Patents

Literature

147results about How to "Reduced bending strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

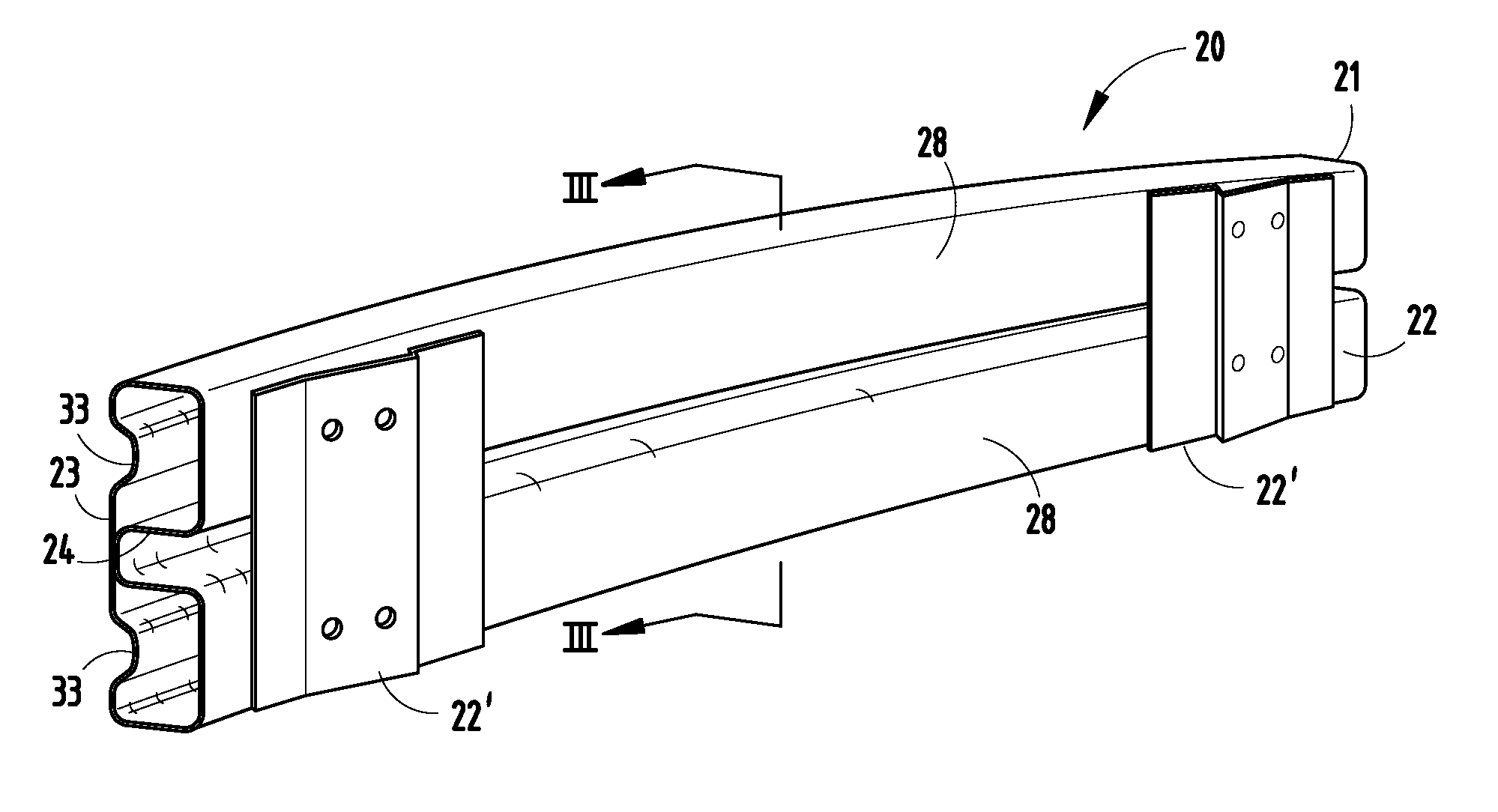

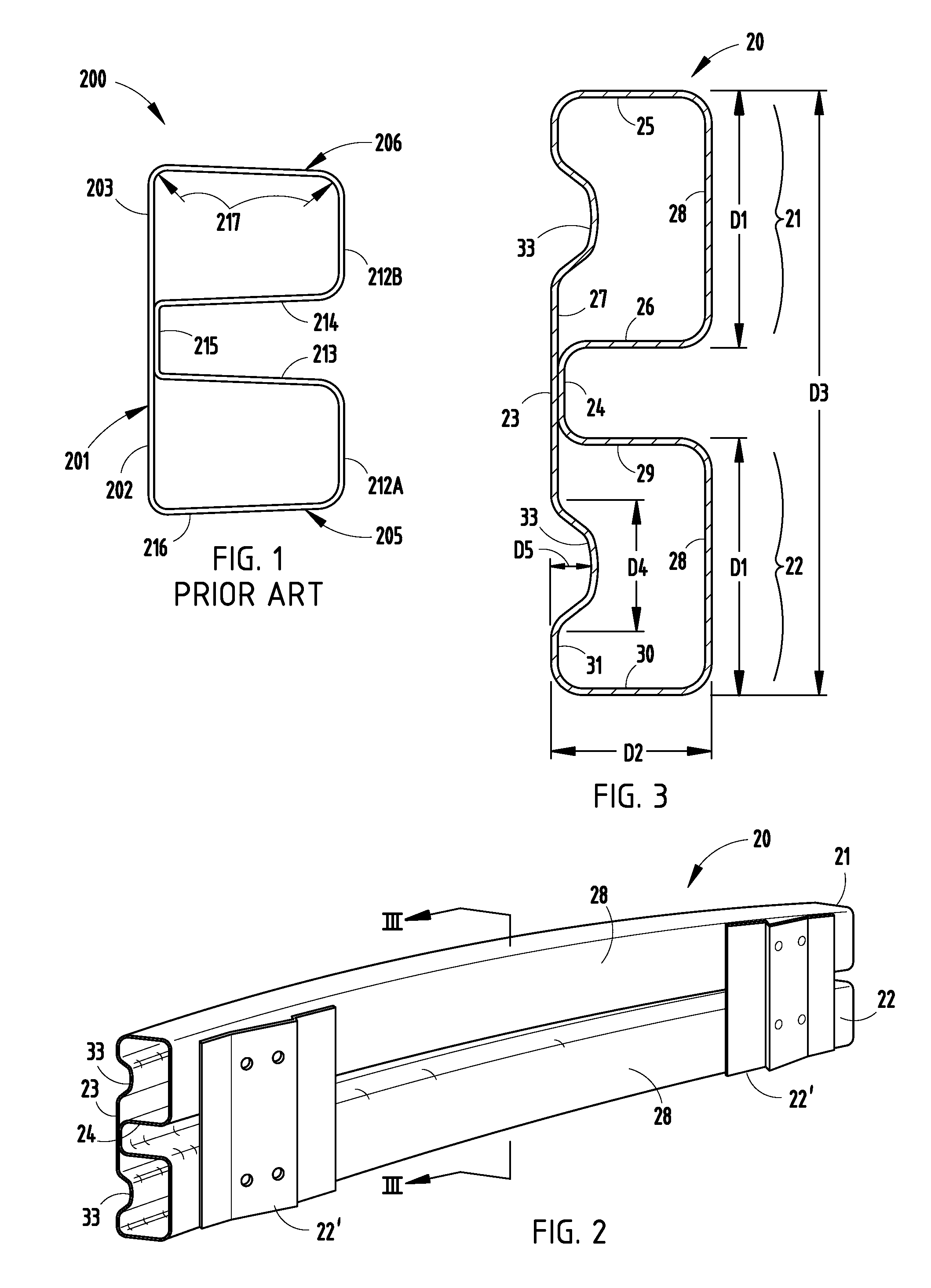

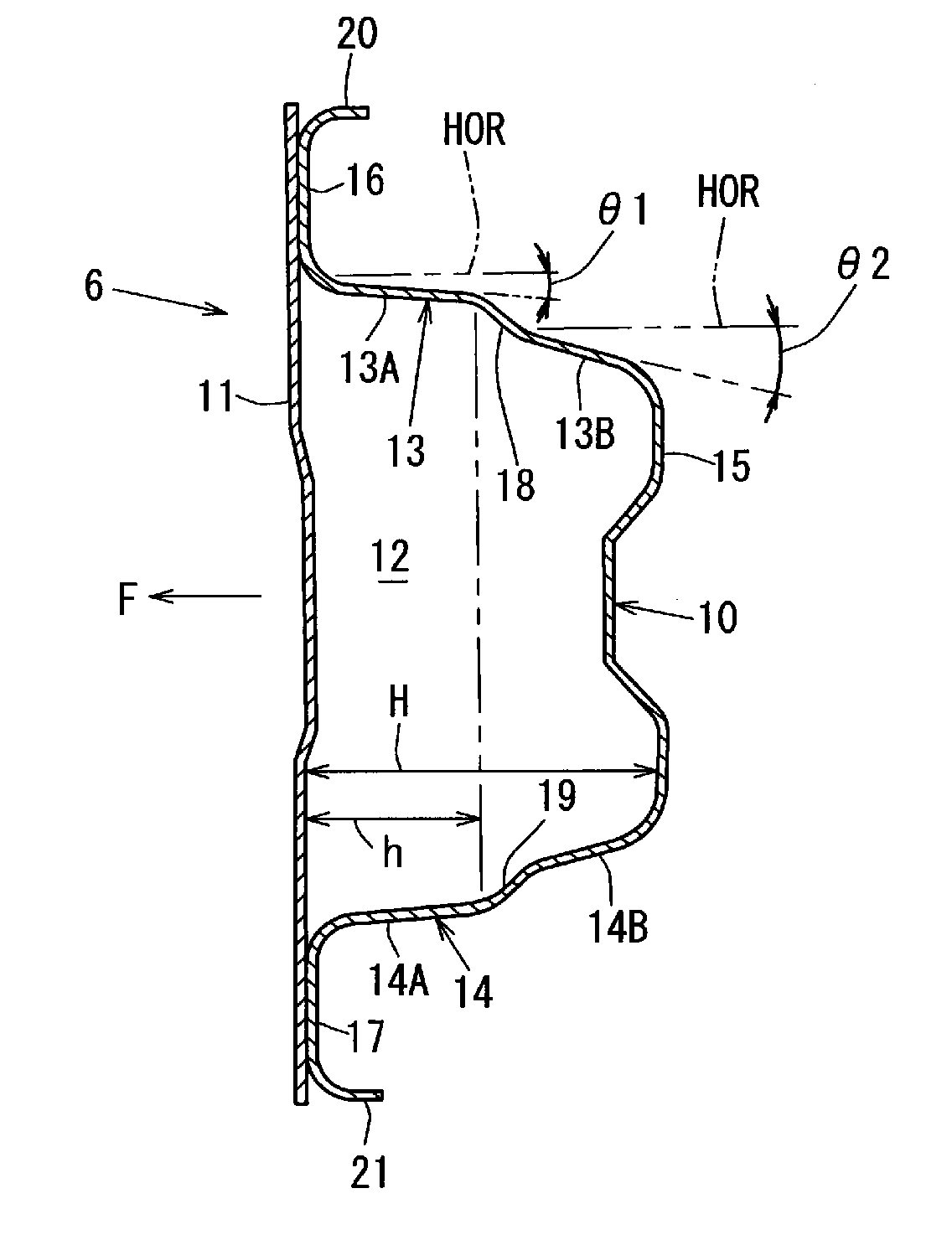

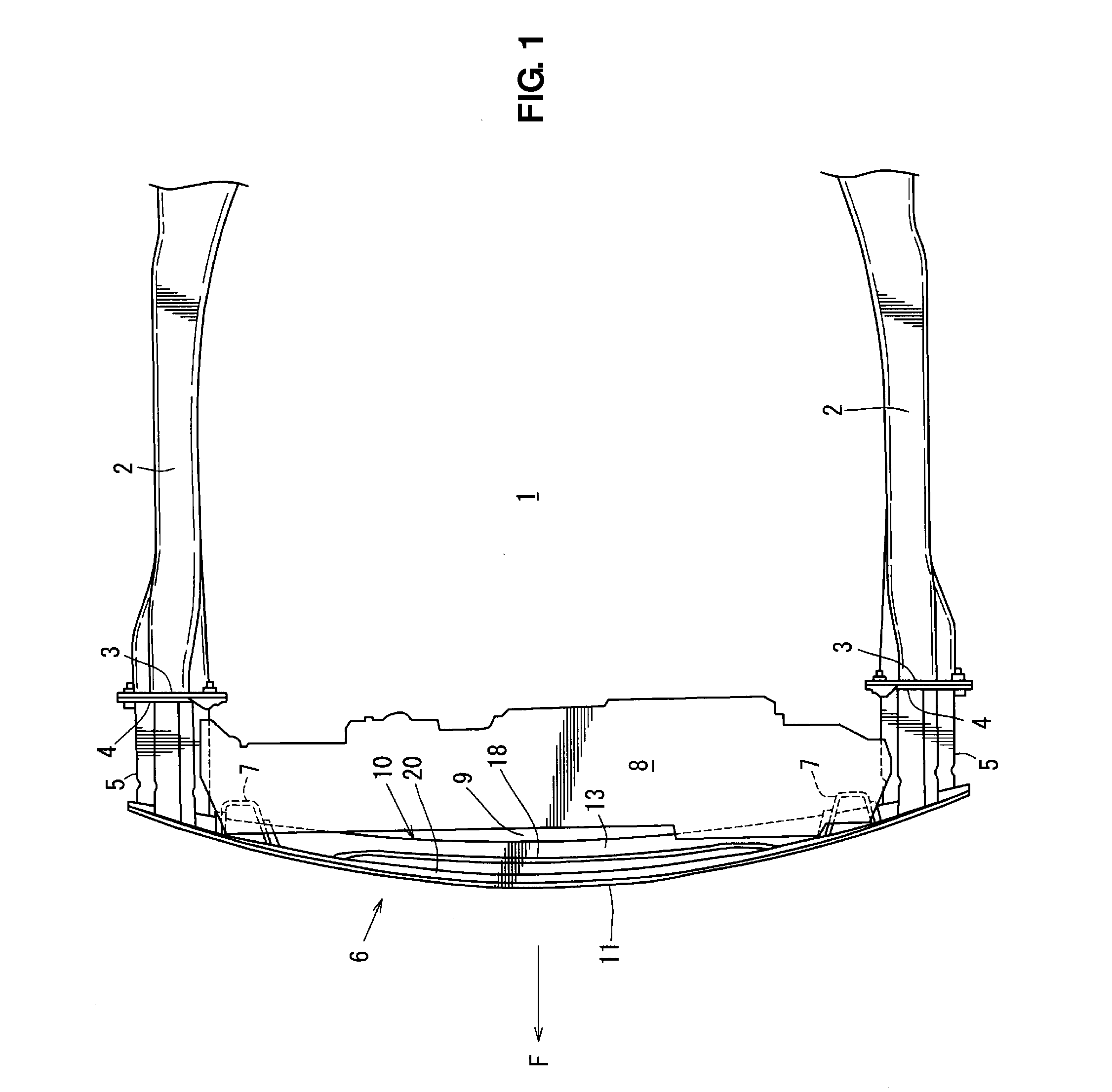

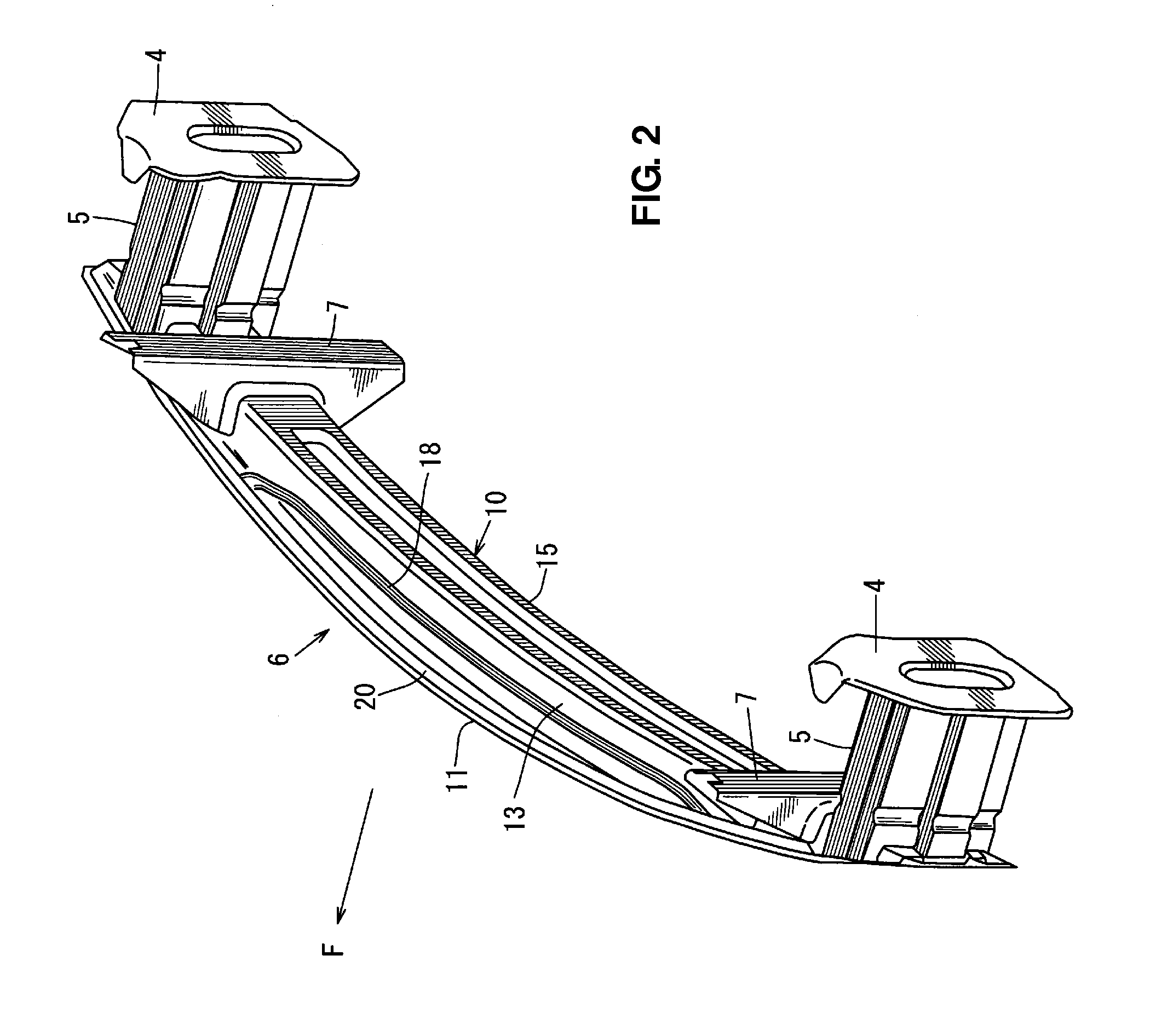

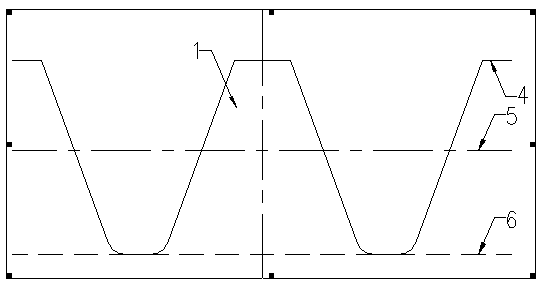

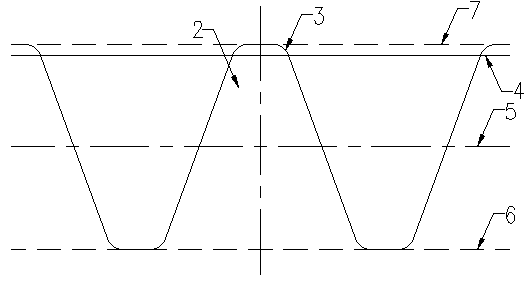

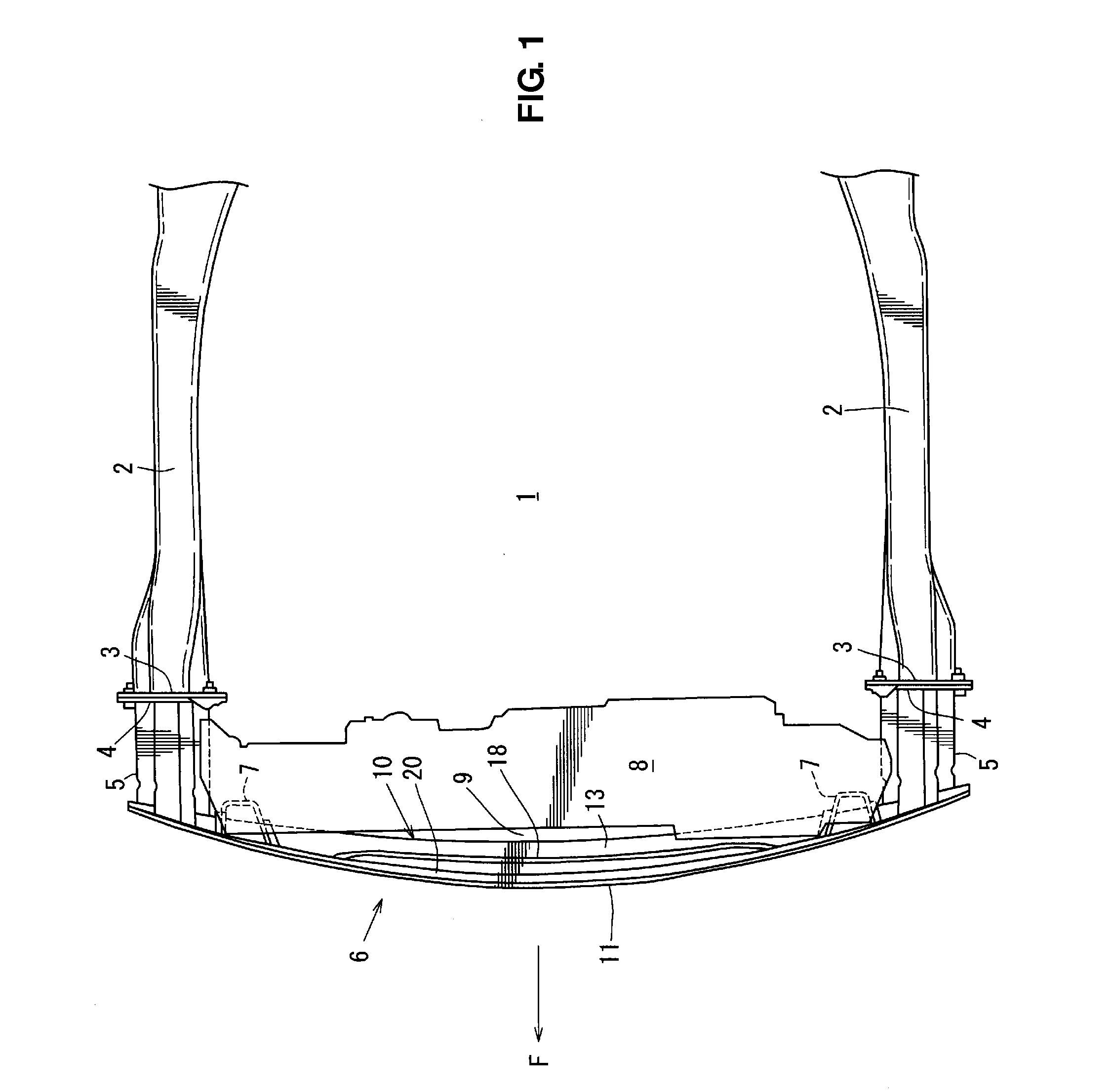

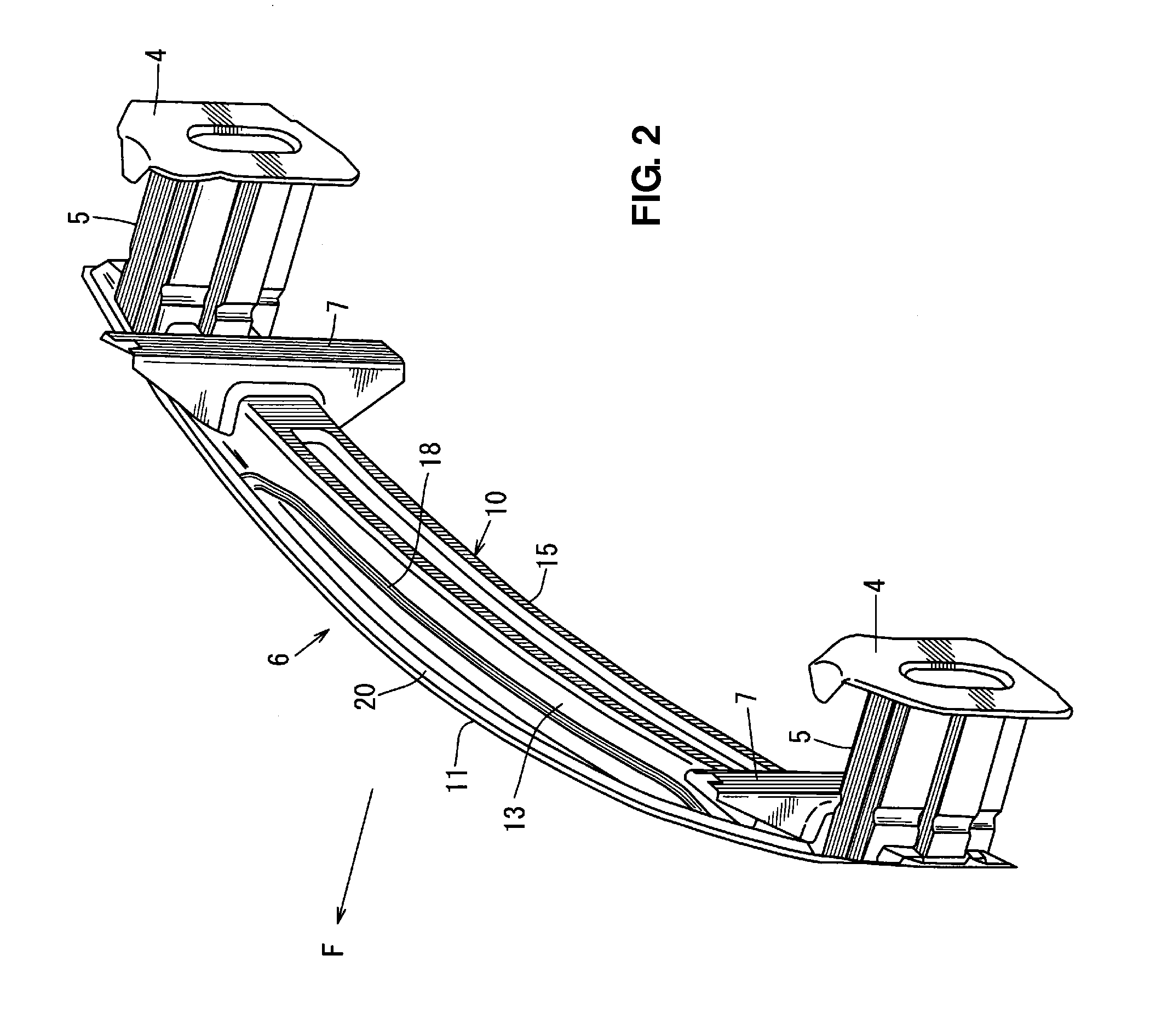

B-shaped beam with integrally-formed rib in face

InactiveUS20080093867A1Reduce “ offset ”Weight increaseBumpersMetal rolling arrangementsShaped beamEngineering

