Patents

Literature

91results about How to "Less octane loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

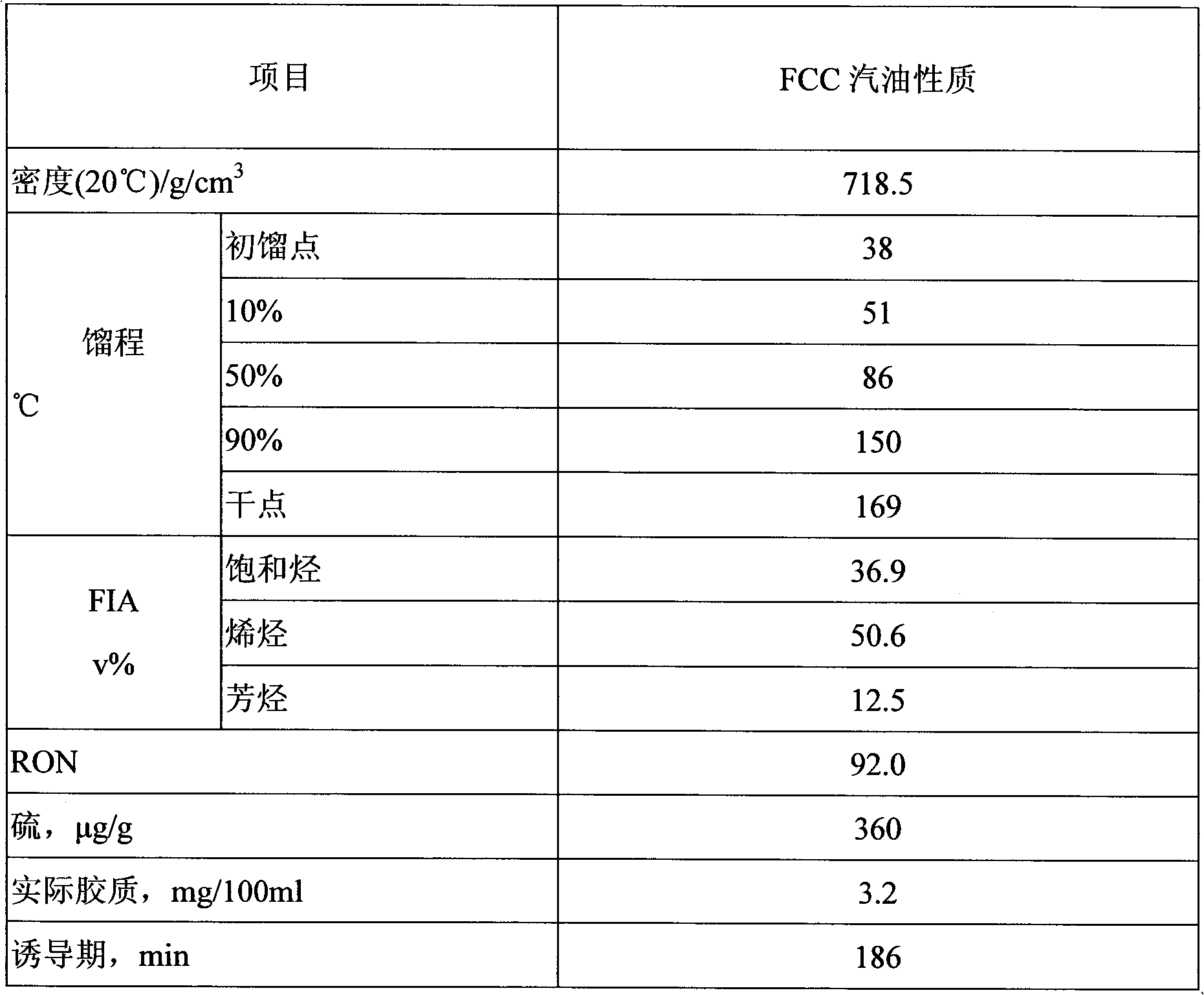

Method of heavily desulfurating and reducing olefinic hydrocarbon for gasoline

InactiveCN1465666ALess octane lossMeet sulfur content standardsHydrocarbon oils treatmentRefining to eliminate hetero atomsHydrogenGasoline

The method for further desulfurization and reducing olefine content in the gasoline includes the following steps: cutting the gasoline raw material into light fraction and heavy fraction, making the light fraction undergo the processes of alkali refinement treatment and removing mercaptans, and making the heavy fraction and hydrogen gas successively contact with hydrogenation refining catalyst and octane value restoring agent, then mixing the above-mentioned desulfurized light fraction and heavy fraction so as to obtain the invented gasoline product in which the sulfur content is less than 200 ppm and olefine content is less than 20 V%.

Owner:CHINA PETROLEUM & CHEM CORP +1

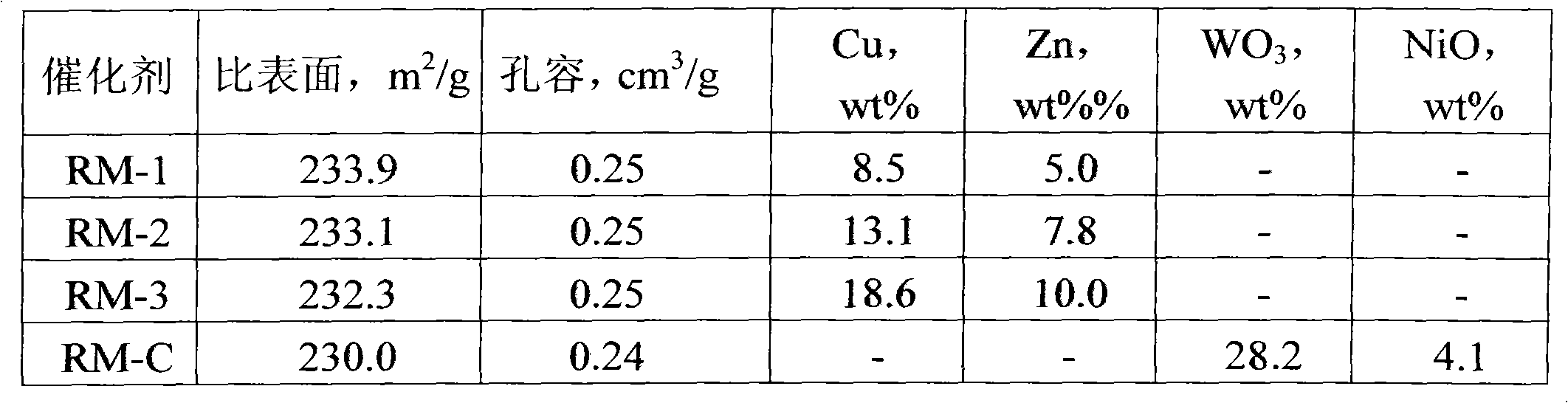

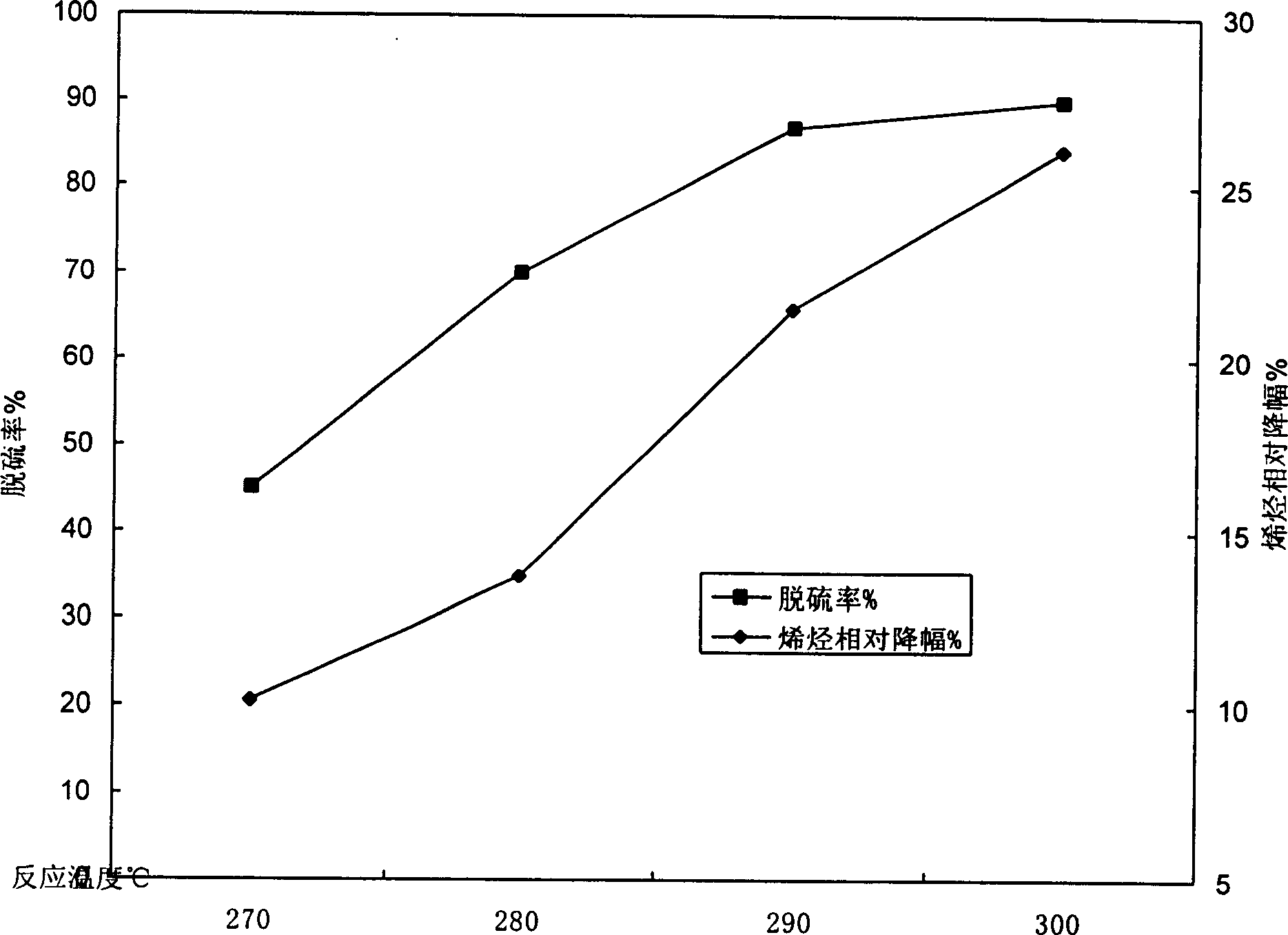

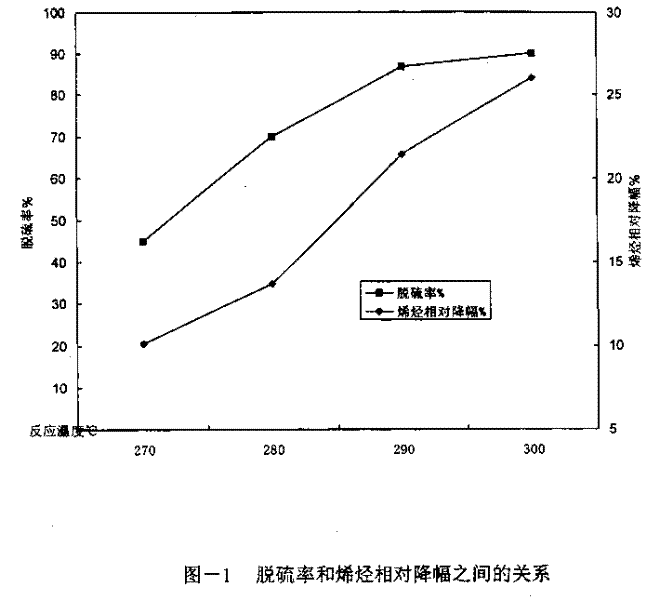

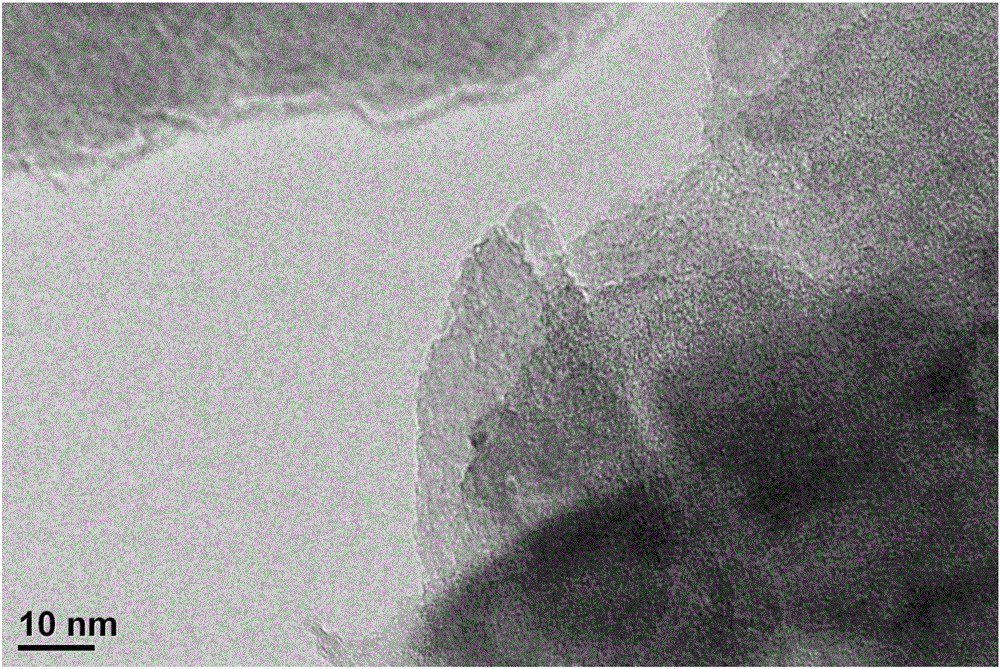

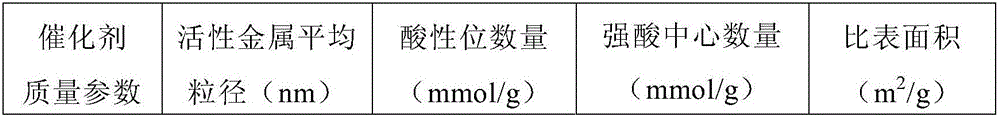

Hydrogenation sweetening catalyst, preparing method and application thereof

ActiveCN102039154AHigh yieldLow hydrogenation activityMolecular sieve catalystsCatalyst activation/preparationMolecular sieveHydrodesulfurization

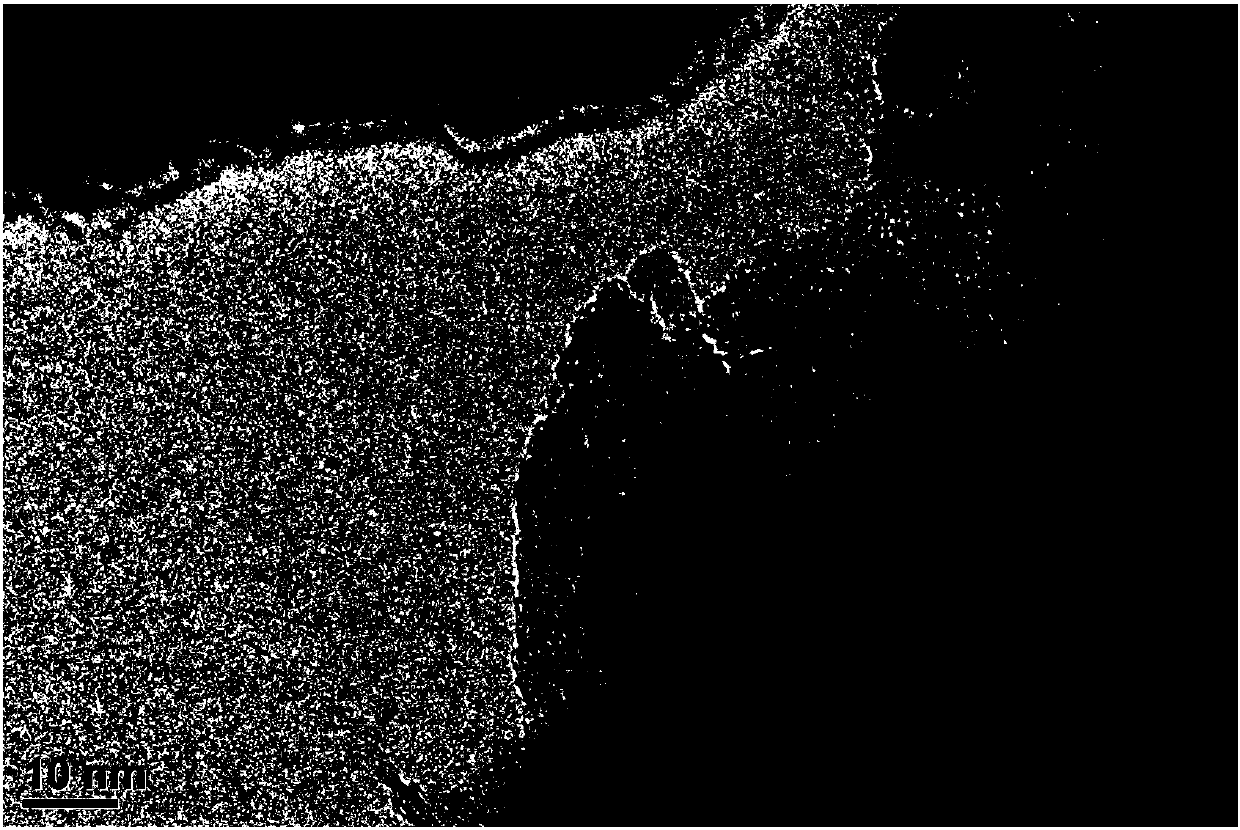

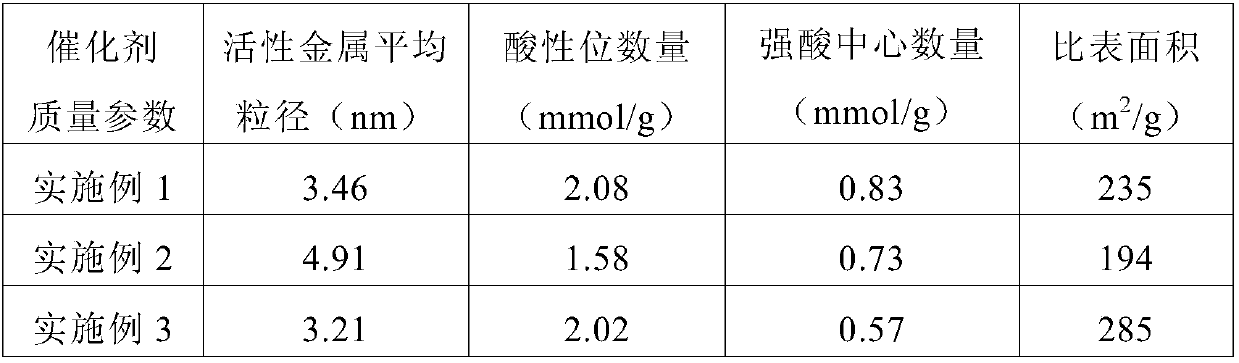

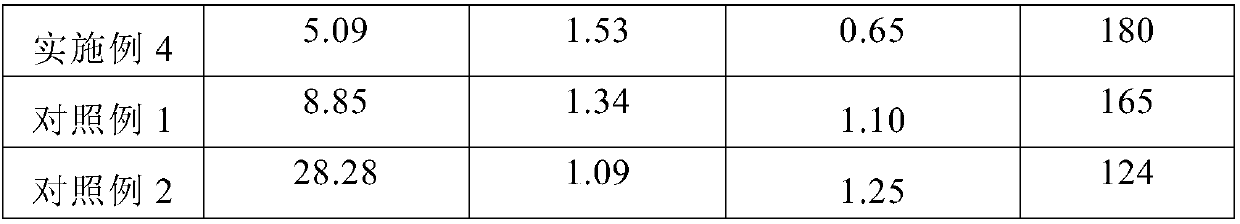

The invention discloses a hydrogenation sweetening catalyst, a preparing method and application thereof. The catalyst has the main carrier component of an HZSM-5 molecular sieve, and the active components of Cu and Zn. The active components contain 5% to 27% of copper oxide and 3% to 15% of zinc oxide according to the weight of oxide, and are prepared by adopting a saturation and co-leaching technique. The catalyst is suitable for selective hydrogenation sweetening reactions of light oil products and has the advantages of high sweetening activity, low olefin hydrogenation activity, high recovery rate of liquid and less octane number loss after reactions and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrodesulfurization method of gasoline

