A kind of preparation method and application of α-manganese oxide supported cobalt strontium catalyst

A catalyst, manganese oxide technology, used in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of complete catalytic elimination of benzene series reaction temperature and high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) the preparation method of above-mentioned catalyst provided by the present invention, comprises the steps:

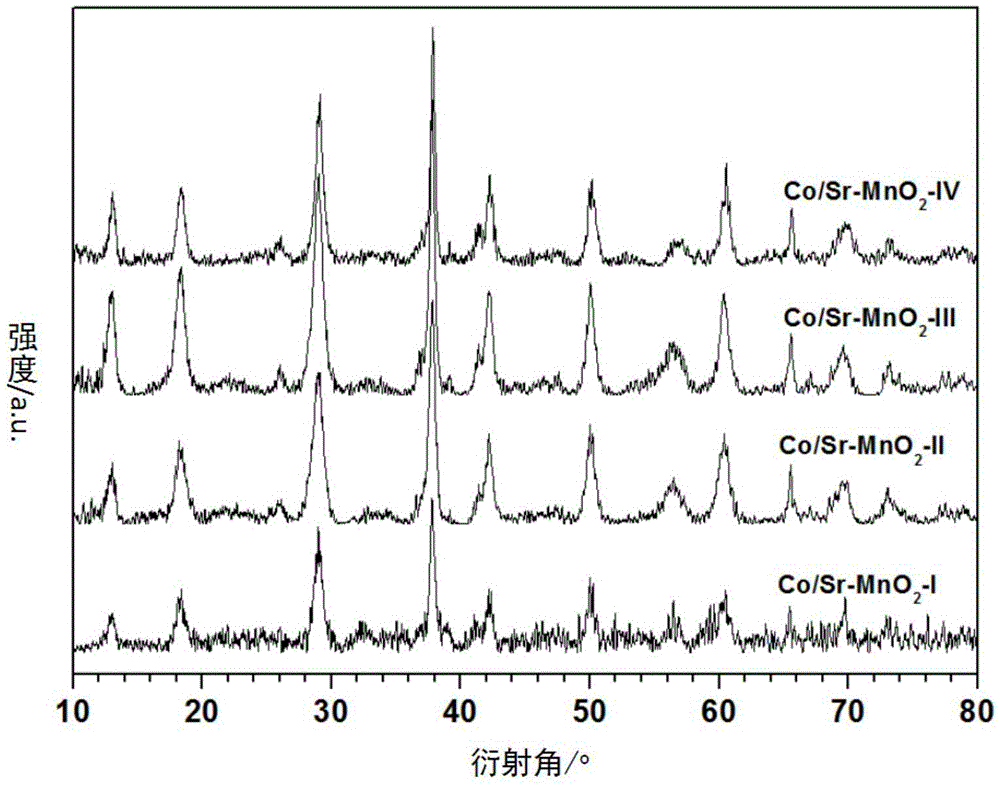

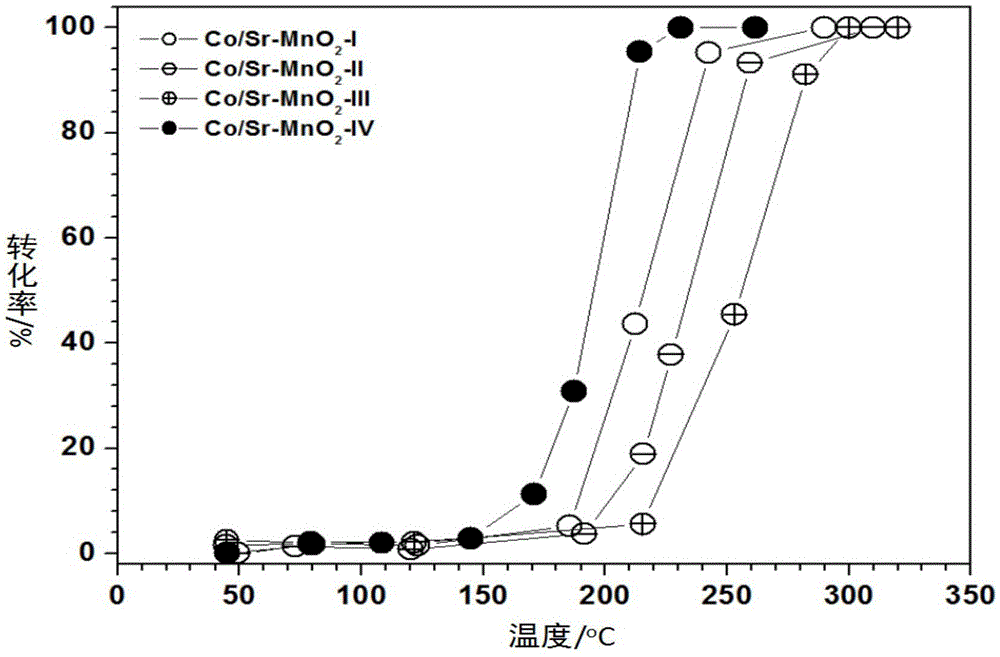

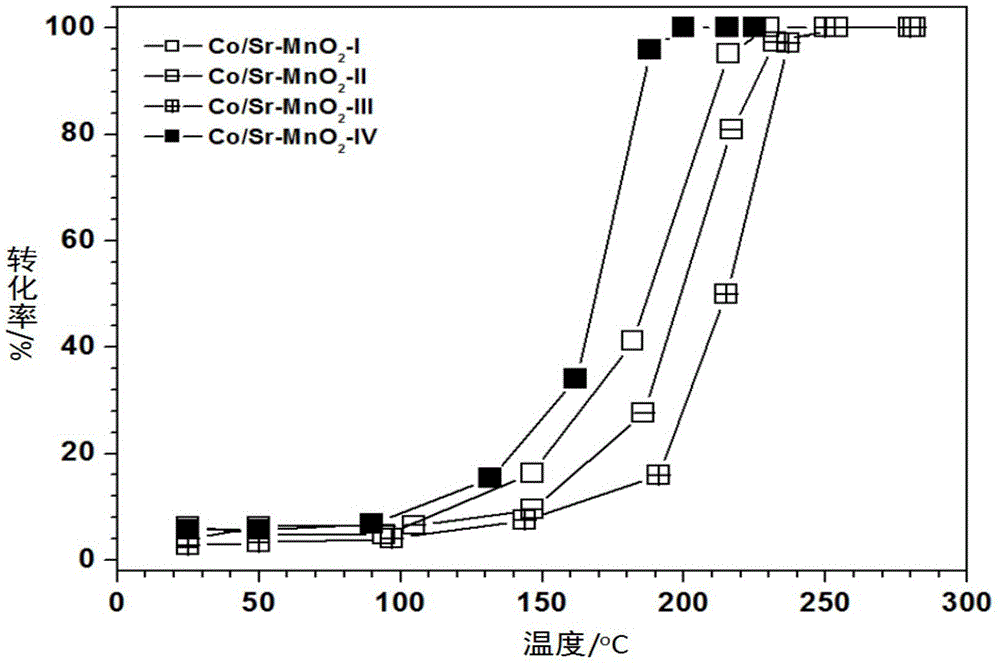

[0018] KAc with a concentration of 0.1mol / L and 0.1mol / LHAc are mixed into a buffer solution according to the ratio of KAc / HAc molar ratio=0.1, and the pH=3.74 is adjusted, and then 0.01g of SrSO 4 and 0.29gCo(NO 3 ) 2 ·6H 2 O was dissolved in the above 40ml acetic acid buffer solution. Add the above buffer solution containing metal salts to 24ml1.0mol / LMnSO 4 solution, mix well. Then 120ml concentration is 0.1mol / LKMnO 4 The solution was dropped into the above mixed solution, in which KMnO 4 / MnSO 4 (molar ratio) = 0.5, stirred for 2 hours, sealed and aged for 12 hours, refluxed at 80°C for 20 hours, rotary steamed for 3 hours until powdery, washed with deionized water until neutral, dried at 100°C for 10 hours, and then ground into powder to obtain a black precursor. Take the above precursor and pure ethanol at a ratio of 8g: 200ml and mix. The mi...

Embodiment 2

[0021] (1) the preparation method of above-mentioned catalyst provided by the present invention, comprises the steps:

