Gasoline hydrogenation catalyst, its prep. and application in lowering olefin by desulfurization

A gasoline hydrogenation and catalyst technology, applied in refining to remove heteroatoms, etc., can solve problems such as low total liquid yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

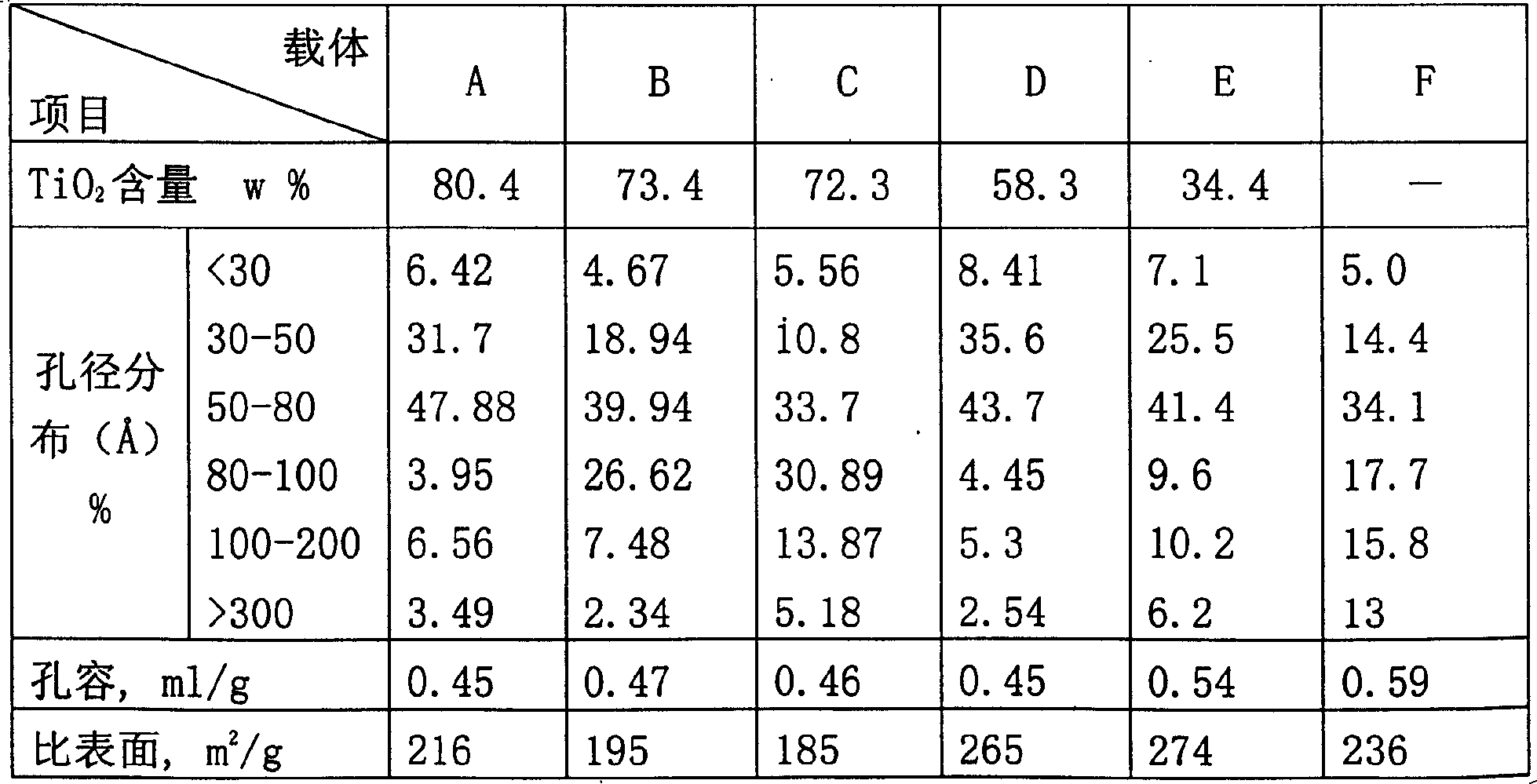

[0040] The dry titanium dioxide powder (containing TiO2) produced by Deqing Branch of Beijing Haishunde Titanium Catalyst Co., Ltd. 2 80%) 200g, add Tian Qing powder 10g, mix well. Add aluminum gel: silica sol (1: 1) 120g in the aforementioned material, after fully kneading, extrude into the clover-like strip that equivalent diameter is 1.4mm on the extruding type twin-screw extruder, gained wet strip, at 60 Drying at 120°C for 2 hours, drying at 120°C for 2 hours, and calcining at 500°C for 3 hours, the carrier A was obtained. Catalyst A1, its properties are shown in Table 2.

Embodiment 2

[0042] The dry titanium dioxide powder (containing TiO2) produced by Deqing Branch of Beijing Haishunde Titanium Catalyst Co., Ltd. 2 80%) 100g and titanium-zirconium dry rubber powder (containing ZrO 2 25%) 100g, add Tian Qing powder 10g, mix well. Add 120g of 1:1 aluminum gel and silica sol to the above-mentioned materials, and after fully kneading, extrude into clover-like strips with an equivalent diameter of 1.4mm on a front-extrusion twin-screw extruder, and dry the obtained wet strips at 60 degrees Dry at 120°C for 2 hours for 2 hours, and bake at 500°C for 3 hours to obtain carrier B, whose properties are shown in Table 1. After being impregnated with Mo-Co solution, dried at 110°C for 5 hours, and calcined at 450°C for 2 hours, catalyst B1 was obtained, and its properties are shown in Table 2.

Embodiment 3

[0044] The dry titanium dioxide powder (containing TiO2) produced by Deqing Branch of Beijing Haishunde Titanium Catalyst Co., Ltd. 2 80%) 100g and titanium-silica colloidal powder (containing SiO 2 25%) 100g, add Tian Qing powder 10g, mix well. Add 120g of aluminum gel to the aforementioned materials, after fully kneading, extrude into clover-like strips with an equivalent diameter of 1.4mm on a front-extrusion twin-screw extruder, and dry the obtained wet strips at 60°C for 2 hours, then dry them at 120°C Drying for 2 hours, calcining at 500°C for 3 hours to obtain carrier C, whose properties are shown in Table 1, impregnated with Mo-Co solution, dried at 110°C for 5 hours, and calcined at 450°C for 2 hours, to obtain catalyst C1, whose properties are shown in Table 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com