Mg/Al/X ternary composite metal oxide catalyst and preparation method thereof

A ternary composite, catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve problems such as inability to meet the requirements and the performance of polyether products needs to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

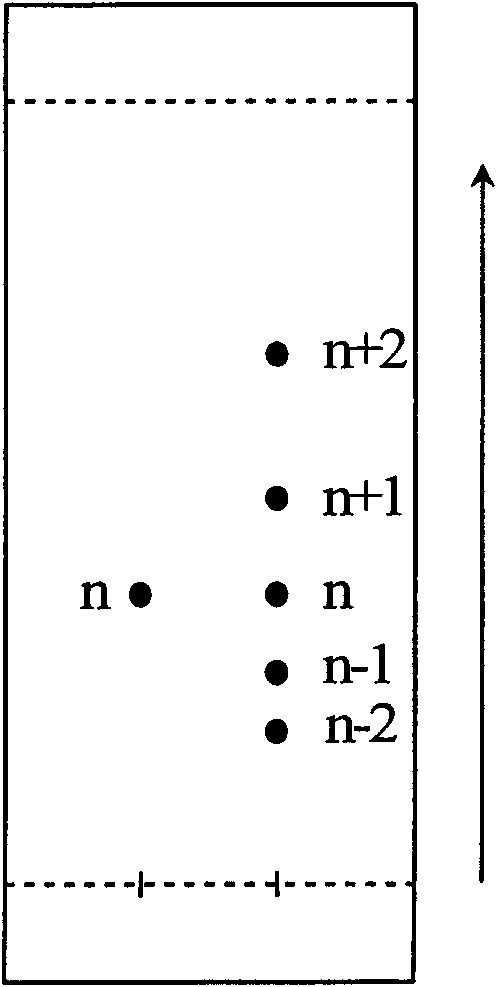

[0019] The catalyst preparation method designed at the same time in the present invention includes precursor preparation, crystallization, secondary crystallization, molding and calcination processes in sequence, mainly adopting the co-precipitation method to drop Mg at the same time 2+ 、Al 3+ And the third element metal ion, and then through the preparation process of molding and calcination, the catalyst product of the present invention is obtained. Catalyst preparation method of the present invention comprises following specific technique:

[0020] 1. Preparation of precursors. The preparation concentration is the NaOH aqueous solution (solution A) of 1-5mol / L and the NaOH of 2-10mol / L 2 CO 3 Aqueous solution (solution B); preparation containing 0.1-10mol / L Mg 2+ Aqueous solution (solution C); preparation containing 0.1-10mol / L Al 3+ the aqueous solution (solution D); prepare the aqueous solution (solution E) of the tertiary metal ion of 0.05-2mol / L; Add it dropwise i...

