Paper machine fabric

A technology for paper machines and fabrics, applied in the directions of paper machines, fabrics, paper making, etc., can solve problems such as increasing the cost of paper machines, and achieve the effects of good operation, improved diagonal stability, and small water storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

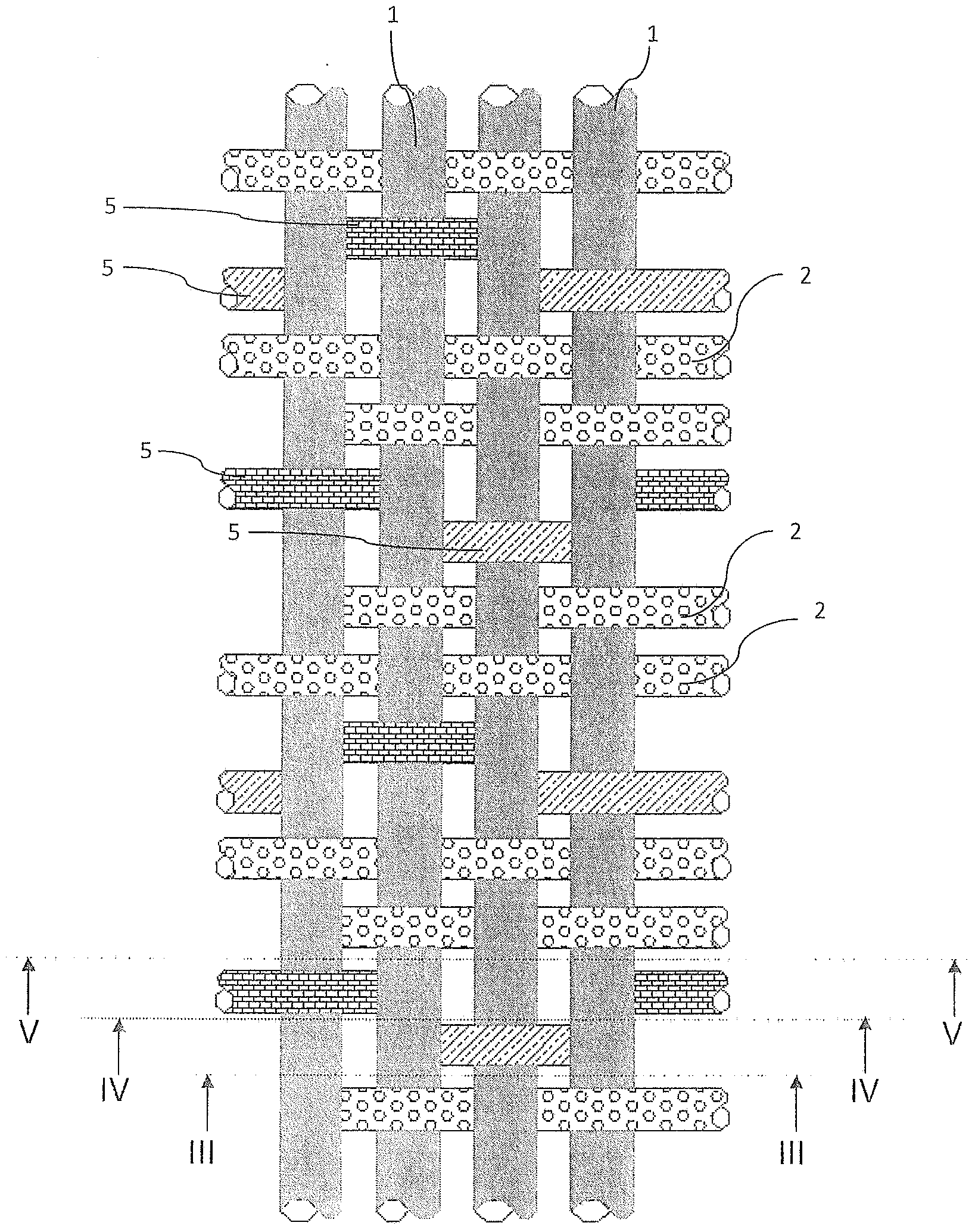

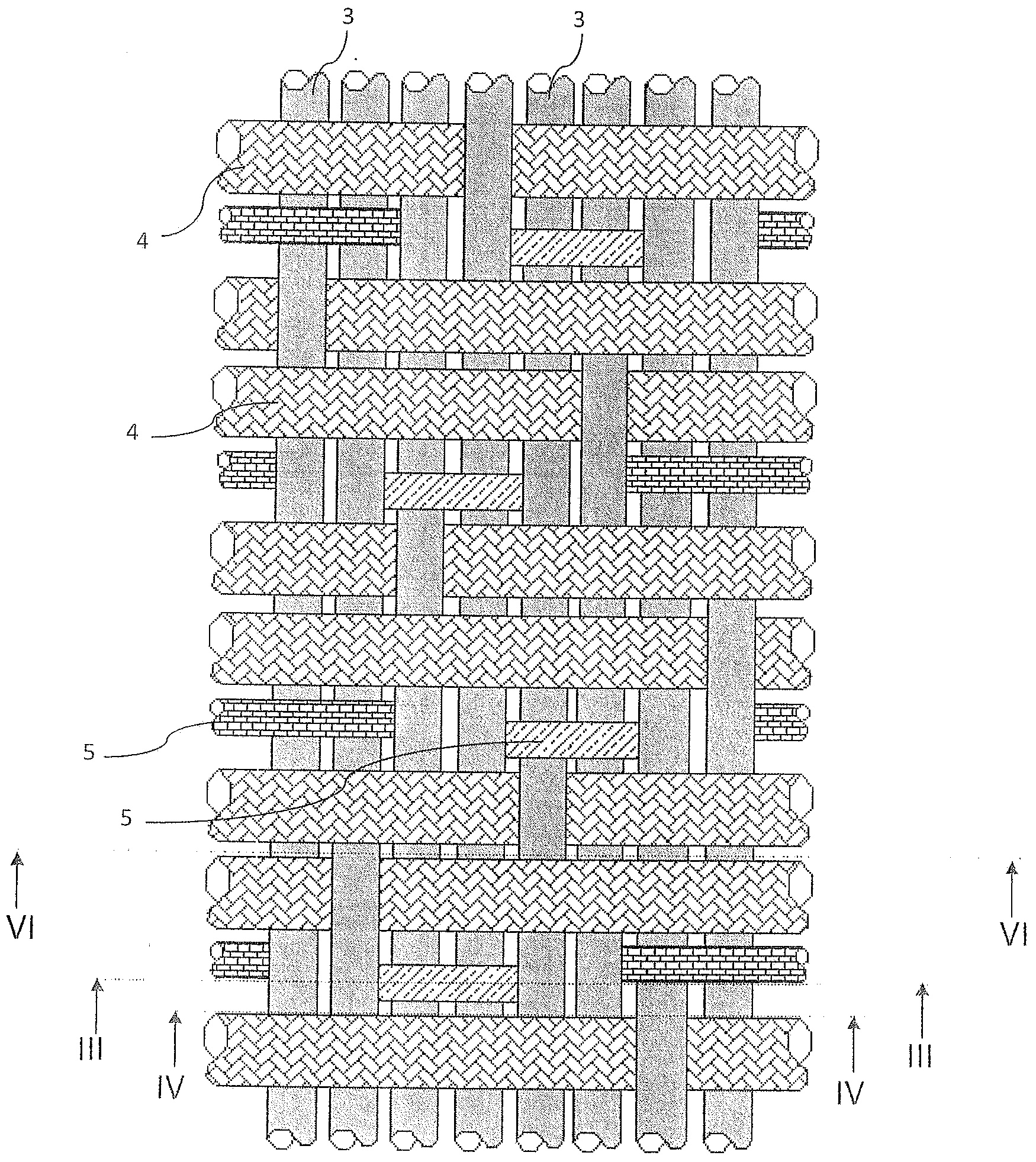

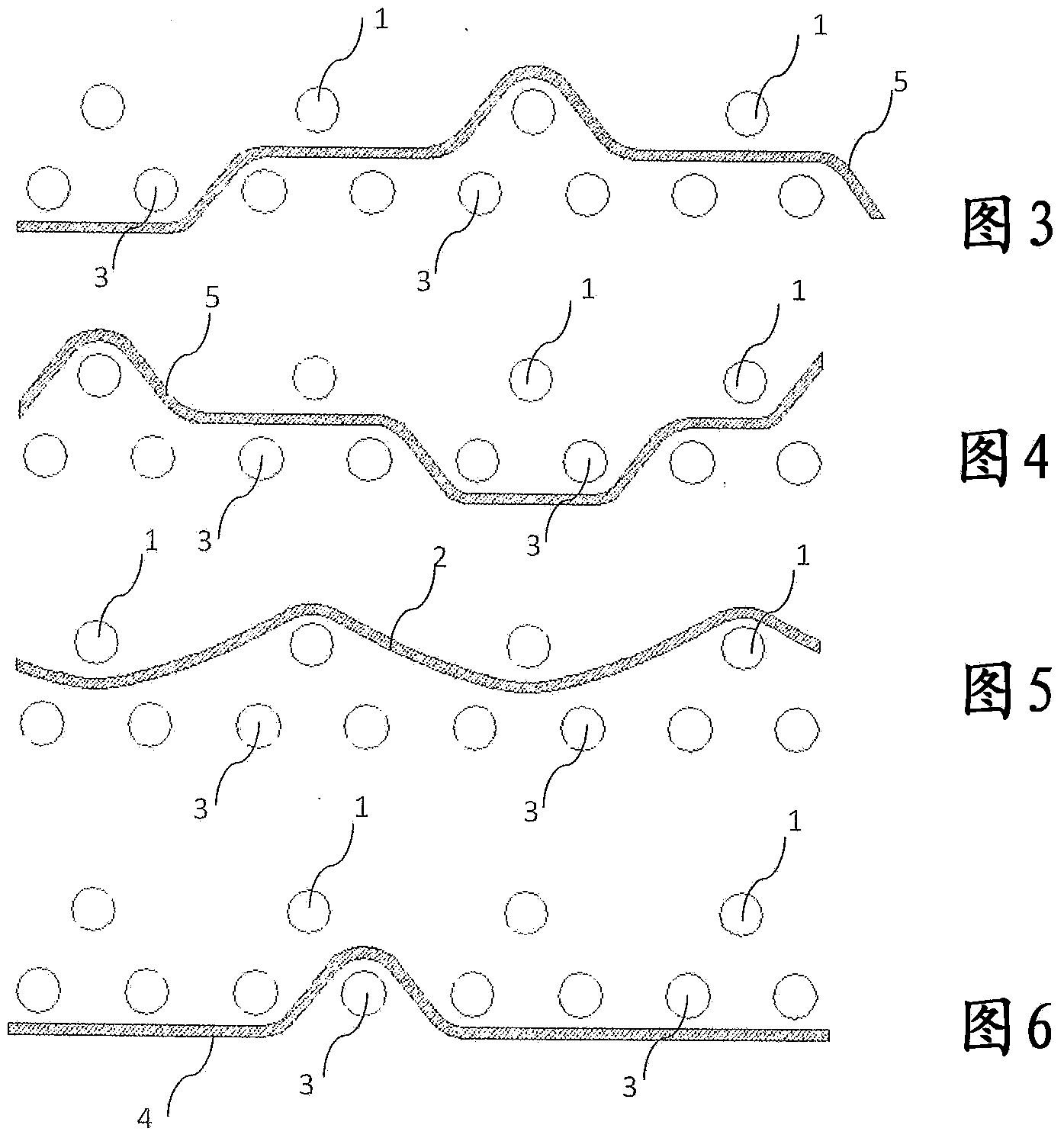

[0064] Figure 1-6 A first embodiment of a papermachine clothing according to the invention is shown. figure 1 The embodiments are shown in a view from the side of the paper, while figure 2 Shown in view from the worn side figure 1 the embodiment. Figure 3 to Figure 6 in the direction along the warp and according to figure 1 and figure 2 The view of the observer marked with the arrow shows the figure 1 and figure 2 the embodiment.

[0065] Figure 1 to Figure 6 An embodiment of the invention comprises at least two separate layers formed from at least two separate yarn systems. The above-mentioned yarn system consists of a yarn system forming the paper side and consisting of longitudinal threads and transverse threads, and a thread system forming the wearing side and consisting of longitudinal threads and transverse threads arranged along the The longitudinal and transverse directions of the fabric form mutually independent structures. The structures formed in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com