Preparation method of high-purity phase spherical molybdenum disulfide

A nano-molybdenum disulfide, spherical technology, applied in the direction of molybdenum sulfide, nanotechnology, nanotechnology, etc., can solve the problems of uneven surface of molybdenum disulfide spheres, achieve uniform size, prevent agglomeration, and regular shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The mixed solution (V 无水乙醇 / V 去离子水 =1 / 19), add 2 mL of hydrazine hydrate after stirring evenly, transfer the solution into a high-pressure reactor with a volume of 100 mL after mixing evenly, seal it and place it in a 200°C incubator, keep it warm for 24 hours, cool to room temperature, and use After washing with deionized water and absolute ethanol, place it in a vacuum oven at 70°C for 8 hours to obtain the high-purity spherical nanomolybdenum disulfide required in this case.

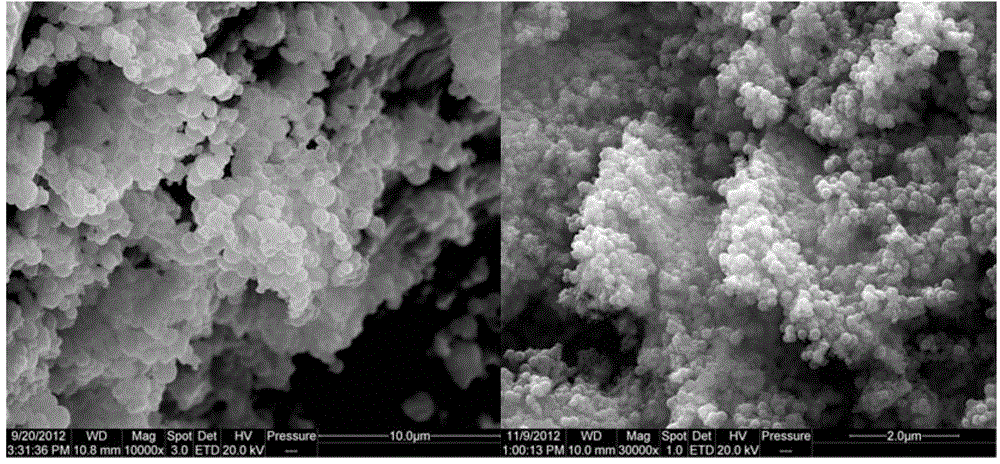

[0034] Depend on figure 1 It can be seen that the product is composed of nanospheres with a particle size of about 400nm, the particle size distribution range of the spheres is narrow, the spherical structure is complete, and the dispersibility of the spheres is good.