Owner:SHAPE CORP

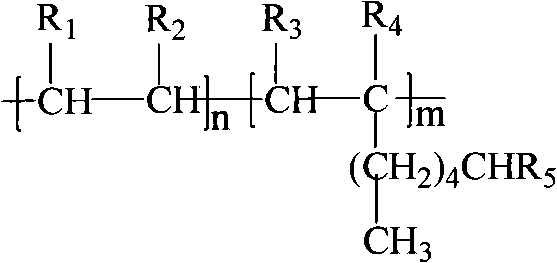

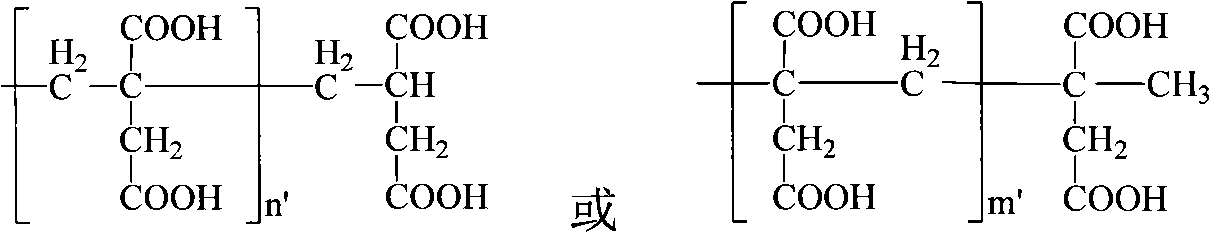

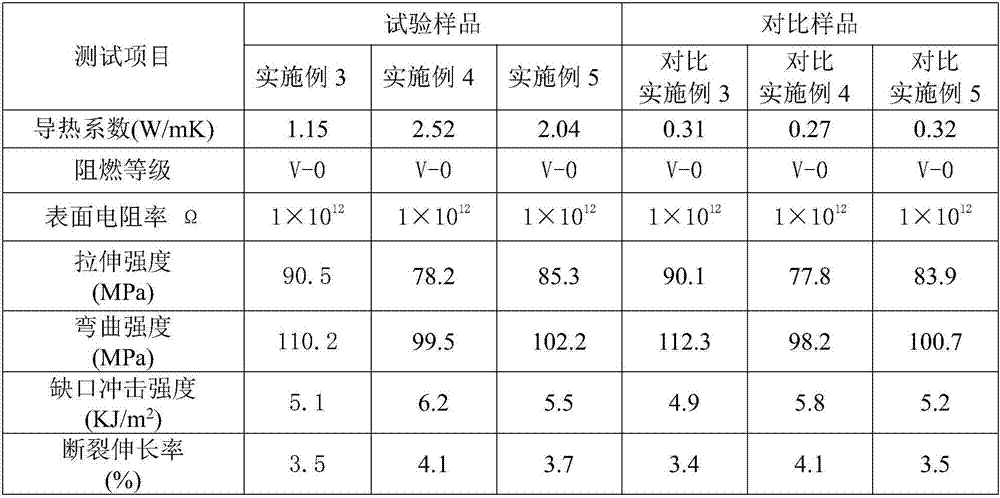

Super-tough nylon alloy and preparation method thereof

The invention discloses a super-tough nylon alloy, which is characterized by comprising raw material by weight percent: 65-90% of nylon, 10-35% of itaconic acid grafting ethylene-alpha-octylene copolymer (POE-g-ITA), 0.1-1% of antioxygen, 0.2-1% of lubricating agent, TAF. A method for preparing the super-tough nylon alloy is characterized by comprising the following steps: placing all raw material into a high mixer and mixing the raw materials for 5-10min; then placing the mixed raw materials into a double screw extrusion machine for extrusion and pelleting; carrying out traction, cooling and grain-sized dicing, finally drying the grain material; wherein main engine speed is 200-400r / min, temperature is 250-280 DEG C. The invention aims to prepare a novel super-tough nylon material which can be widely applied to the fields such as automobiles, electric products, office appliances and constructional engineering.

Owner:BEIJING UNIV OF CHEM TECH

Carbon ceramic braking pad for high-speed train and preparation method of carbon ceramic braking pad

ActiveCN103511525ALess impact on friction and wear propertiesHigh and stable coefficient of frictionFriction liningFiberCeramic composite

The invention relates to a carbon ceramic braking pad for a high-speed train and a preparation method of the carbon ceramic braking pad. The carbon ceramic braking pad is made of carbon ceramic composite material; the carbon ceramic composite material comprises the following components in percentage by mass: 16-30 percent of carbon fibers, 20-36 percent of pyrolytic carbon, 28-46 percent of silicon carbide, 6-12 percent of molybdenum disilicide and 2-6 percent of simple substance silicon; the density of the carbon ceramic composite material is 1.8-2.4g / cm<3>; the carbon fibers are uniformly distributed in the carbon ceramic composite material in a three-dimensional network structure. According to the invention, after the high-temperature heat treatment is performed on a carbon fiber felt with the density of 0.20-0.65g / cm<3>, the pyrolytic carbon is generated in the carbon fiber felt through the thermal-gradient chemical vapor deposition carburizing treatment, then the catalytic graphitization treatment, non-immersion type melting infiltration and assembly are performed, so that the carbon ceramic braking pad for the high-speed train is obtained.The carbon ceramic braking pad is simple in preparation technology, moderate in friction coefficient, good in abrasion performance, stable in braking and strong in environmental suitability and can meet braking requirements of the high-speed train with the speed of 200Km / h.

Owner:HUNAN SHIXIN NEW MATERIALS CO LTD

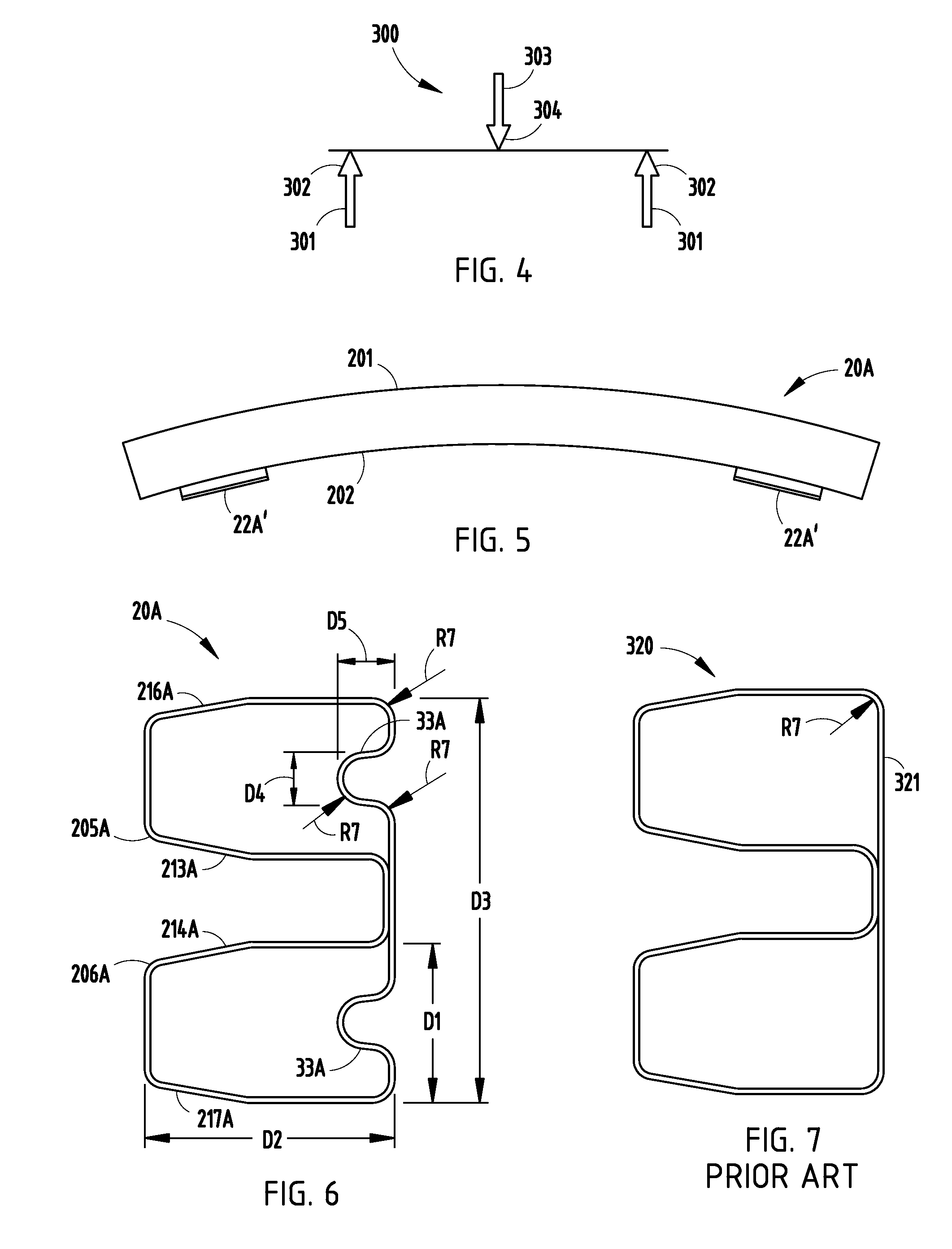

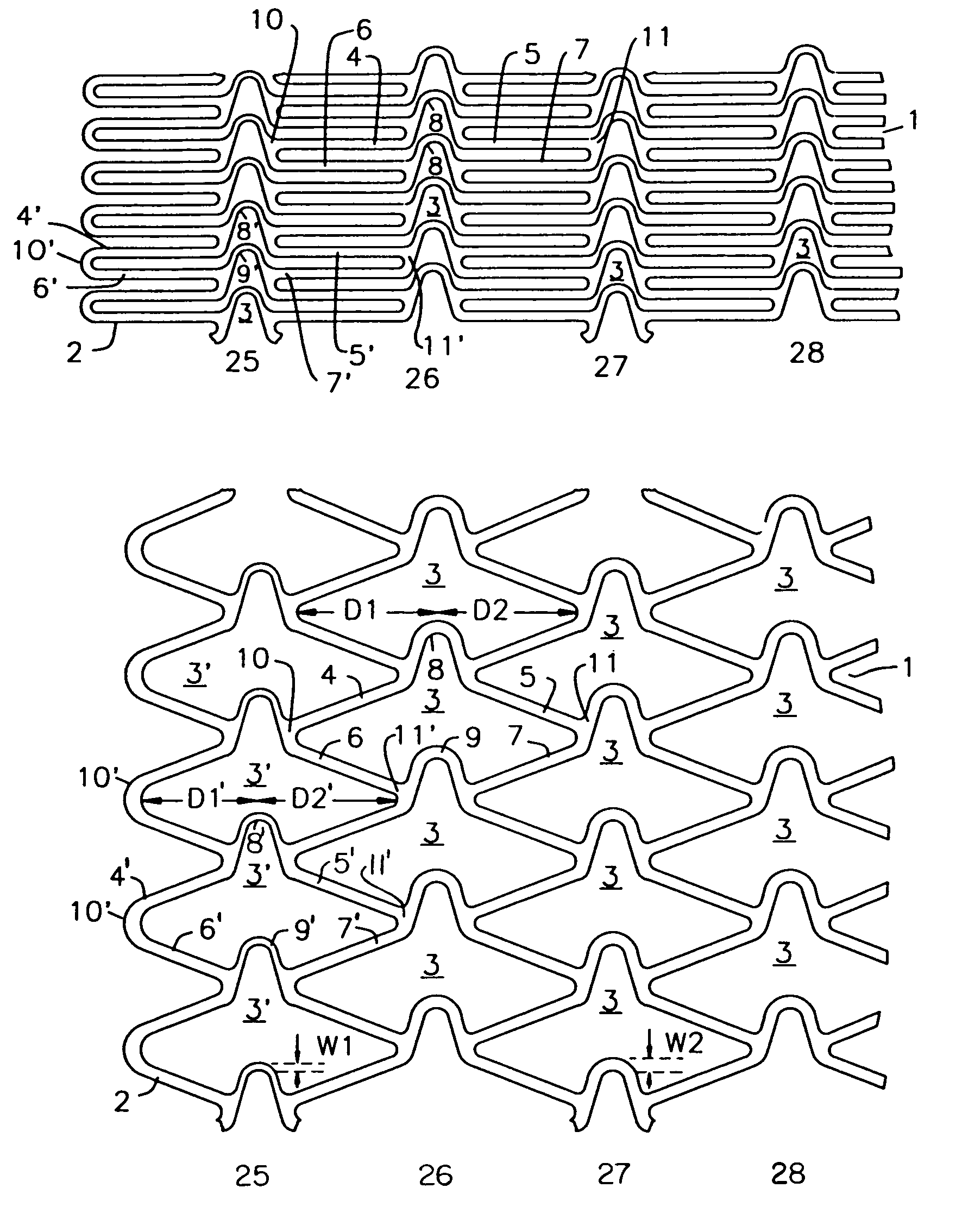

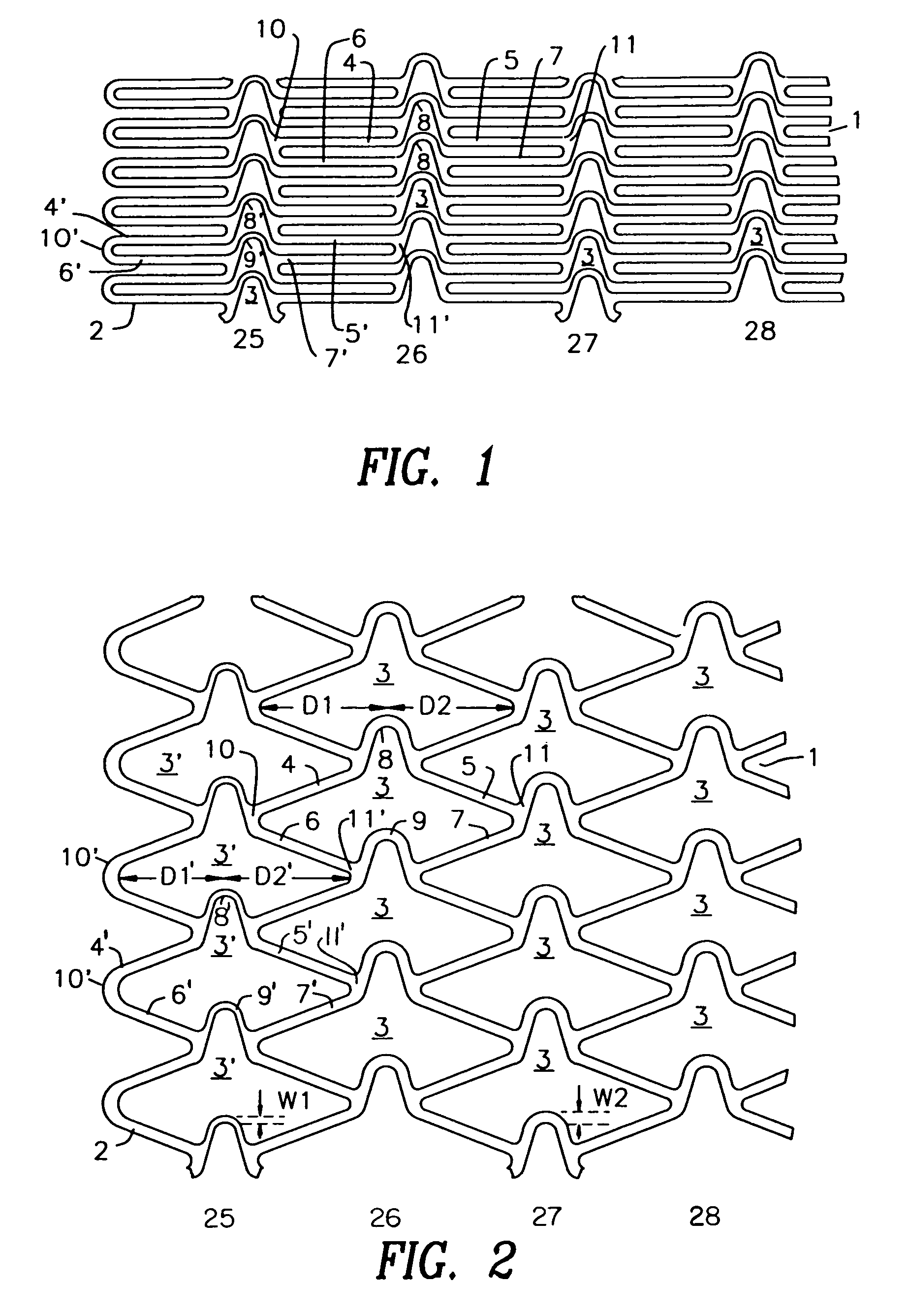

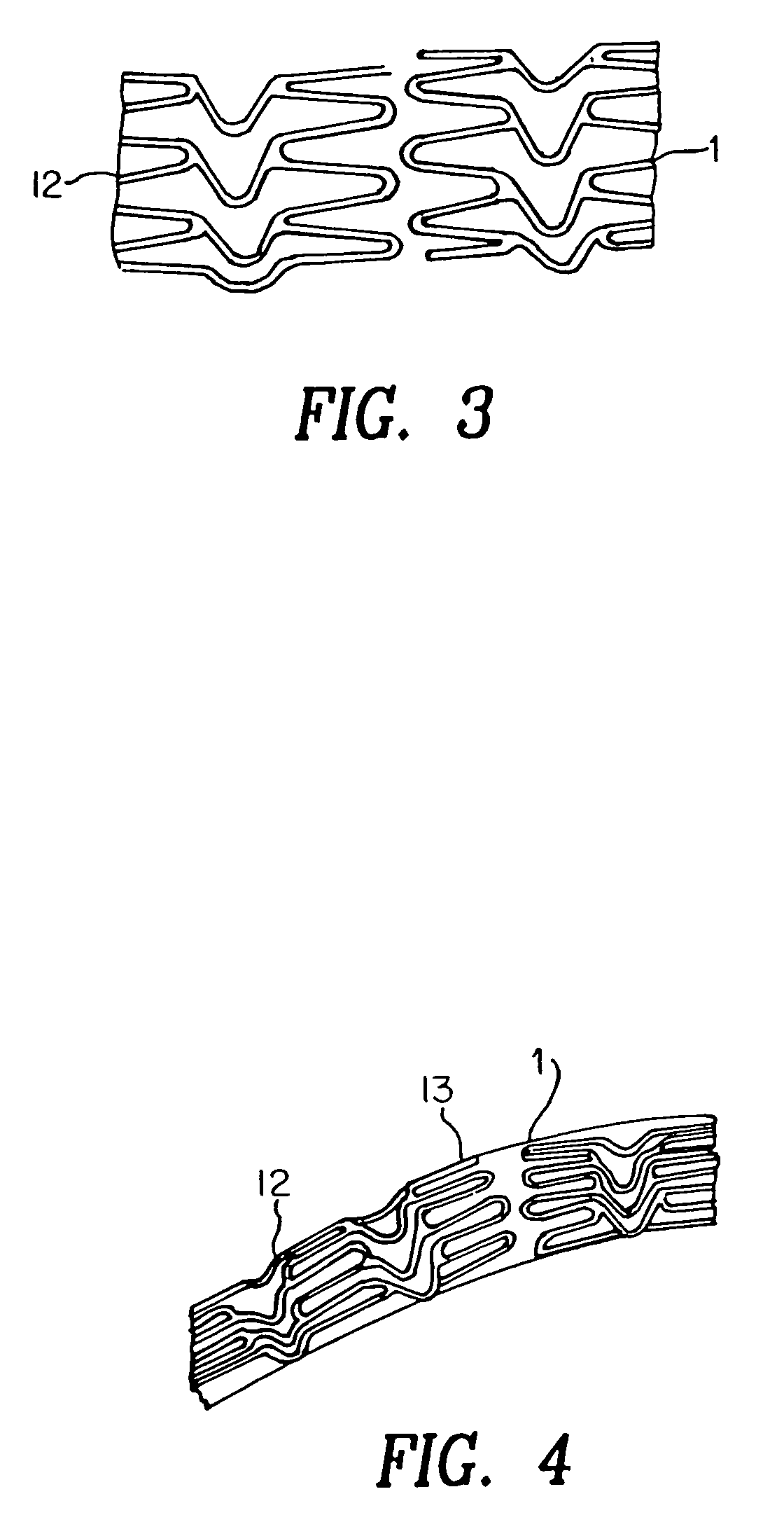

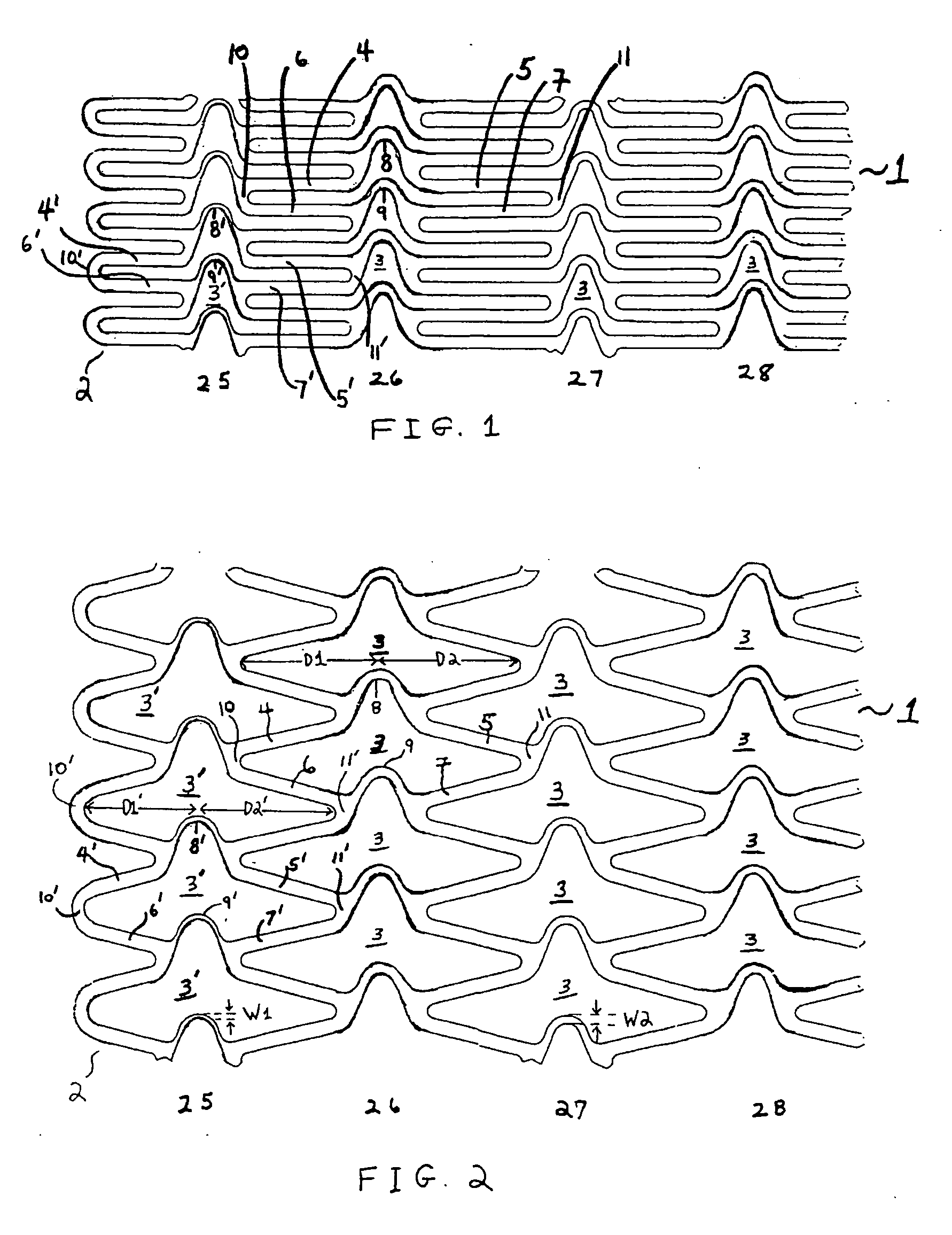

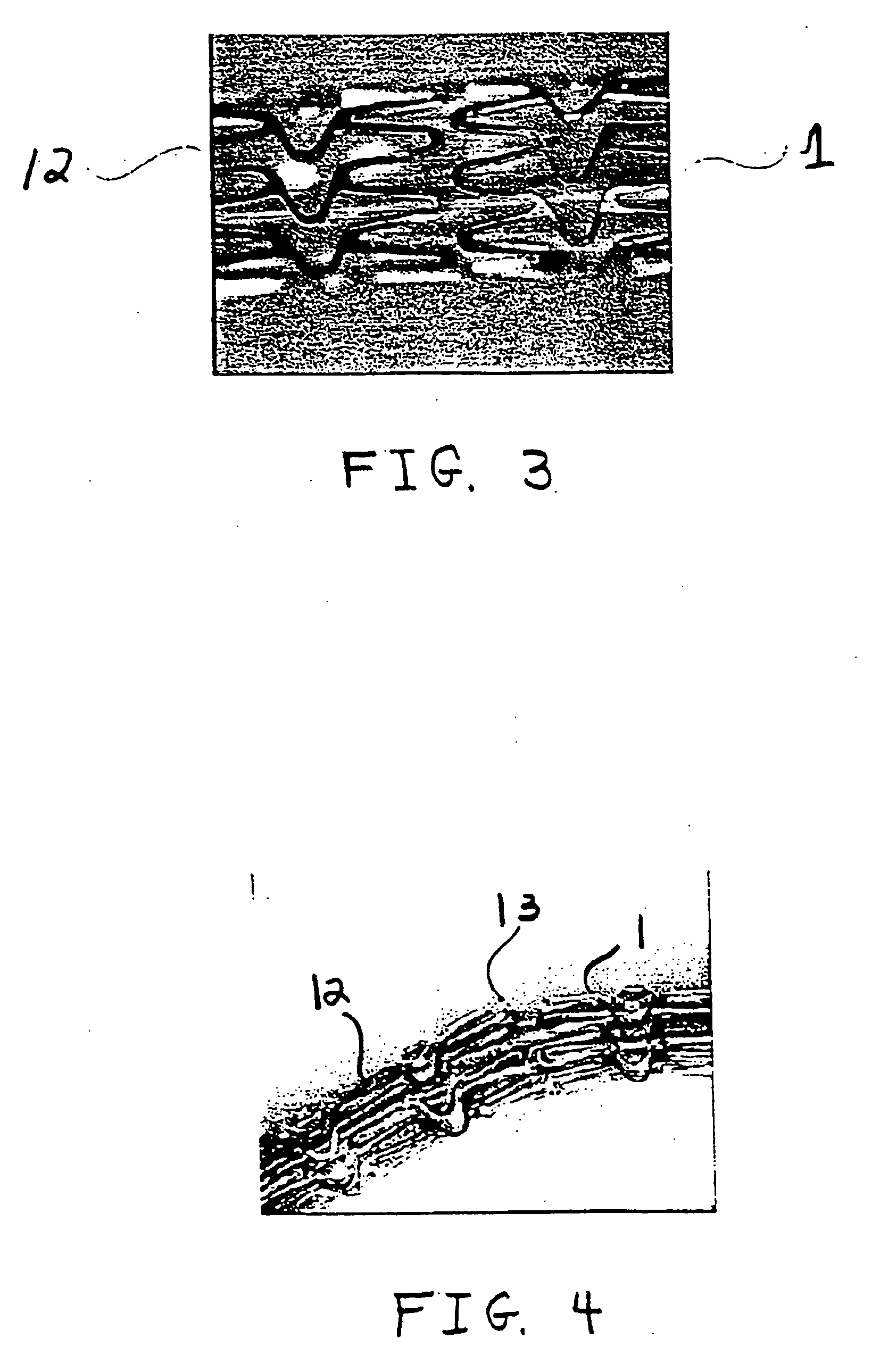

Stent with variable features to optimize support and method of making such stent

InactiveUS7044963B1Improve stent end effectIncrease or decrease thicknessStentsSurgeryVariable featuresIntravascular stent

An intravascular stent especially suited for implanting in curved arterial portions or ostial regions. The stent can include an end region which is fabricated to have a greater radial strength than the remaining axial length of the stent. Such a stent is particularly suited for use in ostial regions, which require greater support near the end of the stent. The stent alternatively can include sections adjacent the end of the stent with greater bending flexibility than the remaining axial length of the stent. Such a stent is particularly suited for use in curved arteries. The stent can also be constructed with an end that has greater radial strength and sections adjacent the end with greater bending flexibility. Such a stent prevents flaring of the stent end during insertion.

