Patents

Literature

159results about How to "Can work continuously" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nitrogen oxide oxidizing catalyst and preparation method of nitrogen oxide oxidizing catalyst

InactiveCN102553573AImprove conversion rateReduce energy consumptionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNitrogen dioxideFlue gas

The invention provides a catalyst for purifying nitrogen oxide. In the presence of oxygen, conversion from nitrogen oxide (such as NO, N2O and the like) to nitrogen dioxide can be realized at lower temperature. The catalyst is prepared by a coprecipitation method or a soaking method and the main active component of the catalyst is manganese oxide. The catalyst is suitable for catalytic oxidation of nitrogen monoxide in flue gas and then integrated control of desulfurization and denitrification is realized. The catalyst is applied to a purification test of simulated flue gas with NO concentration of 200ppm, the conversion from the NO to the NO2 can be realized at lower temperature, and the NO2 is fed into a desulfurizing tower for further reacting with a desulfurizing agent so as to realize removal of nitrogen oxides in flue gas. The catalyst has remarkable effect in flue gas denitrification of coal-fired industrial boilers, and has better practical value and economic benefit.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

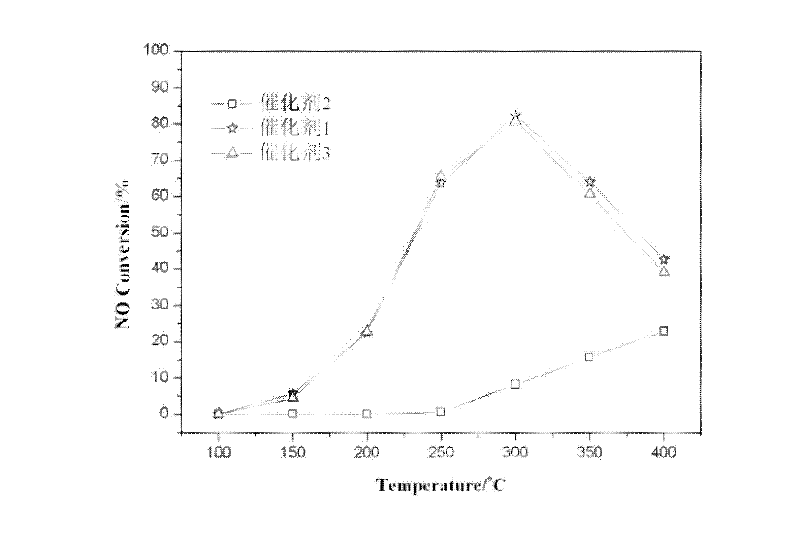

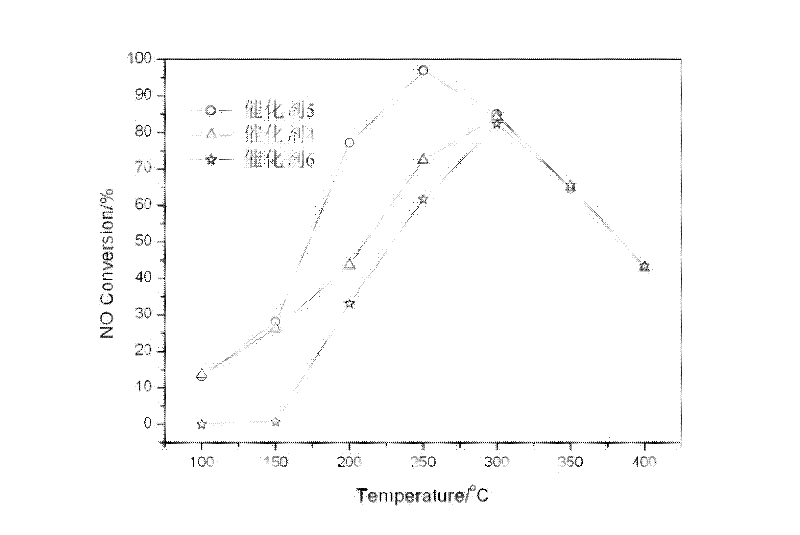

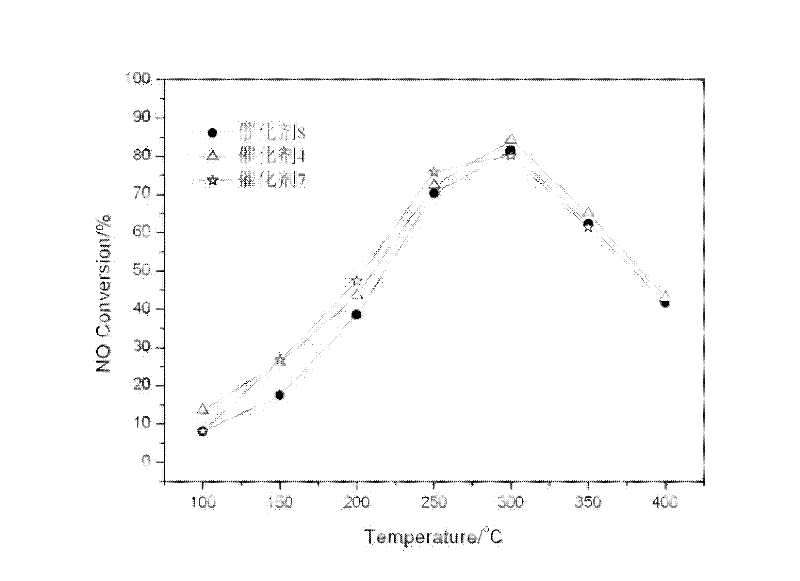

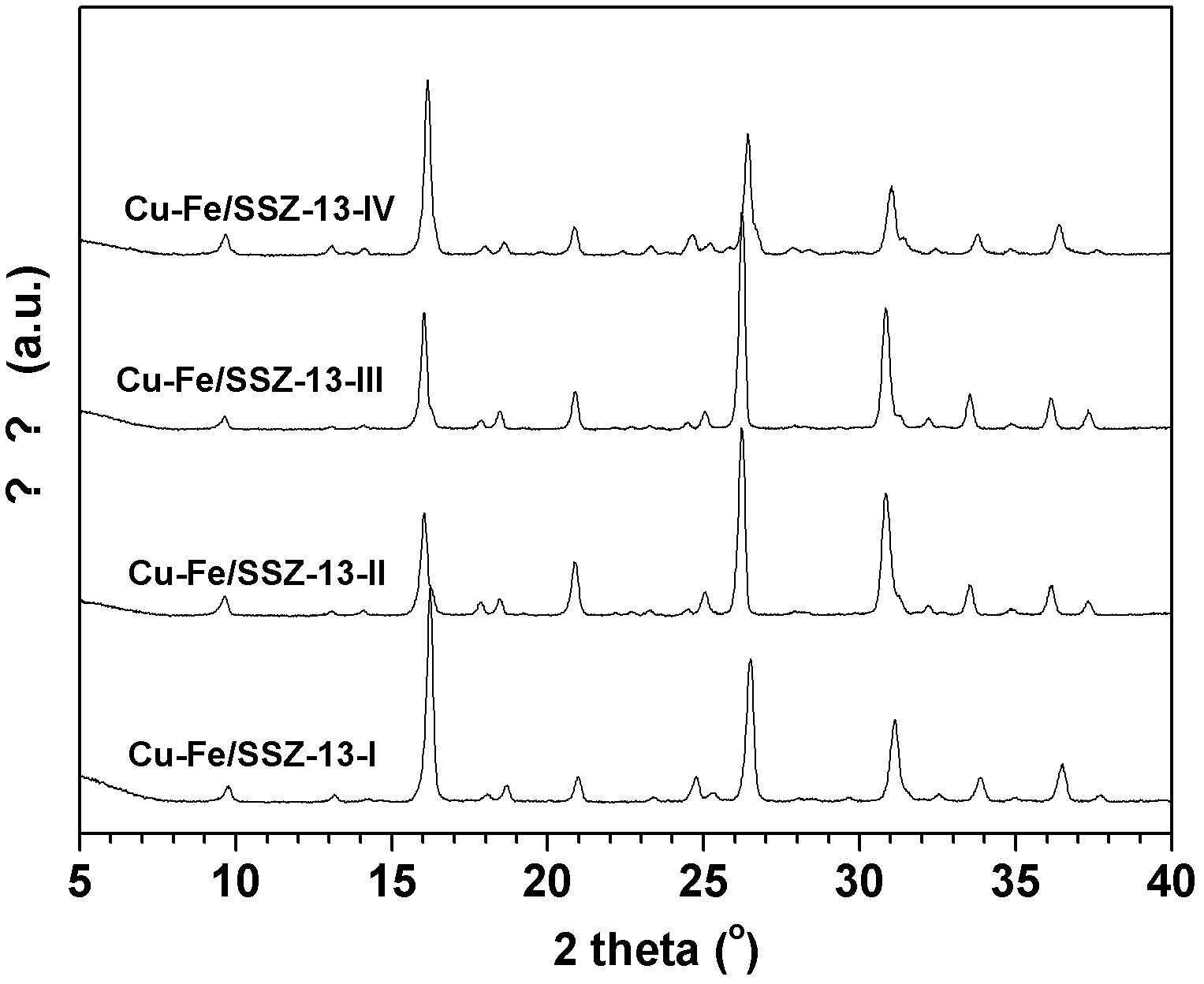

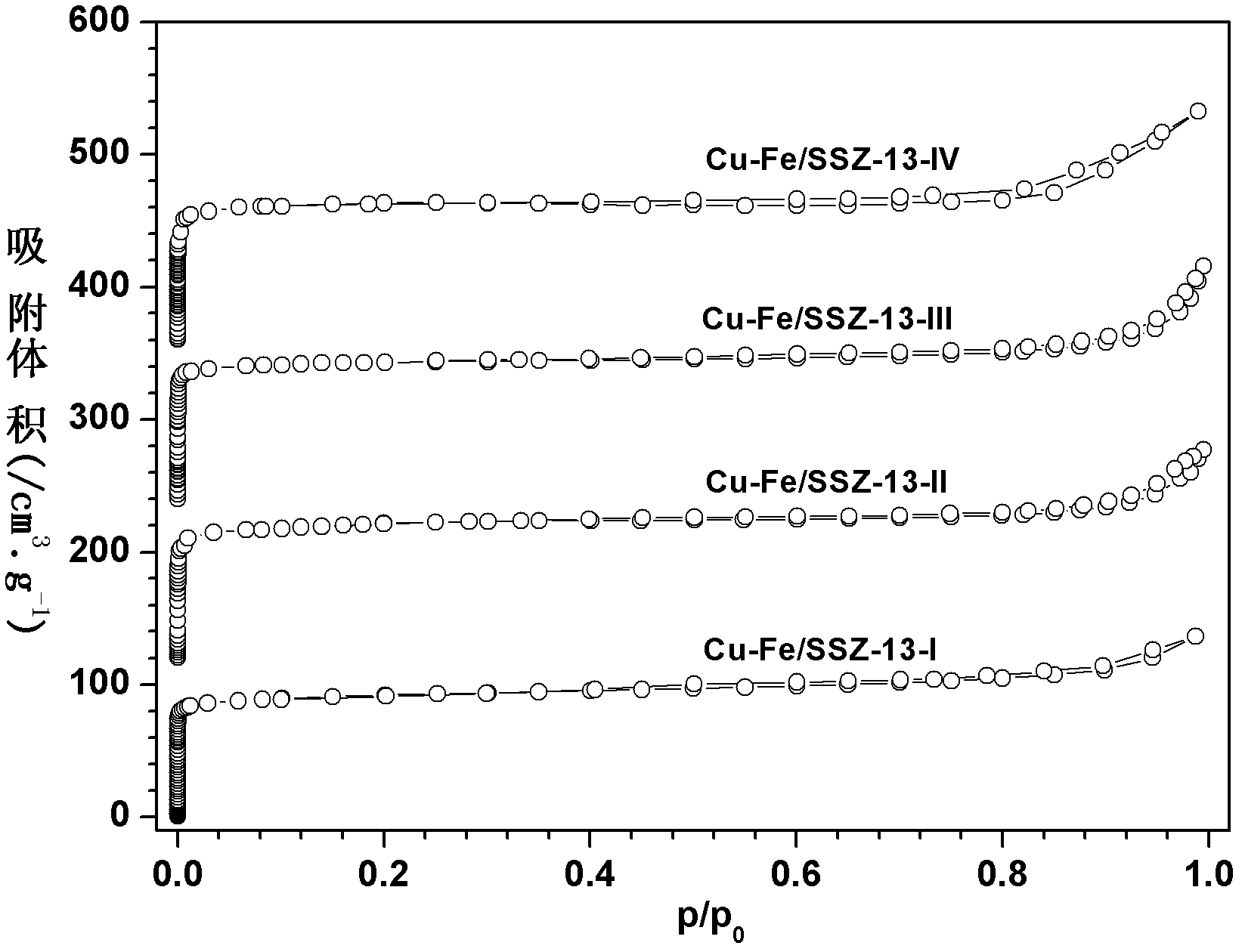

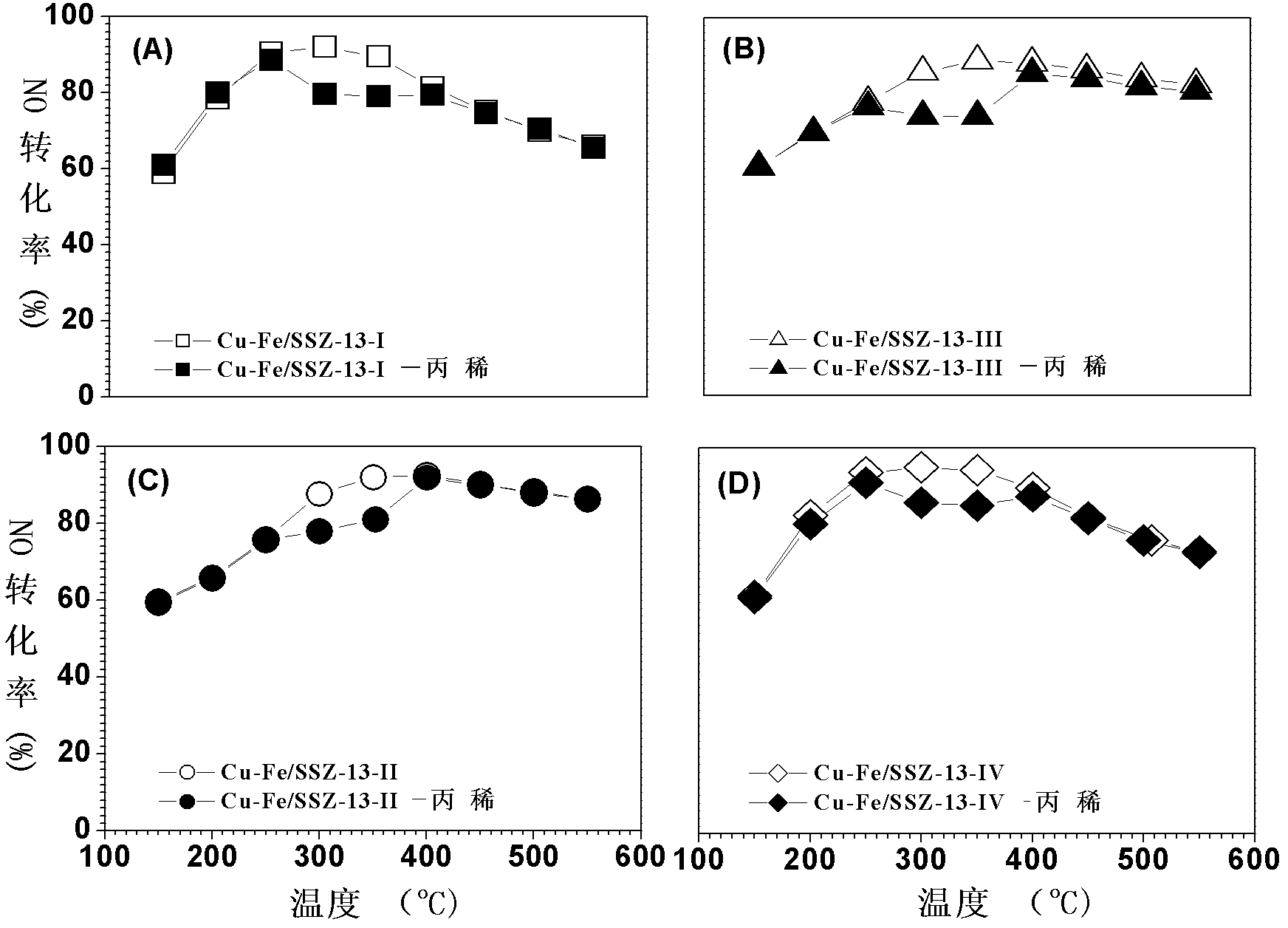

Preparation method of SSZ-13 loaded Cu-Fe catalyst for selectively catalyzing and eliminating NOx by ammonia

InactiveCN102614908AImprove anti-carbon performanceStable activityMolecular sieve catalystsDispersed particle separationIonIon exchange

The invention provides a preparation method of a SSZ-13 loaded Cu-Fe catalyst for selectively catalyzing and eliminating NOx by ammonia. The catalyst is used for catalyzing and eliminating nitrogen oxides. A micropore SSZ-13 molecular sieve carrier with high specific surface area (400-550 m2 / g) is prepared by using a soft template method. And then by using a mixed solution of ferric chloride and copper chloride as well as a SSZ-13 molecular sieve ion exchanging method, the SSZ-13 molecular sieve loaded Cu-Fe composite catalyst is prepared. According to the invention, within a wide temperature range (150-550 DEG C), high catalytic eliminating effect and higher stability are obtained for a pollutant with high airspeed (120, 000 mL. (g.h)-1 - 1-360,000 mL.(g.h)-1), high O2 concentration (10vl.%-20v1.%), high H2O content (5wt%-10wt%) and low concentration NO (300-1000 ppm). After a hydrocarbon compound (300-1000 ppm propylene) is added to a reaction system, the catalyst prepared by the preparation method provided by the invention has the advantages of high carbon deposition resistance and high hydrothermal stability.

Owner:BEIJING UNIV OF TECH

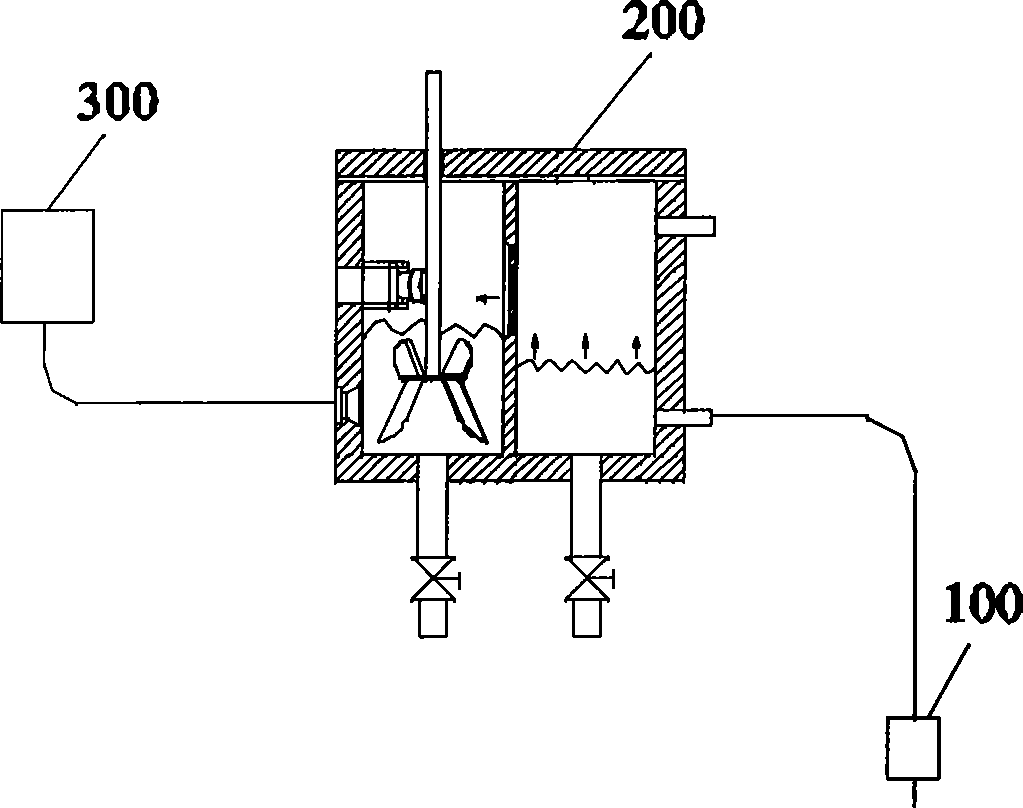

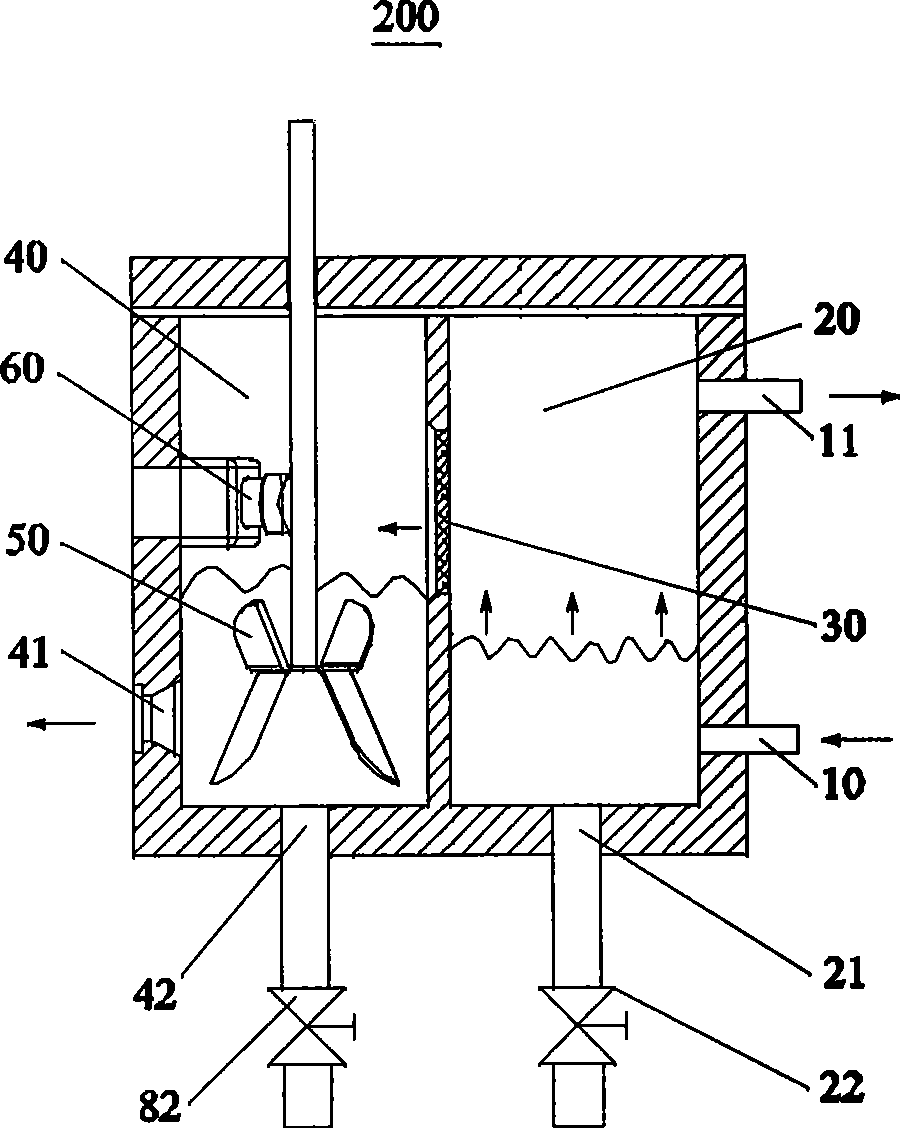

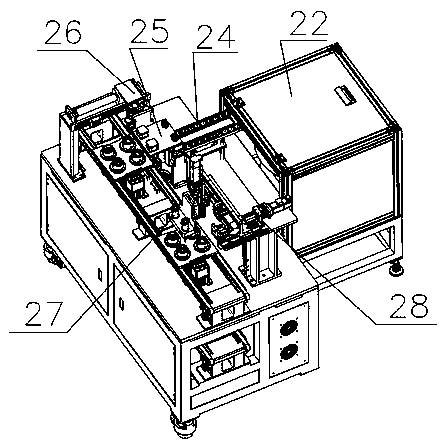

Water quality on-line detection method and system

ActiveCN101430312ANot easy to blockImprove reliabilityPreparing sample for investigationTesting waterOnline analysisWater velocity

The invention discloses a method for on-line detecting water quality, which comprises the following steps: a. sample collecting, wherein, water sample in the test environment is collected and delivered to pretreatment device; b, pretreatment, wherein, water sample flows out from an inlet tube into a water container after flowing through a filter screen, wherein, the angle formed between the water velocity attitude and the filter screen is an acute or a right angle; and c. measuring, wherein, the water sample to be tested is collected from the water container, and the water parameter is obtained by analyzing the test water sample to be tested. The invention also discloses a system for on-line detecting water quality. The invention has the advantages of continuous working, uneasy blockage, low cost, and the like, and the invention can be applied in various water sample on-line analysis.

Owner:FOCUSED PHOTONICS +1

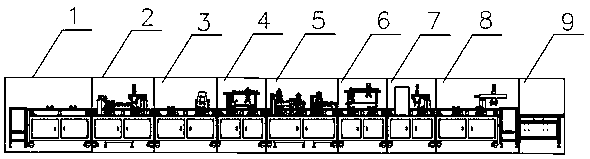

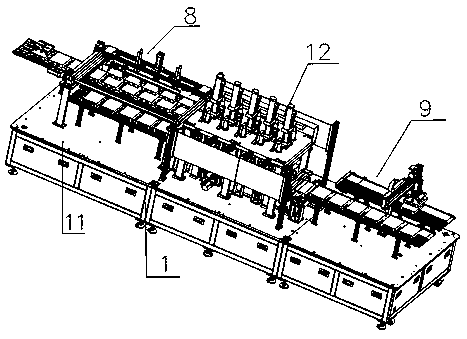

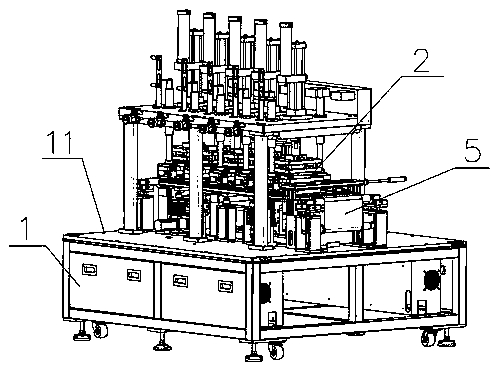

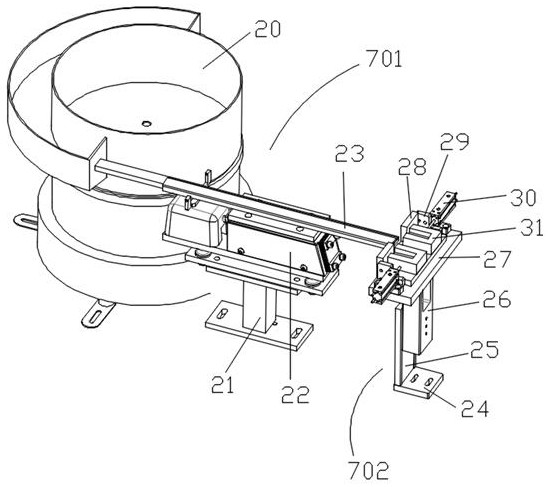

Automatic assembly system of LED bulb lamp

ActiveCN108655725ASimple structureEasy to useAssembly machinesSemiconductor devices for light sourcesLamp shellManipulator

The invention discloses an automatic assembly system of an LED bulb lamp. The system comprises a frame, a loading worktable, a radiator mounting worktable, an aluminum substrate mounting worktable, afirst overturning worktable, a lamp base mounting worktable, a second overturning worktable, a lamp cover mounting worktable, an unloading worktable and a collecting worktable; all the worktables areindependently operated, and are combined in sequence to form an assembly production line; a supply manipulator of a loading component clamps a lamp shell to put in a positioning cylinder of a carrierplate; the carrier plate with the lamp shell is driven through a conveying belt to move to each worktable; assembly of a radiator, assembly of an aluminum substrate, overturning, assembly of a lamp base, assembly of a lamp cover, unloading and detection are finished on the corresponding worktable; all parts are riveted and glued to finish assembly; and the system is simple in structure and convenient to use, realizes full automation, can continuously work, saves the manpower, meets the production demands, improves the production efficiency, and achieves excellent market application value.