InactiveCN106867576AAdaptableHigh activityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsHydrogenHydrodesulfurization

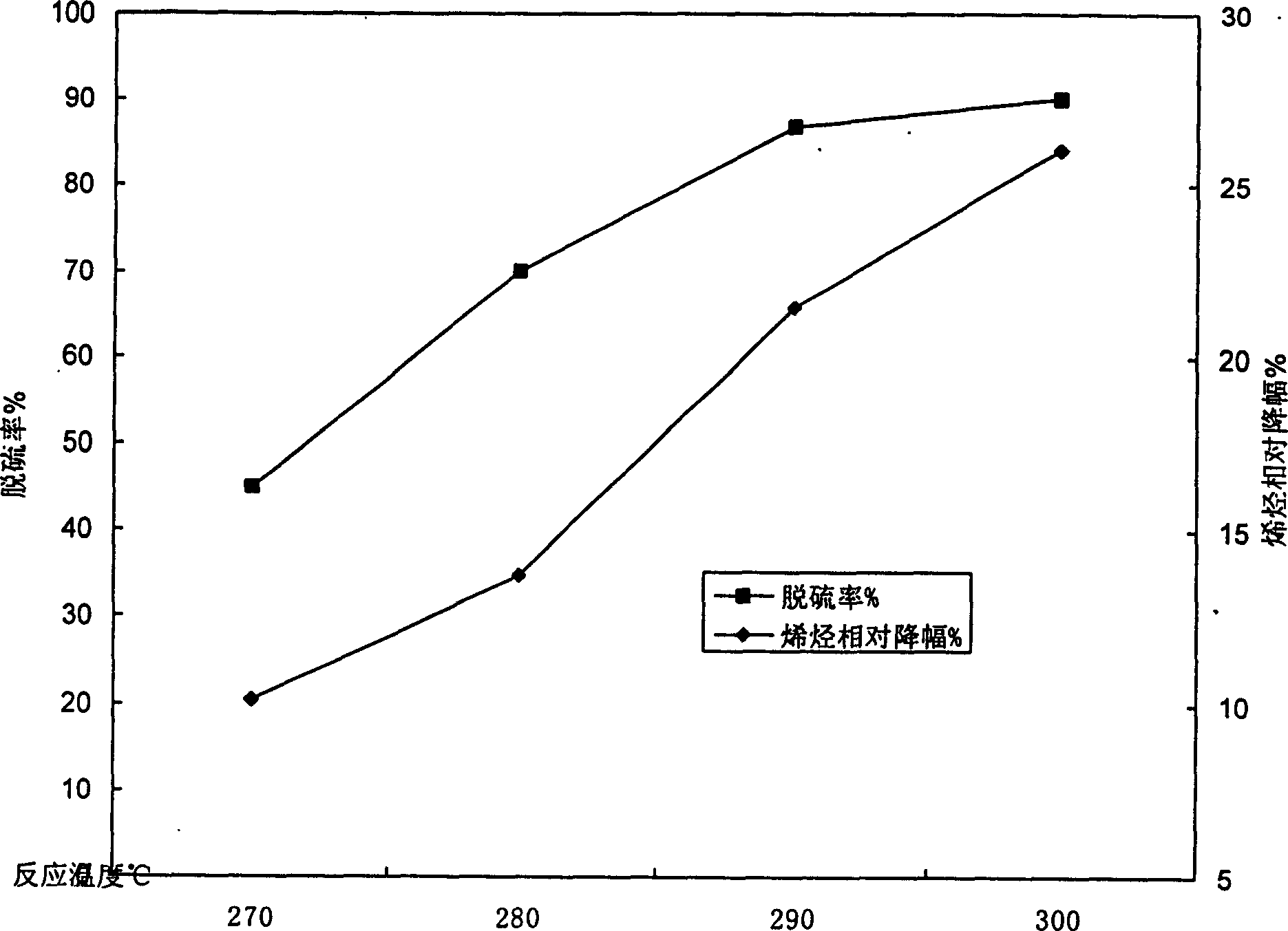

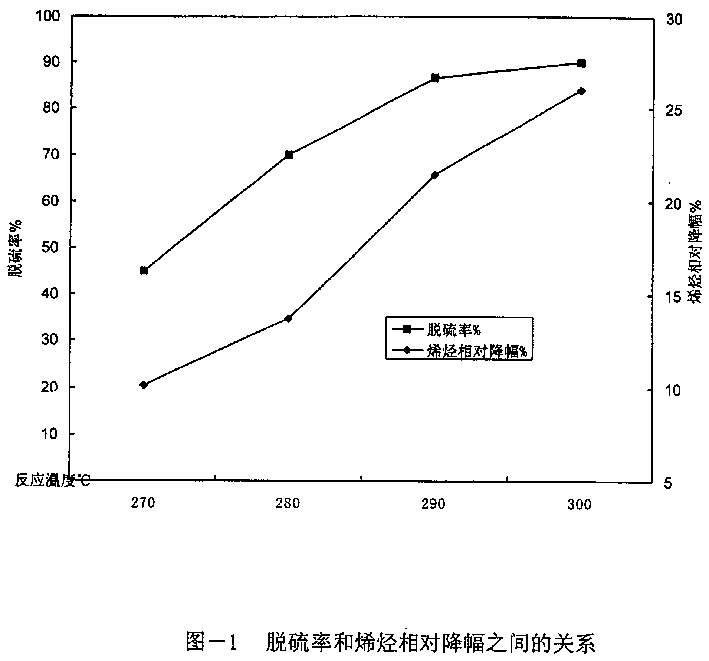

The invention discloses a hydrodesulfurization method of gasoline. The method adopts a fixed bed reactor. The catalyst is a loaded cobalt molybdenum catalyst, the hydrodesulfurization process conditions are: a reaction temperature of 190-310DEG C, a reaction pressure of 1.3-2.6MPa, a volume space velocity of 1.3-3.5h<-1>, and a hydrogen-to-oil volume ratio of 180-400:1. The hydrodesulfurization method provided by the invention has the advantages of mild process conditions, strong adaptability to different raw materials, low octane value and high desulfurization rate.

Owner:QINZHOU UNIV

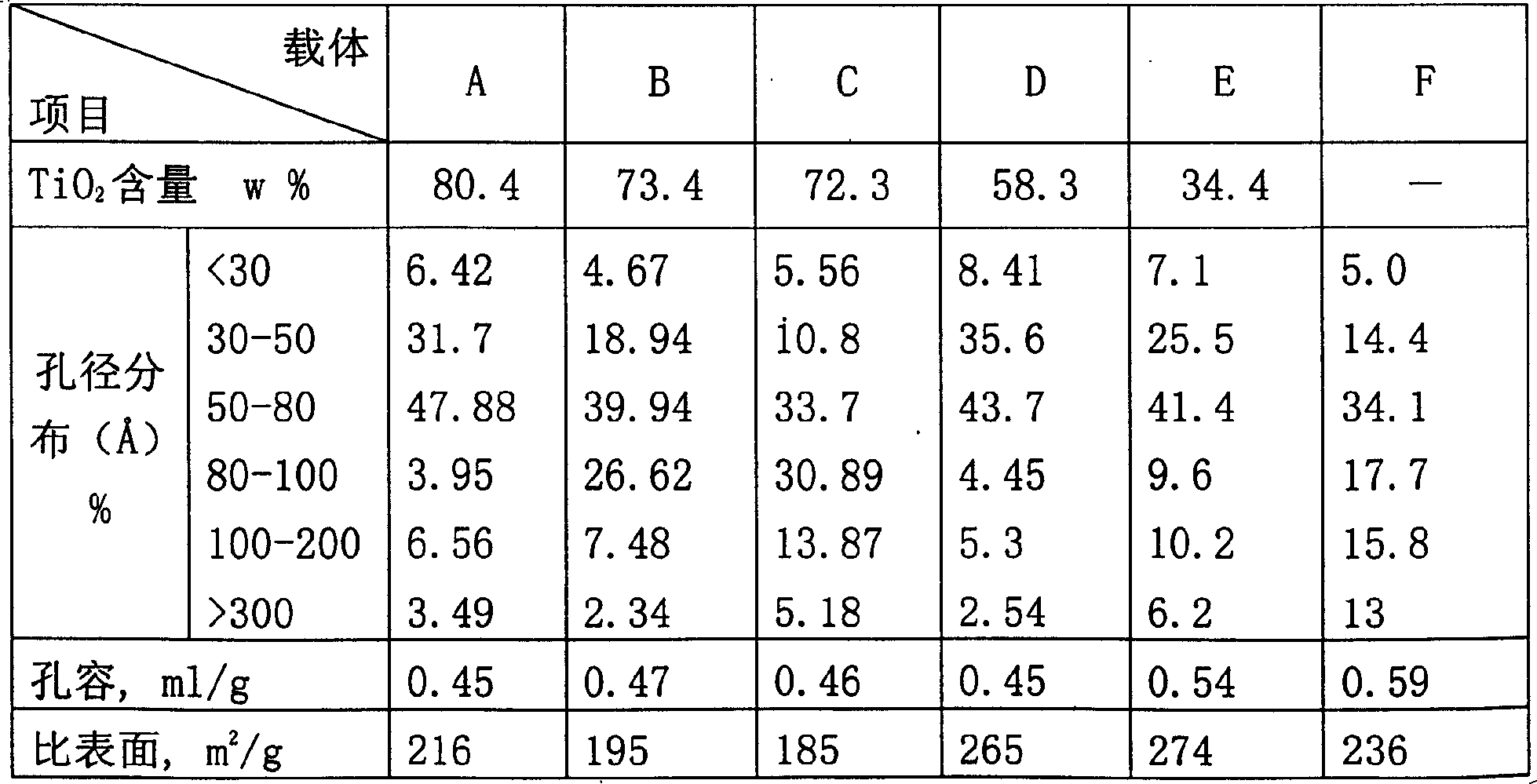

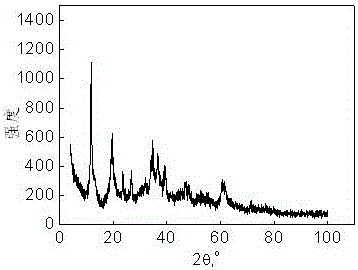

Gasoline hydrogenation catalyst, its prep. and application in lowering olefin by desulfurization

InactiveCN1448471AImprove anti-coking performanceHigh activityRefining to eliminate hetero atomsLiquid productActive component

The gasoline hydrogenating catalyst includes the components of carrier with TiO2 in 20-90 wt%; active component A of VIII metal oxide in 0.1-8 wt%; active component B of VIB metal oxide in 1-13 wt%; and adhesive in the rest content. After being pre-sulfurized, the catalyst of the present invention is used to process FCC gasoline in condition of mild hydrogenation and exhibits very high hydrodesulfurization activity and selectivity. Compared with traditional hydrogenation catalyst, the catalyst of the present invention has less loss of gasoline octane number and higher liquid product yield, up to 99 wt%, in the condition of same hydrodesulfurization level.

Owner:BEIJING HAISHUNDE TITANIUM CATALYST

Method for producing clean gasoline

ActiveCN101161791ALess octane lossImprove adaptabilityTreatment with hydrotreatment processesHydrogenSulfur

