Patents

Literature

46results about How to "Increase active center" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of attapulgite-based refining agent for lubricant base oil adsorption refining

InactiveCN104028211AFacilitated DiffusionHigh specific surface areaOther chemical processesHydrocarbon oils refiningActivated attapulgiteBase oil

The invention discloses a preparation method of an attapulgite-based refining agent for lubricant base oil adsorption refining. The preparation method comprises the following main processes: acid-activating raw attapulgite, drying, crushing, screening, roasting and activating to obtain the acid-activated attapulgite, organically modifying the acid-activated attapulgite, drying, crushing, and screening to obtain the attapulgite-based refining agent. The attapulgite-based refining agent prepared by the invention has the characteristics that the refining agent can be easily separated from the product without polluting and corroding equipment, and the post-treatment of the product is simple.

Owner:盱眙凹土能源环保材料研发中心

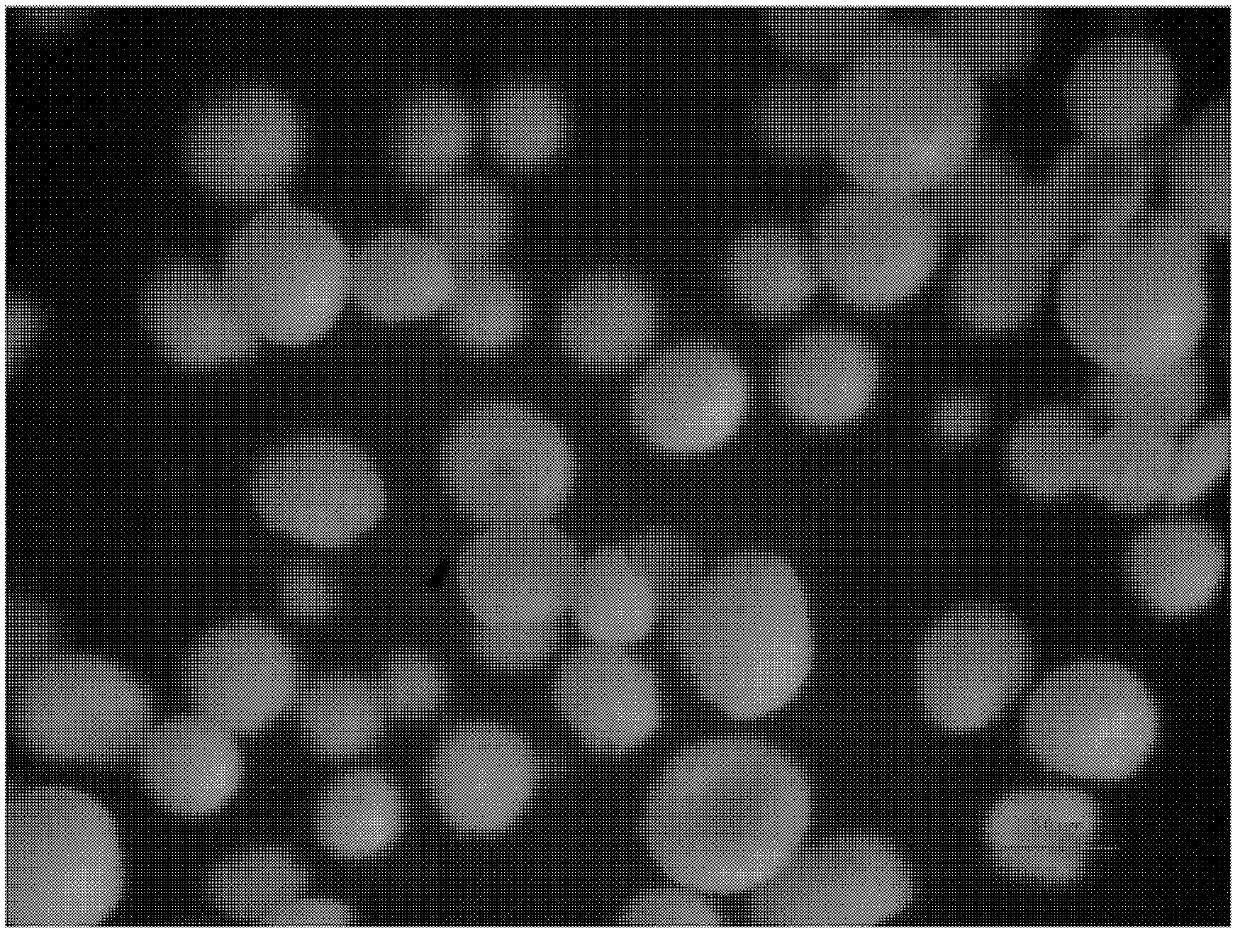

Catalyst for use in preparation of propylene by olefin cracking

InactiveCN102069007AIncrease surface areaIncrease active centerMolecular sieve catalystsHydrocarbonsMolecular sieveWater vapor

The invention discloses a catalyst for use in the preparation of propylene by olefin cracking, and a preparation method thereof. The catalyst is prepared by using molecular sieve raw powder of which the silicon to aluminum (molar) ratio is smaller than 300 as an active main body and by uniformly mixing the molecular sieve raw powder, silica sol and / or alumina sol and a template agent, forming by crystallization, drying, roasting, performing hydro-thermal treatment with high-temperature water vapor, and modifying by using rare earth metal and / or phosphorus as a modifier. The modifier comprises the following components in percentage by weight: 0.2 to 8 percent of rare earth metal, 0.1 to 5 percent of non-metal phosphorus and the balance of molecular sieve. The catalyst has high activity and stability and high propylene selectivity, and can be used in the field of propylene production industry.

Owner:王伟跃

Mg/Al/X ternary composite metal oxide catalyst and preparation method thereof

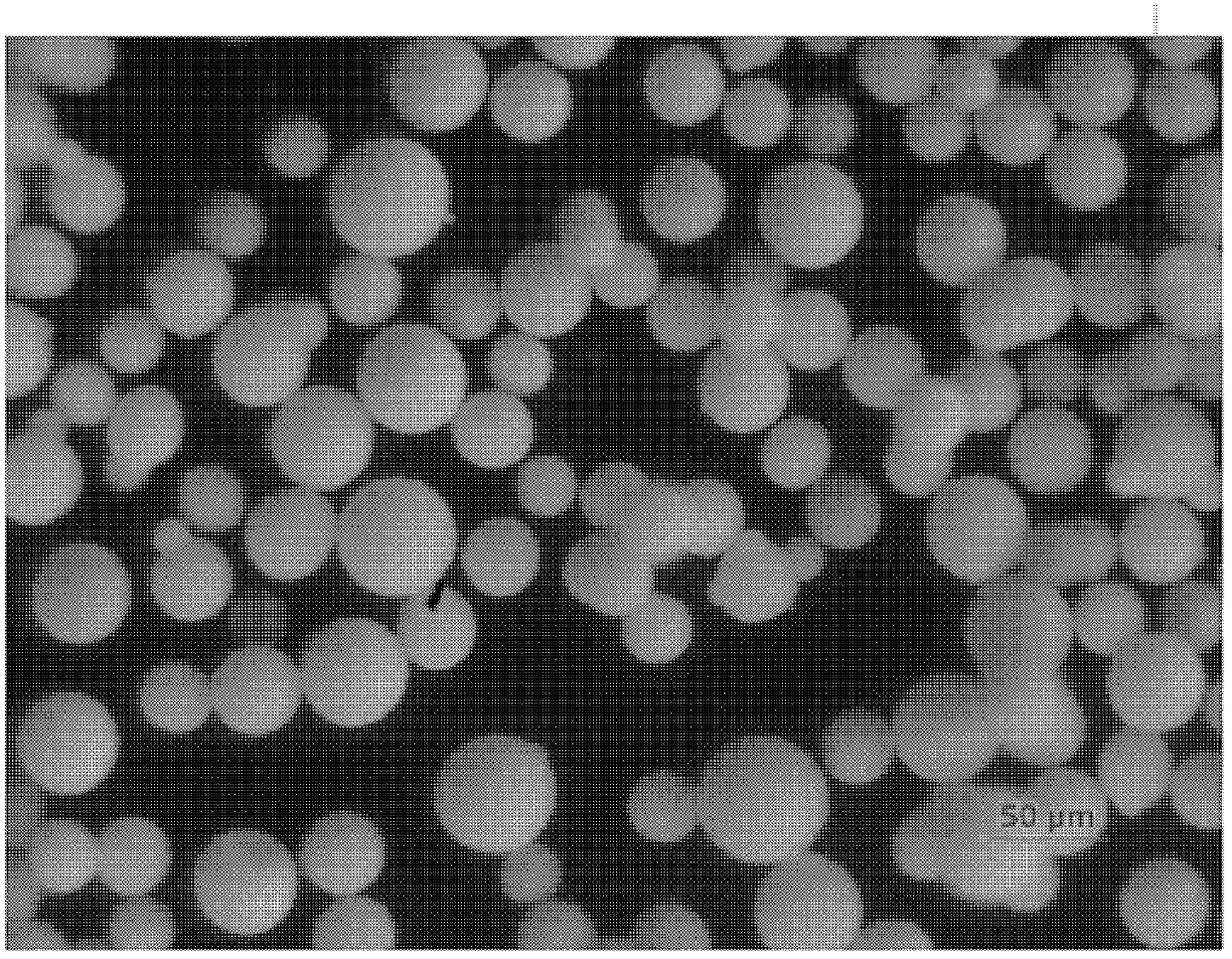

InactiveCN101559361AGood shape selective catalytic functionIncrease active centerCatalyst activation/preparationEther preparation from oxiranesPhosphateCalcination

The invention relates to an Mg / Al / X ternary composite metal oxide catalyst and a preparation method thereof. The catalyst is characterized in that the catalyst consists of magnesium, aluminum and ternary metal elements, and the surface of a catalyst product is distributed with an aperture of which diameter is 1 to 20mu m and a protrusion of which height is 0.1 to 10mu m; and the ternary metal elements contain Ce, Dy, Fe, Mn, Co, Cd, Zn or Ni soluble salt comprising nitrate, hydrochloride, sulfate, phosphate or perchlorate. The preparation method for the catalyst comprises the following processes in turn: precursor preparation, crystallization, secondary crystallization, molding and calcination. The catalyst is applicable to the production process of the conventional kettle-type or intermittent polyether product, has good narrow molecular-weight distribution effect for the synthesis of the polyether product, has high catalytic rate, and can be recycled.

Owner:TIANJIN POLYTECHNIC UNIV

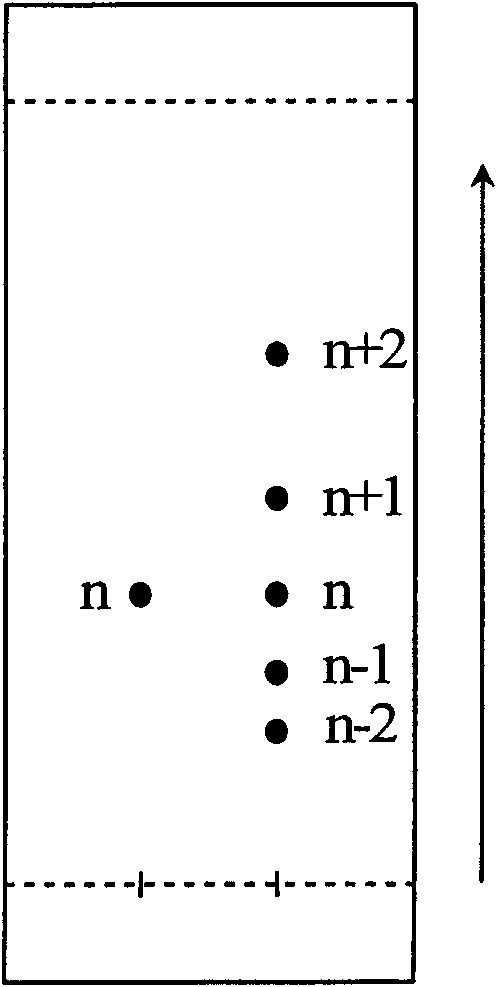

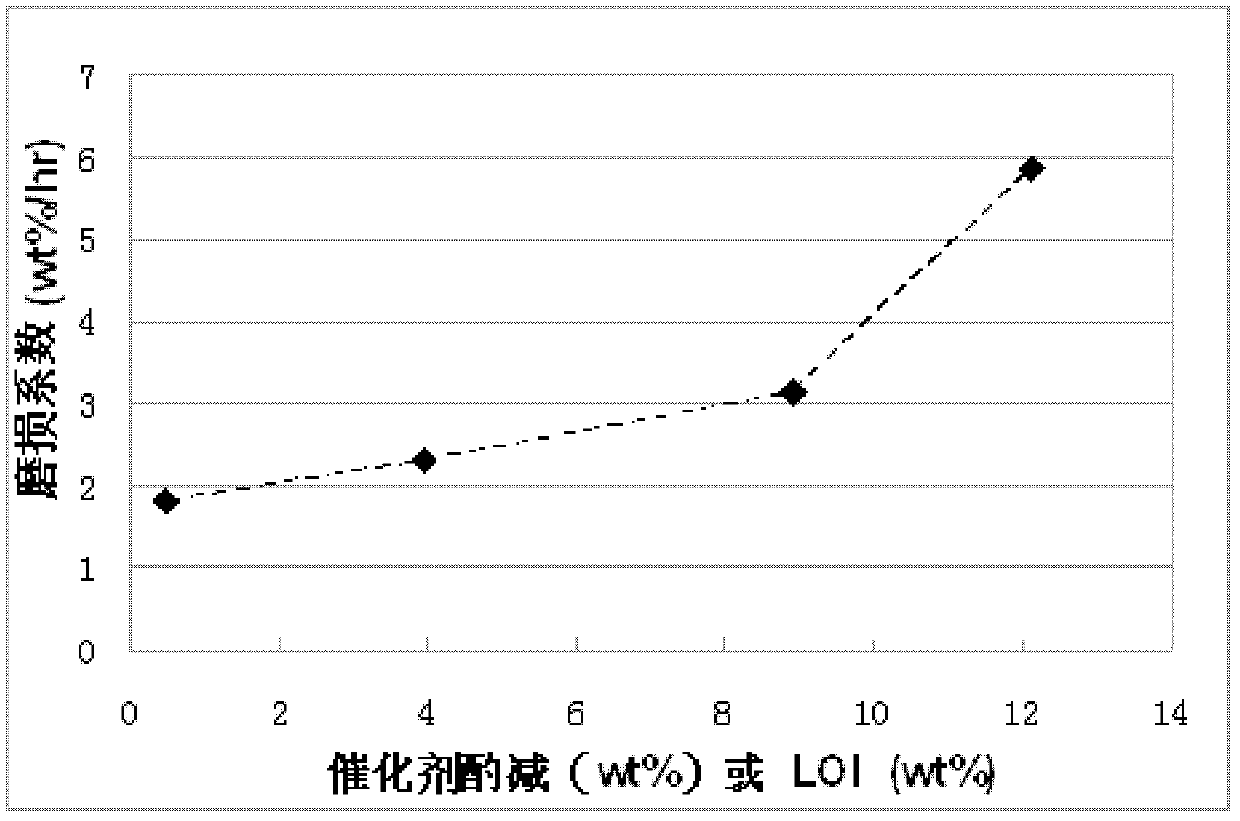

Preparing method of wearing-resistant catalyst

InactiveCN102631945AReduce LOI (discretionary) valueReduce wear rateCatalytic crackingMolecular sieve catalystsMolecular sieveWear resistant