Owner:江门市云聚照明科技有限公司

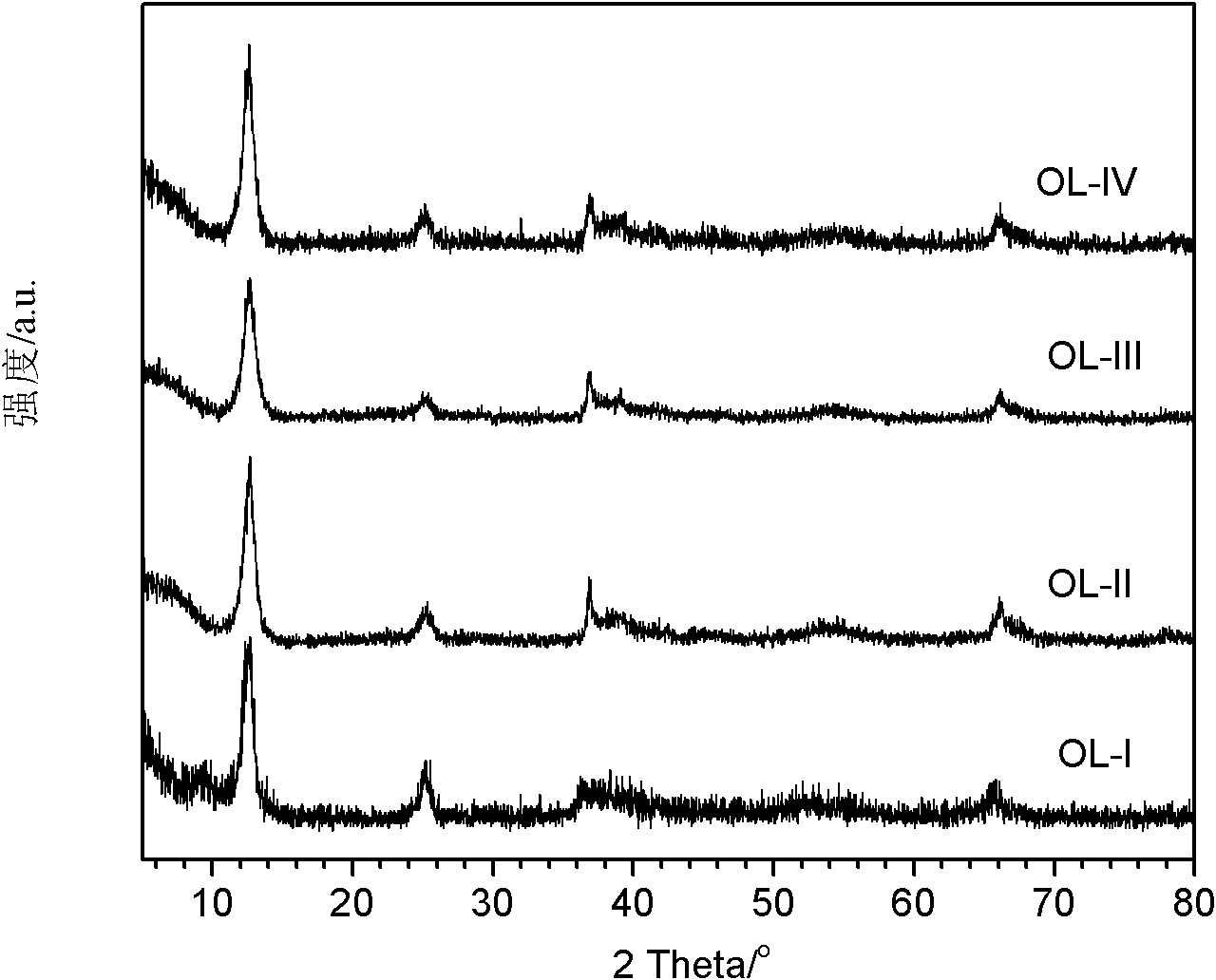

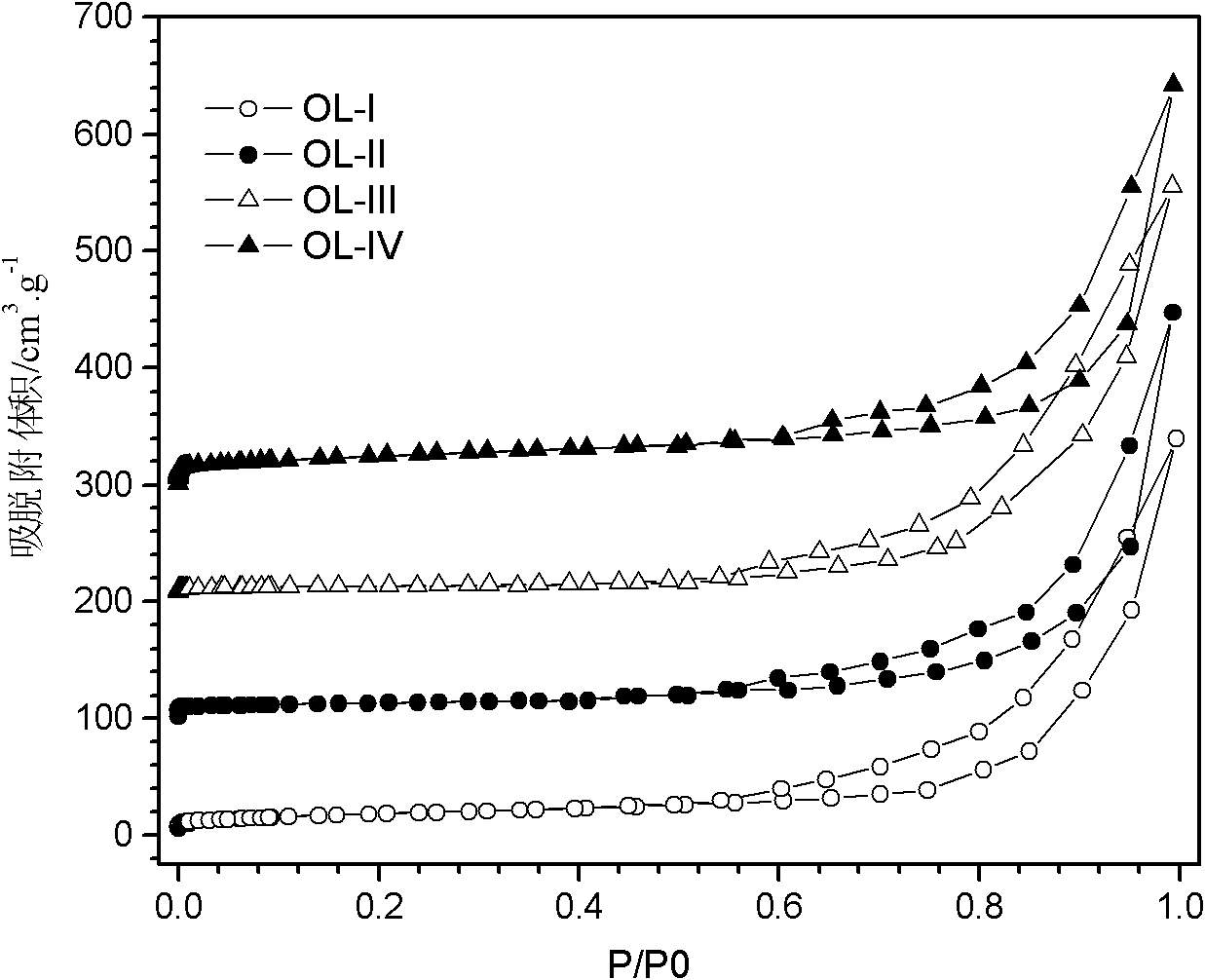

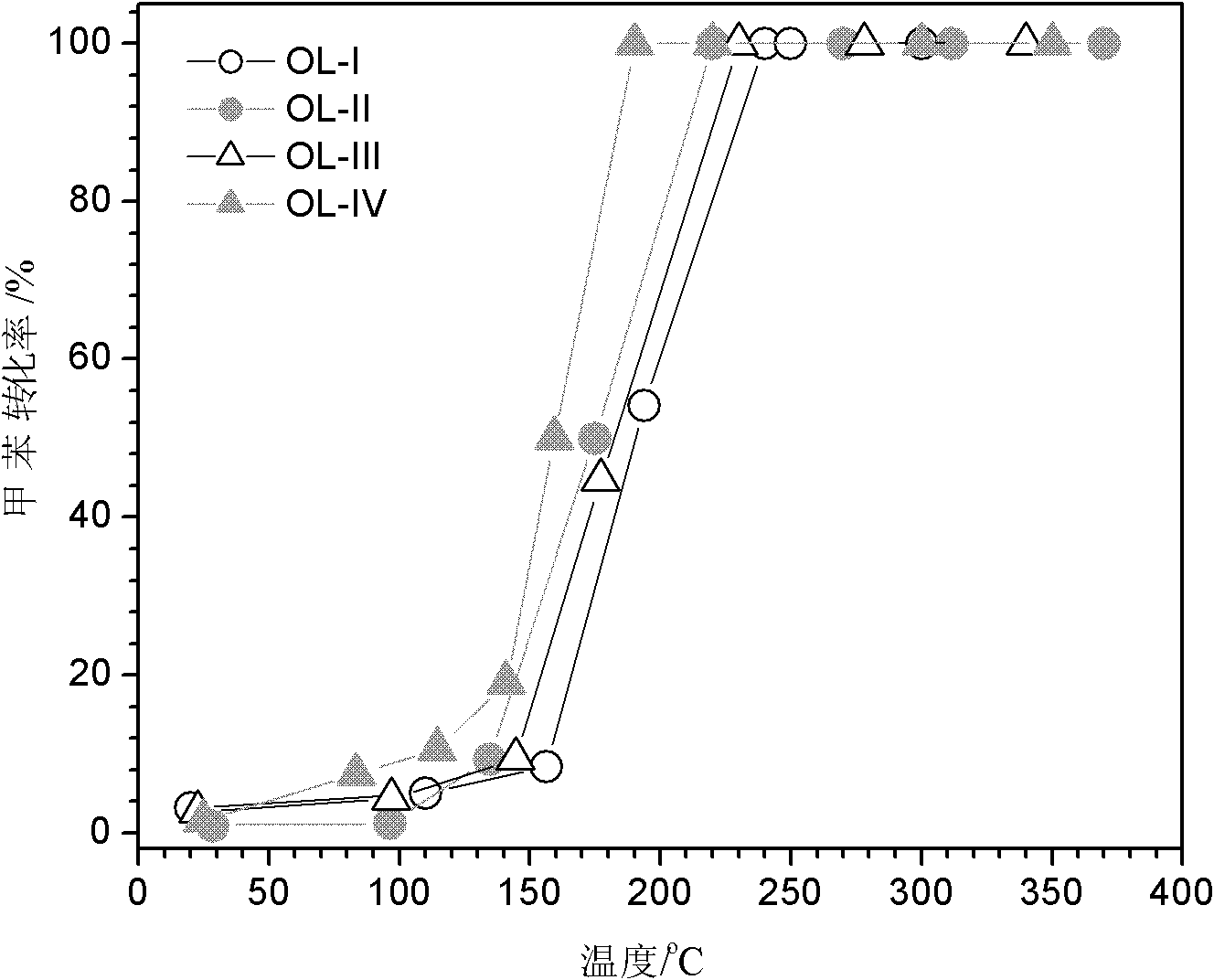

Preparation method and application of lamellar manganese oxide catalyst used for eliminating VOCs (volatile organic compounds) gases at low temperature

InactiveCN102172524AEasy to makeReduce energy consumptionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsMolecular sievePtru catalyst

The invention discloses a preparation method and application of lamellar manganese oxide catalyst used for eliminating VOCs (volatile organic compounds) gases at low temperature. The low-cost potassium permanganate and alcohol are adopted as raw materials for the catalyst, and alkaline solution and dispersing agent are used for adjustment, thus a lamellar manganese oxide structure type molecular sieve (OL, open loop) with high specific surface area (97m<2> / g) and high thermal stability (more than 500 DEG C) is prepared. The catalyst prepared by the invention has higher eliminating efficiency on high-airspeed (60000-100000 / h) and low-concentration (500-1000ppm) VOCs gases. When the temperature is 190 DEG C, methylbenzene can be completely converted into non-poisonous materials CO2 and H2O, and elimination factor of methylbenzene can be maintained to be more than 90% within 100 hours; and when the temperature is 90 DEG C, formaldehyde can be completely converted into non-poisonous materials CO2 and H2O, and the elimination factor of formaldehyde can be maintained to be more than 90% within 100 hours. The catalyst prepared by the invention has the advantages of available raw materials, simple preparation process, strong practicability, low temperature high efficiency and no secondary pollution, VOCs gases can be completely eliminated.

Owner:BEIJING UNIV OF TECH

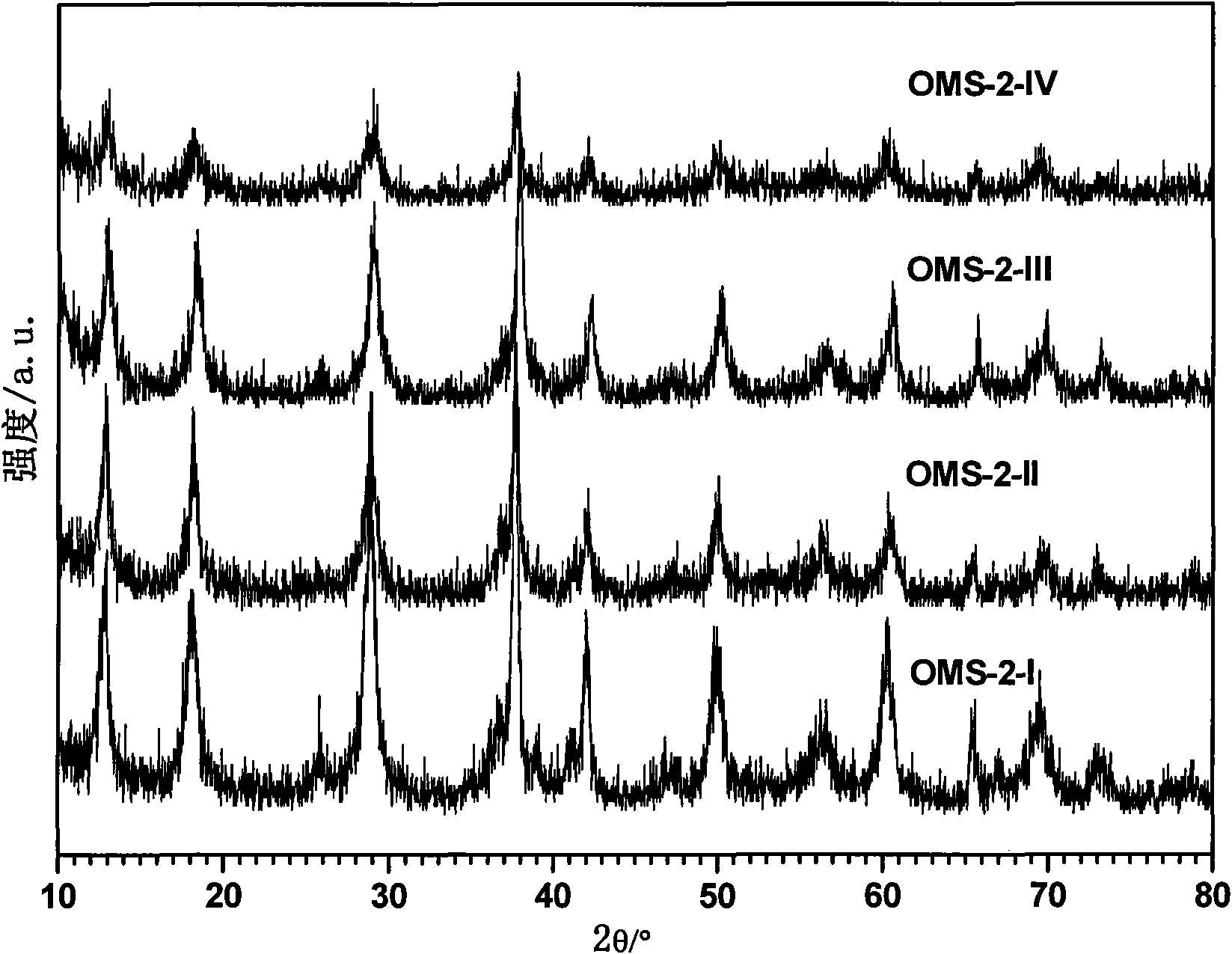

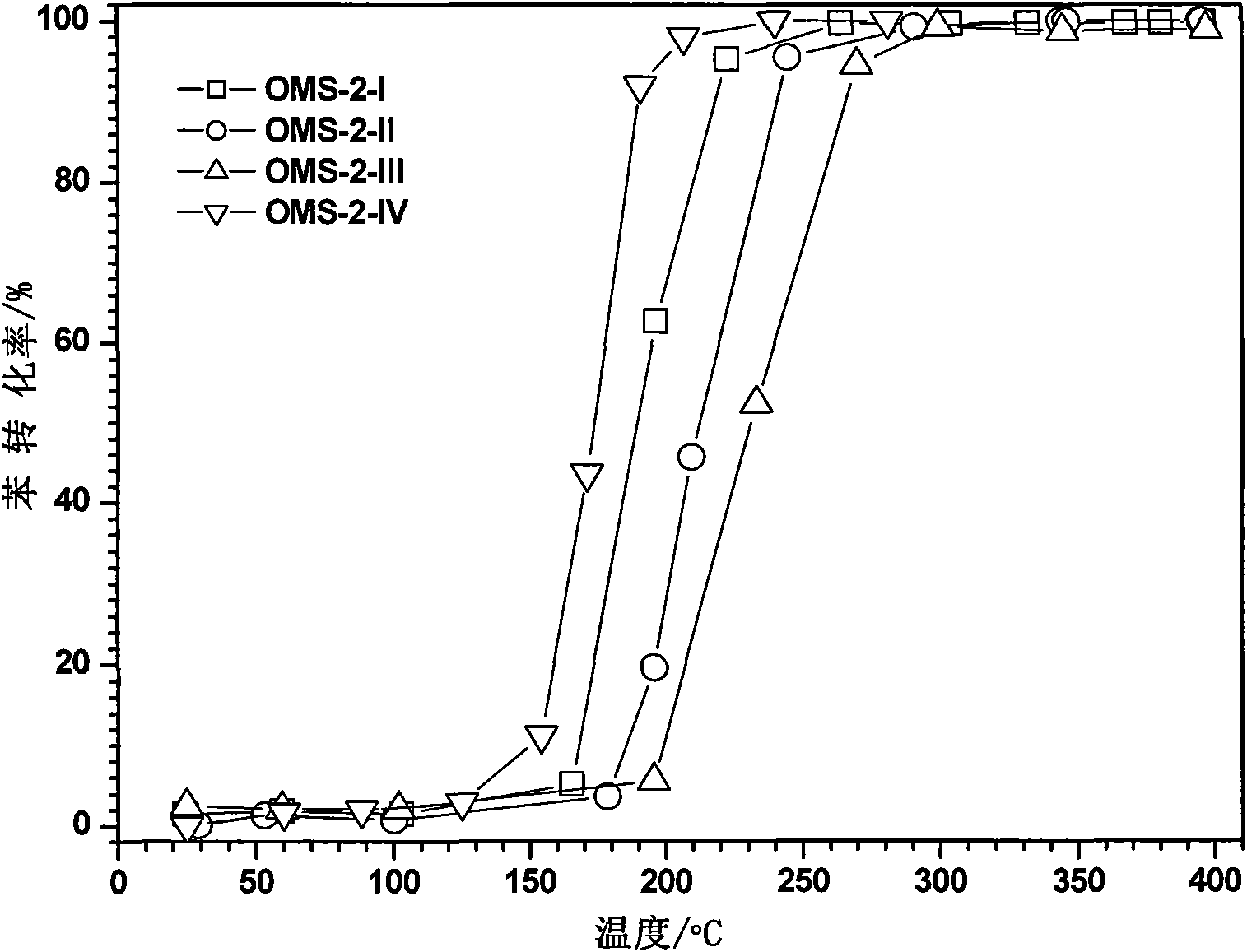

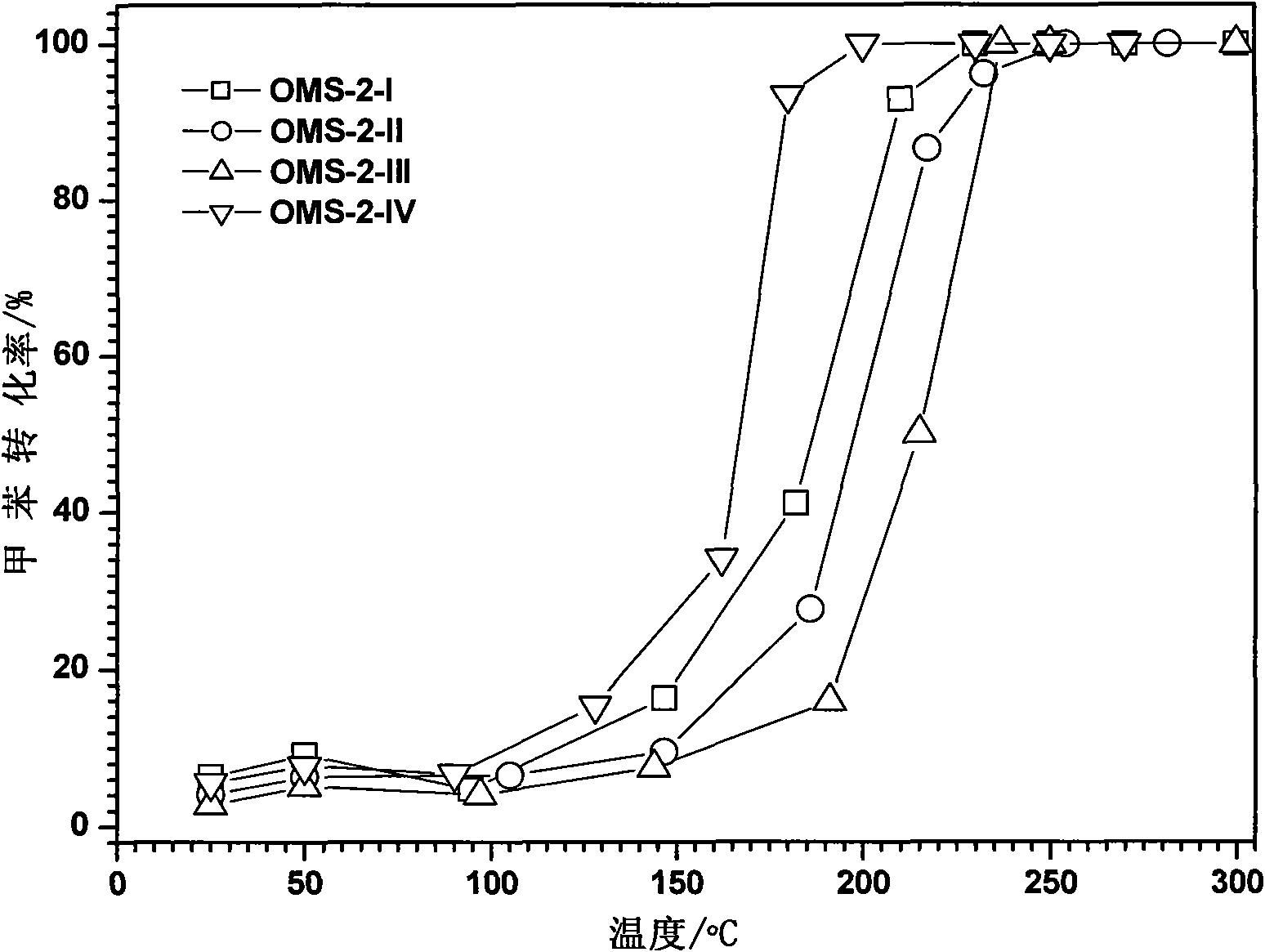

OMS-2 catalyst used in elimination of benzene series at low temperature and preparation and application

InactiveCN101927179AEasy to makeHigh and low temperature catalytic combustion to eliminate activityMolecular sieve catalystsDispersed particle separationMANGANESE ACETATEMolecular sieve

The invention discloses an OMS-2catalyst used in the elimination of benzene series at the low temperature, preparation and application. The catalyst is a manganese oxide octahedral molecular sieve and has a molecular formula of KMn8O16.nH2O. The material is prepared by using a reflux method which comprises the following steps of: preparing buffer solution of KAc-HAc with a pH value of 3.7 to 5.6; adding the buffer solution into PVP-containing Mn(Ac)2 solution; adding solution of KMnO4; stirring; refluxing; aging by sealing; filtering; washing with water; drying; baking; and performing other processing. The catalyst of the invention has the advantages of higher specific area and heat stability, high activity and high stability when the catalyst is applied to the elimination of the benzene series through low-temperature catalytic combustion, capacity of keeping the elimination ratio of the benzene series over 90 percent and not changed within 100 hours, cheap used raw material, namely manganese acetate, simple preparation process, no load of other metals or noble metals,.

