A kind of hydrodepreciation catalyst and preparation method thereof

A technology for depressurization of hydrogen and catalyst, which is used in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Catalyst Preparation

[0031] 22.4g dry basis content 67wt% small hole alumina (specific surface area is 290m 2 g -1 , pore volume 0.48mL·g -1 ) and 1.5mol / L, 65mL nitric acid aqueous solution were stirred to prepare peptized binder. 45g dry basis content 67wt% macroporous alumina (specific surface 320m2 g -1 , pore volume 1.10mL·g -1 ) and hydrogen nano ZSM-5 molecular sieve 41.2g (grain size is 50nm, specific surface area is 380m 2 g -1 , Manufacturer: Tianjin Shenneng Technology Co., Ltd., SiO 2 / Al 2 o 3 Mole ratio = 25, 97% by weight on a dry basis) was mixed with the above-mentioned peptized binder. Add 1% of the extruding aid squash powder based on the weight of the dry basis of the catalyst to the above mixture, knead and extrude, then dry at 100°C for 4 hours, and roast at 580°C for 6 hours to obtain the carrier. The carrier is impregnated with an equal volume of 70mL impregnation solution containing 12.0g ammonium metatungstate (tungsten oxide 83w...

Embodiment 2

[0036] 1. Catalyst Preparation

[0037] 15g dry basis content 67wt% small hole alumina (specific surface area is 290m 2 g -1 , pore volume 0.48mL·g -1 ) and 1.5mol / L, 65mL nitric acid aqueous solution were stirred to prepare peptized binder. 44.7g dry basis content 67wt% macroporous alumina (specific surface area is 350m 2 g -1 , pore volume 0.87mL·g -1 ) and hydrogen nano ZSM-5 molecular sieve 46.4g (grain size is 70nm, specific surface area is 360m 2 g -1 , Manufacturer: Tianjin Shenneng Technology Co., Ltd., SiO 2 / Al 2 o 3 Mole ratio = 50, 97% by weight on a dry basis) was mixed with the above-mentioned peptized binder. Add 1% extrusion aid carbon black to the above mixture, knead and extrude, then dry at 100°C for 4 hours and calcined at 580°C for 6 hours to obtain the carrier. The above carrier is impregnated with an equal volume of 65mL impregnating solution containing 12.0g ammonium metatungstate (tungsten oxide content 83wt%) and 20.8g nickel nitrate (nicke...

Embodiment 3

[0041] 1. Catalyst Preparation

[0042] The specific preparation process is the same as in Example 1, except that the catalyst proportioning ratio is different. Small pore alumina 15.0g; macroporous alumina 44.7g, hydrogen nano ZSM-5 molecular sieve 51.5g (grain size is 80nm, specific surface area is 360m 2 g -1 , Manufacturer: Tianjin Shenneng Technology Co., Ltd., SiO 2 / Al 2 o 3 Molar ratio=80, dry basis 97wt%), ammonium metatungstate (tungsten oxide 83wt%) 8.4g, nickel nitrate (nickel oxide 24wt%) 12.5g, obtain catalyst C, its properties are shown in Table 1.

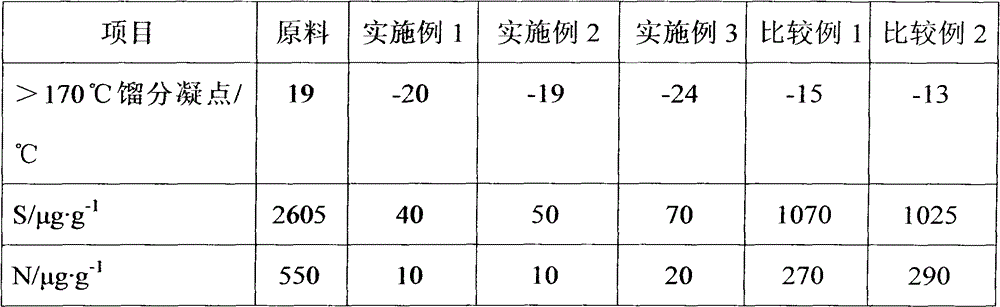

[0043] 2. Process evaluation

[0044] Process conditions are the same as in Example 1, and the reaction results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com