Owner:常云峰 +1

Selective hydrodesulfurization process

ActiveCN106221794AHigh desulfurization rateHigh activityTreatment with hydrotreatment processesHydrocarbon oils treatment productsChemistryOxide

The invention provides a selective hydrodesulfurization process which comprises the following steps: cutting a gasoline feedstock into light ends and heavy ends; performing liquid-liquid extraction for the light ends to obtain light end raffinate containing olefins and light end extraction oil containing sulfide and aromatics; and using selective hydrodesulfurization catalysts to perform selective hydrodesulfurization for the light end extraction oil and the heavy ends, wherein the main component of the selective hydrodesulfurization catalyst is obtained by loading an active metal component with a metal oxide, treated with a metal salt, as the carrier, wherein the active metal is selected from more than two elements in IA, VIII, VIB and VIIB groups in the periodic table. The selective hydrodesulfurization process provided by the invention has the advantages of high desulfurization rate and small loss of the octane value of sweet gasoline.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Hydrocracking method

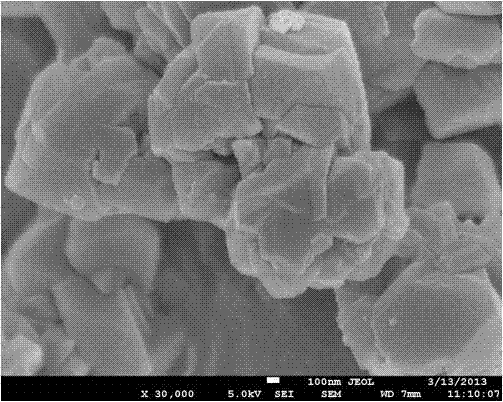

ActiveCN107345155AThe skeleton structure is stable and perfectElimination of non-skeletal structuresMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNaphtha

The invention discloses a hydrocracking method which comprises the following steps that a straight-run diesel oil raw material is in contact with a hydrocracking catalyst to carry out hydrocracking reaction, and an obtained hydrocracking product is separated to obtain heavy naphtha, diesel oil, a jet fuel and hydrogenation tail oil, wherein the used hydrocracking catalyst adopts a modified Y-shaped molecular sieve, amorphous silica-alumina and aluminum oxide as carriers, and the modified Y-shaped molecular sieve is an Y-shaped molecular sieve which is rich in meso pores and is concentrated in effective pore size distribution. The hydrocracking method is particularly suitable for a hydrocracking technology for carrying out hydro-conversion on straight-run diesel oil to produce the jet fuel, and has very high catalytic activity and aviation fuel product yield and the quality of a product is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Attapulgite adsorbent for treating COD in wastewater and preparing method

InactiveCN106925209AChange activityIncrease active centerWater treatment parameter controlOther chemical processesCross-linkAfter treatment

The invention belongs to the technical field of an attapulgite adsorbent for treating COD in wastewater and a preparing method. The attapulgite adsorbent for treating the COD in the wastewater is prepared from, by weight, 70-85 parts of modified attapulgite, 15-20 parts of aluminum oxide and 5-10 parts of cross-linking agent. The attapulgite adsorbent for treating the COD in the wastewater is prepared by modifying attapulgite, adding the cross-linking agent and aluminum oxide and conducting heat treatment. The attapulgite adsorbent for treating the COD in the wastewater is simple in technology, low in cost and remarkable in COD treatment effect, the removal rate is up to 85% or above, and the discharge concentration after treatment is lower than a state-specified first grade discharge standard.

Owner:MINGGUANG GUOXING ATTAPULGITE CLAY

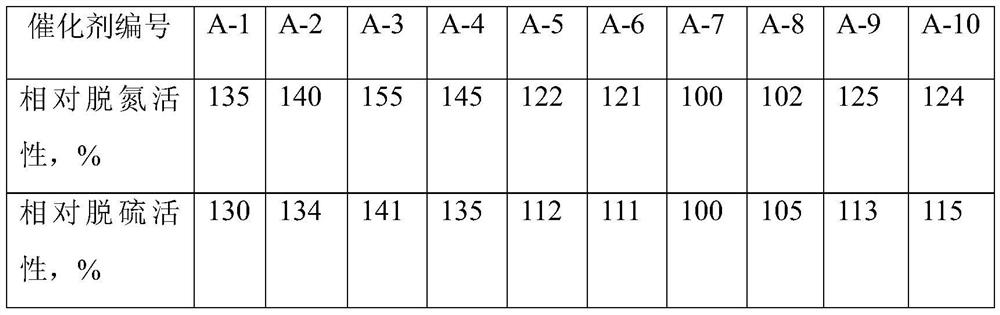

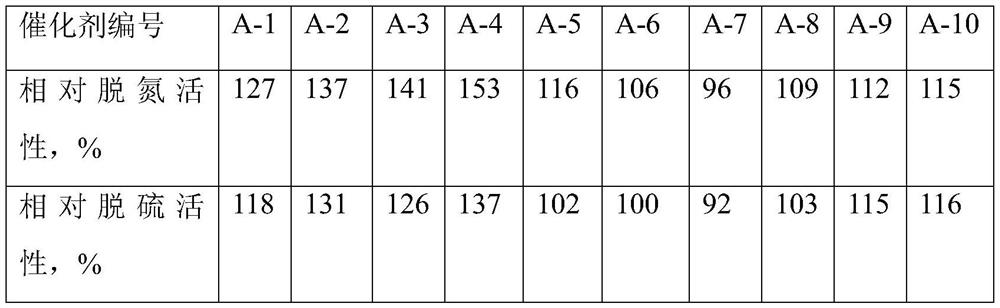

Selective hydrodesulfurization catalyst and desulfurization method

InactiveCN106311316AHigh desulfurization rateLess octane lossMolecular sieve catalystsHeterogenous catalyst chemical elementsHydrodesulfurizationAdditive ingredient

The invention provides a selective hydrodesulfurization catalyst and a desulfurization method. The main ingredient of the selective hydrodesulfurization catalyst is obtained in the manner that metal-salt-treated metallic oxide serves as a carrier and is loaded with an reactive metal ingredient, wherein the reactive metal is selected from two or more elements in the groups IA, VIII, VIB and VIIB in the periodic table. Besides, according to the selective hydrodesulfurization method, extractive distillation is carried out on a gasoline raw material, and selective hydrodesulfurization is carried out with the selective hydrodesulfurization catalyst. The desulfurization method is low in energy consumption and high in desulfurization rate; besides, the octane value loss of desulfurized gasoline is small.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