Owner:BEIJING UNIV OF TECH

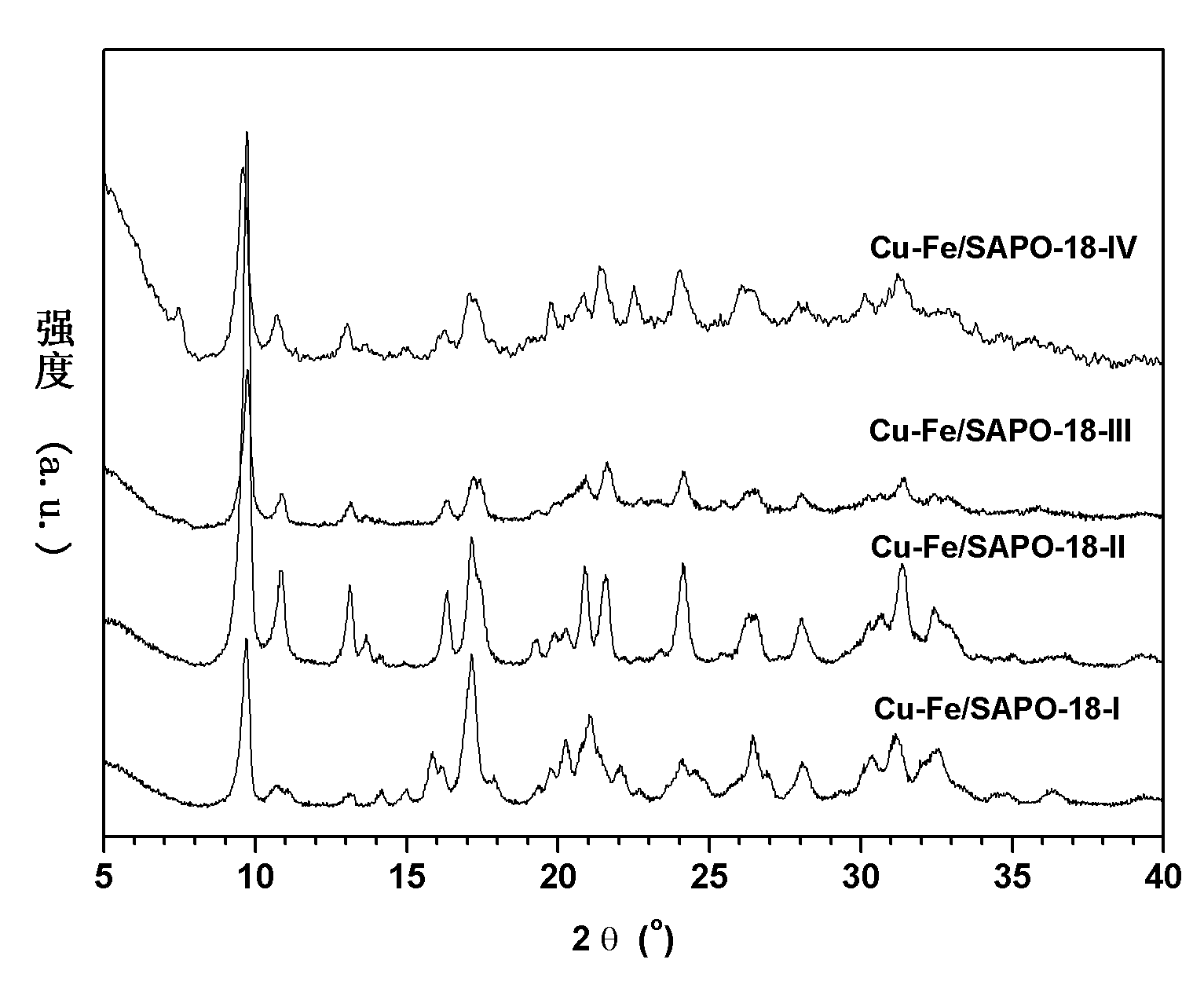

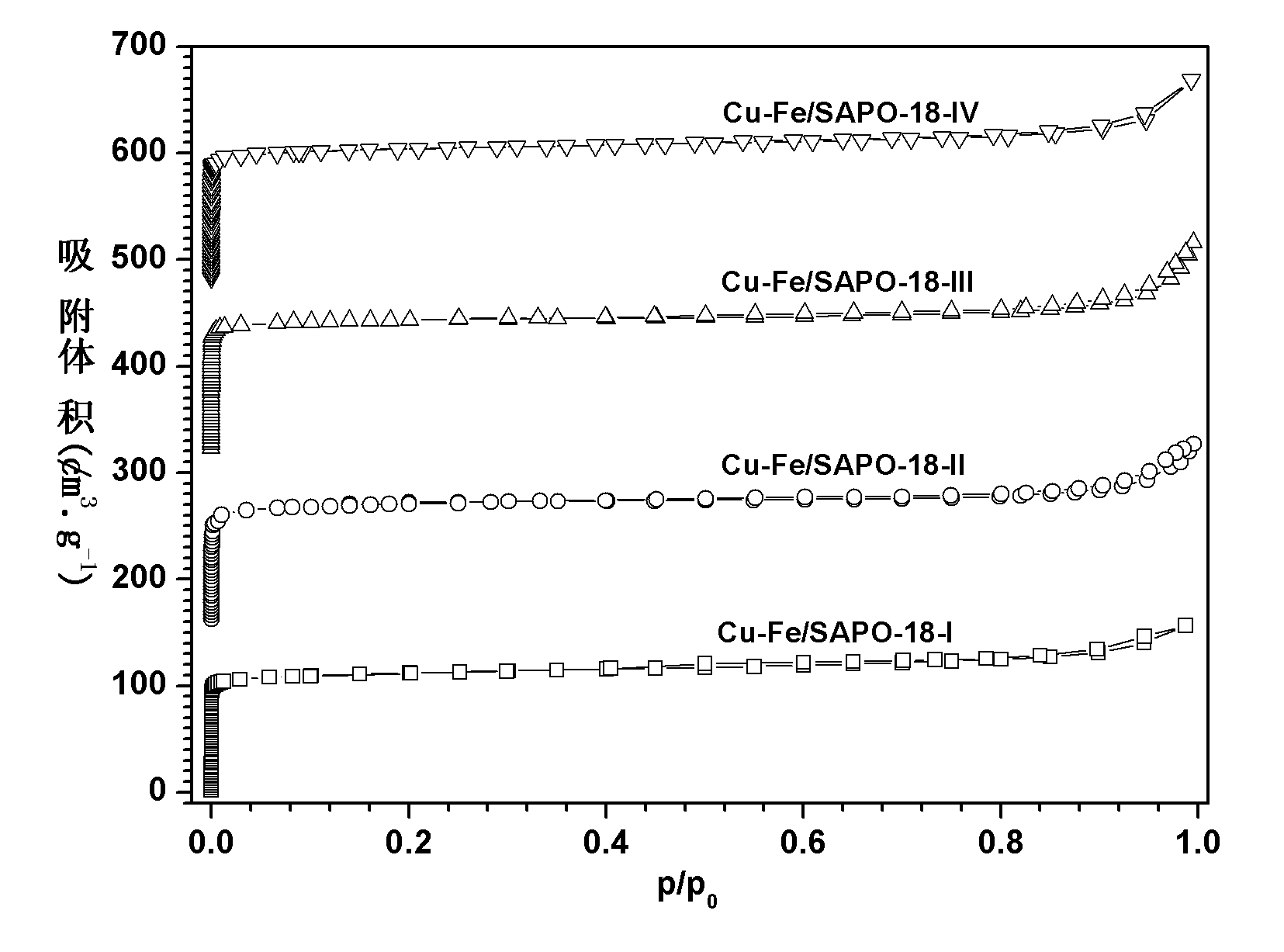

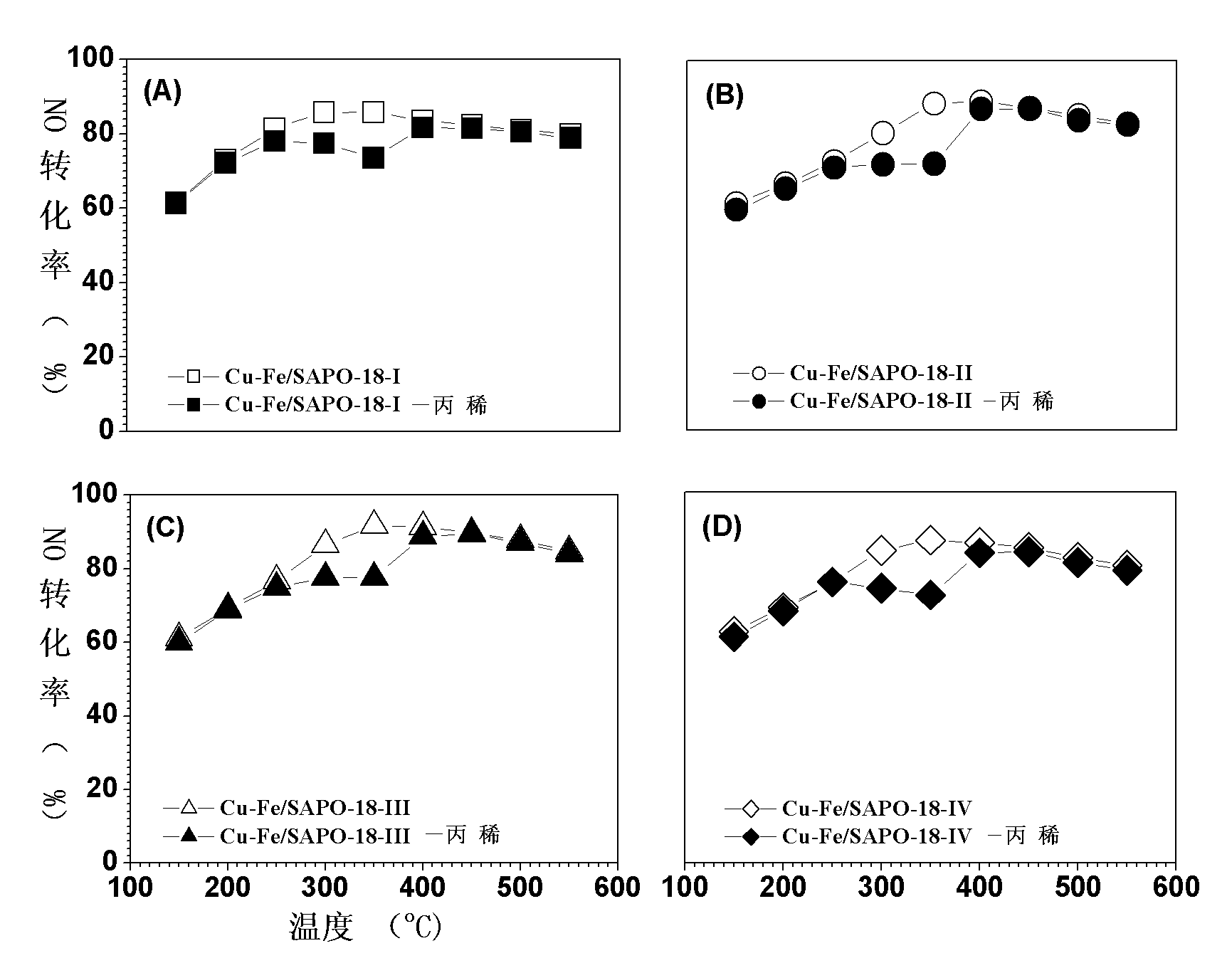

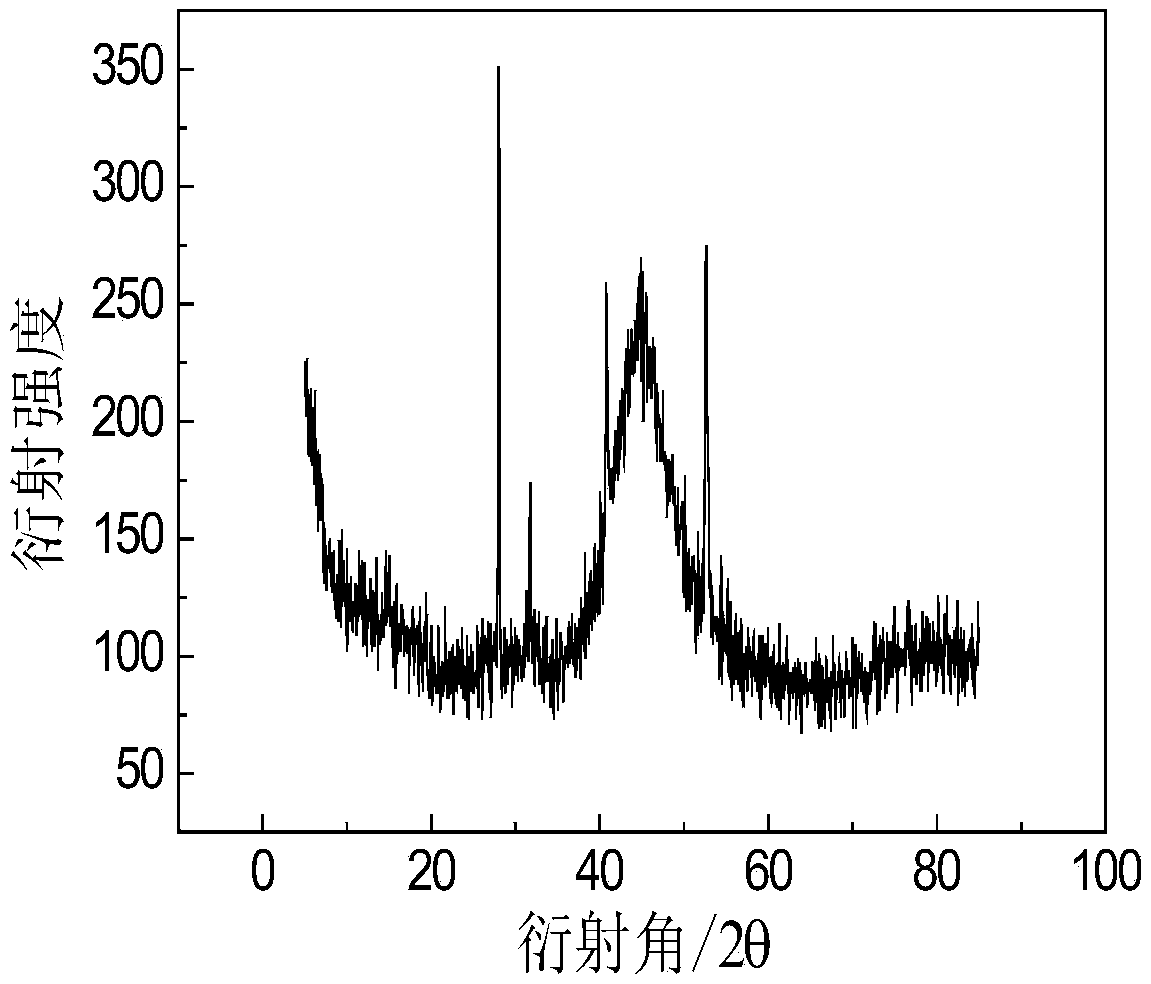

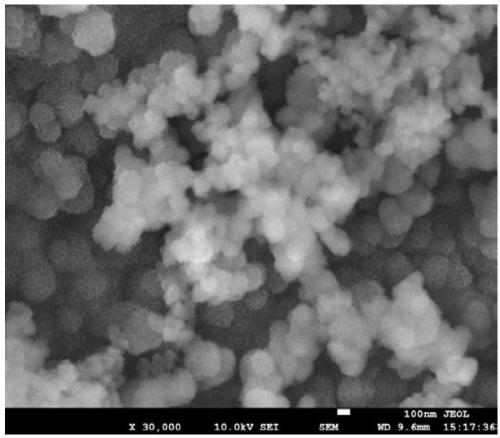

Preparation method of SAPO-18-carried Cu-Fe catalyst for ammonia-selective catalytic elimination of NOx

InactiveCN102626653AImprove anti-carbon performanceHigh activityMolecular sieve catalystsDispersed particle separationMolecular sieveHigh carbon

The invention discloses a preparation method of a SAPO-18-carried Cu-Fe catalyst for ammonia-selective catalytic elimination of NOx. The SAPO-18-carried Cu-Fe catalyst is used for selective catalytic elimination of nitric oxides. The preparation method is characterized in that SAPO-18 foraminate molecular sieve carriers having high specific surface areas of 400 to 550m<2> / g are prepared by a soft template synthesis method; and a FeCl3-CuCl2 mixed solution and the SAPO-18 foraminate molecular sieve carriers are prepared into the SAPO-18-carried Cu-Fe catalyst by an ion exchange method. In a wide temperature range of 150 to 550 DEG C, the SAPO-18-carried Cu-Fe catalyst has high catalytic elimination effects on pollutants having a high airspeed of 120000 to 360000mL.(g.h)<-1>, a high O2 concentration of 10 to 20vl.%, high H2O content of 5 to 10wt% and a low NO concentration of 300 to 1000ppm, and has high stability. After adding a hydrocarbon (300 to 1000ppm of propylene) into a reaction system, the SAPO-18-carried Cu-Fe catalyst has high carbon deposition resistance and high hydrothermal stability.

Owner:BEIJING UNIV OF TECH

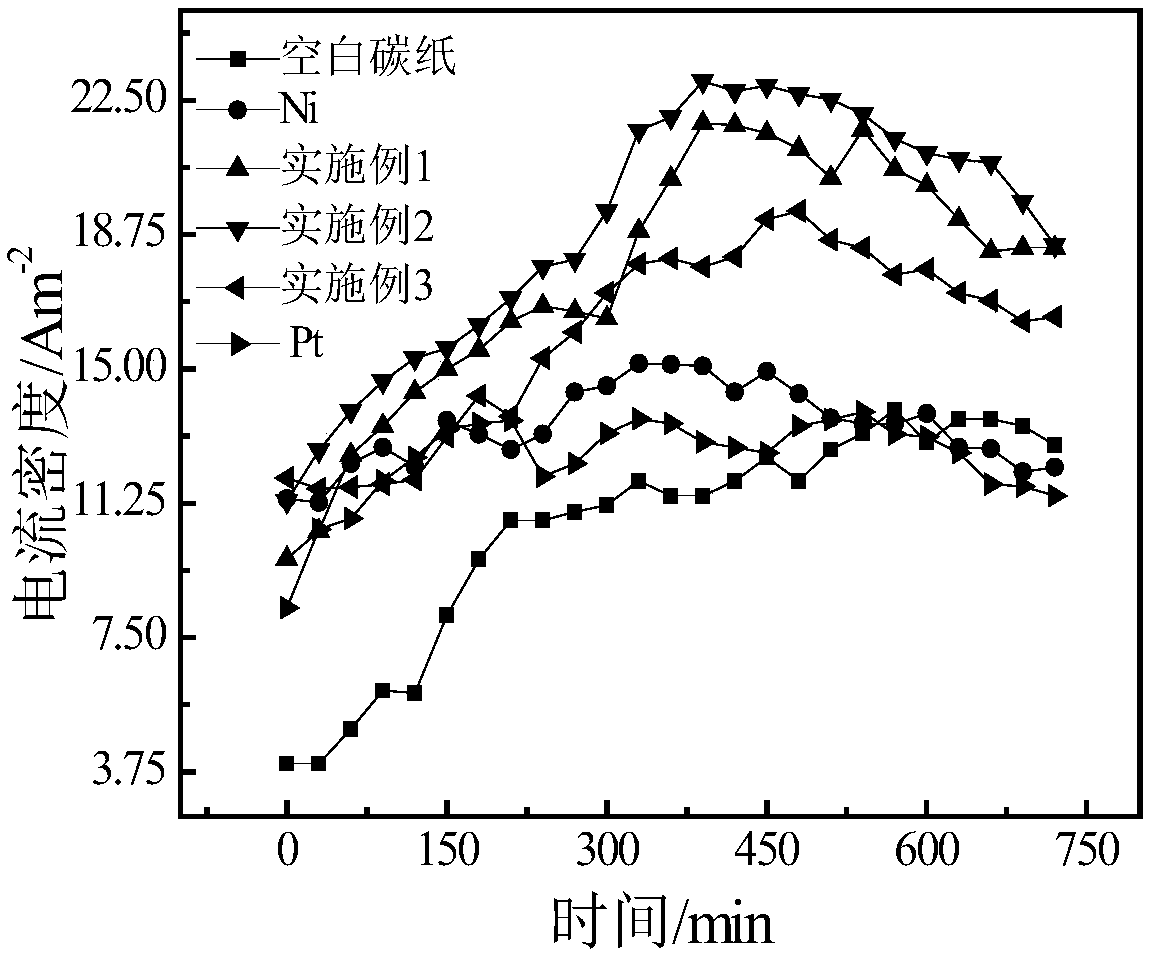

Mo/Ni/Co/P/C composite material as well as preparation method and application thereof

InactiveCN109136983ALow priceLow hydrogen evolution overpotentialTreatment by combined electrochemical biological processesElectrodesAuxiliary electrodeWorkstation

The invention belongs to the technical field of composite materials, and particularly relates to an Mo / Ni / Co / P / C composite material as well as a preparation method and an application thereof. The material is prepared with the following method: in a three-electrode system, a carbon-based substrate taken as a working electrode, a platinum net taken as an auxiliary electrode and Ag / AgCl taken as a reference electrode are connected with an electrochemical workstation, potentiostatic deposition is conducted in a mixed solution of nickel sulfate with concentration of 30-70 g / L, sodium hypophosphitewith concentration of 20-40 g / L, nickel chloride with concentration of 10-20 g / L, boric acid with concentration of 30-35 g / L, cobalt chloride with concentration of 30-50 g / L and sodium molybdate withconcentration of 40-50 g / L, magnetic stirring is conducted throughout the deposition process, initial potential set on the working electrode during electroplating is (-1.5)V-(-1)V, electroplating timeis 5-30 min, electroplating temperature is set to be 25-35 DEG C, a power supply is turned off finally, and the Mo / Ni / Co / P / C composite material is prepared. The Mo / Ni / Co / P / C composite material is taken as a cathode material of a microbial electrolytic cell to treat coking wastewater and produce hydrogen synchronously, waste is changed into treasure, and a new idea and a new perspective are provided for impending coking wastewater treatment.

Owner:TAIYUAN UNIV OF TECH

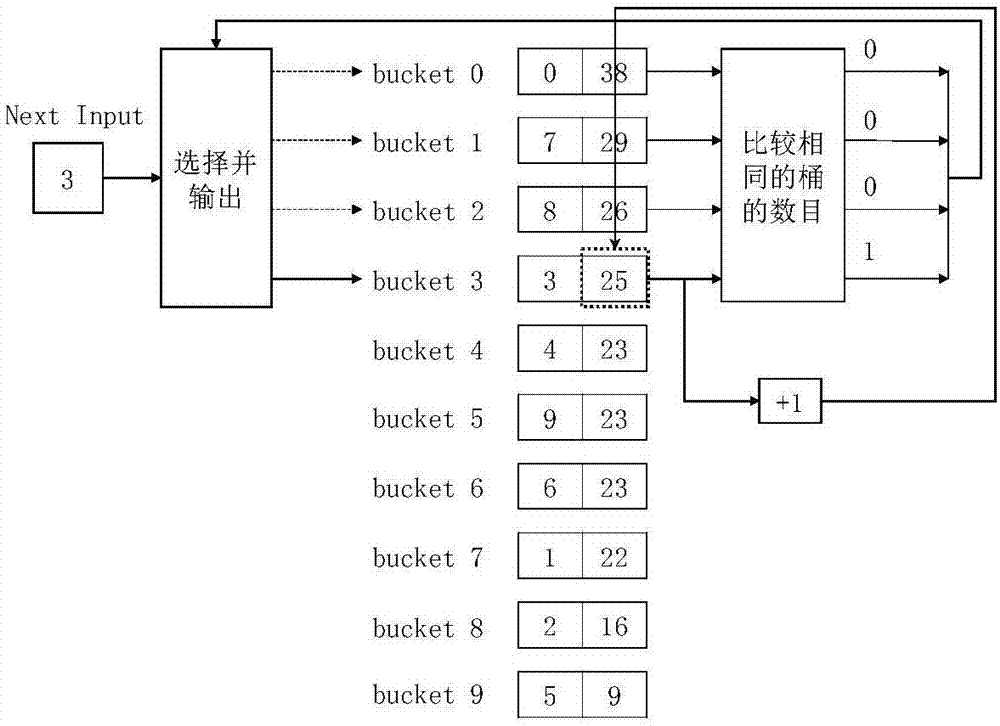

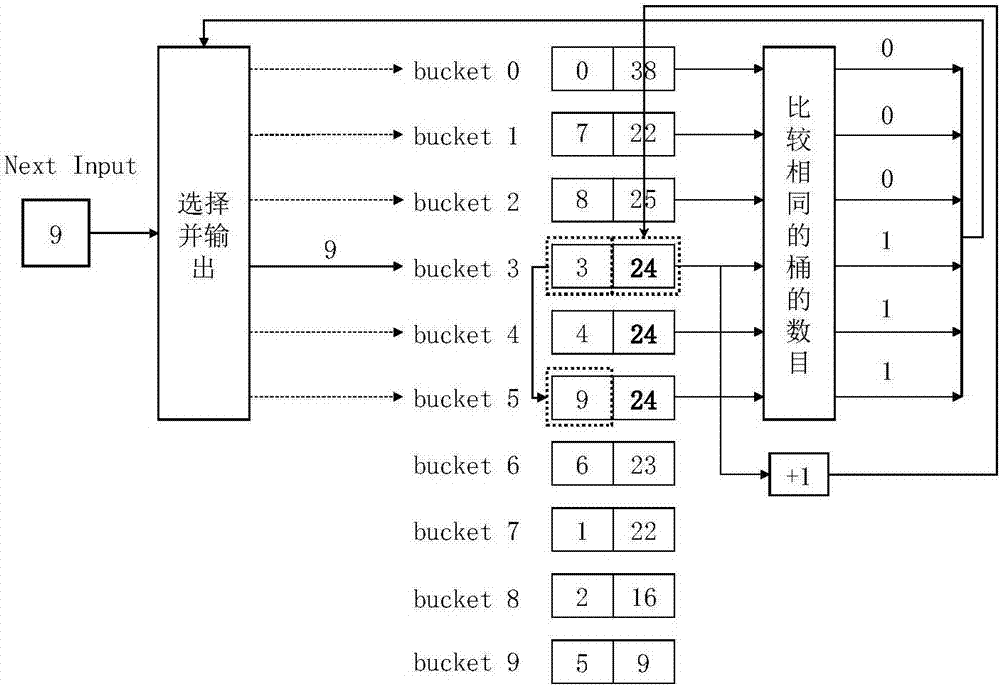

Quasi dynamic Huffman hardware encoder and encoding method

ActiveCN107294539AImprove encoding speedCan work continuouslyCode conversionComputer scienceNetwork module

The invention discloses a quasi dynamic Huffman hardware encoder and an encoding method; the encoder receives 2n BCD code data each time for encoding, wherein n is a positive integer; the encoder comprises a ranking network module, a tree building module, a tree parsing module, a cascade FIFO, and an output module; the ranking network module and the cascade FIFO are respectively connected with a 4-bit data input port, a start signal port, a clock port and a low level reset port; the ranking network module, the tree building module, the tree parsing module and the output module are connected in sequence; the cascade FIFO is connected with the output module; the output module is provided with a n+1-bit data output port, a n+1-bit data valid port, a data output start signal port and a data output end signal port. The design result shows that when a Nexys4 DDR platform is used, the encoder can work at a frequency above 100MHz; the encoder is high in throughput, low in delay, high in coding efficiency, and simple in structure.

