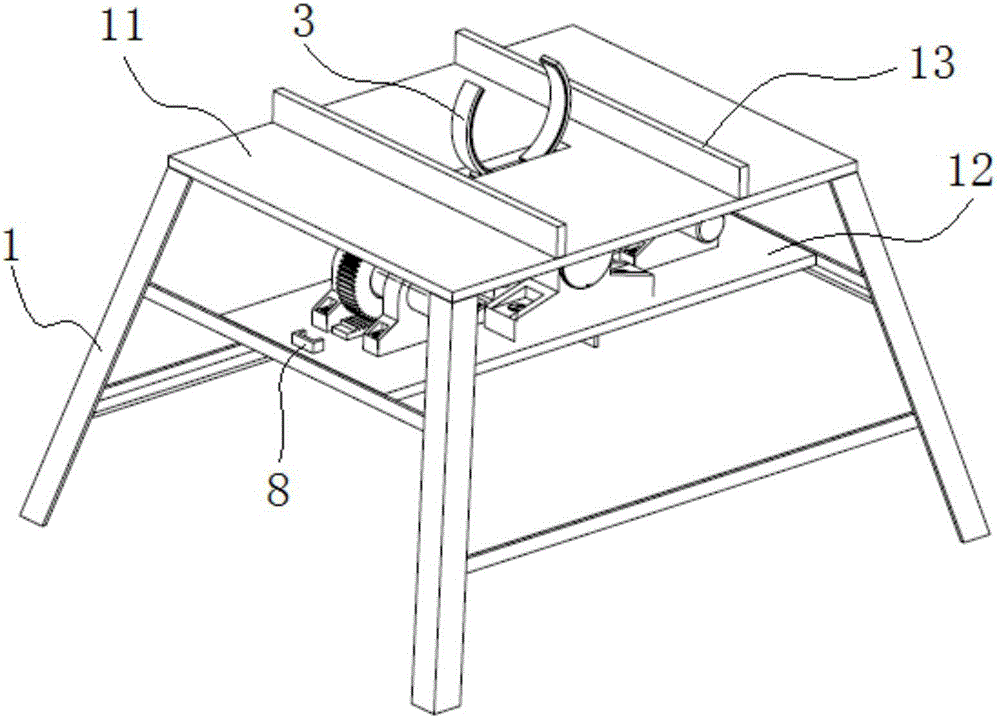

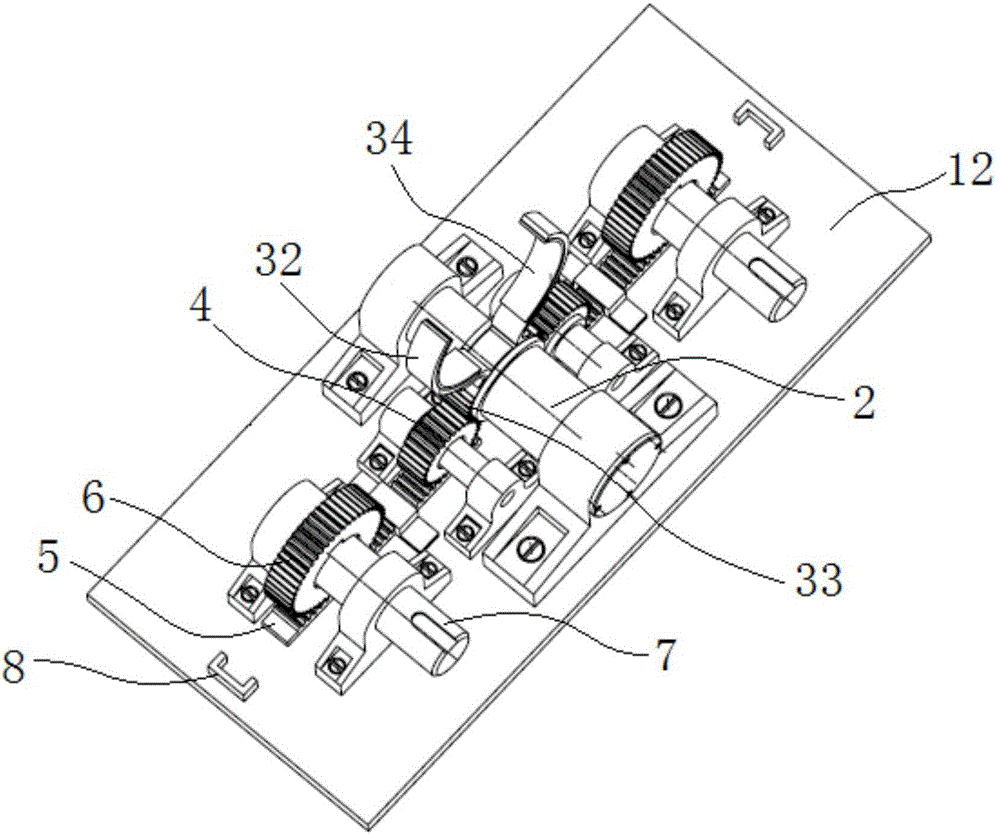

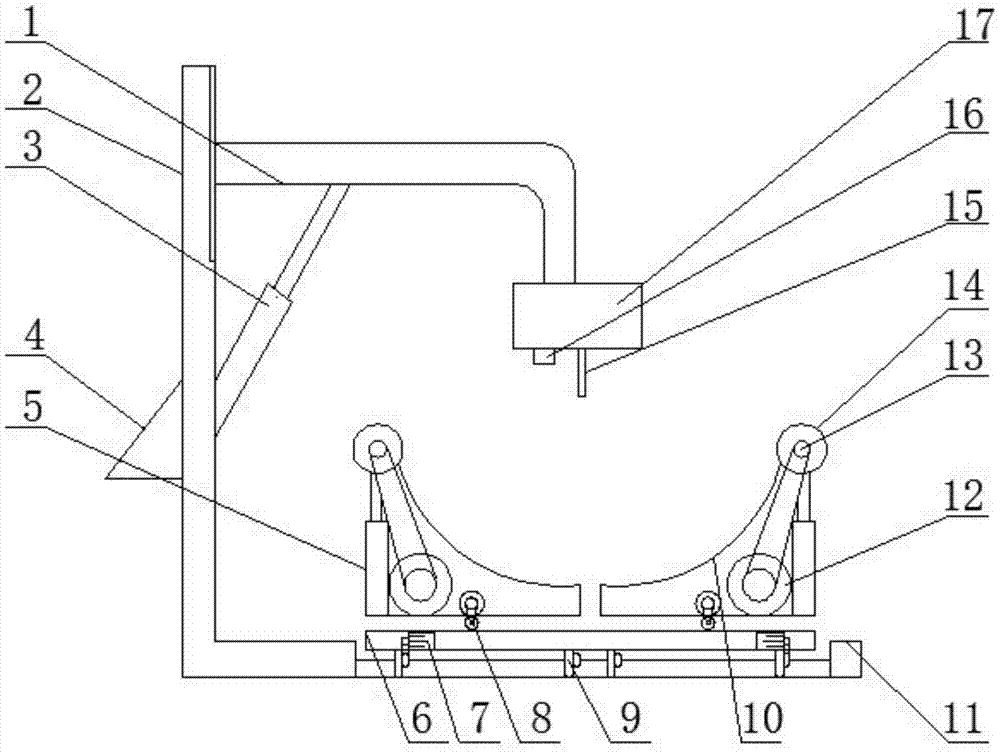

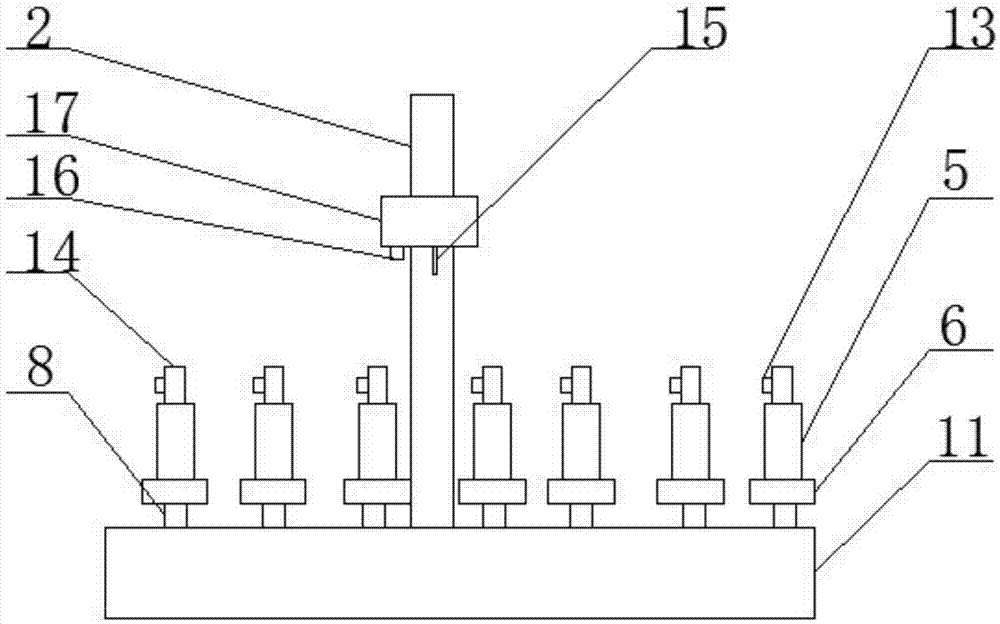

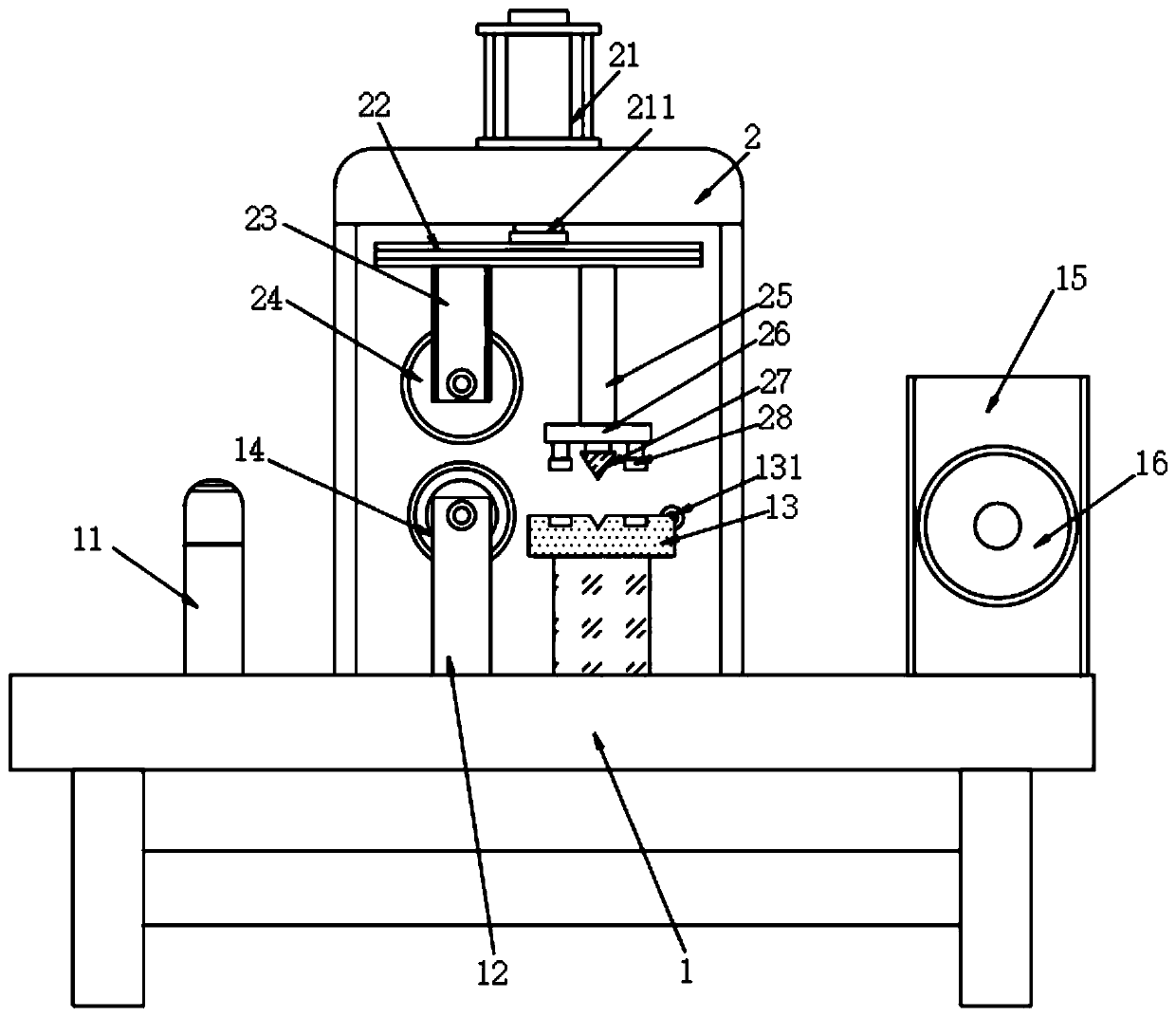

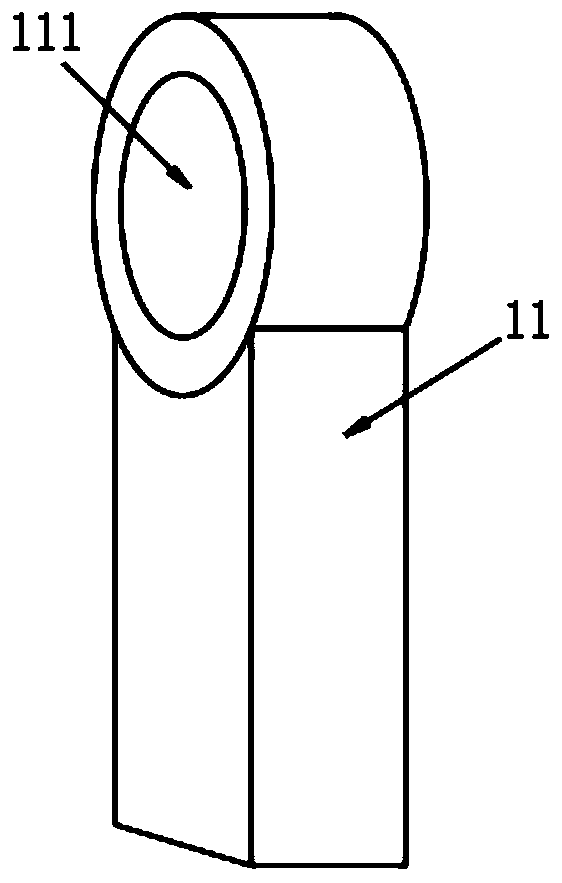

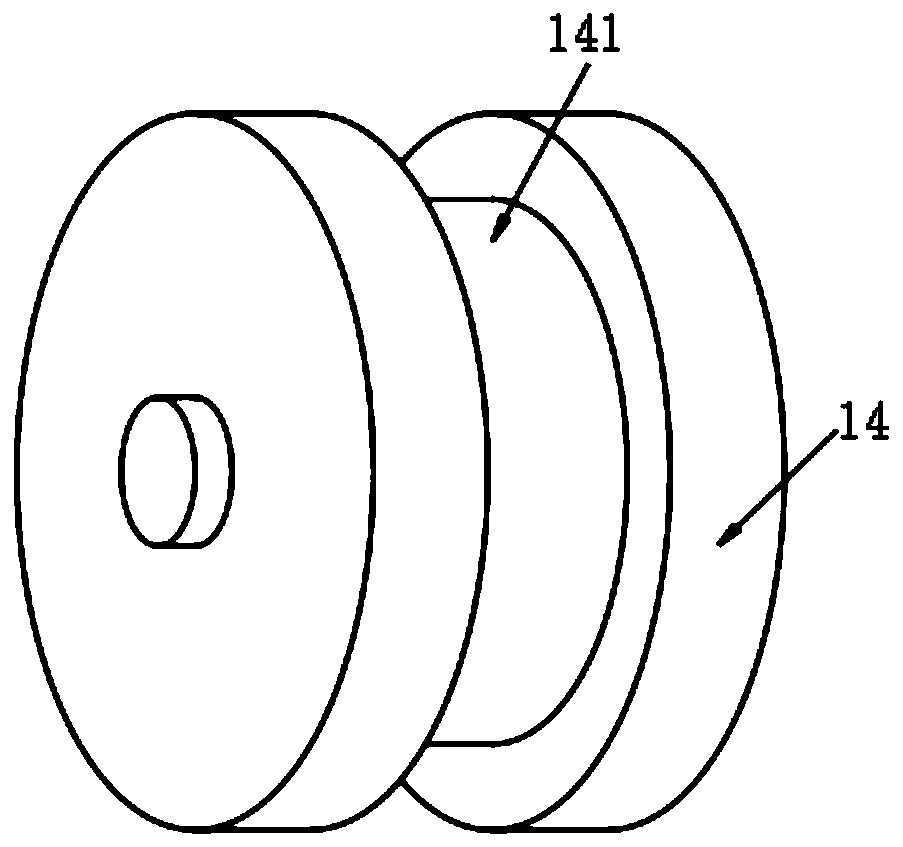

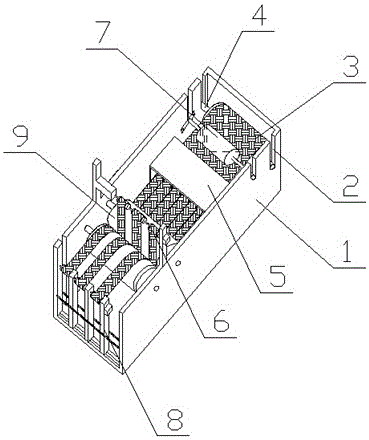

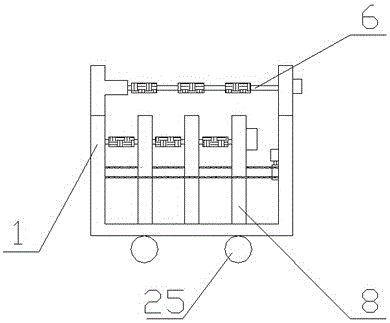

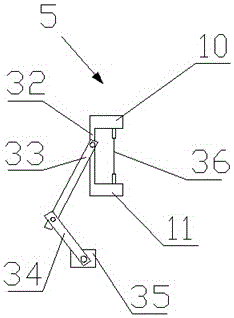

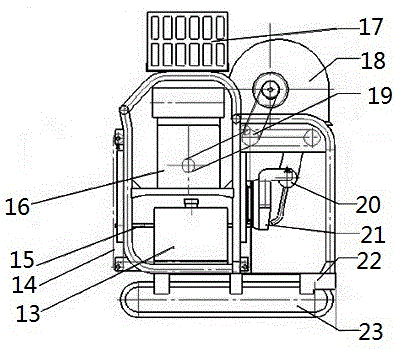

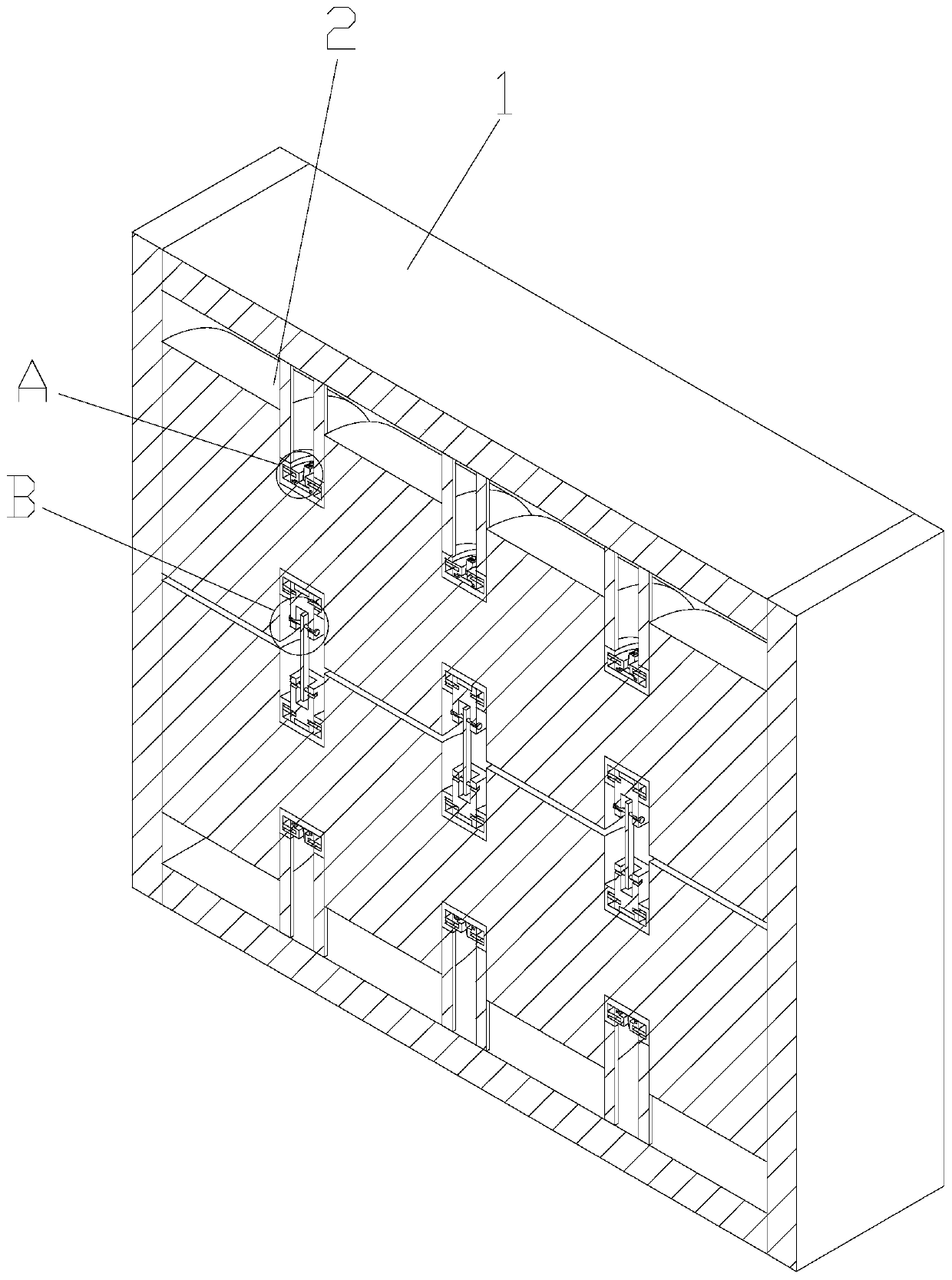

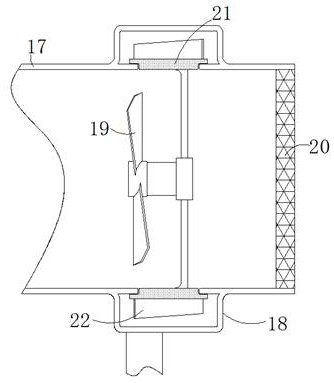

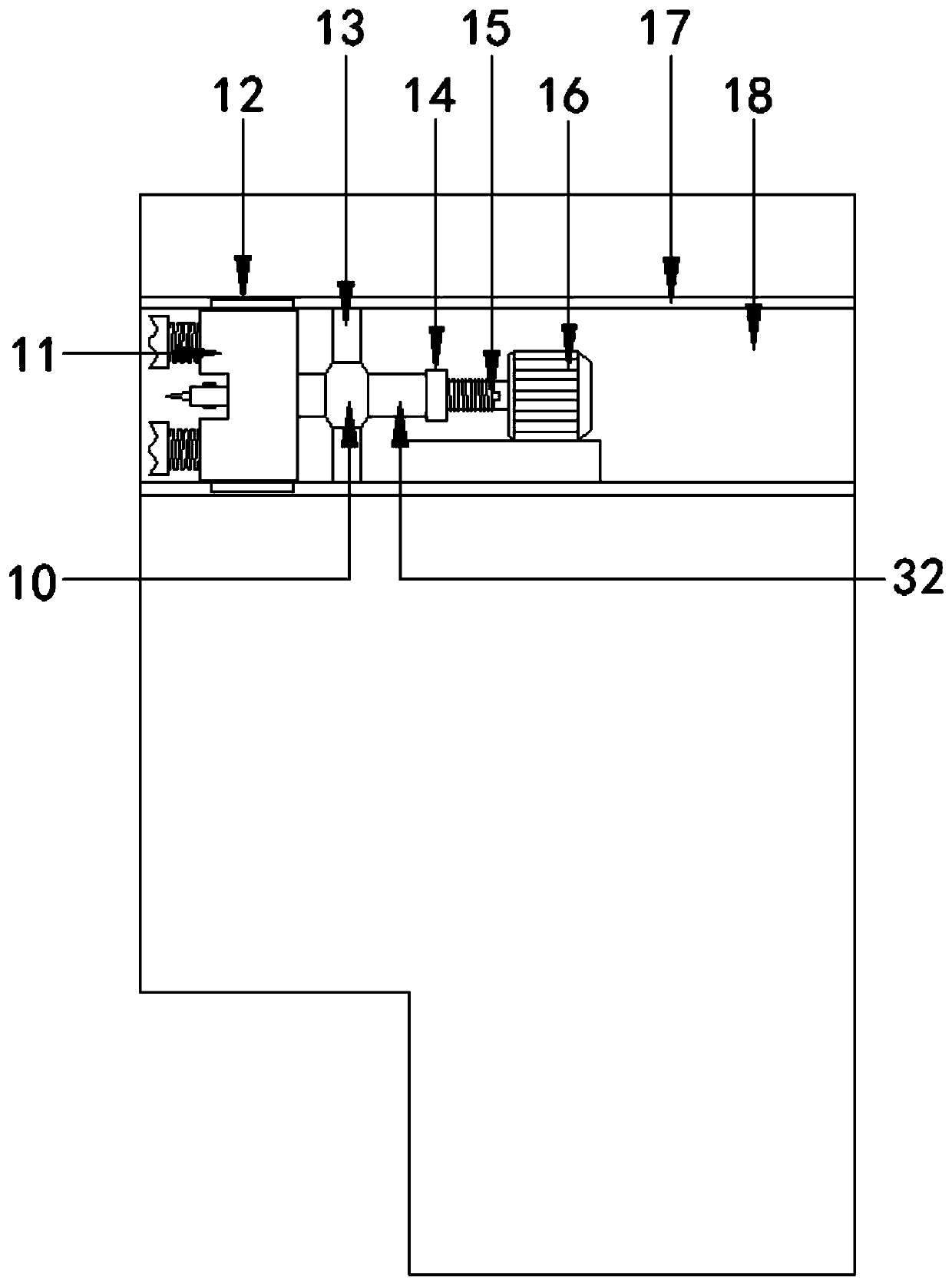

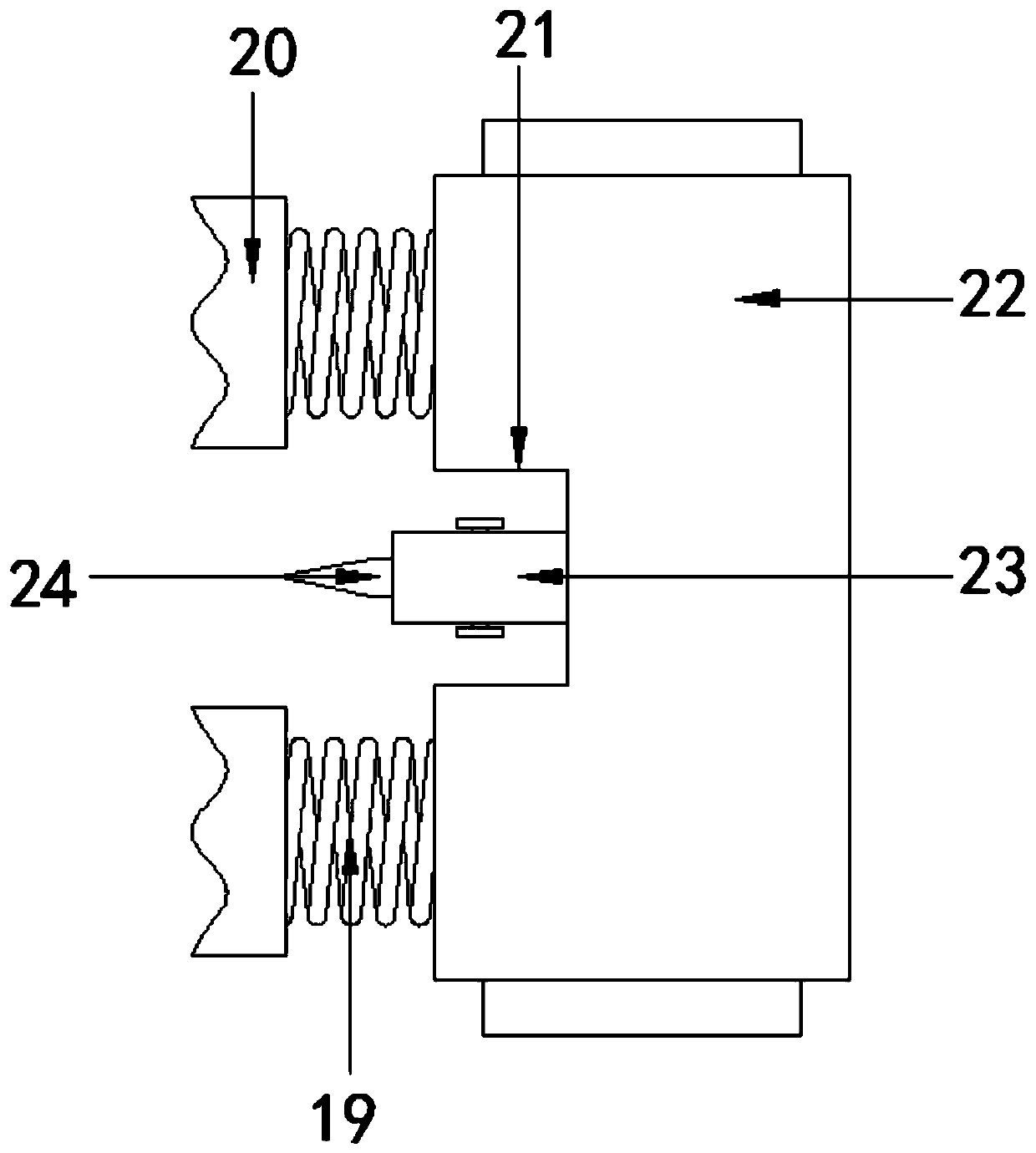

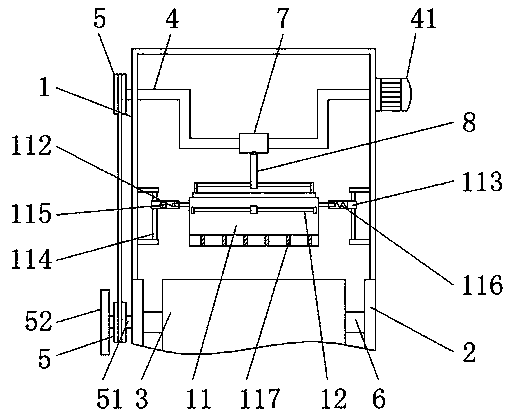

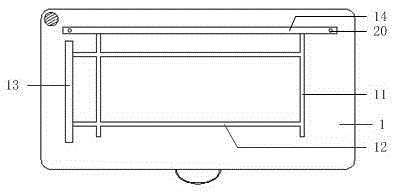

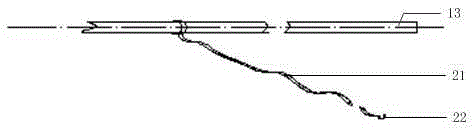

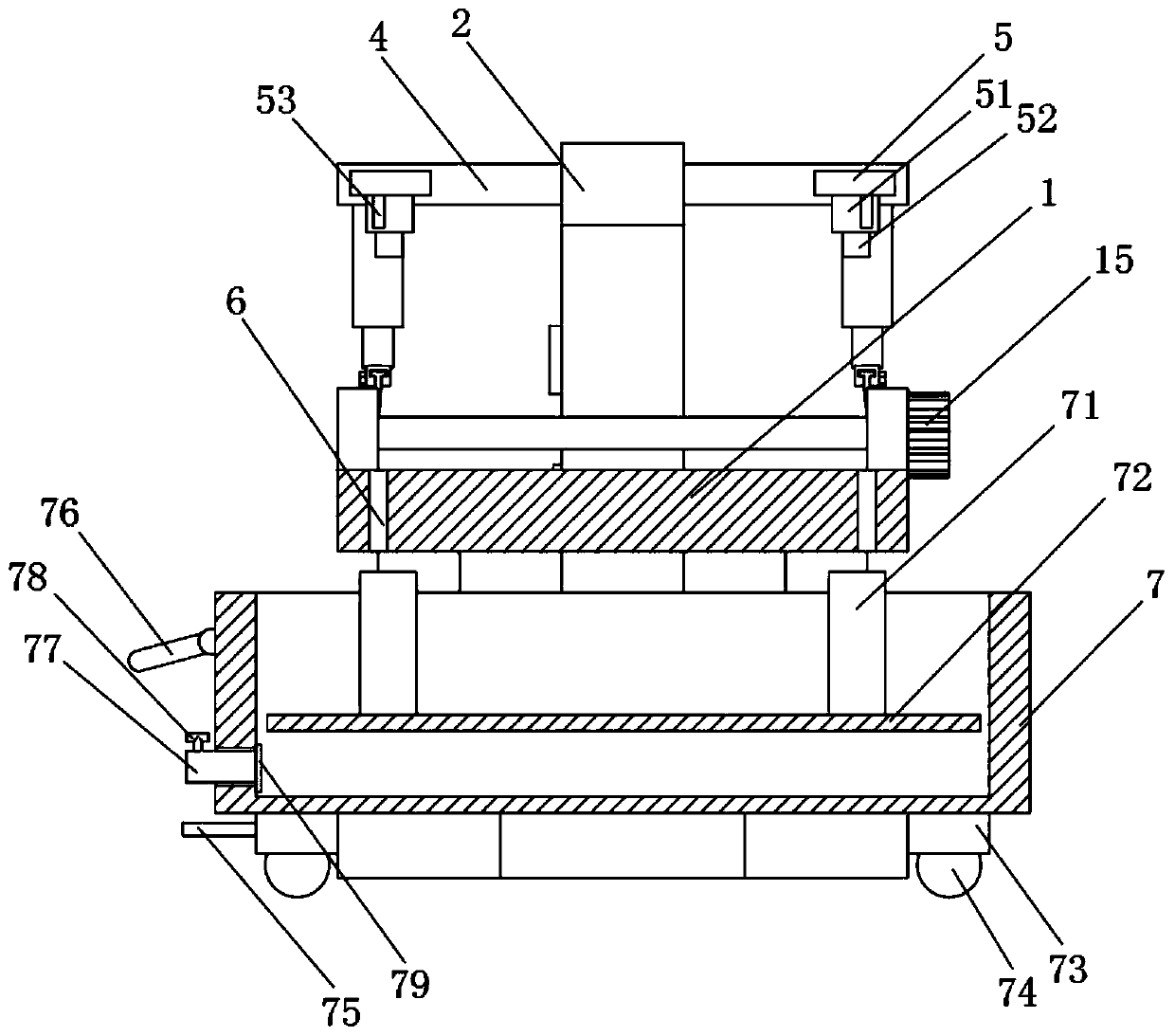

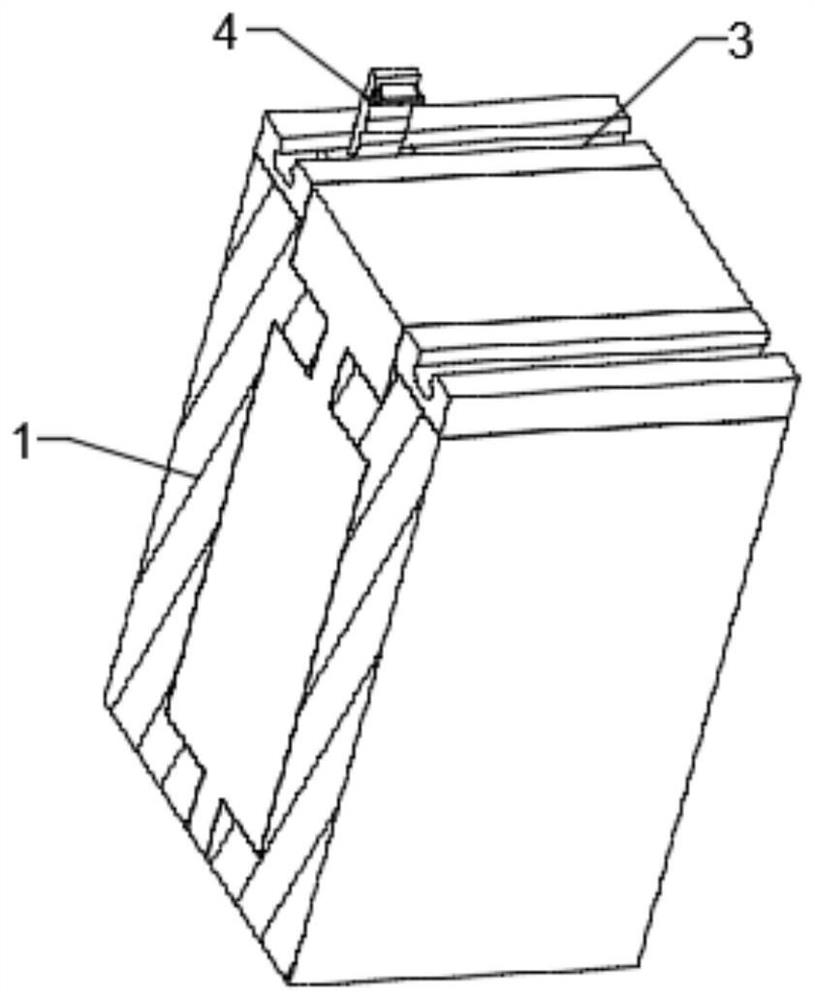

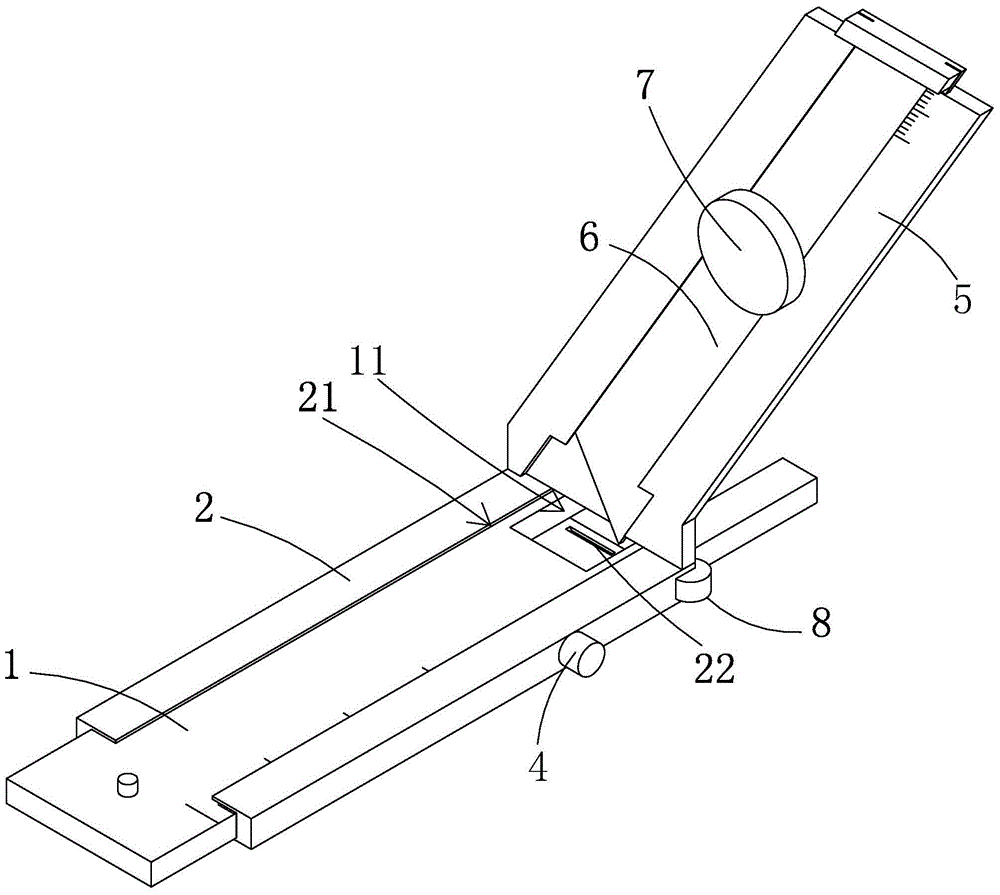

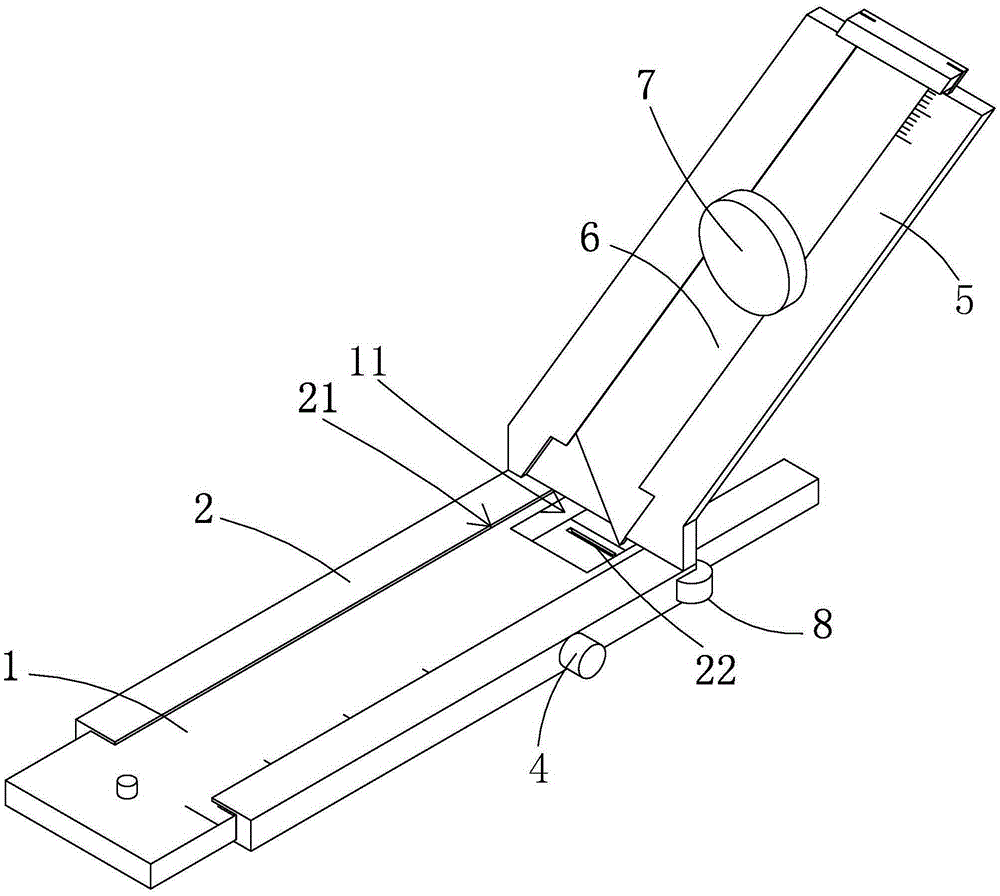

Toner cartridge splitting apparatus provided with binding band

The invention discloses a toner cartridge splitting apparatus provided with a binding band. The apparatus comprises an operating console (1); a movable horizontal support (13) and a vertical support (14) are arranged on the operating console (1); the horizontal support (13) and / or the vertical support (14) are provided with