Owner:MEDINOL LTD

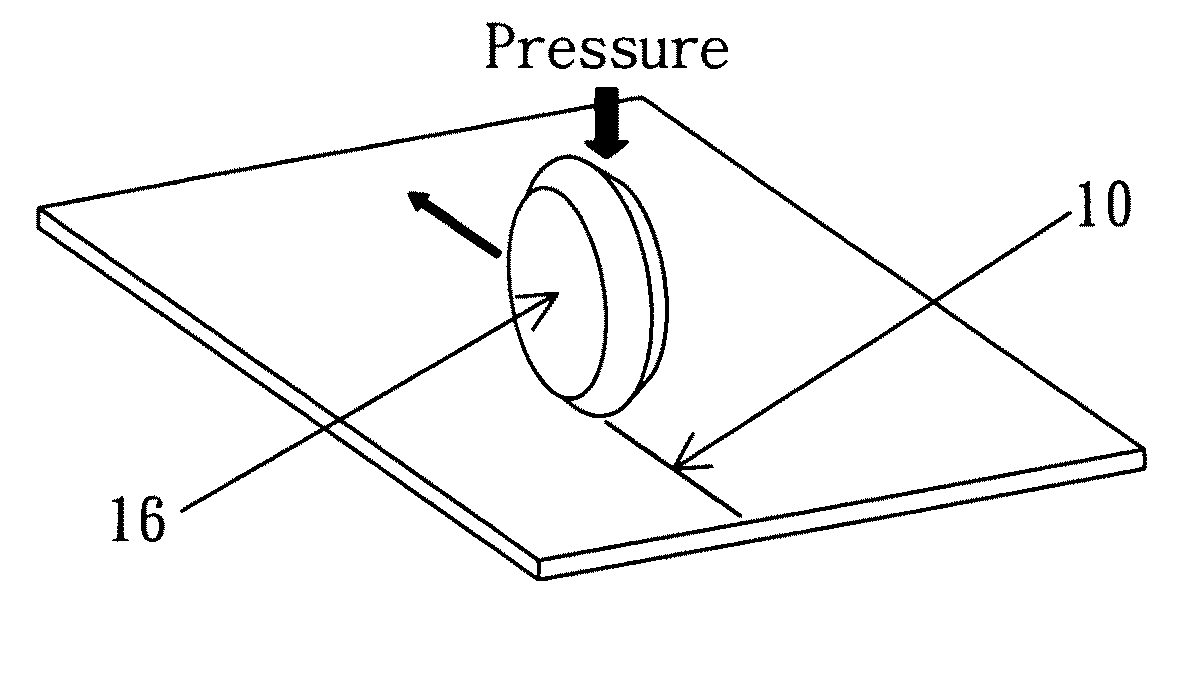

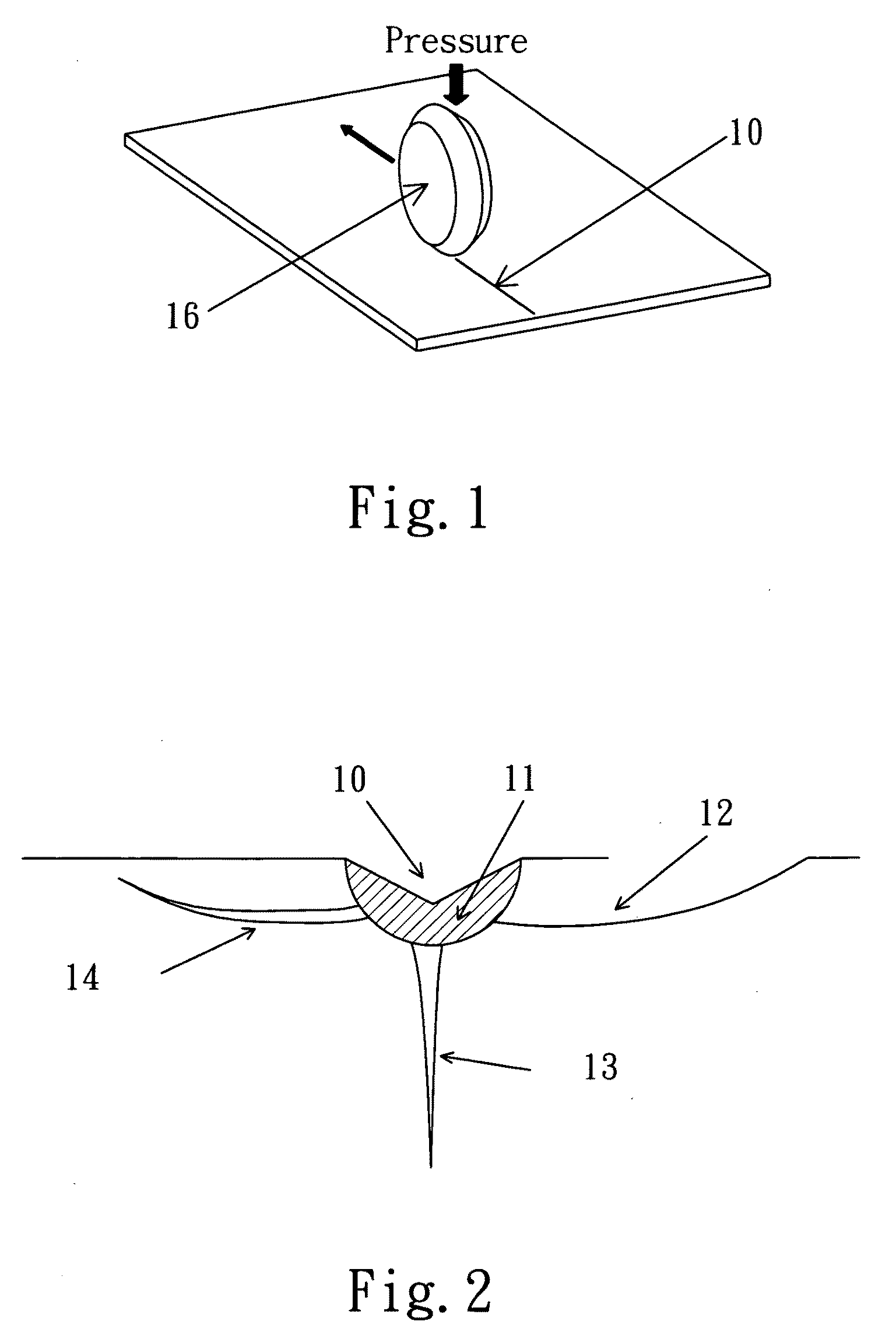

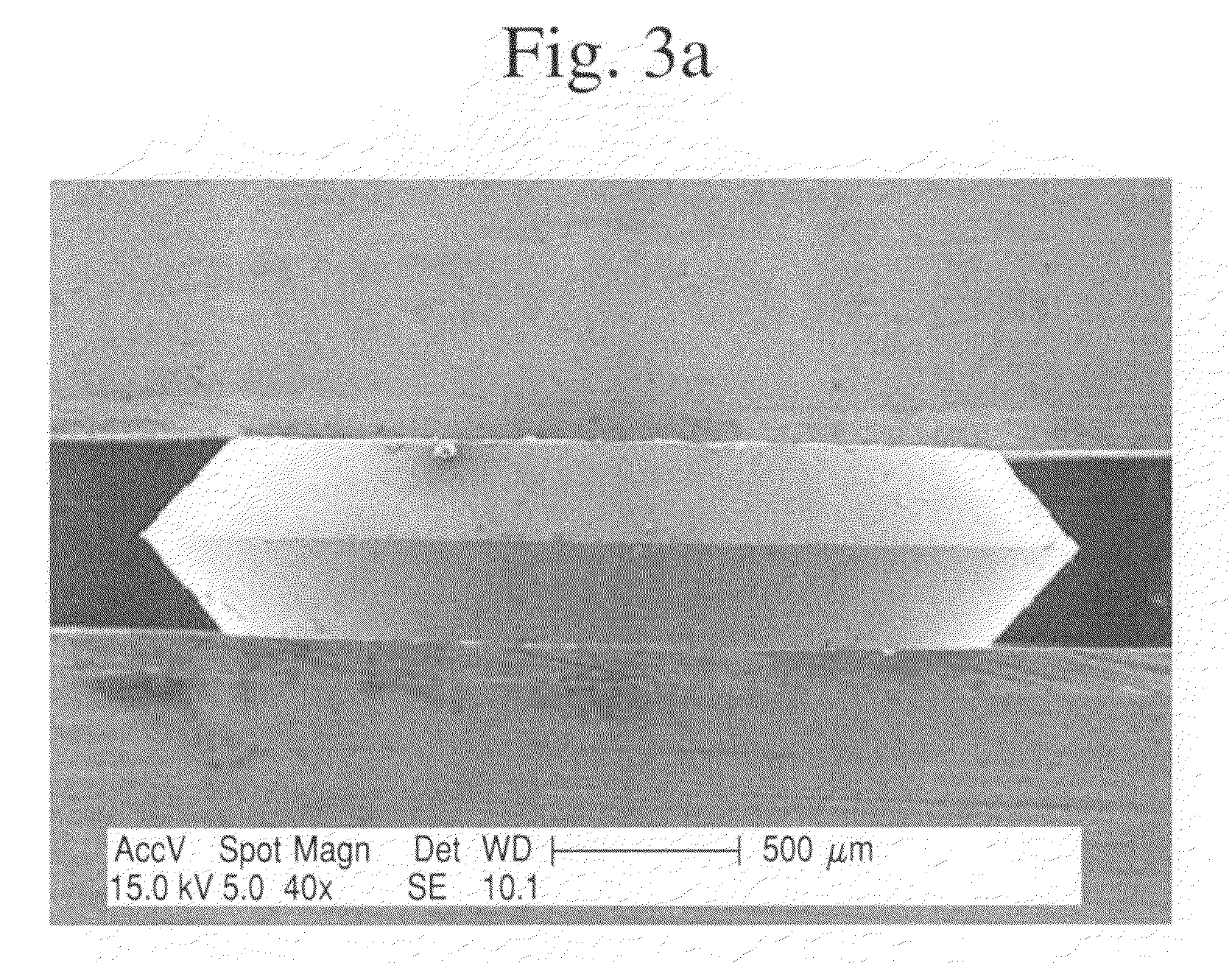

Method and device for vibration Assisted scribing process on a substrate

InactiveUS20100154614A1Avoids disadvantageIncrease depthFine working devicesGlass severing apparatusEngineeringMechanical engineering

Owner:LIAO YUNN SHIUAN

Asbestos-free clutch facing used in vehicle and manufacture method therefor

InactiveCN101033786AImprove performanceHigh strengthFriction liningHeat treatedTemperature and pressure

The invention discloses a kind of none asbestos clutch facing used in cars and its production technology. The recipe of the component is that: E-glass fiber 30~50%, fragrance fiber 1~4%, polyacrylonitrile fiber 0.6~1.2%, the oil of cashew shell friction-type mix 3~6%, oil coke blacking 3~5%, particle graphite 5~8%, zinc oxide 0.2~1%, calcium sulfate 5~15%, heavy calcium carbonate 10~20%, flour acrylonitrile butadiene rubber 15~25%, anti-aging protective TMQ 0.2~0.5%, curing accelerator MBTS 0.2~0.5%, the oil of cashew shell resin modified 6~12%. Banburying mix the component told above in proportions at the proper temperature then make up pellicle by smelting and at last rolls in with the E-glass fiber then forms different ordinance blanks by winding. The blanks confect by heat pressing at the proper temperature and pressure then make into production by grinding and drilling holes. It has the merits like that: high strength, good ductility and stabilize coefficient of friction and so on.

Owner:福建冠良汽车配件工业有限公司

Stent with variable features to optimize support and method of making such stent

InactiveUS20060173531A1Improve final performanceIncrease or decrease thicknessStentsSurgeryVariable featuresInsertion stent

An intravascular stent especially suited for implanting in lumens having variable characteristics such as curvatures, changing diameters as found in ostial regions or variable wall compliance during systolic cycles. The stent can include an end region which is fabricated to have a greater radial strength than the remaining axial length of the stent. Such a stent is particularly suited for use in ostial regions, which require greater support near the end of the stent. The stent alternatively can include sections adjacent the end of the stent with greater bending flexibility than the remaining axial length of the stent. Such a stent is particularly suited for use in curved arteries. The stent can be constructed with an end that has greater radial strength and sections adjacent the end with greater bending flexibility. Such a stent prevents flaring of the stent end during insertion. The stent can also be constructed to have increased longitudinal flexibility when expanded such that it flexes with the vessel wall during systolic cycles.

Owner:MEDINOL LTD

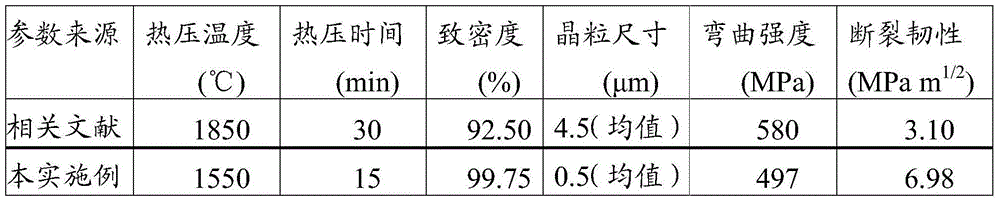

Ceramic matrix composite and preparation method and application thereof

The invention discloses a ceramic matrix composite and a preparation method and application thereof, belongs to the technical field of ultra-high temperature ceramic matrix composites, and relates to a preparation method of a high-strength, high-toughness, high-density and fine-grain organization material. Zirconium diboride powder is used as a matrix phase, and zirconium disilicide powder is used as a sintering aid, so that the optimum sintering temperature, sintering pressure and sintering time of the ceramic matrix composite are lower than the requirements of the hot pressing sintering technology in the prior art; a multi-wall carbon nanotube is used as an additive for improving the internal organization structure of the ceramic matrix composite, obviously reduces the crystal grain size of the ceramic matrix composite, and improves the breaking tenacity of the ceramic matrix composite to 6.98 MPa.m<1 / 2>. The preparation method uses a two-step hot pressing sintering technology with fast and low-temperature characteristics to prepare the zirconium diboride ceramic matrix composite with high density and mechanical properties, and facilitates the subsequent large-scale production preparation and fiber toughening technology.

Owner:DALIAN UNIV OF TECH

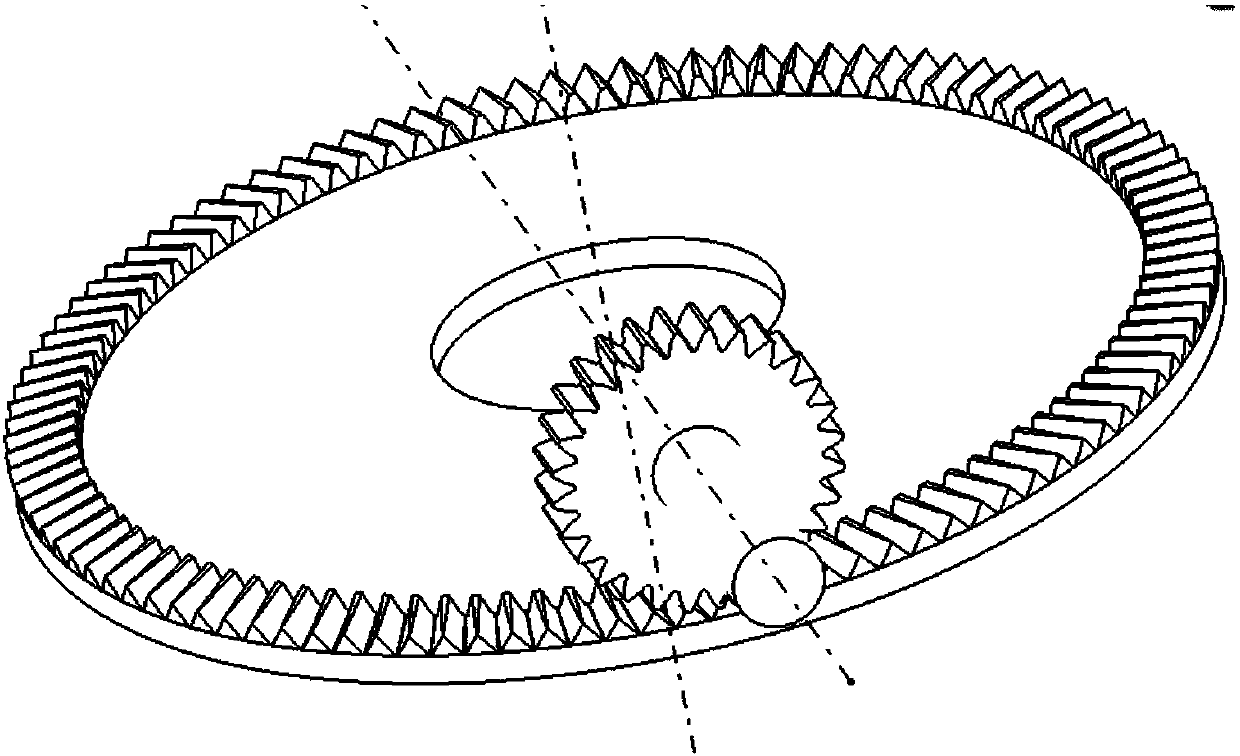

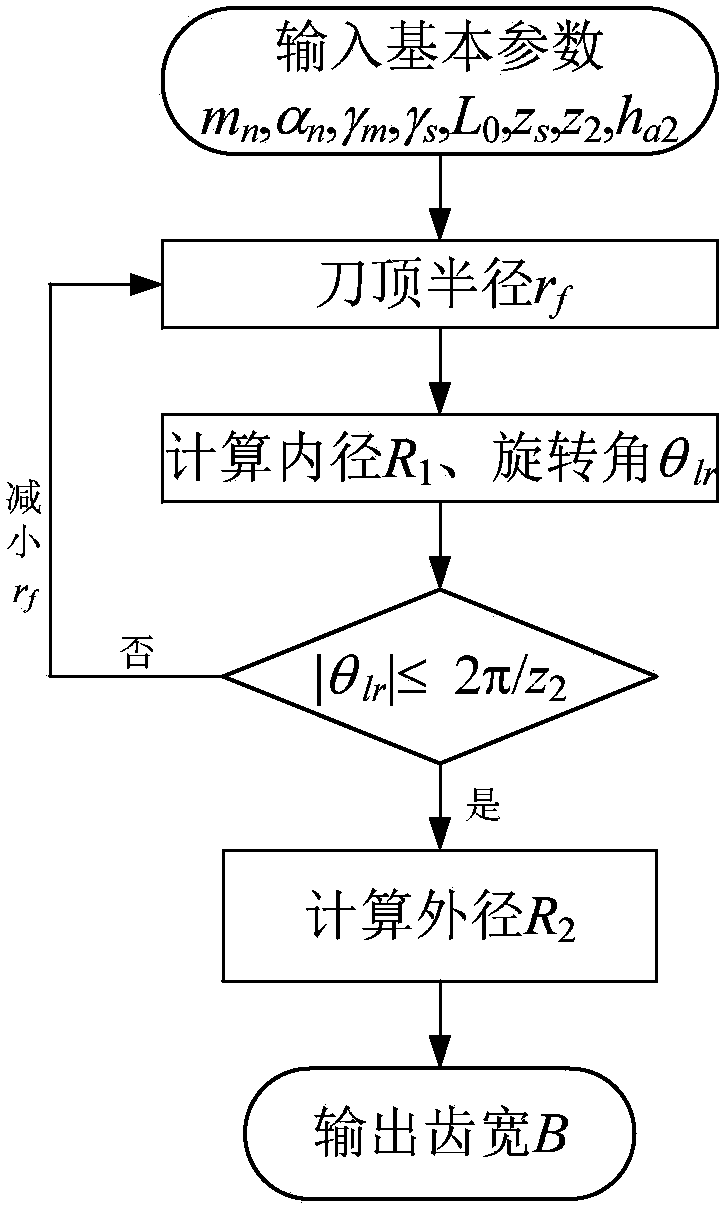

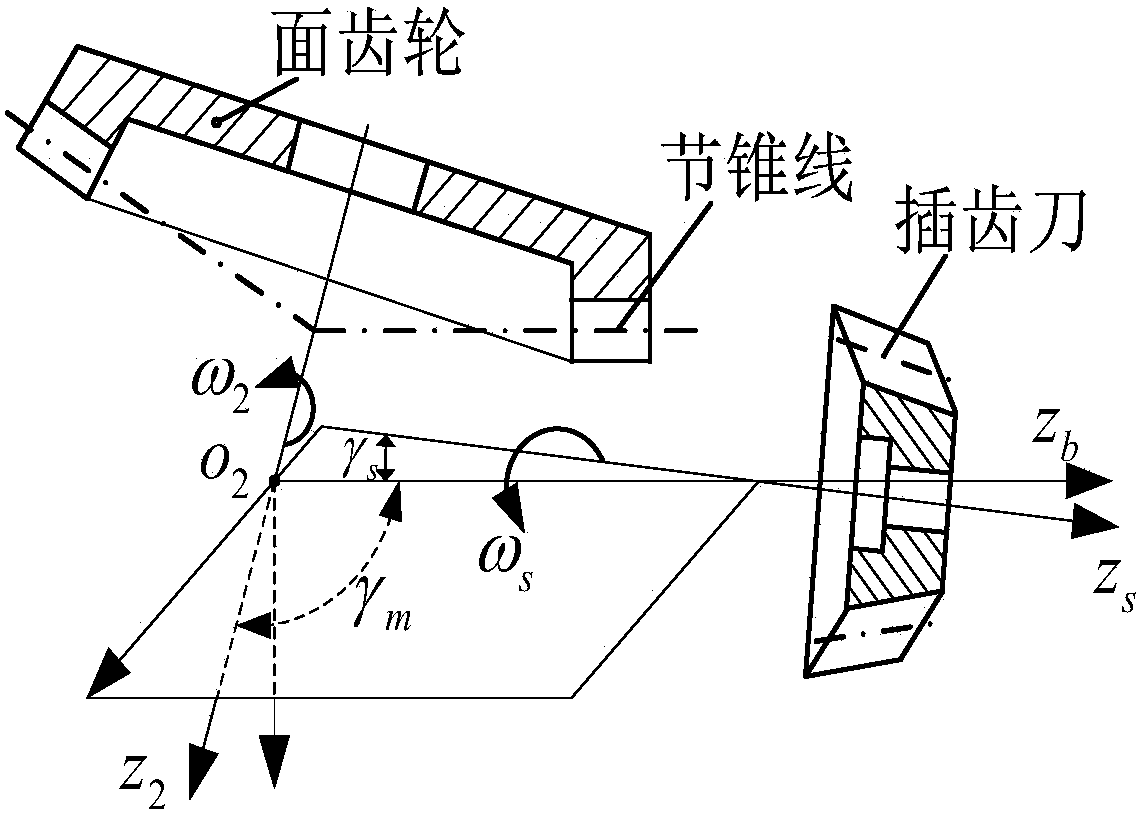

Skew line tooth surface gear transmission pair and tooth width geometric design method

InactiveCN105156637AReduce weightIncrease thrust-to-weight ratioPortable liftingGearing elementsAviationGeometric design

The invention discloses a skew line tooth surface gear transmission pair and a tooth width geometric design method. The skew line tooth surface gear transmission pair adopts an alternating axis transmission form composed of involute spur gears and skew line tooth surface gears. Each skew line tooth surface gear is formed by spreading straight tooth involute slotting cutters in a staggered mode; the skew line tooth surface gears can only mesh with the straight tooth cylindrical gears and can not mesh with the skewed tooth cylindrical gears with helix angle; and the tooth trace is approximate to a skew line and forms an oblique angle with the radius direction, thereby being very suitable for the demands of design diversification for aviation compact space. The method illuminates the gear shaping principle of the skew line gear and skew line tooth surface gear, and deduces the tooth surface equation of the skew line tooth surface gear. The margin line of the involute slotting cutters is utilized to calculate the position of the tangent point of the internal end tooth root. The condition that the outer end tooth top tooth thickness is equal to zero is utilized to obtain the sharpening condition. The condition of avoiding secondary cutting of the tooth root is combined with determine the cutter top fillet radius, thereby finally obtaining the tooth width of the skew line tooth surface gear.