Owner:ZHEJIANG UNIV

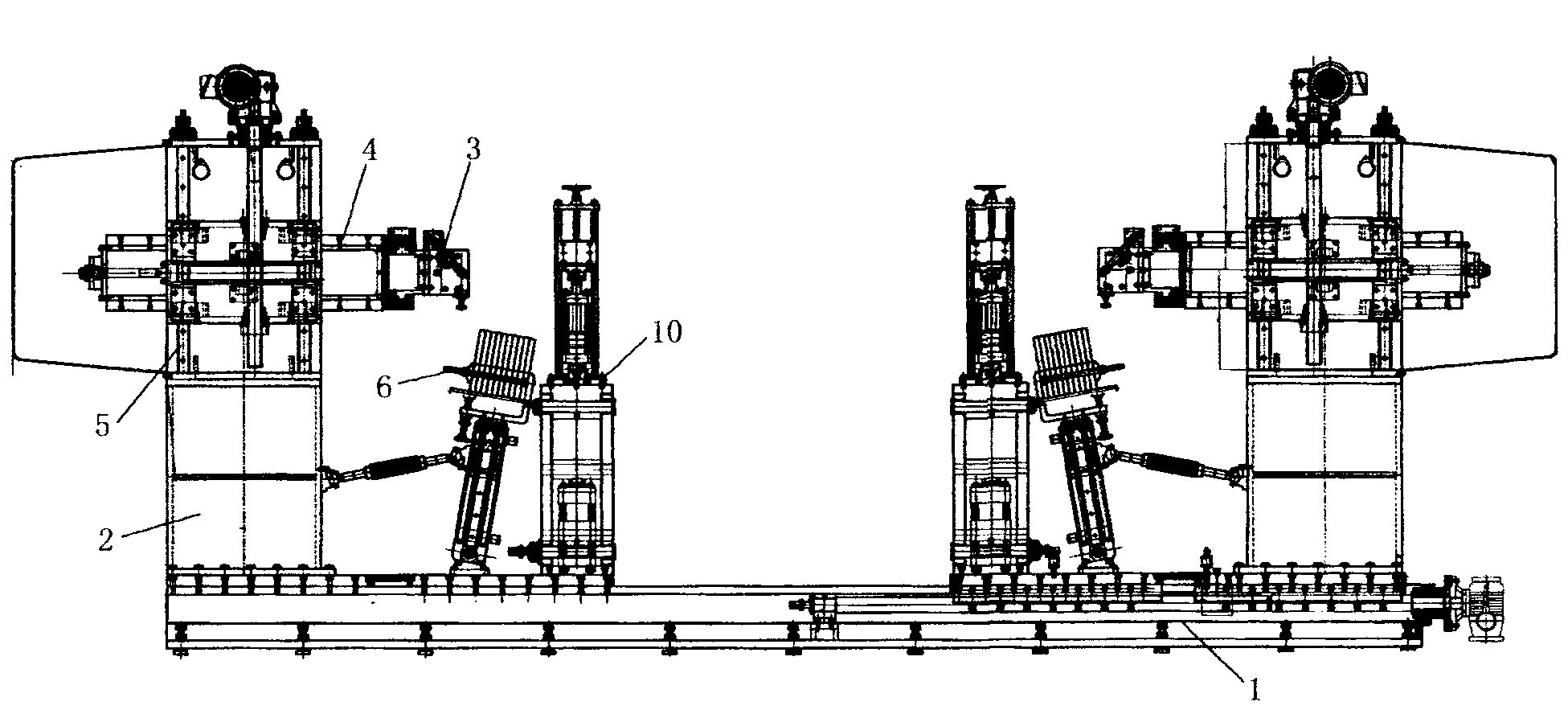

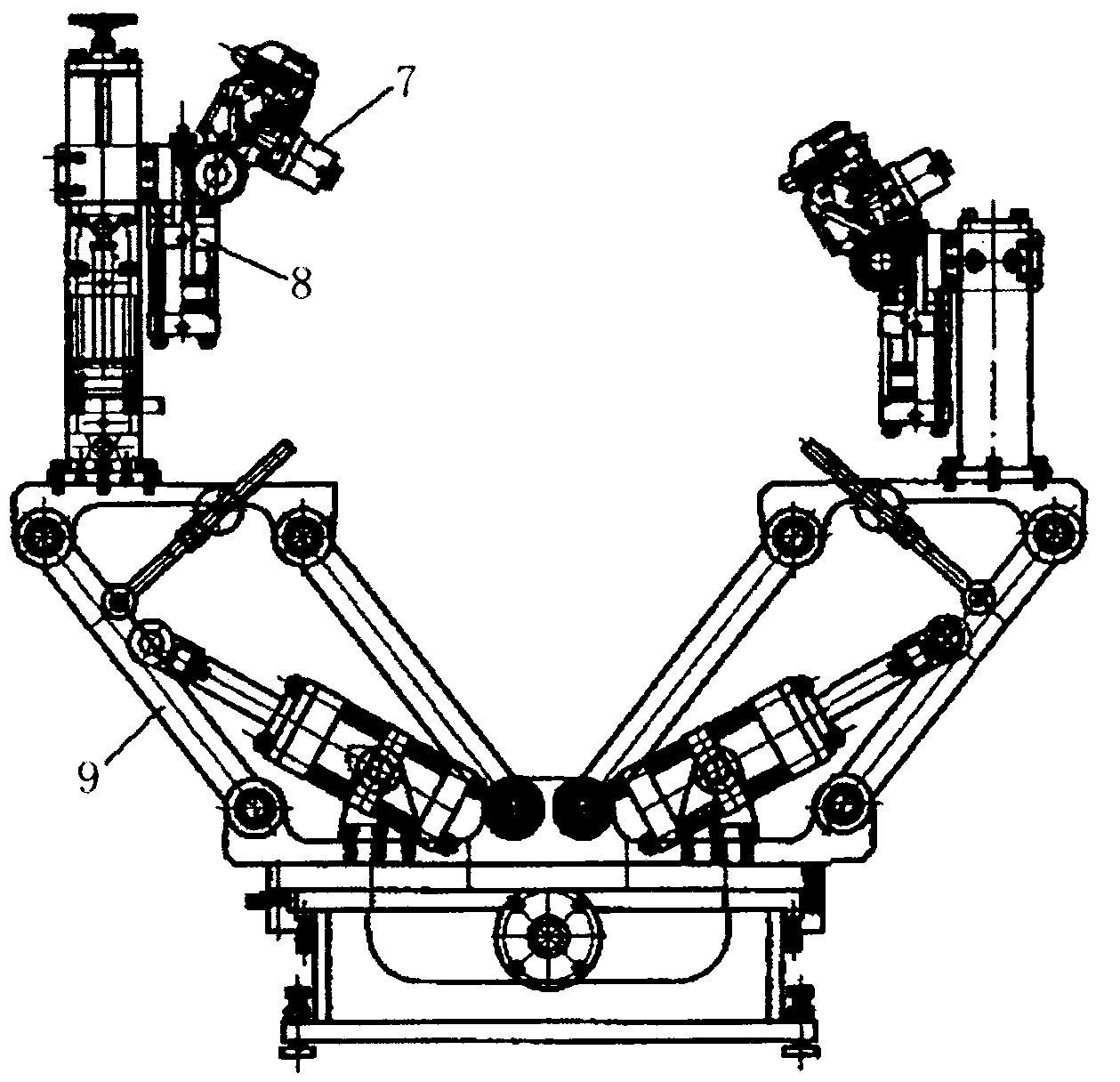

Numerical control roof-arc spreading machine

ActiveCN103208889AWith automatic distanceFunctionalManufacturing dynamo-electric machinesNumerical controlLeft half

A numerical control roof-arc spreading machine comprises a base guide rail mechanism, four bases, two coil nose clamping mechanisms, four coil bar roof radian mechanisms, four coil bar clamping spreading mechanisms, a hydraulic station and a sensor control numerical control circuit system. The two bases are respectively arranged on the left half portion and the right half portion of the upper end of the base guide rail mechanism and the two coil nose clamping mechanisms are respectively connected with the upper ends of the two bases. The other two bases are arranged in the middle of the upper end of the base guide rail mechanism. The four coil bar clamping spreading mechanisms are respectively arranged at the upper ends of the two bases with two coil bar clamping spreading mechanisms as a pair and the four coil bar roof radian mechanisms are respectively arranged on the sides of the four coil bar clamping spreading mechanisms. During working, the four coil bar clamping spreading mechanisms which are symmetrical all around are utilized to spread large coils and the two coil bar clamping spreading mechanisms which are symmetrical in a front-and-back mode are utilized to spread small coils. The numerical control roof-arc spreading machine can accurately and rapidly achieve one-step spreading forming machining of various motor coils.

Owner:上海闵行机械工程技术研究所有限公司

Full-automatic window cleaning machine

InactiveCN102406485ASimple and reasonable structureImprove efficiencyWindow cleanersContinuous operationEngineering

The invention relates to a full-automatic window cleaning machine which comprises a hoisting system and a check cleaning system, wherein the check cleaning system is drawn and hoisted by a winching mechanism on the hoisting system. The full-automatic window cleaning machine is characterized in that the check cleaning system comprises a working platform, a wall leaning wheel, a camera, a cleaning device and a water holding plate; the working platform is drawn and hoisted by the winching mechanism; the wall leaning wheel is installed on the upper part of the working platform and used for being supported on the outer vertical surface of a building; the camera faces to the outer vertical surface of the building and is used for monitoring and checking the condition of the outer vertical surface of the building; the cleaning device is installed in the middle of the working platform and used for cleaning the outer vertical surface of the building; the water holding plate is installed at the lower part of the working platform; and one side of the water holding plate is tightly attached to the outer vertical surface of the building, and the water holding plate is used for recovering cleaning liquid. The full-automatic window cleaning machine has the advantages of simple and reasonable structure, recycling of the cleaning liquid, no damage to environment, high efficiency, continuous operation and higher safety performance and can be used for checking the condition of the outer vertical surface of the building in real time.

Owner:博宇(无锡)科技有限公司

Iron casting piece repairing method

The invention discloses an iron casting piece repairing method. The iron casting piece repairing method comprises the following steps that a defect area on an iron casting piece is identified, polishing equipment is used for cleaning the area, oxidation layers and residue impurities are removed, and a round through hole with the diameter of 5-8mm is formed in the area, so that the defect can be removed from the iron casting piece, an acetylene-oxy torch is used for heating the round through hole wall to dark red, and the surface layer 2-3mm of the round through hole wall is in a liquid form; a round stick with the same material with the iron casting piece fills in the round through hole, and the acetylene-oxy torch is used for heating the round stick to a melting state, so that the round stick and the metal liquid on the surface layer of the round through hole wall are melted, borax is used as a fusion agent, the repairing area is polished and treated after fully fusing, solidifying and cooling to a normal temperature, and the repairing procedure is finished. The repairing method can guarantee the repairing efficiency and satisfy the repairing requirement.

Owner:CHONGQING JIDING METAL CASTING

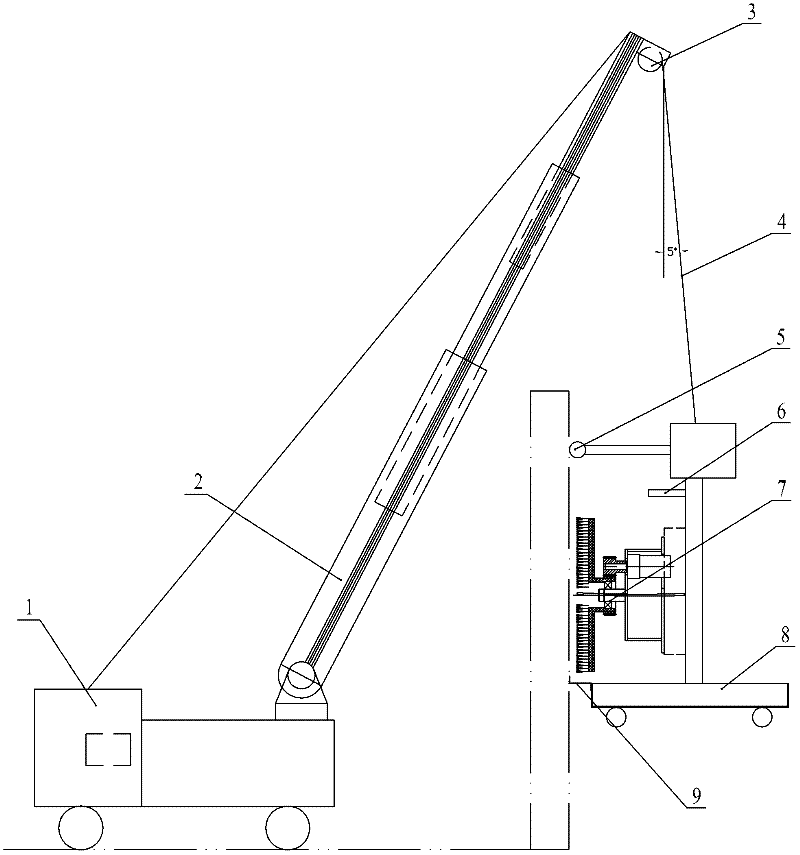

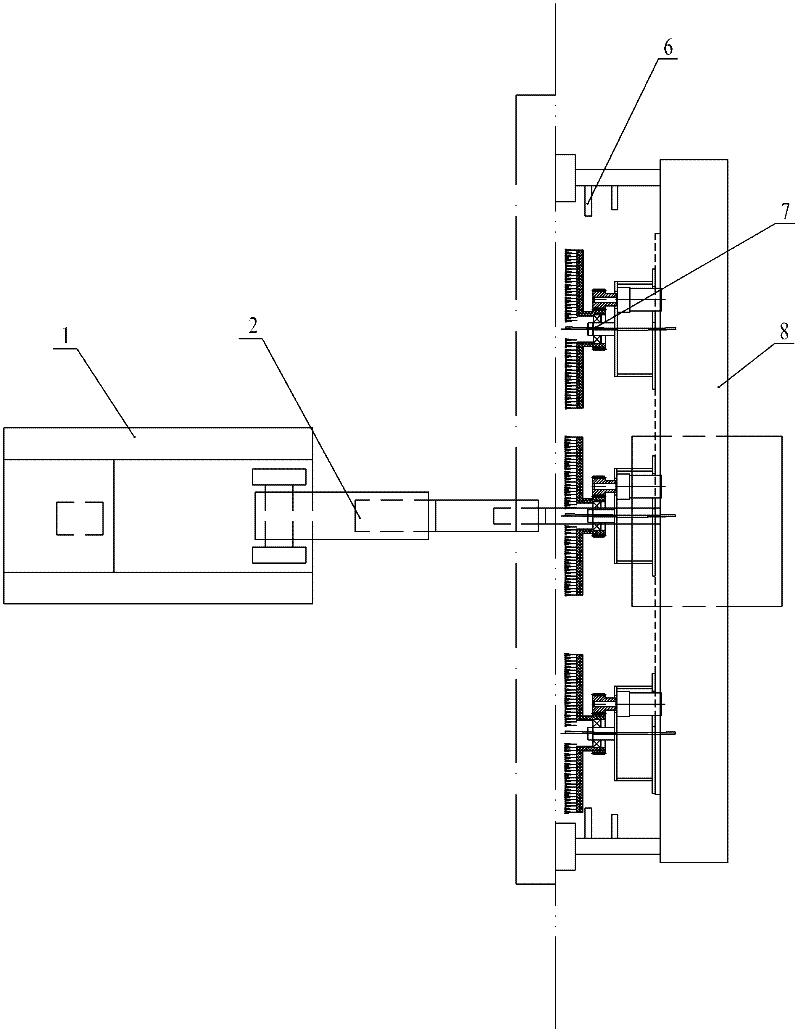

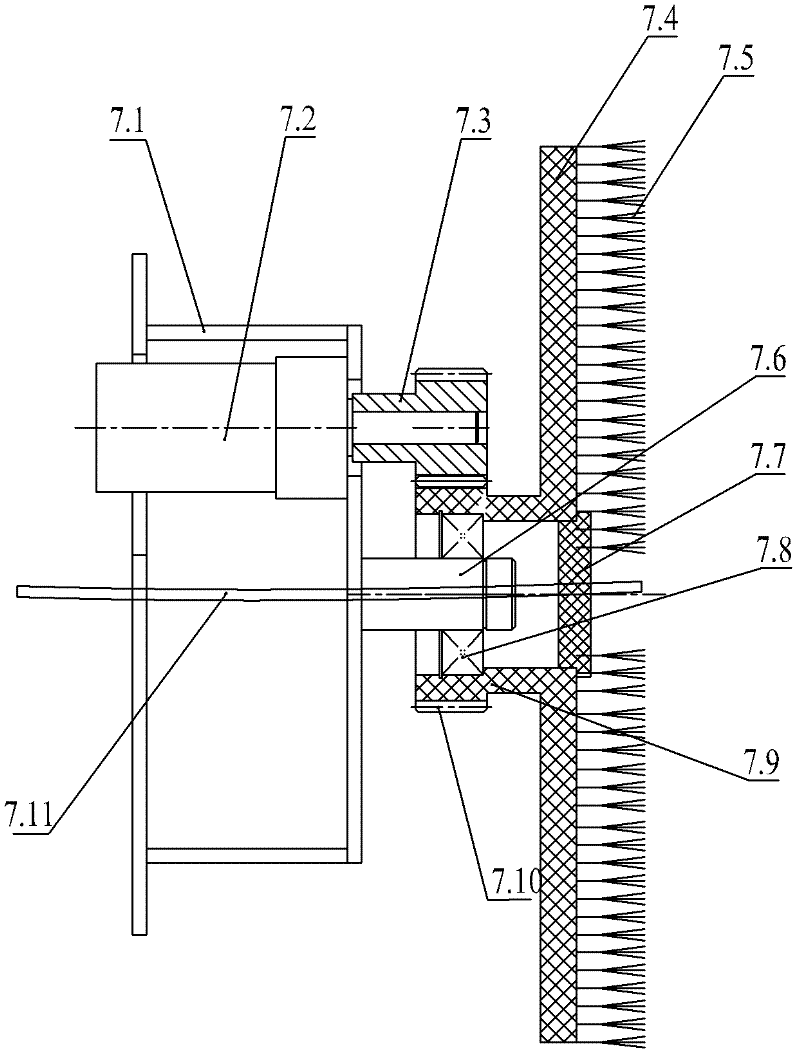

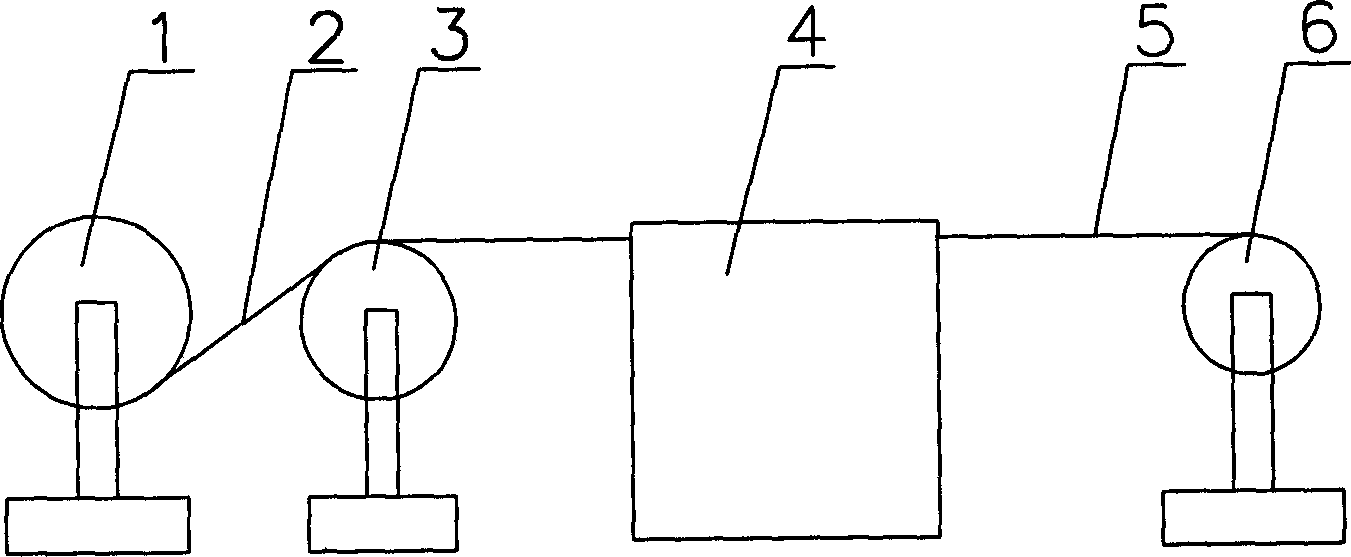

Method for mfg. isolation structure of poly imide film supercondeccting strip material and apparatus thereof

ActiveCN1787132AHigh dielectric strengthMeet technical requirementsTransformersTransformers/inductances coils/windings/connectionsImidePolymer science

The invention is a method and device for making polyimide film-superconductive tape insulating structure, adopting rolled self-adhesive polyimide film tape and rolled superconductive wire, before the rolled superconductive wire is fed in an insulator coating device, lengthways pasting the rolled self-adhesive polyimide film tape on the rolled superconductive wire in the axial direction of the superconductive wire by a self-adhesive polyimide film tape roller, then feeding the superconductive wire into the insulator coating device so that the insulator coating device lengthways coat the self-adhesive polyimide film tape on the superconductive wire in the axial direction of the superconductive wire. The whole system comprises uninsulated wire coiling frame, polyimide film line coiling frame, insulator coating device and insulated superconductive wire coiling frame, where the polyimide film line coiling frame is arranged between the uninsulated wire coiling frame and the insulator coating device, and as passing through the polyimide film line coiling frame, the superconductive wire is in the middle of the polyimide film and the polyimide film-coated superconductive wire coiling frame is behind the insulator coating device.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

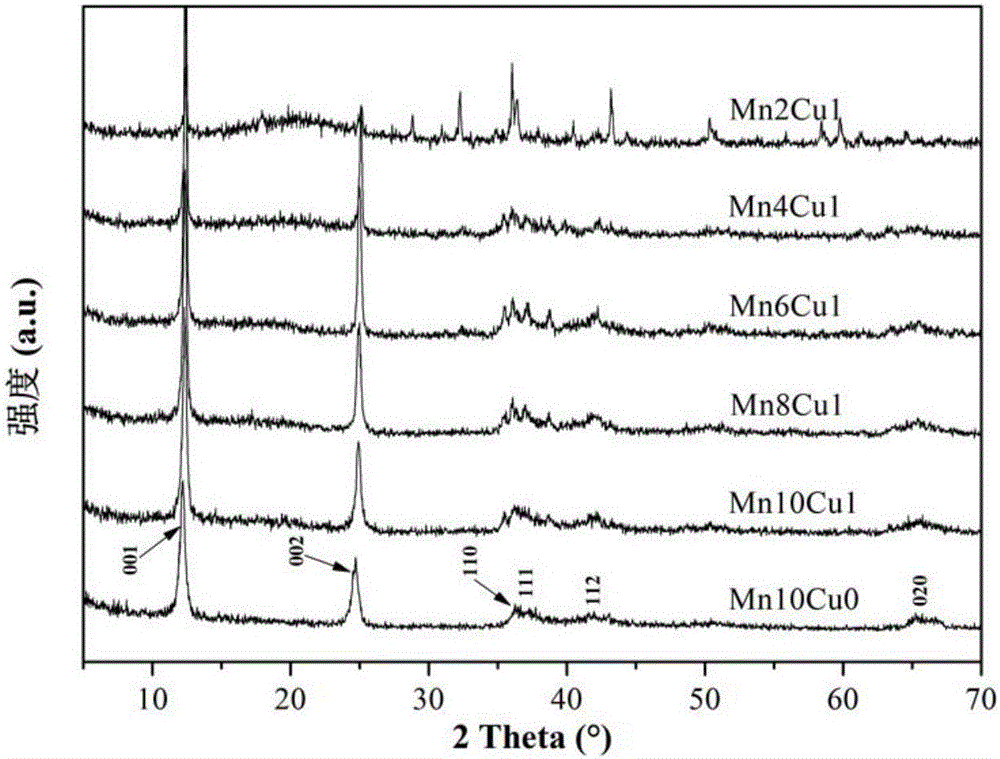

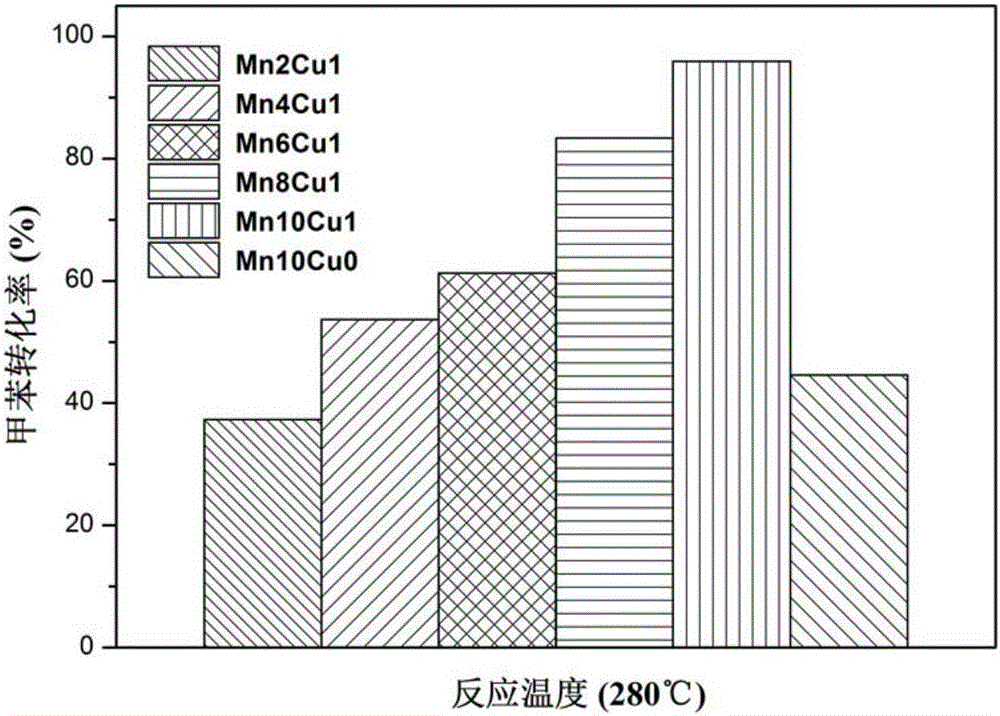

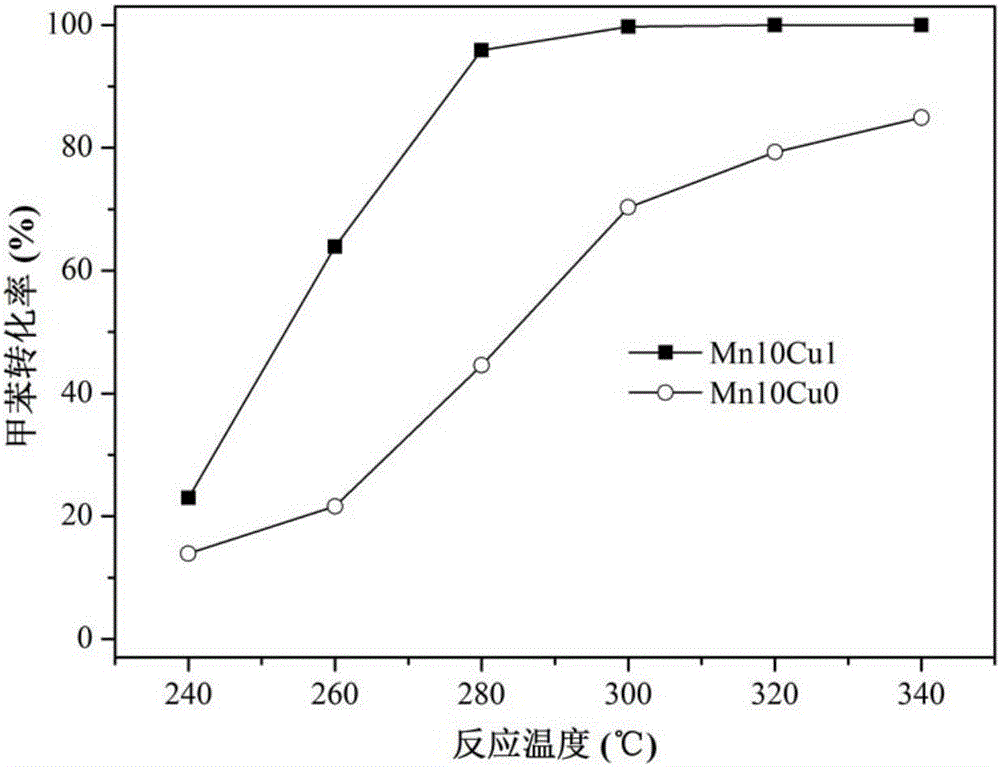

Method for preparing manganese-copper-based catalyst for degrading VOCs (Volatile Organic Compounds)

ActiveCN106179393AHigh catalytic combustion activityCost economyCatalyst activation/preparationIncinerator apparatusVolatile organic compoundPotassium permanganate

The invention discloses a method for preparing a manganese-copper-based catalyst for degrading VOCs (Volatile Organic Compounds). According to the method, the manganese-copper-based catalyst capable of catalytically degrading toluene is prepared rapidly by using a self-propagating reaction between potassium permanganate and cupric acetate; the catalytic activity of the manganese-copper-based catalyst is regulated and controlled through changing the mole ratio of Mn to Cu, and the catalyst can be used for completely (100%) converting a 1000ppm gas mixture of toluene and air into CO2 and H2O at the reaction temperature range of 303 DEG C to 340 DEG C at normal pressure at the air speed of 30,000ml gcatalyst<1>h<1>; and the raw materials used by the catalyst are low in price, the preparation process is simple and efficient and is high in practicability, and toxic and harmful gases such as NOx cannot be produced in the preparation process. The manganese-copper-based catalyst prepared by using the method shows excellent catalytic combustion activity and can be used for completely eliminating low-concentration VOCs.

Owner:SICHUAN UNIV

Recovery method for waste plastics through anhydrous cleaning

ActiveCN107379321AWash thoroughlyCraft briefPlastic recyclingMechanical material recoveryOil and greasePhencyclone

The invention relates to the field of waste recycled plastics, in particular to a recovery method for waste plastics through anhydrous cleaning. According to the recovery method, by adding hard inorganic matter and auxiliary dry powder stripping agents to waste plastic powder, by rotating in a horizontal rotary drum in a dry state, through activation of the stripping agents on highly adhering impurities such as grease and ink during rotation, and through the micro-friction grinding effect generated by hard inorganic particles, the soil, grease and ink on the surface of the waste plastic powder are exfoliated; and the exfoliated fine impurities such as soil, grease and ink are further separated through a cyclone separator; and efficient cleaning of the waste plastics under the anhydrous condition is achieved. According to the recovery method, the highly adhering impurities such as the soil, grease, and ink are effectively removed; and the cleaning process is closed without pollutant discharge, and the recovery method is short in process and continuous in operation, and is of great significance to high-quality recovery and use of waste plastics.