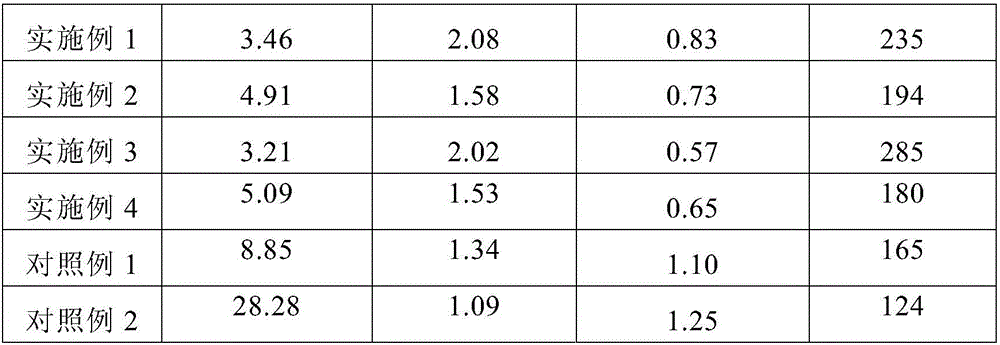

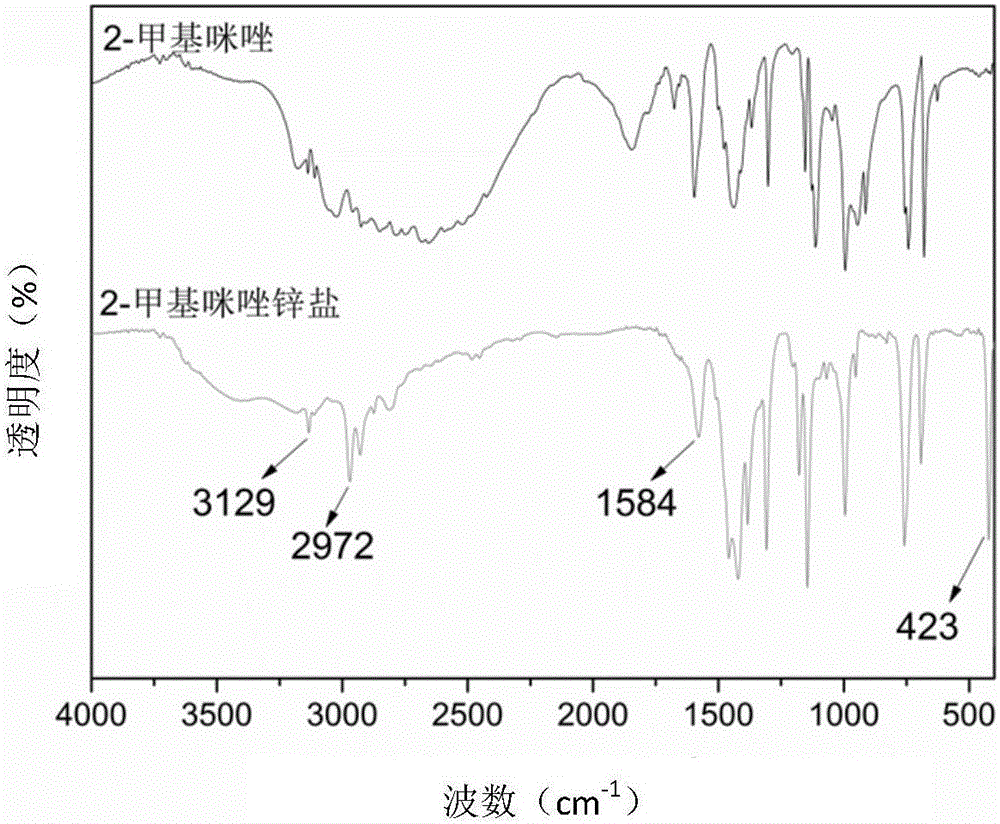

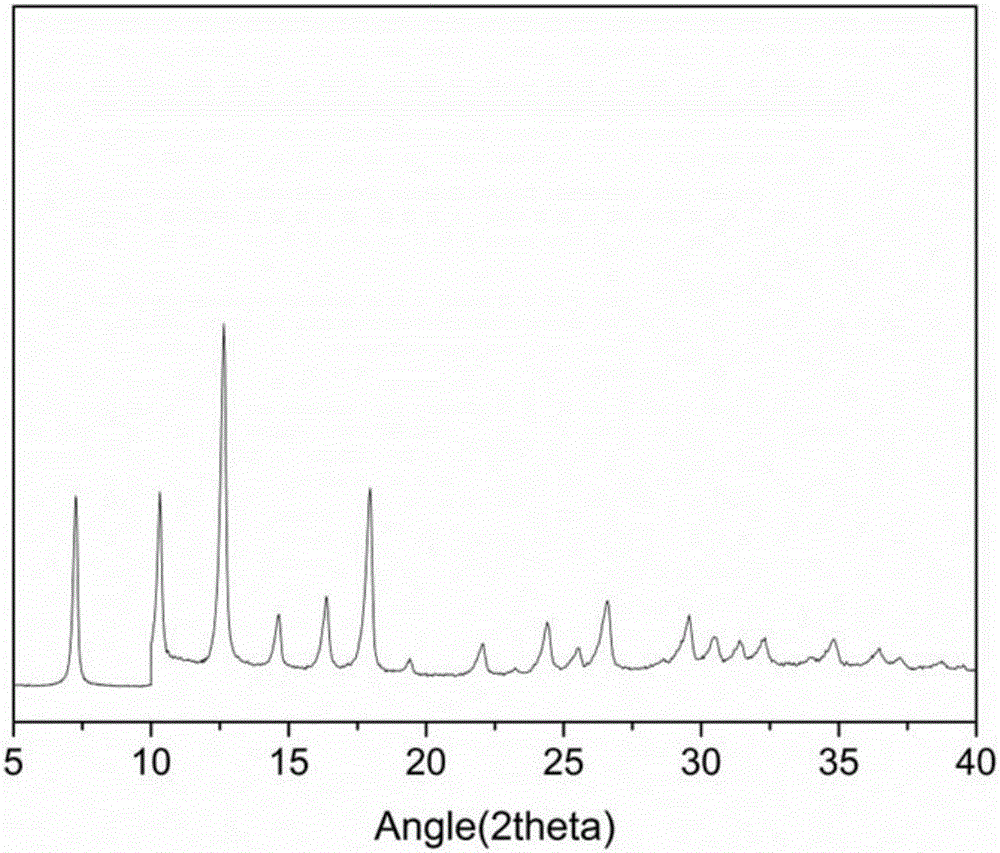

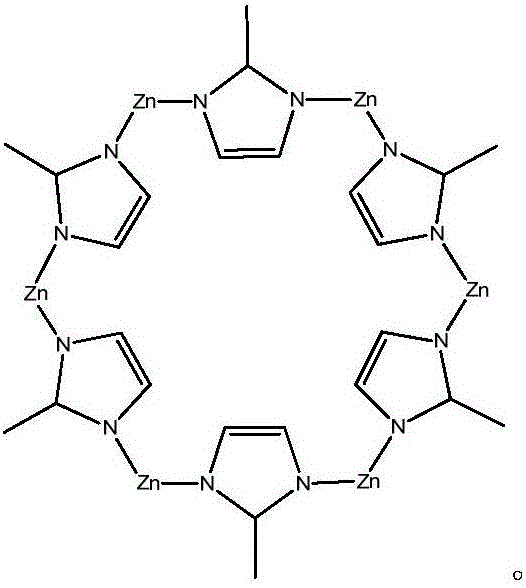

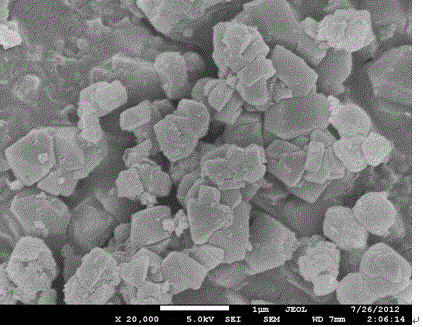

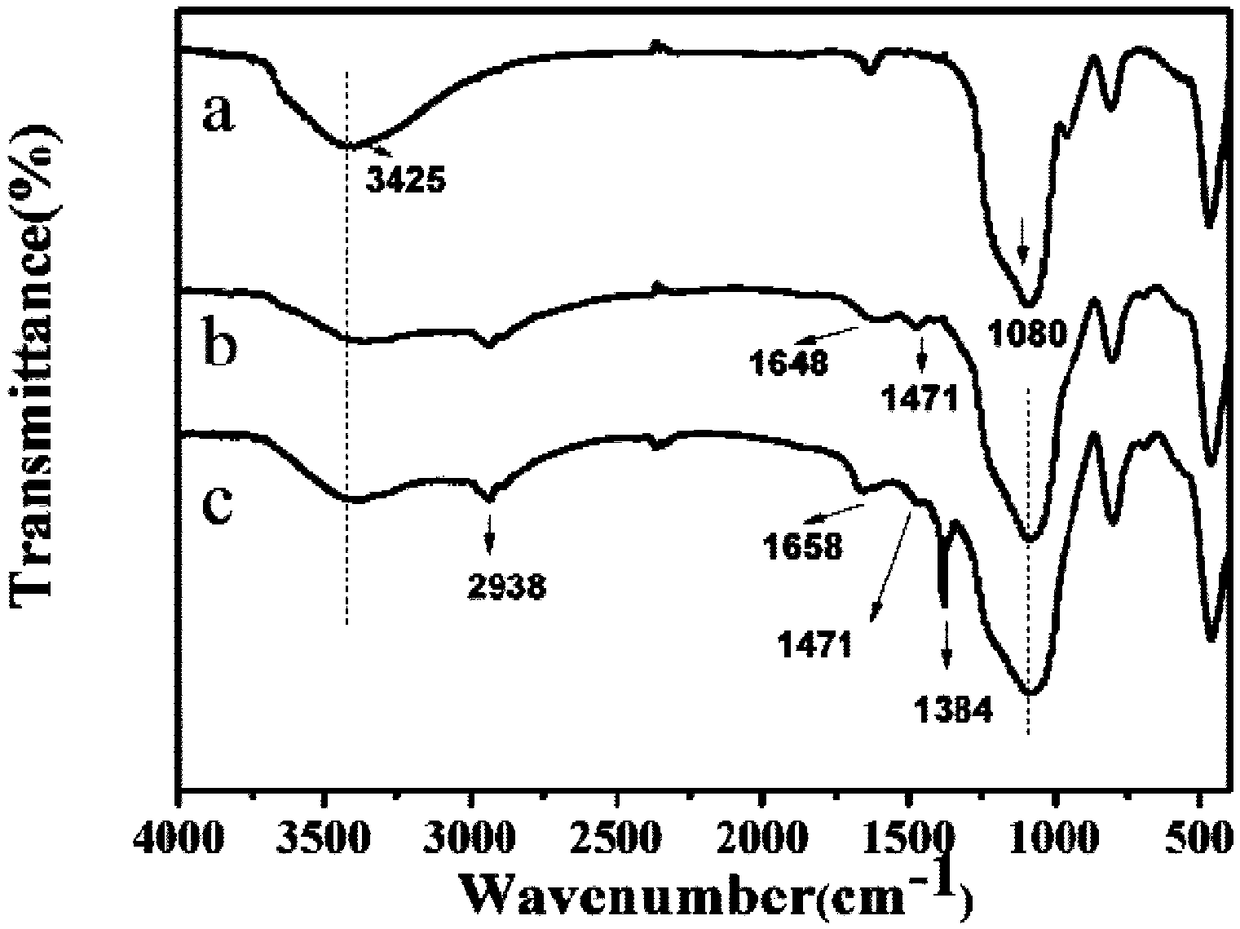

2-methylimidazole zinc salt as well as preparation method and application thereof

InactiveCN106831590AReduce acidityPrevents growth and shortens conjugated polyene segmentsOrganic chemistryThermal stabilityZinc stearate

The invention relates to 2-methylimidazole zinc salt as well as a preparation method and application thereof. The preparation method comprises the following steps: taking zinc nitrate hexahydrate and 2-methylimidazole as raw materials, and obtaining 2-methylimidazole zinc salt (ZIF-8) in presence of a catalyst; and compounding 2-methylimidazole zinc salt with calcium stearate and zinc stearate to obtain a calcium-zinc composite heat stabilizer. The prepared 2-methylimidazole zinc salt heat stabilizer has the characteristics of no toxicity, no heavy metal, large specific surface area, environmental friendliness and the like, the obtained calcium zinc composite heat stabilizer is an efficient composite heat stabilizer, has good compatibility with PVC and can be easily dispersed, and better initial and long-term thermal stabilities and transparency are given to a PVC product. The preparation method is simple and environmentally friendly in technological route, the raw material source is rich, and the price is low.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

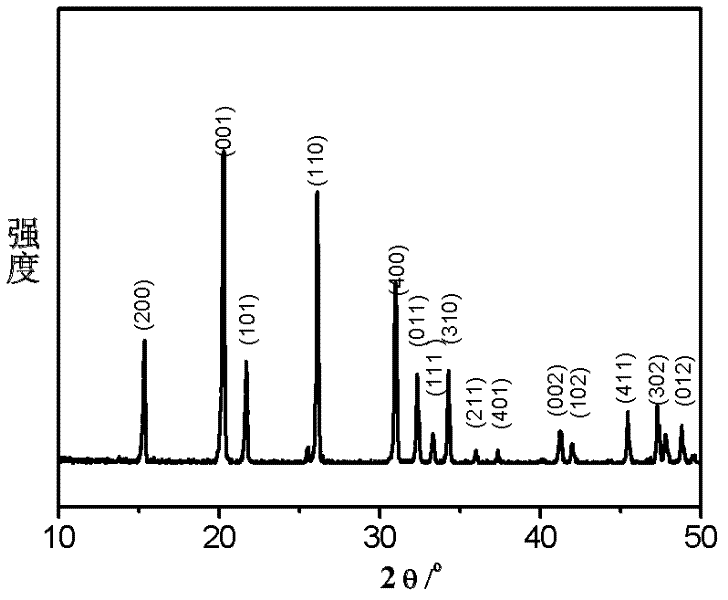

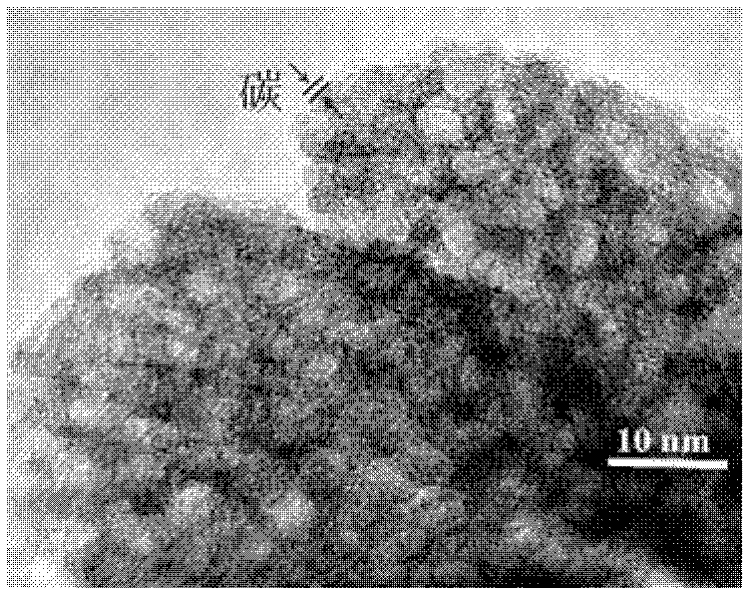

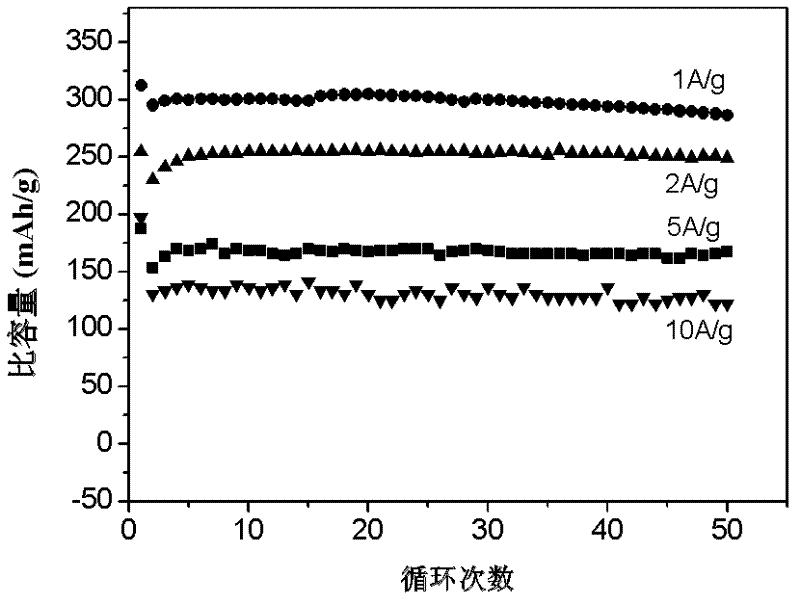

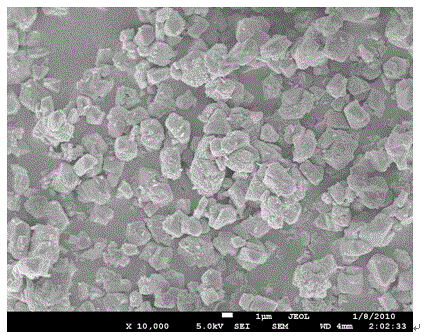

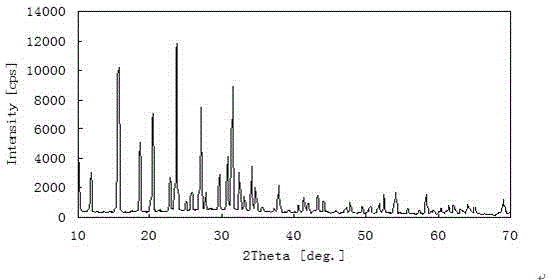

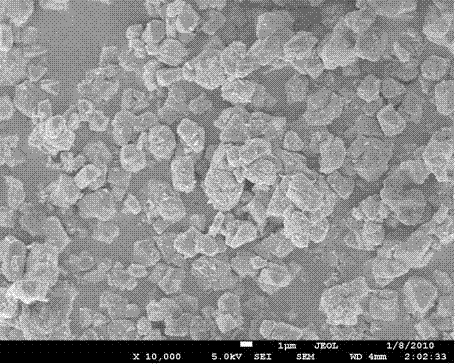

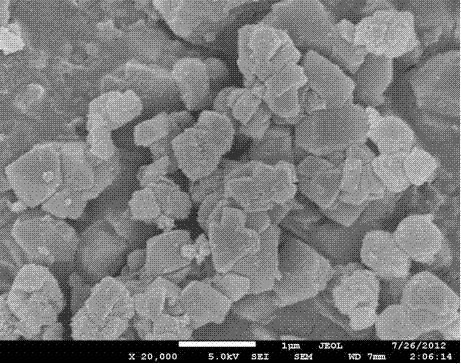

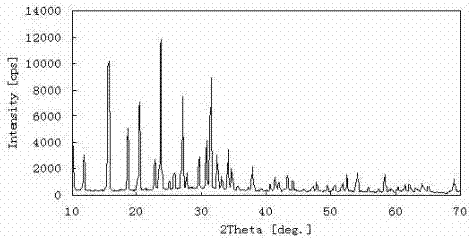

Positive electrode material for lithium ion cells and preparation method thereof

The invention relates to a positive electrode material for lithium ion cells and a preparation method thereof. The material provided by the invention is porous vanadic anhydride with an amorphous carbon layer on the surface of vanadic anhydride, wherein the weight friction of vanadic anhydride is 80-99.9% and the weight friction of carbon is 0.1-20%. In comparison with the prior art, the preparation method provided by the invention has advantages of simple technological process, short reaction time, low production cost and the like.

Owner:CHANGZHOU POWERGENIE MATERIALS

Hydrocracking catalyst carrier and preparation method thereof

ActiveCN105709845AGood product selectionHigh activityCatalyst carriersMolecular sieve catalystsMolecular sievePtru catalyst

The invention discloses a hydrocracking catalyst carrier and a preparation method thereof. The catalyst carrier adopts a large-grained and high-silicon modified Y type molecular sieve with centralized effective aperture distribution as the main cracking component, and takes amorphous silica-alumina as a second cracking component. The prepared hydrocracking catalyst has high activity and medium oil selectivity, and the produced middle distillate oil has good quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

Improved catalyzer of methyl hydride catalyzed partially oxidized synthesis gas and method of manufacturing the same

ActiveCN101108353AImprove activity stabilityImprove conversion rateHydrogenMetal/metal-oxides/metal-hydroxide catalystsSyngasNitrate

An improved catalyst of methane catalyzing part oxidizing syngas is provided, the composite is ABCDOx / Gamma-Al2O3, A is one of Rh, Pd, Pt and Ir, the content making blank space as the standard is 0.1 to 1.0wt per cent; B equals to Ni and / or Co, the content making blank space as the standard is 4.0 to 15.0wt per cent; C is one of La, Ce, Sm and Th, the content making blank space as the standard is 2.0 to 8.0wt per cent; D is one or a mixture of more than one in W, V, Mn or Cr, the content making blank space as the standard is 30 to 60wt per cent. The preparation method is that: use salt solution of D with corresponding measurement to soak in the blank carrier, after drying, high temperature roasting process to achieve improved carrier; then adopt nitrate of A,B,C with corresponding measurement to soak in steps total soak on the improved carrier, after drying, high temperature roasting process to produce improve catalyst. The invention is used for producing syngas, the transforming rate of CH4 reaches 96 to 98 per cent, the selectivity of H2 and CO is above 96.0 per cent, H2 / CO equals to 1.9 to 2.2. Under the reaction pressure of 0.1 to 2.0 Mpa, the invention has good catalyzing activity, selectivity and heat stability.