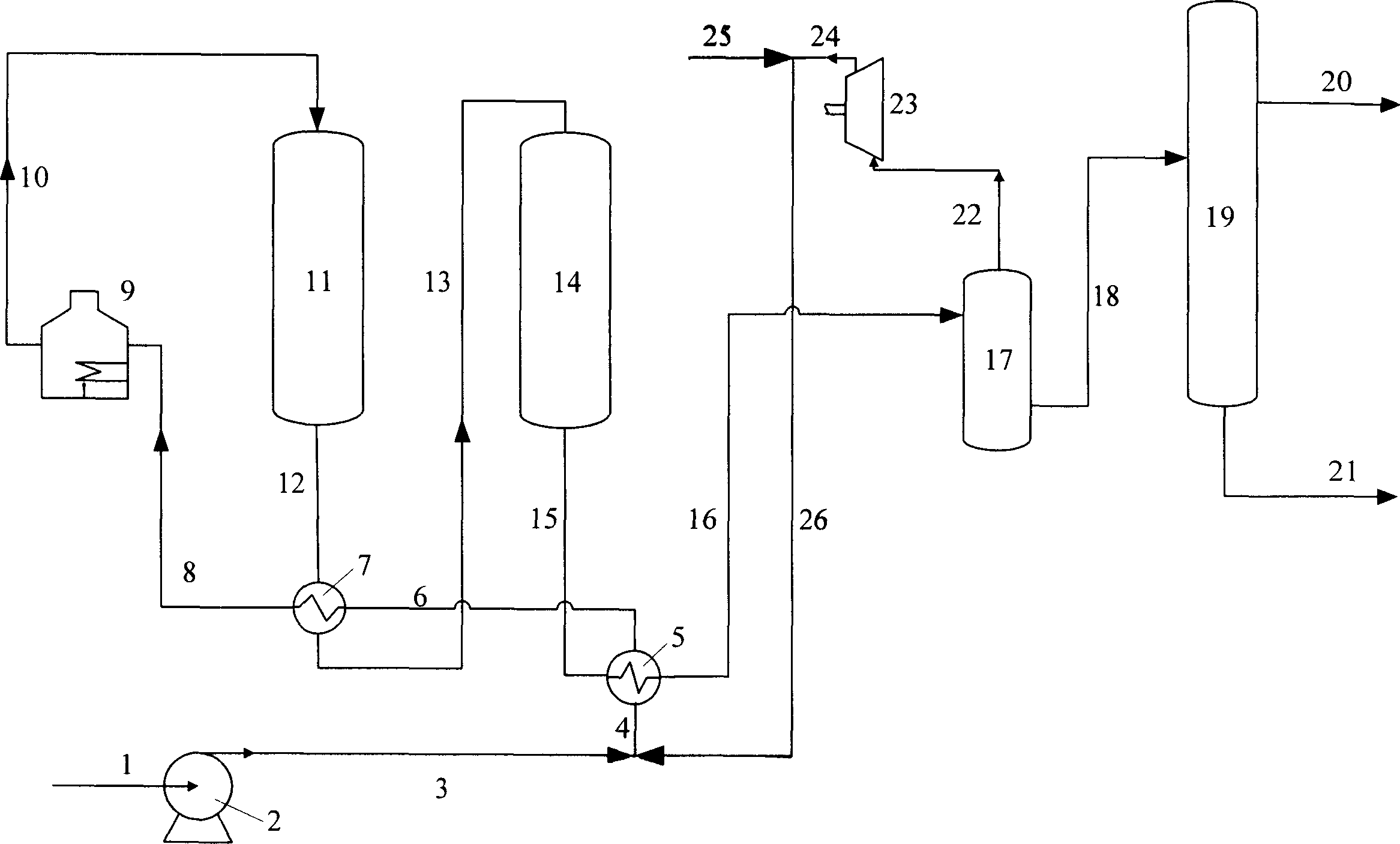

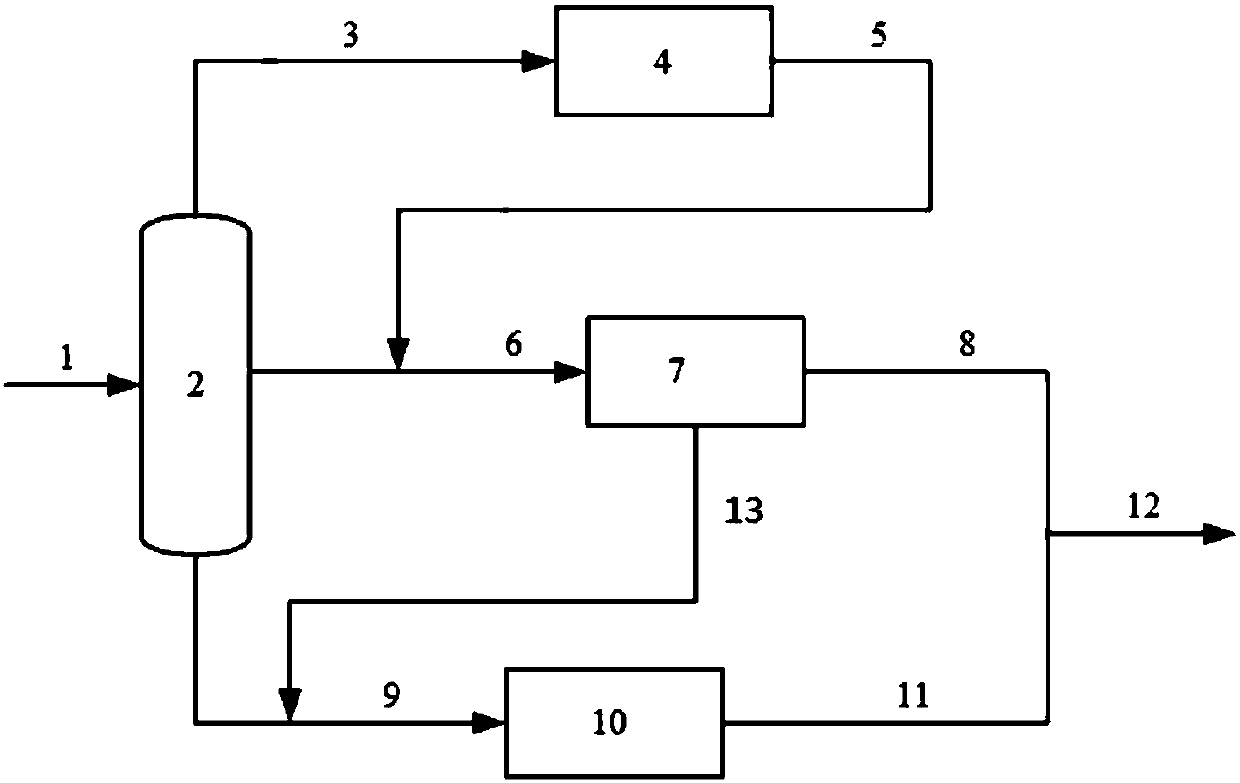

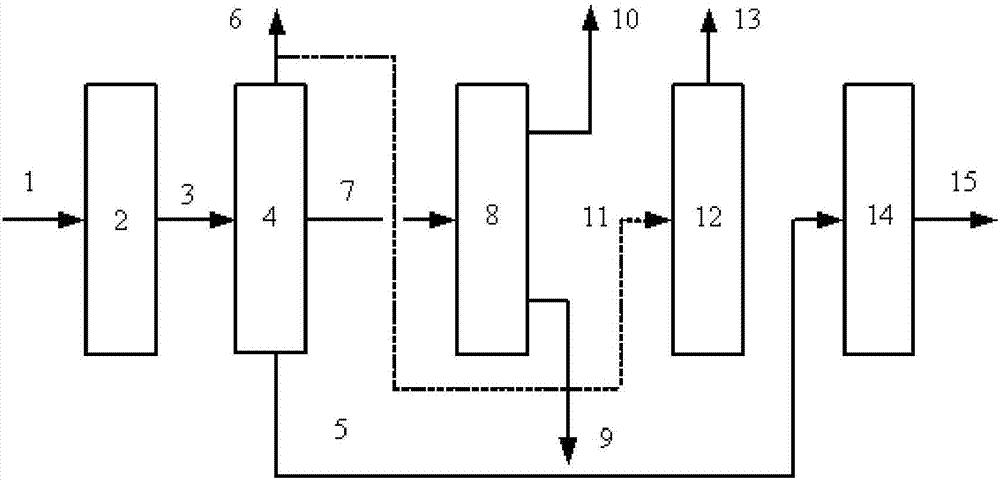

A method for producing clean gasoline adopts the following steps: gasoline raw material and hydrogen are fed into a catalytic distillation tower form the middle part of the tower for fractionation; the fractionated light gasoline fraction and hydrogen pass through the catalyst bed arranged at the upper part of the catalytic distillation tower for hydro-sweetening reaction under the action of hydrofining catalyst so as to obtain hydrogenation light gasoline fraction; the heavy gasoline fraction which flows out from the bottom of the catalytic distillation tower and hydrogen are fed into a hydrogenation reactor for hydrodesulfurization reaction, hydrodenitrogenation reaction, alkene saturated reaction and octane number restoration, etc. under the action of hydrogenation catalyst; finally, the produced hydrogenated heavy gasoline fraction and hydrogenated light gasoline fraction are fed into a stabilizer and gasoline product is output from the bottom of the stabilizer. Through adopting the method, clean gasoline with sulphur content and alkene content meeting the Euro IV gasoline emission standard can be obtained along with low octane number loss.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic process for selective hydrodesulfurization of gasoline

ActiveCN101845321AReduce sulfur contentIncrease liquid collectionTreatment with hydrotreatment processesHydrogenHydrodesulfurization

The invention relates to a catalytic process for selective hydrodesulfurization of gasoline, which comprises the following steps of: performing hydrodesulfurization reaction on heavy gasoline obtained by cutting and fractionating catalytic gasoline under a hydrogenation condition through a catalyst bed, mixing the heavy gasoline and light gasoline subjected to alkaline cleaning, and removing mercaptan to obtain a blended gasoline product, wherein reaction conditions of hydrodesulfurization of the heavy gasoline are that: the temperature is between 150 and 450 DEG C, the pressure is between 1.0 and 5.0MPa, the liquid hourly space velocity is between 1.0 and 6.0 h<-1>, and the hydrogen-gasoline ratio is between 50 and 1,000v / v; and the catalyst takes monomers of Al2O3, TiO2, MgO, SiO2 or composite oxides as a carrier, takes Mo or W and Co or Ni metal as active ingredients and takes P, B or Mg as a modifier. The method can greatly reduce the sulfur content of the catalytic gasoline, wherein the desulfurization rate is no less than 80 percent; and the method can make the octane number loss of gasoline products less, wherein the octane number loss is no more than 1.5 units.

Owner:PETROCHINA CO LTD

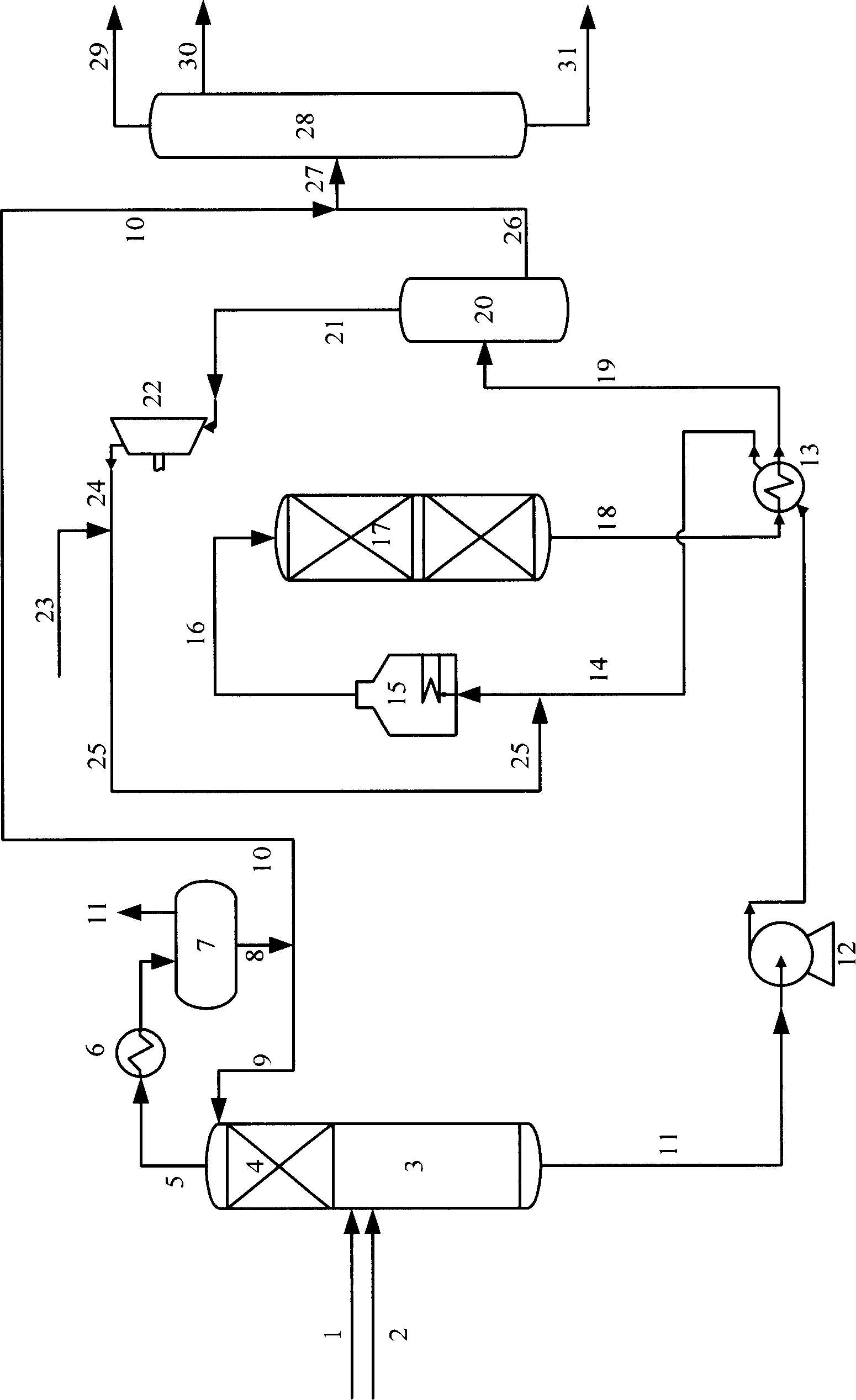

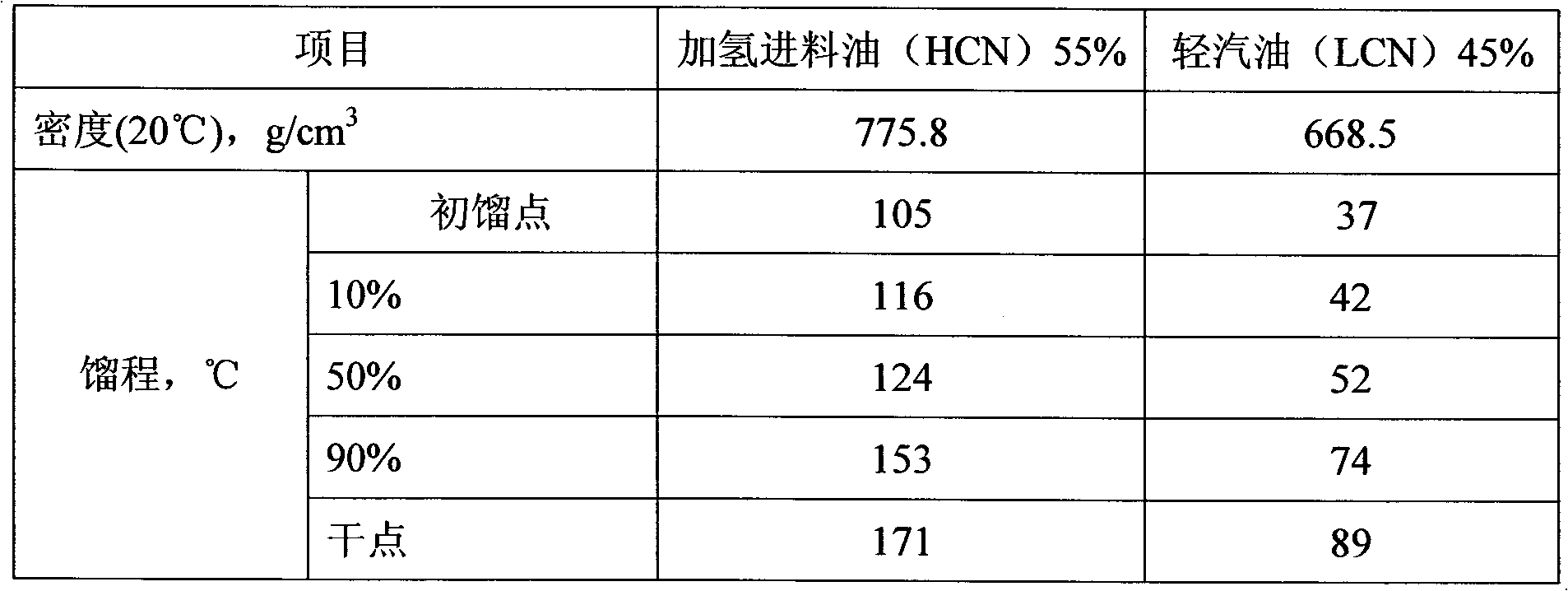

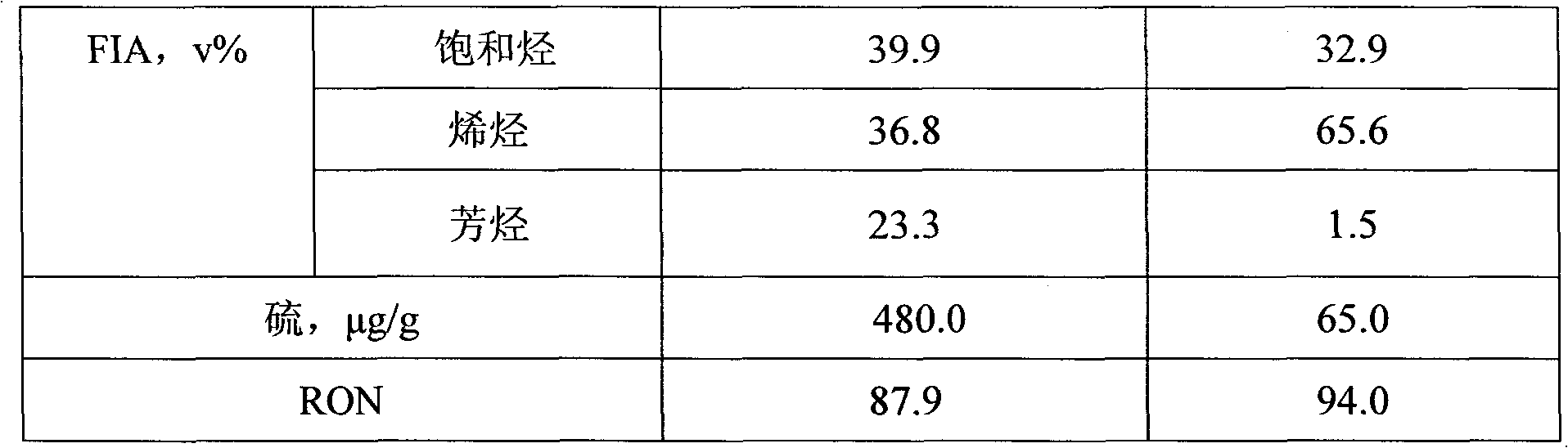

Mixed hydrogenation method for catalytic cracking gasoline and coking diesel oil

ActiveCN103059967AAvoid cokingExtended operating cycleTreatment with hydrotreatment processesAlkali freeHydrodesulfurization

The invention discloses a mixed hydrogenation method for catalytic cracking gasoline and coking diesel oil. The method comprises: subjecting FCC (fluid catalytic cracking) gasoline to alkali-free deodorization, making the deodorized catalytic gasoline enter a prefractionator to be fractionated into light gasoline and heavy gasoline; mixing the heavy gasoline with coking diesel oil, then performing hydrodesulfurization, separating the desulfurization product to obtain hydrogenated heavy gasoline and treated coking diesel oil, and blending the hydrogenated heavy gasoline with the light gasoline to obtain a clean gasoline product. According to the method provided in the invention, when the coking diesel oil and the heavy gasoline are mixed for hydrogenation, the nitride brought in by the coking diesel oil undergoes competitive adsorption at a catalyst hydrogenation center and causes poisoning of the hydrogenation center, thus reducing olefin hydrogenation selectivity and decreasing the octane number loss of hydrogenation. On the other hand, when the mixed feed flows through a heat exchanger and heating furnace, the raw materials are in a gas-liquid mixed phase in the heating furnace and the heat exchanger, so that a coke material can be dissolved and taken away, coking can be avoided in the heat exchanger and the heating furnace, and the operation cycle of the equipment can be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for inferior gasoline modification