Owner:安徽省家家乐塑料制品有限公司

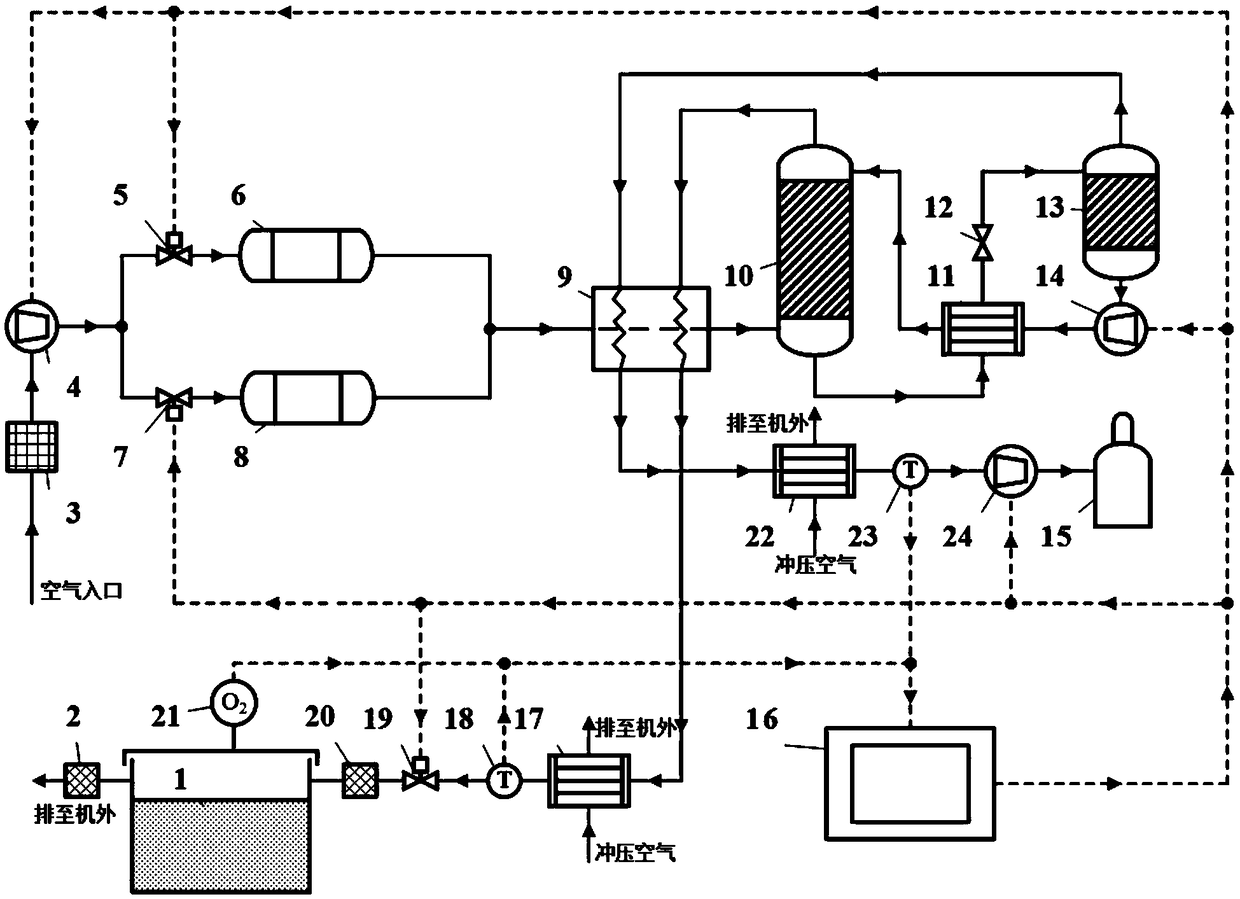

On-board oxygen generation-nitrogen generation system based on chemical circulating air separation technology

ActiveCN108945476AHigh purityImprove separation efficiencyNitrogen purification/separationAir-treatment apparatus arrangementsOn boardExplosion protection

The invention discloses an on-board oxygen generation-nitrogen generation system based on a chemical circulating air separation technology. Air is introduced into a separation system; by using characteristics that a partial chemical material (an oxygen absorbent) can absorb oxygen under a condition of a certain pressure and temperature and can release the oxygen under different conditions, the oxygen and nitrogen in the air are separated. The obtained oxygen with higher purity is used for cabin passengers to breathe or other purposes; nitrogen-enriched air is introduced into a fuel tank to flush and inert the fuel tank so as to achieve a fire and explosion protection purpose. The on-board oxygen generation-nitrogen generation system based on the chemical circulating air separation technology has the advantages that the separation efficiency is high, the energy consumption is low, the system can continuously work and so on.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

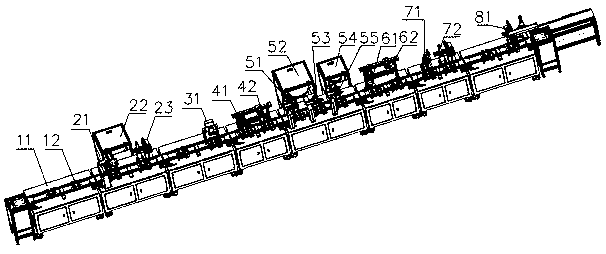

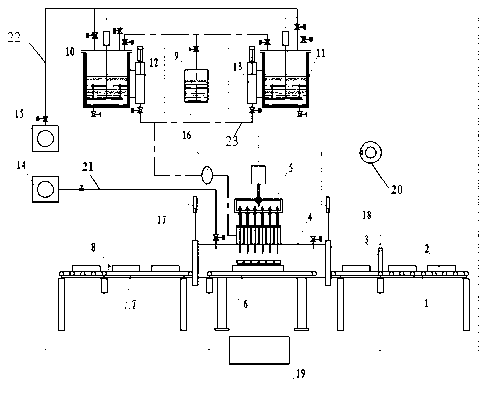

Precise vacuum oiling automation line

ActiveCN103318830AHigh oil injection precisionGuaranteed uptimeLiquid transferring devicesHuman–machine interfaceElectronic control system

The invention discloses a precise vacuum oiling automation line which comprises a front belt unit, an oil barrel, an electronic control system and an air compressor. A vacuum oiling chamber is arranged on one side of the front belt unit, a precise volumetric measuring device is arranged above the vacuum oiling chamber, a pallet transferring device is arranged in the vacuum oiling chamber, and a rear belt unit is arranged on one side of the vacuum oiling chamber. A vacuum oil tank I and a vacuum oil tank II as well as a vacuum oil delivery pump I and a vacuum oil delivery pimp II are arranged on two sides of the oil barrel respectively. The electronic control system is used for performing real-time control on set process parameters such as oil heating temperature, deaeration time, stirring speed, oiling amount, oiling chamber forvacuum, pressure-maintaining time and pallet transferring distance and speed through control programs. The precise vacuum oiling automation line is high in oiling precision, reliable in running and capable of working continuously, automation of oil treatment and oiling processes is realized, and an human-computer interface is friendly, and convenient to operate.

Owner:RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

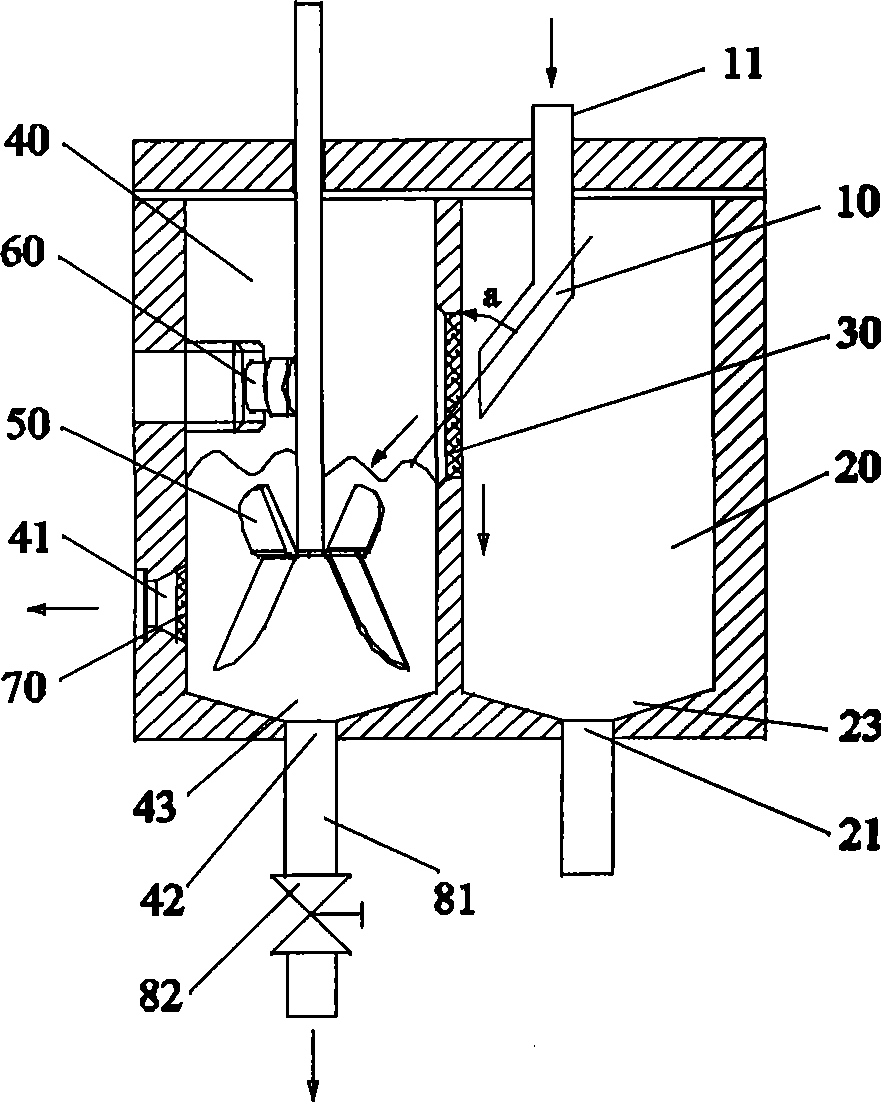

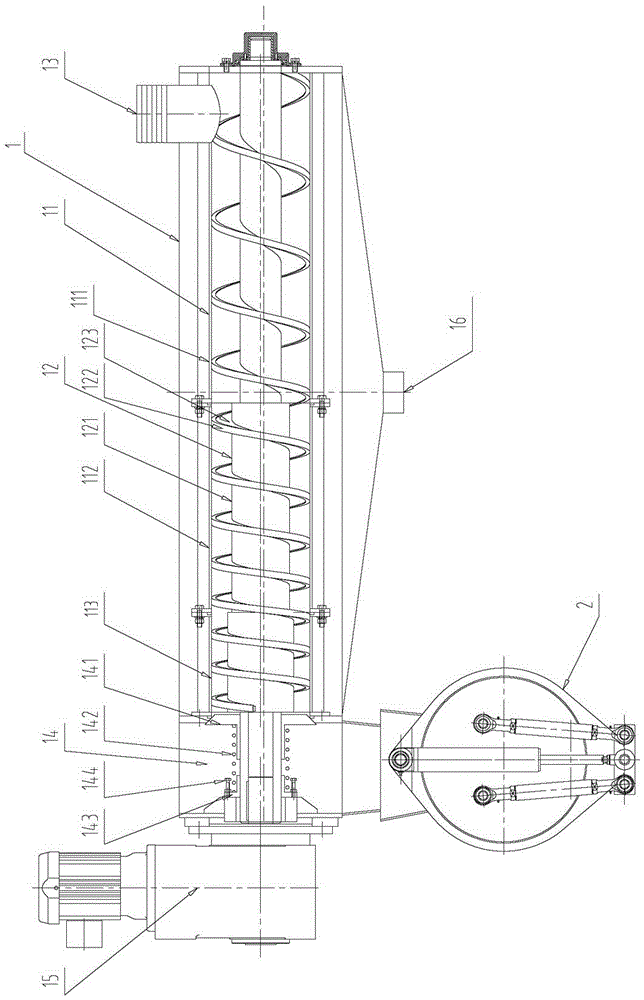

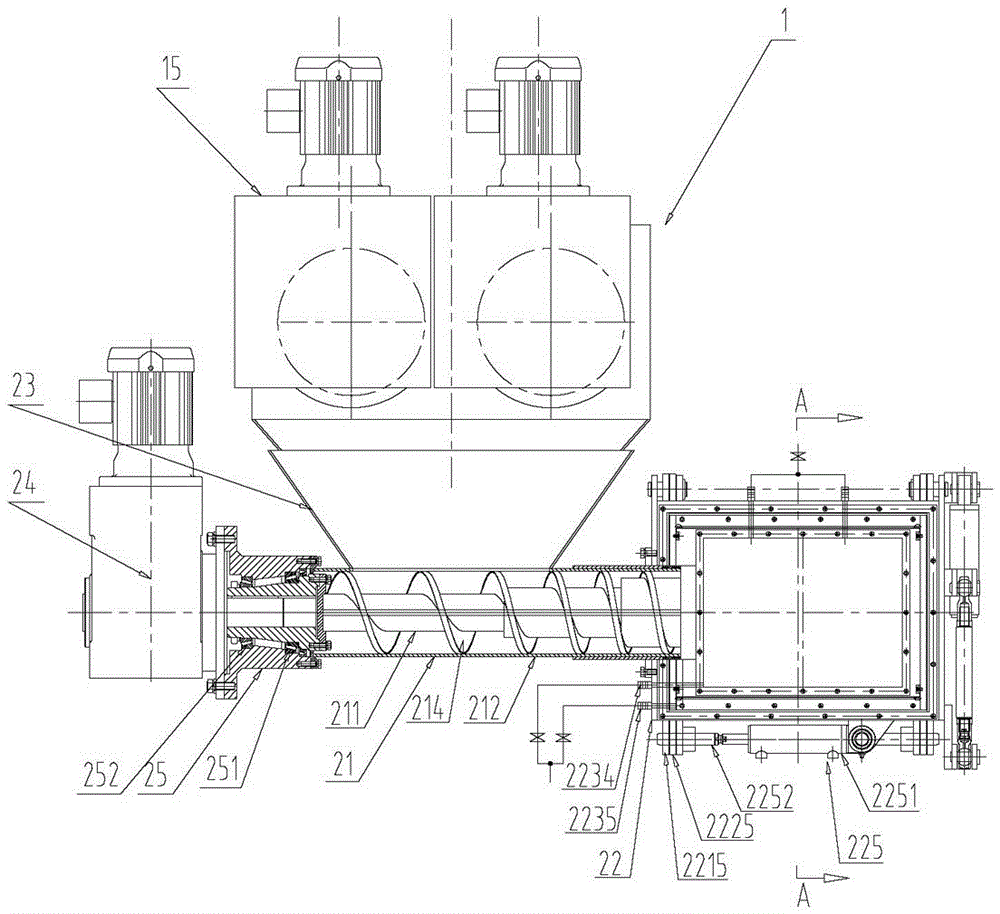

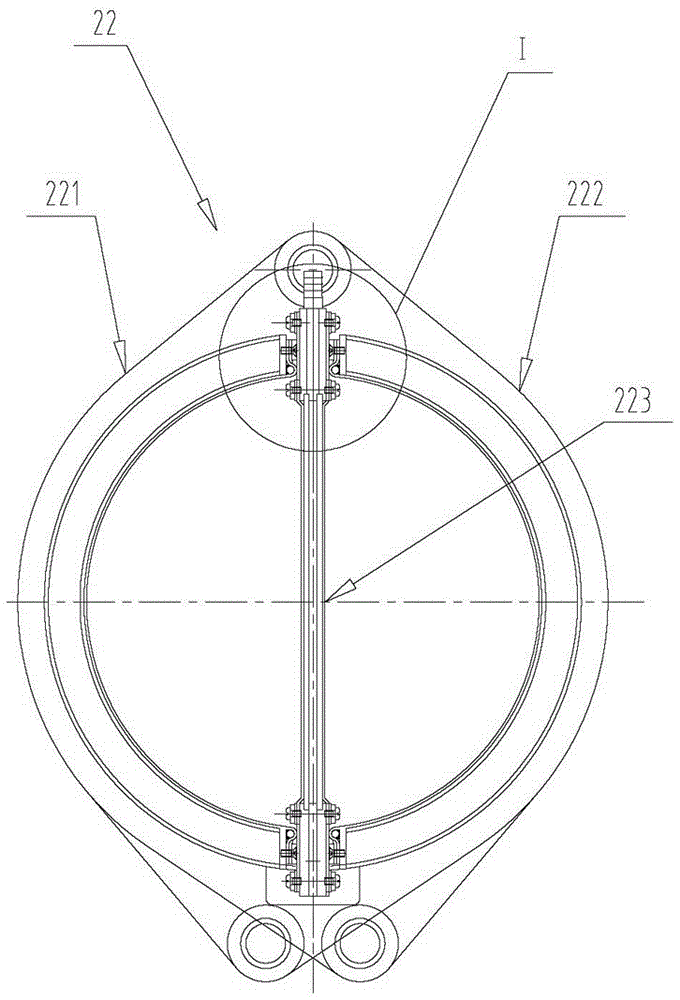

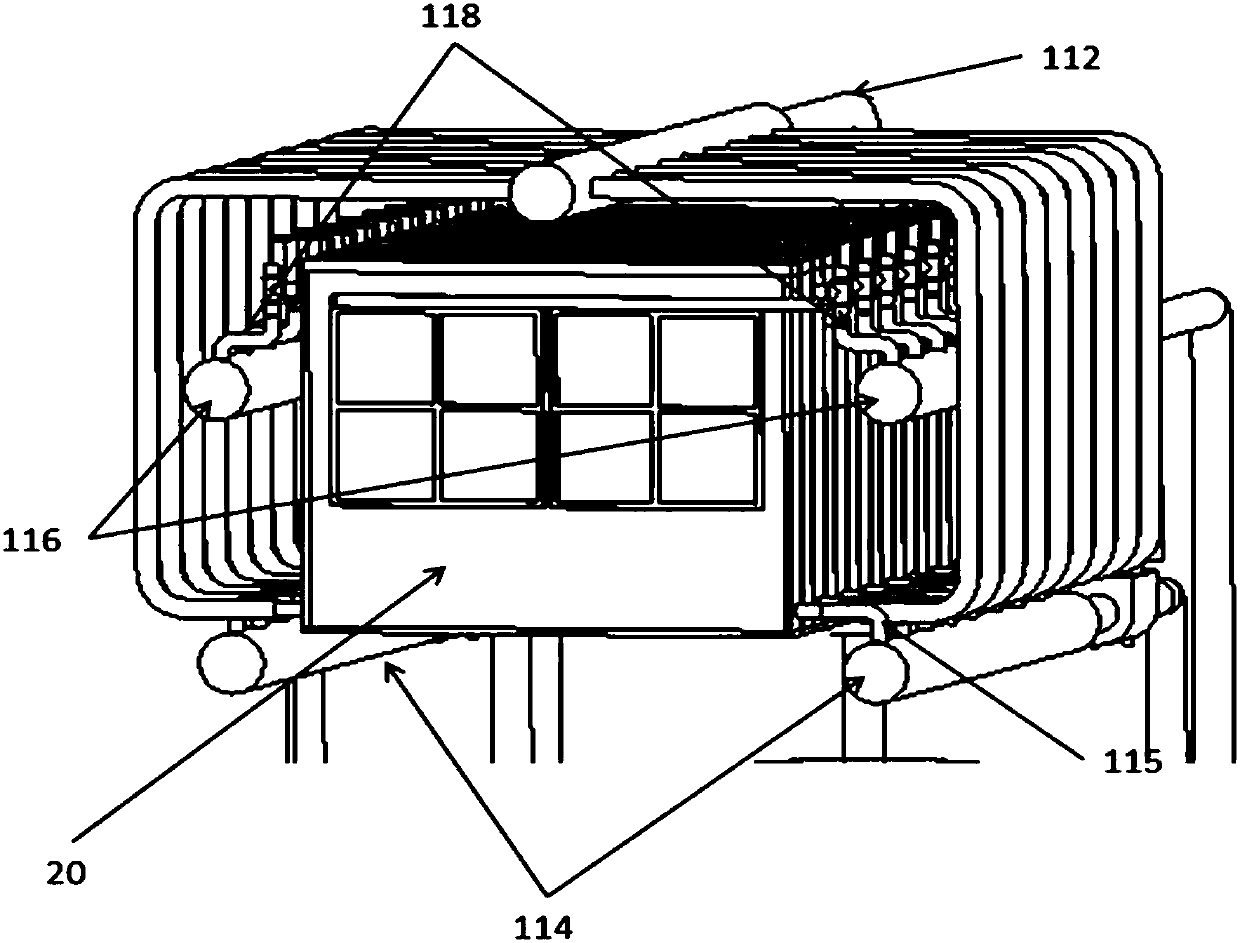

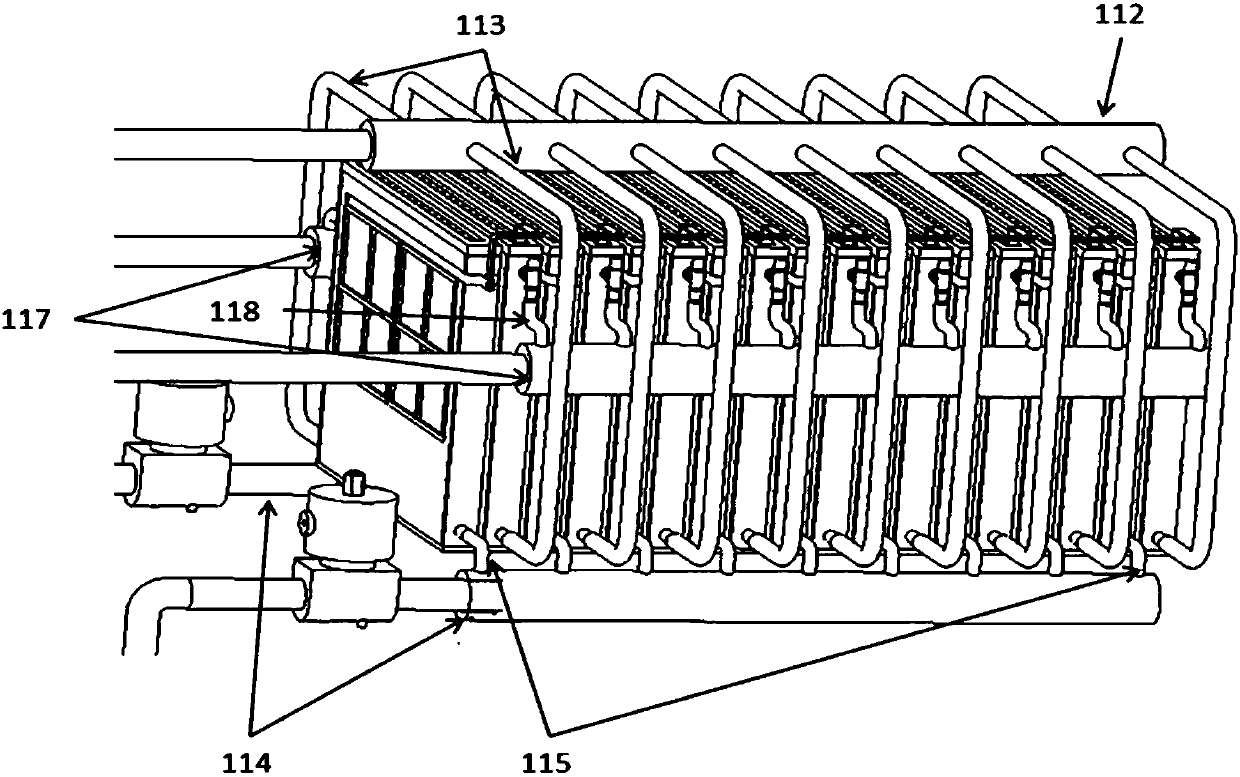

A sludge concentration-dehydration-drying integrated treatment plant and a treating method thereof

ActiveCN106396331AFiltration precision controlEasy to dehydrateSludge treatment by de-watering/drying/thickeningRubber ringSpiral blade

A sludge concentration-dehydration-drying integrated treatment plant and a treating method thereof are disclosed. The integrated treatment plant includes a sludge concentration device and a sludge deep-dehydration device. The sludge concentration device includes a wedge-shaped filter screen and a rotating first spiral shaft. The wedge-shaped filter screen includes a low-concentration sewage filtration segment, a sludge concentration segment and a sludge extruding segment. The first spiral shaft includes a central shaft, a first rubber ring and a first spiral blade. The sludge deep-dehydration device includes a spiral conveying-extrusion integrated machine and an extruding dehydrating chamber. The spiral conveying-extrusion integrated machine includes a second spiral blade, a conveying shell and a second spiral shaft varying in pitch. The extruding dehydrating chamber includes a left filtration plate, a right filtration plate and a middle filtration plate. The left and right filtration plates adopt the middle filtration plate as an axis and expand outward or close inward. The integrated treatment plant overcomes problems of the prior art that water contents after sludge treatment are high and a running cost is high.

Owner:XIAMEN UNIV OF TECH +1

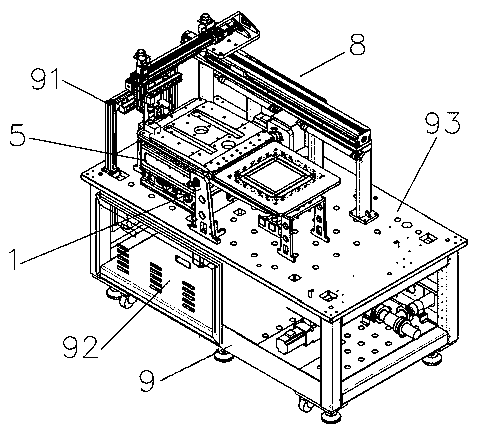

Smartphone touch screen attachment equipment

InactiveCN108920020ASimple structureEasy to useInput/output processes for data processingEngineeringWorkbench

The invention discloses smartphone touch screen attachment equipment. The equipment comprises a lower rack, wherein a workbench is arranged at the upper side of the lower rack, and a CCD alignment mechanism, an attachment mechanism, a turnover plate mechanism and a parallel light mechanism are arranged at the upper side of the workbench; the turnover plate mechanism comprises a turnover plate conveying component, a turnover plate limiting component and a turnover plate supporting component, wherein the turnover plate limiting component is arranged between the parallel light mechanism and the attachment mechanism, and the turnover plate conveying component is arranged between the attachment mechanism and the turnover plate supporting component; the turnover plate conveying component comprises a front turnover plate bearing seat, a rear turnover plate bearing seat, a reducer, a turnover plate rotary shaft, a turnover plate adapting plate and a turnover plate sealing plate; and an adsorption plate is arranged on the turnover plate sealing plate, and an OEM touch screen is adsorbed through the adsorption plate. The smartphone touch screen attachment equipment is simple in structure andconvenient to use, realizes full automation, can operate continuously, saves manpower, meets production requirements, improves production efficiency and has high market application value.

Owner:深圳市中科创想科技有限责任公司

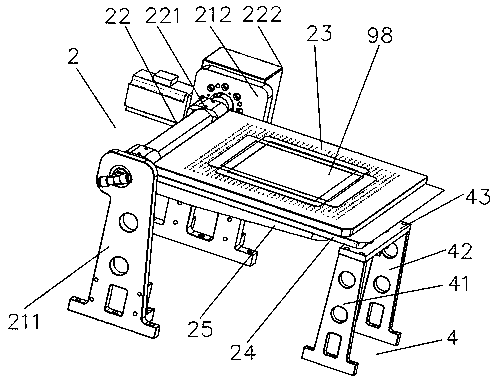

Lamination equipment applicable to touch screen of tablet computer

PendingCN109228607ASimple structureEasy to useLamination ancillary operationsLaminationTablet computerProduction line

The invention discloses lamination equipment applicable to a touch screen of a tablet computer. The lamination equipment comprises a rack, wherein the rack is internally provided with an electric control cabinet; the rack is provided with a feeding and discharging production line, a touchpad lamination device and a display panel lamination device; the feeding and discharging production line comprises a feeding conveyor line and a discharging conveyor line; the feeding conveyor line is arranged at the left side of the rack; the touchpad lamination device is arranged at the right side of the feeding conveyor line; the display panel lamination device is arranged at the right side of the touchpad lamination device; the discharging conveyor line is arranged at the right side of the display panel lamination device; the touchpad lamination device is laminated with a cover plate and a touchpad; then the touchpad and a display panel are laminated through the display panel lamination device andthen the laminated display panel is conveyed into the discharging conveyor line. With the adoption of the manner, the lamination equipment has the advantages of simple structure, convenience for utilization, capability of realizing automation, capability of working continuously and manpower saving; production requirements are met and the production efficiency is improved; the lamination equipmenthas good market application value.

