Phenolic resin composition and application thereof

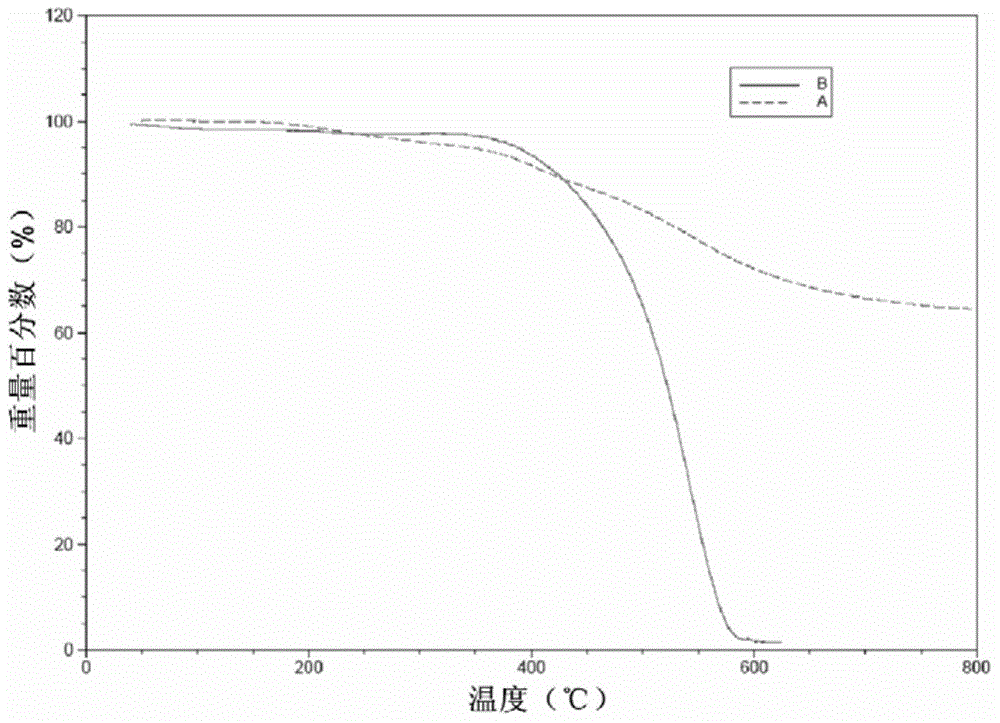

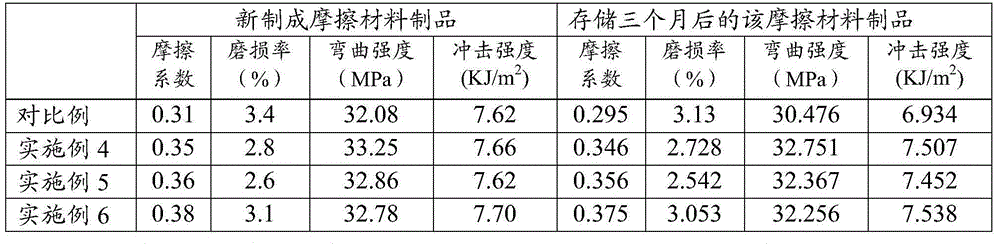

A technology of phenolic resin and boron phenolic resin, applied in the field of phenolic resin composition, can solve the problems of performance decline, low stability, poor thermal stability of phenolic resin, etc., and achieve the effect of slow performance decline and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] In the preparation method of the boron phenolic resin provided by the invention, the phenolic resin and the boron source are mixed. In one embodiment provided by the present invention, the polymerization rate of the phenolic resin is 30-50s / 150°C; in another embodiment provided by the present invention, the polymerization rate of the phenolic resin is 35-40s. In one embodiment provided by the present invention, the fluidity of the phenolic resin is 20-35 mm; in another embodiment provided by the present invention, the fluidity of the phenolic resin is 25-33 mm. In one embodiment provided by the present invention, the weight average molecular weight of the phenolic resin is 1000-20000; in another embodiment provided by the present invention, the weight average molecular weight of the phenolic resin is 2000-3000. In an embodiment provided by the present invention, the phenolic resin contains a certain amount of free phenol. In the embodiment that a phenolic resin provide...

Embodiment 1

[0051] Preparation of phenolic resin composition

[0052] Add 300g of phenol and 4g of oxalic acid into a four-necked flask, raise the temperature to 70-72°C, add 203.7g of formaldehyde solution with a concentration of 38.5wt% dropwise, drop it over 0.5h, slowly raise the temperature to 80°C, and react at a constant temperature at this temperature . After reacting for 3 hours, the reaction product is dehydrated and dephenolized by vacuuming until the free phenol content in the reaction product is 0.5 wt%, to obtain a phenolic resin with a weight average molecular weight of 2000-3000 and a water content of less than 1 wt%.

[0053]Add 12 g of boric acid to 350 g of the above phenolic resin in two batches, stir and mix evenly, and react at a constant temperature of 135-140° C. for 1 hour. After reacting for 1 hour, detect the cone-plate viscosity of the reaction product, and stop the reaction when the cone-plate viscosity of the reaction product is 31P at 150°C. The reaction p...

Embodiment 2

[0065] Preparation of phenolic resin composition

[0066] Add 500g of phenol and 5g of oxalic acid into a four-necked flask, raise the temperature to 75°C, add dropwise 344g of formaldehyde solution with a concentration of 38wt%, and drop it in 1.5h, slowly raise the temperature to 83°C, and react at a constant temperature at this temperature. After reacting for 2.5 hours, the reaction product is dehydrated and vacuumized to remove phenols until the free phenol content in the reaction product is 2 wt%, to obtain a phenolic resin with a weight average molecular weight of 2000-3000 and a water content of less than 1 wt%.

[0067] Add 26 g of boric acid to 750 g of the above phenolic resin in two batches, stir and mix evenly, and react at a constant temperature of 135-140° C. for 1 hour. After reacting for 1 hour, detect the cone-plate viscosity of the reaction product, and stop the reaction when the cone-plate viscosity of the reaction product is 35P at 150°C. The reaction prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gel time | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com