Owner:重庆市化工研究院有限公司

Preparation method of copper-containing catalyst

ActiveCN111686739AEvenly dispersedGood dispersionOrganic compound preparationHydroxy compound preparationPtru catalystSodium aluminate

The invention discloses a preparation method of a copper-containing catalyst, which comprises the following steps: (1) carrying out parallel flow gelatinization reaction on a mixed solution A and a sodium metaaluminate solution to obtain slurry I, and aging the slurry I; (2) dropwise adding the mixed solution B and a sodium carbonate solution into the aged slurry I obtained in the step (1) in a parallel flow manner, carrying out a gelling reaction to obtain slurry II, and aging the slurry II; and (3) carrying out solid-liquid separation on the material obtained in the step (2), and drying, roasting and molding the solid phase to obtain the catalyst, wherein a quaternary ammonium salt compound is added before the gelling reaction in the step (1), wherein the mixed solution A is an aqueous solution containing a soluble copper salt, a soluble zinc salt and an organic auxiliary agent, and the mixed solution B is an aqueous solution containing a soluble copper salt and a soluble aluminum salt. The catalyst has characteristics of uniform active metal copper distribution, good synergistic effect, large active metal active center number, catalyst activity improving, catalyst selectivity improving, catalyst thermal stability improving, and good application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

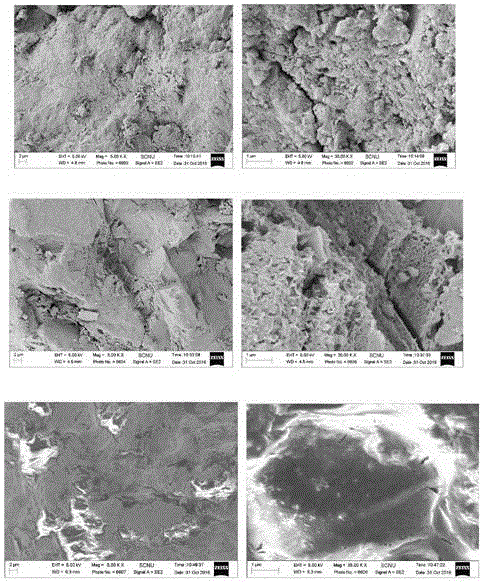

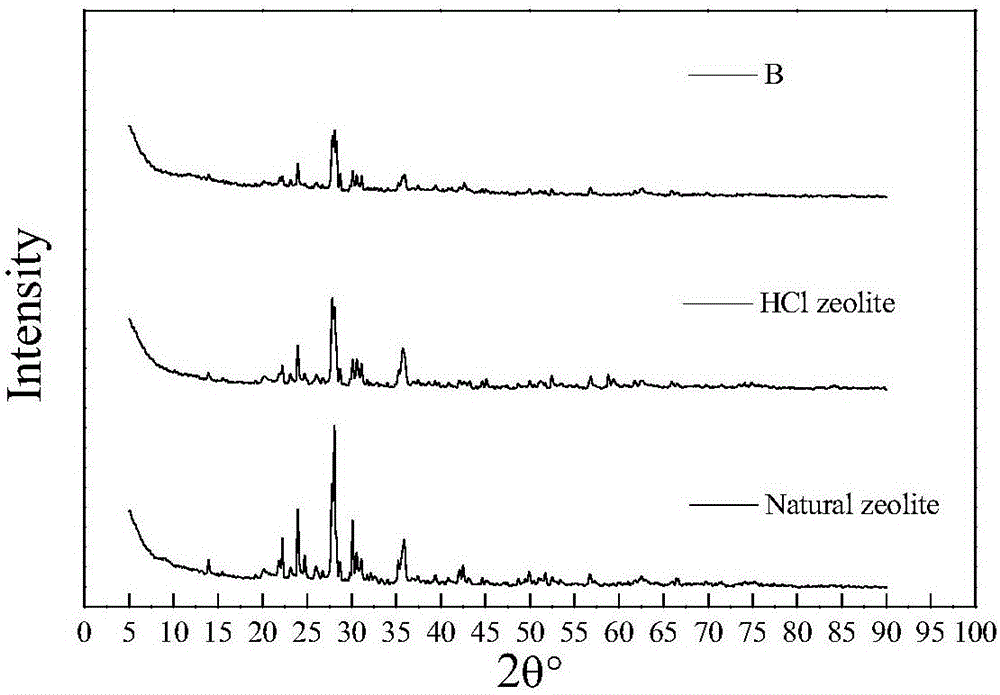

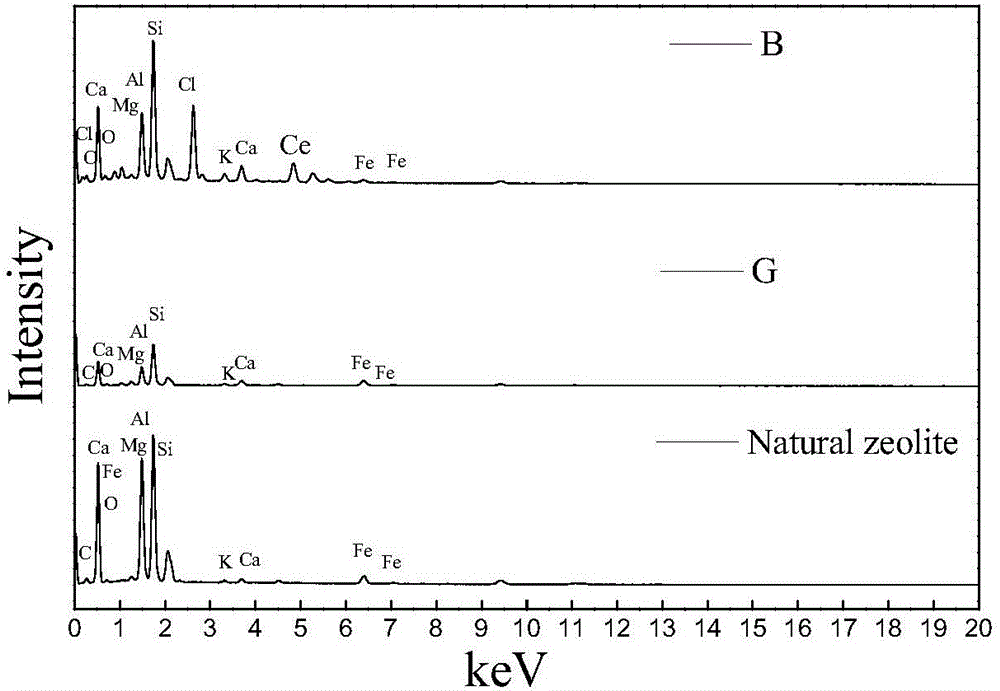

Preparation method of cerium-loaded material of hydrochloric acid modified zeolite and application in norfloxacin-polluted water body

ActiveCN106622118ALow costSimple processOther chemical processesWater contaminantsSecond order kineticsRare-earth element

The invention discloses a preparation method of cerium-loaded material of hydrochloric acid modified zeolite and an application in a norfloxacin-polluted water body. The preparation method comprises the following steps of using natural clinoptilolite as raw material, and modifying the natural clinoptilolite by hydrochloric acid, nitric acid, sodium chloride and sodium hydroxide. The preparation method has the advantages that 0.1mol / L of hydrochloric acid is used as an optimum modifying solution to dissolve the original impurities which are blocked in zeolite pore channels, the original large-radius cation ions in the zeolite pore channels are replaced, the modifying solution reacts with the zeolite, and the specific surface area of the zeolite is increased from 2.89m<2> / g to 10.71m<2> / g; on the basis of modified zeolite, the rare earth element of Ce (cerium) is loaded, the number of active sites of the zeolite is increased, and the absorbing rate on norfloxacin is obviously improved; the cost is low, the technology is simple, and the operation is convenient; the dynamics fitting of Ce@G zeolite to norfloxacin has better effect on secondary dynamics, and compared with the natural zeolite, the constant of secondary adsorbing rate is increased by 2.5 times; in the actual application, the time of the material removing the norfloxacin is shortened.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Preparation method of efficient photocatalytic self-cleaning glass

InactiveCN108147677AImprove photocatalytic efficiencyGood dispersionCoatingsPhotocatalytic reactionPolyvinyl alcohol

The invention relates to the technical field of glass material preparation, in particular to a preparation method of efficient photocatalytic self-cleaning glass. The preparation method comprises thefollowing steps: mixing butyl ester titanate and absolute ethyl alcohol; doping ferric chloride and polyvinyl alcohol under an acid condition; hydrolyzing to obtain titanium dioxide sol; coating a glass plate to obtain efficient photocatalytic self-cleaning glass, wherein iron ions are reacted with titanium dioxide, so that the photocatalytic efficiency of the titanium dioxide is increased; underthe action of titanium dioxide loaded with a layer of silicon dioxide film, increases the adsorption of to a degradation product is increased; stronger hydroxyl groups are formed on the surface, and block the combination of electron hole pairs to generate strongly oxidizing active hydroxy, so that the photocatalytic reaction rate is increased; the titanium dioxide is partially compounded with thesilicon dioxide, so that a film becomes rough, the adsorption performance is enhanced, the efficient photocatalytic self-cleaning glass can change from hydrophobic to hydrophilic quickly and keeps a smaller contact angle, and the hydrophilic property of the self-cleaning glass is improved; and the efficient photocatalytic self-cleaning glass has a wide application prospect.