Owner:深圳市鹏盈贸易有限公司

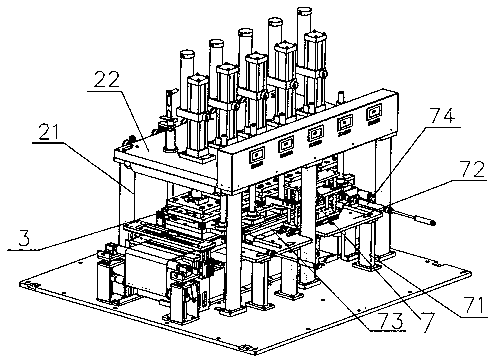

Flat pressing shaping device for new energy automobile battery

ActiveCN109687031ASimple structureEasy to useMetal-working feeding devicesFinal product manufactureElectrical batteryNew energy

The invention discloses a flat pressing shaping device of a new energy automobile battery. The flat pressing shaping device comprises a rack, wherein a feeding device, a flat pressing shaping device and a blanking device are arranged on a workbench on the rack, the feeding device comprises a feeding transmission mechanism, a feeding transfer mechanism and a feeding moving mechanism, the feeding transmission mechanism and the feeding transfer mechanism are arranged on the lower side of the feeding conveying mechanism side by side, and a moving power member is connected with a moving bagging member and drives the moving bagging member to move. The flat pressing shaping device comprises a conveying mechanism and a flat pressing mechanism arranged on the upper side of the conveying mechanism,at least a down pressing member is arranged on a flat pressing fixing plate of the flat pressing mechanism, the down pressing member comprises a down pressing face plate, a down pressing mounting plate, a down pressing connecting plate and a down pressing cylinder which are sequentially arranged from bottom to top, and the down pressing face plate is driven to move up and down by the down pressingcylinder. The flat pressing shaping device is simple in structure, convenient to use and capable of continuously working and saving labor, meets production requirements, improves production efficiency and has a good market application value.

Owner:吉林省田车科技有限公司

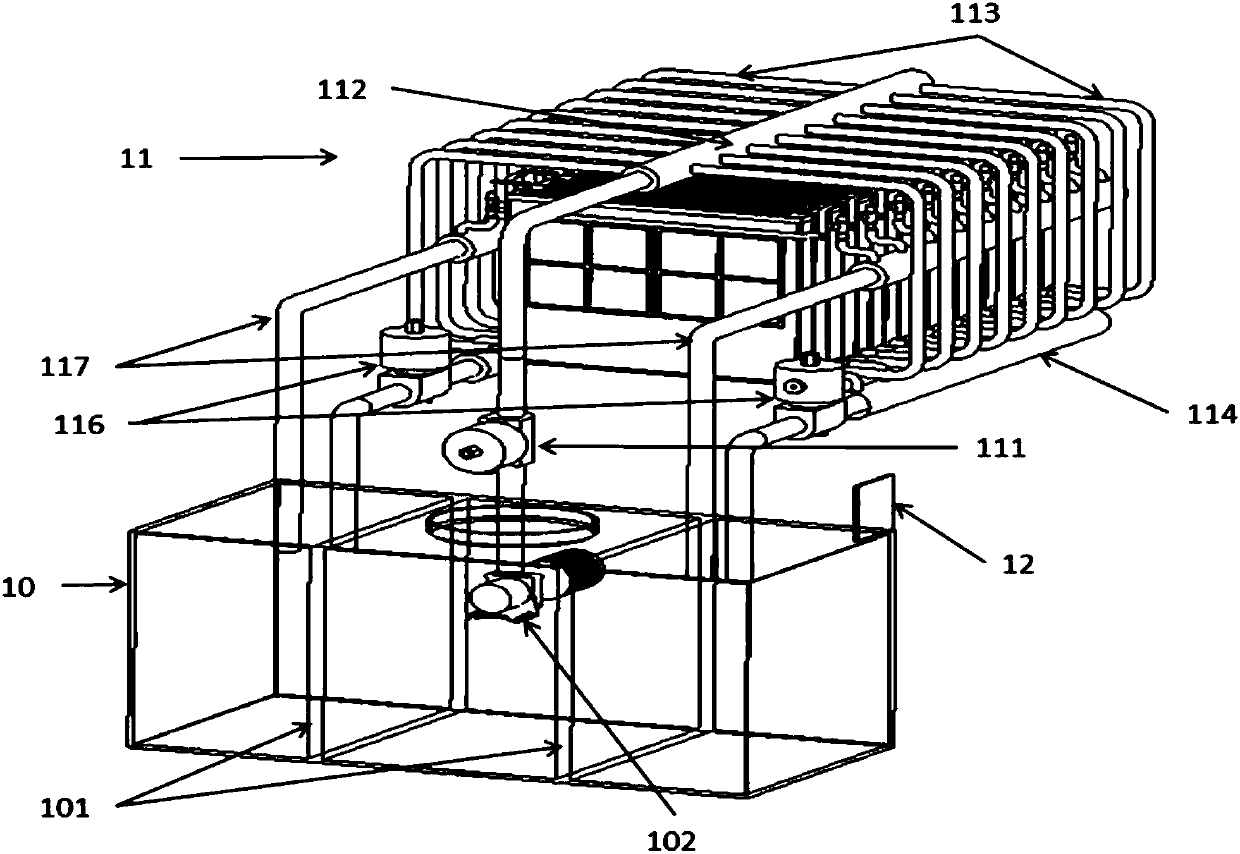

High-power neutral electrolyte metal-air battery system and using method thereof

ActiveCN107611525ASolve temperature problemsSolve cleaningFuel and primary cellsElectrolyte stream managementBusbarElectrical battery

The invention relates to a high-power neutral electrolyte metal-air battery system and a using method thereof. The battery system comprises two or a plurality of basic cell units connected in series or in parallel, an electrolyte filtering box, a circulating pump, a control valve, an electrolyte input distributor, an electrolyte discharge manifold, a drain valve, an electrolyte overflow manifold,a control circuit, a controller, a connecting pipeline and the like. Each basic cell unit consists of a reaction box, an anode, a cathode, electrolyte, a cathode busbar and an anode busbar; and an electrolyte input port, an electrolyte discharge port and an electrolyte overflow exhaust port are formed at both sides of the reaction box. The electrolyte is neutral liquid, such as salt water, seawater and the like. The electrolyte of each basic cell unit is communicated with each other without using an electrolyte isolator. The high-power neutral electrolyte metal-air battery system and the usingmethod thereof, which are disclosed by the invention, are applicable to the high-power power utilization requirements and have the characteristics that after the anodes are used up, the anodes can bereplaced so as to reuse the high-power neutral electrolyte metal-air battery system; the high-power neutral electrolyte metal-air battery system can be stored for long time in a safe and maintenance-free mode, and is simple to start up and use; a load can be cut off at any time; the high-power neutral electrolyte metal-air battery system and the using method thereof have no pollution to the environment; and reaction precipitates can be recovered and recycled.

Owner:IMAY DESIGN

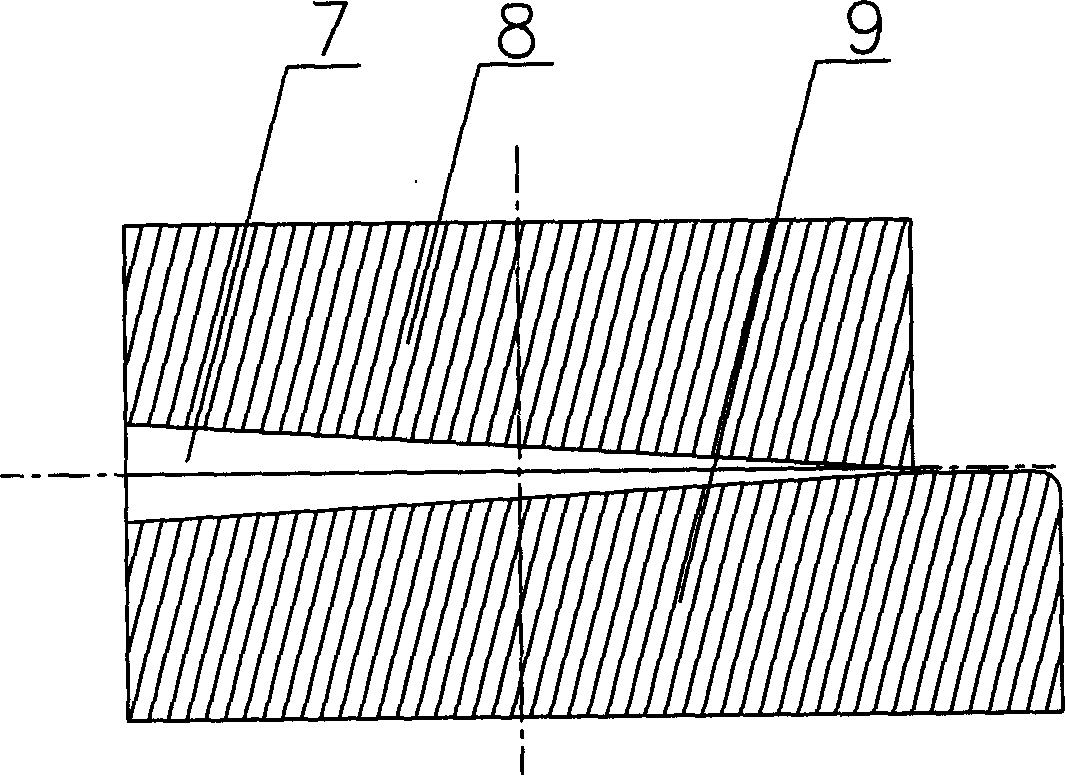

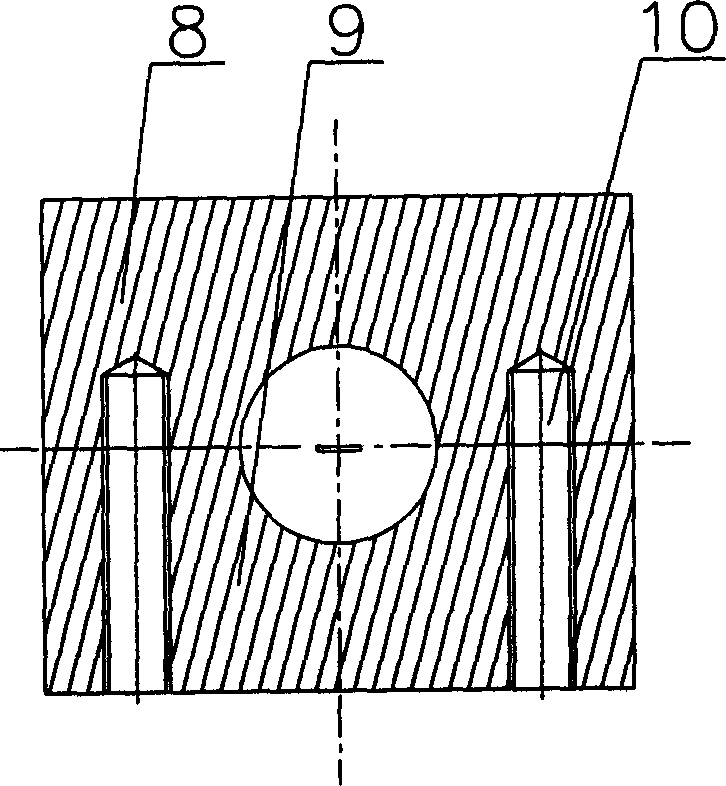

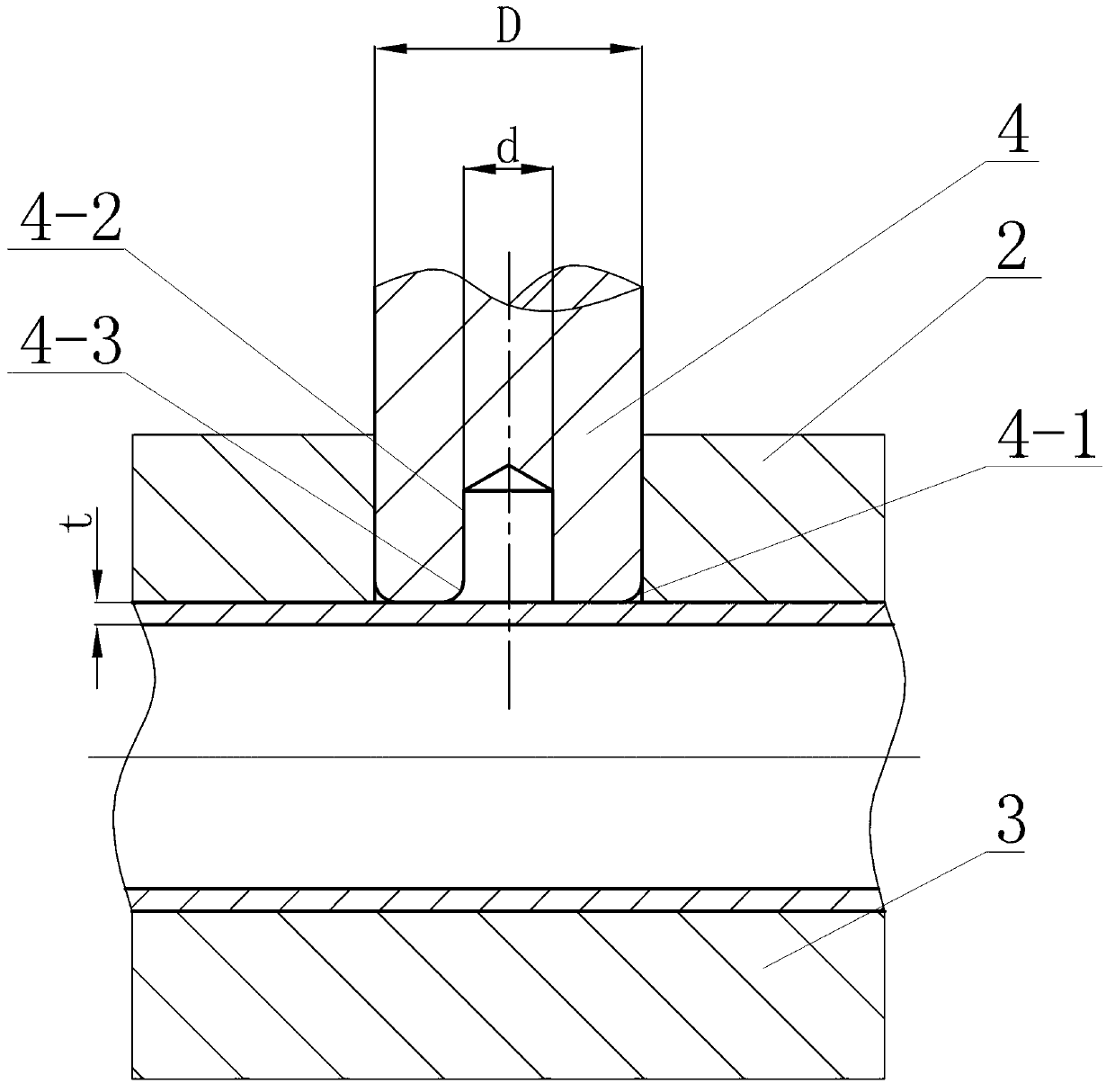

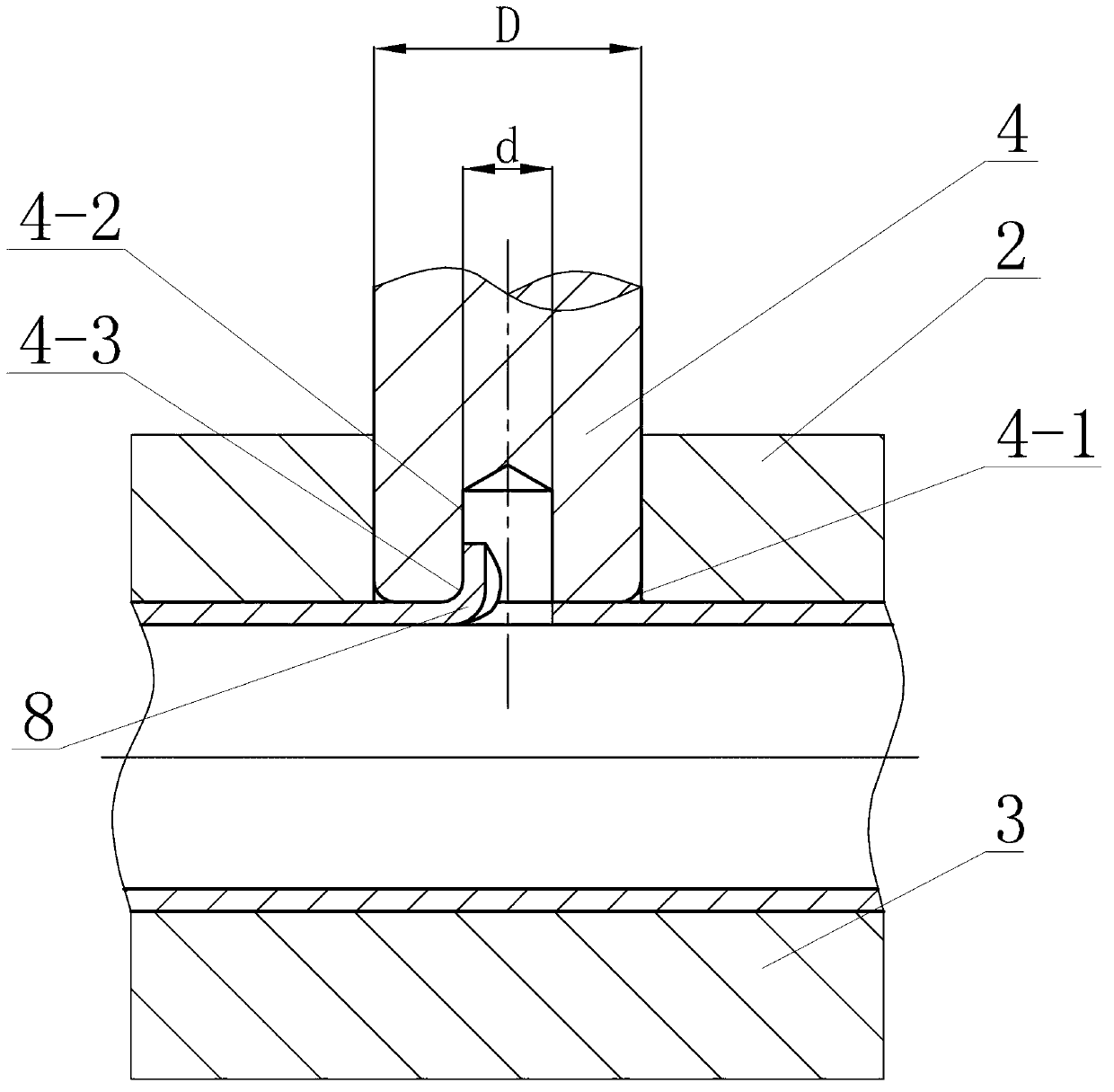

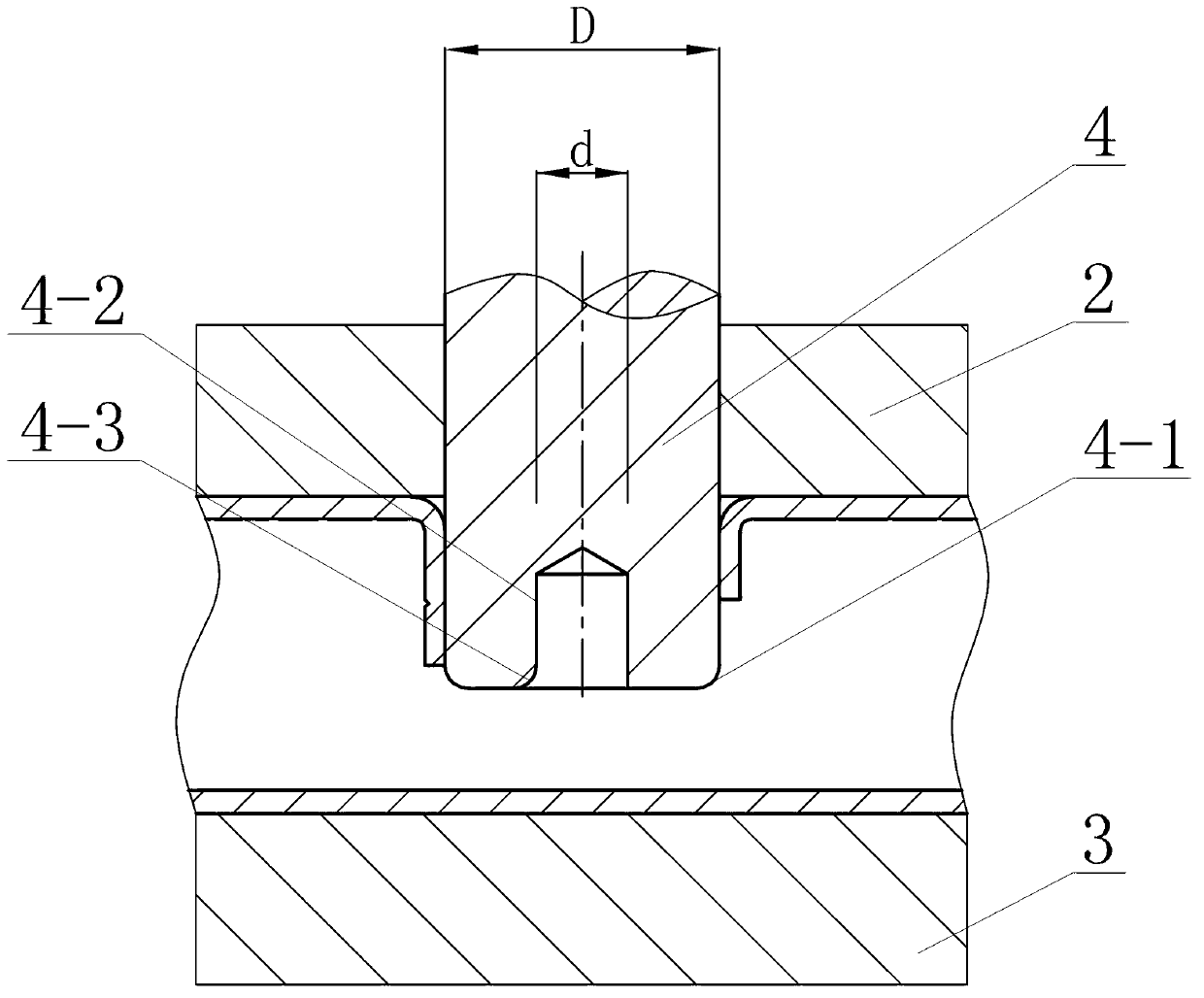

Hydraulic punching and flanging mould used for interior high-pressure forming member

A hydraulic punching and flanging mould used for an interior high-pressure forming member relates to a hydraulic punching and flanging mould. The hydraulic punching and flanging mould solves the problems that a blanking region of the conventional hydraulic punching and flanging mould of the interior high-pressure forming member falls into a to-be-formed pipe blank, a flanging embedded block is difficult to take out, cleaning time is wasted and production efficiency is reduced. An upper mould block is located at the upper end face of a lower mould block; to-be-formed pipe blank cavities are machined on butting surfaces of both the upper mould block and the lower mould block along a length direction; the to-be-formed pipe blank is located in the to-be-formed pipe blank cavity during the interior high-pressure forming process; a punch pin hole is machined on the upper mould block; the lower end of the punch pin is located in the punch pin hole; a first filleted corner is chamfered at the outer edge of the lower end of the punch pin; a central blind hole is machined at the lower end of the punch pin along the axial direction; a second filleted corner is machined at the left half part of the central blind hole; and the radiuses of both the first filleted corner and the second filleted corner are 0.8-2 times the wall thickness of the to-be-formed pipe blank. The hydraulic punching and flanging mould is used for punching and flanging the interior high-pressure forming member.

Owner:HARBIN INST OF TECH

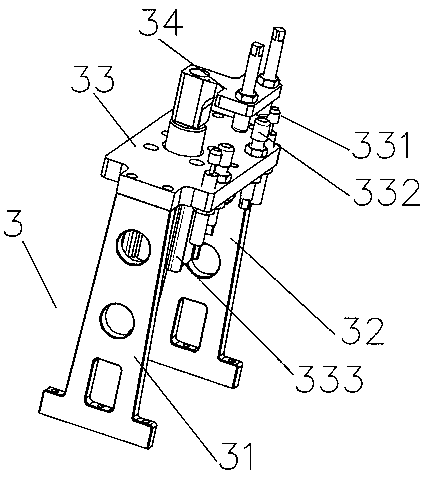

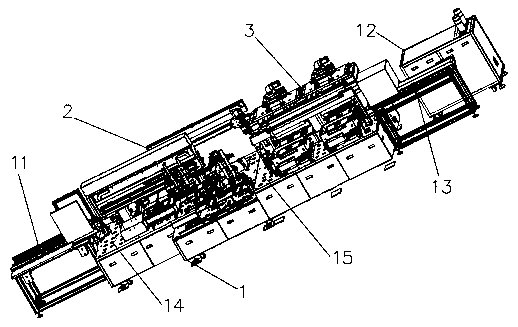

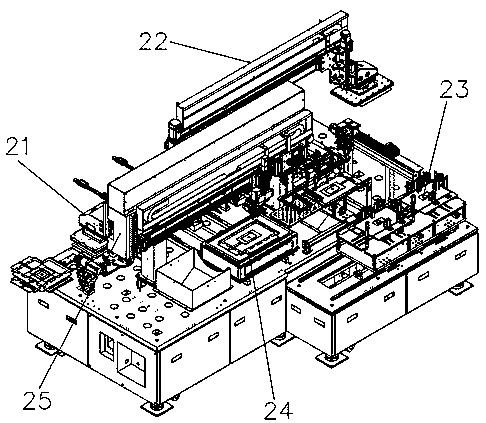

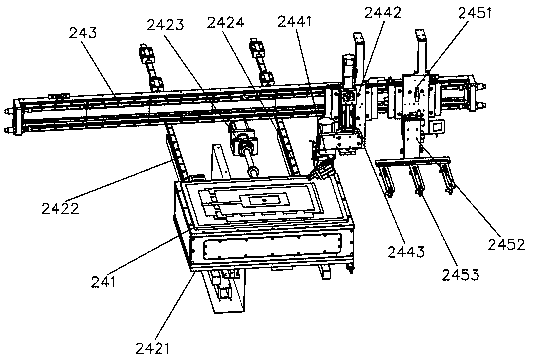

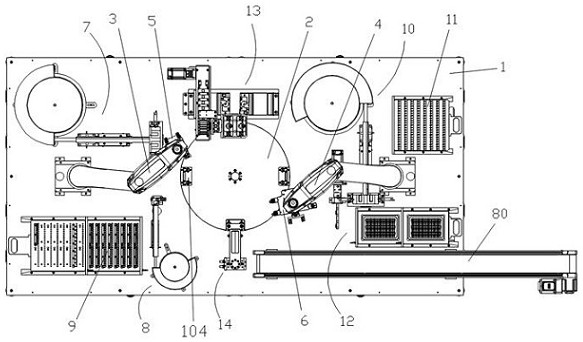

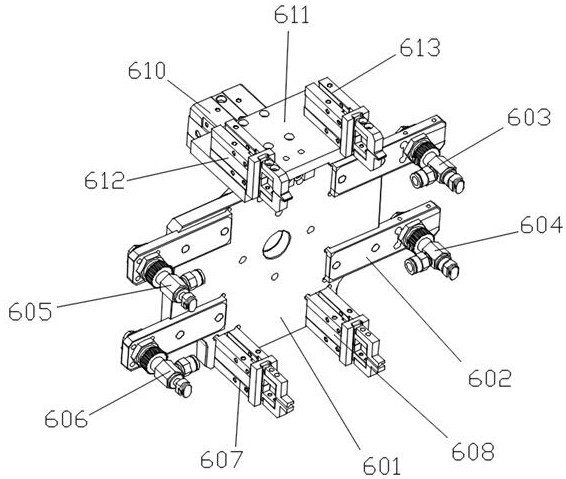

Semiconductor double-optical-filter switcher assembling equipment based on AA manufacturing procedure

ActiveCN112318085ASimple structureEasy to useMountingsMetal working apparatusEngineeringLight filter

The invention discloses semiconductor double-optical-filter switcher assembling equipment based on an AA manufacturing procedure. The semiconductor double-optical-filter switcher assembling equipmentcomprises a workbench, a rotating disc is arranged in the middle of the workbench, four assembling stations are arranged on the rotating disc at equal intervals along the circumference of the rotatingdisc, and each assembling station is provided with two tool stations. A first mechanical arm and a second mechanical arm are arranged corresponding to the left assembling station and the right assembling station of the rotating disc correspondingly, and the working end of the first mechanical arm and the working end of the second mechanical arm are provided with a first clamping jaw mechanism anda second clamping jaw mechanism correspondingly. A bottom shell feeding mechanism, a bracket feeding mechanism and a driver feeding disc are arranged on the portion, within the moving range of the first mechanical arm, of the workbench, and an upper cover feeding mechanism, a rocker arm feeding disc and a moving piece feeding mechanism are arranged on the portion, within the moving range of the second mechanical arm, of the workbench. A screwing mechanism and a discharging mechanism are respectively arranged in front of and behind the rotating disc. The semiconductor double-optical-filter switcher assembling equipment is simple in structure and convenient to use, automation is achieved, labor is saved, and production efficiency is improved.

