In-situ preparation method for Y4Si2O7N2-BN ceramic base composite materials

A composite material, yttrium silicon oxynitride technology, applied in the field of ceramic matrix composite materials, can solve the problems of poor machinability, thermal shock resistance, need to be further improved, and reduced thermal conductivity, and achieve high density and low thermal conductivity The effect of low efficiency and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

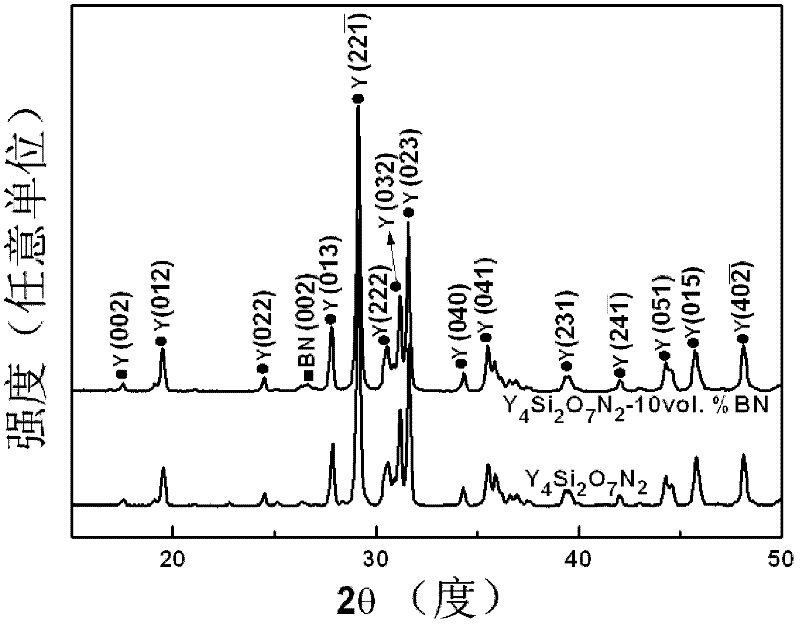

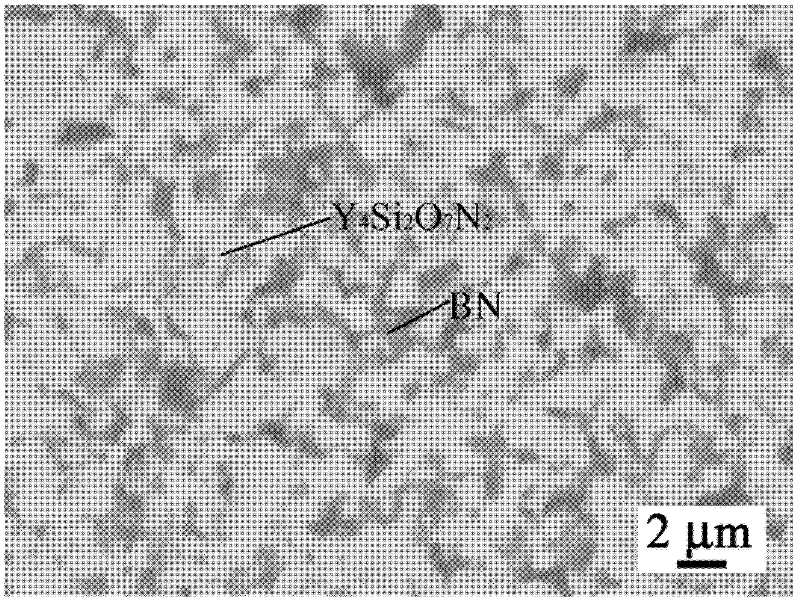

[0021] h-BN powder (100 mesh, purity: 99wt.%) 4.45g, Y 2 o 3 Powder (300 mesh, purity: 99.5wt.%) 69.83g, SiO 2 Powder (200 mesh, purity: 99.5wt.%) 4.66g and Si 3 N 4 10.83 g of the powder (300 mesh, purity: 99 wt.%) was poured into a silicon nitride ball mill jar, wet-milled with silicon nitride balls and ethanol for 12 hours, and then dried at 50° C. for 48 hours. The dried powder is poured into a BN-coated graphite mold with a diameter of 50mm and cold-pressed. After cold pressing at a pressure of 12MPa for 5 minutes, put the mold into a hot-press furnace, under the protection of flowing nitrogen, raise the temperature to 1600°C at a heating rate of 5°C / min, keep it for 30 minutes, and then raise the temperature at a heating rate of 10°C / min to 1800°C, hot pressing for 60 minutes, and the hot pressing pressure is 30MPa. The obtained bulk material was analyzed by X-ray diffraction as Y 4 Si 2 o 7 N 2 and BN two phases, the volume ratio of the two is 90:10, basically ...