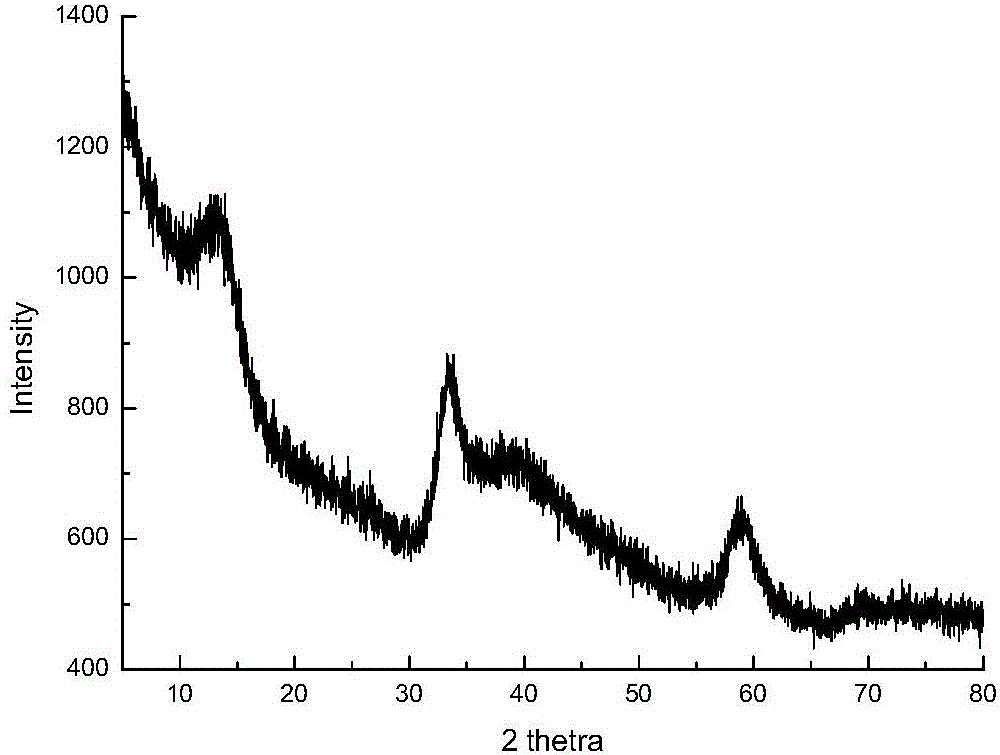

[0035] Depend on figure 2 The XRD shows that the structure of molybdenum disulfide is 2H-MoS 2 .

Embodiment 2

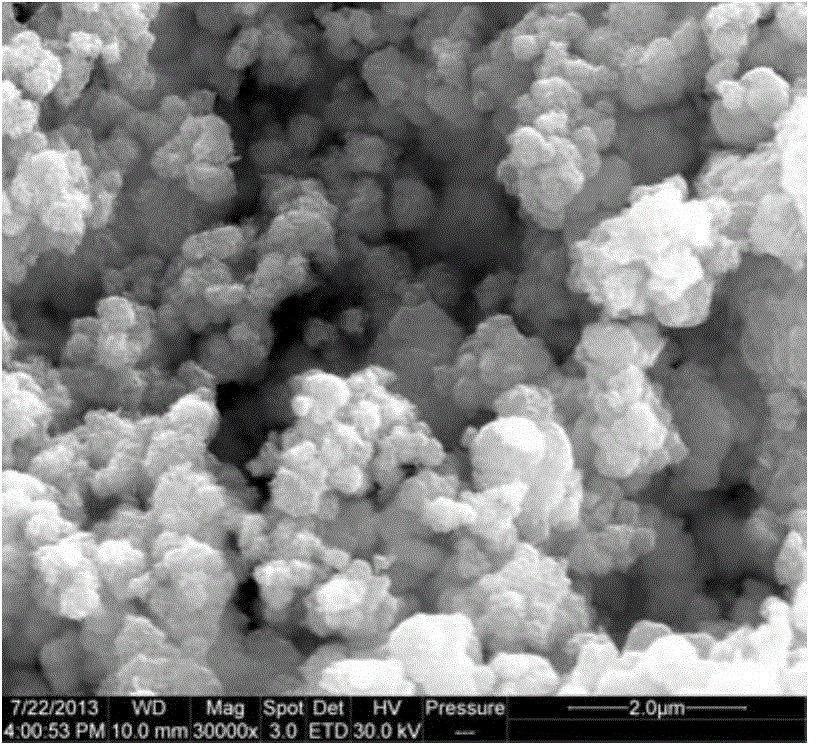

[0037] The mixed solution (V 无水乙醇 / V 去离子水 =3 / 17), after stirring evenly, add 2mL of hydrazine hydrate, after mixing evenly, move the solution into a 100mL autoclave, seal it and place it in a 200°C incubator, keep it warm for 24h, cool to room temperature, and use After washing with deionized water and absolute ethanol, place it in a vacuum oven at 70°C for 8 hours to obtain the high-purity spherical nanomolybdenum disulfide required in this case. For the experimental results, see image 3 .

Embodiment 3

[0039] The mixed solution (V 无水乙醇 / V 去离子水 =1 / 3), after stirring evenly, add 2mL of hydrazine hydrate, after mixing evenly, transfer the solution into a 100mL autoclave, seal it and place it in a 180°C incubator, keep it warm for 12h, cool to room temperature, and use After washing with deionized water and absolute ethanol, place it in a vacuum oven at 70°C for 8 hours to obtain the spherical nanomolybdenum disulfide required in this case. For the experimental results, see Figure 4 .

[0040] According to the SEM image, the spherical structure of the prepared nanomolybdenum disulfide is complete, and the size distribution is narrow at about 400nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com