Preparation method for catalyst for dehydrogenation of low-carbon alkane

A technology for dehydrogenation catalysts and low-carbon alkanes, which is applied in the direction of hydrocarbons, hydrocarbons, chemical instruments and methods, and can solve the problems of Pt sintering, catalyst deactivation, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

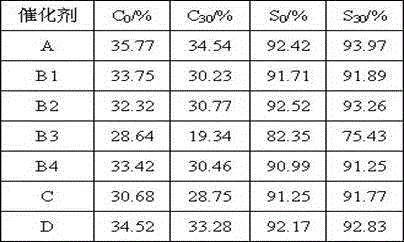

Examples

Embodiment 1

[0030] Preparation of Sn-containing alumina carrier: mix a certain amount of 0.98M aluminum trichloride solution and 0.01M tin tetrachloride solution, add a certain amount of 8% ammonia water, and put it in a neutralization tank at 60~80°C Mix evenly, control the pH value to 7.0~9.0, filter, wash with water, and acidify, pressurize into balls in the oil ammonia column, dry, age, and roast at 650~750°C for 4 hours to obtain Sn-containing powder with a particle size of 1.5mm. 0.3wt% spherical alumina.

[0031] Weigh 0.7 g of potassium nitrate and dissolve it in 100 ml of deionized water. Measure 50ml of spherical alumina carrier containing 0.3wt% Sn and weigh its mass to be about 26g. It was placed in a rotary evaporator and vacuumed for 30 min. Then suck the solution into the rotary evaporator, turn off the vacuum pump, keep the temperature of the water bath at 60° C., and immerse at normal pressure for 6 hours. Then, the temperature of the water bath was raised to 80°C, the...

Embodiment 2

[0049] Spherical silicon oxide with a diameter of 1.8mm was selected as the carrier. Measure 60ml of spherical silica carrier and weigh its mass to be about 25g.

[0050] Weigh 0.66 g of potassium nitrate and dissolve it in 150 ml of deionized water. The measured carrier was placed in a rotary evaporator and vacuumed for 30 min. Then suck the solution into the rotary evaporator, turn off the vacuum pump, keep the temperature of the water bath at 60° C., and immerse at normal pressure for 6 hours. Then, the temperature of the water bath was raised to 80°C, the catalyst was vacuum-dried and then transferred into a beaker and placed in an oven at 80°C. Perform temperature-programmed drying in an oven, raise the temperature to 110°C at a rate of 0.8°C / min, and stay for 6 hours.

[0051] Weigh 0.34 g of solid chloroplatinic acid, dissolve it in 120 ml of anhydrous acetone, and adjust the pH of the solution to 1 with glacial acetic acid. The above dried carrier was placed in a r...

Embodiment 3

[0055] Spherical zirconia with a diameter of 1.4 mm is selected as the carrier. Immerse in an aqueous solution containing cerium nitrate and zinc nitrate for 3 hours, dry at 110°C for 2 hours, and bake at 500°C for 4 hours. Measure 50ml of the spherical zirconia carrier loaded with auxiliary agent and weigh its mass as about 34g.

[0056] Weigh 1.1 g of potassium nitrate and dissolve it in 150 ml of deionized water. The measured carrier was placed in a rotary evaporator and vacuumed for 30 min. Then suck the solution into the rotary evaporator, turn off the vacuum pump, keep the temperature of the water bath at 60° C., and immerse at normal pressure for 6 hours. Then, the temperature of the water bath was raised to 80°C, the catalyst was vacuum-dried and then transferred into a beaker and placed in an oven at 80°C. Perform temperature-programmed drying in an oven, raise the temperature to 115°C at a rate of 0.7°C / min, and stay for 6 hours.

[0057] Weigh 0.91 g of solid ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com