Owner:吕莉

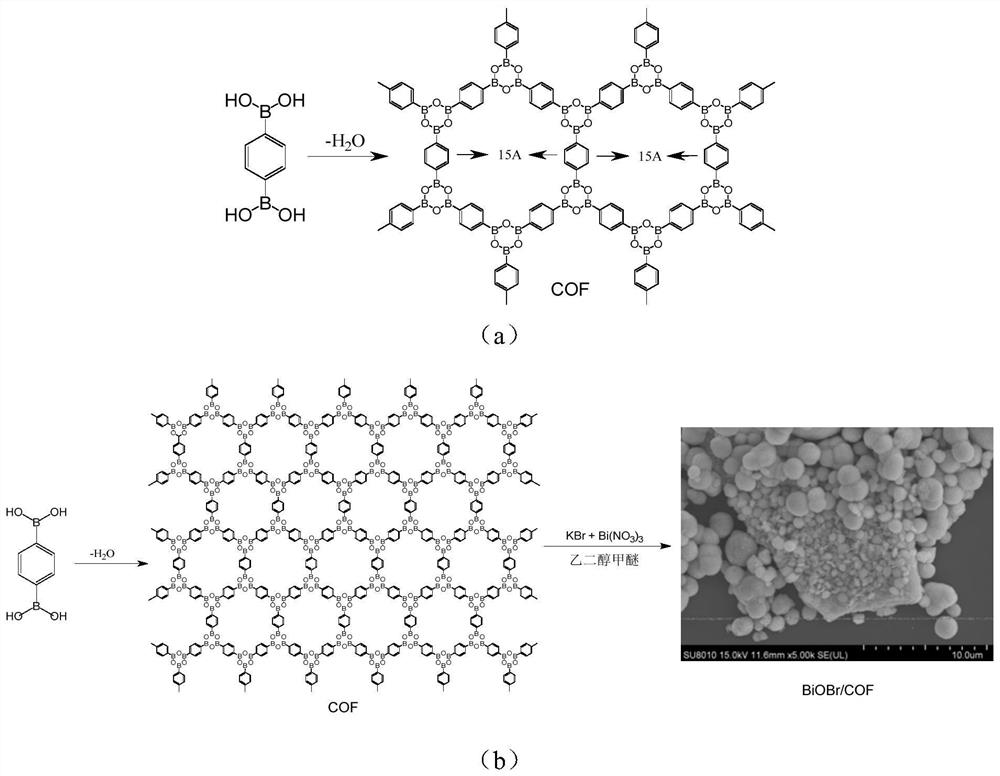

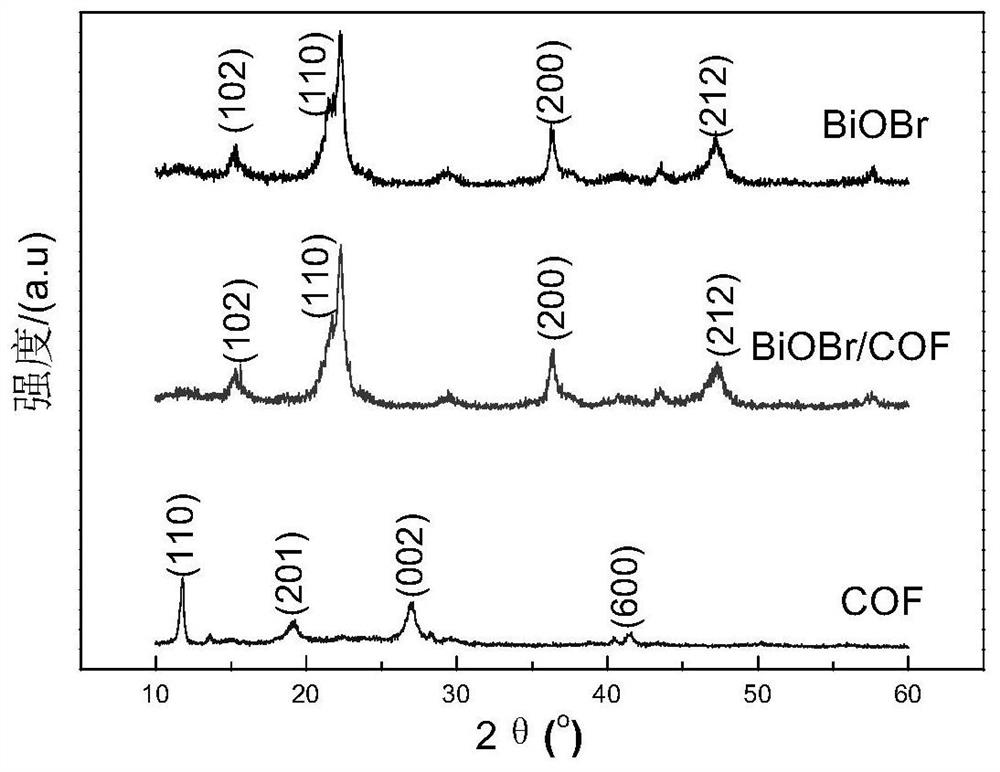

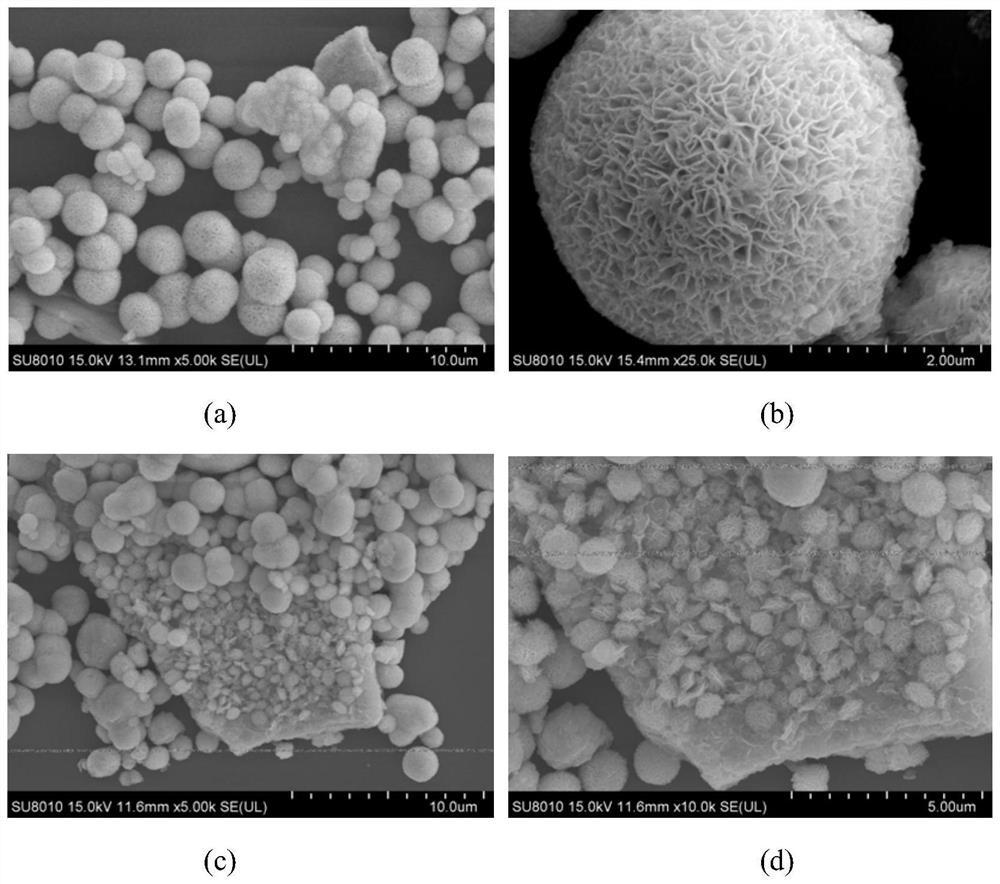

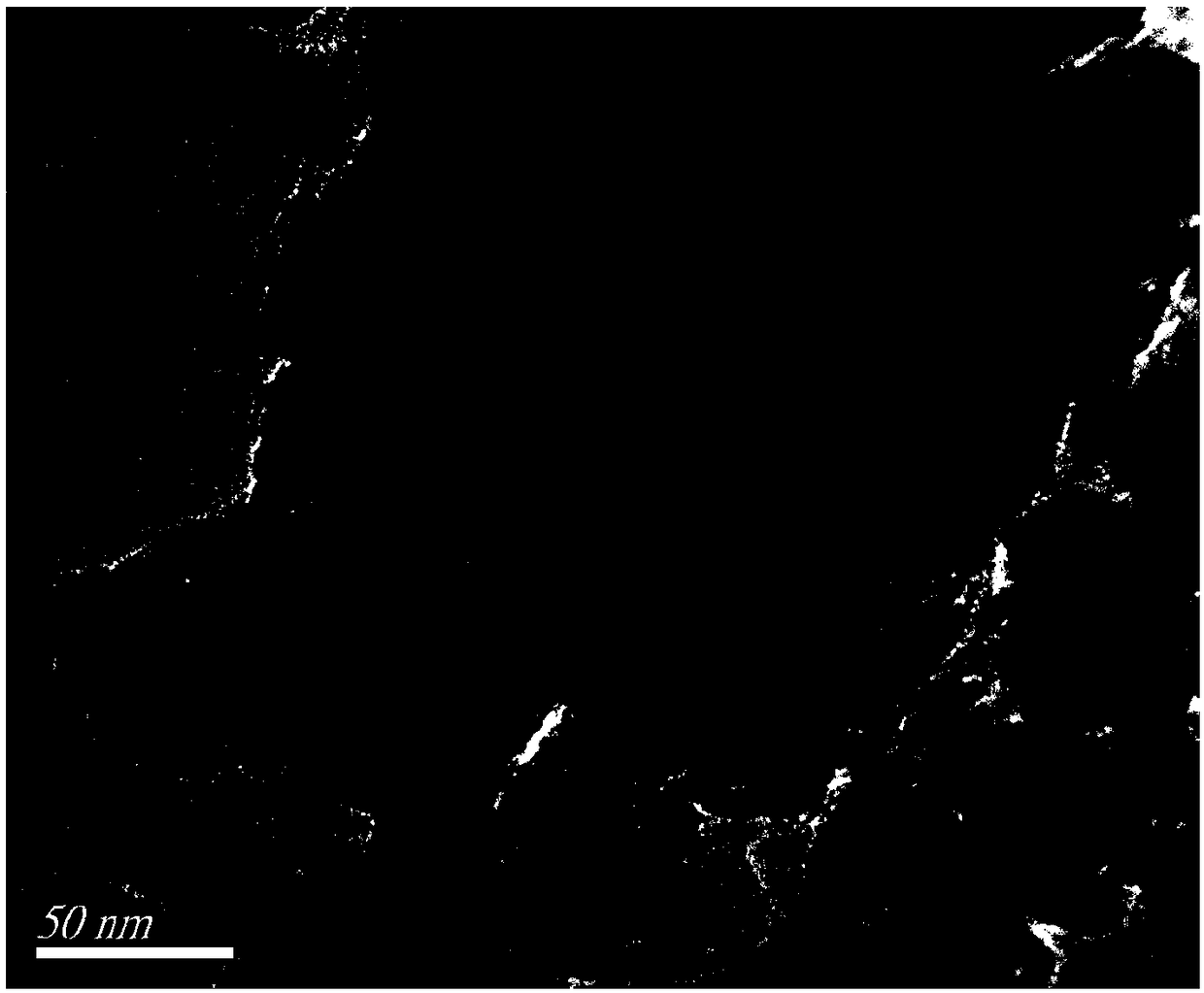

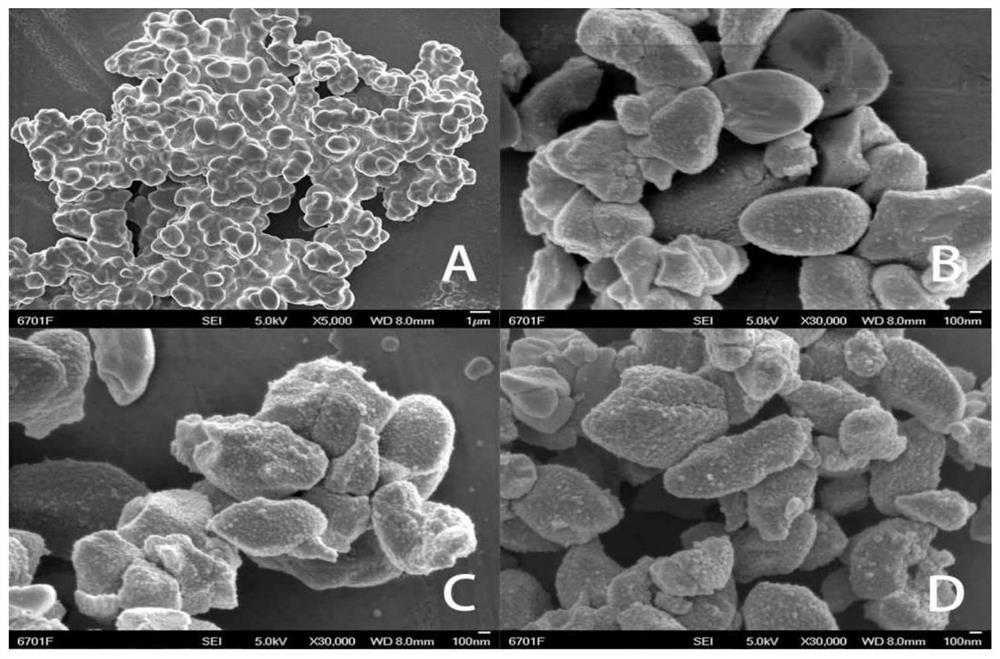

Preparation method and application of BiOBr/COF composite photocatalyst

PendingCN111822055AGood dispersionIncrease active centerWater/sewage treatment by irradiationWater treatment compoundsPhotocatalytic reactionOrganic dye

The invention discloses a preparation method and application of a BiOBr / COF composite photocatalyst, and belongs to the technical field of preparation and application of composite photocatalysts. Thepreparation method comprises the following steps: firstly, synthesizing COF by taking p-phenyldiboronic acid as a raw material and dioxane and mesitylene as solvents and adopting a solvothermal method; then, using bismuth nitrate pentahydrate and potassium bromide as raw materials, using ethylene glycol monomethyl ether as a solvent, adopting an in-situ solvothermal method, depositing nano BiOBr particles on a COF matrix, and preparing the BiOBr / COF composite photocatalyst material. According to the preparation method, COF is selected as a carrier of BiOBr so that the dispersity of BiOBr particles can be improved, the specific surface area can be increased, the active center of a photocatalytic reaction can be increased, and finally, the photocatalytic performance can be improved. The composite photocatalyst prepared by the method shows good stability, has a strong photocatalytic degradation effect on a variety of common organic dyes, and still has a degradation rate of 80% or above after being repeatedly used for 4 times.