Owner:深圳中科精工科技有限公司

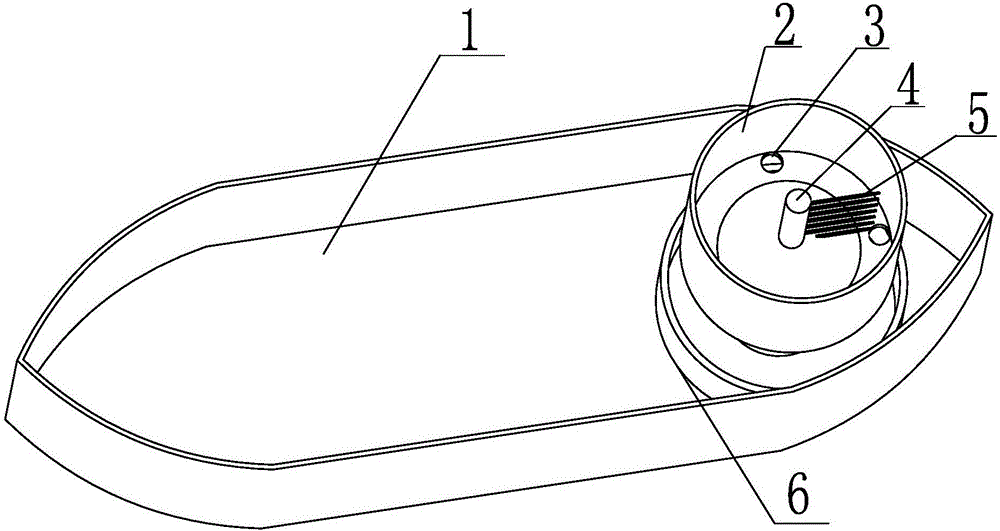

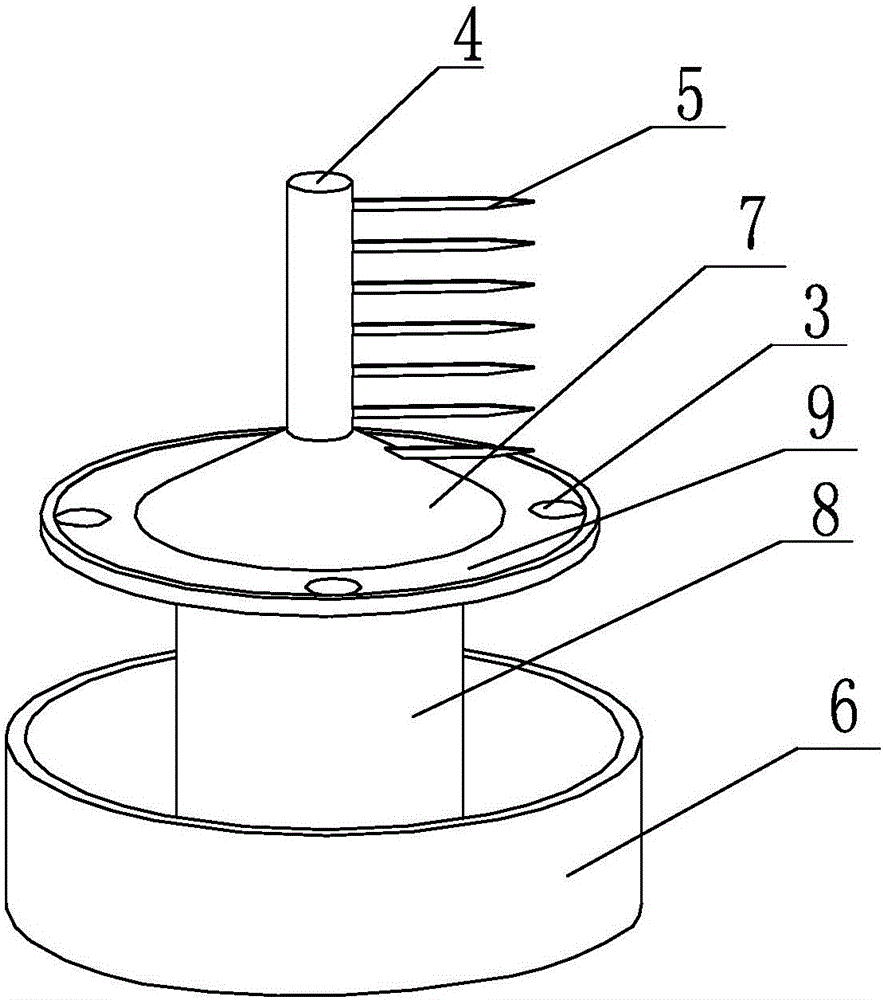

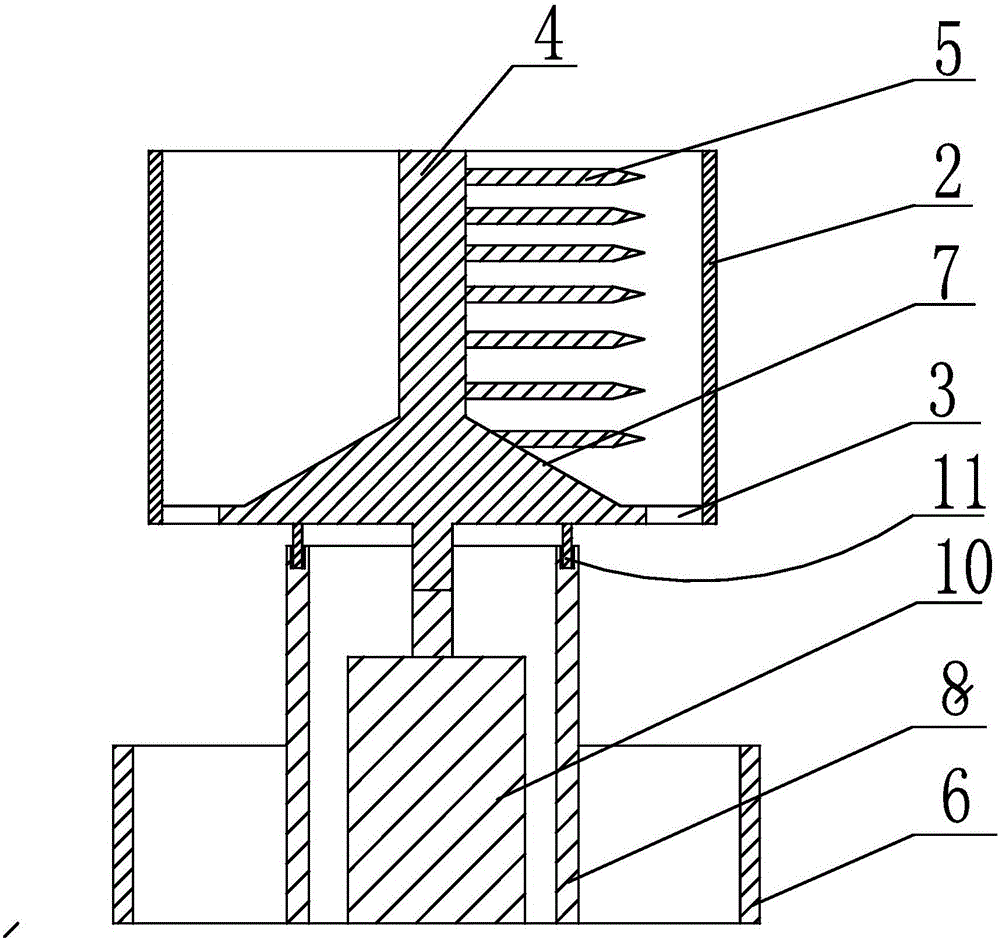

Automatic lotus seedpod threshing and picking boat

ActiveCN106068950ASolve the problem of frequent dockingAchieve pickingWaterborne vesselsThreshersCouplingEngineering

The invention discloses an automatic lotus seedpod threshing and picking boat. The automatic lotus seedpod threshing and picking boat comprises a boat body and a threshing mechanism connected with the bottom of the boat body through screws; the boat body is a common boat body driven by an engine; the threshing mechanism comprises a box, a seed feeding hole, a shaft coupling, a stirring rod, a seed storage box, a trapezoidal cylinder, a supporting pillar, a box bottom, a motor and a sliding block; the seed storage box, the motor and the supporting pillar are all fixedly connected with the bottom of the boat body, a guide rail is arranged at the upper end of the supporting pillar, the sliding block is connected with the guide rail arranged at the upper end of the supporting pillar in a sliding fit mode, the upper end of the sliding block is fixedly connected with the box bottom, the box and the box bottom are connected through screws to form a storage box used for containing picked lotus seedpods, the seed storage box is used for containing unshelled lotus seeds. The automatic lotus seedpod threshing and picking boat can achieve the function of continuous lotus seedpod picking, and lotus seed collection efficiency is improved.

Owner:合肥曌云科技有限公司

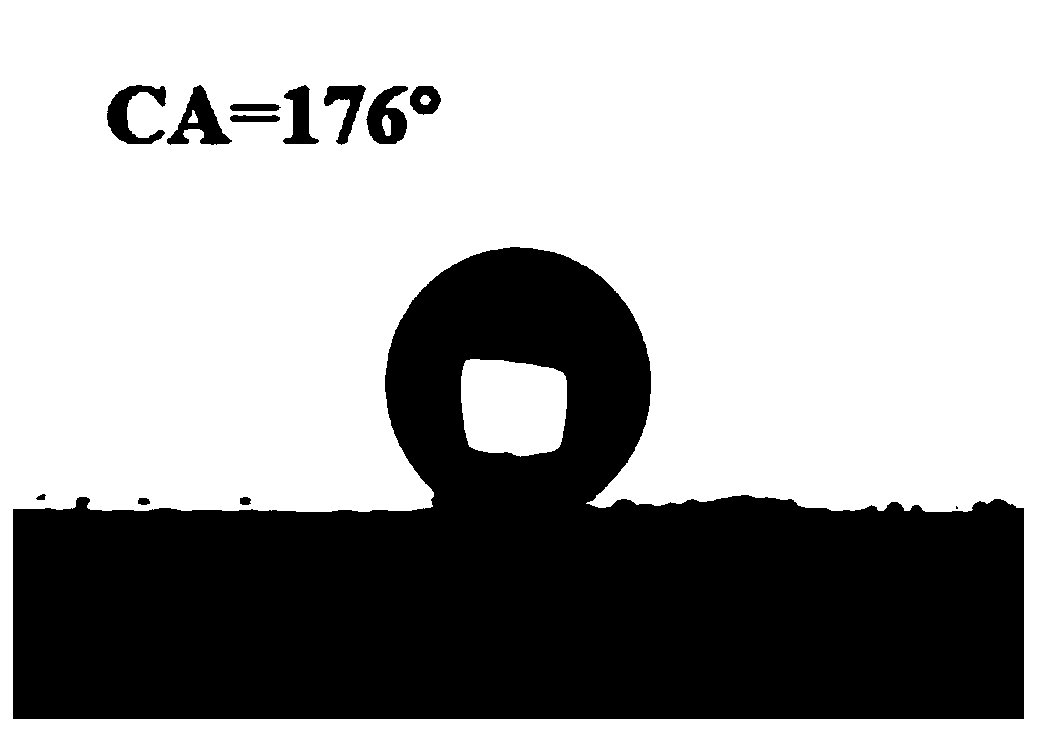

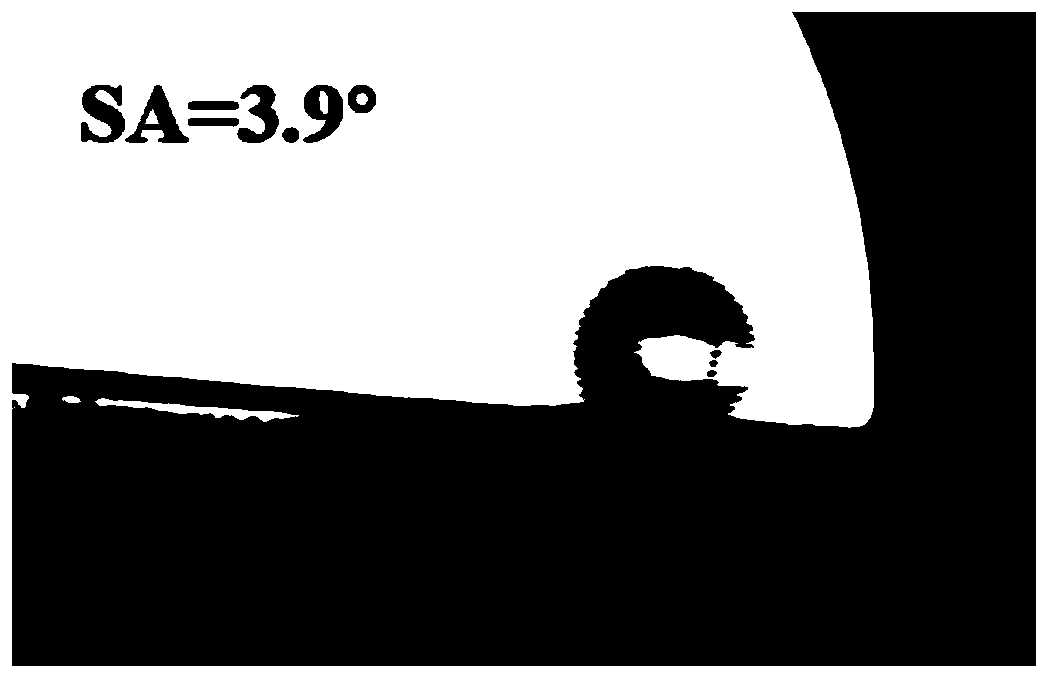

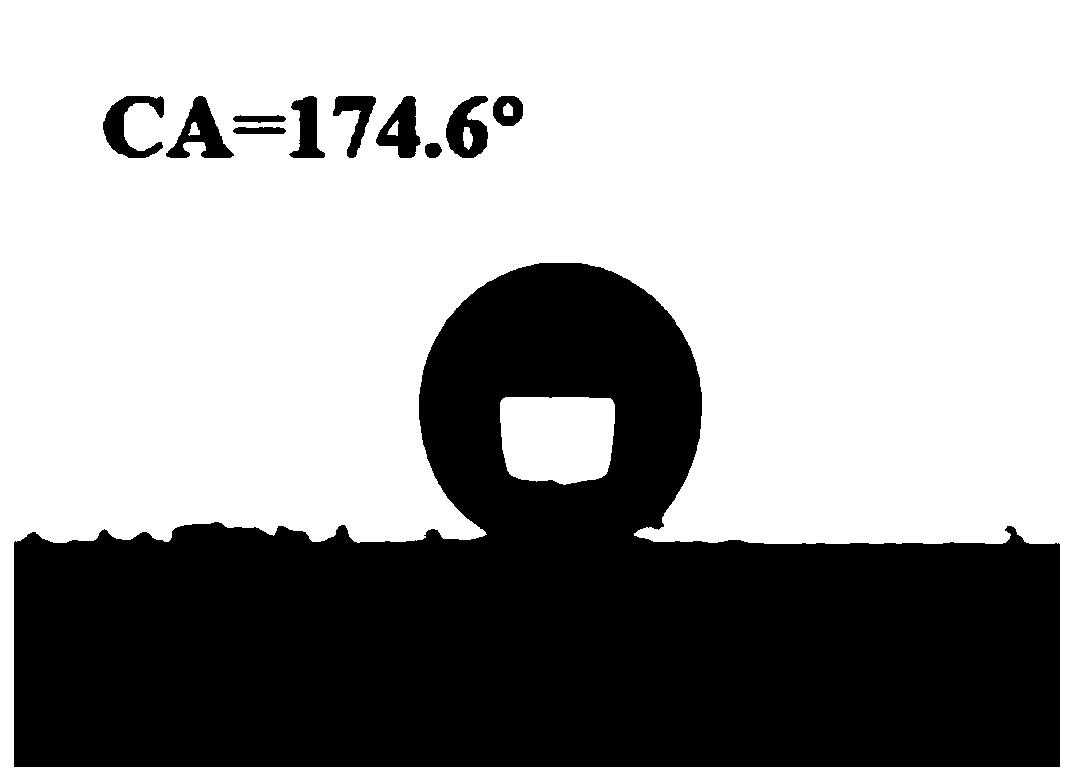

Nano super-hydrophobic coating additive as well as preparation method and application thereof

ActiveCN111440468AEasy to manufactureGood chemical stabilityFireproof paintsAnti-corrosive paintsMicro nanoNano structuring

The invention discloses a nano super-hydrophobic coating additive as well as a preparation method and application thereof. The preparation method of the nano super-hydrophobic coating additive comprises the following steps: uniformly mixing a nano material with a solvent to obtain a solution A, adding a catalyst and a low-surface-energy coupling agent into the solution A to obtain a solution B, uniformly stirring the solution B to obtain a product C, and carrying out solid-liquid separation on the product C to obtain a solid, namely the nano super-hydrophobic coating additive. The method has the remarkable difference from a traditional method for preparing a hydrophobic coating that the preparation of the nano super-hydrophobic coating additive does not need a relatively complex process ofconstructing a micro-nano structure surface, instead, the method starts from the idea of chemically modifying the surface of the nano material, active groups on the surface of the nano material are directly used for carrying out organic covalent chemical modification on the nano material to prepare the nano super-hydrophobic coating additive, so that the preparation process of the super-hydrophobic surface is greatly simplified.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

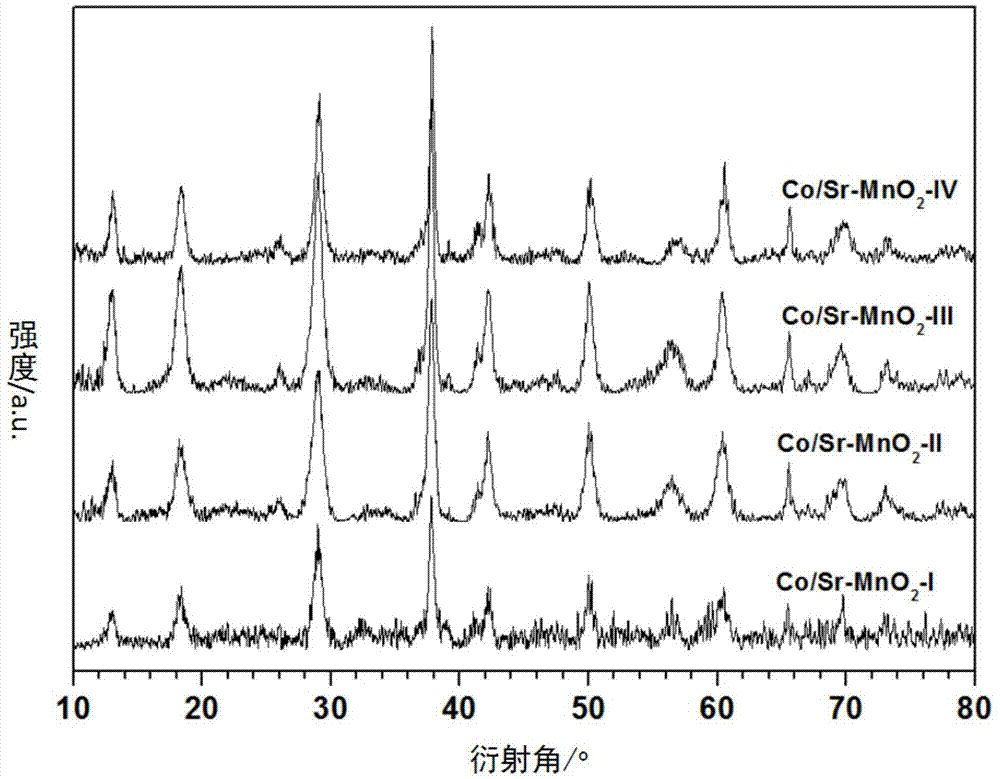

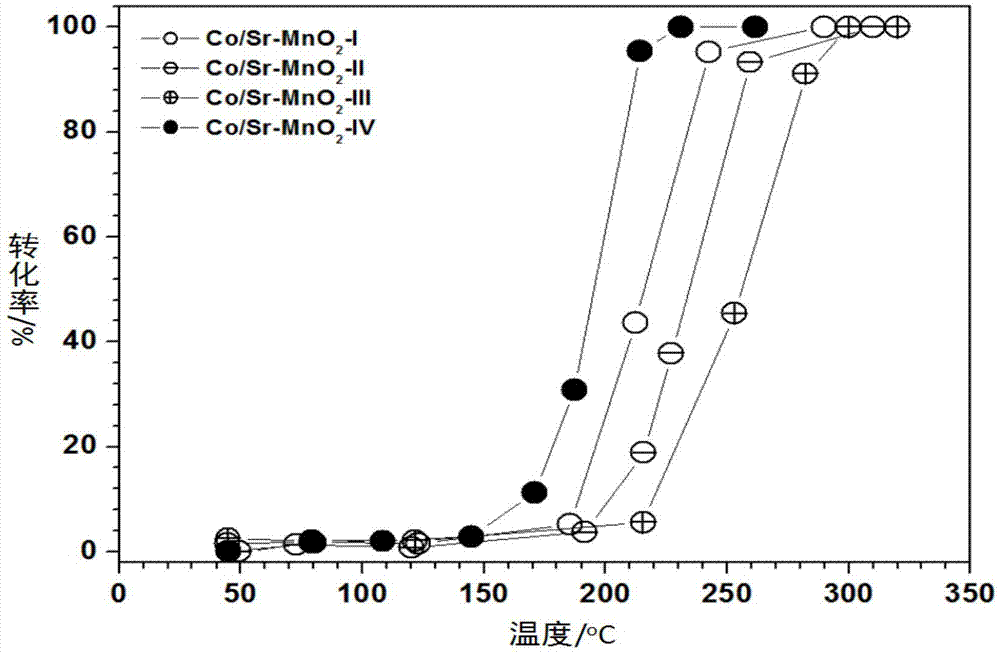

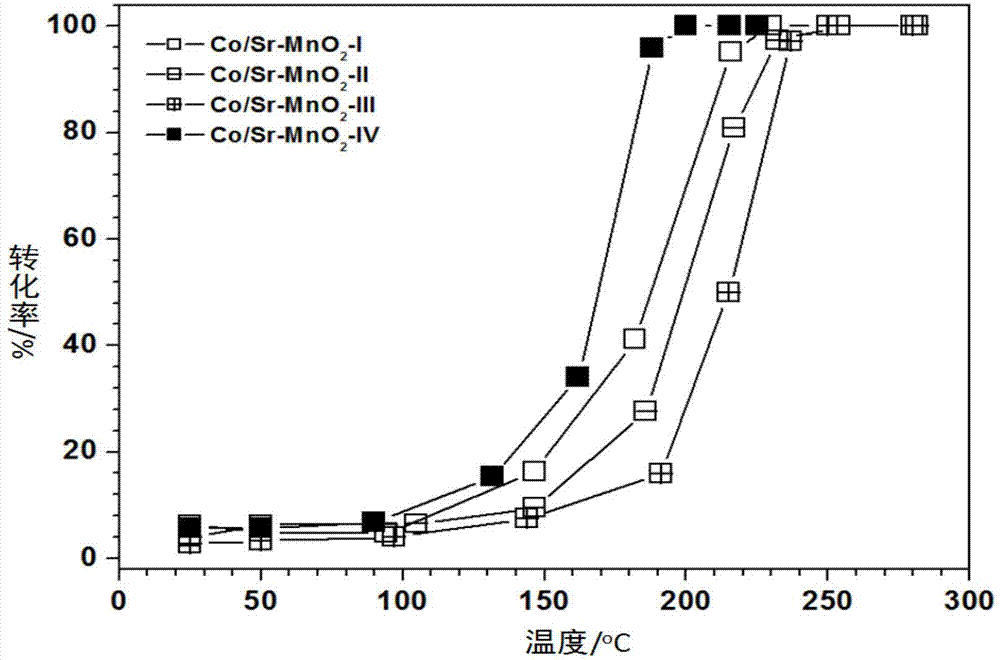

Preparation methods and application of alpha-manganese oxide loaded cobalt strontium catalyst

InactiveCN104511289AEasy to makeLow priceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsManganese oxideCobalt

The invention discloses a preparation method and application of an alpha-manganese oxide loaded cobalt strontium catalyst. The catalyst is prepared as follows: under the regulation of an acetic acid buffer solution, an alpha-manganese oxide loaded cobalt strontium catalyst sample Co / SR-alpha-MnO2 with high specific surface area (100-130 m<2> / g) and high thermal stability (> 650 DEG C) can be prepared by reflux reaction of manganese sulfate, potassium permanganate, cobalt nitrate, strontium sulfate and a dispersion agent. The catalyst has high elimination efficiency to high space velocity (60,000 h<-1>-100,000 <-1>) and low concentration benzene and toluene. The catalyst can completely transform the benzene into non-poisonous materials CO2 and H2O at 230 DEG C, the benzene elimination rate can be kept greater than 90% at 230 DEG C within 100 hours, the toluene can be completely transformed into the non-poisonous materials CO2 and H2O at 200 DEG C, and the toluene elimination rate can be kept greater than 90% at 200 DEG C within 100 hours. The catalyst has the advantage of cheap raw materials, simple catalyst preparation technology, strong practicability, low benzene series complete elimination temperature, high efficiency, no secondary pollution and the like.