[0022] Mix KAc with a concentration of 0.1mol / L and 0.1mol / LHAc at the ratio of KAc / HAc molar ratio = 1.0 to form a buffer solution, adjust the pH to about 4.74, and then add 0.02g of SrSO 4 and 1.00gCo(NO 3 ) 2 ·6H 2 O was dissolved in the above 40ml acetic acid buffer solution. 0.5g of polyvinyl alcohol PVA (molecular formula (C2 h 4 O) n , molecular weight 20000) dissolved in 30ml concentration is 1.3mol / LMnSO 4 solution, the above buffer solution containing metal salts was added to 40ml1.0mol / LMnSO 4 solution, mix well. Then 140ml concentration is 0.2mol / LKMnO 4 The solution was dropped into the above mixed solution, in which KMnO 4 / MnSO 4 (molar ratio) = 0.7, stirred for 2 hours, sealed and aged for 12 hours, refluxed at 90°C for 23 hours, rotary steamed for 3 hours until powdery, rinsed with deionized water until neutral, dried at 110°C for 1...

Embodiment 3

[0025] (1) the preparation method of above-mentioned catalyst provided by the present invention, comprises the steps:

[0026] KAc with a concentration of 0.1mol / L and 0.1mol / LHAc are mixed into a buffer solution according to the ratio of KAc / HAc molar ratio = 5.0, and the pH is adjusted at about 5.44, and then 0.03g of SrSO 4 and 2.50gCo(NO 3 ) 2 ·6H 2 O was dissolved in the above 40ml acetic acid buffer solution. 1.8g of polyvinyl alcohol PVA (molecular formula (C 2 h 4 O) n , molecular weight 20000) dissolved in 40ml concentration is 1.5mol / LMnSO 4 In the solution, add the above buffer solution containing metal salts into this solution, and mix well. Then 160ml concentration is 0.3mol / LKMnO 4 The solution was dropped into the above mixed solution, in which KMnO 4 / MnSO 4 (molar ratio)=0.8, stirred for 3 hours, sealed and aged for 12 hours, refluxed at 110°C for 26 hours, rotary steamed for 4 hours until powdery, washed with deionized water until neutral, dried at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com