Owner:HEFEI UNIV

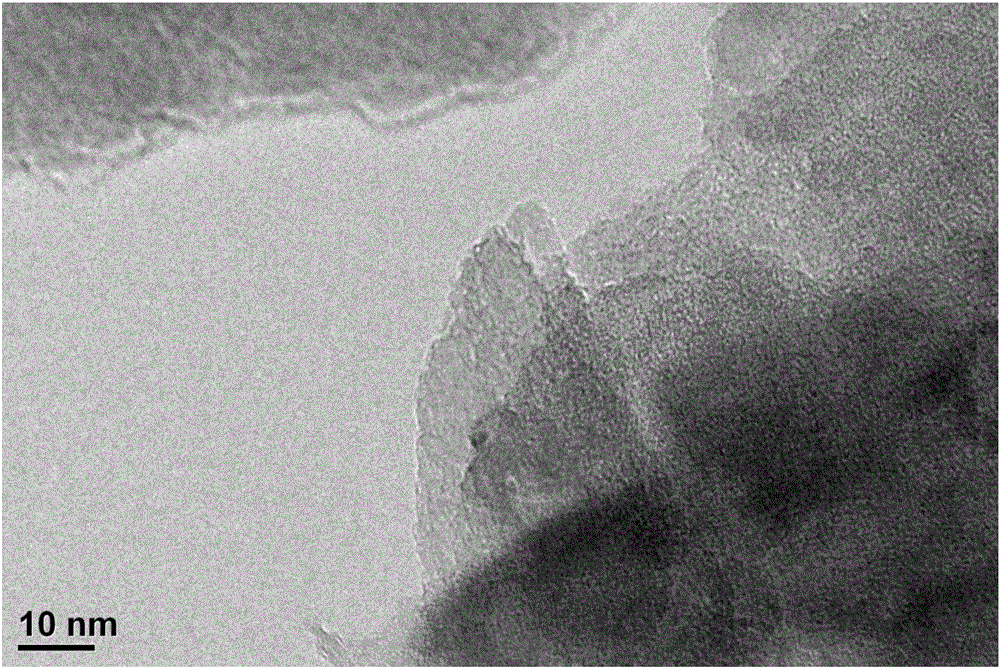

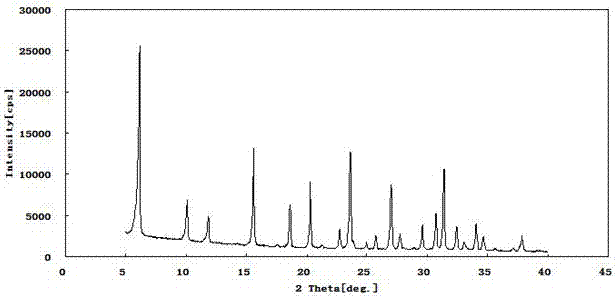

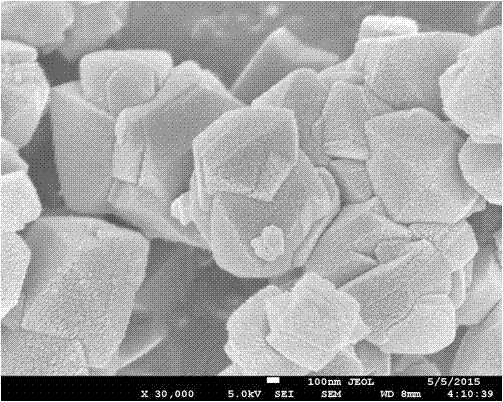

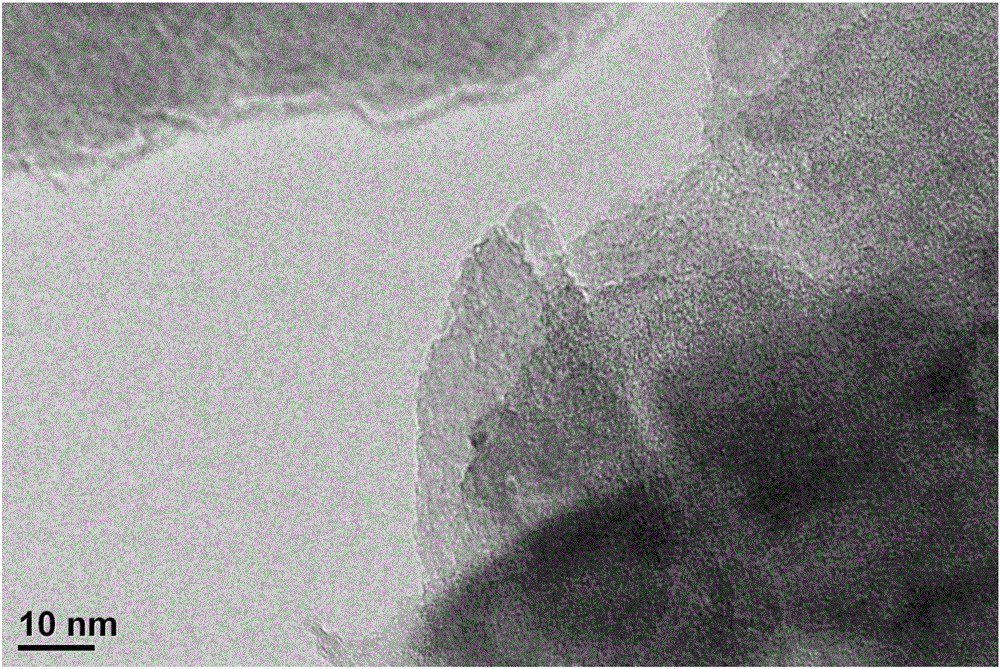

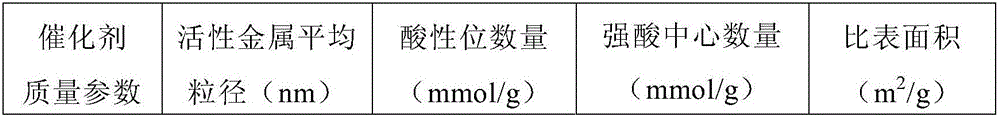

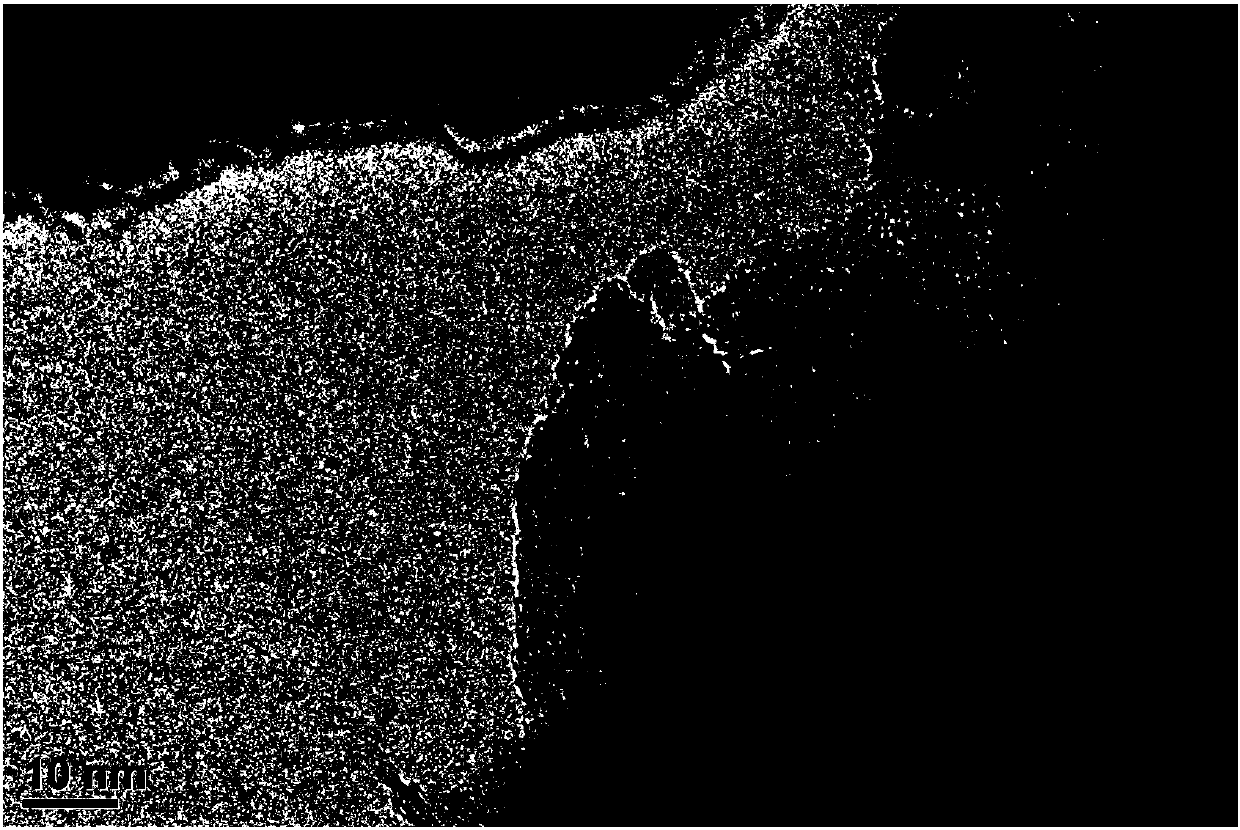

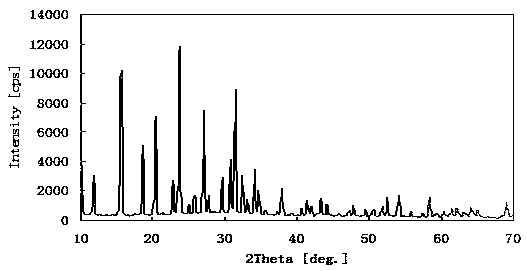

Modified Y type molecular sieve as well as preparation method and application thereof

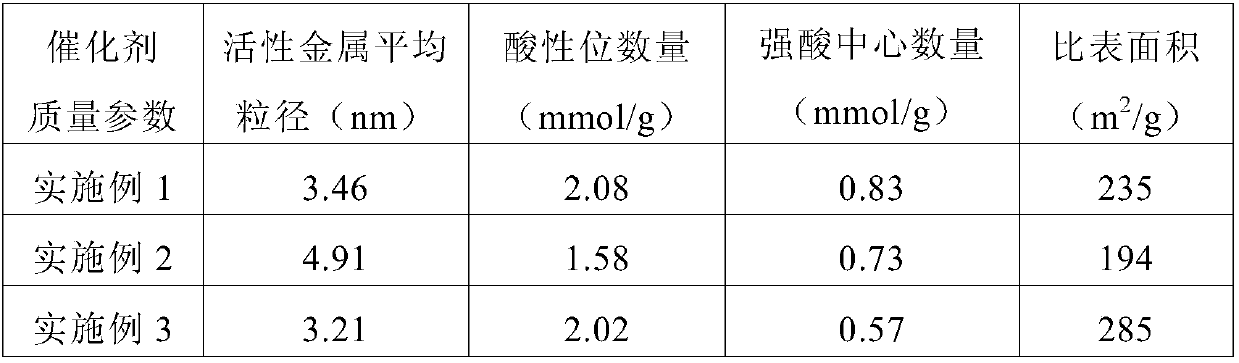

ActiveCN107344721AImprove utilization efficiencyHigh ratio of silicon to aluminumMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveStrong acids

The invention discloses a modified Y type molecular sieve as well as a preparation method and application thereof. The Y type molecular sieve has the following properties: the crystal particle average diameter is 2.0 to 5.0 mu m, the relative crystallinity is 100 percent to 140 percent, the molar ratio of SiO2 / Al2O3 is 30 to 100 and is preferably 40 to 100, the crystal cell parameter is 2.428 to 2.445nm, and the pore volume of a hole with the hole diameter being 2nm to 8nm accounts for 80 percent to 95 percent, preferably 80 percent to 90 percent of the total pore volume. The total acid content of NH3-TPD is 0.2 to 1.0mmol / g, wherein, the strong acid accounts for 75 percent or more of the total acid amount at the temperature larger than 250 DEG C, the pore volume of the Y type molecular sieve is 0.55cm<3> / g to 0.70cm<3> / g, and the specific surface area is 700m<2> / g to 1000m<2> / g. The molecular sieve has the advantages of large crystal particle, high crystalline, high silicon, more concentrated effective hole diameter distribution, favorable heat stability and hydrothermal stability and the like, and is suitable to be used for preparing a hydrogenation catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

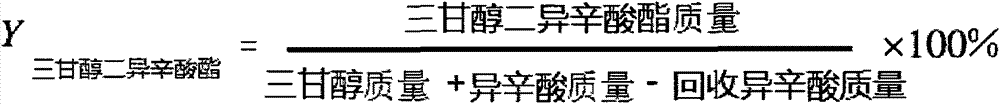

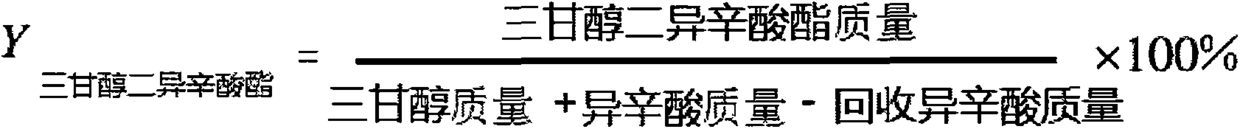

Method for synthesizing triethylene glycol di-2-ethylhexoate

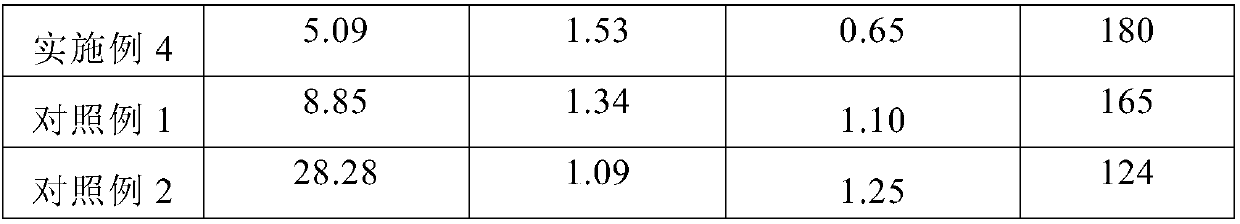

ActiveCN105439850AIncrease acidityHigh reaction yieldOrganic compound preparationCarboxylic acid esters preparationDistillationReaction temperature

The present invention discloses a method for synthesizing triethylene glycol di-2-ethylhexoate. The method comprises the following steps of: adding triethylene glycol and isocaprylic acid into a reactor; adding a catalyst into the reactor, wherein in the molar ratio of the triethylene glycol to the isocaprylic acid of 1:(2.5-5), the addition amount of the catalyst accounts for 1-5% of the total mass of the triethylene glycol and the isocaprylic acid; performing a reaction for 3-10 hours at the reaction temperature of 180-250 DEG C; obtaining a crude product of triethylene glycol di-2-ethylhexoate after the reaction; performing washing and distillation purification on the crude product of triethylene glycol di-2-ethylhexoate to remove the redundant isocaprylic acid; and obtaining the final product of triethylene glycol di-2-ethylhexoate.

Owner:SHENYANG ZHANGMING CHEM

Preparation method and use of lanthanum coordinated diamino-functionalized mesoporous silica film

InactiveCN109200990AHigh purityHigh degree of polymerizationWater contaminantsAlkali metal oxides/hydroxidesSeparation technologyPhosphoric acid

The invention belongs to the field of material preparation technology and separation technology, and relates to a preparation method and use of a lanthanum-coordinated diamino functionalized mesoporous silica film in phosphorus adsorption in a water body. The lanthanum-coordinated diamino-functionalized mesoporous silica film is prepared by first preparing a CNCs / silicon film from cellulose nanocrystals (CNCs) as a template and tetramethoxysilane (TMOS) as a silicon source by solvent evaporation self-assembly method and then removing CNCs by calcinations. The amino-functionalized mesoporous silica film is prepared by a post-synthesis grafting method and finally a lanthanum coordination method. The adsorption of phosphoric acid in the water body is carried out by an oscillating method, andthe lanthanum-coordinated diamino functionalized mesoporous silica film has excellent adsorption properties. The lanthanum-coordinated diamino functionalized mesoporous silica film has the advantagesthat the lanthanum-coordinated diamino functionalized mesoporous silica film is obtained by a simple preparation method, and has large adsorption capacity, and the membrane material can be recovered without causing secondary pollution.