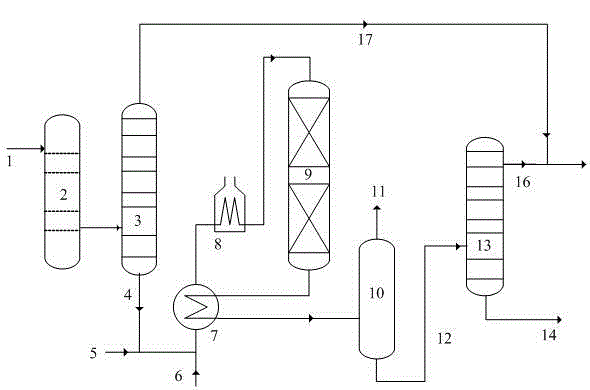

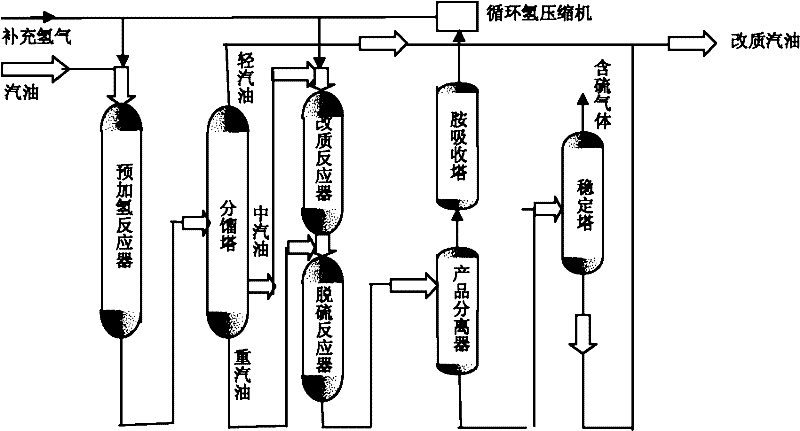

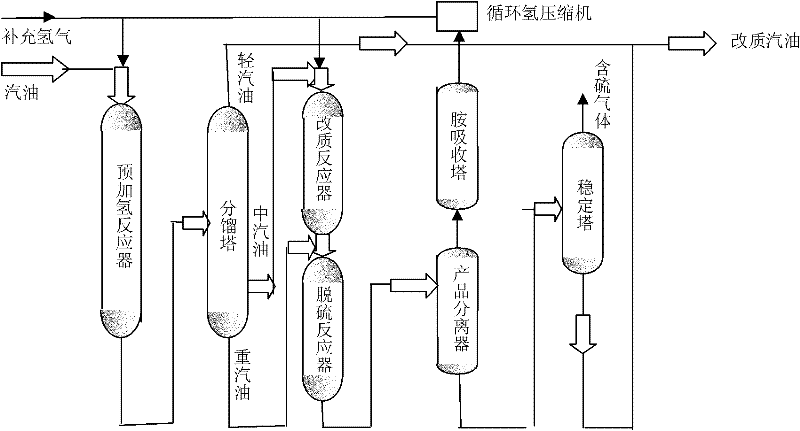

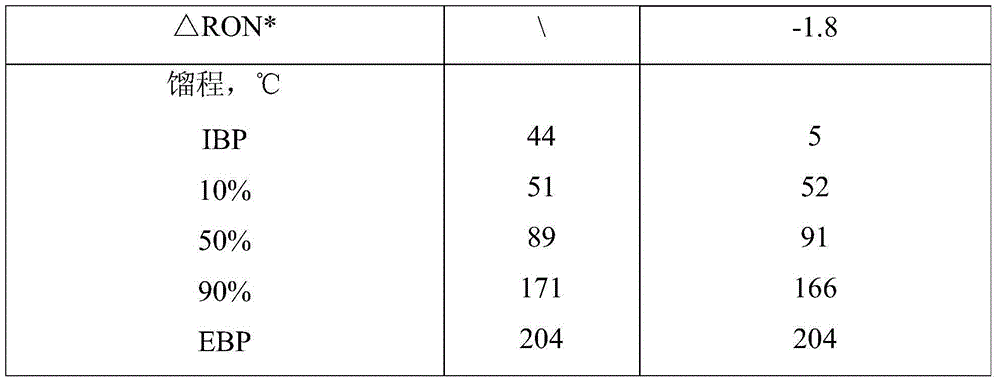

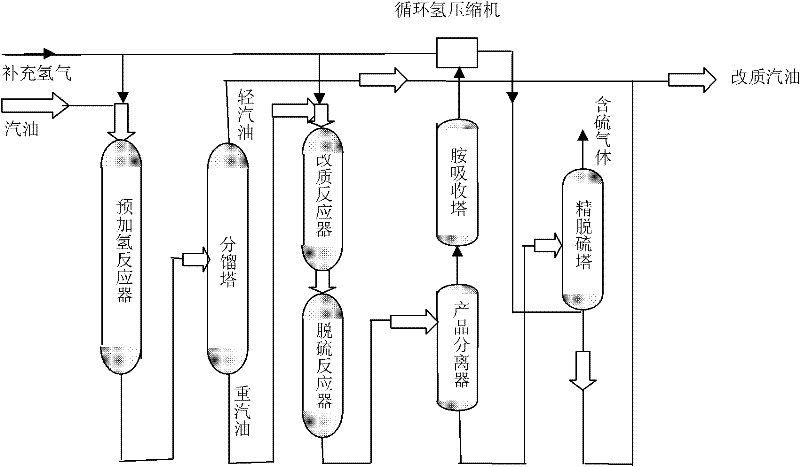

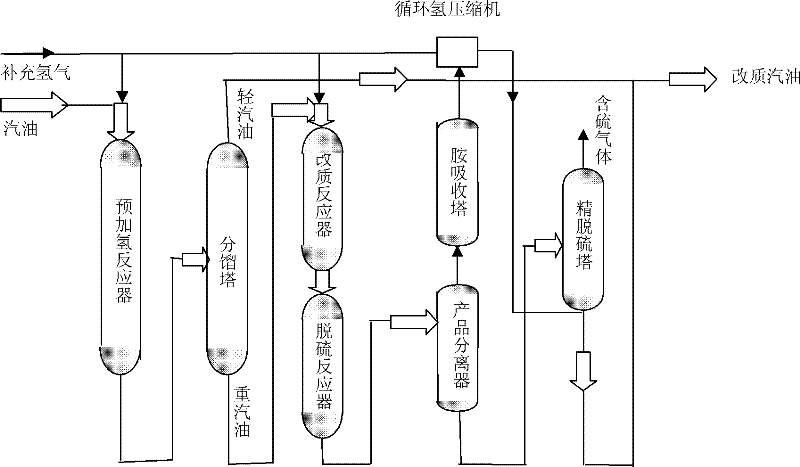

ActiveCN102634368AReduce olefin contentReduced mercaptan contentTreatment with hydrotreatment processesLiquid productIsomerization

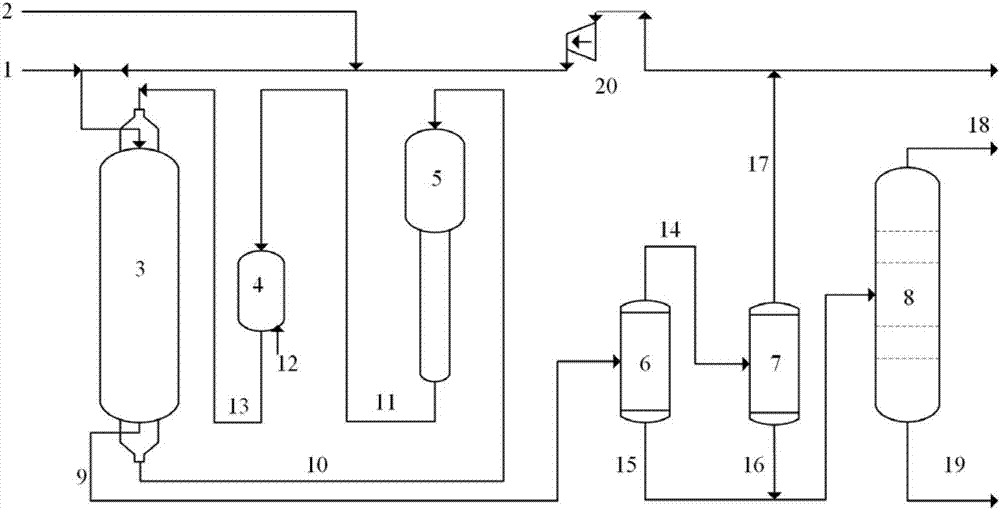

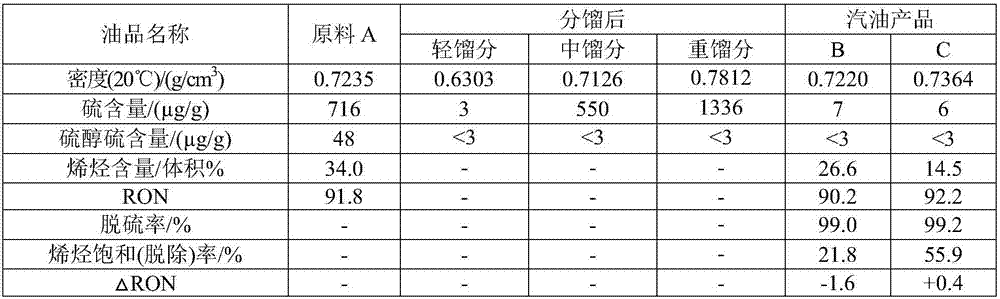

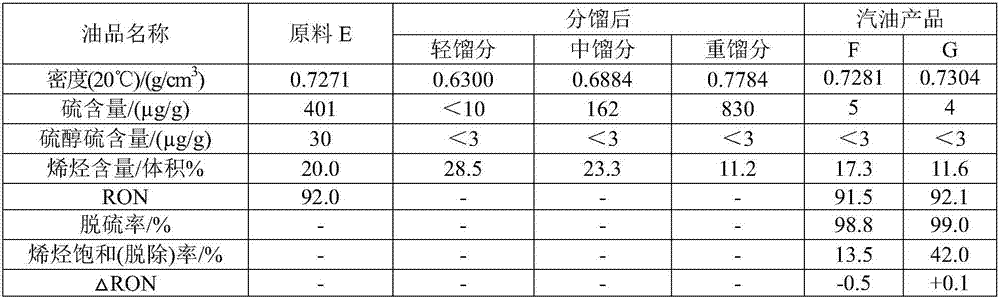

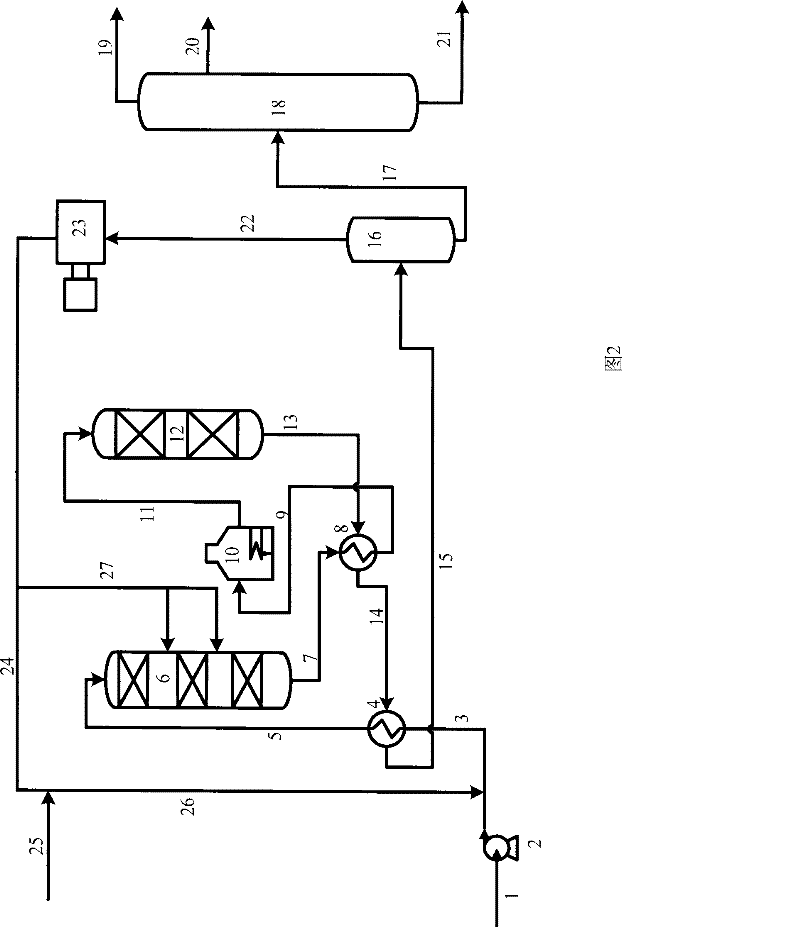

The invention relates to a method for inferior gasoline modification; gasoline raw materials and hydrogen are mixed, and the mixture is allowed to enter a prehydrogenation reactor for dialkene removal; the prehydrogenation products are allowed to enter a fractionating tower so as to cut the gasoline into light, medium, and heavy components; light gasoline from the tower top is directly used as a clean gasoline blending component; the medium gasoline component from the lower section of the fractionating tower is allowed to enter a hydrogenation modification reactor firstly for reactions such as aromatization, isomerization, and the like, then to mix with heavy gasoline from the bottom of the fractionating tower and to enter a hydrodesulfurization reactor; materials from the hydrodesulfurization reactor is cooled, and is allowed to enter a product separation device for gas-liquid separation; hydrogen from the gas-liquid separation device is treated by desulphurization and then recycled; liquid products enter a product stabilization tower to remove light hydrocarbon and hydrogen sulfide generated during the reaction, and then are mixed with the light gasoline to obtain the modified gasoline products; the method of the invention can greatly reduce sulfur and alkene contents in gasoline, and can reduce octane number loss due to the modification process.

Owner:PETROCHINA CO LTD

Gasoline hydrogenation catalyst, its prep. and application in lowering olefin by desulfurization

InactiveCN1218021CImprove anti-coking performanceHigh activityRefining to eliminate hetero atomsLiquid productActive component

The gasoline hydrogenating catalyst includes the components of carrier with TiO2 in 20-90 wt%; active component A of VIII metal oxide in 0.1-8 wt%; active component B of VIB metal oxide in 1-13 wt%; and adhesive in the rest content. After being pre-sulfurized, the catalyst of the present invention is used to process FCC gasoline in condition of mild hydrogenation and exhibits very high hydrodesulfurization activity and selectivity. Compared with traditional hydrogenation catalyst, the catalyst of the present invention has less loss of gasoline octane number and higher liquid product yield, up to 99 wt%, in the condition of same hydrodesulfurization level.

Owner:BEIJING HAISHUNDE TITANIUM CATALYST

Hydrodesulfurization method of catalytic cracking gasoline

ActiveCN106635135AAdaptableHigh activityHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsMolybdateHydrogen

The invention relates to a hydrodesulfurization method of catalytic cracking gasoline. A fixed bed reactor is adopted, wherein the catalyst is a supported cobalt-molybdate catalyst; and the hydrodesulfurization method comprises the following technologic conditions: the reaction temperature is 180-310 DEG C, the reaction pressure is 1.5-2.5MPa, the volume velocity is 1.5-3.5h<-1> and the volume ratio of hydrogen to oil is (180-400):1. The hydrodesulfurization method is mild in technologic conditions, high in adaptive capacity on different raw materials, low in octane value loss and high in desulfurization rate.