a binding band (21); the other side of the binding band (21) is provided with a hook (22); the lateral side of the operating console (1) is provided with a snap ring (23) corresponding to the hook (22); and when a toner cartridge is fixed, the hook (22) is hung on the snap ring (23). By moving the horizontal support (13) and the vertical support (14), the toner cartridge is limited in a certain range; through the binding band (1), the toner cartridge can be firmly fixed on the operating console, the cutting can be carried out successfully; the structure is simple, the operation is easy, and the work efficiency is effectively improved.

Owner:SHANGHAI XUNXI INFORMATION TECH CO LTD

A portable sugarcane peeler

InactiveCN109247592BSimple structureEasy to operateVegetable peelingAgricultural engineeringElectric machinery

Owner:NANJING LISHUI HIGH-TECH VENTURE CAPITAL MANAGEMENT CO LTD

Cutting device for shielding layer of communication wire and cable

ActiveCN110661207BAvoid shakingAvoid uneven cutsApparatus for removing/armouring cablesElectric machineGear wheel

The invention discloses a cutting device for a communication wire and cable shielding layer. The device comprises a bottom plate, and a motor and a sleeve are mounted on the top wall of the bottom plate, wherein the motor is located at the outer side of the sleeve; two annular groove plates are arranged on the symmetrical outer side walls of the sleeve, and supporting plates are mounted on the bottom walls of the two annular groove plates; the bottom ends of the two supporting plates are mounted on the top wall of the bottom plate; a gear is installed at the driving end of the motor, a ring gear meshed with the gear is installed on the side wall of one end of the sleeve, a cable is arranged in the sleeve in a penetrating mode, four cutting devices are symmetrically installed on the outer side wall of the sleeve, and a positioning groove is formed in the top wall of the bottom plate. Through the mutual cooperation of all the structures, a shielding layer and an insulating layer of the cable can be cut, and the cutting length of the cable and the depth of a notch can be simply and effectively adjusted; the device has the beneficial effects that the cutting speed is high, the notch isneat, and a cable core cannot be damaged.

Owner:四川越洋电子科技有限责任公司

A cloth transport device capable of hair removal

ActiveCN108893967BEasy to replaceEasy to assemble and disassembleSevering textilesElectric machineEngineering