Owner:JIANGSU UNIV

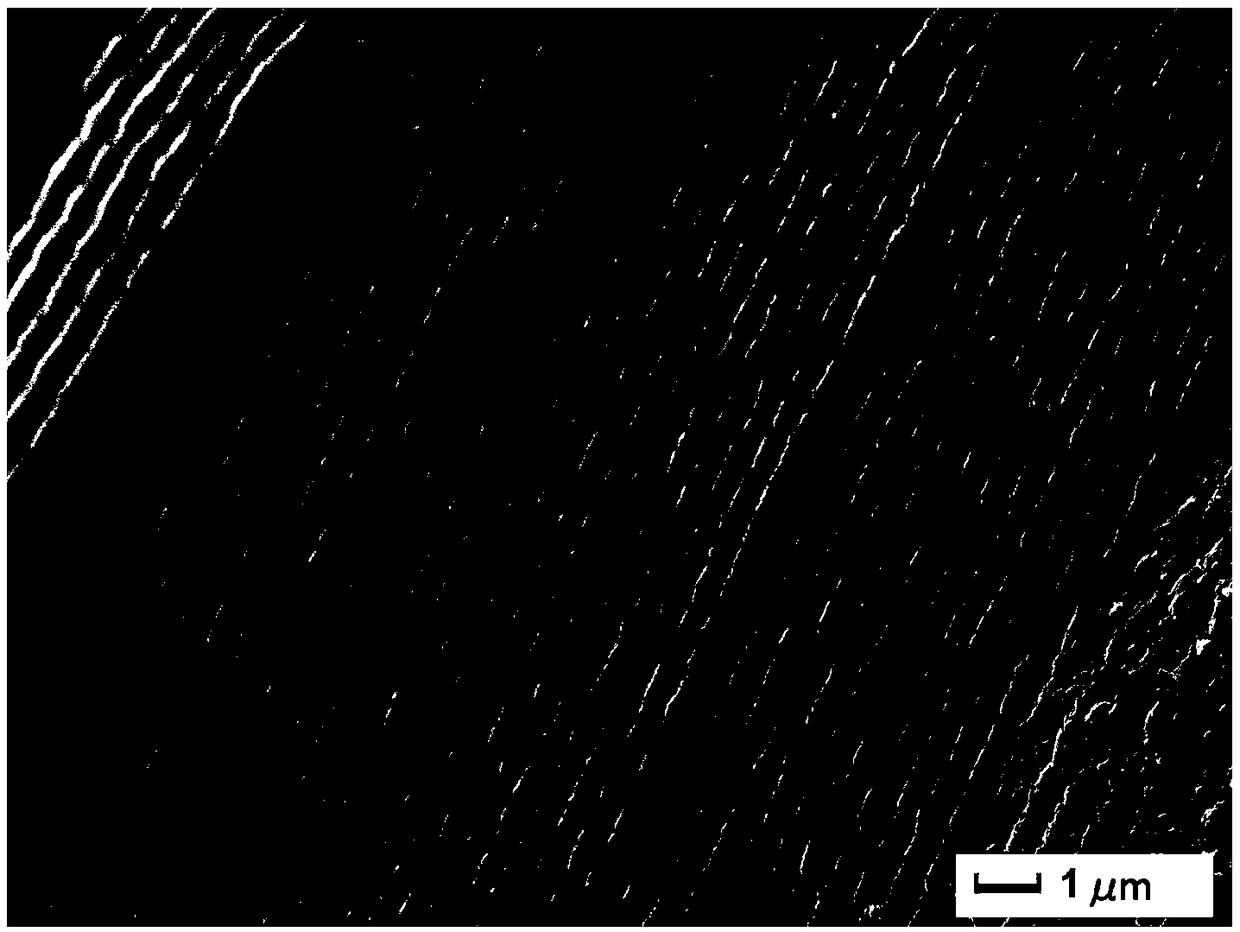

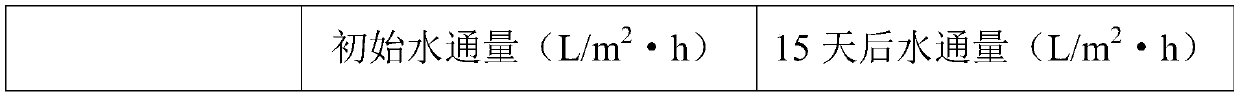

Ultrafiltration membrane surface modifier and modification method

ActiveCN110523291AImprove performanceReduce pollutionMembranesUltrafiltrationDecompositionChlorinated paraffins

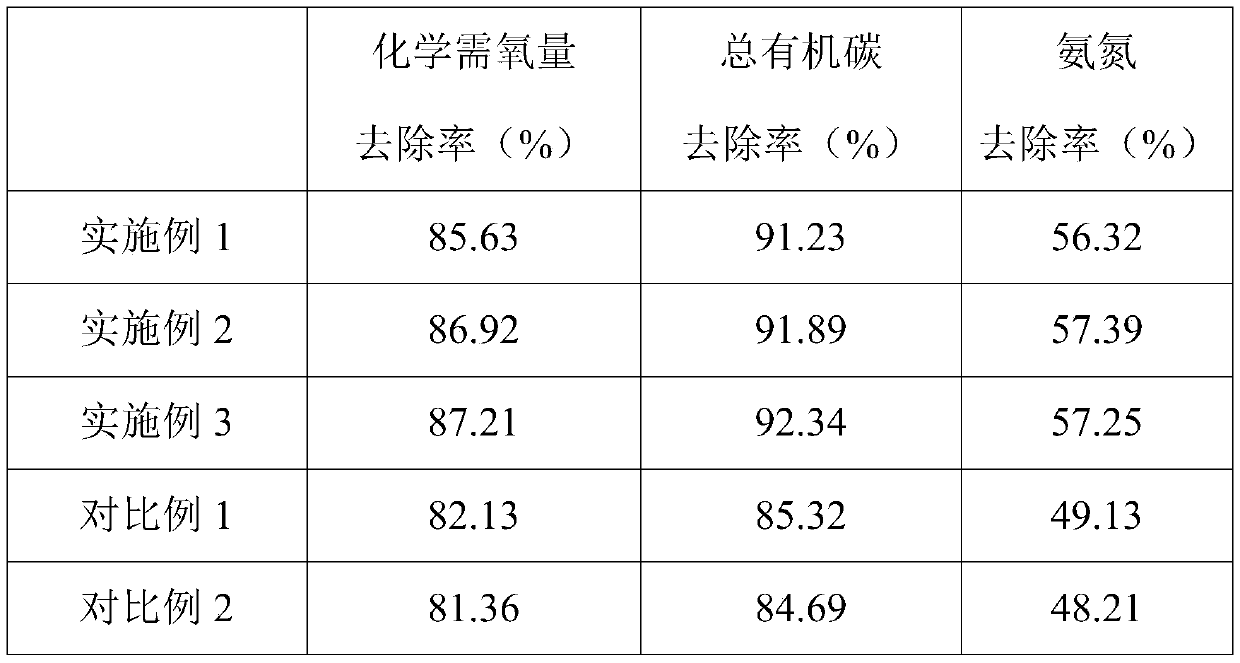

The invention provides an ultrafiltration membrane surface modifier. By mixing diatomaceous earth with titanium dioxide, a mixture is added to an yttrium sulfate solution and mixed with chlorinated paraffin, and then calcining is performed; modification of diatomaceous earth is performed by yttrium sulfatecan to increase internal channels of diatomaceous earth and increase the active center of diatomaceous earth; the decomposition of added chlorinated paraffin during calcining can further increase the channels of the diatomaceous earth, and the performance of the ultrafiltration membrane is enhanced; the surface modification of the ultrafiltration membrane is performed by the modifier to form a coating on the surface of the ultrafiltration membrane, direct contact between the pollutant andthe ultrafiltration membrane is reduced, the pollution of the ultrafiltration membrane is reduced, and anti-pollution ability of the ultrafiltration membrane is increased; and after the ultrafiltration membrane is modified by the ultrafiltration membrane surface modifier, the removal rate of chemical oxygen demand, total organic carbon and ammonia nitrogen in sewage is improved compared with an ultrafiltration membrane without modification, and meanwhile, the surface modifier further contains titanium dioxide, and can catalyze the decomposition and degradation of the pollutants.

Owner:HEBEI ZHONGQUAN ENVIRONMENT PROTECTION TECHCO LTD

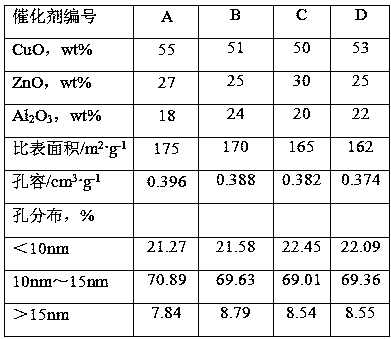

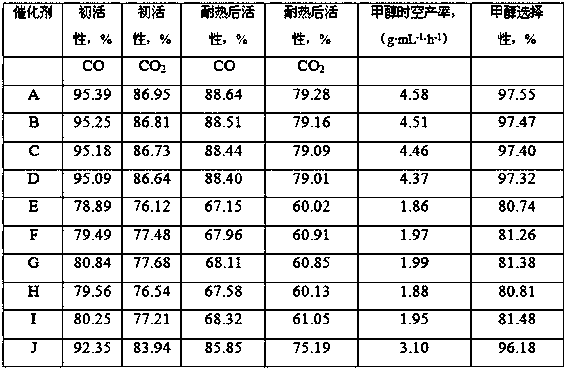

Preparation method of methanol synthesis catalyst

ActiveCN110935456AGood dispersionOptimized areaOrganic compound preparationHeterogenous catalyst chemical elementsPtru catalystSodium aluminate

The invention discloses a preparation method of a methanol synthesis catalyst. The preparation method comprises the following steps: (1) carrying out a parallel flow gelling reaction on a mixed solution A and a sodium metaaluminate solution to obtain a slurry I, and aging; (2) adding a mixed solution B and a sodium carbonate solution into the aged slurry I obtained in the step (1) in a dropwise and parallel flow manner, carrying out a gelling reaction to obtain a slurry II, and aging; and (3) carrying out solid-liquid separation on the material obtained in the step (2), and drying, roasting and molding the solid phase to obtain the catalyst, wherein the mixed solution A is an aqueous solution containing a soluble copper salt and a soluble zinc salt, and the mixed solution B is an aqueous solution containing a soluble copper salt and a soluble aluminum salt. The catalyst prepared by the method has the advantages of uniform distribution of active metal copper and auxiliary agent zinc, good synergistic effect, large number of active metal active centers, improved activity, improved selectivity, improved thermal stability and prolonged service life.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of copper-zinc catalyst

ActiveCN110935457AHigh activityGood synergyOrganic compound preparationHeterogenous catalyst chemical elementsPtru catalystSodium aluminate

The invention discloses a preparation method of a copper-zinc catalyst. The preparation method comprises the following steps: (1) carrying out a parallel flow gelling reaction on a mixed solution A and a sodium metaaluminate solution to obtain a slurry I, and aging; (2) adding a mixed solution B and a sodium carbonate solution into the aged slurry I obtained in the step (1) in a dropwise and parallel flow manner, carrying out a gelling reaction to obtain a slurry II, and aging; and (3) carrying out solid-liquid separation on the material obtained in the step (2), and drying, roasting and molding the solid phase to obtain the catalyst, wherein the mixed solution A is an aqueous solution containing a soluble copper salt, a soluble zinc salt and an organic auxiliary agent, and the mixed solution B is an aqueous solution containing a soluble copper salt and a soluble aluminum salt. The catalyst prepared by the method has the advantages of uniform distribution of active metal copper, good synergistic effect, large number of active metal active centers, improved activity, improved selectivity, improved thermal stability and prolonged service life.