Owner:BEIJING UNIV OF TECH

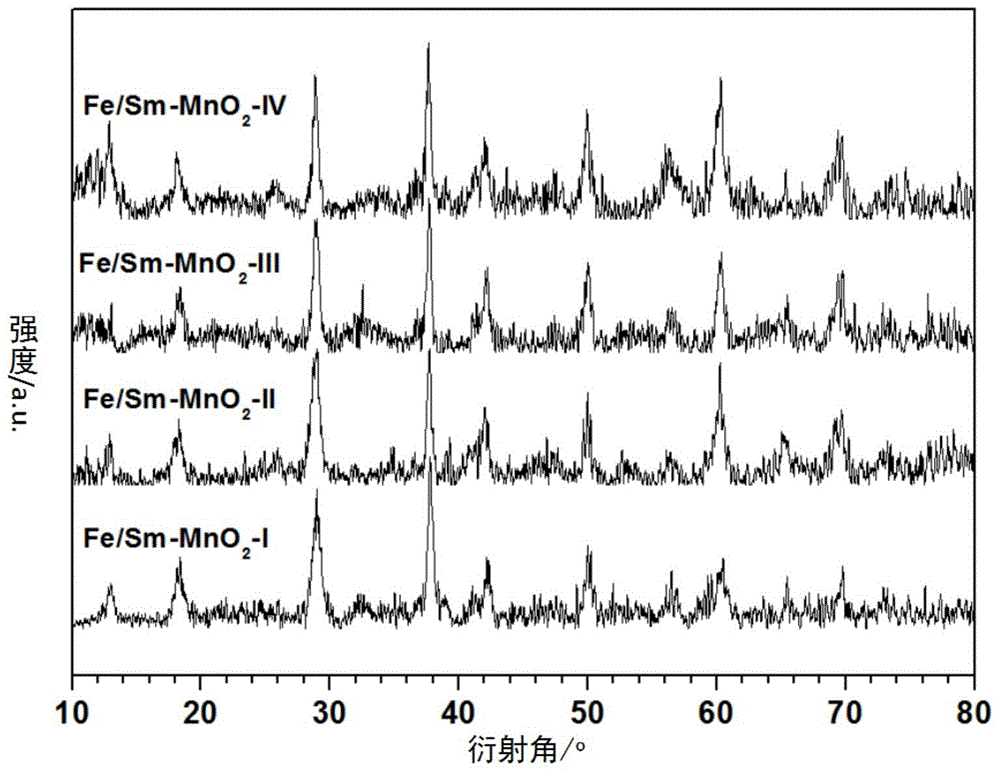

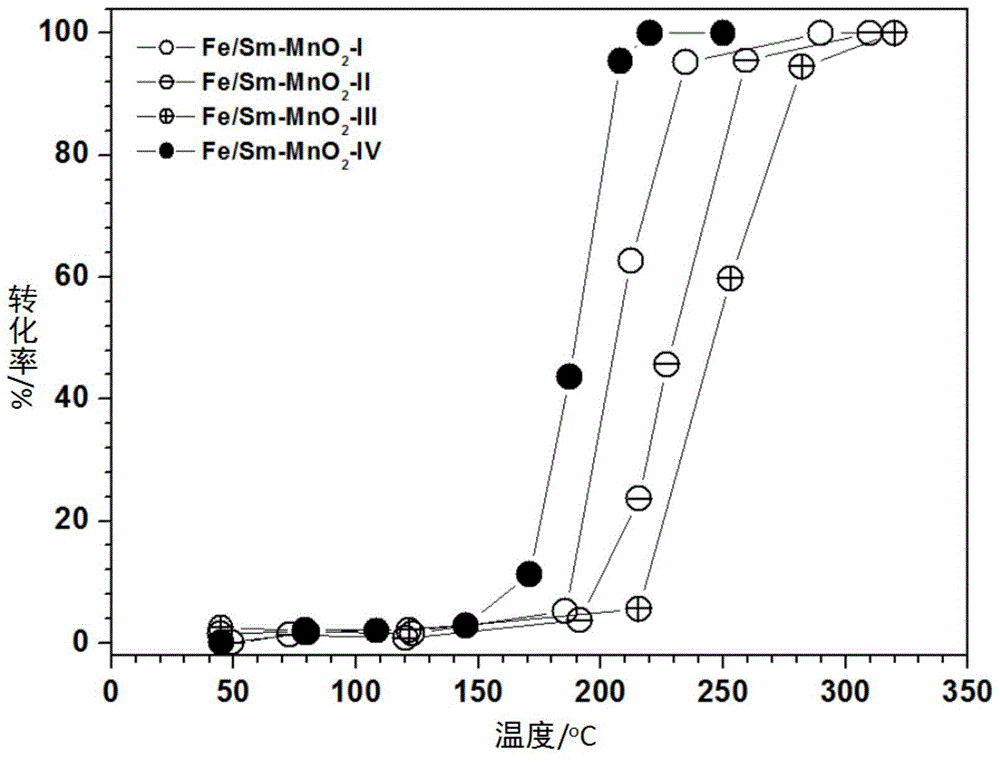

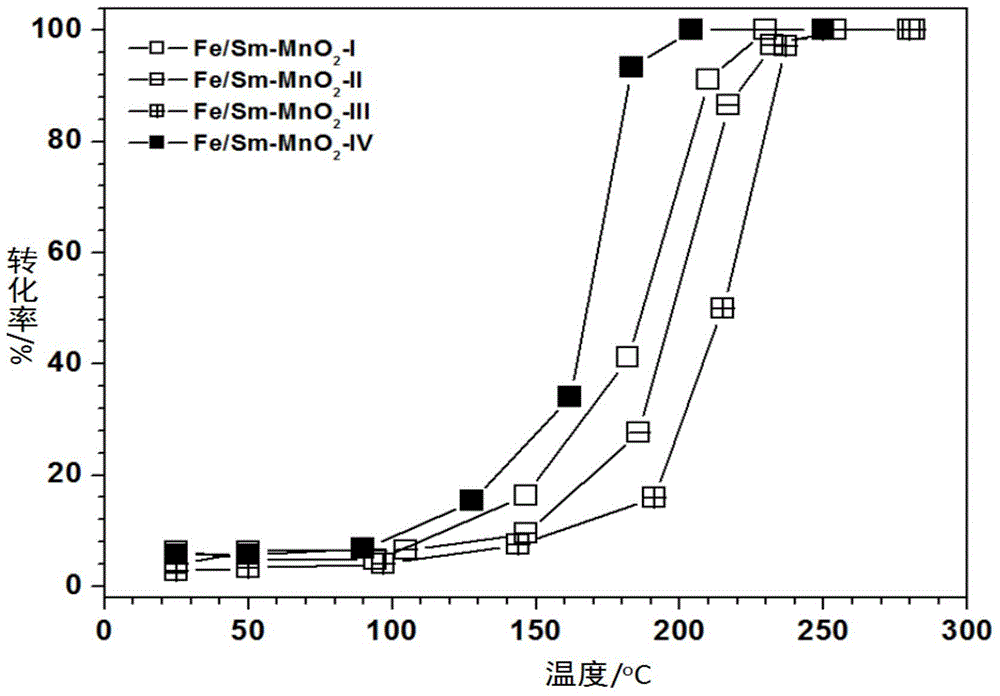

Preparation method and application of alpha-manganese oxide supported iron-samarium catalyst

ActiveCN104525214AEasy to makeLow priceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsToxic materialManganese oxide

The invention discloses a preparation method and an application of an alpha-manganese oxide supported iron-samarium catalyst. Under adjustment of a citric acid buffer solution, manganese sulfate, potassium permanganate, ferric nitrate, samarium nitrate and a dispersing agent are subjected to a refluxing reaction to prepare an alpha-manganese oxide supported iron-samarium sample Fe / Sm-alpha-MnO2 with high specific surface area (100-130 m<2> / g) and high thermal stability (more than 650 DEG C). The catalyst has relatively high eliminating efficiency on benzene and toluene with high space velocity (60000 h<-1>-100000 h<-1>) and low concentration (500 ppm-1000 ppm). At the temperature of 220 DEG C, benzene is completely converted into non-toxic substances CO2 and H2O, and under the temperature of 220 DEG C, the benzene elimination rate in 100 h is kept at more than 90%; at the temperature of 200 DEG C, toluene can be completely converted into non-toxic substances CO2 and H2O, and under the temperature of 200 DGE C, the toluene elimination rate in 100 h is kept at more than 90%. The catalyst has the advantages of cheap raw materials, simple preparation process, high practicability, low temperatures for completely eliminating benzene-series compounds, high efficiency, no secondary pollution and the like.

Owner:BEIJING UNIV OF TECH

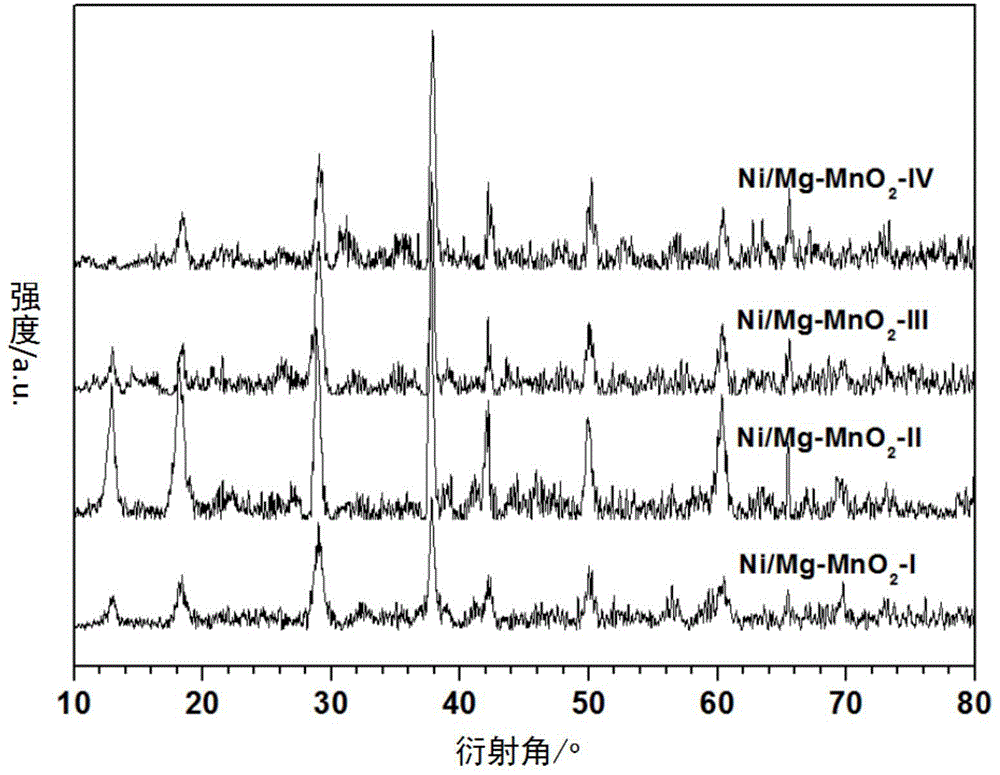

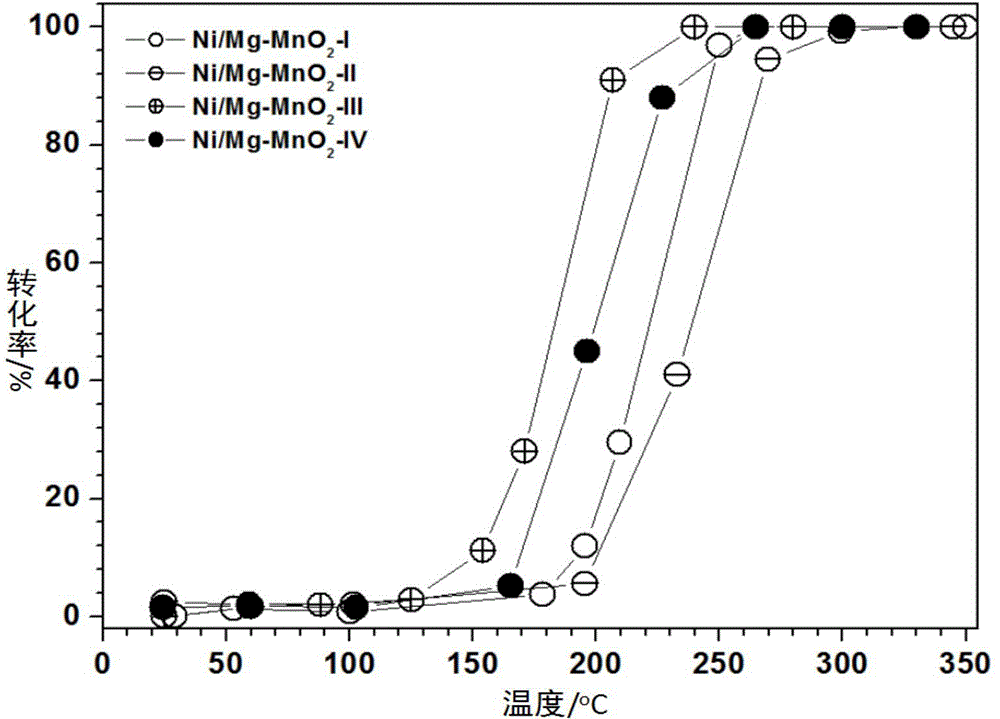

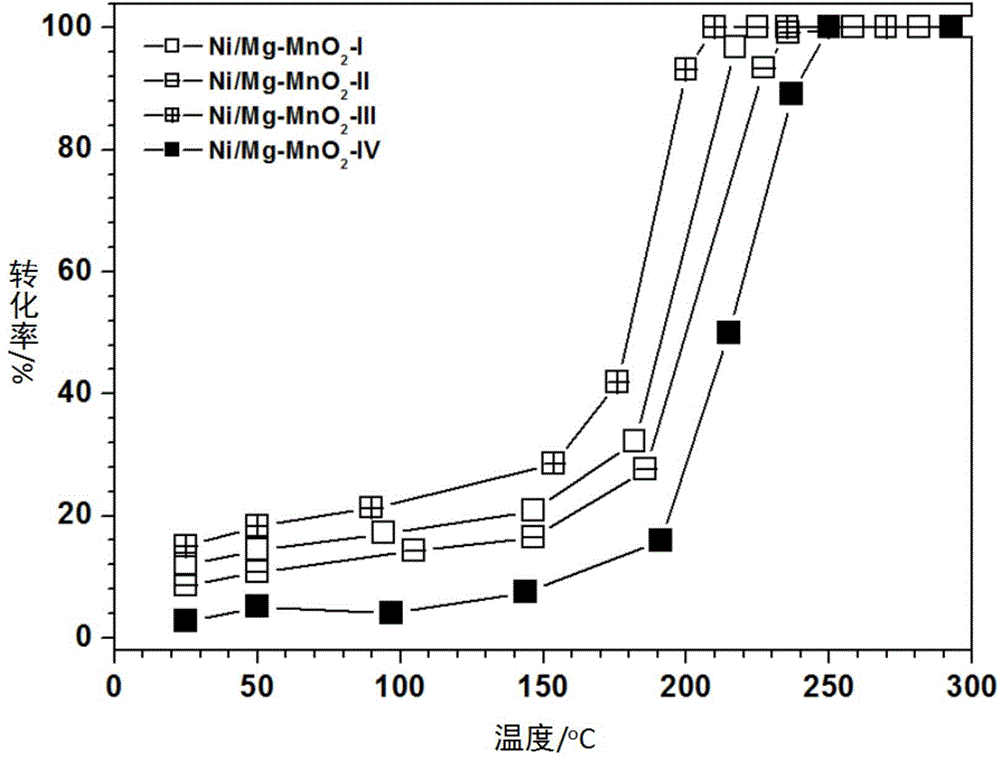

Preparation method and application of alpha-manganese oxide loaded nickel-magnesium catalyst

InactiveCN104525215AEasy to makeLow priceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsToxic materialManganese oxide

The invention discloses a preparation method and an application of an alpha-manganese oxide loaded nickel-magnesium catalyst. The catalyst is used in low-temperature high-efficiency catalysis of combustion for removing benzene-series substances. Under the adjustment of an acetic acid buffering solution, manganese sulfate, potassium permanganate, nickel nitrate, magnesium nitrate and a dispersing agent are subjected to a reflux reaction, such that an alpha-manganese oxide loaded nickel-magnesium Ni / Mg-alpha-MnO2 sample with high specific surface area (120-130m<2> / g) and high thermal stability (higher than 650 DEG C) is prepared. The catalyst has high removal rate towards high-space-velocity (60,000h<-1>-100,000h<-1>) and low-concentration (500ppm-1000ppm) benzene and toluene. Under a temperature of 240 DEG C, benzene can be completely converted into non-toxic substances CO2 and H2O. Under the temperature, a benzene removal rate can be maintained higher than 90% within 100h. Under a temperature of 210 DEG C, toluene can be completely converted into non-toxic substances CO2 and H2O. Under the temperature, a toluene removal rate can be maintained higher than 90% within 100h. The catalyst has the advantages of cheap raw materials, simple preparation process, and high practicality. With the catalyst, benzene-series substances can be completely eliminated with low temperature, high efficiency, and no secondary pollution.

Owner:BEIJING UNIV OF TECH

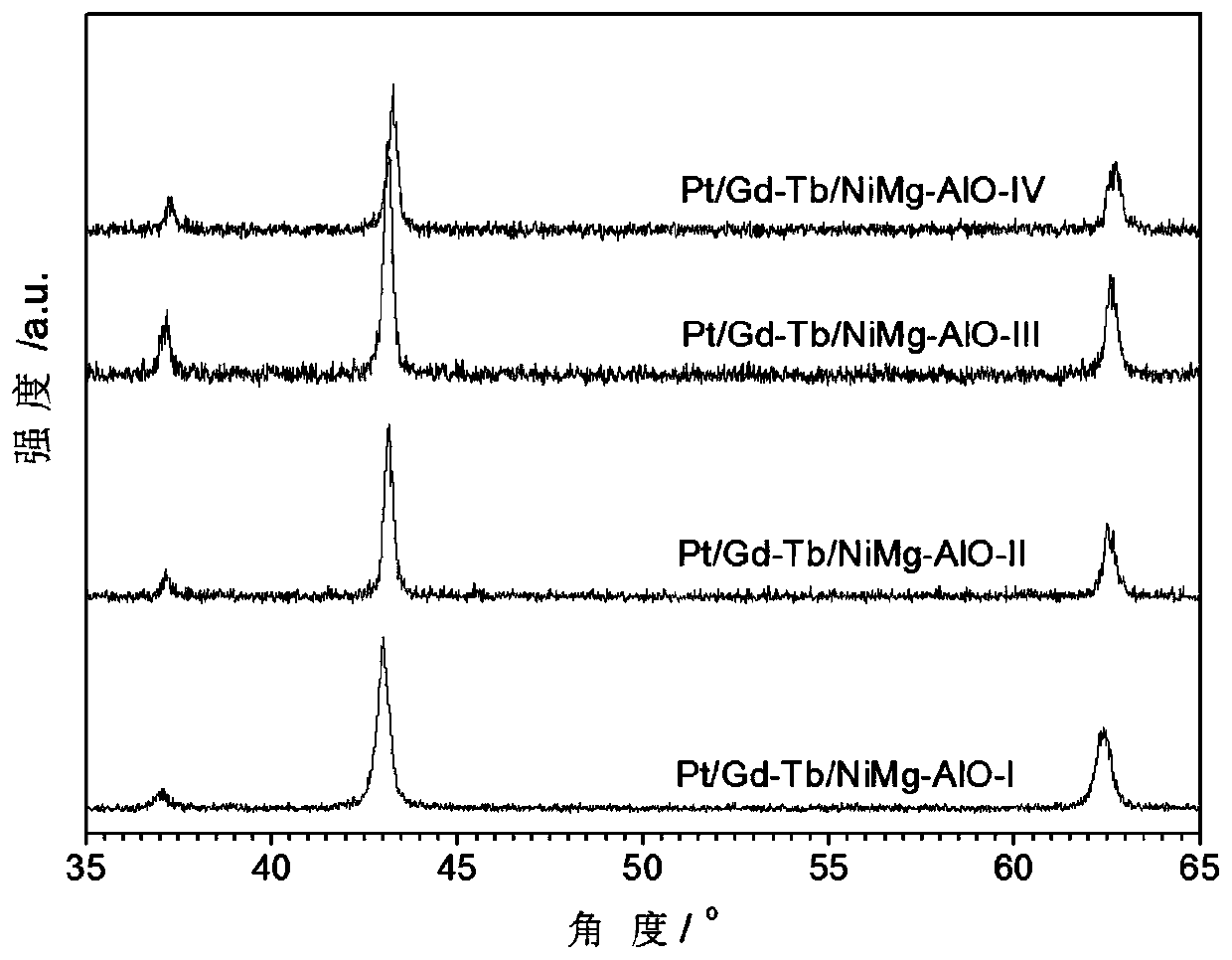

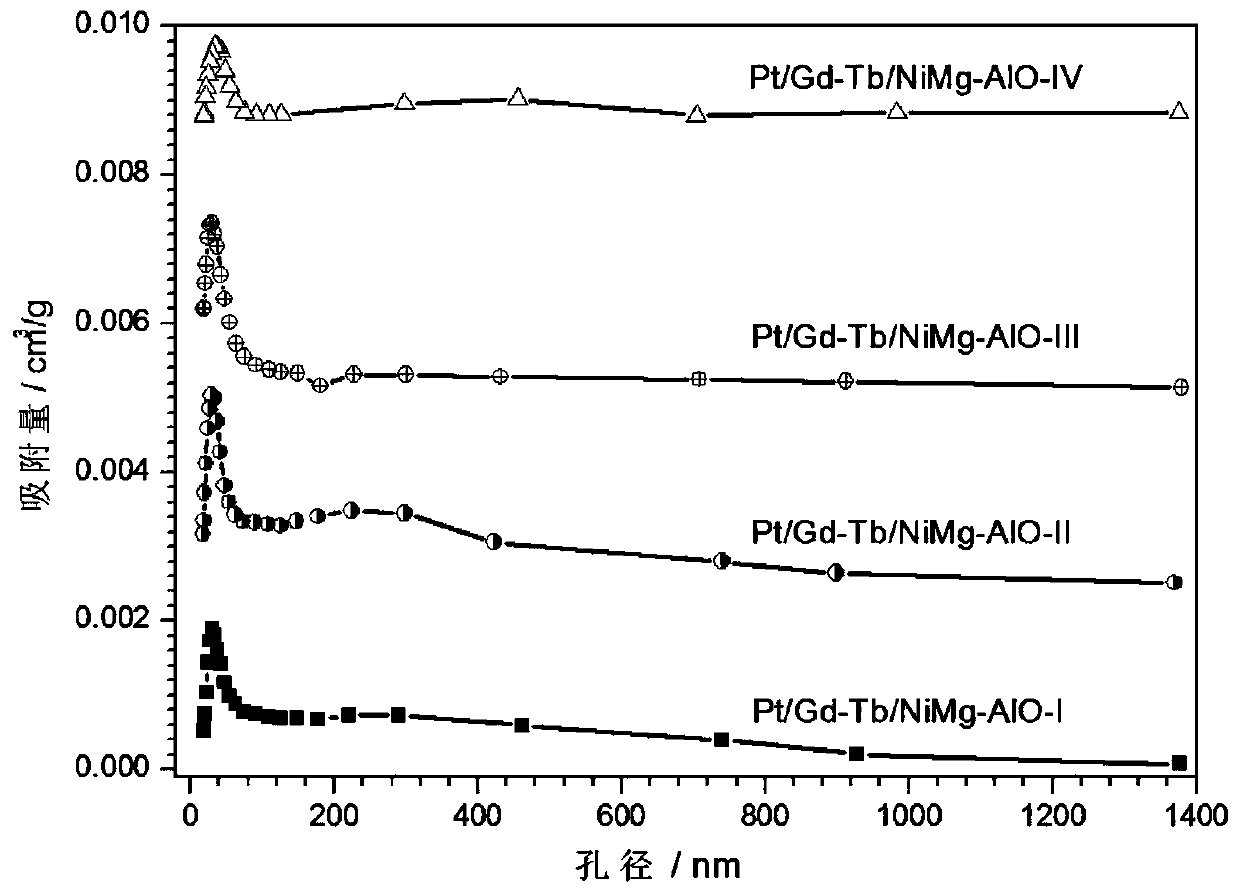

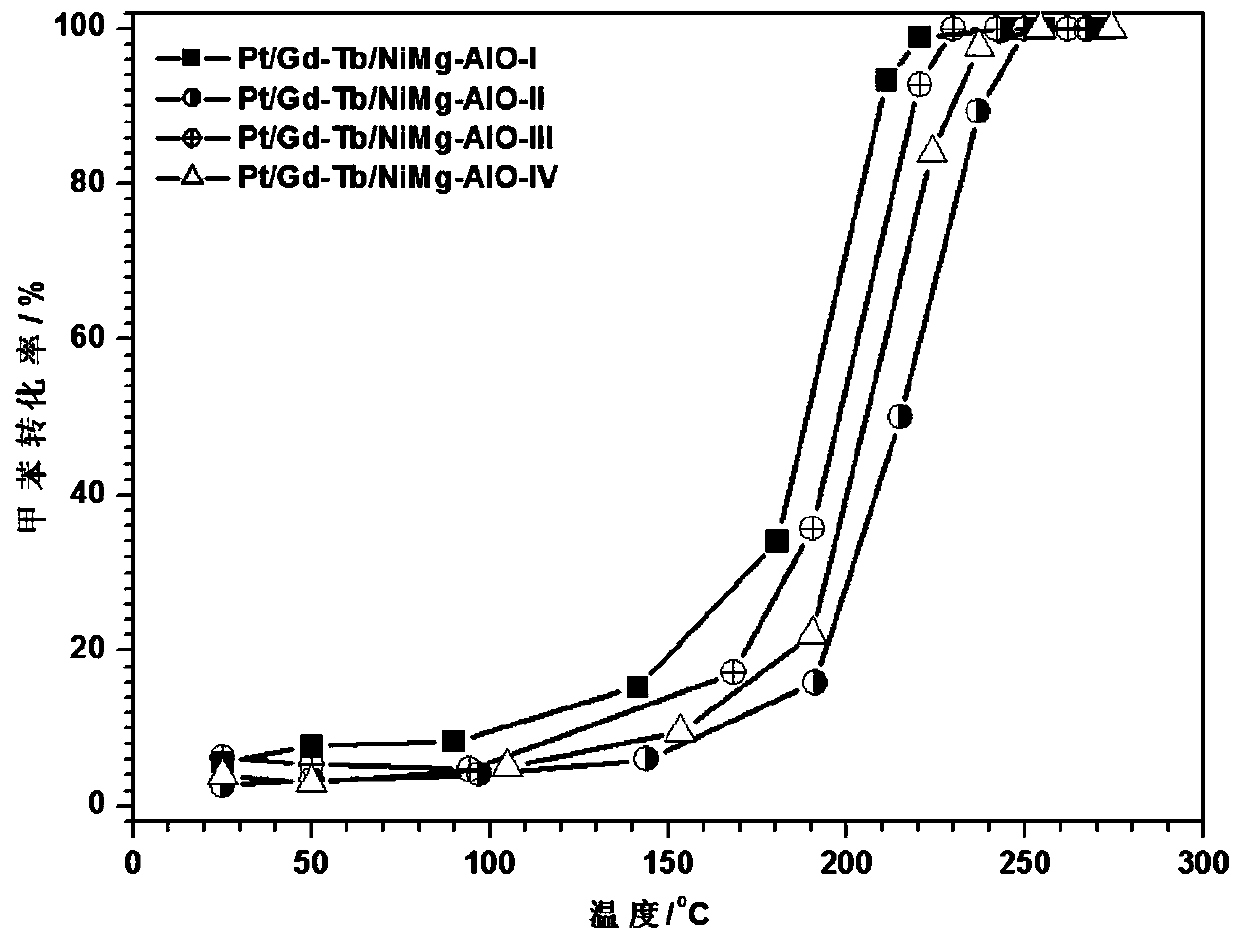

Preparation method and application of gadolinium terbium nickel magnesium aluminum composite supported platinum catalyst taking hydrotalcite as precursor

ActiveCN111185195AHigh and low temperature catalytic combustion to eliminate activityEasy to makeIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsPtru catalystEthylic acid

The invention discloses a preparation method and application of a gadolinium terbium nickel magnesium aluminum composite supported platinum catalyst taking hydrotalcite as a precursor. The preparationmethod of the catalyst comprises the following steps: preparing a [MgNiAl-NO3]-LDHs hydrotalcite precursor from ternary mixed salts of Mg(NO3)2, Ni(NO3)2 and Al(NO3)3 through a deposition-precipitation method; carrying out anion exchange with hydrotalcite through acetate radical, [Gd(EDTA)]<2-> and [Tb(EDTA)]<2-> to form acetate radical- and gadolinium terbium rare earth-intercalated [Gd-Tb-NiMgAl-Ac]-LDHs hydrotalcite-like compound, and roasting to obtain hydrotalcite-like compound oxide loaded rare earth oxide Gd-Tb / NiMg-AlO. Noble metal platinum is loaded through an impregnation method andNaBH4 reduction to finally obtain the gadolinium-terbium-doped nickel-magnesium-aluminum oxide loaded platinum catalyst Pt / Gd-Tb / NiMg-AlO with high specific surface area and thermal stability. The catalyst prepared in the invention has high elimination efficiency on high-space-velocity and low-concentration toluene and formaldehyde. The catalyst prepared by the invention has the advantages of cheap raw materials, simple catalyst preparation process, strong practicability, complete elimination of volatile organic compounds, low temperature, high efficiency, no secondary pollution and the like.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com