The invention discloses a cloth conveying device capable of performing deburring treatment. The cloth conveying device comprises a main body and an installing frame. The installing frame is installedat the side face of the main body. The side surface of the installing frame is provided with a PLC controller. An input end of the PLC controller is electrically connected with an output end of an external power source. Four corners of the lower surface of the main body are uniformly provided with support columns. The lower surfaces of the support columns are provided with ground legs. Two sides of the upper surface of the main body are provided with fixing bases. The side surface of one group of the fixing base is provided with a first motor. An input end of the first motor is electrically connected with an output end of the PLC controller. An output shaft of the first motor passes through the side surface of the fixing base and is connected with a feed roller through a coupling. The sidesurface of the other group of the fixing base is provided with a second motor. The beneficial effect is that the cloth conveying device is capable of performing the deburring treatment, improving anintelligent degree, automatically removing raw edges of cloth, and improving working efficiency.

Owner:临沂恩科开发建设有限公司

Thin-wall cable cutting device for new energy automobiles

PendingCN112053805AAvoid dangling stateAvoid incomplete cuttingCable/conductor manufactureNew energyEngineering

The invention discloses a thin-wall cable cutting device for new energy automobiles. The device comprises a bottom plate, supporting plates are fixedly connected to the two sides of the top of the bottom plate, a top plate is fixedly connected between the tops of the two supporting plates, an air cylinder is fixedly connected to the top of the top plate, a fixing rod is fixedly connected to the output end of the air cylinder, and the output end of the fixing rod penetrates through the top plate and extends to the bottom of the top plate.The invention relates to the technical field of cable processing. According to the thin-wall cable cutting device for new energy automobiles, the supporting plates are fixedly connected to the two sides of the top of the bottom plate, a cable is fixed and limited, the position of the cable is prevented from deviating in the cutting process, and the cutting quality is improved. Meanwhile, a blade moves downwards under the action of an air cylinder to cutthe cable pressed on a cutting table. Supporting frames are fixedly connected to the two sides of the top of the bottom plate correspondingly, the cable can be driven to move under the rotating action of a roller and a limiting cylinder, and manual operation is reduced.