Owner:LANZHOU PETROCHEM COLLEGE OF VOCATIONAL TECH

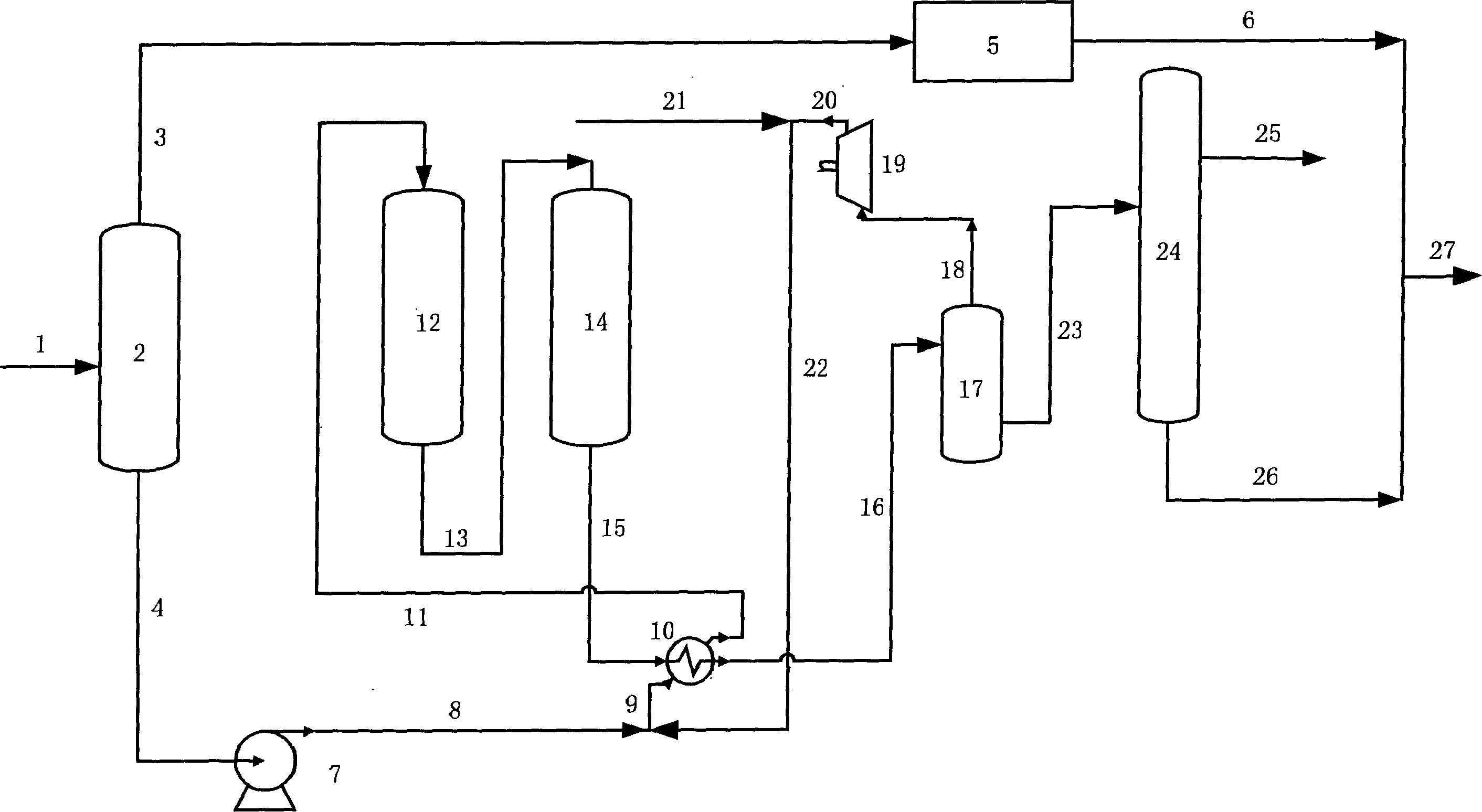

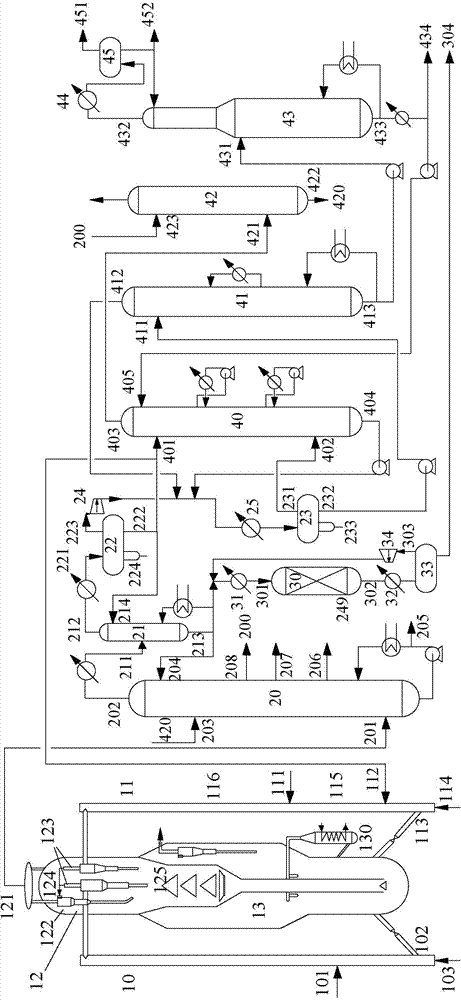

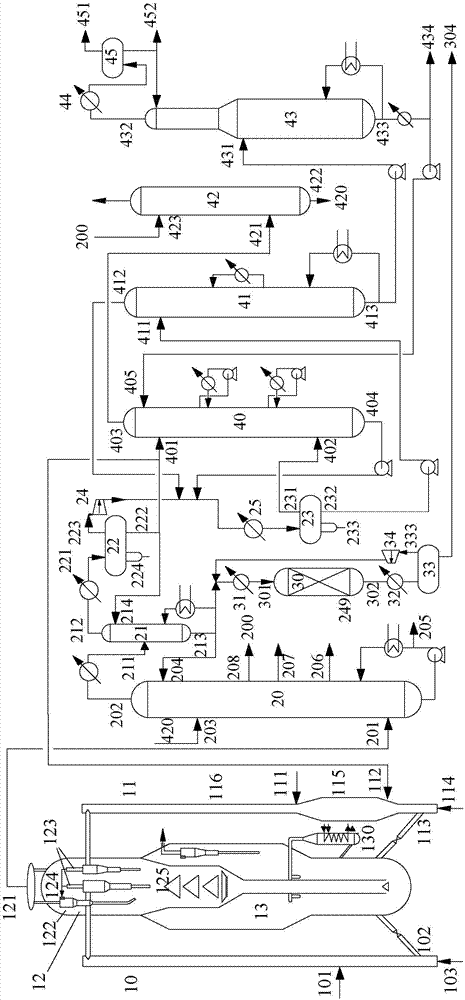

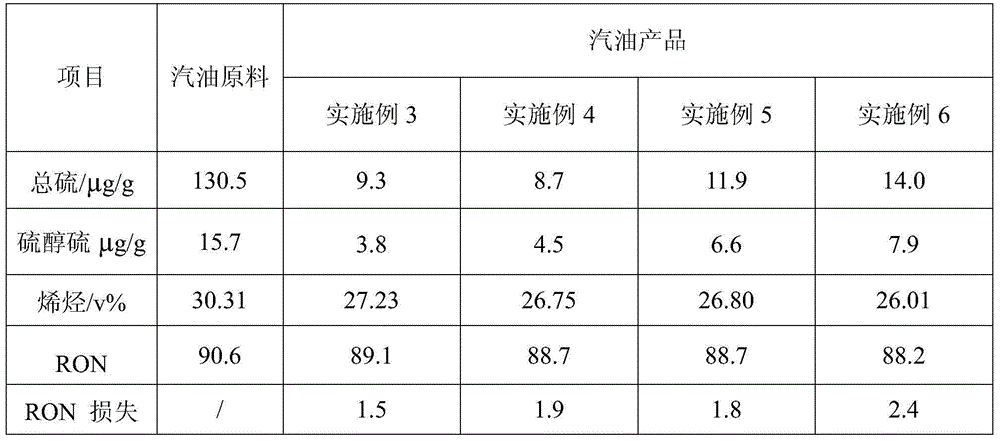

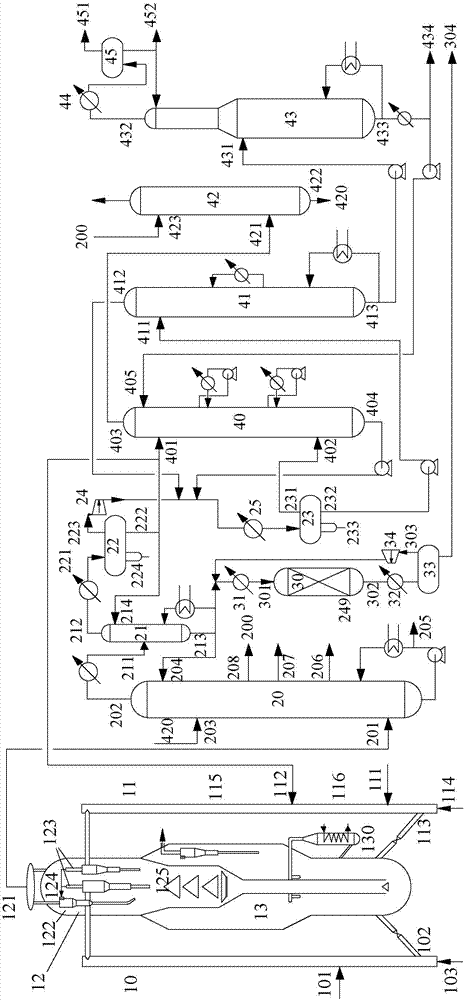

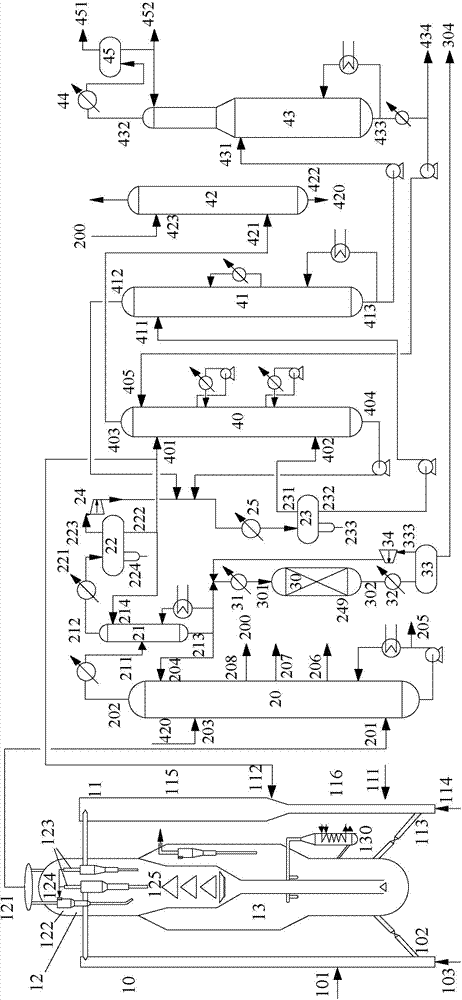

Device and method for producing clean gasoline and increasing propylene yield through catalytic cracking and hydrogenation

InactiveCN103571536APromote absorptionReduce Saturation RequirementsTreatment with hydrotreatment processesGasolineTower

The invention discloses a device and method for producing clean gasoline and increasing propylene yield through catalytic cracking and hydrogenation. The device comprises a reaction-regeneration system, a fractionating system, an absorption stable system and a hydrofining unit. The method comprises the following steps: adding a gasoline fractionating tower to the top of a catalytic cracking fractionating tower to divide crude gasoline into a light fraction and a heavy fraction, wherein the heavy gasoline enters the hydrogenation unit for refining, and one part of the light gasoline enters the absorption stable system to obtain stable light gasoline, and the other part of the light gasoline directly returns to the upper part of a catalytic cracking riser reactor to be cracked to increase the propylene yield under a relatively harsh reaction condition; and finally, blending the stable light gasoline and the modified heavy gasoline to obtain the product of clean gasoline. By adopting the method, the catalytic cracking gasoline is efficiently modified, the propylene yield is increased, and the catalyst-oil ratio of a catalytic cracking device can be increased to promote the conversion of heavy petroleum hydrocarbon; and meanwhile, the load and energy consumption of the absorption stable system are reduced, the process is simplified, the synergistic effect between the two devices of catalytic cracking and hydrofining is enhanced, and the processing cost is lowered.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

Deep desulfurization method of gasoline

ActiveCN104650975AReduce the severity of the reactionReduce lossesTreatment with hydrotreatment processesHydrodesulfurizationGasoline

The invention relates to a deep desulfurization method of gasoline. A gasoline raw material firstly enters a first reactor to remove dialkene and simultaneously mercaptan becomes heavier; the gasoline raw material then enters a fractionating tower to be cut and fractioned into light and heavy gasoline; heavy gasoline enters a second reactor to remove the vast majority of sulfide, and a reaction product enters a third reactor to further undergo desulfurization; and a heavy gasoline hydrodesulfurization product obtained is mixed with the light gasoline so as to obtain a qualified gasoline product. By additionally arranging the third reactor after the second reactor, further deep desulfurization is realized. Meanwhile, reaction severity of the second reactor is remarkably reduced, and octane number loss and hydrogen-consumption optimization are realized.

Owner:PETROCHINA CO LTD

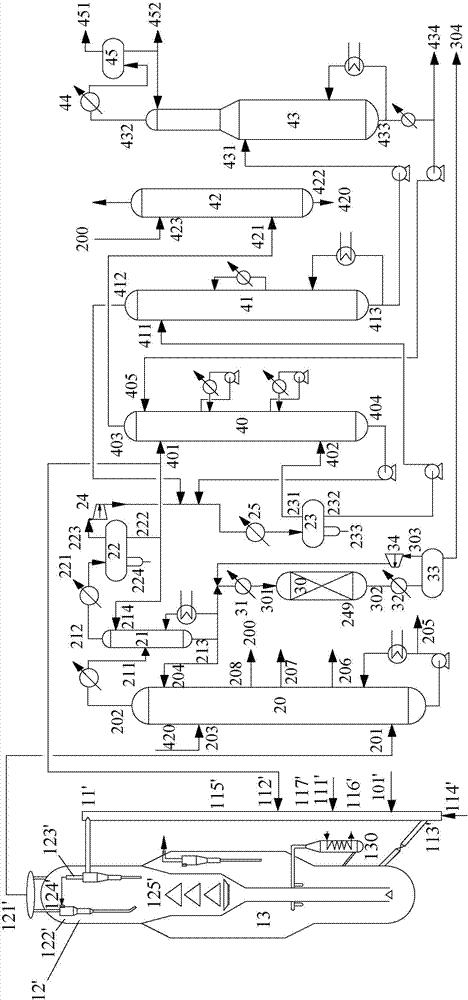

Device and method for producing clean gasoline by combining catalytic cracking and hydrofining

InactiveCN103571534APromote absorptionReduce loadTreatment with hydrotreatment processesGasolineTower

The invention discloses a device and method for producing clean gasoline by combining catalytic cracking and hydrofining. The device comprises a reaction-regeneration system, a fractionating system, an absorption stable system and a hydrofining unit. The method comprises the following steps: adding a gasoline fractionating tower to the top of a catalytic cracking fractionating tower to divide crude gasoline into a light fraction and a heavy fraction, wherein the heavy fraction gasoline enters the hydrofining unit for selective hydrogenation desulfurization, and one part of the light fraction gasoline enters the absorption stable system to obtain stable light gasoline, and the other part of the light fraction gasoline directly returns to a reaction area at the upper part of a catalytic cracking second riser reactor to be modified under a mild condition; and blending the stable light gasoline and the modified heavy gasoline to obtain the product of clean gasoline. By adopting the method, the catalytic cracking gasoline is efficiently modified, and the catalyst-oil ratio of a catalytic cracking device can be increased to promote the conversion of heavy petroleum hydrocarbon; and meanwhile, the load and energy consumption of the absorption stable system are reduced, the synergistic effect between the two devices of catalytic cracking and hydrofining is enhanced, and the processing cost is lowered.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

Selective hydrodesulfurization catalyst and desulfurization method

InactiveCN106311316AHigh desulfurization rateLess octane lossMolecular sieve catalystsHeterogenous catalyst chemical elementsHydrodesulfurizationAdditive ingredient

The invention provides a selective hydrodesulfurization catalyst and a desulfurization method. The main ingredient of the selective hydrodesulfurization catalyst is obtained in the manner that metal-salt-treated metallic oxide serves as a carrier and is loaded with an reactive metal ingredient, wherein the reactive metal is selected from two or more elements in the groups IA, VIII, VIB and VIIB in the periodic table. Besides, according to the selective hydrodesulfurization method, extractive distillation is carried out on a gasoline raw material, and selective hydrodesulfurization is carried out with the selective hydrodesulfurization catalyst. The desulfurization method is low in energy consumption and high in desulfurization rate; besides, the octane value loss of desulfurized gasoline is small.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for desulfurizing and reducing olefine for gasoline

The process of desulifurizing gasoline and reducing olefin content includes contacting gasoline material with hydrogen and hydrogen isomerization catalyst for hydrogen desulfurizing, saturating olefin, isomerizing olefin and cracking olefin; contacting the reaction effluent with selectively hydrogen desulfurizing catalyst; and separating hydrogen desulfurizing produced oil to obtain light olefin and gasoline fractions; and circulating the hydrogen-rich gas. The said process can produce high quality gasoline with low sulfur and olefin content and lowest octane number loss.

Owner:CHINA PETROLEUM & CHEM CORP +1

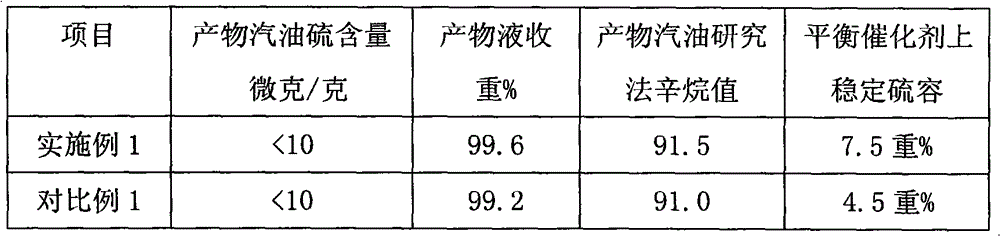

Catalytic cracking gasoline adsorption desulfurizing agent as well as preparation method and application thereof

InactiveCN107159096AReduce hydrogenation saturationReduced chemical hydrogen consumption and octane lossOther chemical processesHydrocarbon oils refiningSulfur contentAdsorption reaction

The invention relates to an adsorption desulfurizing method for catalytic cracking gasoline. The method comprises the following steps: S201, carrying out an adsorption desulfurizing reaction between the catalytic cracking gasoline and an adsorption desulfurizing agent under a hydrogen present condition, and obtaining a desulfurization product and an inactivated desulfurizing agent; S202, separating and purifying the adsorption desulfurizing product, thereby obtaining gasoline components with the sulfur content of less than or equal to 10<mu>g.g<-1>. With the adoption of the method provided by the invention, hydrogenation saturation of olefins can be effectively reduced while realizing ultra-deep reaction adsorption desulfurization of high-sulfur inferior catalytic cracking gasoline, and chemical hydrogen consumption and octane loss are reduced. Moreover, the adsorption desulfurizing agent provided by the invention has the advantages of high sulfur capacity, low wear rate, low adsorption reaction temperature, capability of obviously reducing operating cost and the like. Meanwhile, the adsorption desulfurizing agent provided by the invention can realize continuous regeneration on line, so that the defect that the running period of the adsorption desulfurizing agent is low due to inactivation is overcome.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for improving selectivity of catalyst

ActiveCN104549556ADecreased Hydrogen SaturationReduced activityCatalyst regeneration/reactivationCatalyst activation/preparationHydrogenation reactionAtmosphere

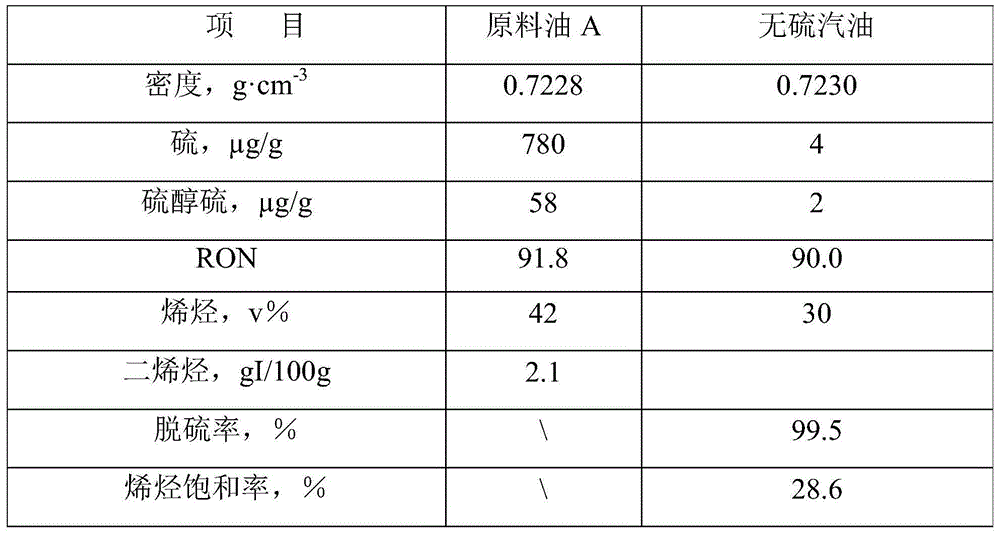

The invention relates to a method for improving selectivity of a catalyst. A catalyst selectivity regulation and control process is increased between a desulfurization process and a normal production process, and the catalyst selectivity regulation and control process is that activity catalytic raw materials are in contact with the catalyst for 24-96h in an atmosphere of activity catalytic gas under activity catalytic reaction conditions, wherein the activity catalytic gas comprises hydrogen gas and hydrogen sulfide, and based on the whole activity catalytic gas, the volume fraction of the hydrogen gas is not less than 70%, and the volume fraction of hydrogen sulfide is 0.2%-5%; and the normal production process is that gasoline raw material is in contact with the catalyst in the atmosphere which is rich in the hydrogen gas under normal reaction conditions to be in hydrogenation reaction. By adopting the method provided by the invention, the selectivity of the catalyst can be improved. Compared with the prior art, under the situation that the sulfur content in a gasoline product is the same, the olefin saturation rate is lower and the loss in octane number of a product is smaller.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for improving desulfurization selectivity of catalyst