Owner:CHANGAN UNIV

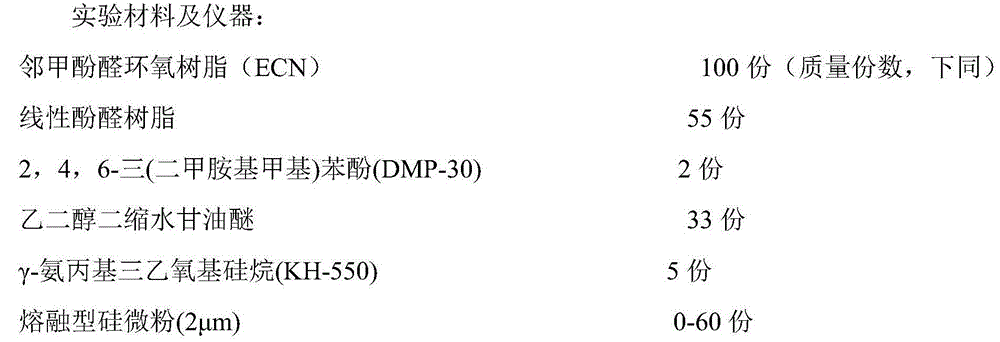

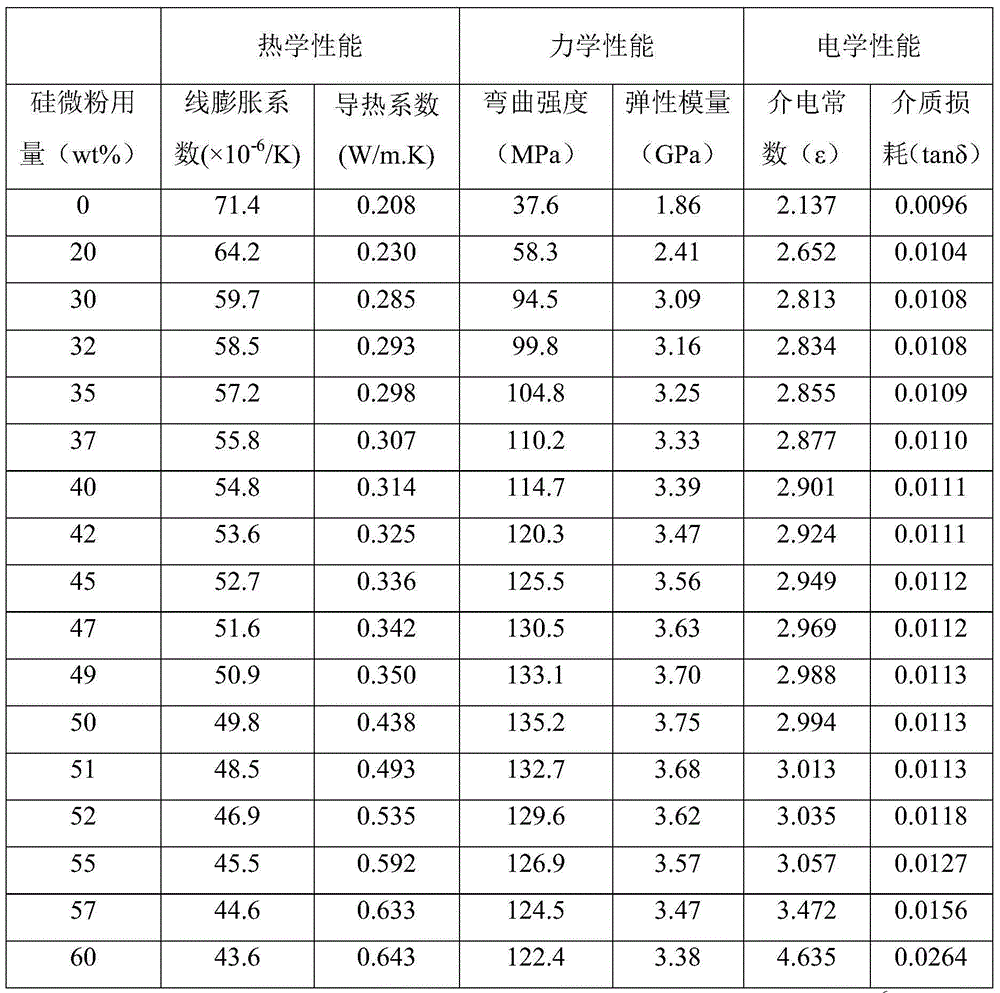

Epoxy molding compound and preparation method thereof

ActiveCN104672785ASmall coefficient of linear expansionImprove thermal conductivityMicroelectronicsSilane coupling

The invention discloses an epoxy molding compound and a preparation method thereof. The epoxy molding compound comprises the following components: epoxy resin, a coupling agent, a curing agent, a curing accelerator and filler, wherein the epoxy resin is o-cresol formaldehyde epoxy resin (ECN); a diluent is an epoxyactive diluent; the coupling agent is a silane coupling reagent; the curing agent is a latent curing agent; the curing accelerator is a latent curing accelerator; and the filler is silica powder. The thermal property, the mechanical property, the electric property and the like of the epoxy molding compound reach a balanced and relatively good level and can meet the requirements of the modern microelectronics packaging technology.

Owner:GUANGDONG DANBOND TECH

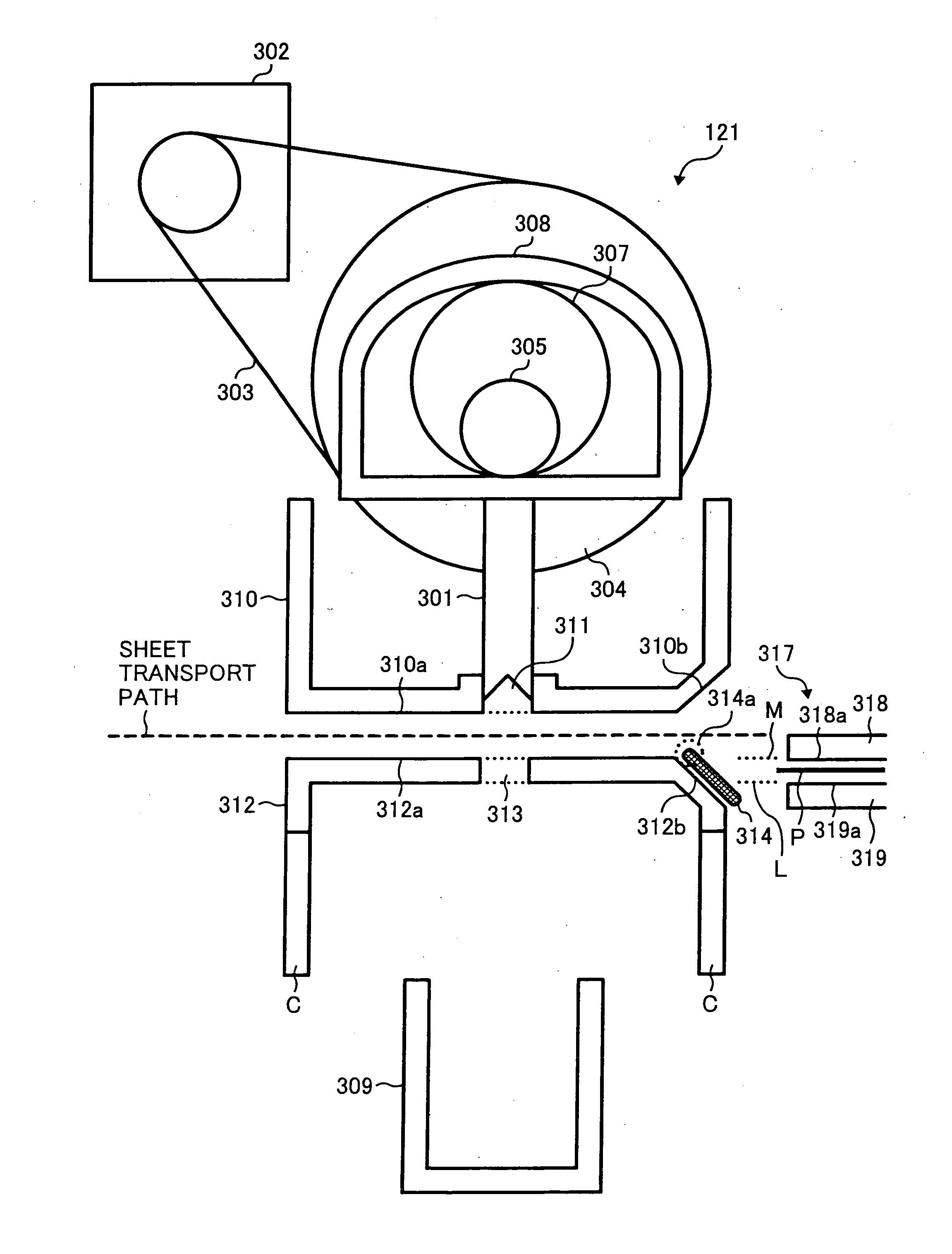

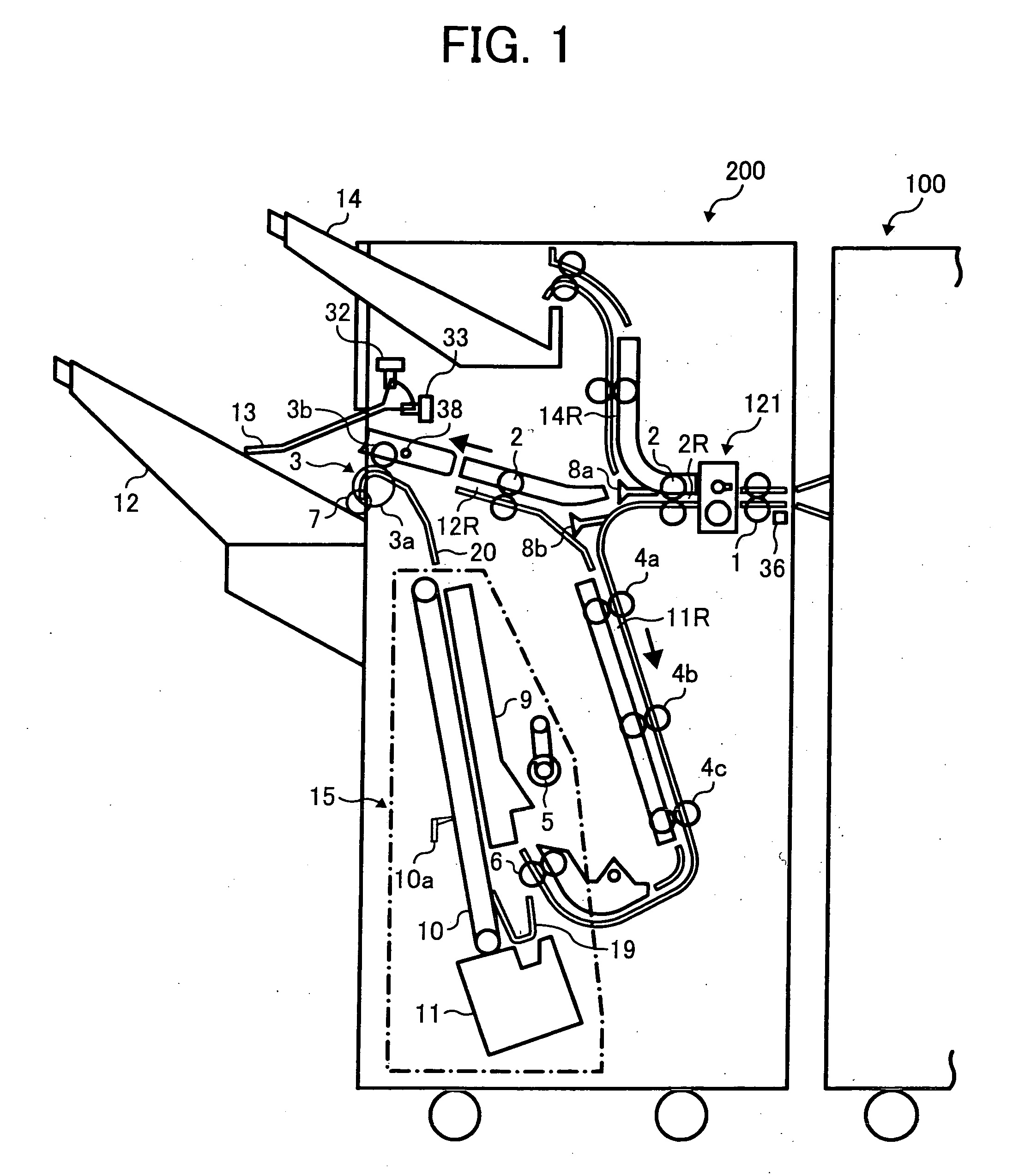

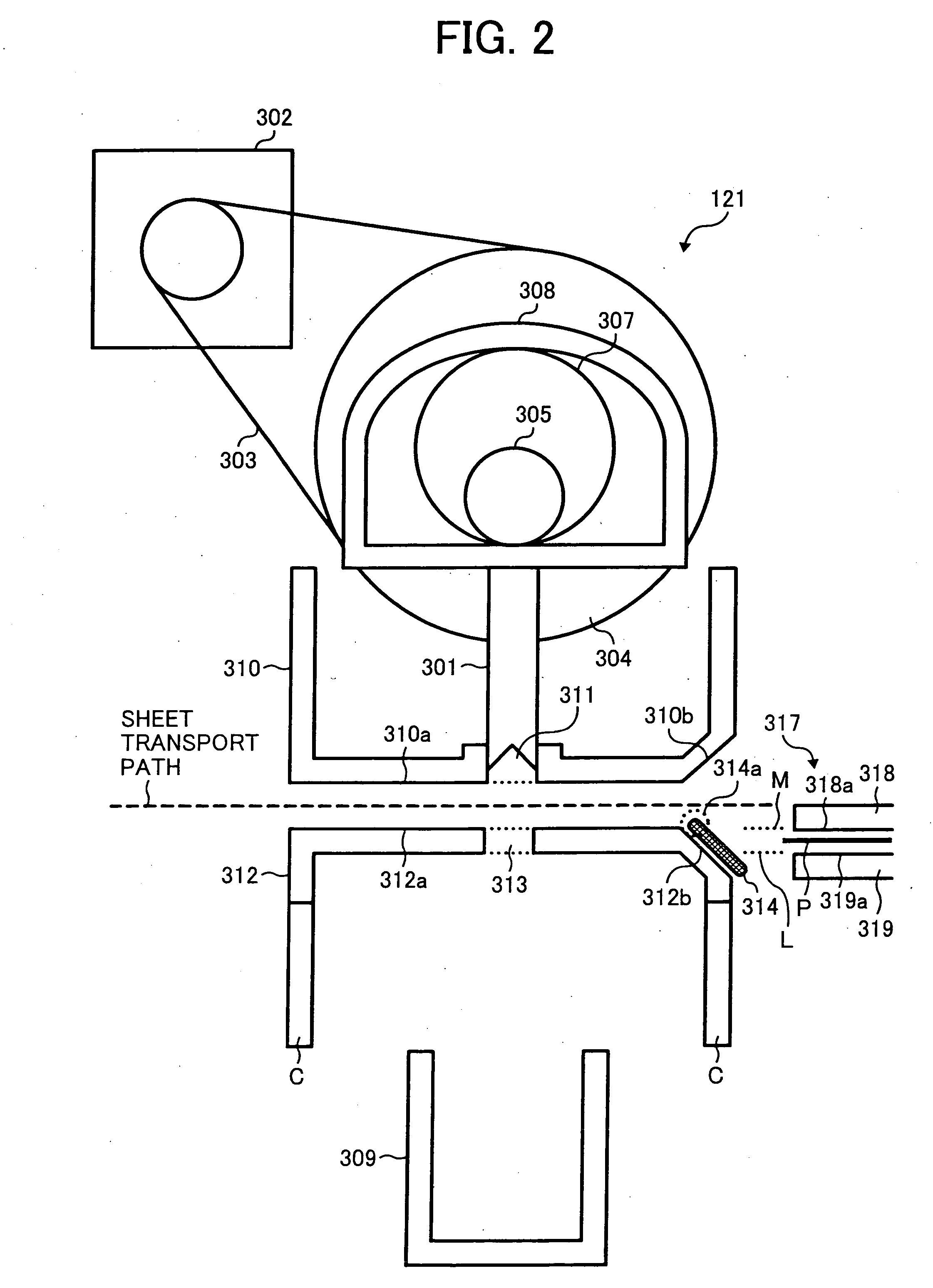

Heat-effect reduceable finishing unit and image forming system using the same

InactiveUS20070056423A1Reduced bending strengthElectrographic process apparatusMetal working apparatusFlexural strengthEngineering

Owner:RICOH KK

Porous corundum ceramics used for heating atomizer and production method of porous corundum ceramics used for heating atomizer

The invention discloses a production method of porous corundum ceramics used for a heating atomizer. The production method of the porous corundum ceramics used for the heating atomizer comprises the following steps: (1) weighing the raw materials according to the following proportions: 40-70 wt% of corundum, 10-30 wt% of adhesive, 10-30 wt% of sintering aids and 10-30 wt% of pore-forming agents; (2) putting the raw materials into mixing equipment to obtain slurry; (3) conducting spray drying granulation on the ceramic slurry; (4) placing granulated ceramics into a mould, and conducting dry pressing to obtain a green body; (5) placing the green body into a sintering furnace for sintering; and (6) soaking porous ceramics by adopting an edible acid solution, and conducting drying after cleaning is conducted. According to the method, carbon powder and an organic pore-forming agent are adopted for controlling the pore size and the porosity, clay and glass powder are used as the sintering aids for sintering a corundum main body, the porous ceramics have a super-hydrophilic effect on water-based liquid and alcohol-based liquid, and the porous corundum ceramics which have high porosity andhigh strength and absorb liquid fast are produced.

Owner:NINGBO VULCAN TECH CO LTD

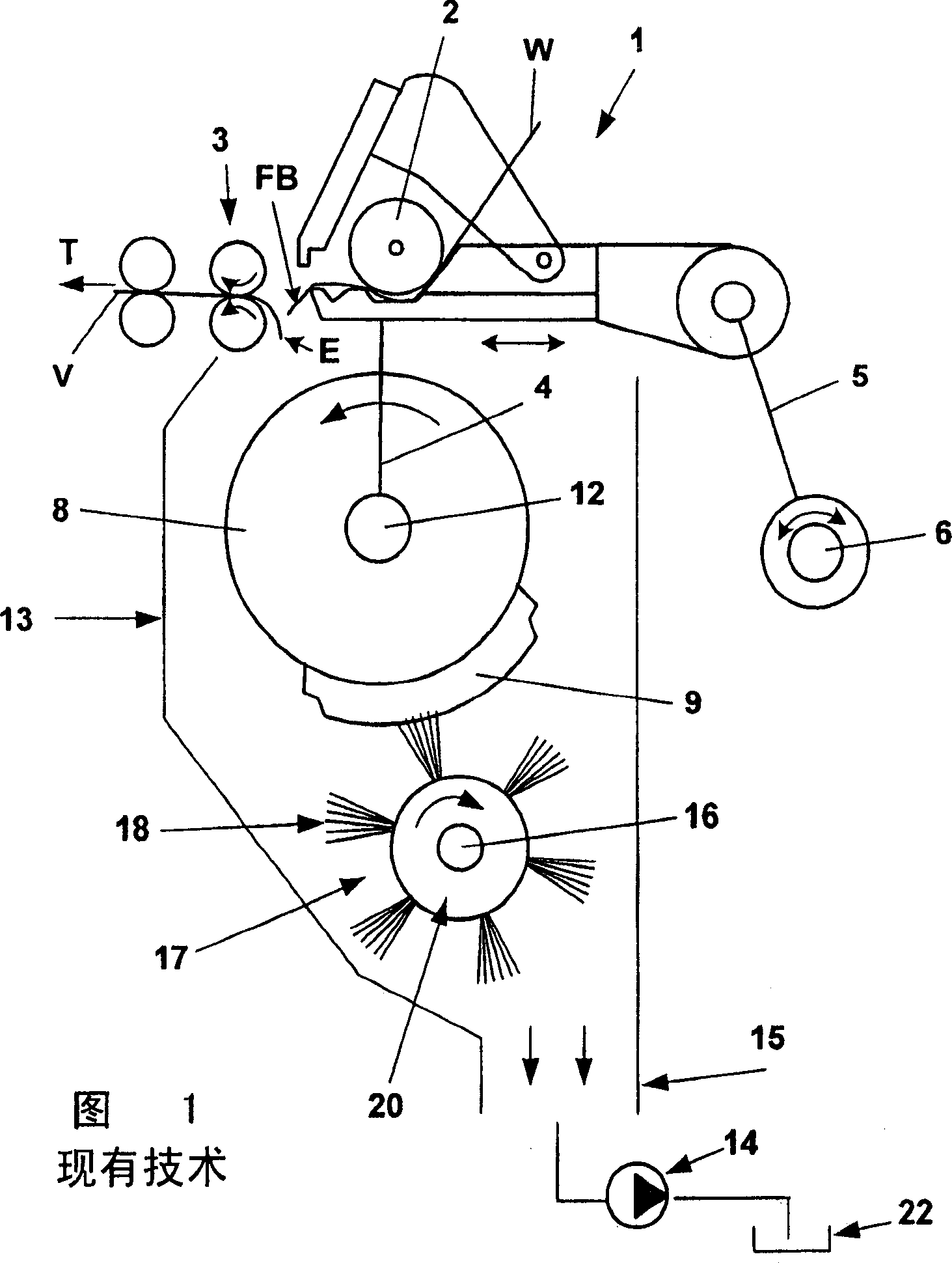

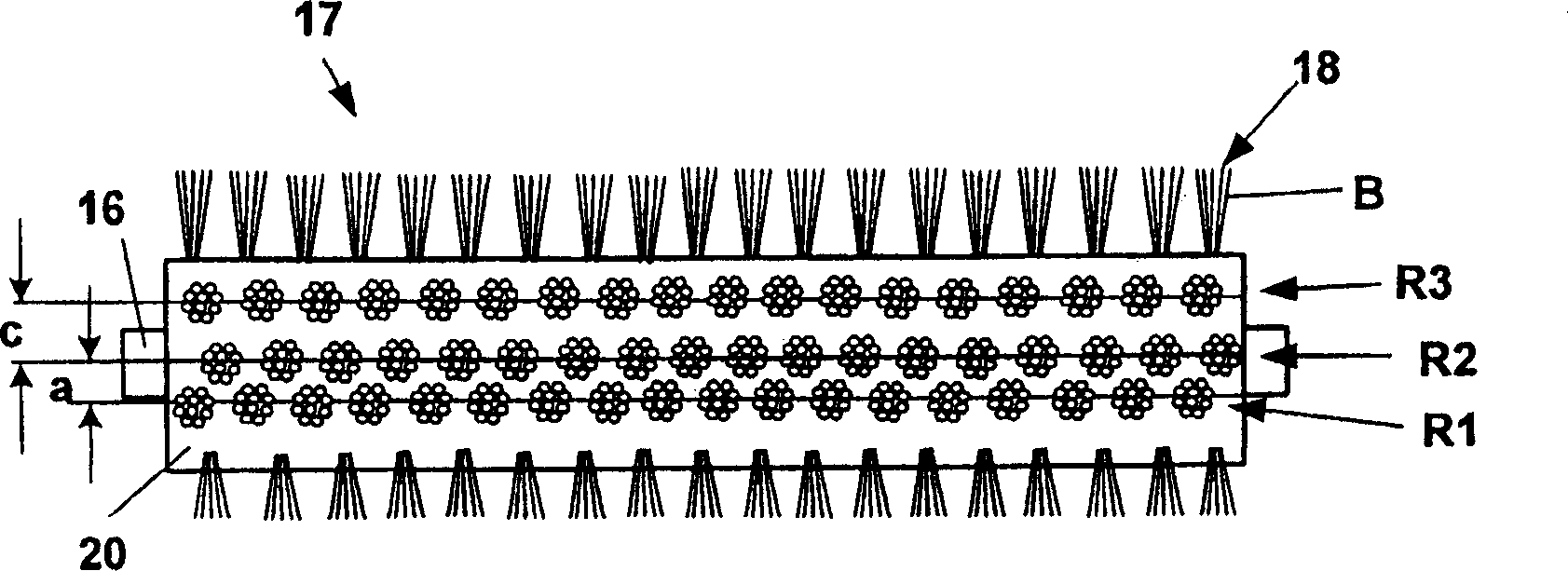

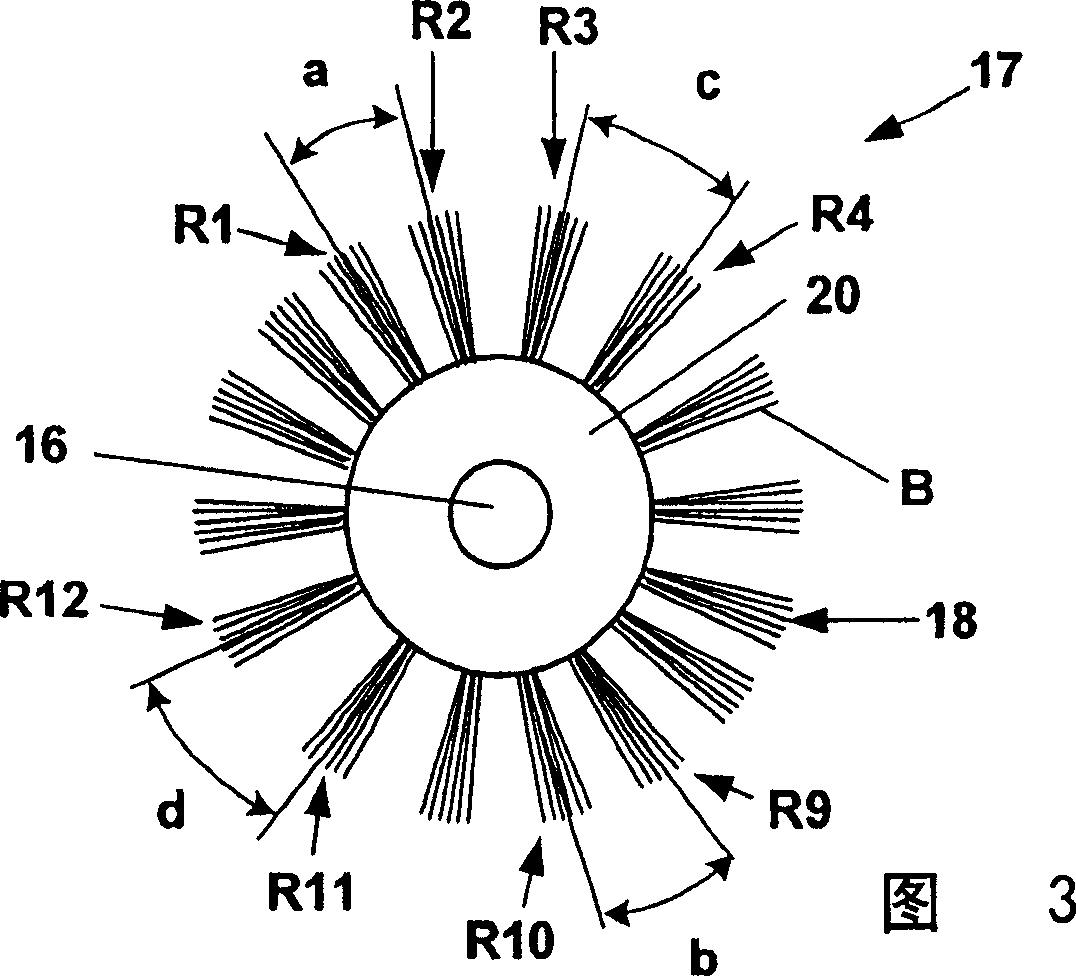

Device for cleaning a combing segment in a combing machine

InactiveCN1884648AImprove bending strengthHigh or low flexural strengthCombing machinesMechanical engineeringEngineering

In apparatus for cleaning the comb segments of a circular comb in a combing machine, comprising a cleaning roller (17) parallel to and spaced from the round comb and with peripheral cleaning elements (18) temporarily contacting the segments during rotation of the roller, some of the cleaning elements differ from the other cleaning elements in geometrical location, geometrical pattern and / or material.

