High-damage-tolerance aluminum alloy for aviation and preparation method

A damage tolerance, aluminum alloy technology, applied in the field of aluminum alloy manufacturing, can solve the problems of small total deformation, insufficient core compound and grain breakage, difference in core and surface deformation, etc. The effect of bite, fracture toughness and stress corrosion resistance reduction, reduction of flat rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

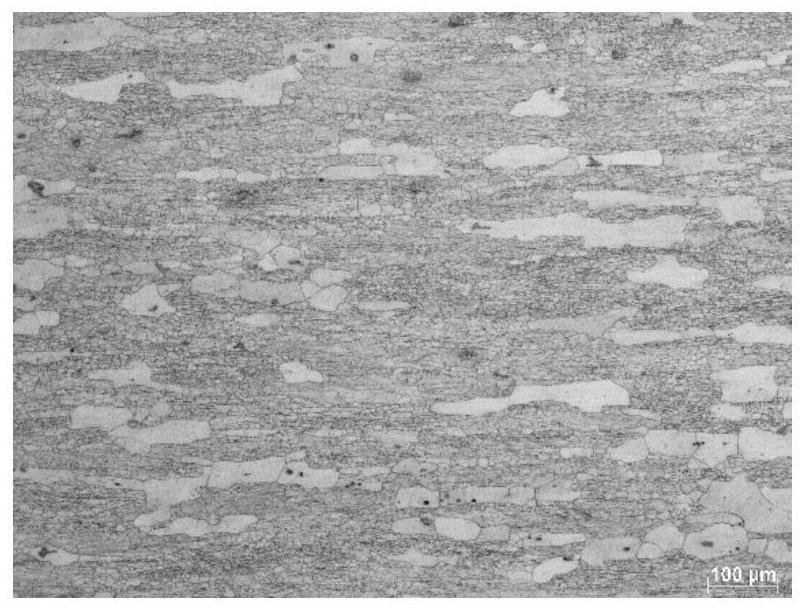

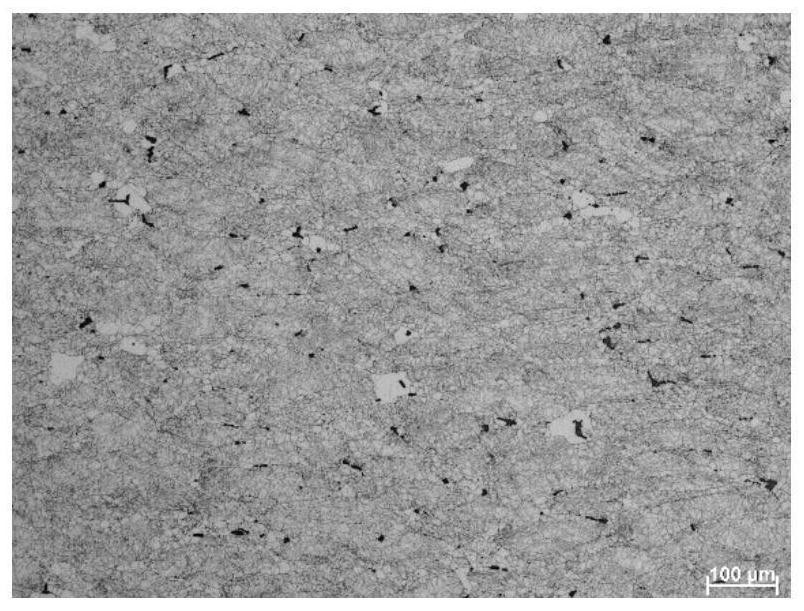

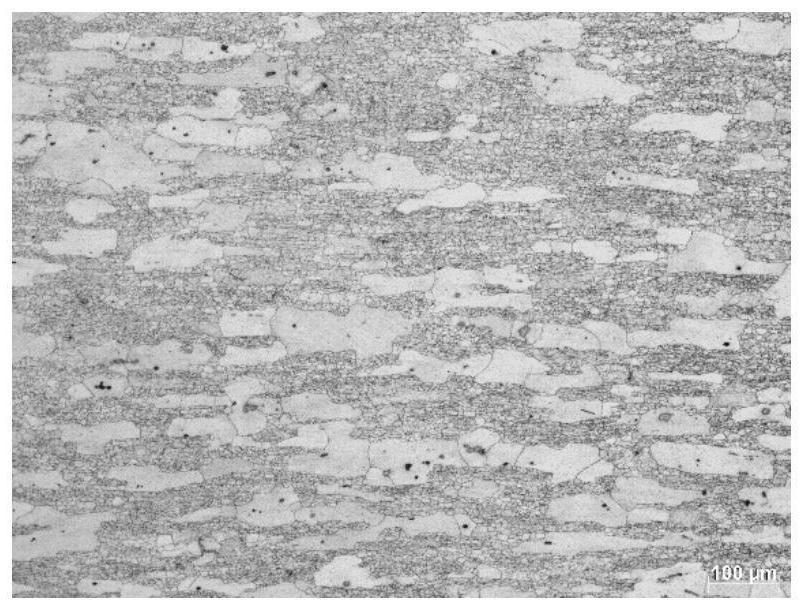

Image

Examples

Embodiment 1

[0029] A method for preparing a high damage tolerance type aluminum alloy for aviation, comprising the following steps:

[0030] A. Calculate the amount of each aluminum alloy raw material and prepare the aluminum alloy raw material according to the ratio. The ratio of the mass percentage of each element of the aluminum alloy raw material is as follows:

[0031] element Si Fe Cu mn Mg Cr Zn Ti Zr Impurities Al content 0.033 0.067 2.21 0.002 2.18 0.001 6.08 0.038 0.097 0.10 margin

[0032] The ratio of Zn / Mg is 2.79, and the ratio of Cu / Mg is 1.01. Put the prepared aluminum alloy raw materials into the melting furnace for melting. After stirring, slag removal, degassing and impurity removal, and filtering, the aluminum liquid is semi-continuously cast into aluminum alloy through a crystallizer. Alloy hot-rolled slab stock.

[0033] B. Perform three-level homogenization treatment on the cast aluminum alloy ingot after stress rel...

Embodiment 2

[0039] The difference between embodiment 2 and embodiment 1 is that, in step A, the mass percentage ratio of each element of the aluminum alloy raw material is as follows:

[0040] element Si Fe Cu mn Mg Cr Zn Ti Zr Impurities Al content 0.03 0.078 2.17 0.001 2.08 0.004 6.14 0.023 0.093 0.10 margin

[0041] Zn / Mg ratio 2.95, Cu / Mg ratio 1.04.

[0042] Step C is rolled to a thickness of 60 mm through 9 passes, and the reductions of each pass are 40 mm, 40 mm, 50 mm, 65 mm, 65 mm, 65 mm, 30 mm, 30 mm, and 20 mm to ensure the shape of the prepared aluminum alloy profile.

[0043] The amount of tensile deformation in step E is 2.4-2.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com