ActiveCN104560133AReduced activityHigh selectivityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsSaturation rateRaw material

The invention relates to a method for improving desulfurization selectivity of a catalyst. A catalyst selectivity regulation and control process is increased between a desulfurization process and a normal production process, and the catalyst selectivity regulation and control process is that activity catalytic raw materials are in contact with the catalyst for 24-96h in an atmosphere of activity catalytic gas under activity catalytic reaction conditions. By adopting the method provided by the invention, the selectivity of the catalyst can be improved. Compared with the prior art, under the situation that the sulfur content in a gasoline product is the same, the olefin saturation rate is lower and the loss in octane number of a product is smaller.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for lowering gasoline sulphur content

ActiveCN106147839AReduce lossesGuaranteed service lifeTreatment with hydrotreatment processesHydrogenGasoline

Disclosed is a method for lowering the gasoline sulphur content. Gasoline raw materials are fractionized into light fraction gasoline and heavy fraction gasoline, the light fraction gasoline enters an alkali extraction unit, and refined light fraction gasoline is obtained, after heavy fraction gasoline and hydrogen are mixed, the mixture enters a first hydrogenation reactor, a second hydrogenation reactor and a third hydrogenation reactor in sequence to make contact with a first selective hydrogenation diene removal catalyst and a second selective hydrogenation diene removal catalyst II for reactions, the first selective hydrogenation diene removal catalyst and the second selective hydrogenation diene removal catalyst are subjected to selectivity control treatment respectively, and reaction effluents of the third hydrogenation reactor are separated to obtain hydrogenation heavy fraction gasoline. The refined light fraction gasoline and hydrogenated heavy fraction gasoline are mixed to obtain an ultralow sulfur gasoline product. The method can treat high-sulfur high-olefin catalytic gasoline, the product sulfur content is smaller than 10 microgram / g, octane value losses are small, and the gasoline yield reaches 99% or above.

Owner:CHINA PETROLEUM & CHEM CORP +1

Deep desulfurization method for gasoline

ActiveCN102994148AAdd weight gain stepsHigh yieldTreatment with hydrotreatment processesHydrodesulfurizationCatalytic distillation

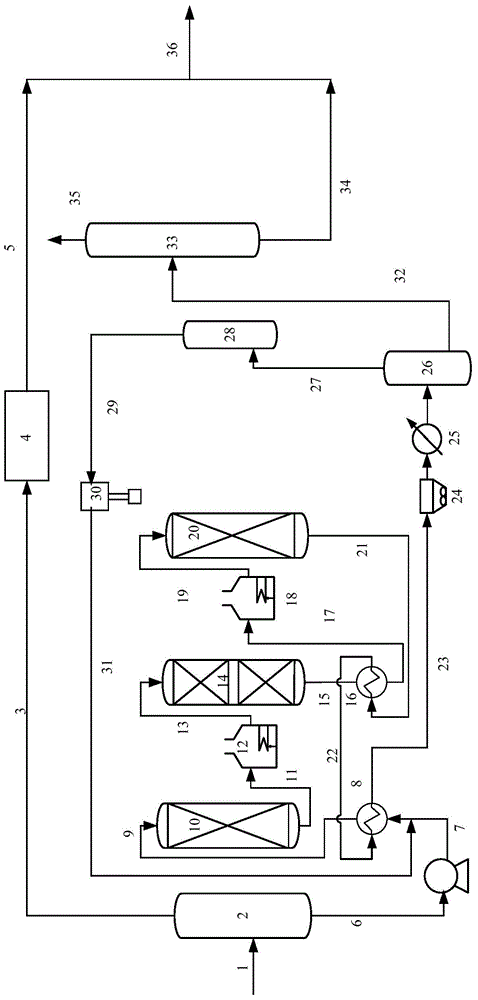

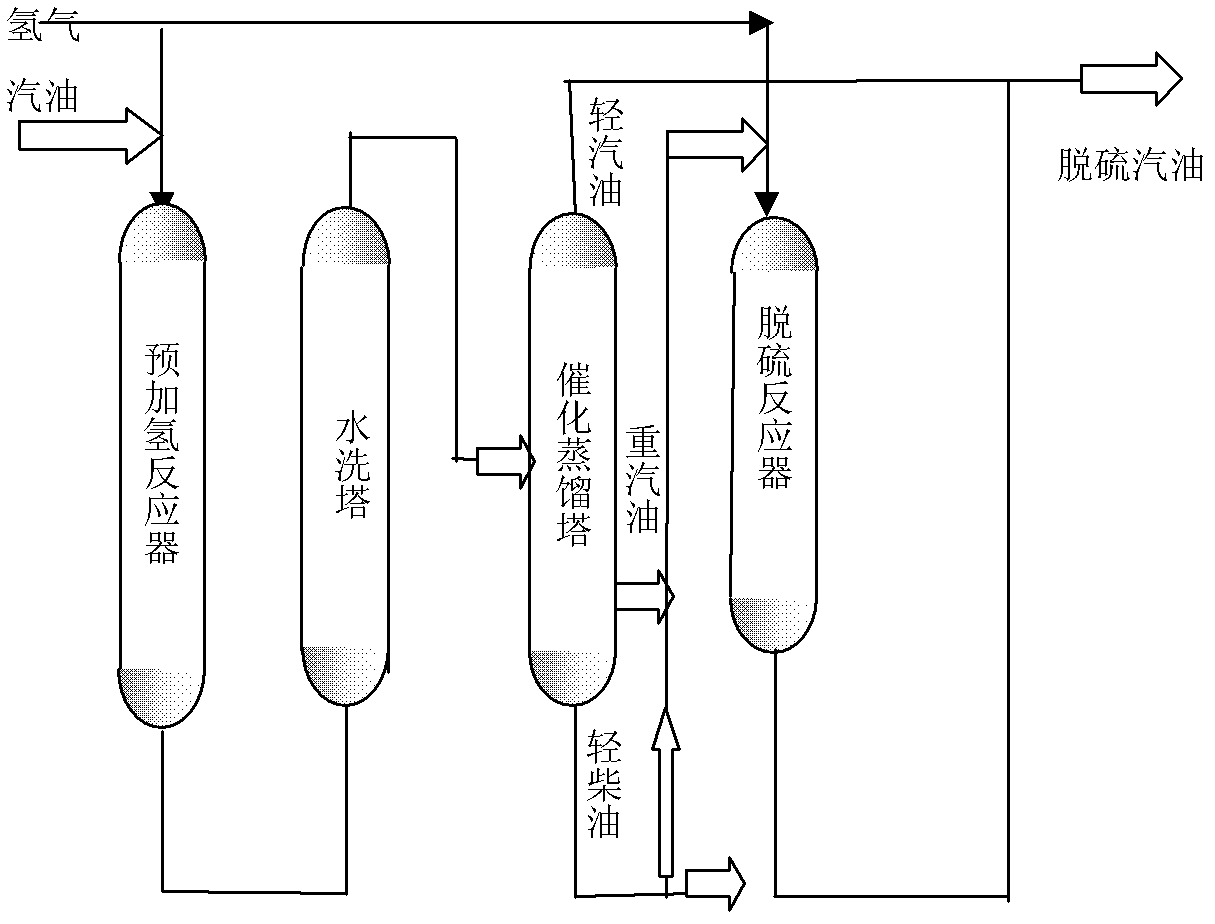

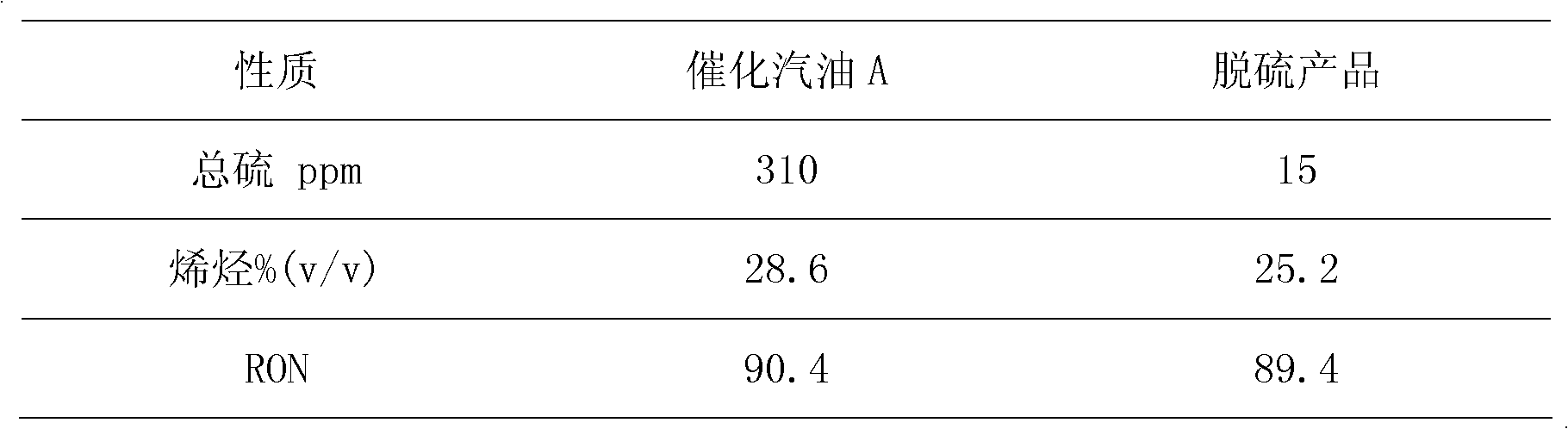

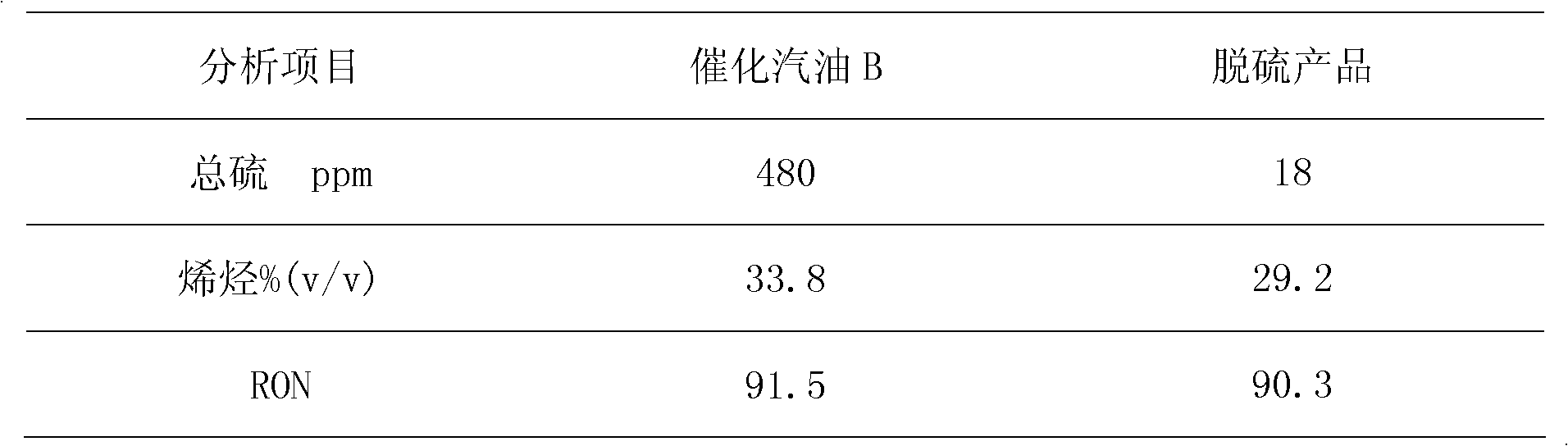

The present invention relates to a deep desulfurization method for a gasoline. According to the method, a gasoline raw material and hydrogen are mixed, and then enter a pre-hydrogenation reactor to carry out hydrogenation on diene in catalytic gasoline to obtain mono olefin; the pre-hydrogenation product enters a water washing tower to carry out water washing, partial alkaline nitrides in the gasoline is removed, the obtained material enters a catalytic distillation tower, partial thiophene sulfides in the gasoline is subjected to weight gain under an effect of an olefin thiophene alkylation catalyst on the upper portion of the catalytic distillation tower, and concurrently the gasoline is divided into three components such as light gasoline, heavy gasoline and light diesel oil; the heavy gasoline component enters a selective hydrodesulfurization reactor to carry out deep desulfurization, hydrogen sulfide generated during the reaction is removed from the desulfurization product, and the hydrogen sulfide-removed desulfurization product is mixed with the light gasoline to obtain the deep desulfurization gasoline product; and light diesel oil on the bottom of the tower is adopted as a hydrodesulfurization raw material, or is adopted as low freezing point diesel oil blending component to be subjected to blending producing. With the method, sulfur content in gasoline can be substantially reduced, and octane number loss caused by the deep desulfurization process can be reduced.

Owner:PETROCHINA CO LTD

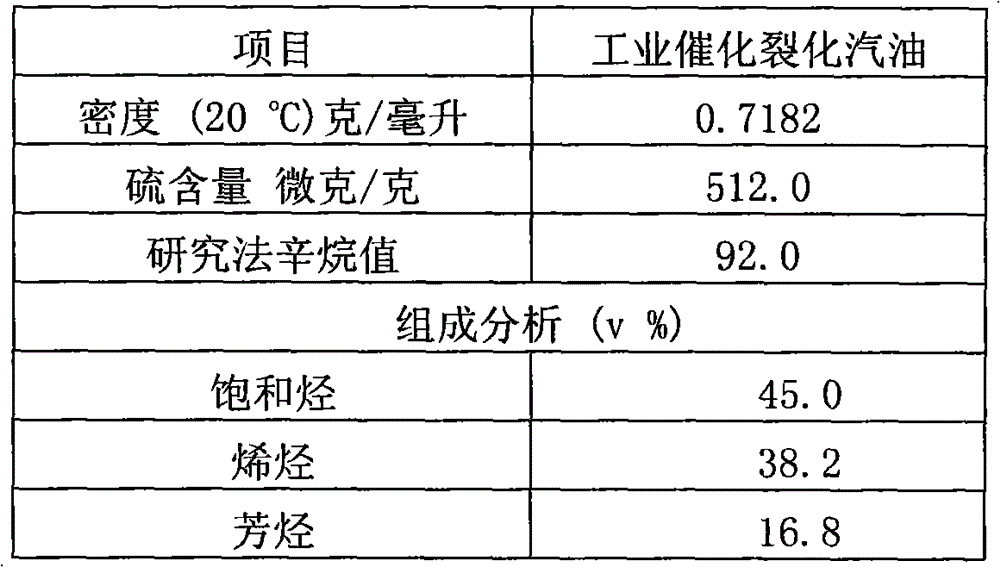

Method for hydro-upgrading inferior gasoline

ActiveCN106929099AReduced diene contentReduced mercaptan contentTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrogenSulfur

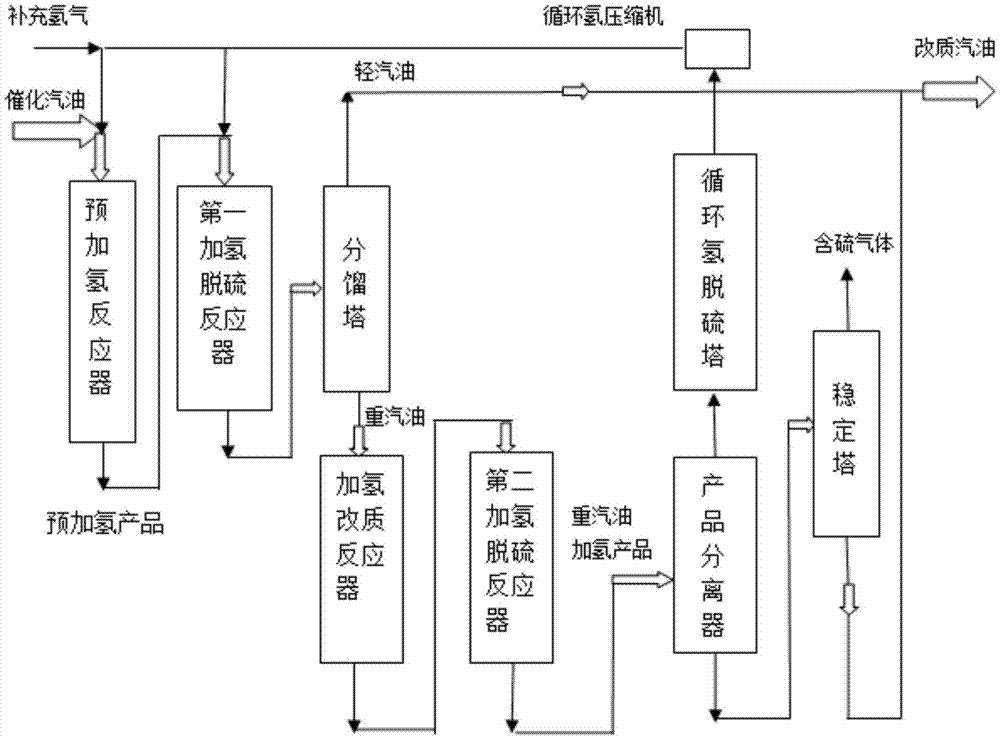

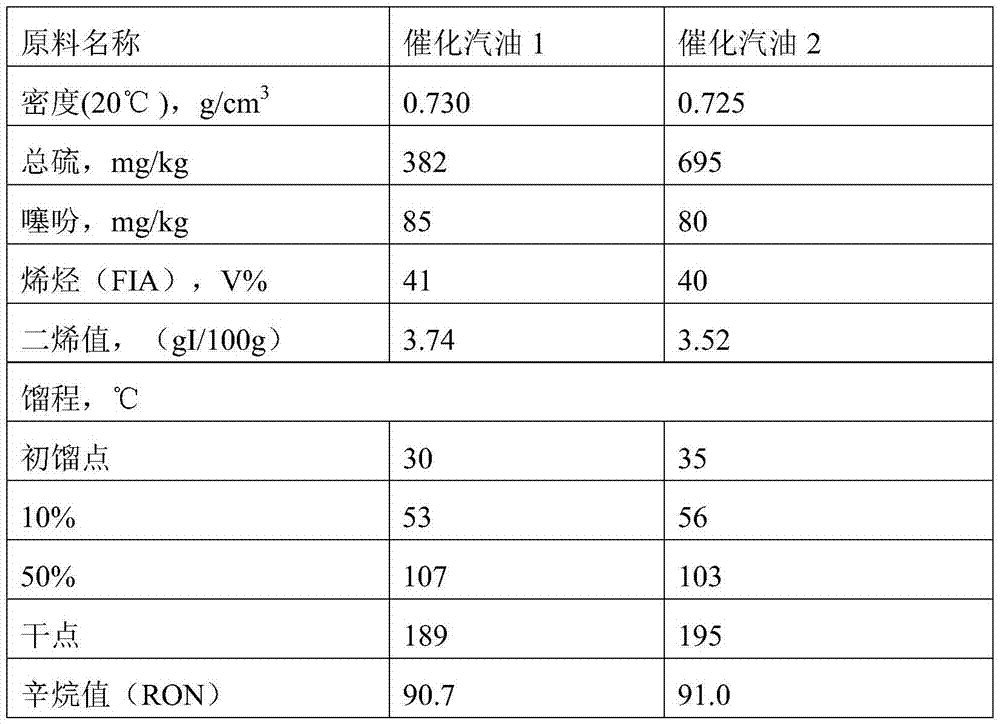

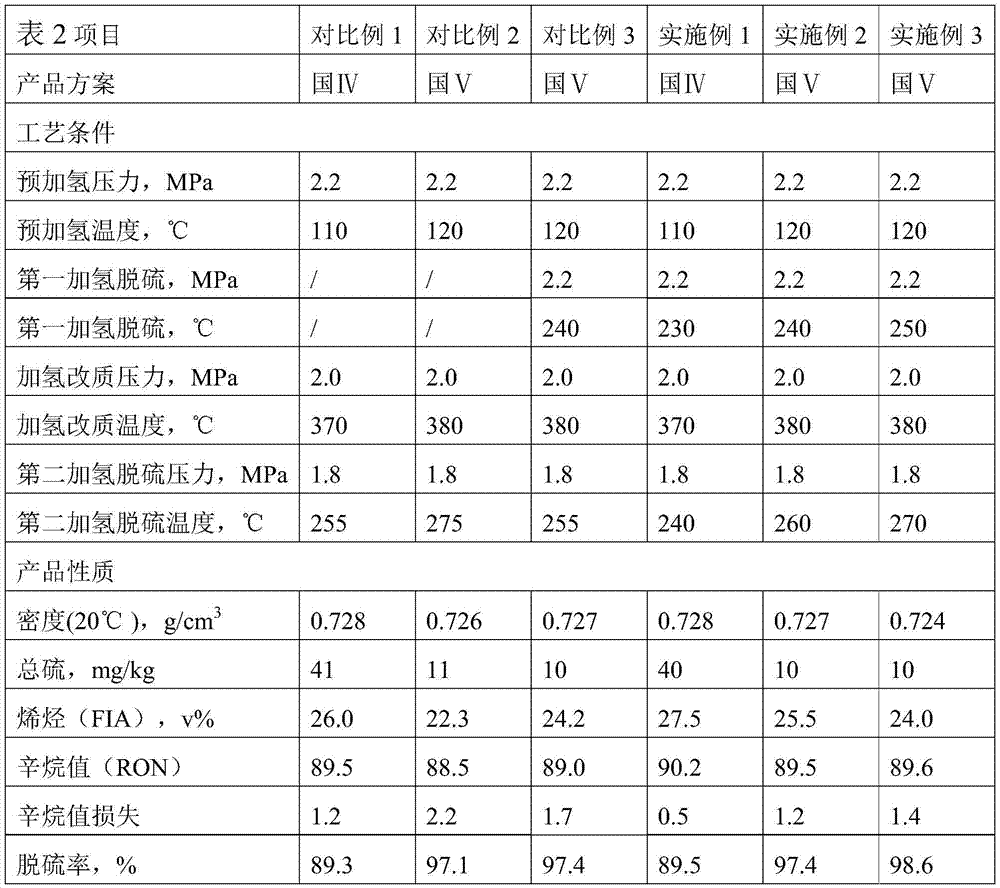

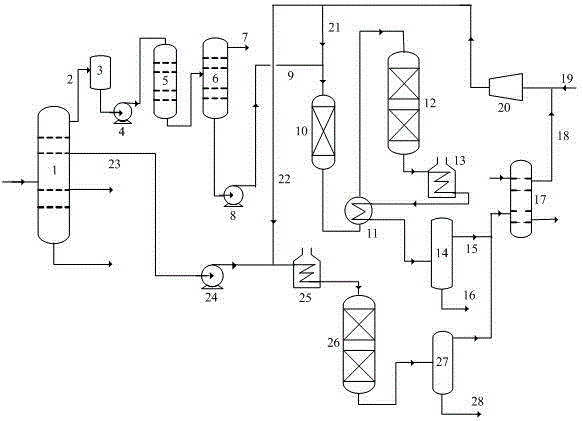

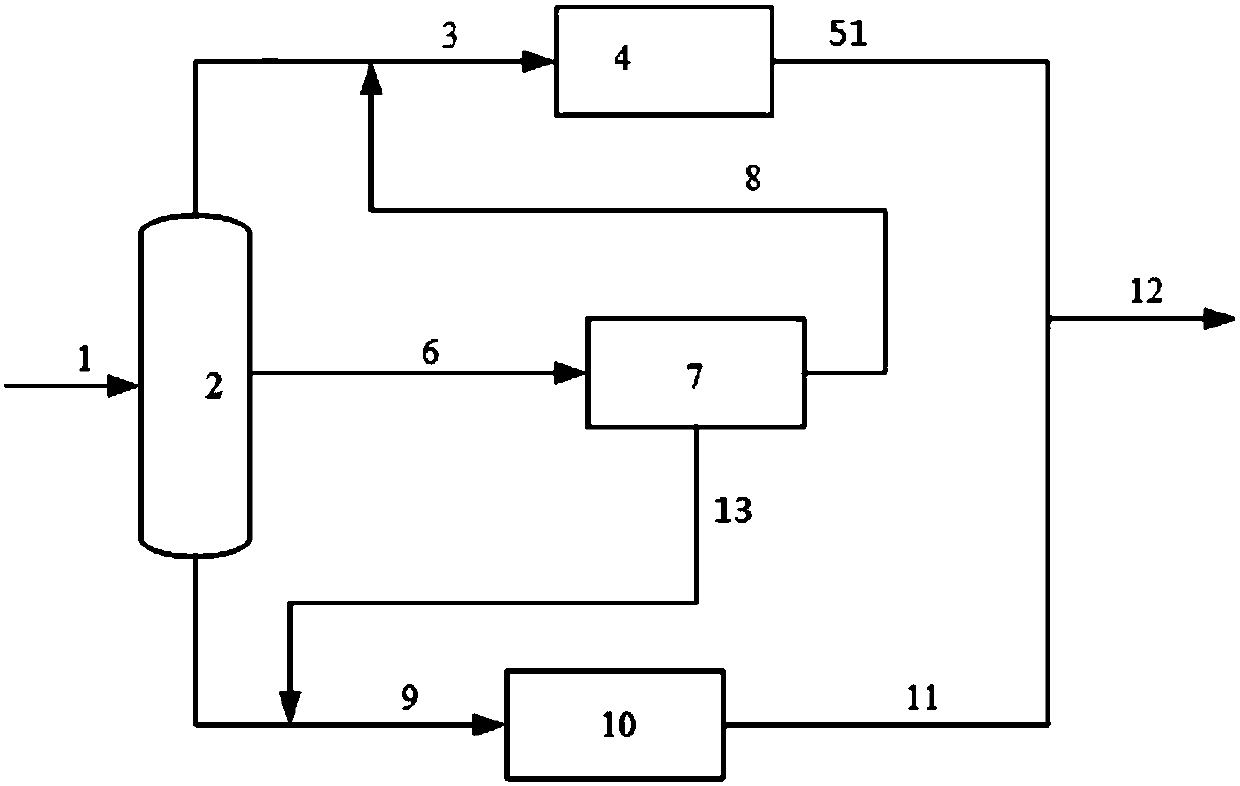

The invention discloses a method for hydro-upgrading inferior gasoline. The method comprises the following steps: (1) mixing catalytic gasoline and hydrogen, feeding the mixture into a pre-hydrogenating reactor and reacting; (2) mixing a pre-hydrogenated product and hydrogen, feeding the mixture into a first hydrogen desulfurization reactor and reacting; (3) feeding the product of the step (2) into a fractionating tower, and dividing the product into a light gasoline component and a heavy gasoline component; (4) taking the light gasoline component discharged from the top of the fractionating tower gas an upgraded gasoline blending component, mixing the heavy gasoline component discharged from the bottom of the tower and hydrogen, then feeding the mixture into a hydro-upgrading reactor and reacting; (5) feeding the product of the step (4) into a second hydrogen desulfurization reactor and reacting; and (6) after the product of the step (5) is cooled down, feeding the product into a product separator and carrying out gas-liquid separation, recycling the hydrogen discharged from the top of the product separator, feeding a liquid phase at the bottom into a stabilizer to remove sulfurous gas, and mixing the liquid phase with light gasoline to obtain the upgraded gasoline product. According to the method, while the content of olefin and the content of sulphur are greatly reduced, loss of octane value in hydro-upgrading of the catalytic gasoline is reduced.

Owner:PETROCHINA CO LTD

Catalytic gasoline deep hydrodesulfurization method

ActiveCN103059965AAchieve pre-separationLow investment costTreatment with hydrotreatment processesAlkali freeHydrodesulfurization

The invention discloses a catalytic gasoline deep hydrodesulfurization method. The method comprises: adjusting the operating conditions of a catalytic device fractionating tower, adding a lateral line, adopting an appropriate cutting point to conduct cutting so as to obtain FCC (fluid catalytic cracking) gasoline light fractions at the tower top and FCC heavy fractions at the lateral line; subjecting FCC gasoline light fractions to alkali-free deodorization, and then separating light gasoline and medium gasoline through a hydrogenation prefractionator; and carrying out moderate selective hydrogenation on the medium gasoline, performing deep selective hydrogenation on the heavy gasoline, and mixing the obtained two parts of refined distillate oil with the light gasoline subjected to alkali-free deodorization, thus obtaining a clean gasoline product or a blending component. Compared with the existing catalytic gasoline hydrodesulfurization technologies, the method provided in the invention can significantly reduce equipment energy consumption, the gasoline octane number loss is small, the obtained gasoline product quality can meet the quality requirement for a sulfur content of less than 10 micrograms / g, and the economic benefits of oil refining enterprises are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for reducing gasoline sulfur content

ActiveCN108018079AReduce sulfur contentImprove effective utilizationTreatment with hydrotreatment processesHydrocarbon oils treatment productsGasolineReaction zone

Relating to the field of hydrocarbon oil refining, the invention discloses a method for reducing the gasoline sulfur content. The method includes: fractionating a gasoline raw material into light fraction gasoline, medium fraction gasoline and heavy fraction gasoline, letting the light fraction gasoline firstly enter an alkaline extraction unit for removal of mercaptan, then mixing the mercaptan removed light fraction gasoline with medium gasoline fraction, and letting the mixture enter a solvent extraction unit; or letting the medium gasoline fraction firstly enter the solvent extraction unit, then mixing the obtained product and the light gasoline fraction, and subjecting the mixture to the alkaline extraction unit; letting the extract oil obtained by the solvent extraction unit and theheavy fraction gasoline enter a first reaction zone and a second reaction zone in order, and separating the reaction effluent of the second reaction zone to obtain hydrogenated heavy fraction gasoline; and mixing the treated light gasoline fraction and the medium gasoline fraction with the hydrogenated heavy fraction gasoline so as to obtain a gasoline product. The gasoline product obtained by themethod provided by the invention has the advantages of low sulfur content, small octane loss value and high gasoline yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of sulfur-free gasoline

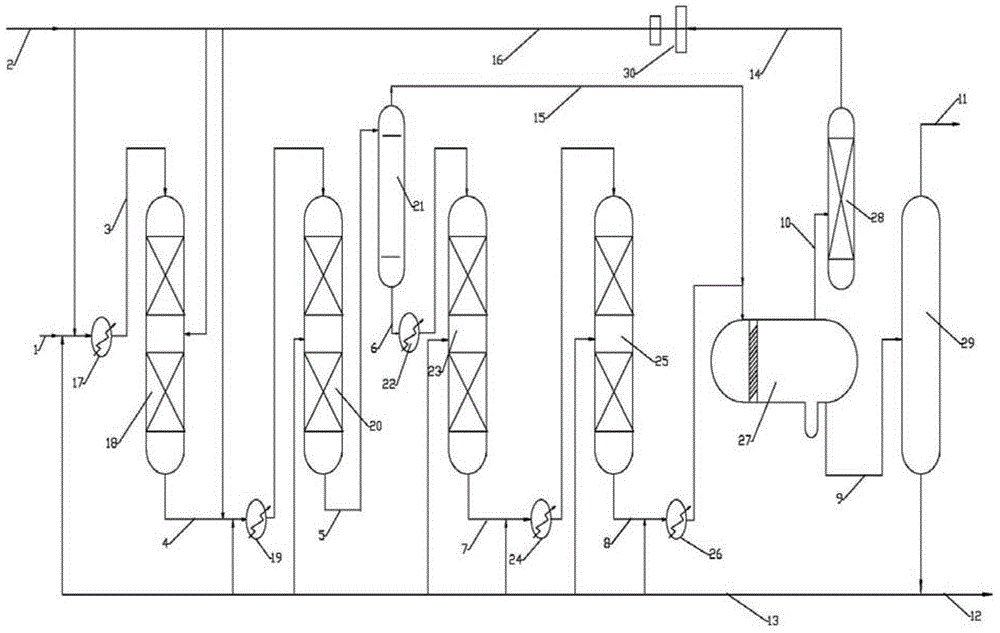

ActiveCN105670688ALess octane lossHigh yieldTreatment with hydrotreatment processesHydrogenation reactionGasoline

The invention provides a preparation method of sulfur-free gasoline. The preparation method of sulfur-free gasoline comprises the following steps: (1), contacting poor-quality gasoline raw materials with selective hydrogenation catalyst in a selective hydrogenation reactor in the presence of hydrogen so as to carry out selective hydrogenation reaction; (2), contacting the product of the step (1) with a first selective hydrogenation and desulfurization catalyst in a first selective hydrogenation and desulfurization reactor so as to carry out the first selective hydrogenation and desulfurization reaction; (3), sending the product of the step (2) into a H2S stripping column, so that an air phase containing H2S is obtained at the top of the column and a liquid phase with H2S removed is obtained at the bottom of the column; (4), contacting the liquid phase obtained in the step (3) with a second selective hydrogenation and desulfurization catalyst in a second selective hydrogenation and desulfurization reactor; and (5), contacting the product obtained in the step (4) with a hydrogenation refining catalyst in a hydrogenation refining reactor. The method disclosed by the invention is capable of preparing sulfur-free gasoline whose sulfur content is no higher than 5 micrograms / gram; moreover, the sulfur-free gasoline is relatively small in octane value loss. In addition, the preparation method is high in product yield.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Preparation method of gasoline desulfurization microsphere catalyst

InactiveCN102744073ALess octane lossHigh activityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsNickel saltMicrosphere

The invention relates to a preparation method of a gasoline desulfurization microsphere catalyst. The method is characterized by: adding activated zinc oxide accounting for 30-60wt% of the total dry basis of the catalyst, expanded perlite powder and / or diatomite accounting for 5-20wt% of total dry basis, and a nickel salt, in terms of nickel oxide, accounting for 10-30wt% of the total dry basis into chemical water for mixing and beating, and raising the temperature to 60-90DEG C, at the same time continuously adding a sodium aluminate solution and an aluminum sulfate solution with a concentration of 1-20 wt%, adjusting and controlling the flow ratio of the two solutions to maintain the pH of the whole slurry at 7.5-9.5; and with the total amount of alumina in the sodium aluminate and aluminum sulfate accounting for 5-20wt% of the total dry basis of the catalyst, atomizing the uniformly mixed material slurry into microspheres with an average particle diameter of 50-80 microns, then conducting washing with chemical water till sodium oxide is less than 1.0wt%, and after drying, carrying out roasting at a temperature of 450-650DEG C for 0.5-4 hours. The prepared catalyst has a pore volume of 0.1-0.4 ml / g, and is characterized by good strength, high activity, large sulfur capacity, as well as low loss of liquid yield and gasoline octane number in a gasoline desulfurization reaction.

