Preparation method and application of gadolinium terbium nickel magnesium aluminum composite supported platinum catalyst taking hydrotalcite as precursor

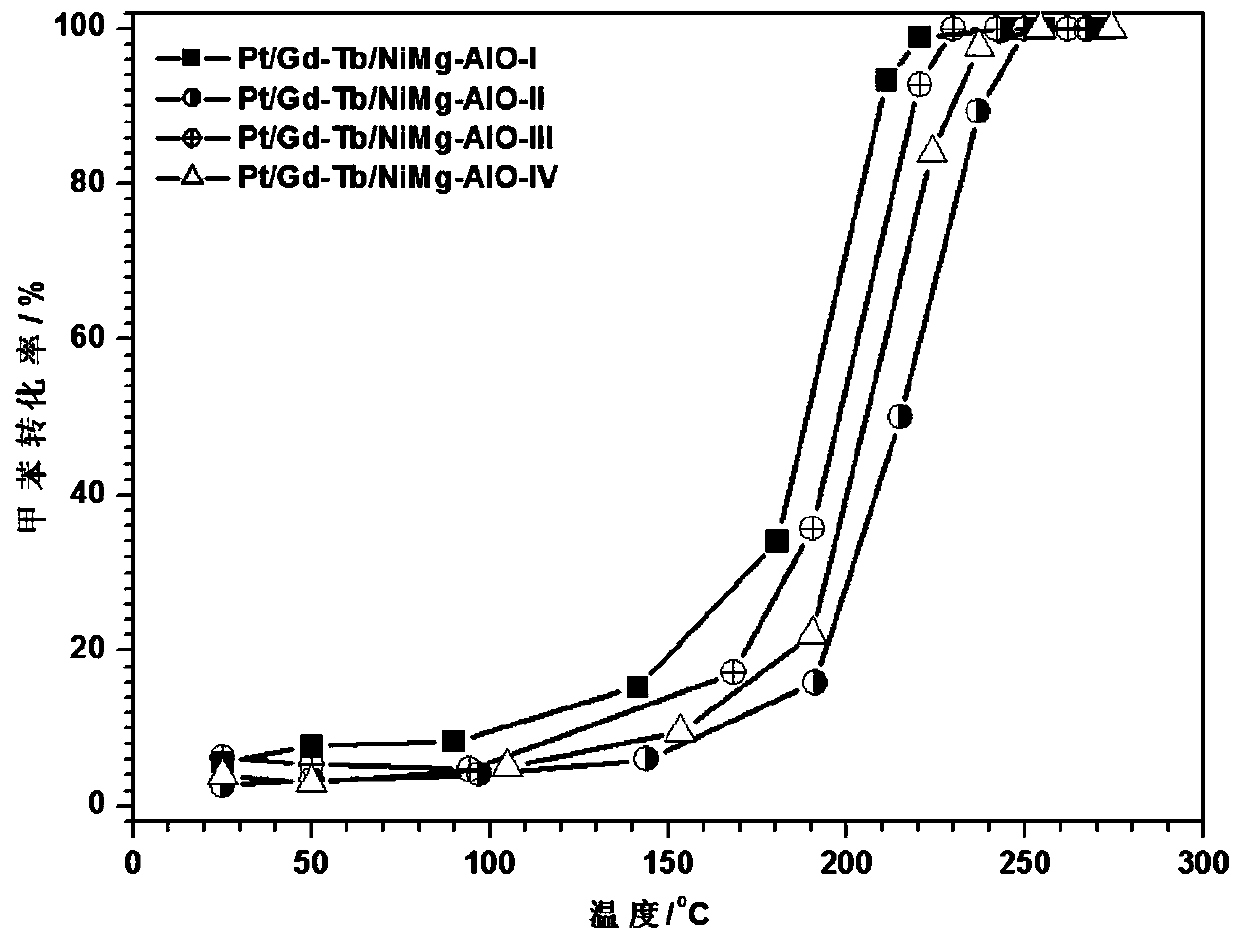

A platinum catalyst and hydrotalcite technology are applied in the field of preparation and application of a platinum catalyst supported by a gadolinium-terbium-nickel-magnesium-aluminum composite with hydrotalcite as a precursor, and can solve the problem of high reaction temperature for completely catalyzing elimination of benzene series compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) the preparation method of above-mentioned catalyst provided by the present invention, comprises the steps:

[0022] Mg(NO 3 ) 2 ·6H 2 O, Ni(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 9H 2 O ternary mixed salt dissolved in 50mL deCO 2 A mixed salt solution is formed in deionized water, and the total molar concentration of all ions is n[Mg 2+ +Ni 2+ +Al 3+ ]=0.48mol / L, divalent and trivalent ion molar ratio is n[(Mg 2+ +Ni 2+ )] / n[Al 3+ ]=2. Then 0.5mL adenosine triphosphate (ATP, adenosinetriphosphate, C 10 h 16 N 5 o 13 P 3 ) solution (10mmol / L) was dissolved in the above salt solution to form a mixed solution A, and at 5W / cm 2 The intensity of ultrasonic 1h, and then continue to stir for 2h. In addition, according to the molar ratio, n[KOH]=n[Mg 2+ +Ni 2+ +Al 3+ ] and n[OH - ]: n[CO 3 2- ]=2 Weigh a certain amount of KOH and K 2 CO 3 Dissolve in 50mL deionized water to make mixed alkali solution B. Then put 50mL deCO2 into the three-neck flask ...

Embodiment 2

[0028] (1) the preparation method of above-mentioned catalyst provided by the present invention, comprises the steps:

[0029] Mg(NO 3 ) 2 ·6H 2 O, Ni(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 9H 2 O ternary mixed salt was dissolved in 70mL to remove CO 2 A mixed salt solution is formed in deionized water, and the total molar concentration of all ions is n[Mg 2+ +Ni 2+ +Al 3+ ]=0.7mol / L, divalent and trivalent ion molar ratio is n[(Mg 2+ +Ni 2+ )] / n[Al 3+ ]=4. Then 0.7mL adenosine triphosphate (ATP, adenosinetriphosphate, C 10 h 16 N 5 o 13 P 3 ) solution (13mmol / L) was dissolved in the above salt solution to form a mixed solution A, and was ultrasonicated at an intensity of 9W / cm2 for 2h, and then continued to stir for 3h. In addition, according to the molar ratio, n[KOH]=n[Mg 2+ +Ni 2+ +Al 3+ ] and n[OH - ]: n[CO 3 2- ]=2 Weigh a certain amount of KOH and K 2 CO 3 Dissolve in 70mL deionized water to make mixed alkali solution B. Then put 70mL deCO2 into t...

Embodiment 3

[0035] (1) the preparation method of above-mentioned catalyst provided by the present invention, comprises the steps:

[0036] Mg(NO 3 ) 2 ·6H 2 O, Ni(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 9H 2 O ternary mixed salt dissolved in 90mL to remove CO 2 A mixed salt solution is formed in deionized water, and the total molar concentration of all ions is n[Mg 2+ +Ni 2+ +Al 3+ ]=0.8mol / L, divalent and trivalent ion molar ratio is n[(Mg 2+ +Ni 2+ )] / n[Al 3+ ]=5. Then 0.9mL adenosine triphosphate (ATP, adenosinetriphosphate, C 10 h 16 N 5 o 13 P 3 ) solution (18mmol / L) was dissolved in the above salt solution to form a mixed solution A, and at 8W / cm 2 The intensity of ultrasound 2h, and then continue to stir for 5h. In addition, according to the molar ratio, n[KOH]=n[Mg 2+ +Ni 2+ +Al 3+ ] and n[OH - ]: n[CO 3 2- ]=2 Weigh a certain amount of KOH and K 2 CO 3 Dissolve in 90mL deionized water to make mixed alkali solution B. Then put 90mL deCO2 into the three-neck ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com