Owner:MASCHINENFABRIK RIETER AG

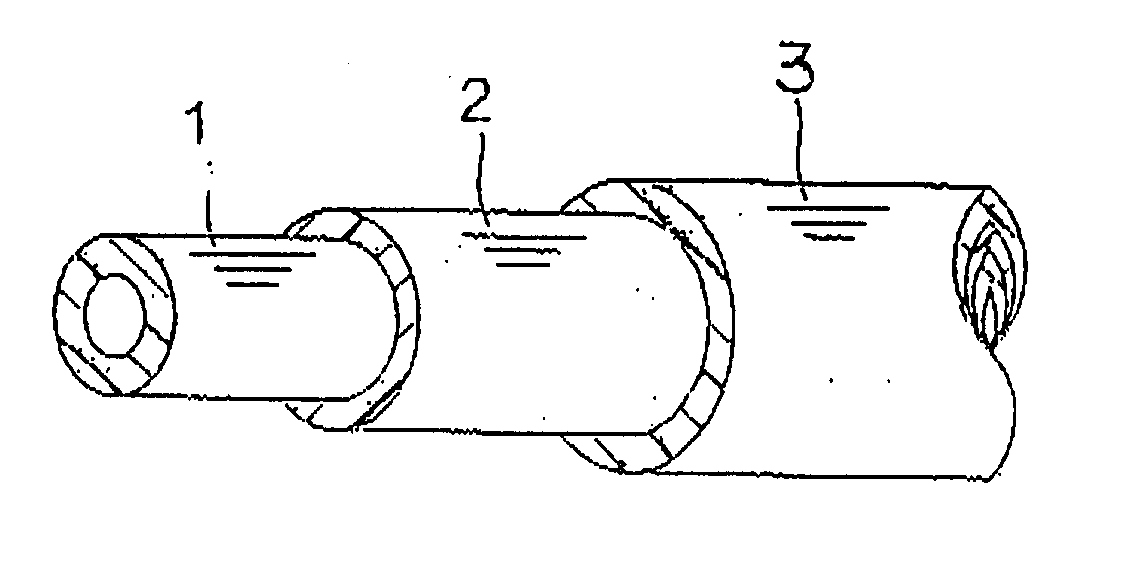

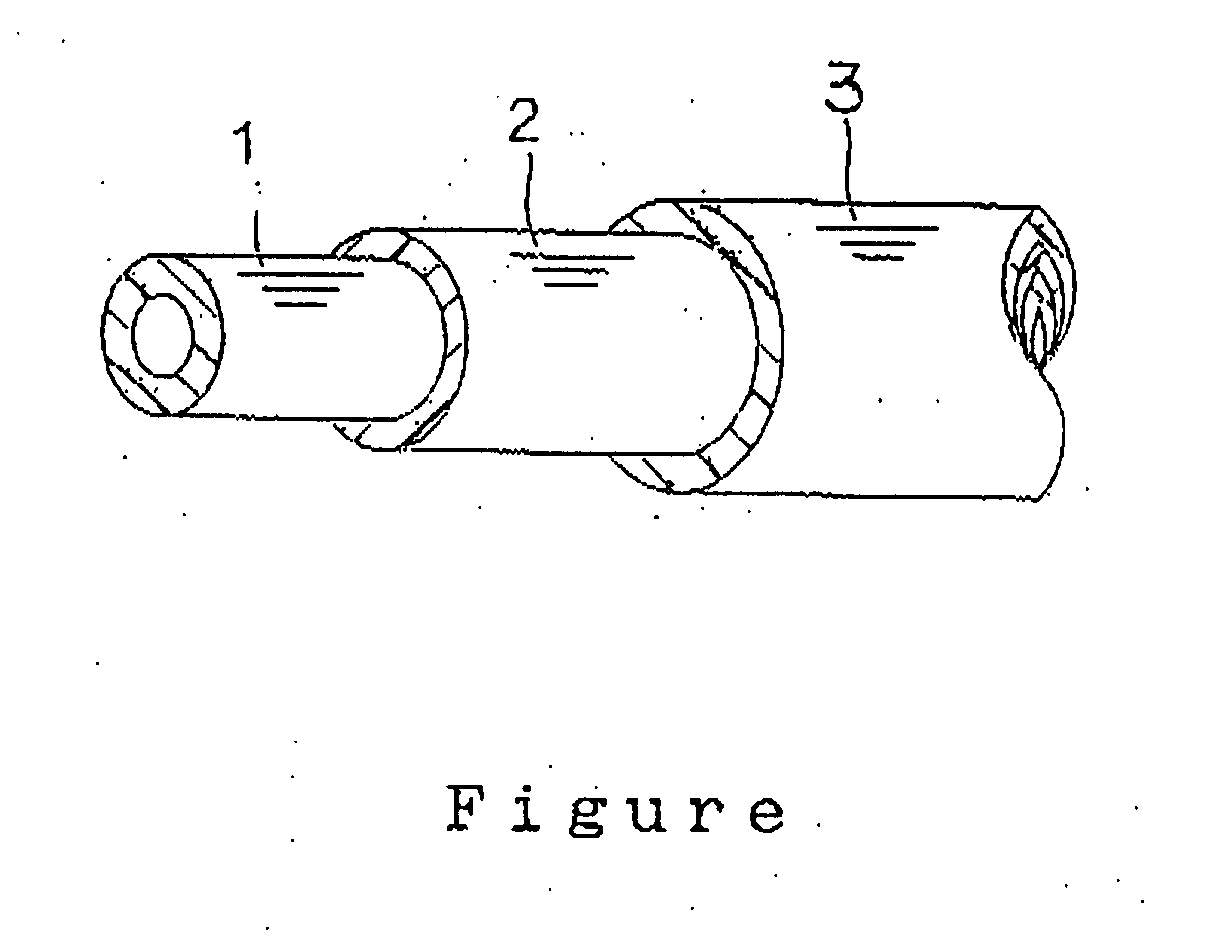

Automotive fuel hose

ActiveUS20050067035A1Reduce crystallinityInferior in sour gasoline resistanceSynthetic resin layered productsMachines/enginesPolyolefinGasoline

An automotive fuel hose having a three-layer structure excellent in sour-gasoline resistance and impact resistance. The automotive fuel hose includes a tubular inner layer in which fuel is adapted to flow; a low fuel permeability layer provided on an outer peripheral surface of the inner layer; and an outer layer provided on an outer peripheral surface of the low fuel permeability layer. The inner layer and the outer layer each including at least one of a polyolefin resin having a functional group and a polyamide resin and the low fuel permeability layer including a polyphenylene sulfide resin.

Owner:SUMITOMO RIKO CO LTD

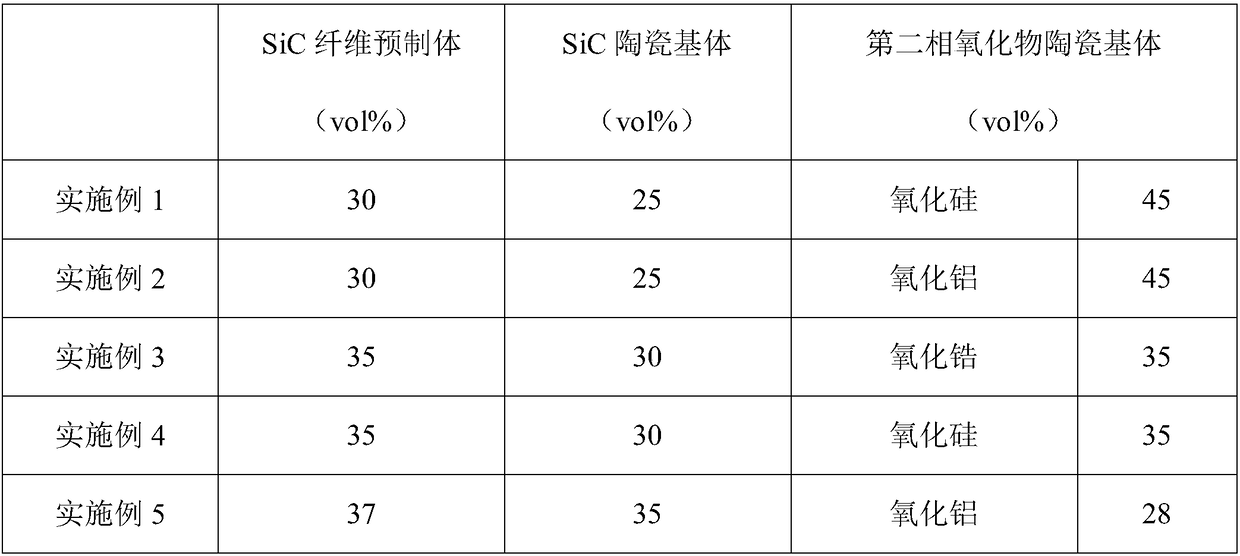

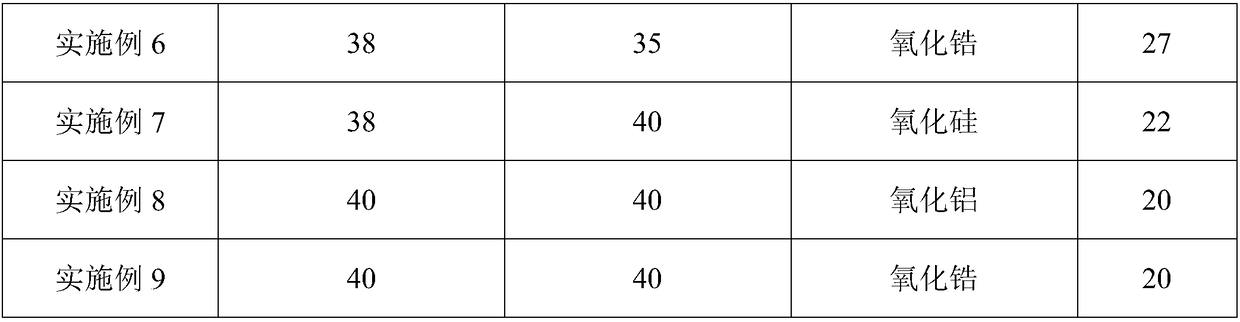

Silicon carbide fiber reinforced ceramic based structure wave absorption composite material and preparation method thereof

The invention relates to a silicon carbide fiber reinforced ceramic based structure wave absorption composite material and a preparation method thereof. The silicon carbide fiber reinforced ceramic based structure wave absorption composite material is prepared from the following ingredients in percentage by volume: 30 to 40 percent of SiC fiber prefabricated bodies, 25 to 40 percent of SiC ceramicsubstrates and 20 to 45 percent of oxide ceramic substrates. Firstly, the SiC fiber prefabricated bodies are subjected to degumming treatment and drying; SiC is decomposed onto the SiC fiber prefabricated body subjected to the degumming treatment and drying; an SiCf / SiC wave absorption composite material is prepared; the obtained SiCf / SiC wave absorption composite material is soaked into silica sol, aluminum sol or zirconium sol; high-temperature treatment is performed; the silicon carbide fiber reinforced ceramic based structure wave absorption composite material is obtained. The SiCf / SiC ceramic with a certain porosity is firstly prepared; then, the materials are soaked into silica sol, aluminum sol or zirconium sol for hihg-temperature treatment; a compact double ceramic base compositematerial is obtained; the dielectric constant of the wave absorption composite material is effectively regulated and controlled; the good wave absorption effect is achieved.

Owner:QINGHAI UNIVERSITY

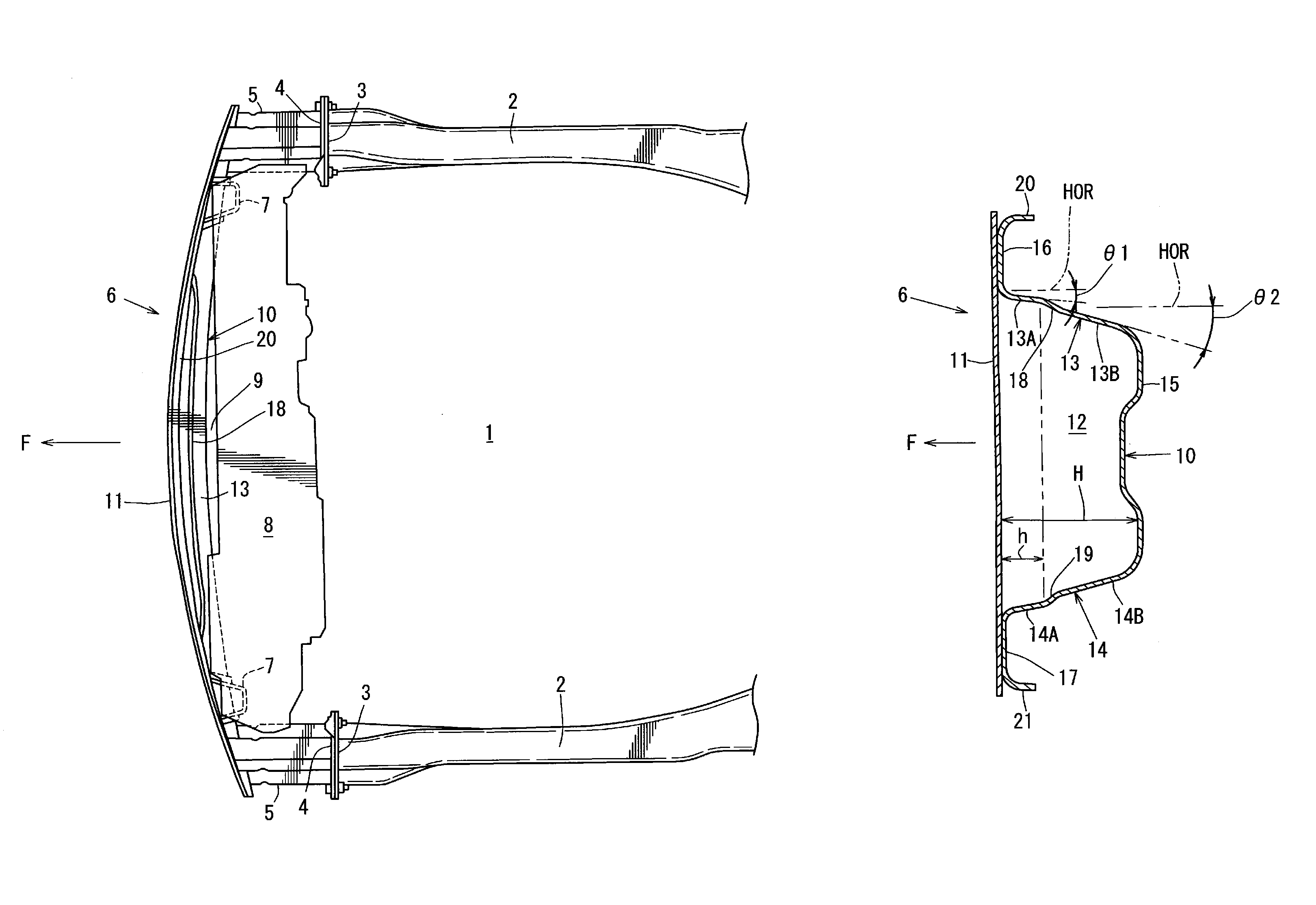

Vehicle-body structure of vehicle

A panel member having a U-shaped cross section includes step portions at an upper face portion and a lower face portion, and a distance, in a vehicle longitudinal direction, of the step potions from a panel member formed substantially in a flat-plate shape, is configured such that the distance at a central portion, in the vehicle width direction, of a bumper reinforcement is the maximum and the distance decreases gradually toward an outward direction of the vehicle. Accordingly, the vehicle-body structure which can properly ensure the bending strength and also attain the light weight of the bumper reinforcement, improving the load transmission from the bumper reinforcement to crash cans, can be provided.

Owner:MAZDA MOTOR CORP

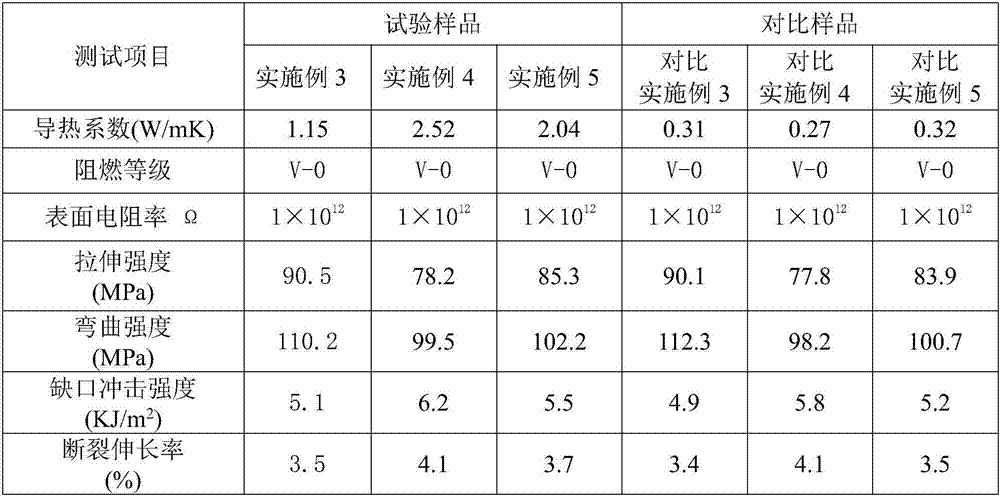

Preparation method for heat-conducting anti-flaming PET/PBT composite material and application thereof

ActiveCN107383803AImprove thermal conductivityImprove flame retardant performanceCross-linkActivated carbon

The invention relates to a preparation method for a heat-conducting anti-flaming PET / PBT composite material. The method comprises the following steps: 1) adding a dispersing agent and graphene into a solvent and ultrasonically treating, thereby acquiring a graphene suspension, and then adding activated carbon into the suspension, continuously ultrasonic dispersing, washing and performing centrifugal suction filtration, thereby acquiring an activated carbon intercalated graphene prefab, and lastly, adopting microwave for heating the prefab, thereby acquiring activated carbon intercalated graphene powder; and 2) preparing polymeric monomer into solution by using deionized water, adding dispersing agent and ultrasonically dispersing the coupled activated carbon intercalated graphene powder, thereby acquiring an activated carbon intercalated graphene suspension; increasing the temperature to 40-90 DEG C and then adding cross-linking agent and initiator for triggering polymerization; pelletizing or crushing and drying, thereby acquiring the grained or powdered shell-core activated carbon intercalated graphene; and blending and extruding the shell-core activated carbon intercalated graphene and the components, thereby acquiring the heat-conducting anti-flaming PET / PBT composite material.