Owner:崔超

Method for gasoline modification

InactiveCN102634371ALess octane lossReduce olefin contentTreatment with hydrotreatment processesProcess engineeringSulfur content

The invention relates to a method for gasoline modification; gasoline raw materials and hydrogen are mixed, and the mixture is allowed to enter a prehydrogenation reactor for dialkene removal, and to enter a fractionating tower so as to cut the gasoline into light and heavy components; light gasoline from the fractionating tower top is directly used as a clean gasoline blending component; heavy gasoline from the bottom of the fractionating tower is allowed to enter a hydrogenation modification reactor for reaction, and then to enter a hydrodesulfurization reactor for supplementary refining; materials from the hydrodesulfurization reactor is cooled, and is allowed to enter a product separation device for gas-liquid separation; hydrogen from the gas-liquid separation device is treated by desulphurization and then recycled; liquid products are allowed to enter a fine desulfurization tower for further reducing the sulfur content of the gasoline, and then are mixed with the light gasoline to obtain the hydrogenation modified gasoline products; the method of the invention can not only greatly reduce sulfur and alkene contents in the gasoline, but also can reduce octane number loss due to the desulphurization process.

Owner:PETROCHINA CO LTD

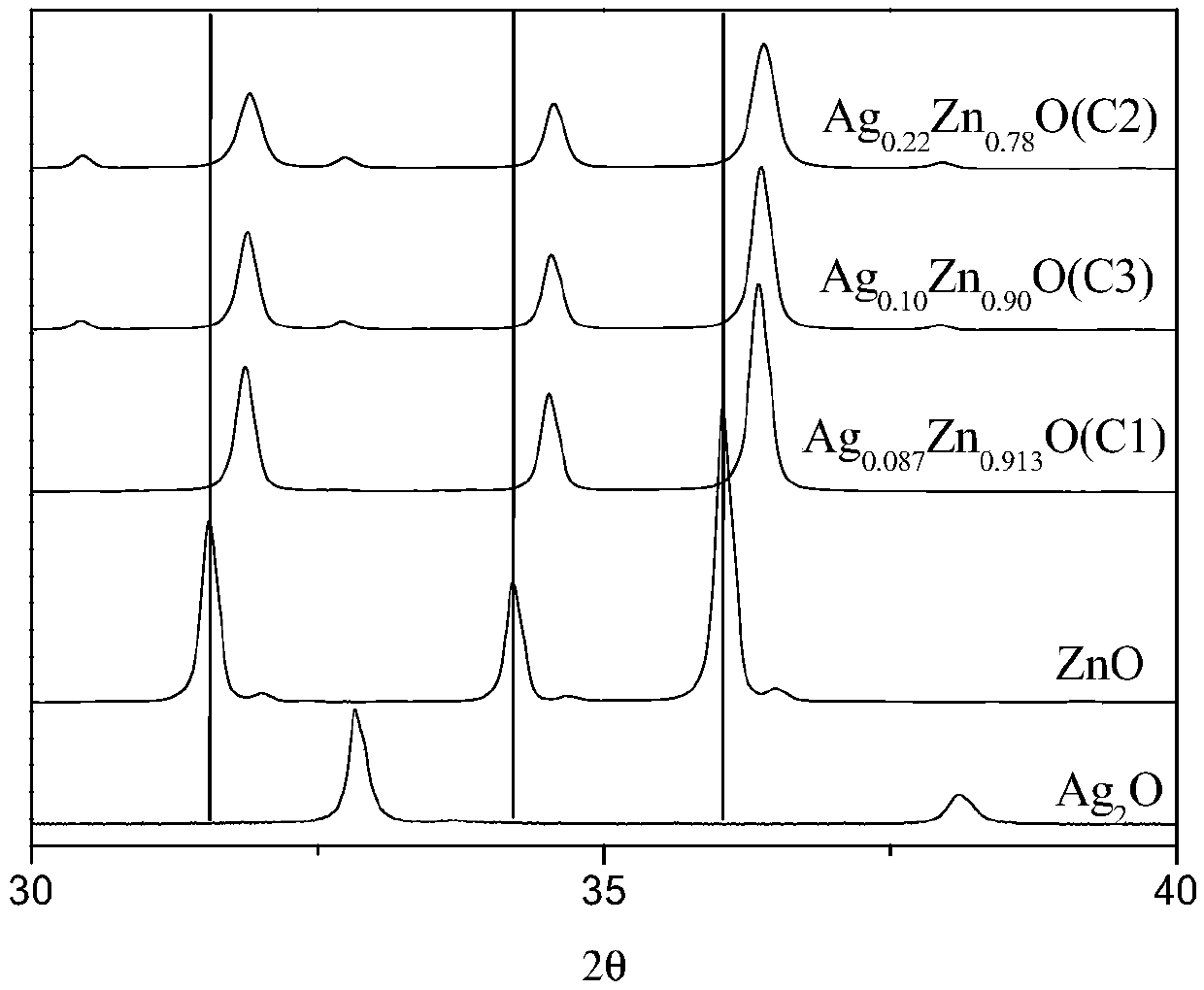

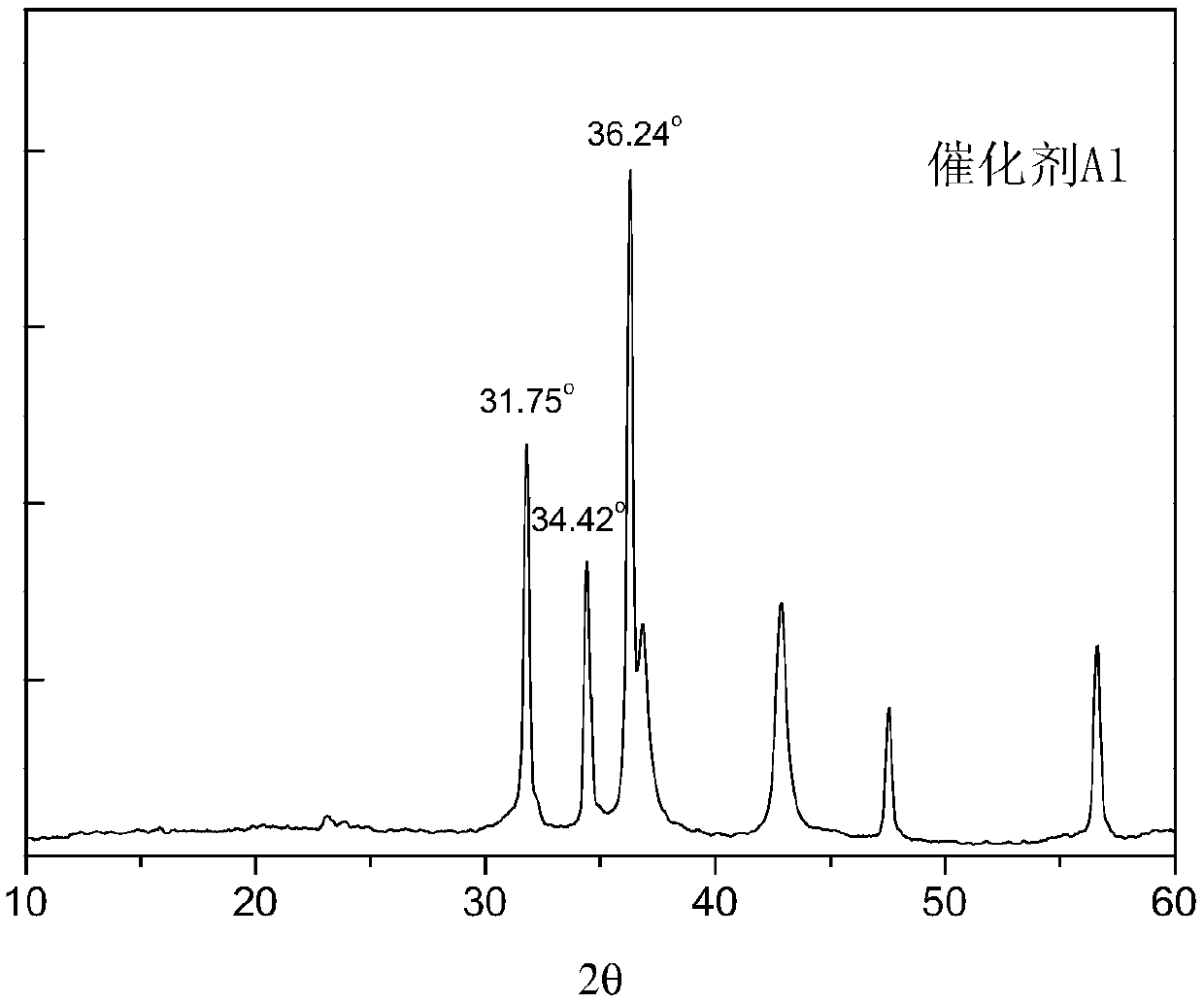

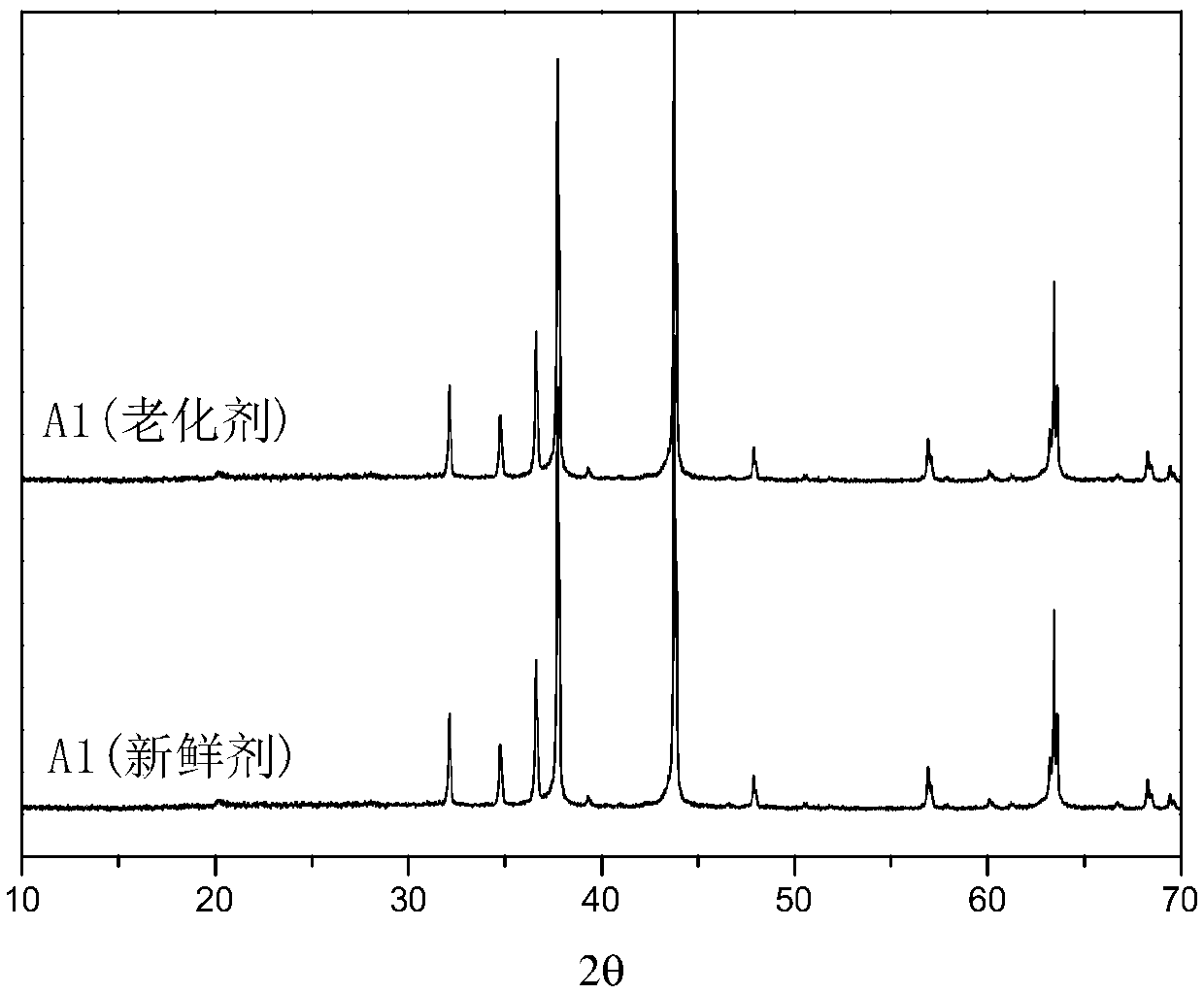

Desulfurization catalyst and preparation method thereof, and hydrocarbon oil desulfurization method

ActiveCN111111754AImprove abrasion resistanceExtended service lifeMolecular sieve catalystsHydrocarbon oil crackingMolecular sievePtru catalyst

The invention discloses a desulfurization catalyst and a preparation method thereof, and a hydrocarbon oil desulfurization method. The desulfurization catalyst is prepared from the following components in percentage by weight: 5-35% of silicon oxide source, 5-35% of aluminum oxide, 30-70% of zinc oxide, 2-15% of silver oxide, 1-20% of a molecular sieve with an MFI structure and 5-30% of an activemetal, wherein at least part of the silver oxide exists in a form of forming a zinc-silver composite metal oxide represented by a general formula AgxZn1-xO with the zinc oxide, x is greater than 0 andless than or equal to 0.24, x represents an atomic molar ratio, the active metal is at least one of cobalt, nickel, iron and manganese, and the sulfur capacity of the zinc-silver composite metal oxide represented by AgxZn1-xO is greater than or equal to 30%. The desulfurization catalyst prepared by adopting the ratio has the characteristics of high desulfurization activity, high stability, long service life and good wear resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of selective hydrodesulfurization method

ActiveCN106221794BReduce loadLess octane lossTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrodesulfurizationGasoline

The invention provides a selective hydrodesulfurization process which comprises the following steps: cutting a gasoline feedstock into light ends and heavy ends; performing liquid-liquid extraction for the light ends to obtain light end raffinate containing olefins and light end extraction oil containing sulfide and aromatics; and using selective hydrodesulfurization catalysts to perform selective hydrodesulfurization for the light end extraction oil and the heavy ends, wherein the main component of the selective hydrodesulfurization catalyst is obtained by loading an active metal component with a metal oxide, treated with a metal salt, as the carrier, wherein the active metal is selected from more than two elements in IA, VIII, VIB and VIIB groups in the periodic table. The selective hydrodesulfurization process provided by the invention has the advantages of high desulfurization rate and small loss of the octane value of sweet gasoline.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Gasoline deep desulfurization method, and equipment used for gasoline deep desulfurization

ActiveCN108003931AReduce lossesImprove the purification effectTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrogenFractionation

The invention belongs to the field of hydrocarbons refining, and discloses a gasoline deep desulfurization method and equipment used for gasoline deep desulfurization. The gasoline deep desulfurization method comprises following steps: 1, gasoline raw material is subjected to pre-hydrogenation so as to obtain pre-hydrogenated gasoline raw materials; 2, the pre-hydrogenated gasoline raw materials are subjected to fractionation so as to obtain light fractions, medium fractions, and heavy fractions; 3, the medium fractions are contacted with an extraction solvent so as to obtain a sulfur-containing solvent and solvent-extracted medium fractions, separation is adopted to separate the sulfur-containing solvent from sulfides contained by the sulfur-containing solvent so as to obtain a solvent extracted sulfur-containing material and a recycled sulfide-free solvent; 4, the heavy fractions are subjected to selective hydrogen desulfurization reaction so as to obtain hydrogenated heavy fractions; and 5, the light fractions, the solvent extracted medium fractions, and the hydrogenated heavy fractions are mixed so as to obtain gasoline products. The gasoline deep desulfurization method is capable of obtaining gasoline products lower in sulfur content without large reduction of octane value.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for lowering olefine content in gasoline in secondary processing

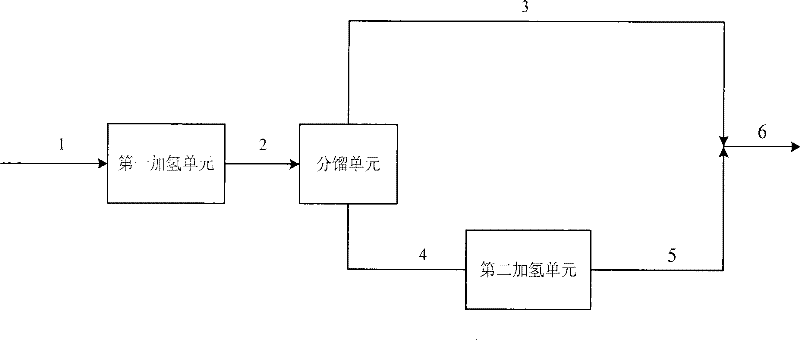

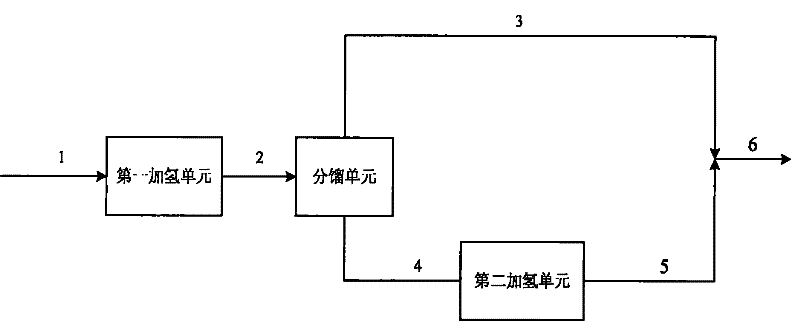

ActiveCN101591567BReduce lossesReduce olefin contentTreatment with hydrotreatment processesSulfurFractionation

The invention discloses a method for lowering olefine content in gasoline in secondary processing. In a first hydrogenation unit, alkadiene is selectively removed from gasoline raw materials; reaction effluent is led into a fractionation unit to be cut so as to obtain light fraction and heavy fraction, wherein, hydrodesulfurization, hydrodenitrogenation, olefin saturation and octane number preservation are carried out on the heavy fraction in a second hydrogenation unit, and obtained light hydrogenation fraction and heavy hydrogenation fraction are mixed to obtain gasoline products. The invention can process MTO gasoline and MTP gasoline, and produces high-quality gasoline which has low sulfur and low alkene and contains less than 25 volume% of olefine, and has smaller octane number loss and higher gasoline yield. The invention can provide more flexibility of operation to chemical devices, and improves the additional value of device products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com