Owner:ANHUI STAR CABLE

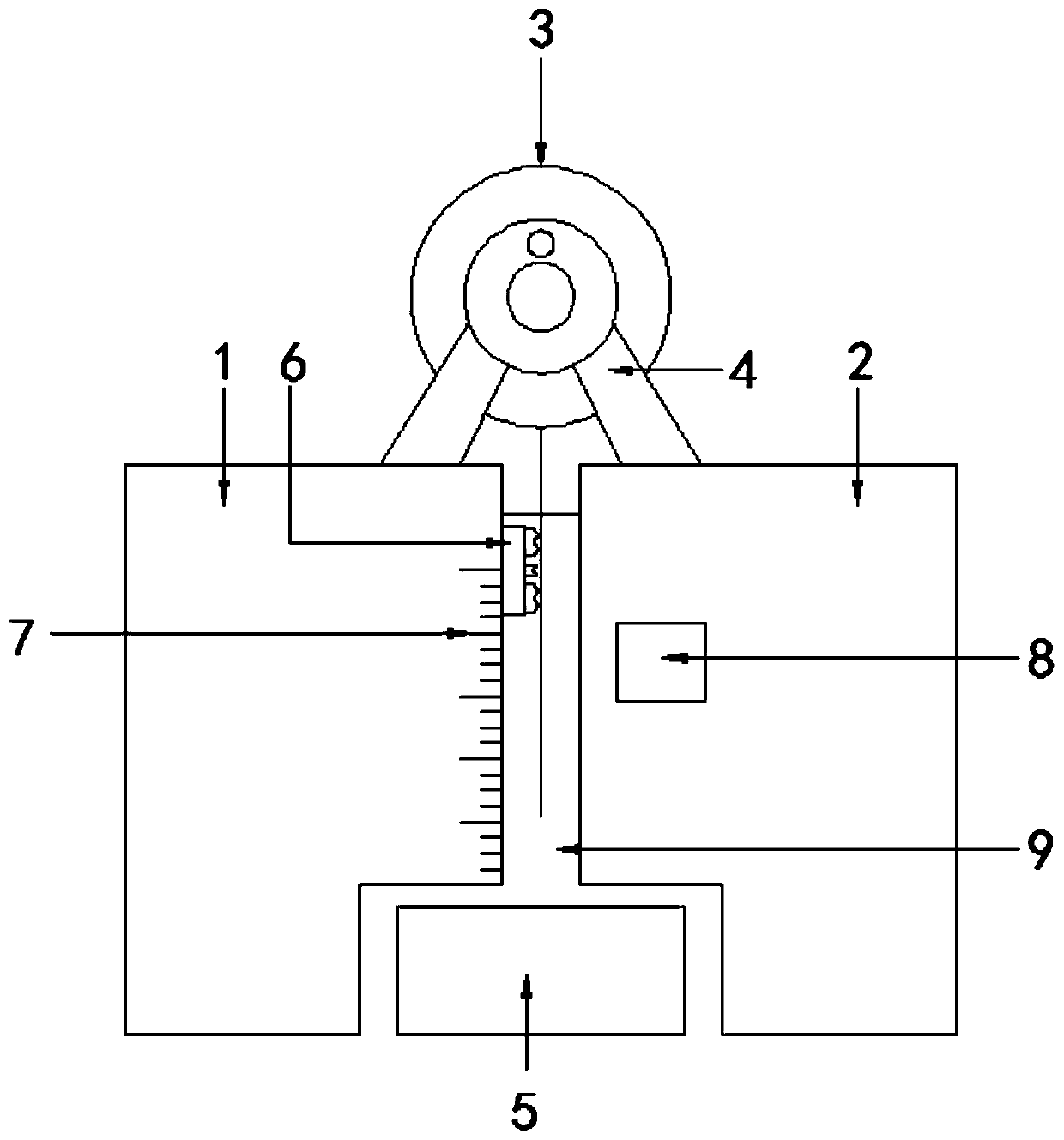

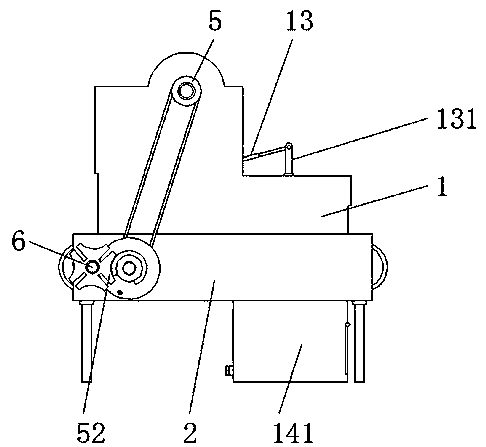

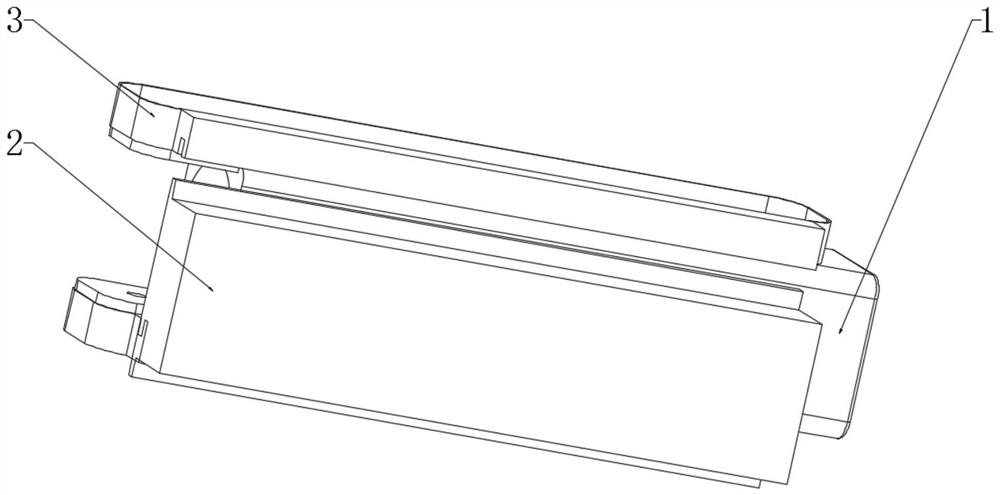

A cloth cutting device

The invention discloses a cloth cutting device. The cloth cutting device comprises a machine body (1) provided with a groove (2). The groove (2) is internally provided with a first shaft (4) provided with a first rotating wheel (3). A cloth control device (7) is arranged in front of the first rotating wheel (3). A cutting device body (5) is arranged in front of the cloth control device (7), a direction dividing device (9) is arranged in front of the cutting device body (5), and a first cloth collecting device (8) is arranged in front of the direction dividing device (9). A second cloth collecting device (6) is arranged above the direction dividing device (9). The first cloth collecting device (8) is connected with the machine body (1) through a sliding groove, and the direction dividing device (9) is arranged on the machine body (1). By means of the cloth cutting device, cloth can be cut, labor is saved, efficiency is high, the size of the cut cloth is even, cloth can be automatically collected, and the cloth cutting device is convenient to use.

Owner:瓮安县雅韵服饰有限公司

tea picker

ActiveCN105123121BIncrease tea productionPossess practical promotionPicking devicesControl engineeringManipulator

Owner:重庆市乾丰茶业有限责任公司

Adjustable cutting machine

InactiveCN113414712AAvoid incomplete cuttingMeeting Diversity RequirementsBlast gunsAbrasive machine appurtenancesStructural engineeringMachine

The invention discloses an adjustable cutting machine. The adjustable cutting machine comprises a cutting seat body used for fixedly clamping a to-be-cut tubular material along the center axis of the cutting seat body, a cutting spray head used for cutting the tubular material, and an adjusting assembly used for driving the cutting spray head to slide according to a preset track so as to adjust the shape and the angle of a cutting surface of the cut tubular material, wherein one end of the adjusting assembly is movably connected to the top end surface of the cutting seat body, and the other end of the adjusting assembly is movably connected to the cutting spray head. According to the invention, the cutting spray head acts on the to-be-cut tubular material through the adjusting assembly, the moving track of the cutting spray head is controlled through the adjusting assembly, and therefore the cutting spray head can move around the edge of any cutting surface by a circle, and in the process, the requirement for diversity of the shape and angle of the cutting surface is met, and the situation that the tubular material is not cut thoroughly due to the fact that the effective cutting distance of the cutting spray head is too short or the cutting energy is attenuated in a long distance can be avoided.