Owner:LEEWAY LIGHTING PARTS XIAMEN

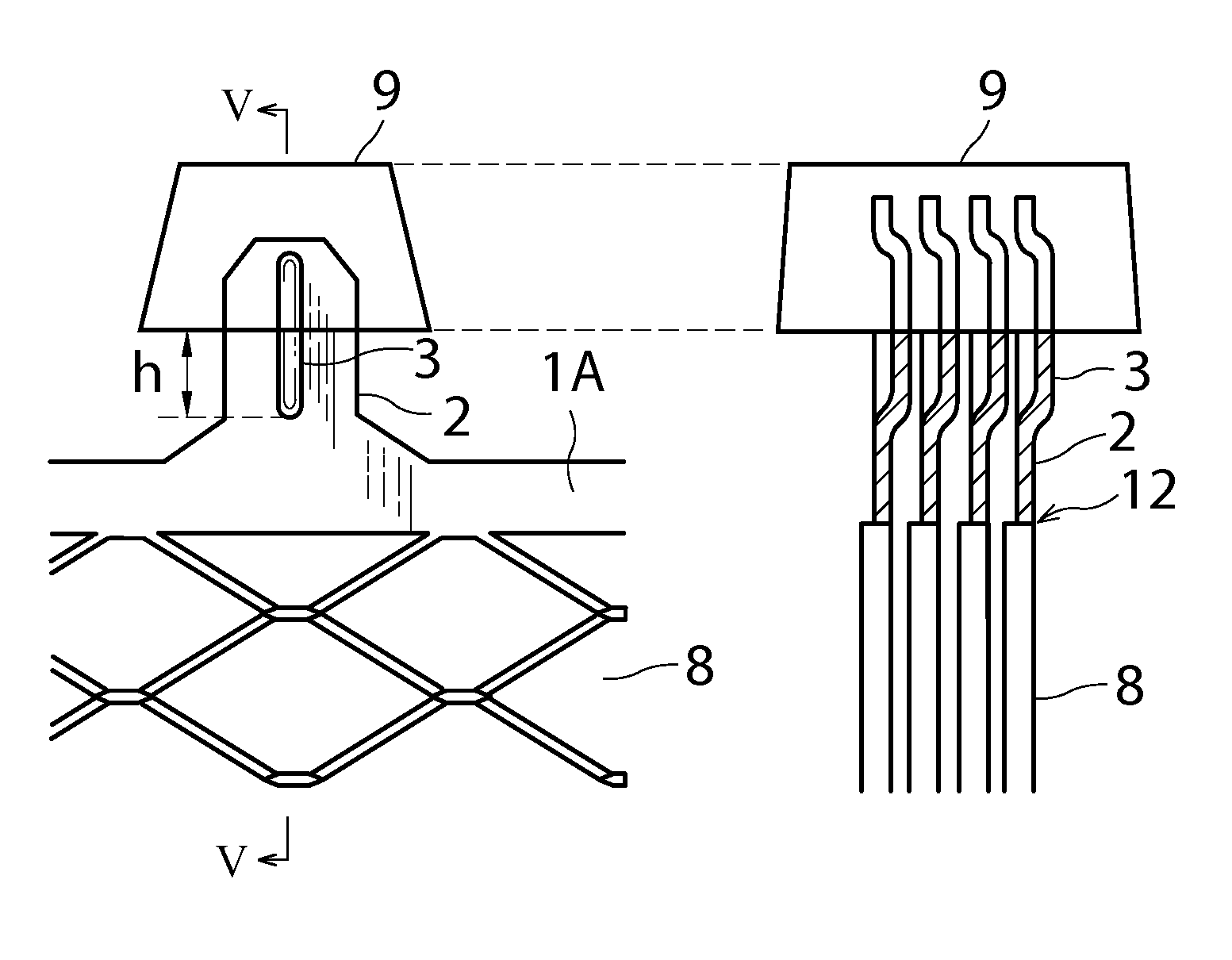

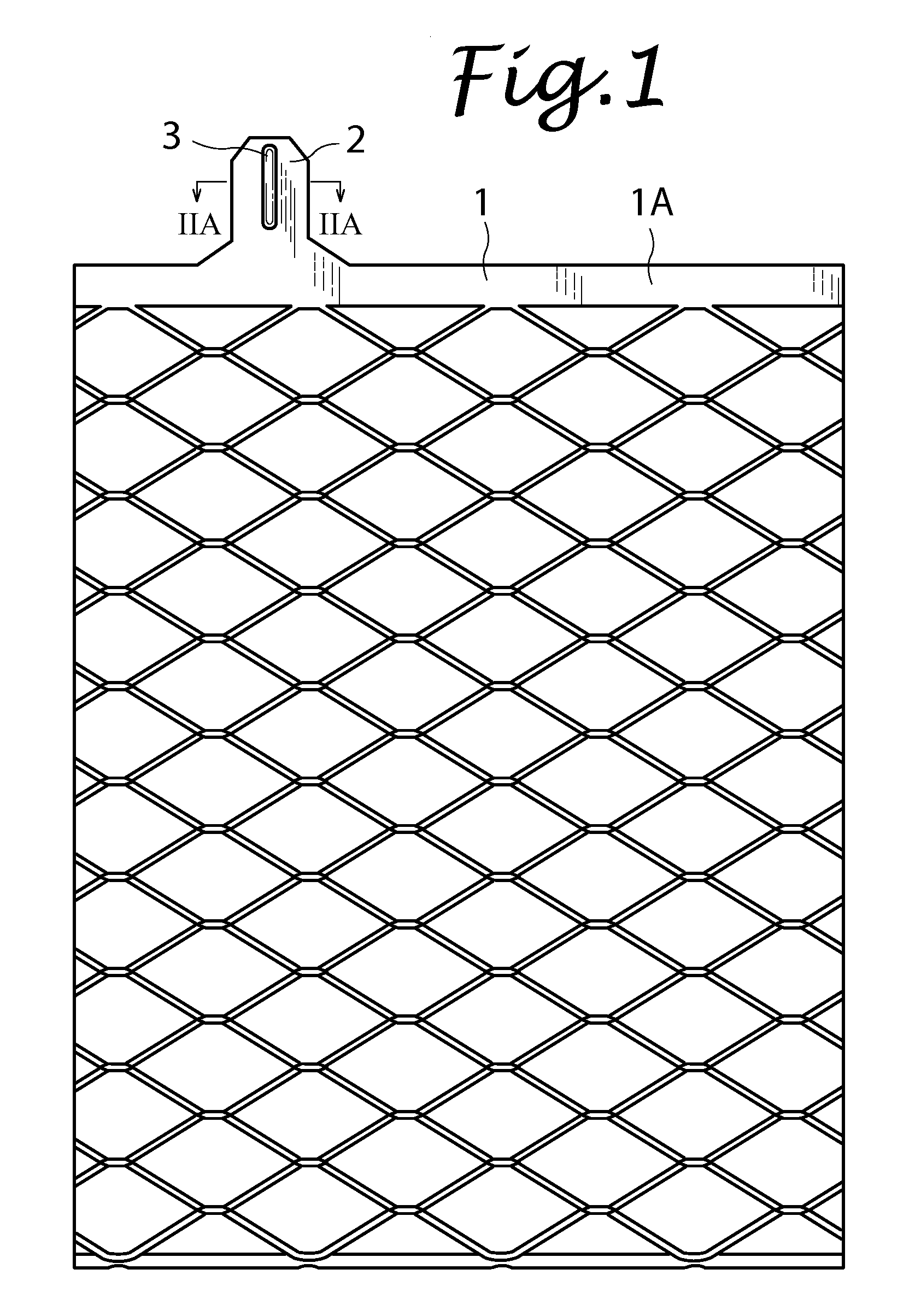

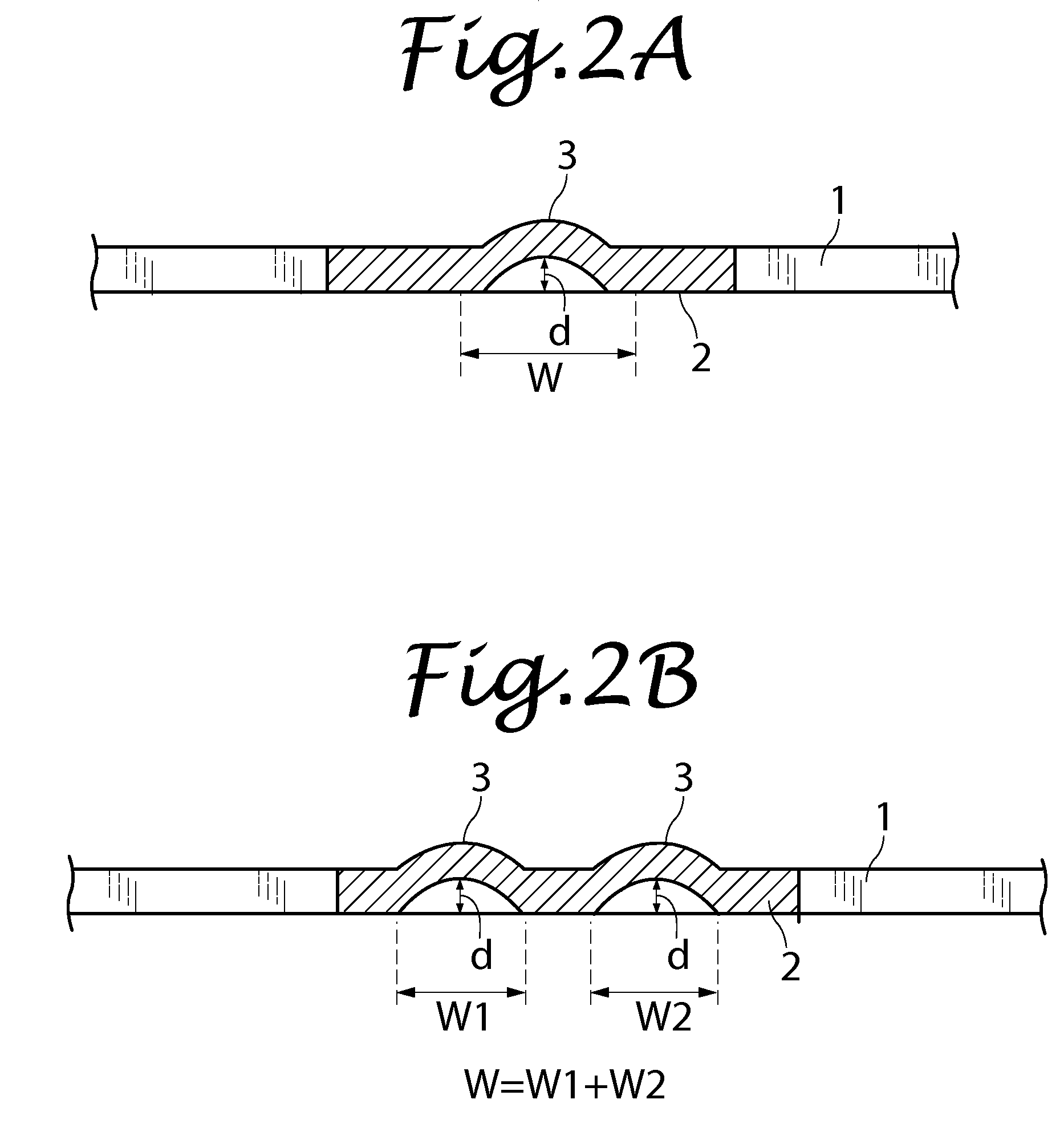

Lead-acid battery and method for manufacturing current collector for lead-acid battery

InactiveUS20120064402A1Reduced bending strengthWell formedPrimary cell manufactureFinal product manufactureEngineeringLead–acid battery

Provided herein is a lead-acid battery for which the risk of breakage of a current collecting lug part of a plate while in use is eliminated by simple means. At least a positive plate group of the lead-acid battery includes: one or more plates each including a current collector having a current collecting portion formed by expanding or punching a lead alloy sheet manufactured by cold rolling, and one or more current collecting lug parts unitarily formed with the current collecting portion; and a strap formed by a cast-on strap casting method and coupled to the one or more current collecting lug parts. The current collecting lug part is formed with an elongated protrusion extending in a direction away from the current collecting portion. The elongated protrusion continuously extends in a direction toward the current collecting portion of the plate from inside the strap.

Owner:HITACHI CHEM CO LTD

Formula of non-painted automobile spoiler with metal luster and production process thereof

The invention provides a formula of a non-painted automobile spoiler with metal luster and a production process thereof. The automobile spoiler is prepared from the following components in part by weight: 90 to 100 parts of PP, 5 to 10 parts of talcpowder and 0.5 to 3.5 parts of aluminum powder; or 90 to 100 parts of ABS and 0.5 to 1.5 parts of aluminum powder. The automobile spoiler produced by blending the aluminum powder and the PP or ABS; by using the PP or ABS as a raw material to produce the automobile spoiler, the surface of the automobile spoiler can obtain the metal luster without spraying treatment, and the metal luster is not lost or fades, the inner part of the product still obtains the metal luster even if the surface of the product is scratched or damaged, the surface treatment process of spraying the metal flashing paint on the surface of the product is unnecessary, and the metal luster is high in durability, particularly excellent in light ageing resistance; and in addition, the paint-spraying process step in a process of producing the automobile spoiler adopting the formula is saved, so that the production flow is simplified, and the production cost is greatly lowered.

Owner:国家复合改性聚合物材料工程技术研究中心

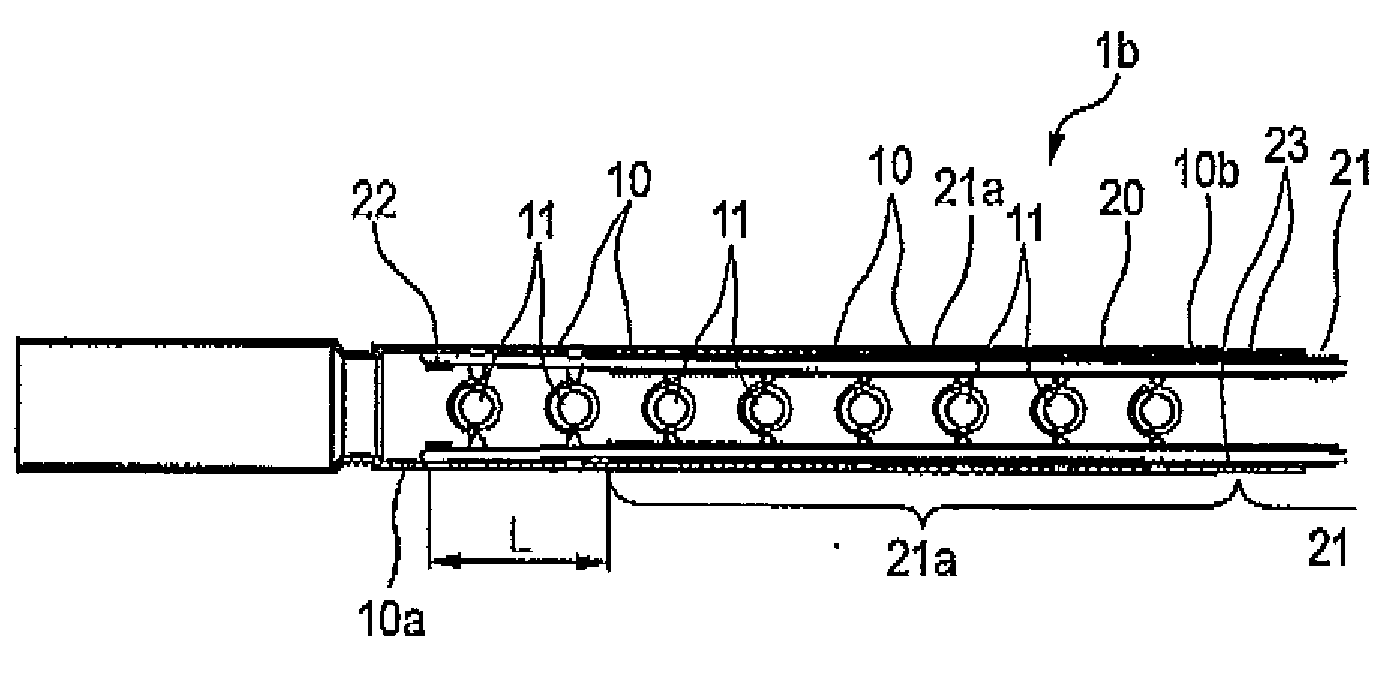

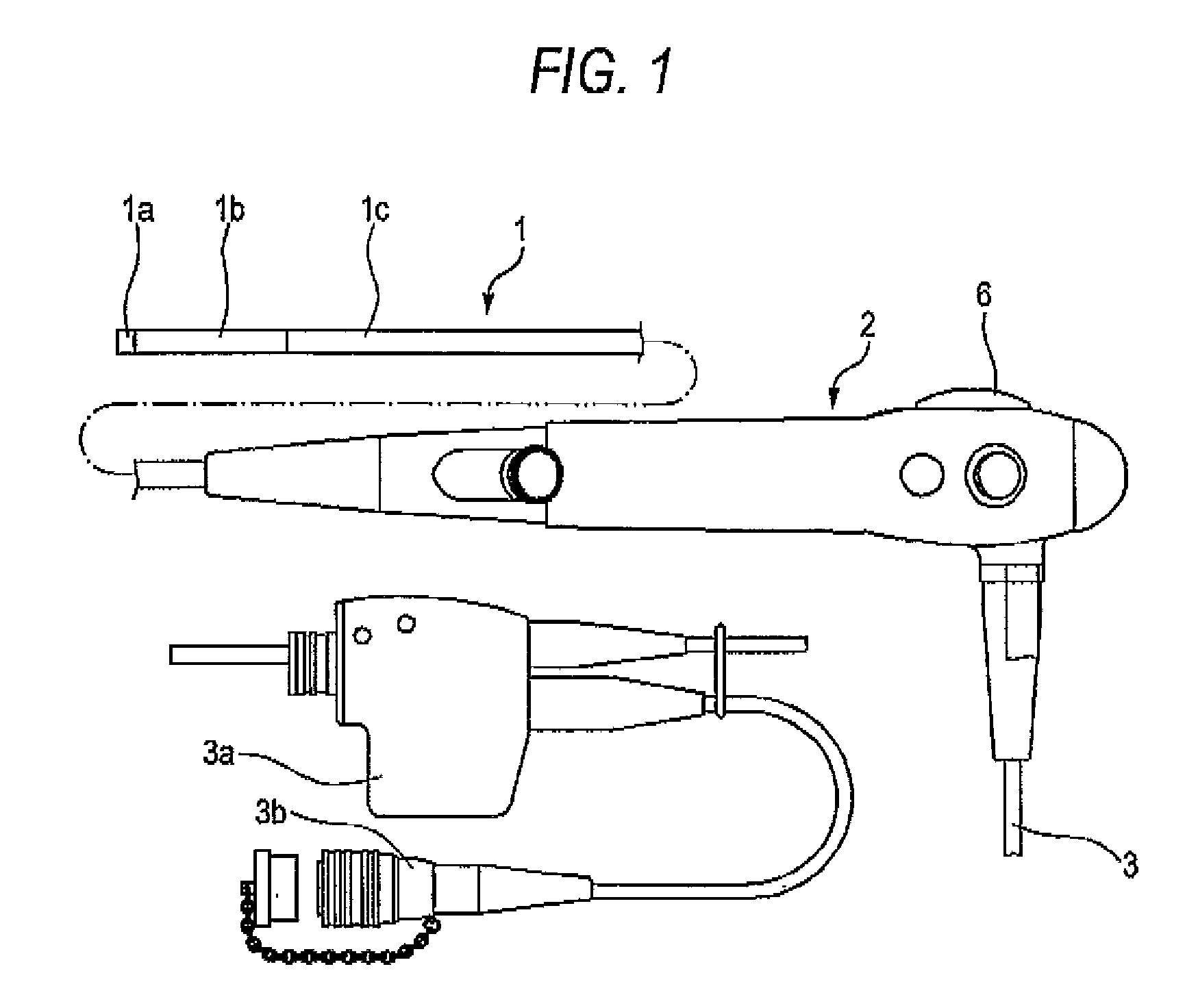

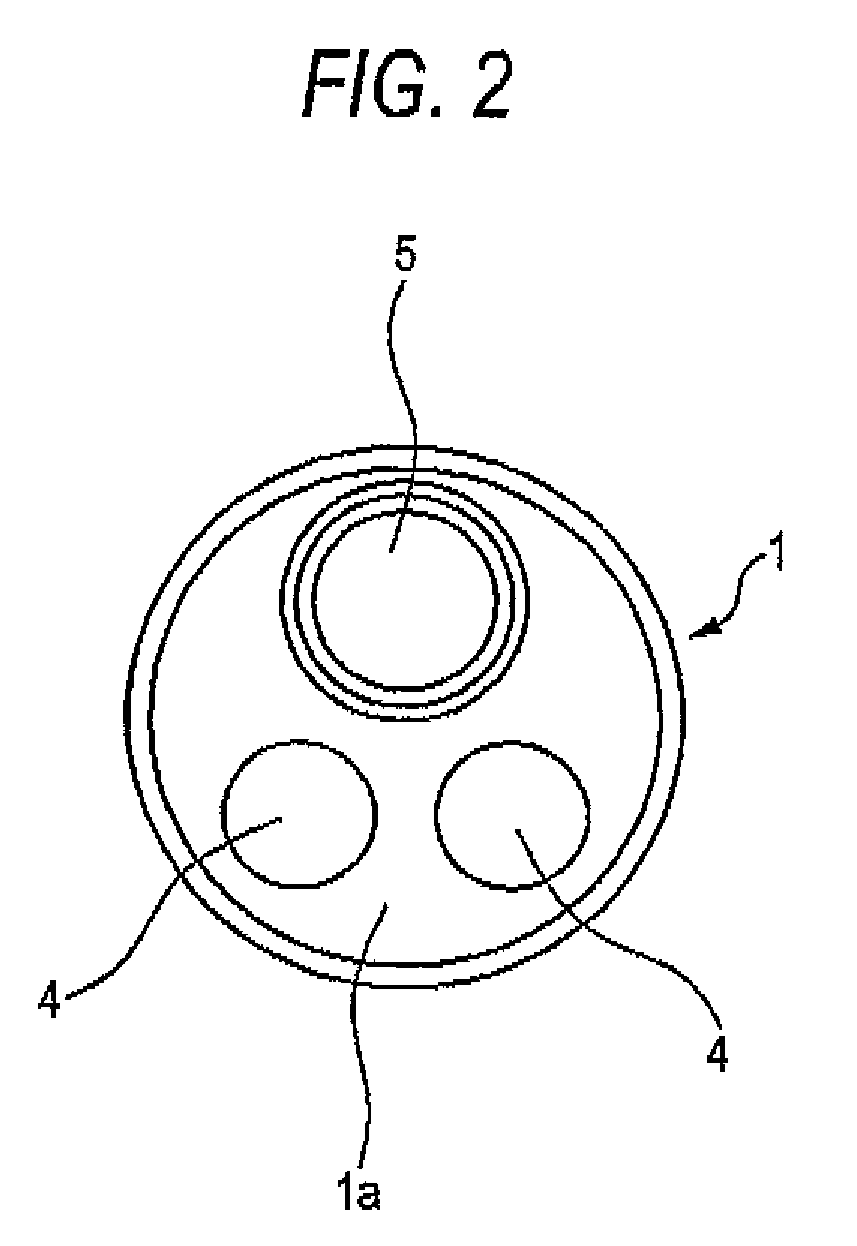

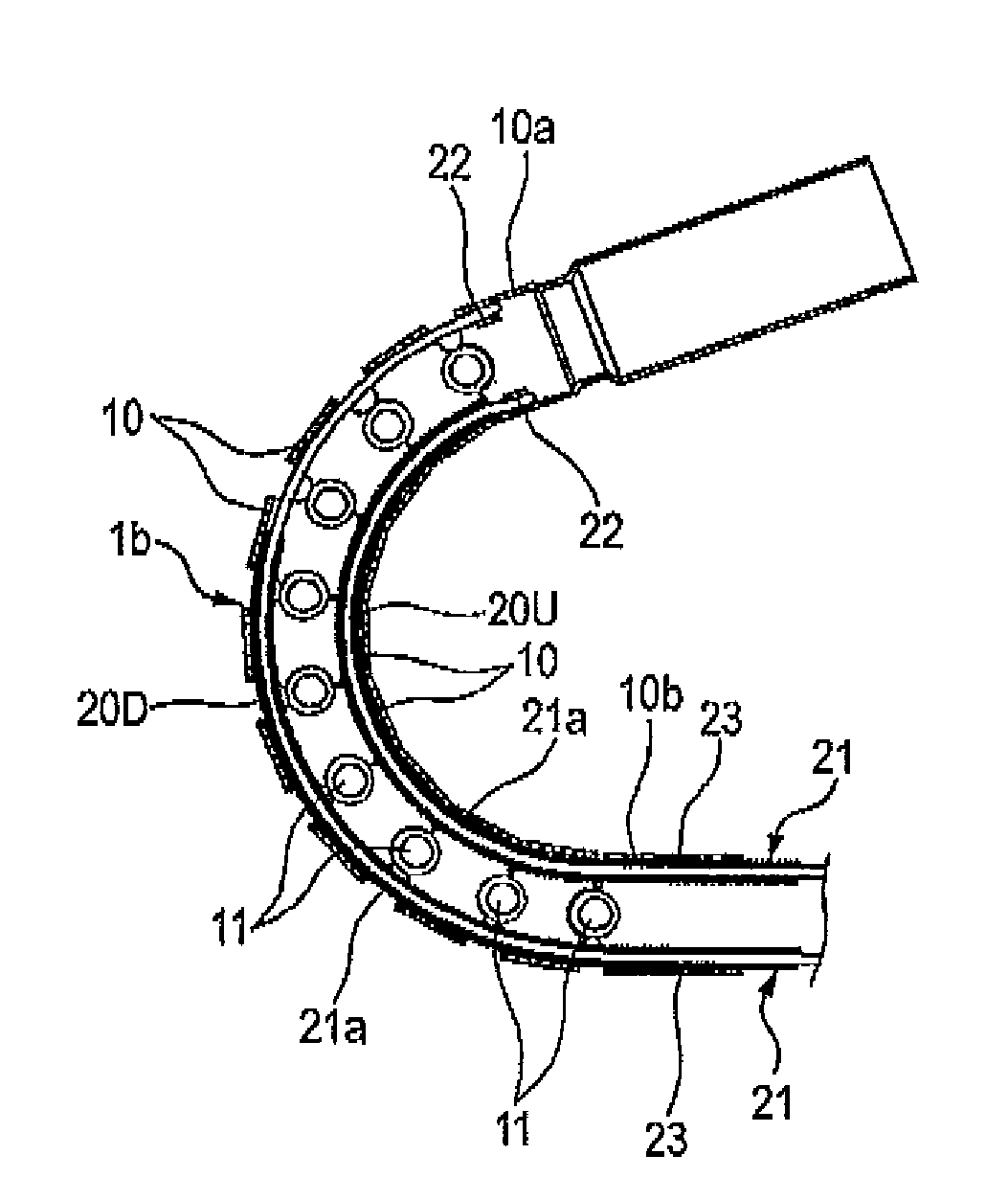

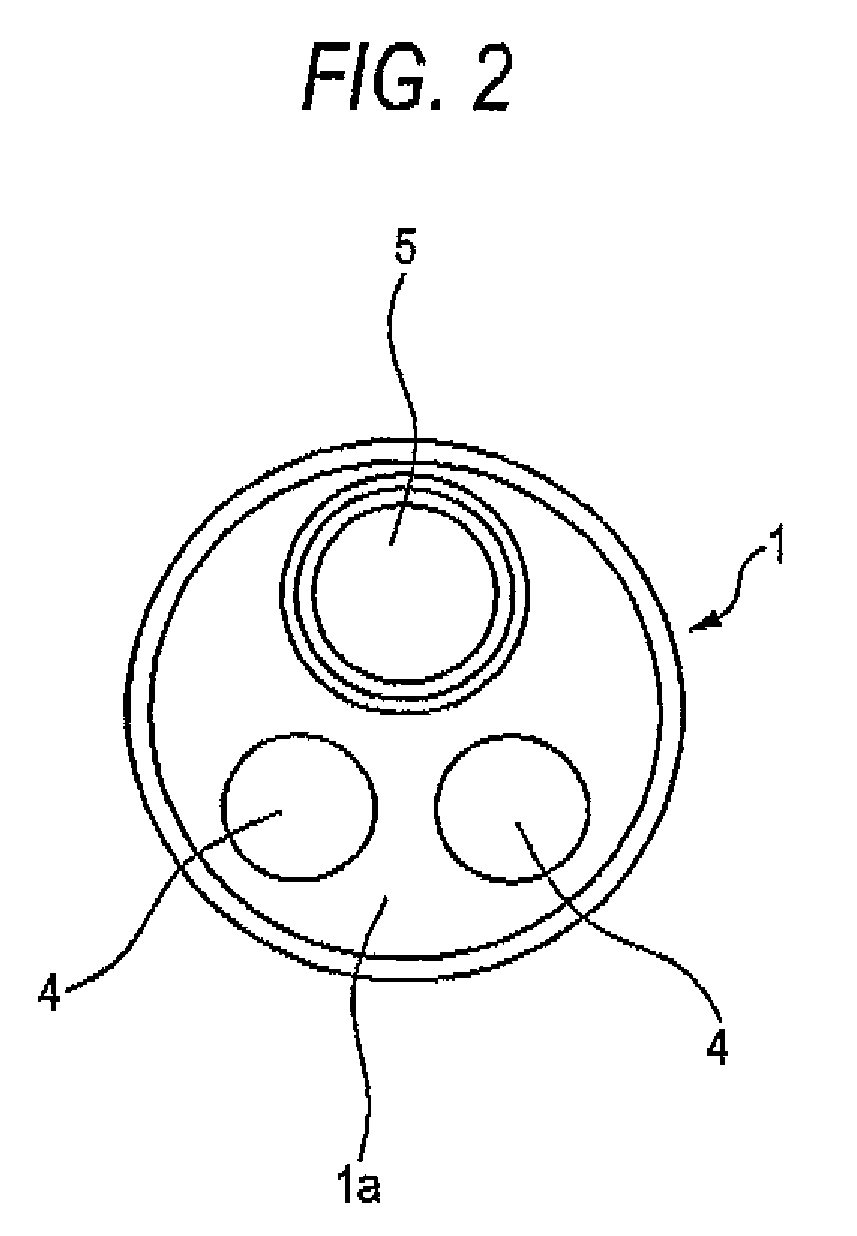

Bending device for endoscope

InactiveUS20080287736A1Reduce the overall diameterImprove fill rateSurgeryEndoscopesRemote controlEngineering

An operating wire is inserted in a close-contact coil in a bendable tube portion through a flexible tube portion. The close-contact coil is such that a fixed portion is provided at the position of a bending piece which is placed at the most base end of the bendable tube portion, and that a close-contact coil extension portion having been put in a non-fixed state extends from the fixed portion in the bendable tube portion. A part between a fixed portion and the fixed portion of the close-contact coil is a remote control cable for transmitting an amount of pushing and pulling an operating wire when operating an operating wire. A close-contact coil extension portion extended from the fixed portion at the side of a tip end of the close-contact coil functions as a positioning guide section for holding the operating wire so as to prevent the operating wire from being displaced in a circumferential direction.