Embodiment 1

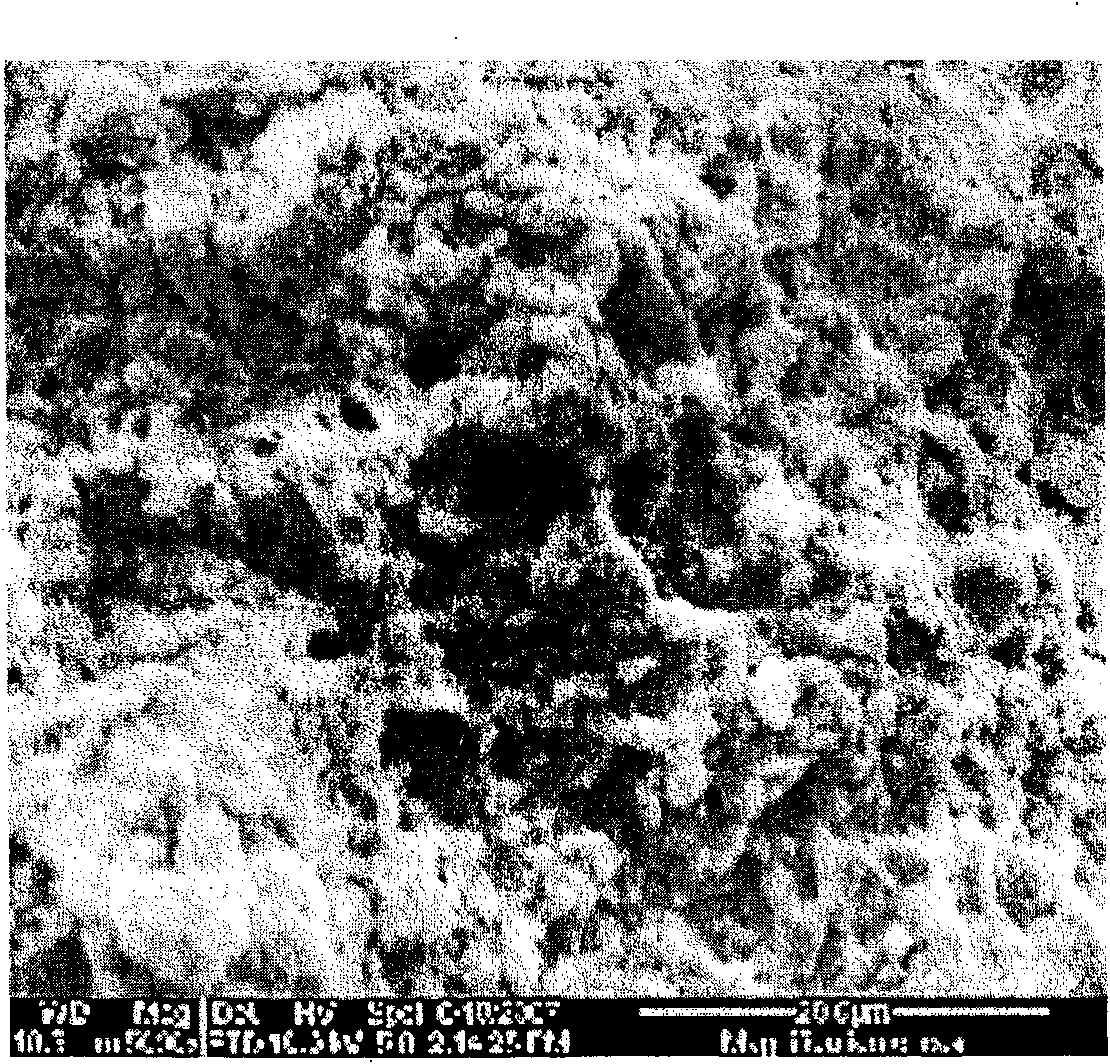

[0036] Preparation. Mg / Al / Dy ternary composite metal oxide catalyst.

[0037] 1. Pre-body preparation. Preparation concentration is the NaOH aqueous solution (solution A) of 1.3mol / L and the NaOH of 3.6mol / L 2 CO 3 Aqueous solution (solution B); preparation containing 1mol / L Mg(NO 3 ) 2 Aqueous solution (solution C); preparation containing 1mol / L AlCl 3 aqueous solution (solution D); prepare 0.5mol / L of Dy(NO 3 ) 3 Aqueous solution (solution E); after preparing the above solution, simultaneously add solutions C, D, and E dropwise at a rate of 0.5ml / min to a beaker containing a mixture of 200ml solution A and 300ml solution B, and the pH is 12.0 ; where Mg in solution C, solution D and solution E 2+ :Al 3+ : Dy 3+ The molar ratio is 0.1:1:0.1, the volume ratio of solution A and solution B in the beaker is 1:10; the reaction temperature is controlled at 40°C, and the reaction is stirred for 800 minutes to obtain the Mg / Al / Dy ternary composite metal oxide precursor slur...

Embodiment 2

[0042] Preparation of Mg / Al / Ce ternary composite metal oxide catalyst.

[0043] 1. Preparation of precursors. The preparation concentration is the NaOH aqueous solution (solution A) of 1.0mol / L and the NaOH of 2.0mol / L 2 CO 3 Aqueous solution (solution B); preparation containing 1mol / L Mg(NO 3 ) 2 Aqueous solution (solution C); preparation containing 3mol / L AlCl 3 aqueous solution (solution D); prepare 0.6mol / L of Ce(NO 3 ) 3 Aqueous solution (solution E); after preparing the above solution, add solutions C, D, and E dropwise at a speed of 8.0ml / min to the beaker containing the mixture of 200ml solution A and 300ml solution B, and control the pH at 9.0 ; Wherein solution C, solution D, solution E in Mg 2+ :Al 3+ : Ce 3+ The molar ratio is controlled at 1:3:0.6, the volume ratio of solution A and solution B in the beaker is controlled at 1:10; the reaction temperature is controlled at 40°C, and the reaction is stirred for 120 minutes to obtain the Mg / Al / Ce ternary comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com