Preparation method of SAPO-18-carried Cu-Fe catalyst for ammonia-selective catalytic elimination of NOx

A SAPO-18, selective technology, used in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., to achieve the effects of simple preparation process, high anti-carbon performance, and high hydrothermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

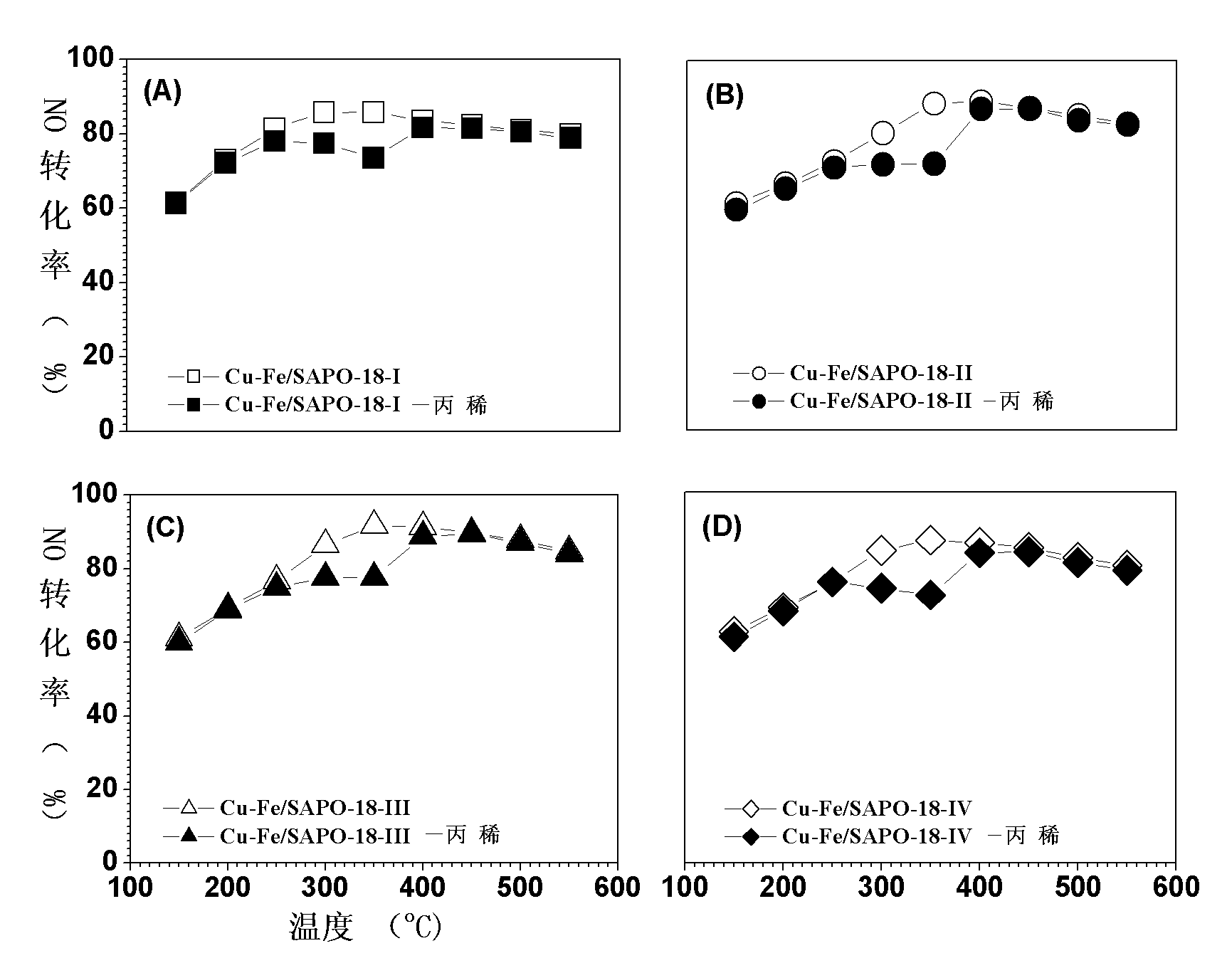

Embodiment 1

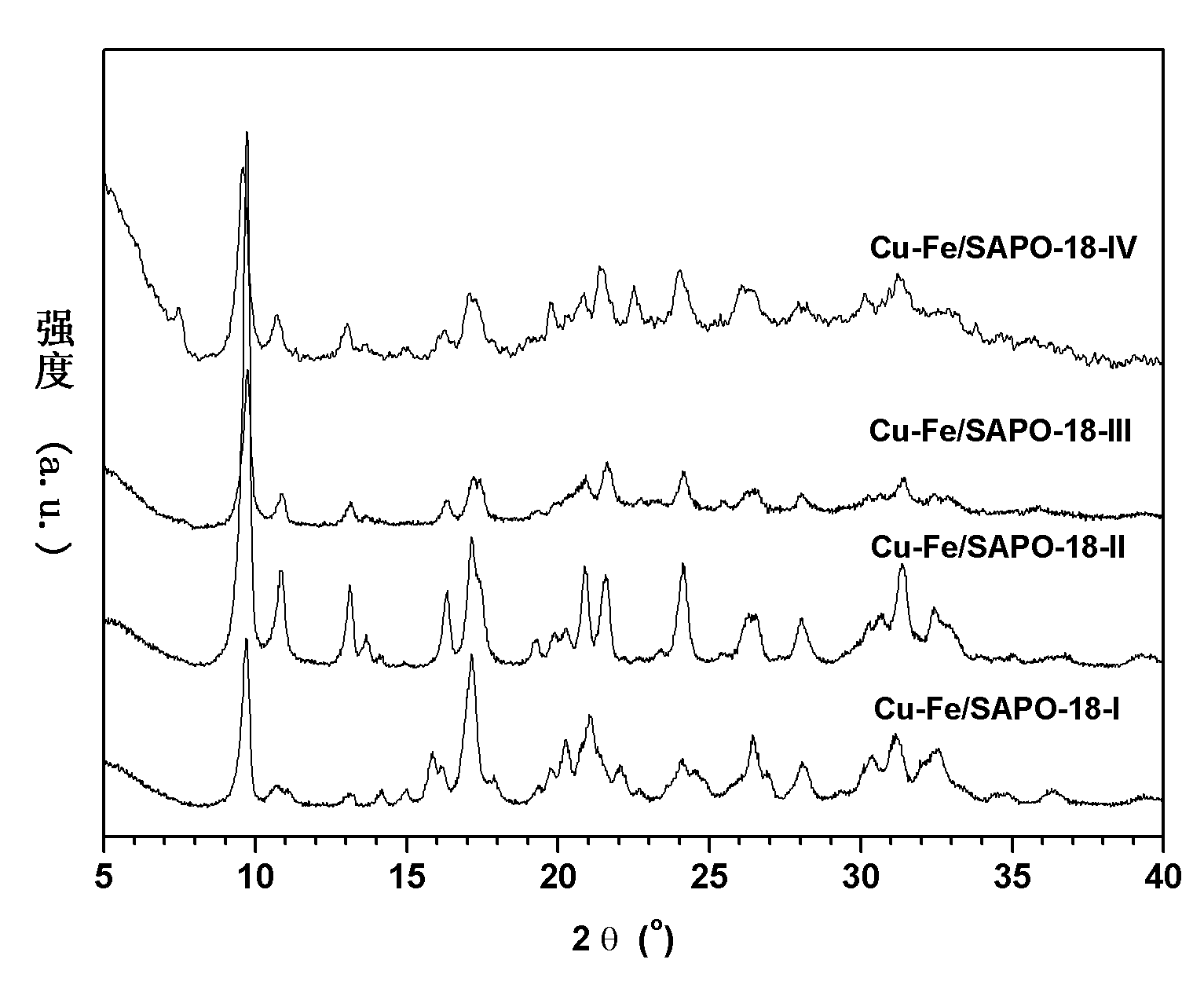

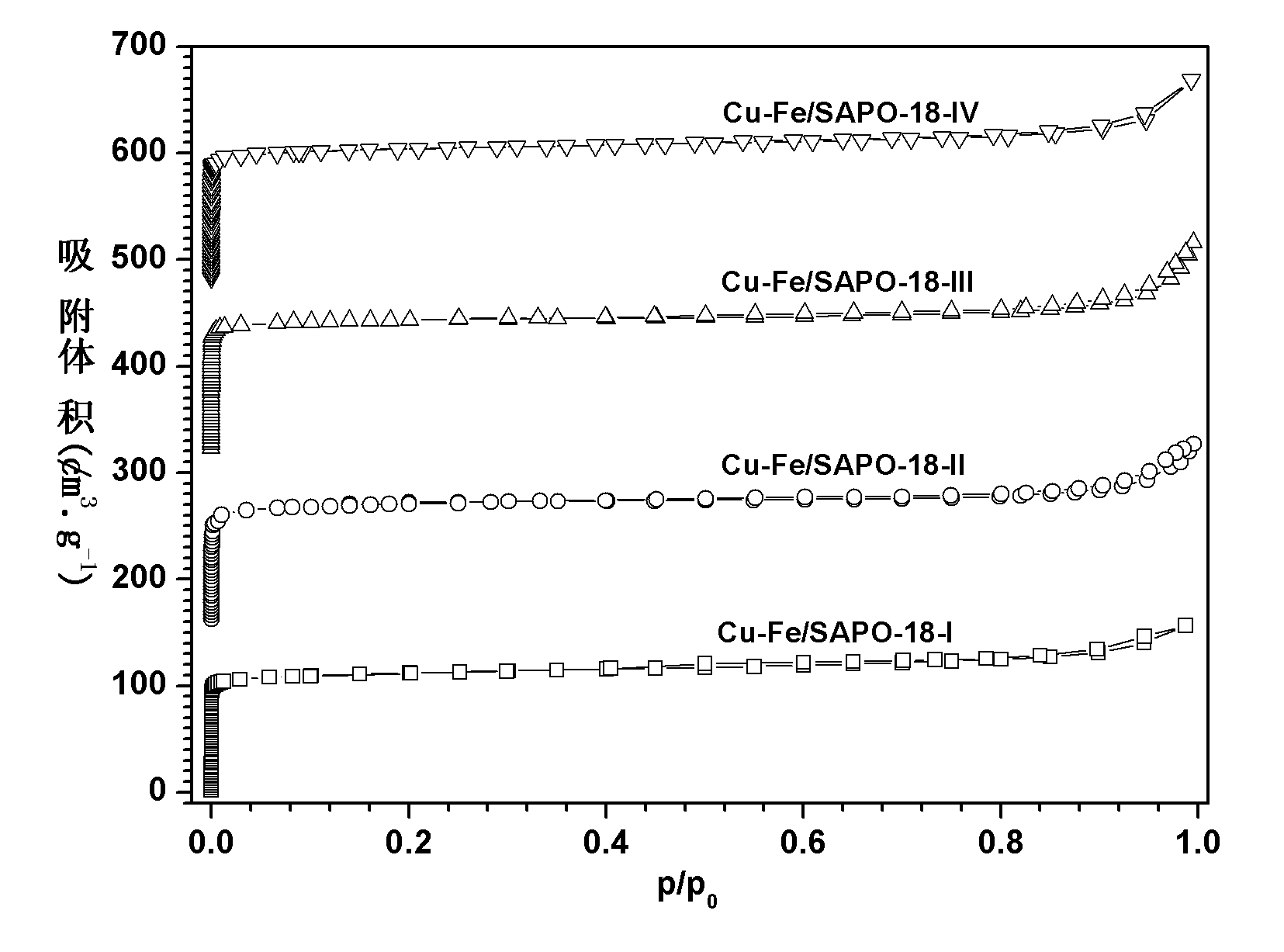

[0022] (1) Preparation of SAPO-18 molecular sieve

[0023] Add aluminum hydroxide to phosphoric acid solution, stir evenly, let stand at room temperature for 5 days, then add SiO 2 and N, N-diisopropylethylamine (C 8 h 19 N) join in above mixed solution, stir, finally obtain sol composition (molar ratio) as follows:

[0024] 0.93C 8 h 19 N:0.33SiO2 2 : 0.44Al 2 o 3 : 0.35P 2 o 5 :33H 2 o

[0025] Put the sol in a closed container at room temperature for 5 days, then add it to a stainless steel reaction kettle lined with polytetrafluoroethylene, heat it to 160 ° C, keep the temperature for 5 days, then filter and wash the solid product, and put it in the air at 30 ° C dry. In order to remove the template agent and other impurities, the obtained solid matter was calcined at 400° C. for 15 hours in an oxygen atmosphere. The above prepared SAPO-18 molecular sieve carrier has a specific surface area of 400m 2 / g, total pore volume 0.25cm 3 / g.

[0026] (2) NH 4 P...

Embodiment 2

[0032] (1) Preparation of SAPO-18 molecular sieve

[0033] Add aluminum hydroxide to the phosphoric acid solution, stir evenly, let it stand at room temperature for 7 days, and then add SiO 2 and N, N-diisopropylethylamine (C 8 h 19 N) join in above mixed solution, stir, finally obtain sol composition (molar ratio) as follows:

[0034] 1.4C 8 h 19 N:0.60SiO2 2 : Al 2 o 3 : 0.79P 2 o 5 :40H 2 o

[0035] The sol was left at room temperature in an airtight container for 7 days, then added to a stainless steel reactor lined with polytetrafluoroethylene, heated to 170°C, and kept at a constant temperature for 7 days. The solid product was then filtered, washed and dried in air at 50°C. In order to remove the template agent and other impurities, the obtained solid matter was calcined at 500° C. for 15 hours in an oxygen atmosphere. The above prepared SAPO-18 molecular sieve carrier has a specific surface area of 440m 2 / g, total pore volume 0.31cm 3 / g.

[0036] (2...

Embodiment 3

[0042] (1) Preparation of SAPO-18 molecular sieve

[0043] Add aluminum hydroxide to the phosphoric acid solution, stir evenly, let stand at room temperature for 8 days, and then add SiO 2 and N, N-diisopropylethylamine (C 8 h 19 N) join in above mixed solution, stir, finally obtain sol composition (molar ratio) as follows:

[0044] 1.05C 8 h 19 N:0.45SiO2 2 : Al 2 o 3 : 0.78P 2 o 5 : 28H 2 o

[0045] The sol was left at room temperature in an airtight container for 8 days, then added to a stainless steel reactor lined with polytetrafluoroethylene, heated to 170°C, and kept at a constant temperature for 8 days. The solid product was then filtered, washed and dried in air at 70°C. In order to remove the template agent and other impurities, the obtained solid matter was calcined at 550° C. for 18 hours in an oxygen atmosphere. The above prepared SAPO-18 molecular sieve carrier has a specific surface area of 510m 2 / g, total pore volume 0.33cm 3 / g.

[0046] (2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com