Owner:FUJIFILM CORP

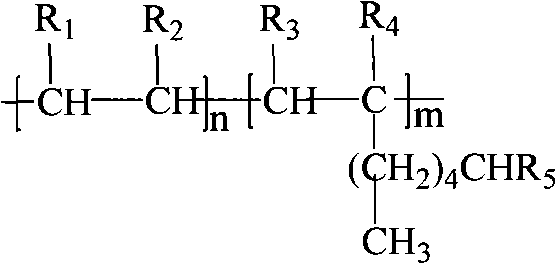

Anti-aging lubricating nylon-66 material with appropriate rigidness and flexibility

ActiveCN102816428AImprove tribological propertiesImprove mechanical propertiesEngineering plasticUltimate tensile strength

The invention belongs to the technical field of a novel material, relates to the engineering plastics modification technology, and in particular to the engineering plastics flexible balance modification technology. The invention relates to an anti-aging lubricating nylon-66 material with appropriate rigidness and flexibility, which is prepared by adopting inorganic powder, anti-wear agent, flexibilizer, anti-aging assistant, internal lubricating processing assistant and the like to compositely modify the nylon-66 material. The anti-aging lubricating nylon-66 material at least comprises following ingredients (by weight percent): 100 parts of nylon-66, 5 to 25 parts of flexibilizer, 5 to 50 parts of talcum powder, 2 to 10 parts of molybdenum disulfide and 2 to 5 parts of channel black. The material has excellent tribology performance, excellent physical mechanical performance and excellent anti-aging performance, after being accelerated to age for 3500h under the hot and damp condition, the tensile strength is only reduced by 11.7 percent, the bending strength is reduced by 12 percent, and the notch impact performance is reduced by 4.5 percent. The anti-aging lubricating nylon-66 material can be widely applied to the parts requiring the lubrication and anti-aging performance such as a lubricating bearing, a shaft sleeve, a gear, a bearing holder and the like. The preparation method is simple, and the anti-aging lubricating nylon-66 material has industrialized application prospect.

Owner:NO 53 RES INST OF CHINA NORTH IND GRP

Bending device for endoscope

An operating wire is inserted in a close-contact coil in a bendable tube portion through a flexible tube portion. The close-contact coil is such that a fixed portion is provided at the position of a bending piece which is placed at the most base end of the bendable tube portion, and that a close-contact coil extension portion having been put in a non-fixed state extends from the fixed portion in the bendable tube portion. A part between a fixed portion and the fixed portion of the close-contact coil is a remote control cable for transmitting an amount of pushing and pulling an operating wire when operating an operating wire. A close-contact coil extension portion extended from the fixed portion at the side of a tip end of the close-contact coil functions as a positioning guide section for holding the operating wire so as to prevent the operating wire from being displaced in a circumferential direction.

Owner:FUJIFILM CORP

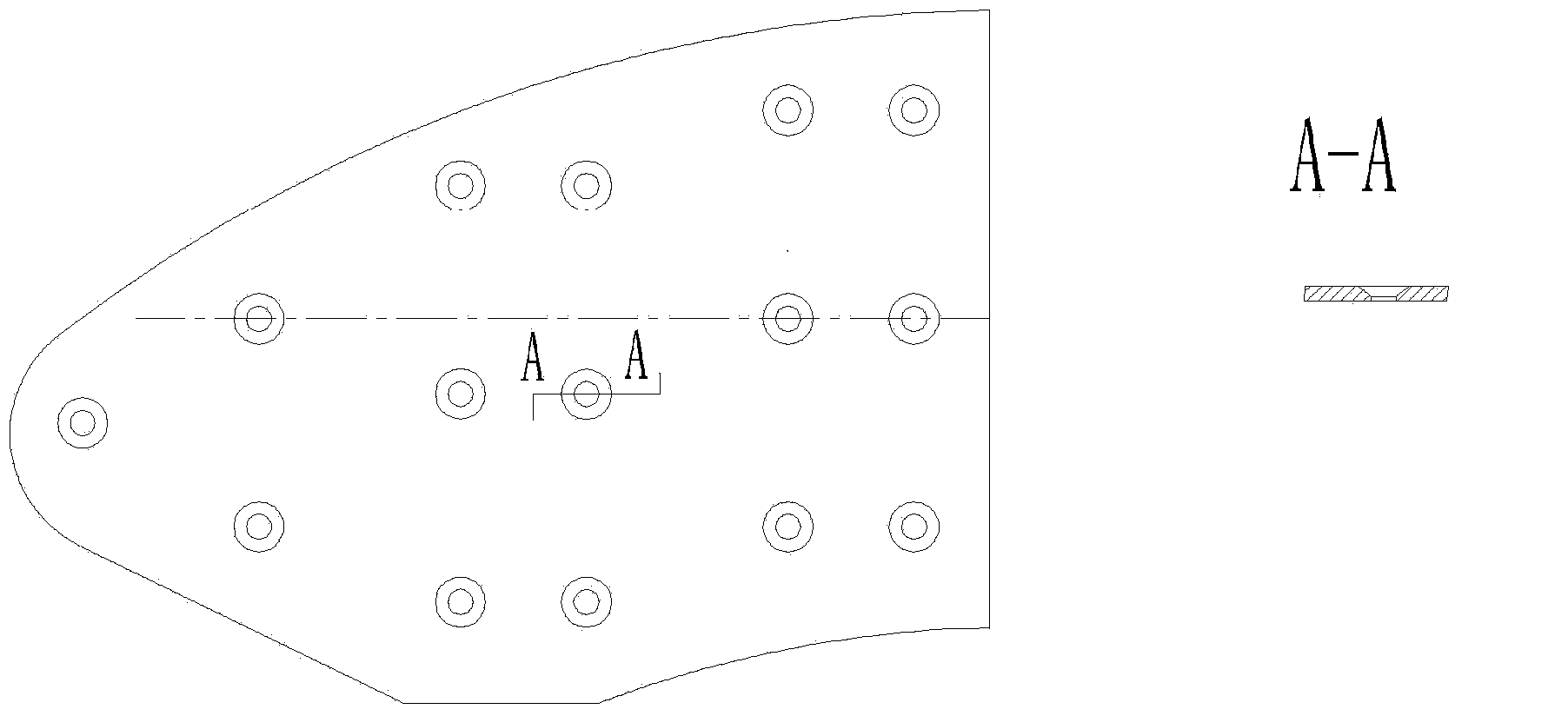

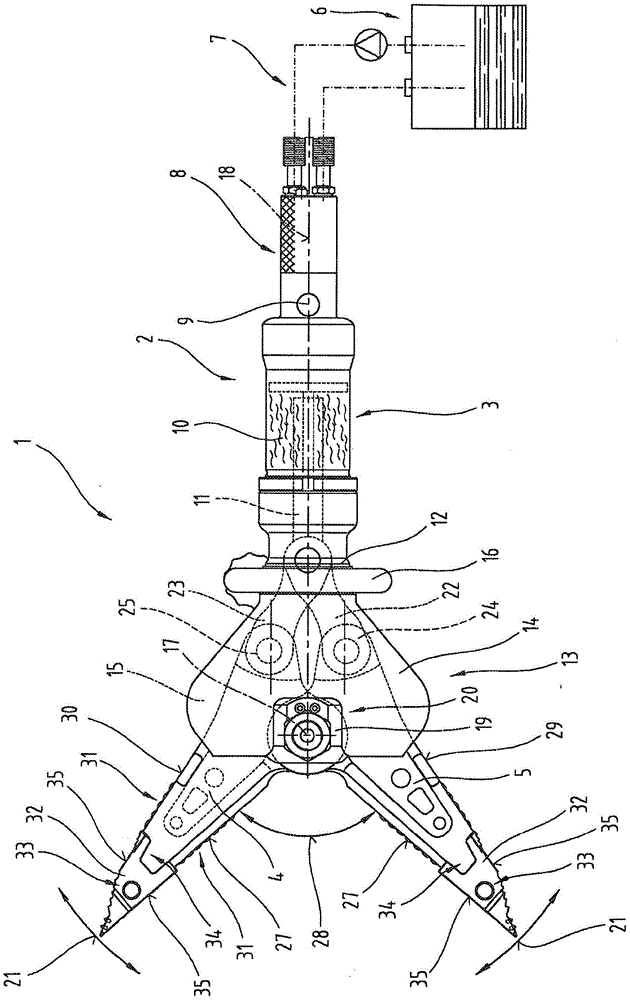

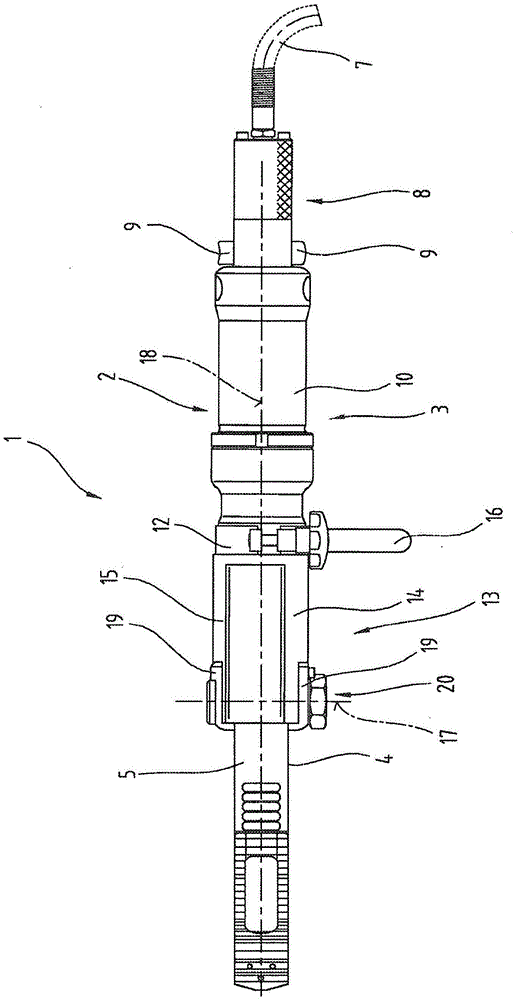

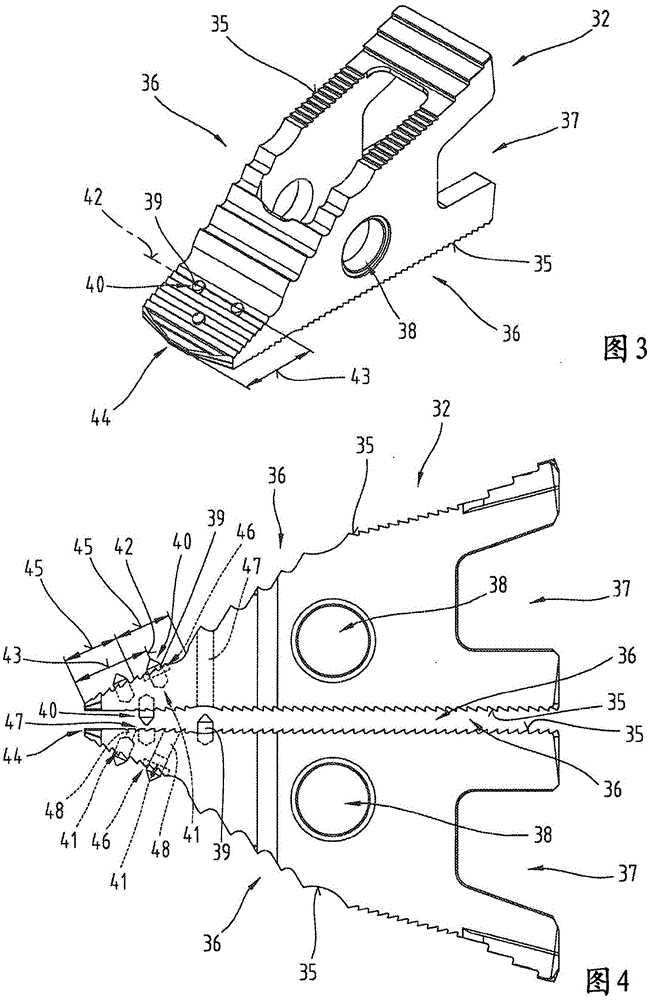

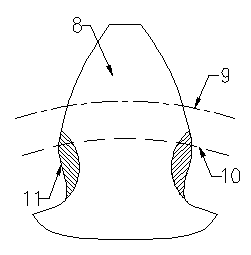

Spreader tip for a rescue tool

ActiveCN105658284AEasy to useHigh wear resistanceShacklesBuilding rescueMechanical engineeringEngineering

Owner:WEBER HYDRAULIK GMBH

Thermally conductive flame-retardant PET/PBT composite material and lamp holder body prepared therefrom

InactiveCN107474499AImprove thermal conductivityImprove flame retardant performancePlastic/resin/waxes insulatorsHeat-exchange elementsActivated carbonFire retardant

Owner:LEEWAY LIGHTING PARTS XIAMEN

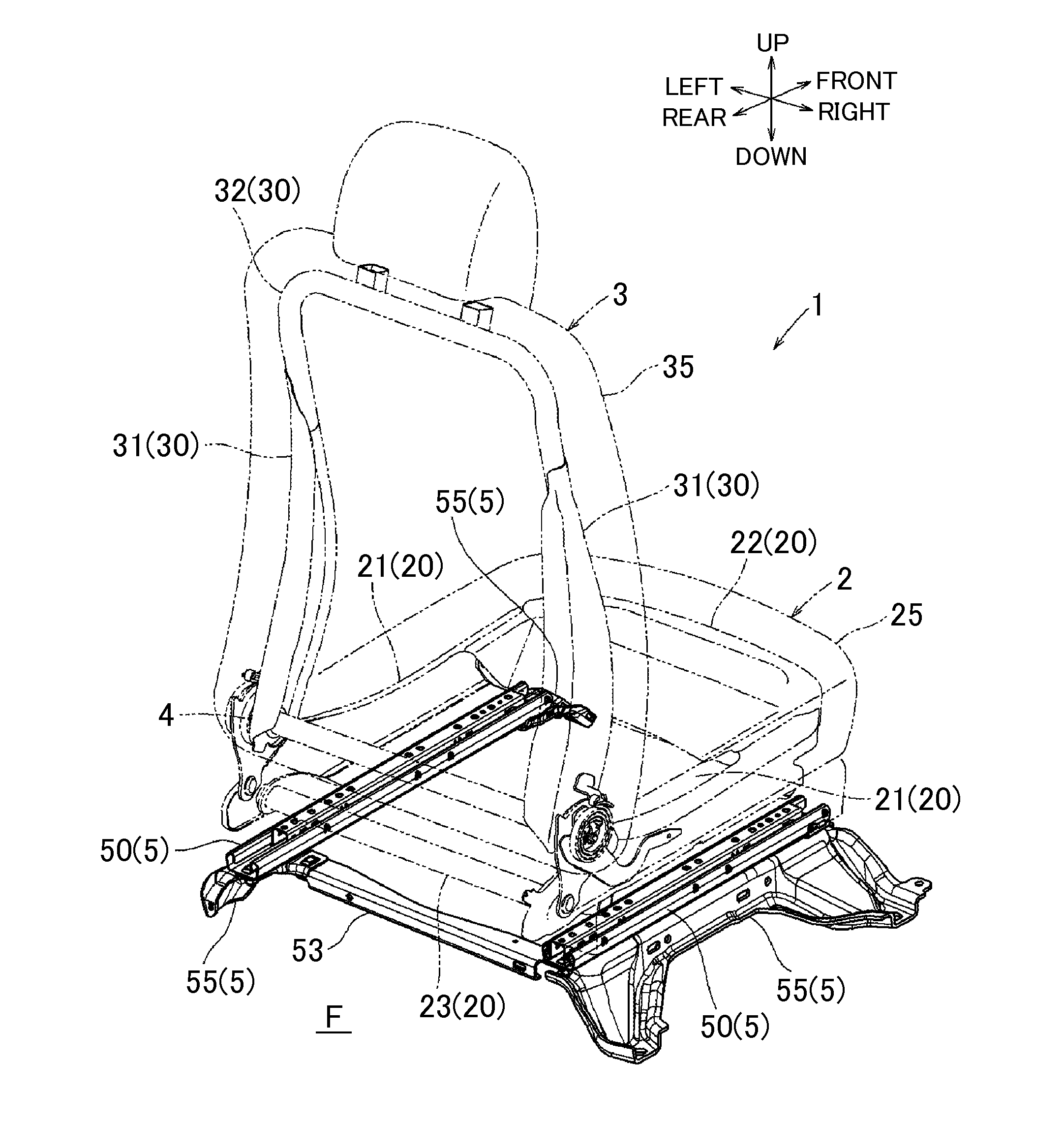

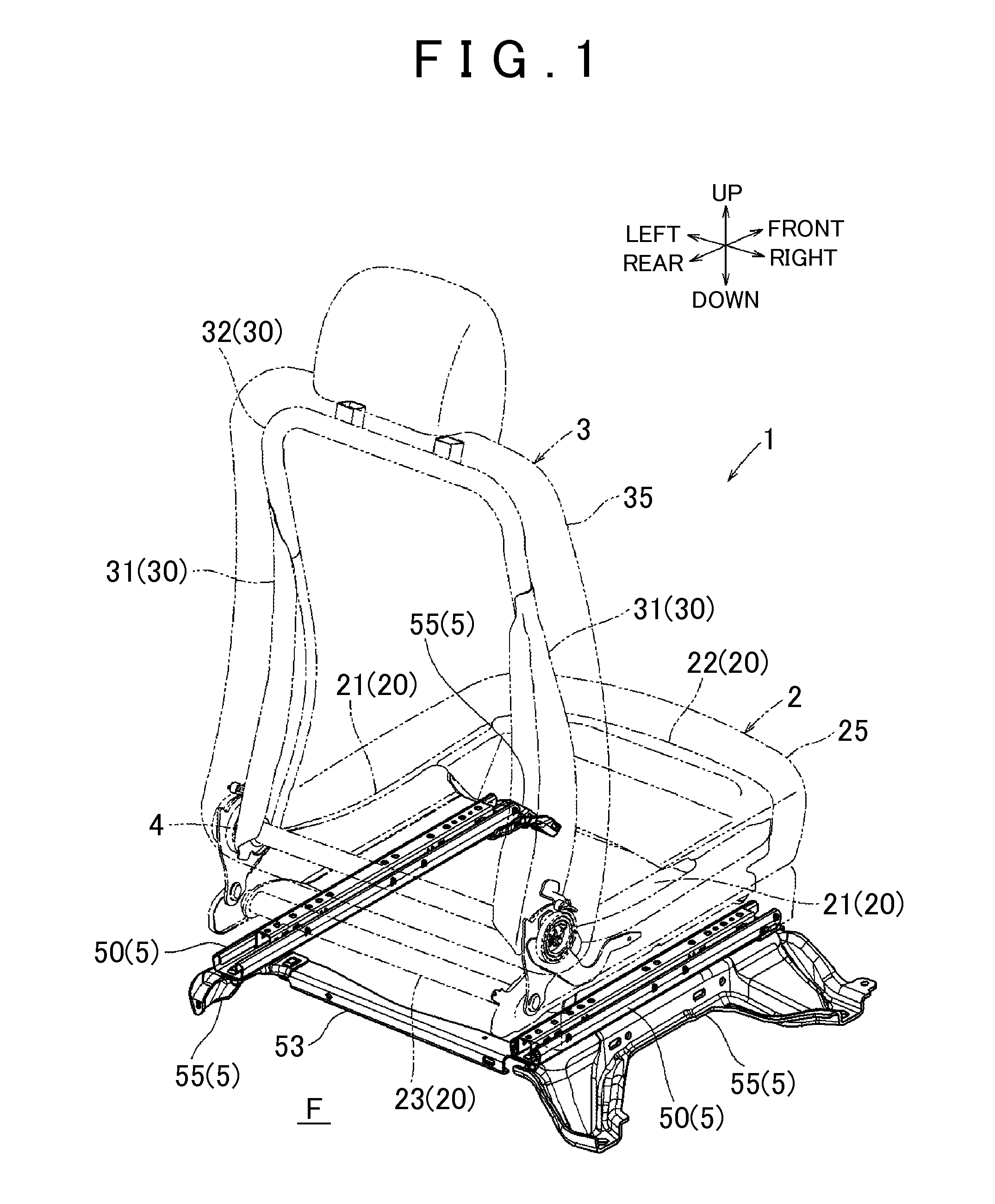

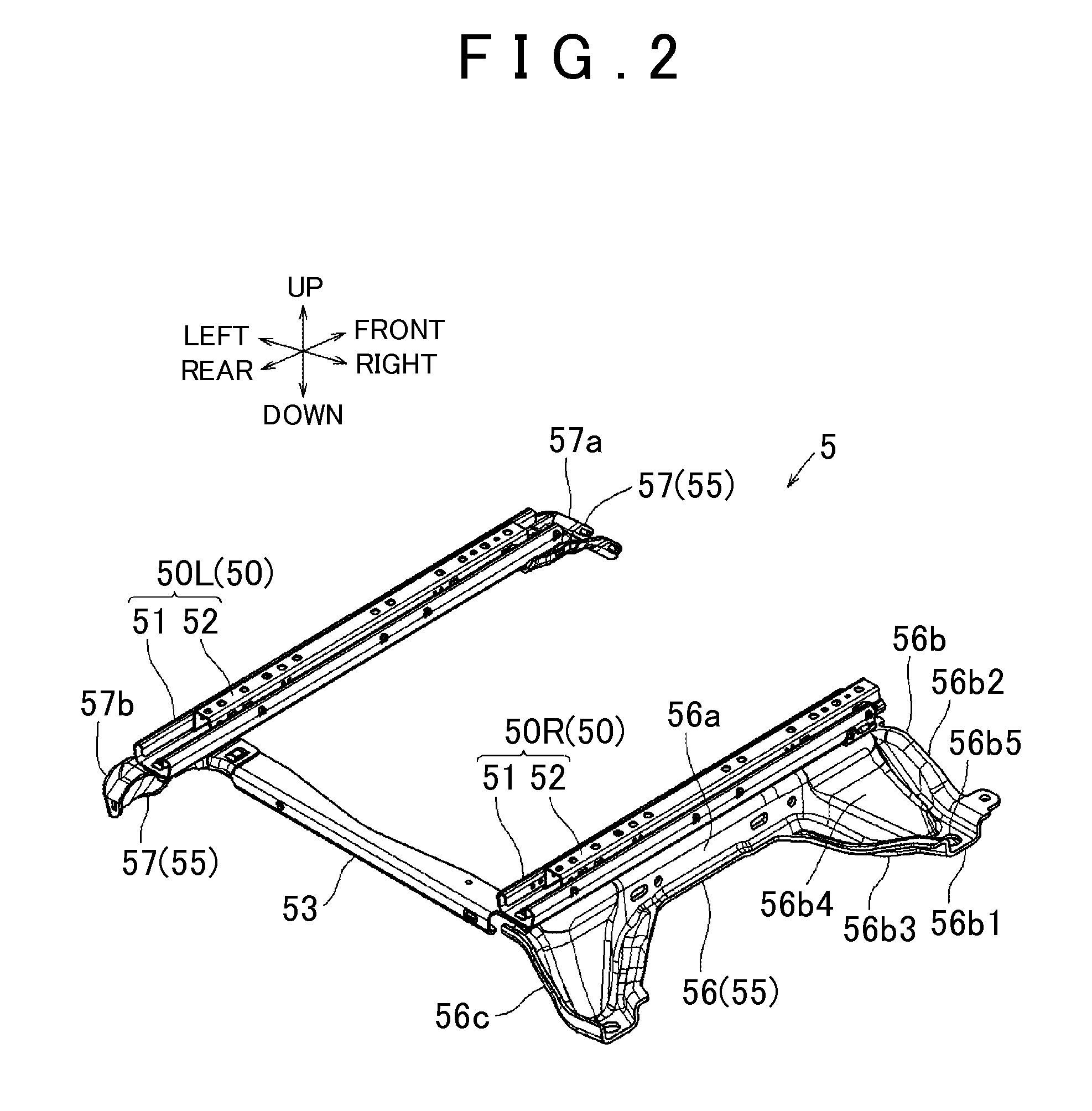

Vehicle seat

ActiveUS20160137109A1Simple structurePrevent fallingPedestrian/occupant safety arrangementMovable seatsFlexural strengthMechanical engineering

Owner:TOYOTA BOSHOKU KK

Method for eliminating undercut of involute gear

InactiveCN103234020AEliminate hazardsReduced bending strengthPortable liftingSpecial data processing applicationsSpur gearBevel gear

The invention relates to a method for eliminating undercut of an involute gear, and belongs to the technical field of transmission designs and manufacture of involute gears in mechanical equipment. Firstly, the minimum number of teeth which cannot cause undercut of the involute gear is calculated, and a calculation formula of the minimum number of the teeth which cause no undercut during processing is obtained when the involute gear is a straight toothed spur gear, a helical gear or a straight tooth bevel gear respectively; and then the involute gear is processed according to a calculation result, so that the involute gear without the undercut is obtained. The method can eliminate harms of intensity reduction caused by undercut.