Owner:曹松禄

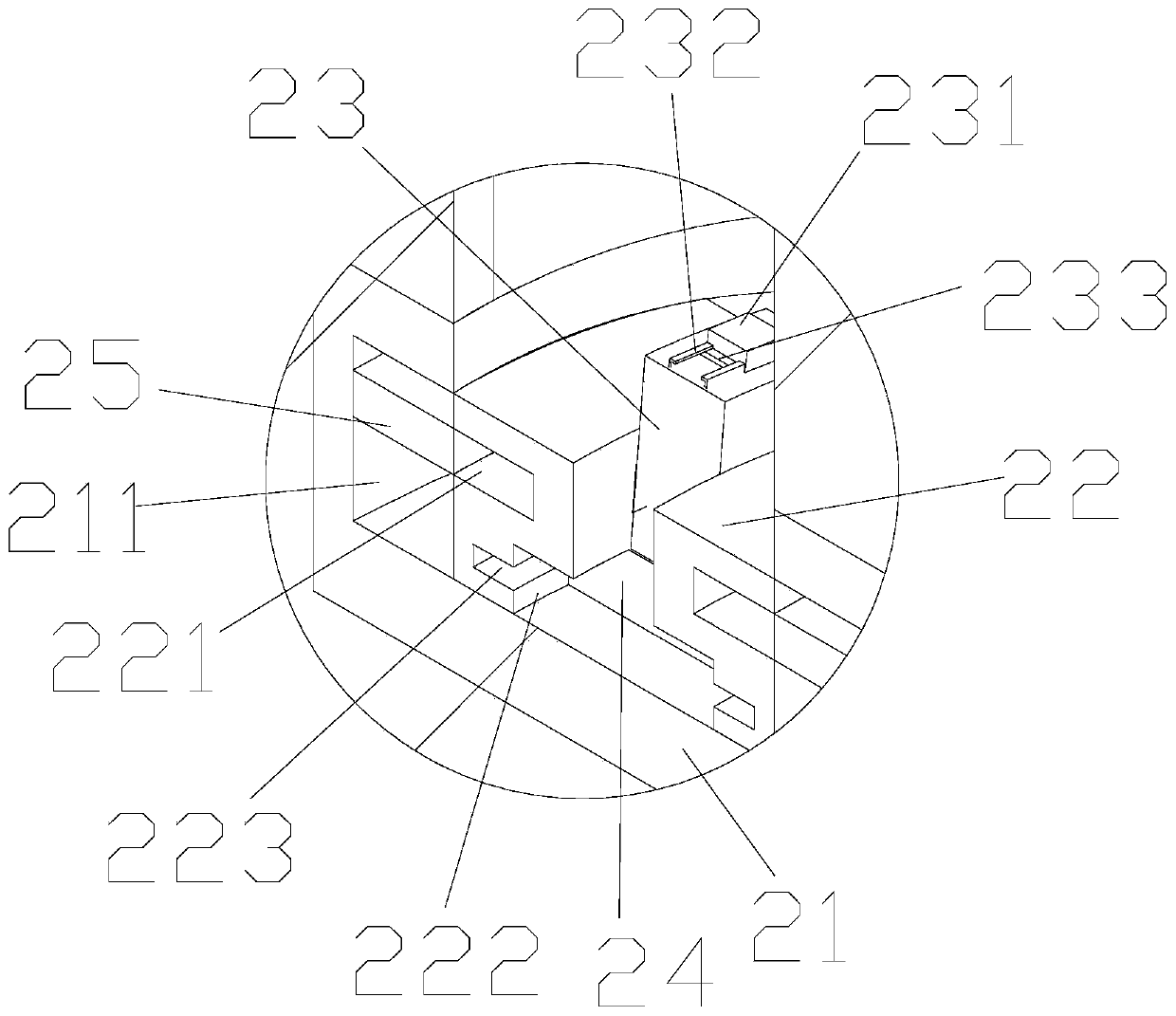

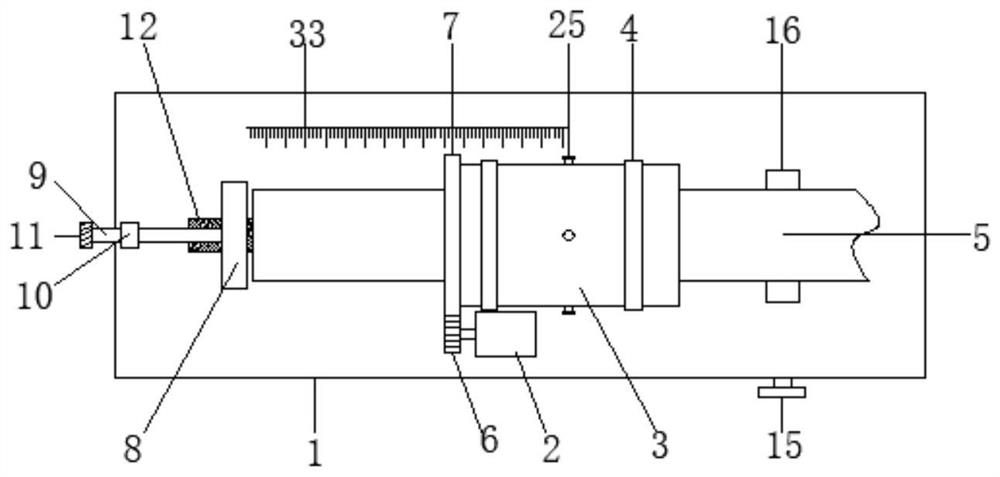

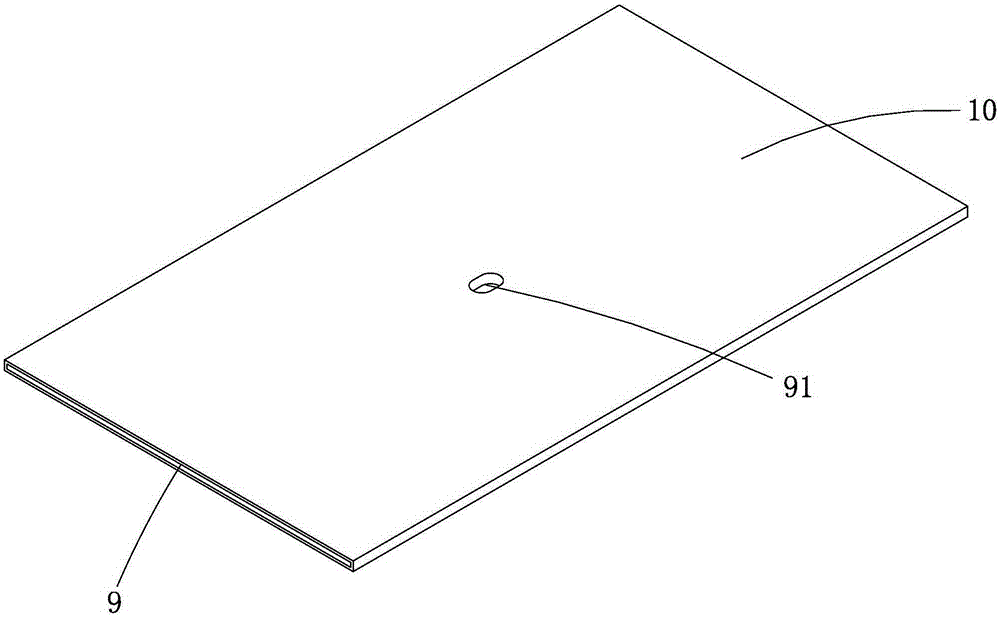

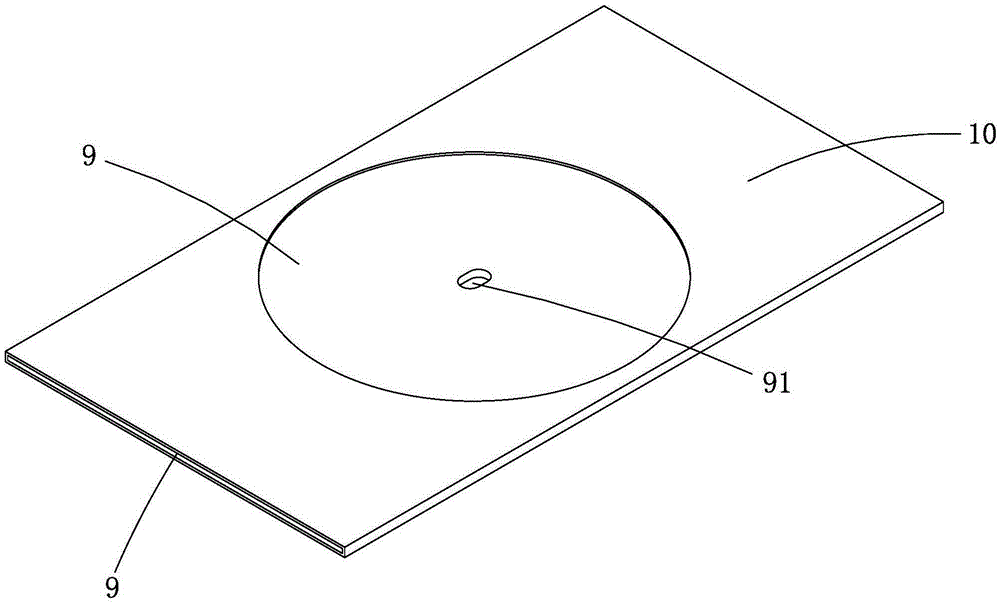

Busbar Heat Shrink Tube Hole Cutter

Owner:STATE GRID CORP OF CHINA +1

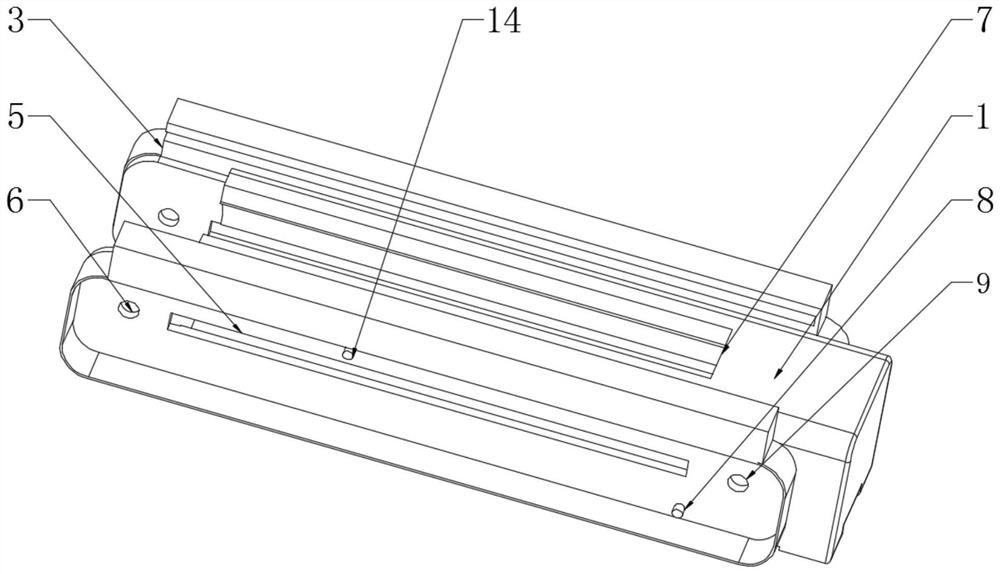

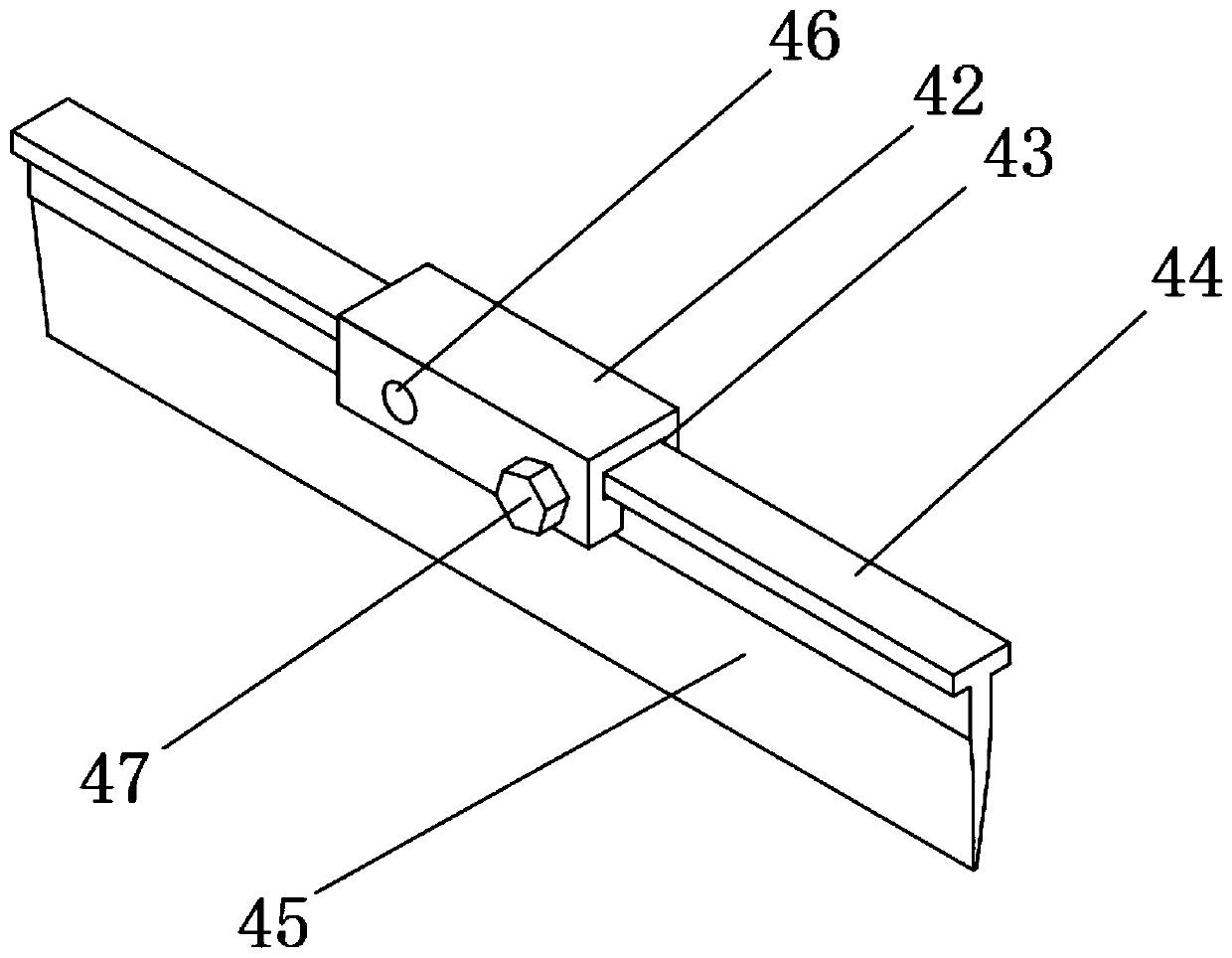

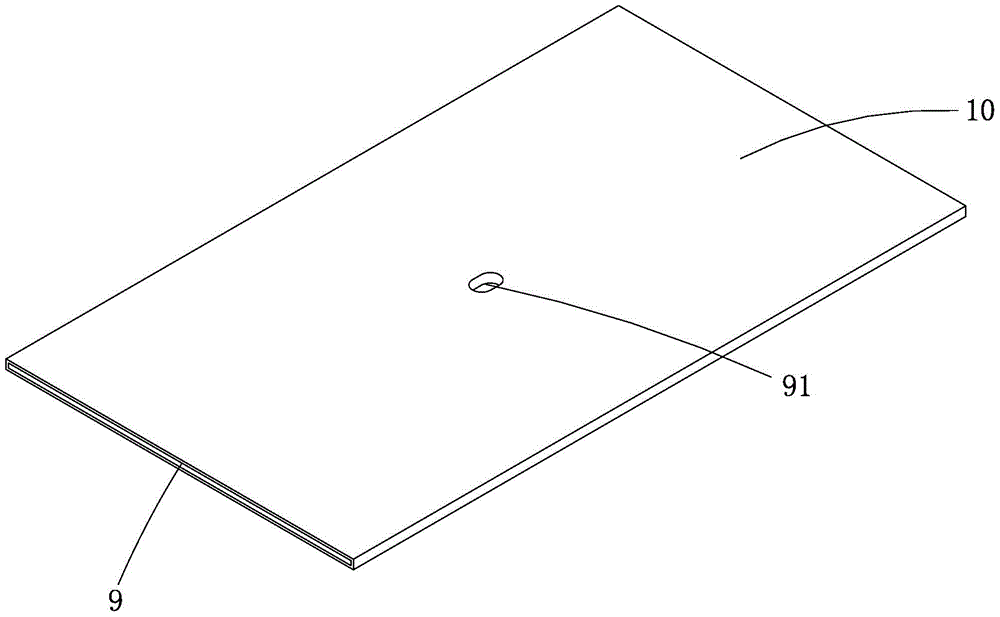

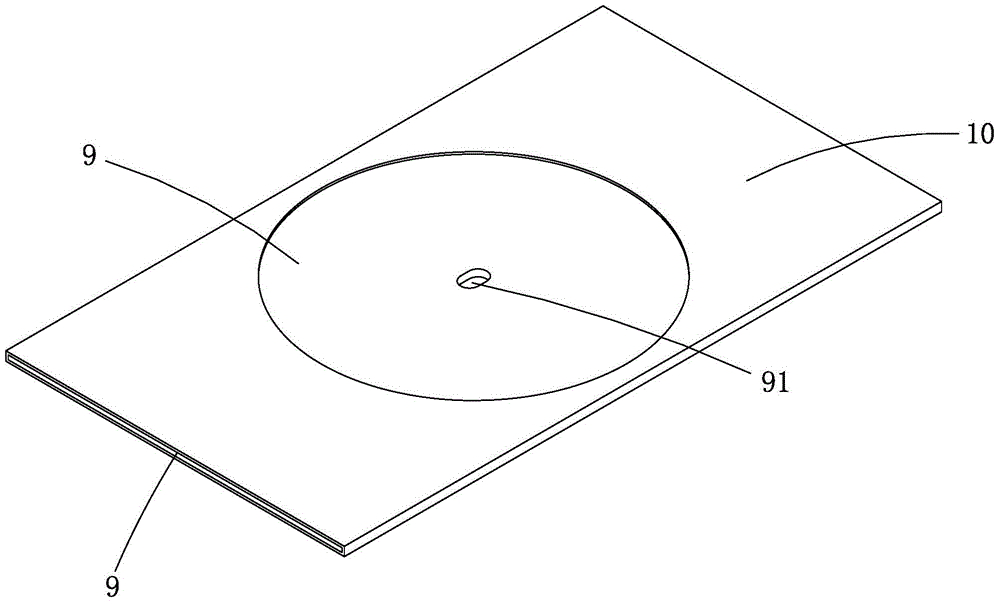

Busbar heat-shrinkable tube hole cutting device

The invention relates to a busbar heat-shrinkable tube hole cutting device. The busbar heat-shrinkable tube hole cutting device comprises a telescopic rotating assembly and a feed assembly which is perpendicularly arranged on the telescopic rotating assembly. The telescopic rotating assembly comprises a positioning plate, a sliding sleeving part, a positioning block and a locking part A, wherein the positioning plate is sleeved with the sliding sleeving part in a sliding mode, the positioning block is hinged to the bottom surface of the front side of the positioning plate, and the locking part A is used for locking the sliding sleeving part and the positioning plate. The feed assembly comprises a blade fixing sliding rail, a feed blade and a locking part B, wherein the blade fixing sliding rail is fixedly arranged at the rear end of the sliding sleeving part, the feed blade is arranged on the blade fixing sliding rail in a sliding mode, and the locking part B is used for locking the blade fixing sliding rail and the feed blade. The feed direction of the feed blade is perpendicular to the positioning plate, and the feed blade penetrates out of the bottom of the telescopic rotating assembly. The busbar heat-shrinkable tube hole cutting device is simple in structure and convenient to operate. The busbar heat-shrinkable tube hole cutting device has the advantages that the hole cutting efficiency is greatly improved, and generated circular holes are regular and attractive.

Owner:STATE GRID CORP OF CHINA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com