Middle hole ZSM-5 zeolite microsphere and preparation method thereof

A ZSM-5, microsphere technology, applied in the direction of crystalline aluminosilicate zeolite, borocarbonane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of increased cost, complicated preparation process, etc., and achieves reduction of preparation cost and simplification Preparation process, overcoming the effect of difficult separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

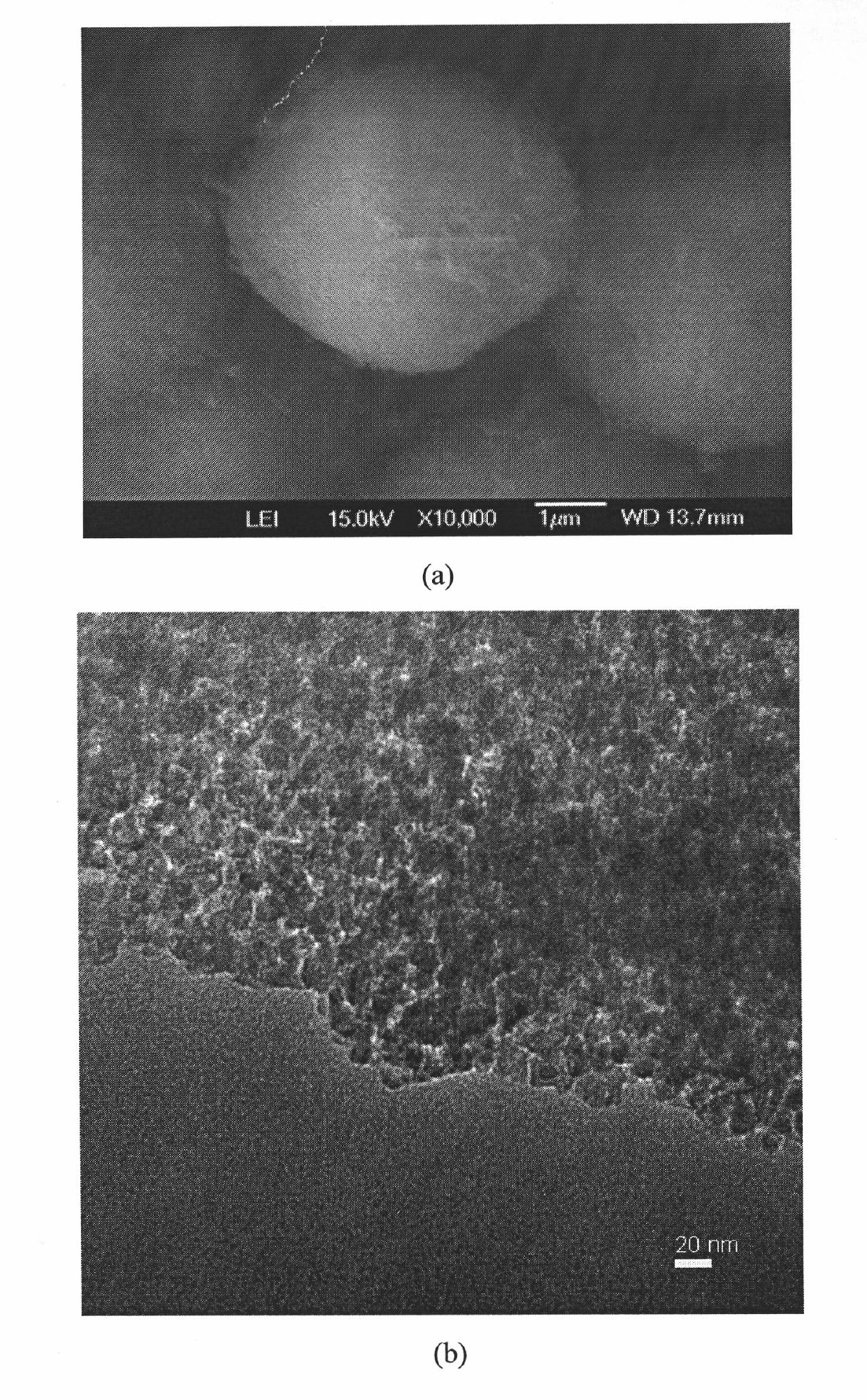

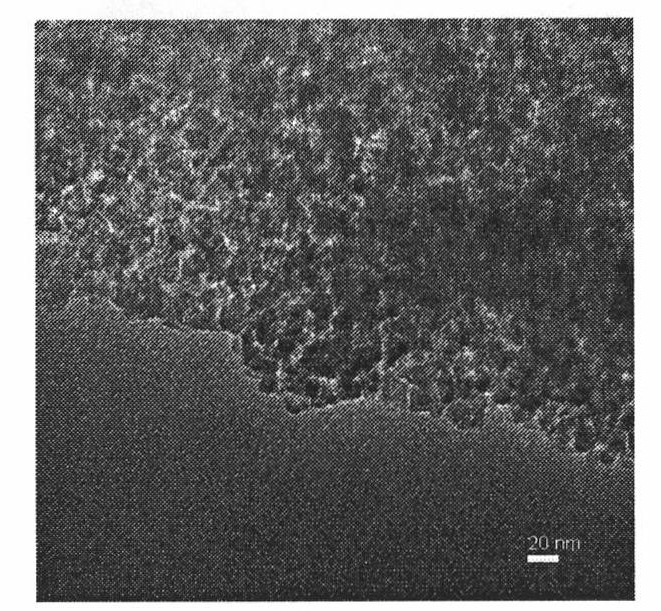

[0021] Take 0.1mol of anilinopropyltrimethoxysilane and dissolve it in 670mL of alcoholic aqueous solution containing 60% (w / w) of methanol. After the dissolution is complete, add 30g (0.5mol) with a specific surface area of 200m 2 / g, silicon dioxide with a particle size of 12nm, poured into a 1500mL three-necked flask, refluxed and stirred at 100°C for 8h, separated from solid and liquid, washed with ethanol at room temperature, and dried at 100°C to obtain a solid surface silanized silica powder. Take 4.3 g of the above-mentioned silanized silica, add 1.33 g of tetrapropylammonium bromide (TPABr) and 72 mL of deionized water, stir in a three-necked flask at room temperature for 10 h, then add 0.1 g of aluminum isopropoxide, 0.2 g of hydroxide Sodium, reflux and stir at 90°C for 20h; put it into a sealed reaction kettle, crystallize at 180°C for 3 days; centrifuge the crystallized product from solid and liquid, wash at room temperature, dry at 100°C, and roast in air at 600...

Embodiment approach 2

[0024] Change the amount of anilinopropyltrimethoxysilane in embodiment 1 to 0.0625mol, and keep the other conditions unchanged, carry out silanization to silica; then take 3.9g of the silanized silica to synthesize mesoporous ZSM-5 Zeolite microspheres. The X-ray diffraction spectrum shows that the product is ZSM-5 zeolite with high crystallinity; the scanning electron microscope photos show that the diameter of the microspheres is about 5-7 μm; The size of the mesopores in the small crystal grains is 3-4nm; the external specific surface area is 205m 2 / g, the mesopore volume is 0.19mL / g.

Embodiment approach 3

[0026] Change the amount of anilinopropyltrimethoxysilane in Embodiment 1 to 0.025mol, and keep other conditions unchanged, carry out silanization to silicon dioxide; take 3.3g of the silanized silicon dioxide to synthesize mesoporous ZSM-5 zeolite Microspheres. The results show that the diameter of the microspheres is about 5-7μm; the size of the small grains is 15-30nm; the size of the inner and middle pores in the small grains is 3-4nm; 2 / g, the mesopore volume is 0.14mL / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com