Owner:KUNMING UNIV OF SCI & TECH

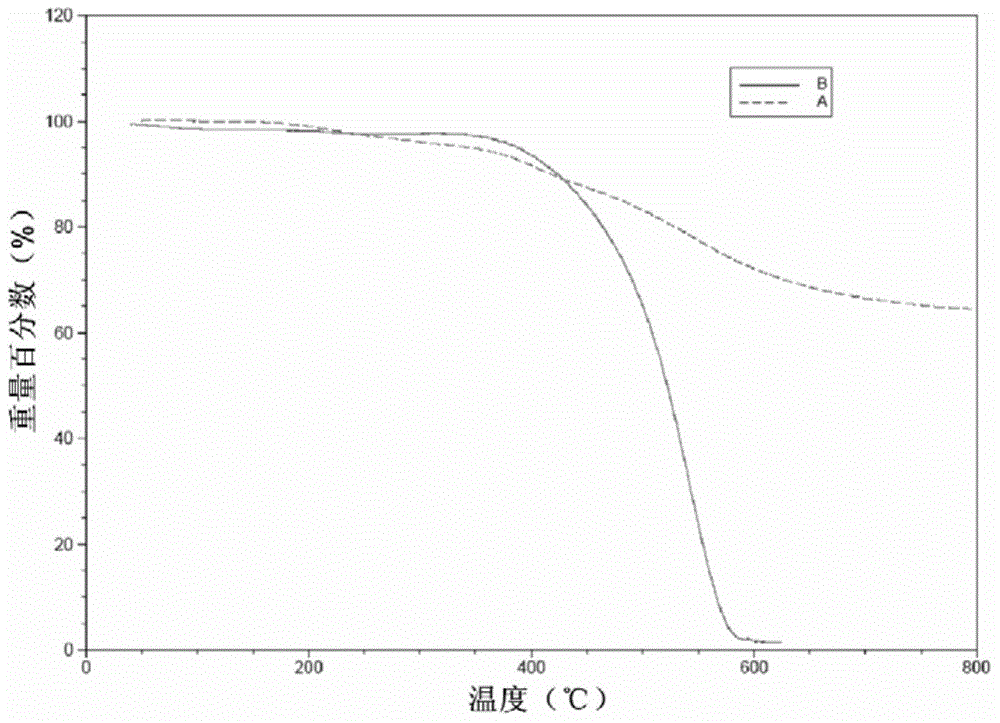

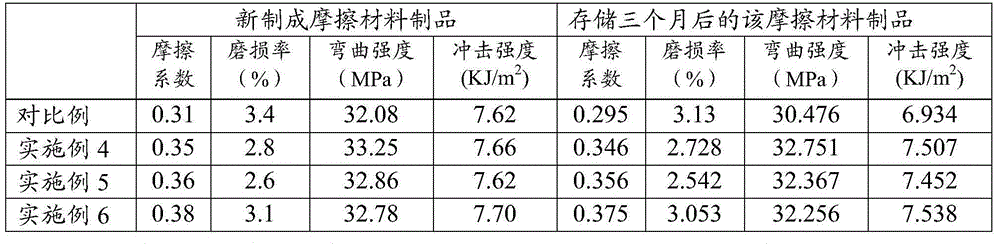

Phenolic resin composition and application thereof

The invention belongs to the field of synthetic resin and particularly relates to a phenolic resin composition and application thereof. The phenolic resin composition provided by the invention mainly comprises boron phenolic resin, an amino compound and a phosphorus-containing flame retardant. The resin composition is high in thermal stability at a high temperature and the performance of a friction material product prepared from the phenolic resin composition as a binder is slowly degenerated during storage. Experimental results show that the heat loss of the phenolic resin composition provided by the invention is less than 40% when the phenolic resin composition is cured at 800 DEG C, and the heat losses of the phenolic resin composition which is respectively cured for 3 minutes and 5 minutes at 500 DEG C, are sequentially less than 0.5% and 1.2%; the coefficient of friction attenuation amount the friction material product prepared from the phenolic resin composition is less than 1.5%, the wear rate attenuation amount is less than 3%, the bending strength attenuation amount is less than 2% and the impact strength attenuation amount is less than 2.5%.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

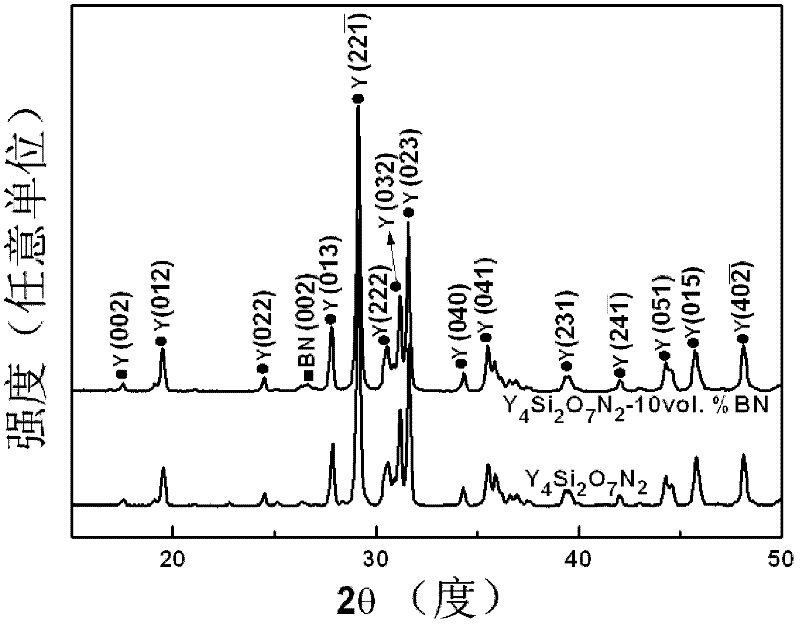

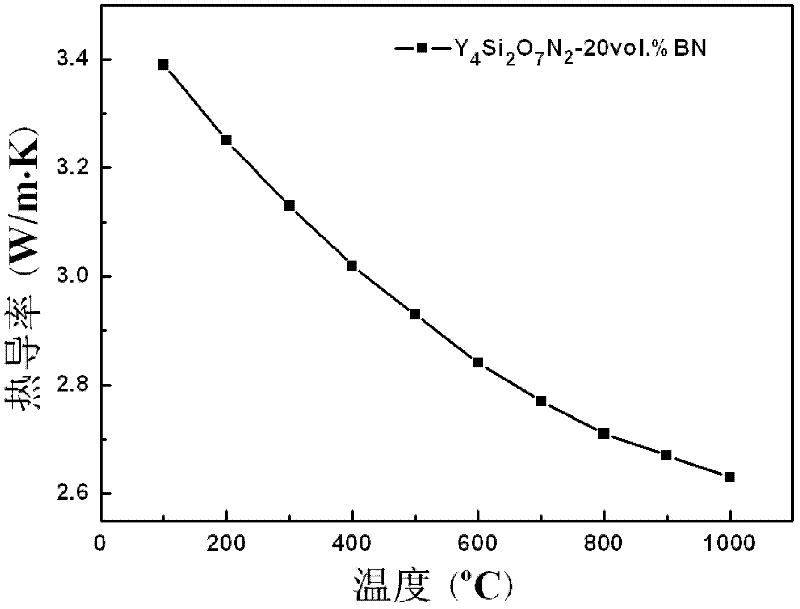

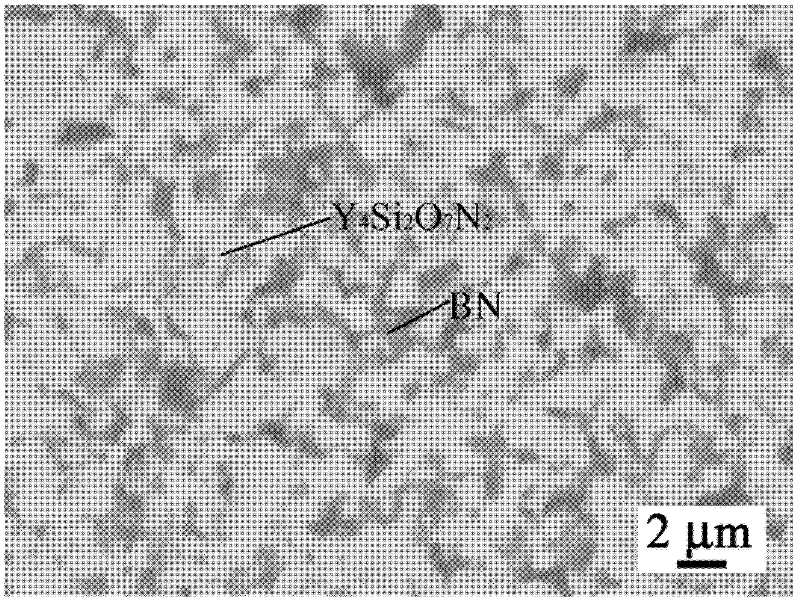

In-situ preparation method for Y4Si2O7N2-BN ceramic base composite materials

The invention relates to the field of ceramic base composite materials, in particular to an in-situ preparation method for Y4Si2O7N2-BN ceramic base composite materials. The composite materials consist of two phases: Y4Si2O7N2 and BN, wherein the content of the BN in the composite materials is 5 to 95 percent through being metered in percentage by volume, and the balance is the Y4Si2O7N2. Yttriumoxide powder, silicon oxide powder, silicon nitride powder and BN powder are used as raw materials, material powder carries out ball milling for 1 to 24 hours, the materials are charged into a graphite mold after being baked and sieved, the cold pressing is carried out at 10 to 15MPa, then, the temperature is raised to 1500 to 1700 DEG C at a temperature rise velocity of 5 to 40 DEG C / min in a hot pressing furnace by using nitrogen gas as protection atmosphere, the temperature is preserved for 0.5 to 1 hour, then, the temperature is raised to 1800 to 2100 DEG C at a temperature rise velocity of 5 to 40 DEG C / min, the temperature is preserved for 1 to 3 hours, and the hot pressing pressure is 10 to 40 MPa. The Y4Si2O7N2-BN ceramic base composite materials with high purity, good density, high intensity and low heat conductivity can be sintered through hot pressing in a short time.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Vehicle-body structure of vehicle

A panel member having a U-shaped cross section includes step portions at an upper face portion and a lower face portion, and a distance, in a vehicle longitudinal direction, of the step potions from a panel member formed substantially in a flat-plate shape, is configured such that the distance at a central portion, in the vehicle width direction, of a bumper reinforcement is the maximum and the distance decreases gradually toward an outward direction of the vehicle. Accordingly, the vehicle-body structure which can properly ensure the bending strength and also attain the light weight of the bumper reinforcement, improving the load transmission from the bumper reinforcement to crash cans, can be provided.

Owner:MAZDA MOTOR CORP

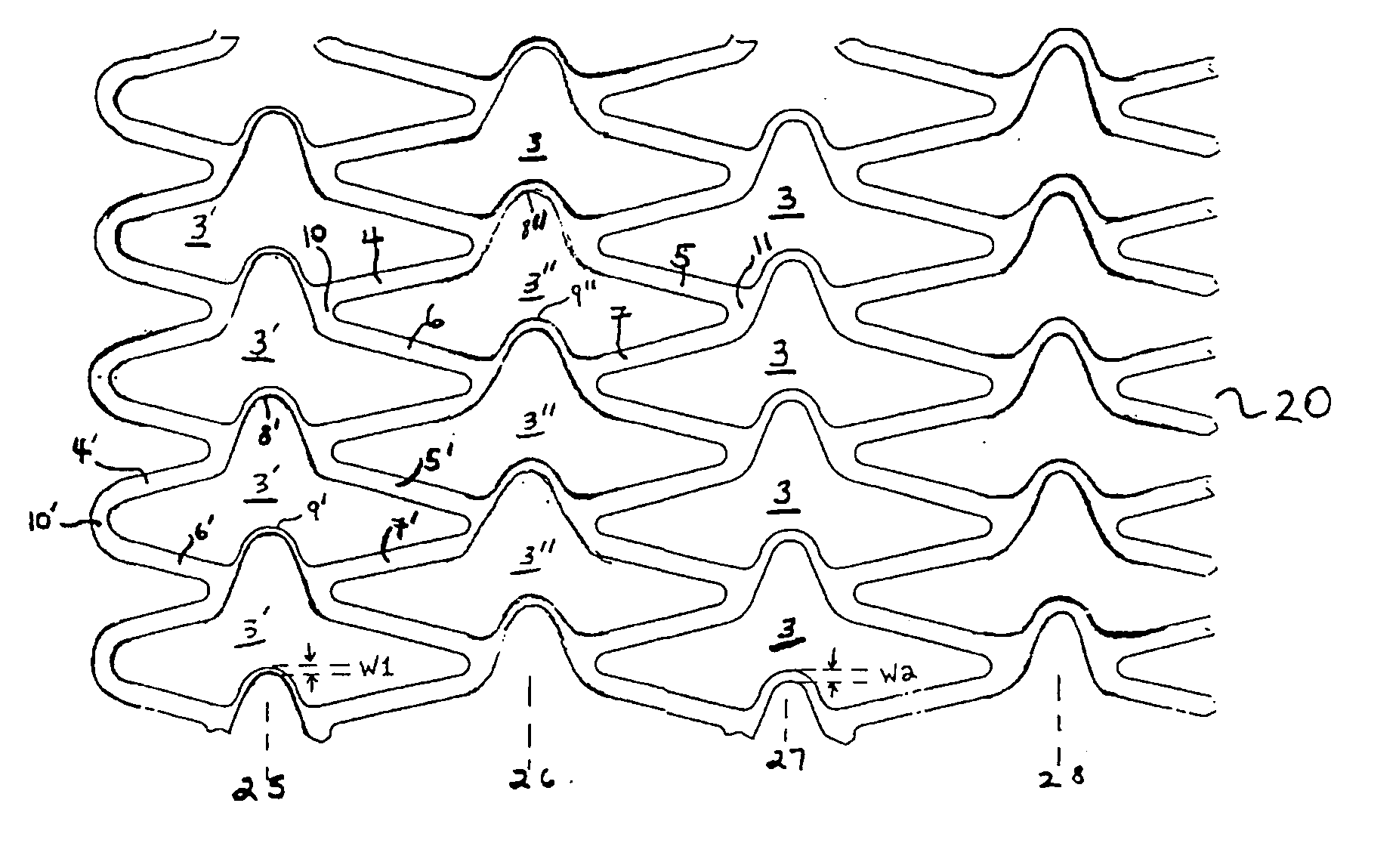

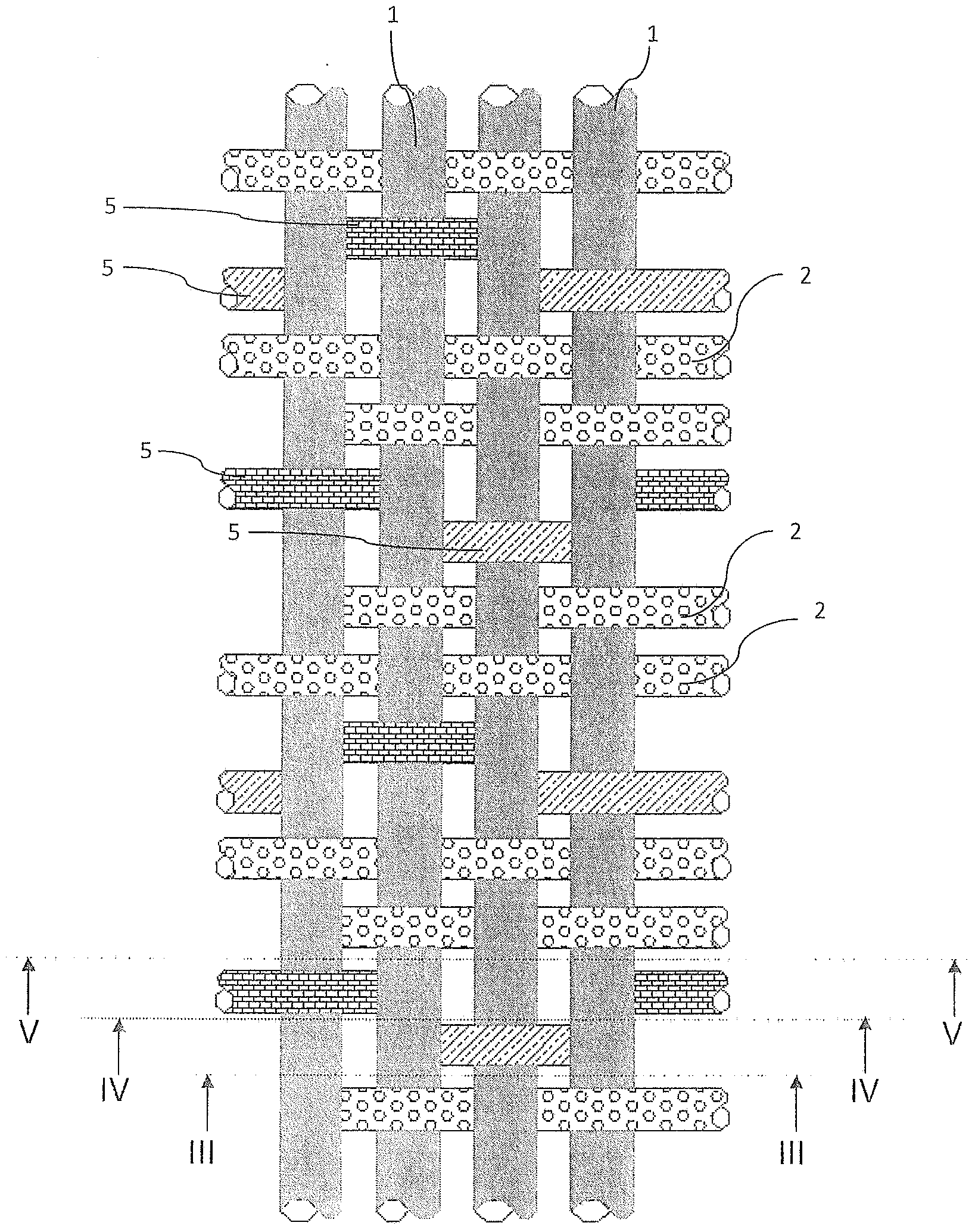

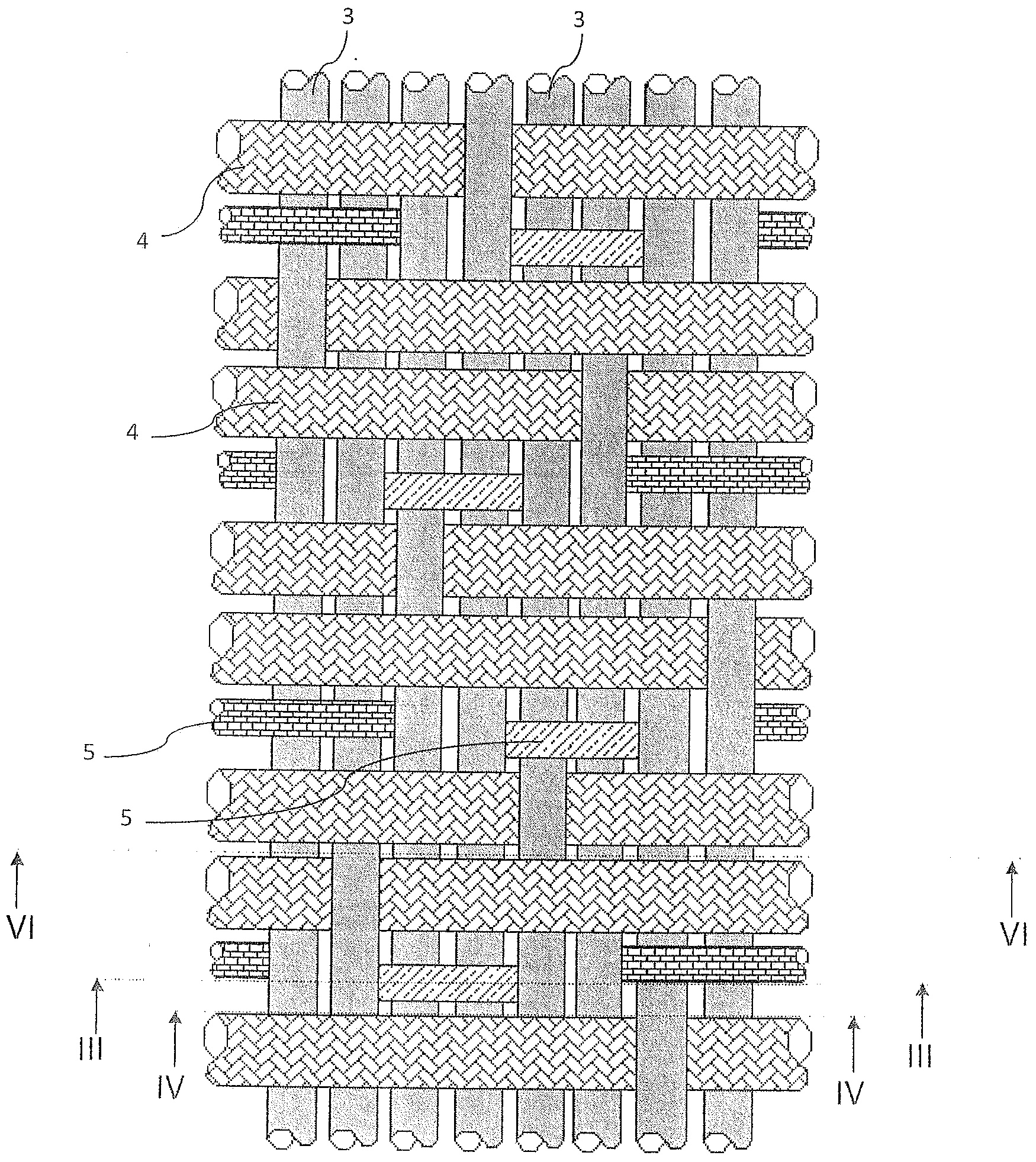

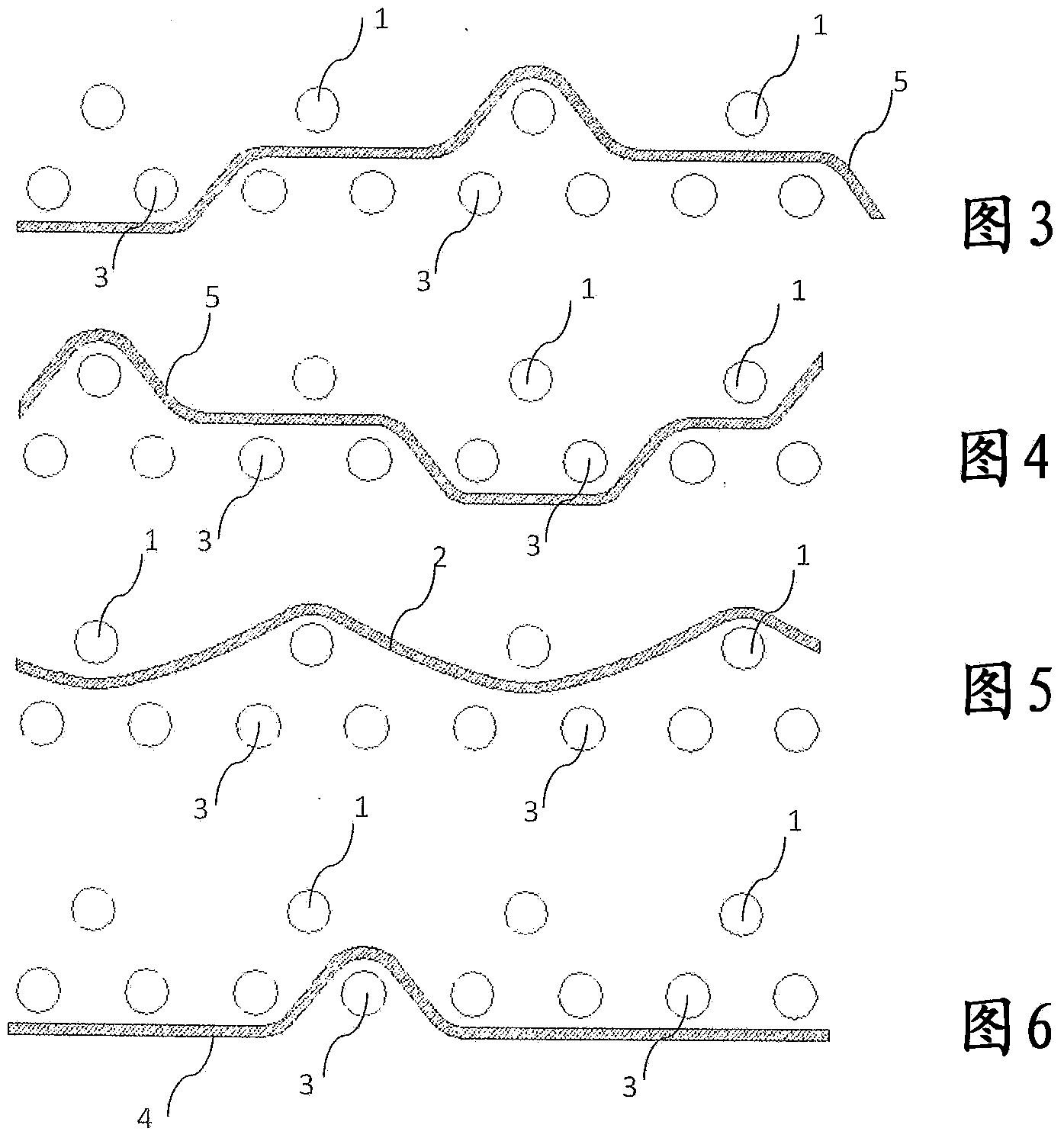

Paper machine fabric

InactiveCN103443356AReduced bending strengthGood for edge trimmingMachine wet endMulti-ply fabricsYarnPaper machine

The invention relates to a paper machine fabric that comprises at least two separate layers that are formed of at least two separate yarn systems, one forming the paper side and composed of longitudinal and crosswise yarns (1, 2) and one forming the wear side and composed of longitudinal and crosswise yarns (3, 4), the yam systems being arranged to form structures independent of each other in the longitudinal and cross directions of the fabric. The structures are bound to each other by means of a binding yarn system, whereby the binding yarns (5) in the binding yarn system are arranged to form part of the layer on the paper-side surface. Each binding yarn (5) of the binding yarn system is arranged on the wear side to bind in the weave pattern repeat to more yarns than on the paper side.

Owner:VALMET TECH OY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com