Preparation method and application of BiOBr/COF composite photocatalyst

A catalyst, composite light technology, applied in catalyst activation/preparation, organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

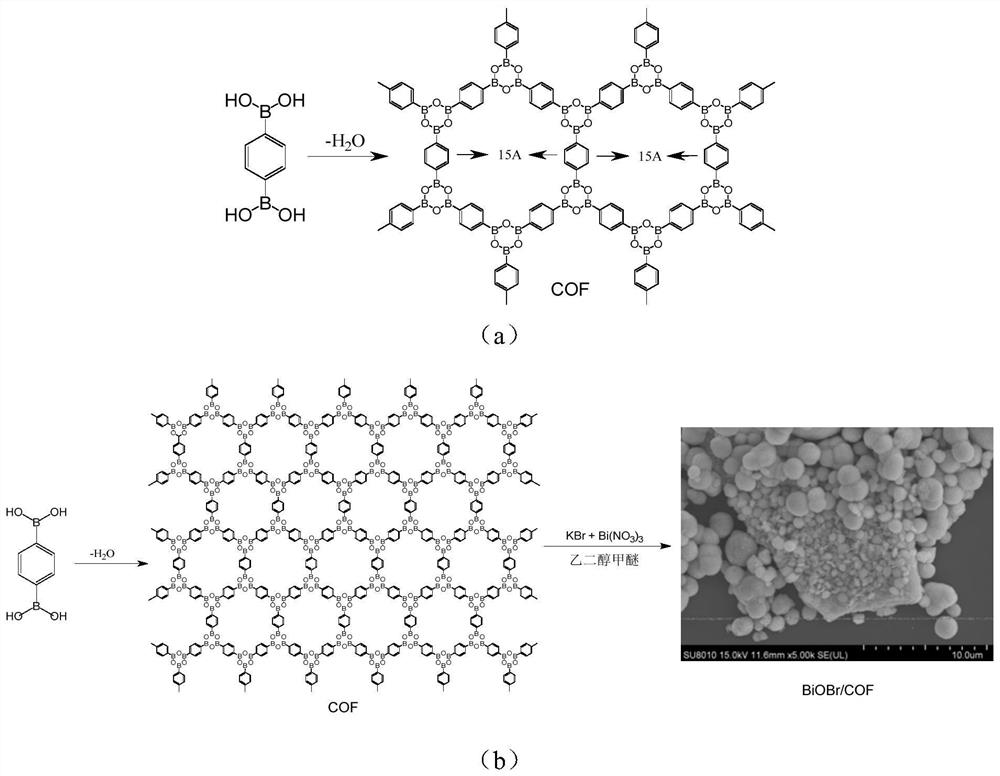

[0030] The preparation method of BiOBr / COF composite photocatalyst, the steps are as follows:

[0031] ① Preparation of COF

[0032] Weigh 0.5g terephthalic acid, add 20mL dioxane and 20mL mesitylene, stir well for 2h.

[0033] The mixed solution was placed in a 50mL autoclave, raised from room temperature to 120°C at a rate of 5°C / min, and kept for 24h.

[0034] Cool naturally to room temperature. After washing with acetone for several times, and drying in vacuum at 50°C for 4 hours, a white COF powder was obtained.

[0035] ② Preparation of BiOBr / COF composite photocatalyst

[0036] Weigh 0.238g of KBr and dissolve it in 40mL of ethylene glycol methyl ether to obtain liquid A.

[0037] Weigh 0.4g of COF and 0.970g of Bi(NO 3 ) 3 ·5H 2 O, add 40mL of ethylene glycol methyl ether, and sonicate for 30min to obtain liquid B.

[0038] Under constant stirring, add liquid A dropwise to liquid B, sonicate for 30 min, and stir for 2 h.

[0039] The mixed solution was transfe...

Embodiment 2

[0046] Photocatalytic degradation of RhB experiment

[0047] Take 20 mg of photocatalyst, add it into newly prepared 100 mL RhB (5 mg / L) solution, put it into a photochemical reaction apparatus, and stir at room temperature in the dark for 30 min to achieve adsorption equilibrium. Turn on the light source, irradiate the solution with a 700W xenon lamp, take samples every 10 minutes to measure the absorbance, use the standard curve to obtain the concentration C of the RhB solution, and set the initial concentration of RhB as C 0 , according to the formula: (1-C / C 0 )*100%, calculate the degradation rate of RhB.

[0048] In order to investigate the effects of different COF / BiOBr mass ratios, solvothermal temperature and solvothermal time on the photocatalytic activity, different conditions were changed to obtain various degradation rate curves.

[0049] Figure 6 It is the comparison curve of the degradation rate of RhB for different COF / BiOBr mass ratios, by Figure 6 It ca...

Embodiment 3

[0054] Degradation performance of BiOBr / COF composite photocatalysts for different dyes

[0055] The experimental process is the same as in Example 2, and a total of 5 dyes are selected to be prepared in Example 1, including Rhodamine B (RhB), Acid Fuchsin (AF), Methyl Orange (MO), Methyl Blue (MB), and Brilliant Green (BG). The photocatalytic effect of the composite photocatalyst was evaluated.

[0056] Figure 9 For the effect of BiOBr / COF composite photocatalyst on the photocatalytic activity of different dyes, by Figure 9 It can be seen that the degradation rates of RhB, AF, MO, MB, and BG by BiOBr / COF photocatalyst are all above 90%, respectively 98.69%, 99.26%, 98.03%, 97.5%, and 91.33%. Photocatalysts have strong photocatalytic degradation effects on common organic dyes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com