Method for synthesizing triethylene glycol di-2-ethylhexoate

A technology of isooctanoate and triethylene glycol diethylene glycol, which is applied in the field of synthesizing triethylene glycol diisocaprylate, can solve the problems of restricting production scale and low technical yield, and achieve the improvement of overall acidity, increase of reaction yield, The effect of strong chemical electrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

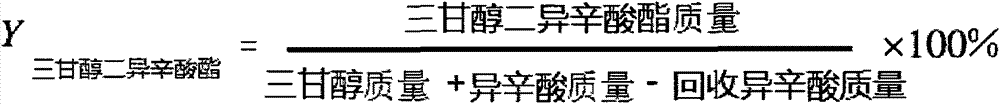

Examples

Embodiment 1

[0020] (1) Pretreatment of catalyst:

[0021] Add 100Kg of stannous oxide, 0.2Kg of zinc bis(trifluoromethylsulfonyl)imide, and 0.2Kg of boron trifluoride ether solution into a 500L high-speed mixer and mix evenly to prepare the catalyst.

[0022] (2) Synthesis reaction:

[0023] Add 100Kg triethylene glycol and 336Kg isooctanoic acid into a 1000L reactor, add 8.72Kg of the catalyst prepared in the above steps into the reactor, react at a temperature of 220°C, and react for 5 hours. After the reaction, the crude product triethylene glycol diisocaprylate is obtained. , the crude triethylene glycol diisocaprylate is washed again, purified by distillation, and excess isooctanoic acid is removed to obtain the final product triethylene glycol diisocaprylate. Numbered M-1.

Embodiment 2

[0025] (1) Pretreatment of catalyst:

[0026] Add 100Kg of stannous oxide, 0.1Kg of zinc bis(trifluoromethylsulfonyl)imide, and 0.1Kg of boron trifluoride ether solution into a 500L high-speed mixer and mix evenly to prepare the catalyst.

[0027] (2) Synthesis reaction:

[0028] Add 100Kg triethylene glycol and 240Kg isooctanoic acid into a 1000L reactor, add 3.4Kg of the catalyst prepared in the above steps into the reactor, react at a temperature of 180°C, and react for 10 hours. After the reaction, the crude product triethylene glycol diisocaprylate is obtained. , the crude triethylene glycol diisocaprylate is washed again, purified by distillation, and excess isooctanoic acid is removed to obtain the final product triethylene glycol diisocaprylate. Numbered M-2.

Embodiment 3

[0030] (1) Pretreatment of catalyst:

[0031] Add 100Kg of stannous oxide, 0.5Kg of zinc bis(trifluoromethylsulfonyl)imide, and 0.5Kg of boron trifluoride ether solution into an 800L high-speed mixer and mix evenly to prepare the catalyst.

[0032] (2) Synthesis reaction:

[0033] Add 100Kg triethylene glycol and 480Kg isooctanoic acid into a 1000L reactor, add 29Kg of the catalyst prepared in the above steps into the reactor, and react at a temperature of 250°C for 3 hours. After the reaction, the crude product triethylene glycol diisocaprylate is obtained. The crude triethylene glycol diisocaprylate is washed again, purified by distillation, and excess isooctanoic acid is removed to obtain the final product triethylene glycol diisocaprylate. Numbered M-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com