Owner:CHINA PETROLEUM & CHEM CORP +1

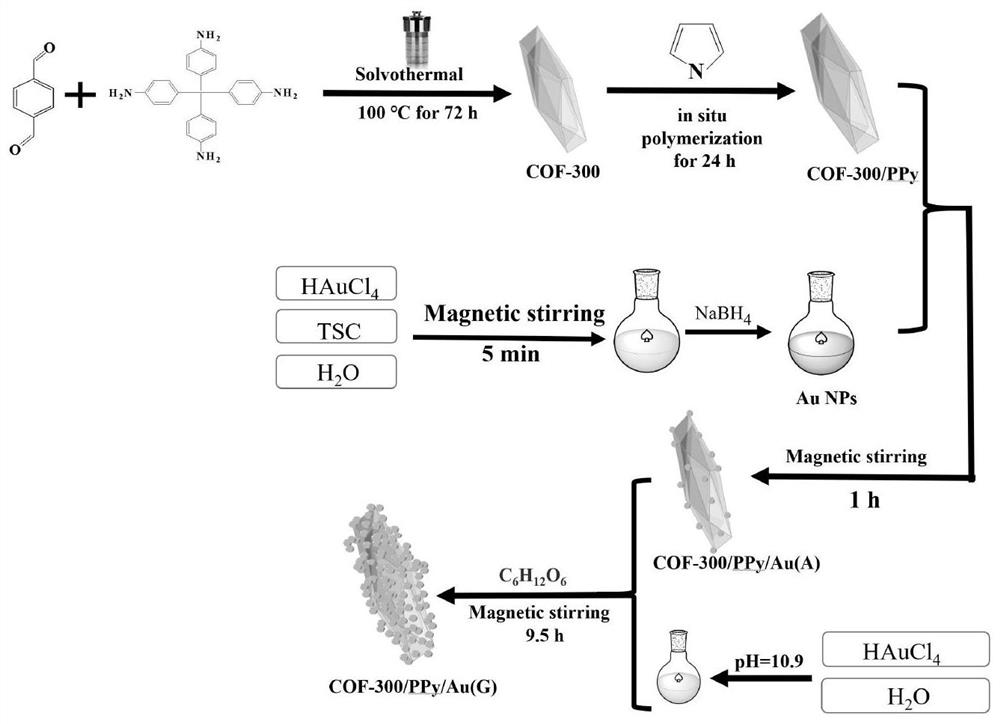

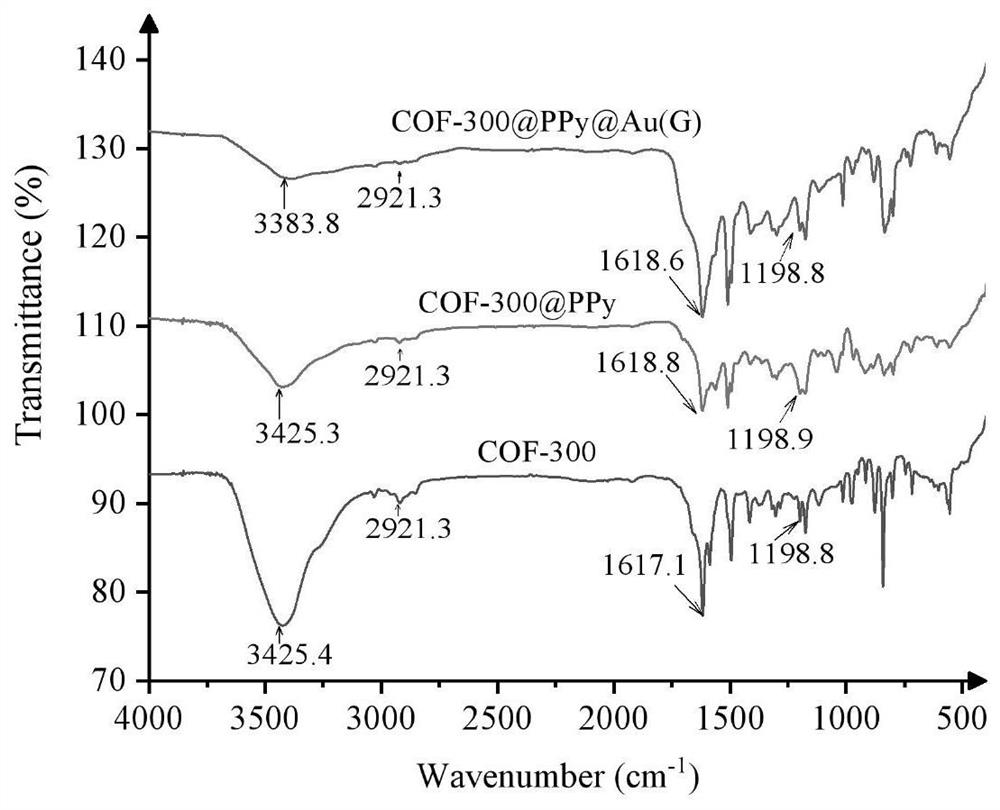

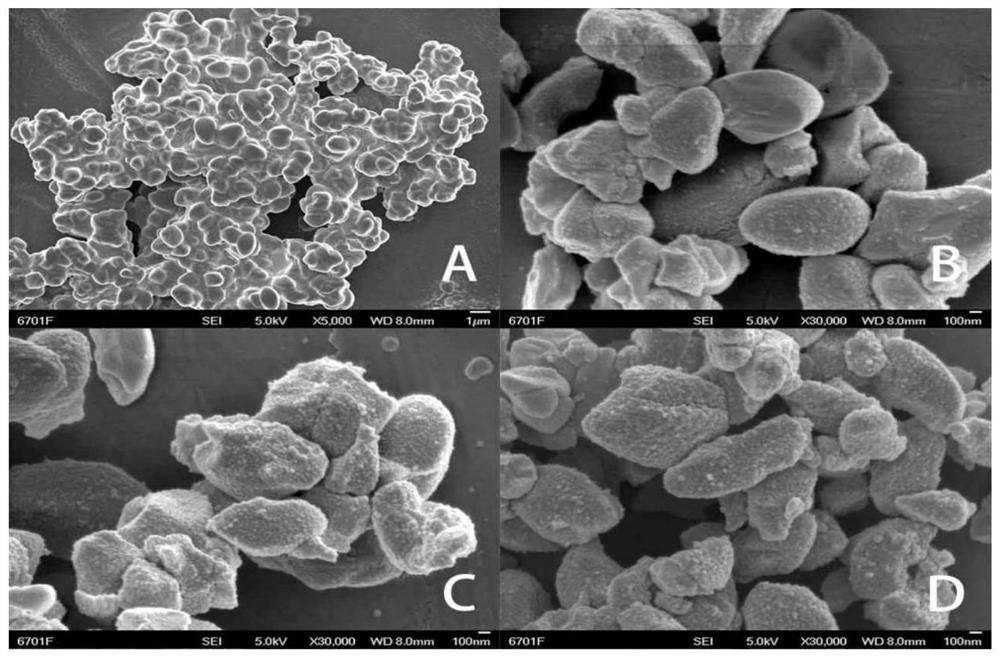

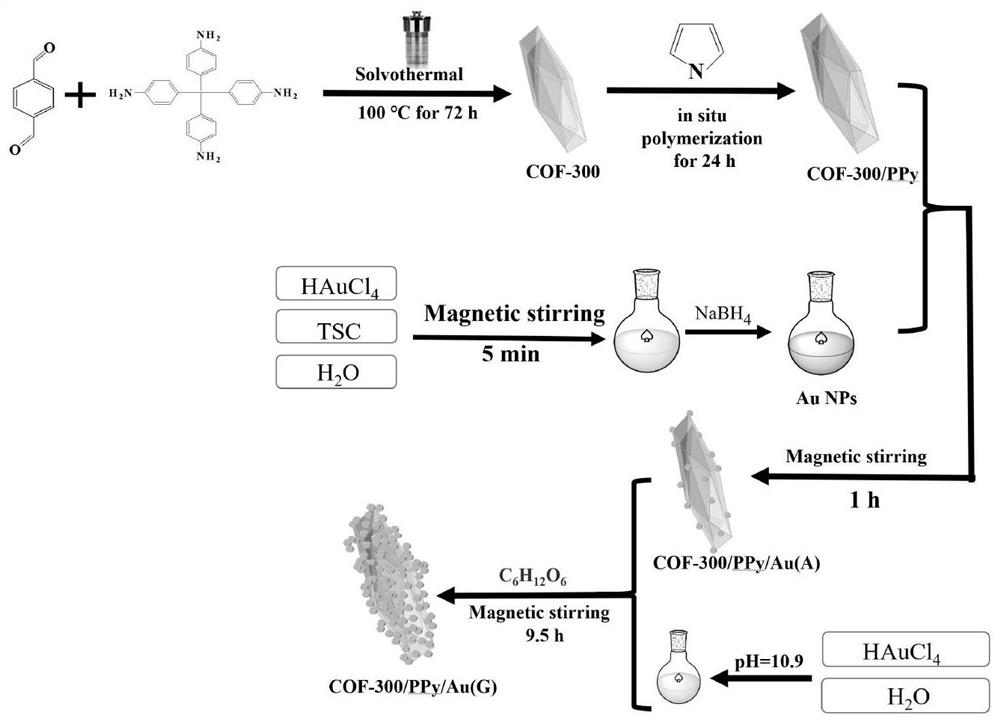

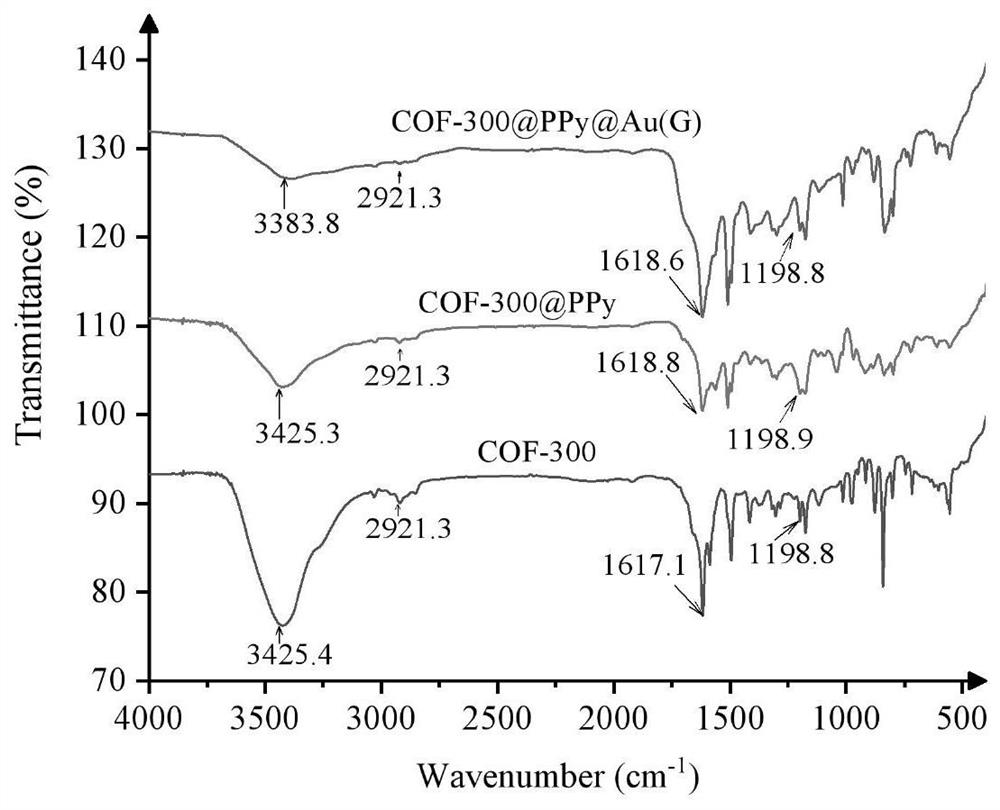

Preparation method and application of COF-300/PPy/Au (G) nano-enzyme catalyst

ActiveCN112403519AGood dispersionLarge specific surface areaWater/sewage treatment by irradiationWater treatment compoundsPtru catalystIn situ polymerization

The invention belongs to the technical field of preparation and application of nano materials, and particularly relates to a preparation method and application of a COF-300 / PPy / Au (G) nano-enzyme catalyst. The preparation method comprises the following steps: firstly, adding terephthalaldehyde and tetra (4-aminophenyl) methane into 1, 4-dioxane, stirring for dissolving, adding acetic acid, standing, and preparing COF-300 by using a solvothermal method; then, by taking a pyrrole monomer as a raw material and water as a solvent, stirring at normal temperature by adopting an in-situ polymerization method to obtain a COF-300-coated PPy composite nano material; finally, using chloroauric acid as a raw material, using trisodium citrate as a reducing agent, and preparing the multilayer gold nanoparticle (AuNPs) modified COF-300 / PPy / Au (G) nano-enzyme catalyst through a reduction and in-situ growth method. The COF-300 / PPy / Au (G) nano-enzyme catalyst prepared by the preparation method shows anefficient broad-spectrum catalytic action, shows a relatively strong catalytic degradation removal effect on various organic matters, and is mild in preparation condition, simple in method, economicaland feasible.

Owner:LANZHOU UNIVERSITY

Preparation method of grafted catalyst for continuous catalytic synthesis of isobutyl isobutyrate

ActiveCN111992247ALow priceLower conversion rateOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by aldehyde oxidation-reductionPtru catalystReaction temperature

The invention relates to the technical field of catalysts, in particular to a preparation method of a grafted catalyst for continuous catalytic synthesis of isobutyl isobutyrate. An active center of the grafted catalyst prepared by the method belongs to a molecular form uniformly grafted on a carrier and is higher. Isobutyraldehyde is used as a reactant and reacts under the action of a grafting catalyst to prepare isobutyl isobutyrate, the reaction steps are few, byproducts are avoided, the reaction temperature is low, and the defects that the catalyst is inactivated and is difficult to separate from the product are overcome; besides, no byproducts except water are generated in the reaction process, the influence of water on the product is eliminated, and large-scale production can be achieved. The content of isobutyl isobutyrate in the prepared product is greater than 90%, and the requirements of industrial products are met.

Owner:RUNTAI CHEM TAIXING CO LTD

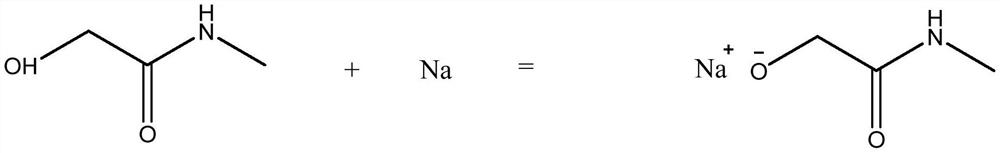

Regeneration and reactivation method of heavy distillate oil hydrotreatment catalyst

PendingCN112076804AIncrease the effective surface areaReduce manufacturing costCatalyst regeneration/reactivationCatalyst activation/preparationAmmoniacal nitrogenPtru catalyst

The invention relates to a regeneration and reactivation method of a heavy distillate oil hydrotreatment catalyst, which comprises the following steps: putting a regenerated catalyst into a solution containing an inorganic assistant and an organic chelating ligand assistant, and dipping under sound field conditions; airing an impregnated sample at room temperature; and carrying out two-step heat treatment to obtain the activated catalyst. According to the method, the effective specific surface area of the regenerated catalyst is increased, the dispersity of active components is improved, the catalyst treated and regenerated by the method is high in vulcanization degree, the number of active phases is increased, the reaction activity of the catalyst is improved, no ammonia nitrogen is discharged in the catalyst reactivation process, and the environment is not polluted.

Owner:湖北中超化工科技有限公司

A kind of selective hydrodesulfurization method

ActiveCN106221794BReduce loadLess octane lossTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrodesulfurizationGasoline

The invention provides a selective hydrodesulfurization process which comprises the following steps: cutting a gasoline feedstock into light ends and heavy ends; performing liquid-liquid extraction for the light ends to obtain light end raffinate containing olefins and light end extraction oil containing sulfide and aromatics; and using selective hydrodesulfurization catalysts to perform selective hydrodesulfurization for the light end extraction oil and the heavy ends, wherein the main component of the selective hydrodesulfurization catalyst is obtained by loading an active metal component with a metal oxide, treated with a metal salt, as the carrier, wherein the active metal is selected from more than two elements in IA, VIII, VIB and VIIB groups in the periodic table. The selective hydrodesulfurization process provided by the invention has the advantages of high desulfurization rate and small loss of the octane value of sweet gasoline.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

A kind of method of synthesizing triethylene glycol diisocaprylate

ActiveCN105439850BIncrease acidityHigh reaction yieldOrganic compound preparationCarboxylic acid esters preparationDistillationReaction temperature

The present invention discloses a method for synthesizing triethylene glycol di-2-ethylhexoate. The method comprises the following steps of: adding triethylene glycol and isocaprylic acid into a reactor; adding a catalyst into the reactor, wherein in the molar ratio of the triethylene glycol to the isocaprylic acid of 1:(2.5-5), the addition amount of the catalyst accounts for 1-5% of the total mass of the triethylene glycol and the isocaprylic acid; performing a reaction for 3-10 hours at the reaction temperature of 180-250 DEG C; obtaining a crude product of triethylene glycol di-2-ethylhexoate after the reaction; performing washing and distillation purification on the crude product of triethylene glycol di-2-ethylhexoate to remove the redundant isocaprylic acid; and obtaining the final product of triethylene glycol di-2-ethylhexoate.

Owner:SHENYANG ZHANGMING CHEM

Hydrocracking catalyst carrier and preparation method thereof

ActiveCN105709845BGood product selectionHigh activityCatalyst carriersMolecular sieve catalystsMolecular sieveHigh activity

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method and application of cof-300/ppy/au(g) nanozyme catalyst

ActiveCN112403519BGood dispersionLarge specific surface areaWater/sewage treatment by irradiationWater treatment compoundsPtru catalystIn situ polymerization

Owner:LANZHOU UNIVERSITY

Preparation method of copper-zinc catalyst

ActiveCN111686738AHigh activityGood synergyOrganic compound preparationHeterogenous catalyst chemical elementsPtru catalystSodium aluminate

The invention discloses a preparation method of a copper-zinc catalyst, which comprises the following steps: (1) carrying out parallel flow gelatinization reaction on a mixed solution A and a sodium metaaluminate solution to obtain slurry I, and aging the slurry I; (2) dropwise adding the mixed solution B and a sodium carbonate solution into the aged slurry I obtained in the step (1) in a parallelflow manner, carrying out a gelling reaction to obtain slurry II, and aging the slurry II; (3) filtering and drying the material obtained in the step (2), and treating the material with a mixed aqueous solution containing aluminum salt and organic acid; and (4) preparing a catalyst product from the material obtained in the step (3), wherein the mixed solution A is an aqueous solution containing asoluble copper salt, a soluble zinc salt and an organic auxiliary agent, and the mixed solution B is an aqueous solution containing a soluble copper salt and a soluble aluminum salt. The catalyst prepared by the method disclosed by the invention is uniform in active metal distribution, has a good synergistic effect, has a large number of active metal active centers, improves the activity, selectivity and thermal stability of the catalyst, and has a good application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com