Embodiment 2

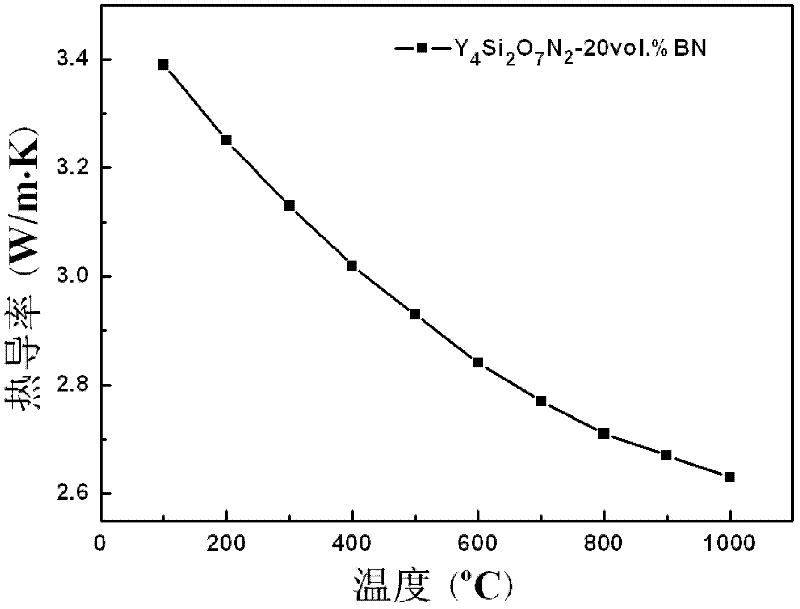

[0023] h-BN powder (100 mesh, purity: 99wt.%) 12.68g, Y 2 o 3 Powder (300 mesh, purity: 99.5wt.%) 88.3g, SiO 2 Powder (200 mesh, purity: 99.5wt.%) 5.89g and Si 3 N 4 13.7 g of the powder (200 mesh, purity: 99 wt.%) was poured into a silicon nitride ball mill jar, wet-milled with silicon nitride balls and ethanol for 24 hours, and then dried at 50° C. for 48 hours. The dried powder is poured into a BN-coated graphite mold with a diameter of 50mm and cold-pressed. After cold pressing at a pressure of 15MPa for 3 minutes, put the mold into a hot-press furnace of a graphite heating element, and under the protection of flowing nitrogen, raise the temperature to 1550°C at a heating rate of 15°C / min, keep it for 40min, and then raise the temperature to 1900°C , hot pressing for 50min, hot pressing pressure is 30MPa. The obtained composite material is analyzed by X-ray diffraction as Y 4 Si 2 o 7 N 2 and BN two phases, the volume ratio of the two is 80:20, basically no other ...

Embodiment 3

[0025] h-BN powder (300 mesh, purity: 99wt.%) 17.82g, Y 2 o 3 Powder (400 mesh, purity: 99.5wt.%) 46, 56g, SiO 2 Powder (200 mesh, purity: 99.5wt.%) 3.11g and Si 3 N 4 7.22 g of powder (300 mesh, purity: 99wt.%) was poured into a silicon nitride ball mill jar, wet-milled with silicon nitride balls and added with ethanol for 6 hours, and then dried at 50°C for 48 hours. The dried powder is poured into a BN-coated graphite mold with a diameter of 50mm and cold-pressed. After cold pressing at a pressure of 10MPa for 4 minutes, put the mold into a hot-press furnace of a graphite heating element, and under the protection of flowing nitrogen, raise the temperature to 1700°C at a heating rate of 30°C / min, keep it for 30min, and then raise the temperature to 2100°C , hot pressing for 30min, and the hot pressing pressure is 20MPa. The obtained composite material is analyzed by X-ray diffraction as Y 4 Si 2 o 7 N 2 and BN two phases, the volume ratio of the two is 60:40. The m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com