Preparing method of wearing-resistant catalyst

The technology of catalyst and auxiliary agent is applied in the field of preparation of wear-resistant catalyst, which can solve the problems of failure to improve the anti-wear performance of the catalyst, the anti-wear performance of the catalyst is not very good, etc., and achieve the effect of reducing the catalyst wear and the wear rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1 (the present embodiment is comparative example)

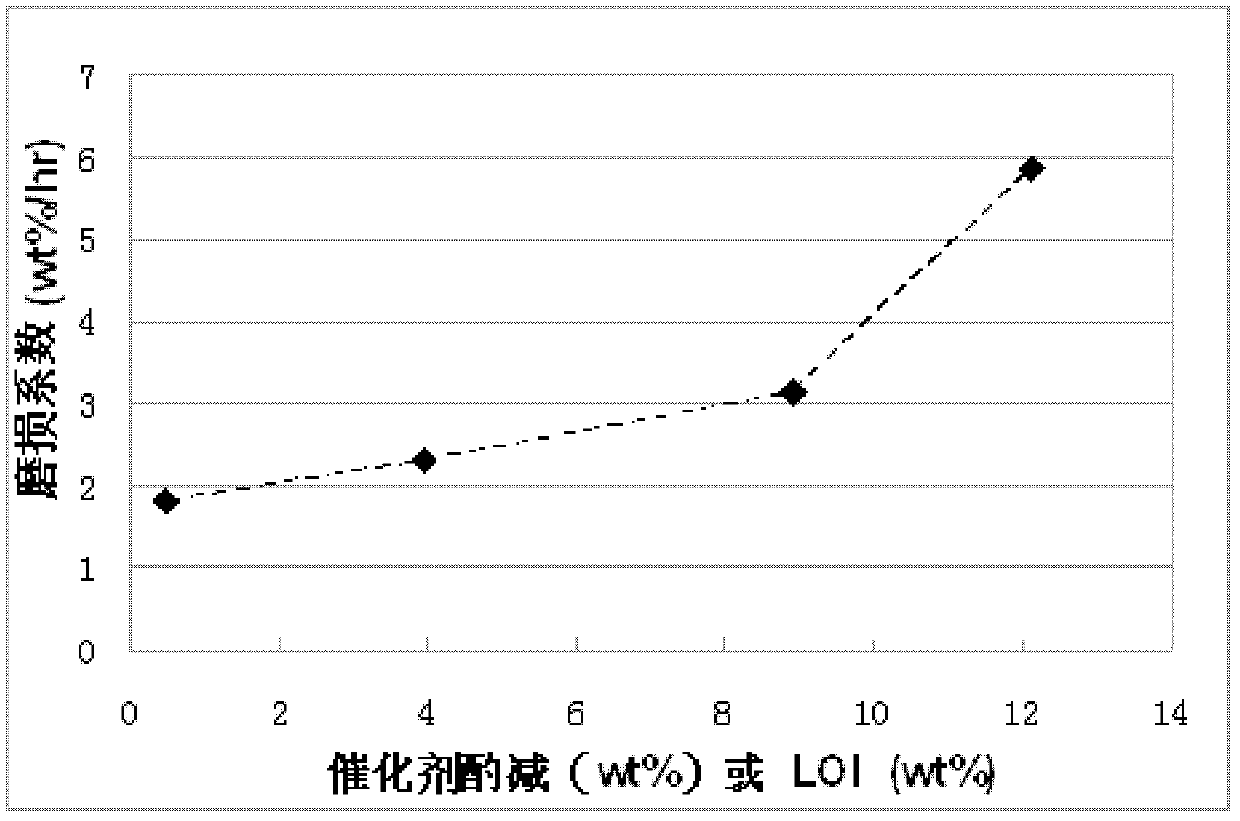

[0058] The FCC catalyst TJPC-F produced by Sinopec Changlian Catalyst Factory has an LOI of 12.1% and an ABD of 0.90g / cm 3 , The wear coefficient is 5.87% / hr.

Embodiment 2

[0060] The TJPC-F catalyst in Example 1 was calcined at 550° C. for 2 hours in a muffle furnace under atmospheric pressure and normal pressure to become TJPC-F-C1. The LOI of the catalyst after calcination is 0.5%, and the ABD is 0.81g / cm 3 , The wear coefficient is 1.81% / hr.

Embodiment 3

[0062] The TJPC-F catalyst in Example 1 was dried in an oven at 110° C. for different times to remove moisture and other volatile matter in the catalyst. The LOI values of the catalyst samples are different with different drying times, and the longer the drying time, the lower the LOI. The wear resistance performance results measured under different LOIs are shown in Table 1.

[0063] Table 1 Comparison of anti-attrition properties of FCC catalysts with different LOI (decrease)

[0064] Sample name

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com