Super-tough nylon alloy and preparation method thereof

A nylon and alloy technology, applied in the field of engineering plastic modification, can solve the problems of poor low temperature resistance, high water absorption, and poor impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

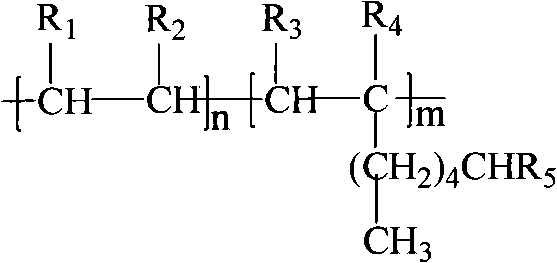

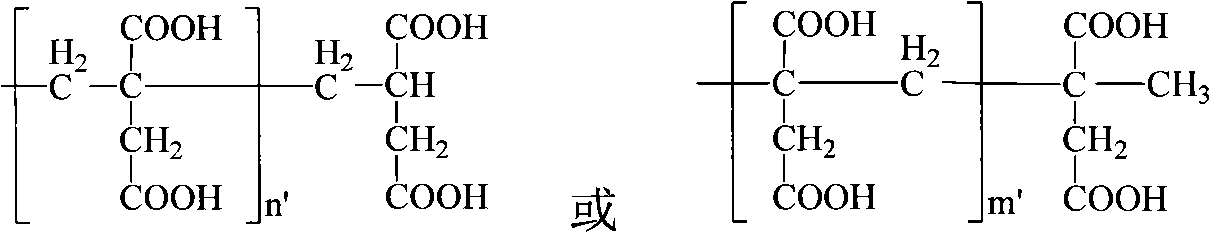

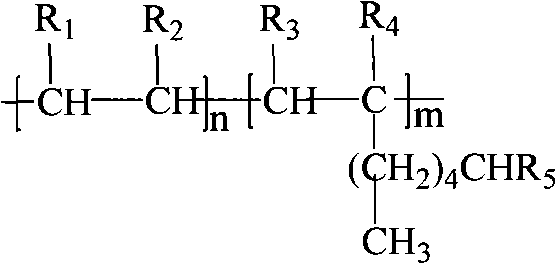

Method used

Image

Examples

Embodiment 1

[0024] The mass percentage is nylon 6665%, itaconic acid grafted ethylene-α-octene copolymer 35%, antioxidant 1010 0.25%, antioxidant 168 0.25%, lubricant TAF 0.5%, in a high mixer After mixing evenly at room temperature, put the material into the twin-screw extruder, the extrusion temperature is 260-280°C, the main engine speed is 300r / min, after traction, cooling, pelletizing, the pellets are vacuumed at 80°C Let dry for 8 hours.

Embodiment 2

[0026] The mass percentage is nylon 66 70%, itaconic acid grafted ethylene-α-octene copolymer 30%, antioxidant 1010 0.25%, antioxidant 168 0.25%, lubricant TAF 0.5%, in the high mixer After mixing evenly at room temperature, put the material into the twin-screw extruder, the extrusion temperature is 260-280°C, the main engine speed is 300r / min, after traction, cooling, pelletizing, the pellets are at 80°C Dry under vacuum for 8 hours.

Embodiment 3

[0028] The mass percent is nylon 66 75%, itaconic acid grafted ethylene-α-octene copolymer 25%, antioxidant 1010 0.25%, antioxidant 168 0.25%, lubricant TAF 0.5%, in the high mixer After mixing evenly at room temperature, put the material into the twin-screw extruder, the extrusion temperature is 260-280°C, the main engine speed is 300r / min, after traction, cooling, pelletizing, the pellets are at 80°C Dry under vacuum for 8 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com