Patents

Literature

258results about How to "Increase thrust-to-weight ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

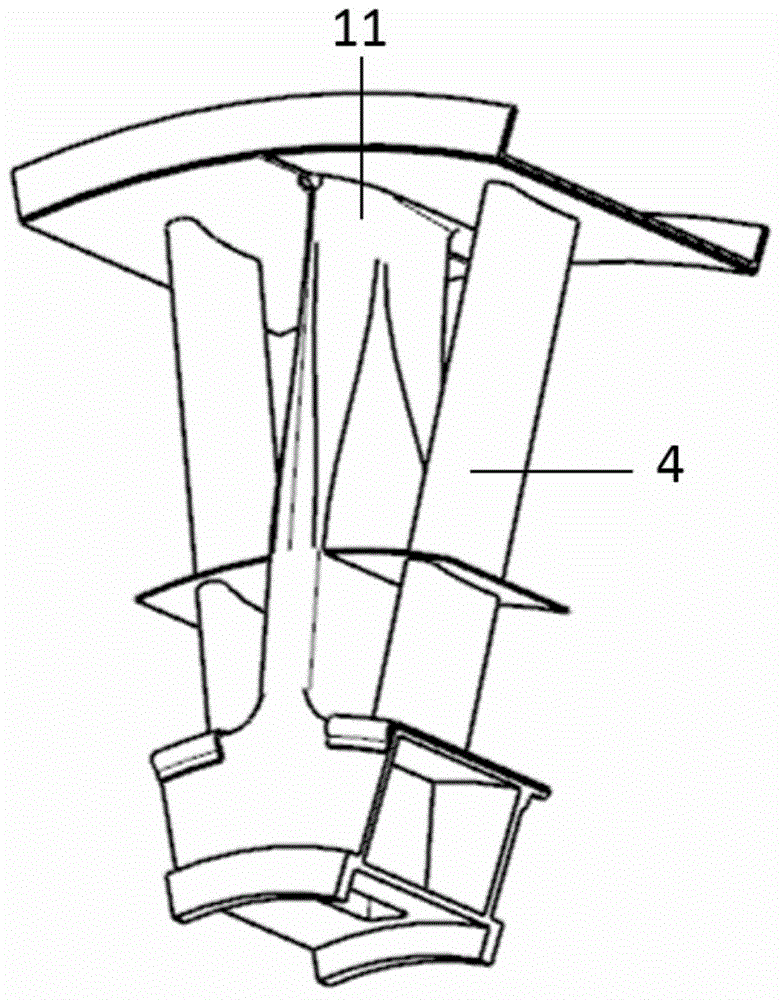

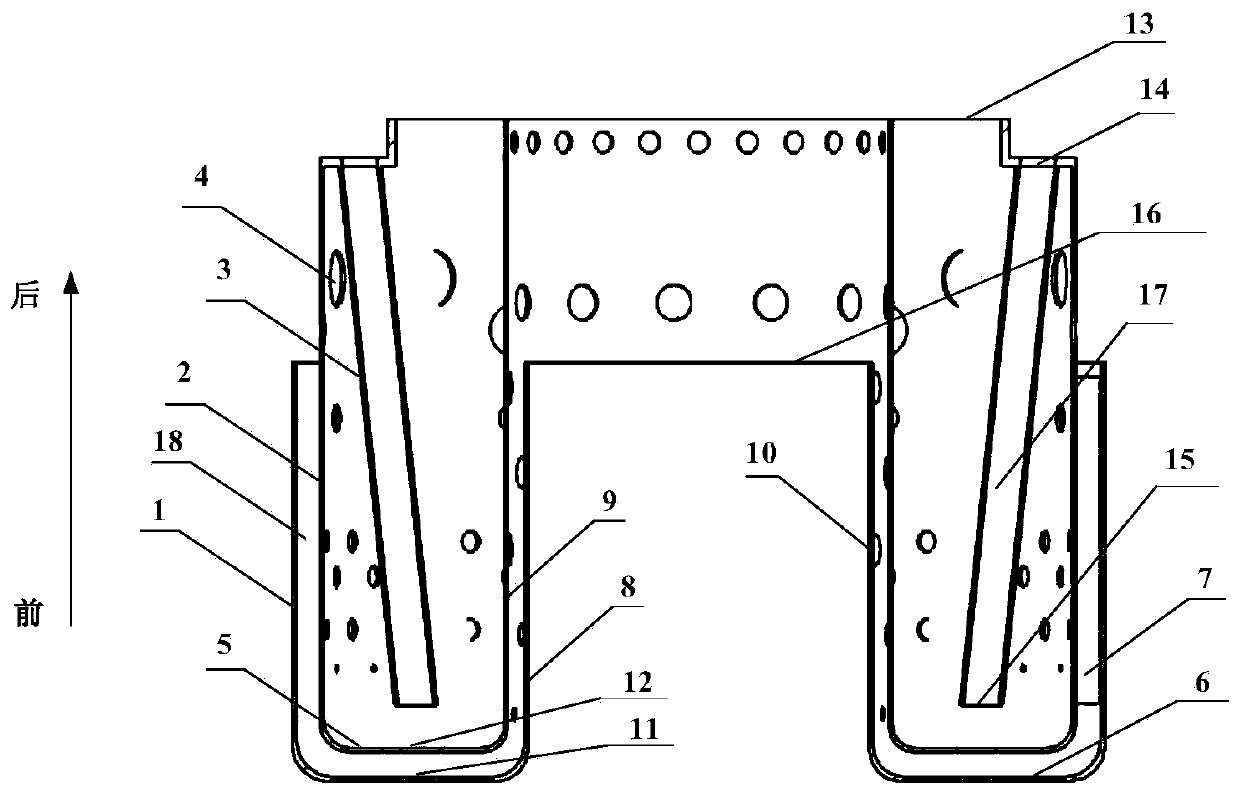

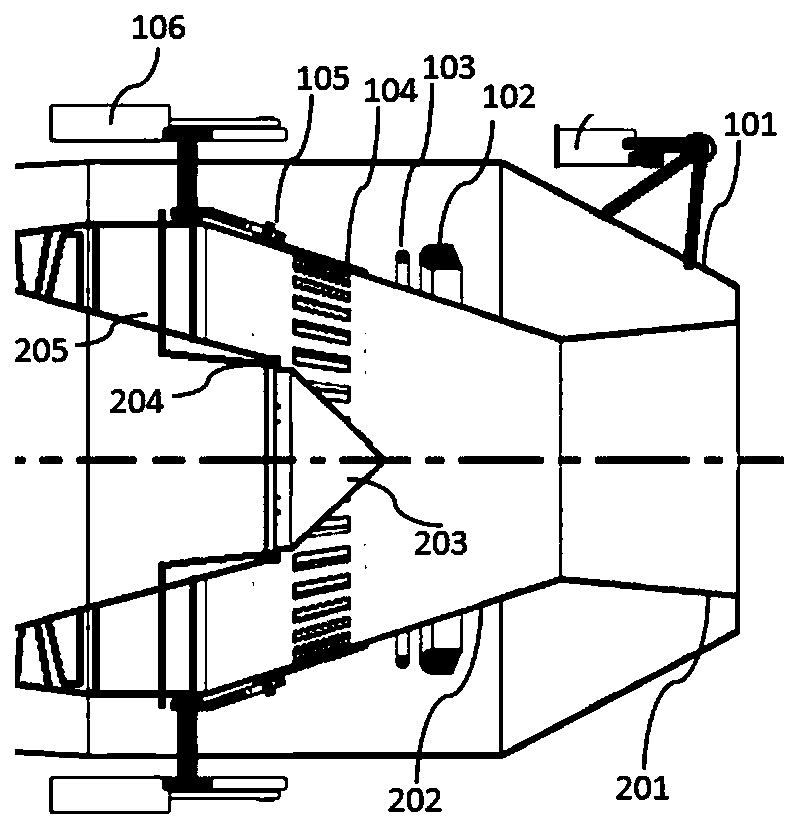

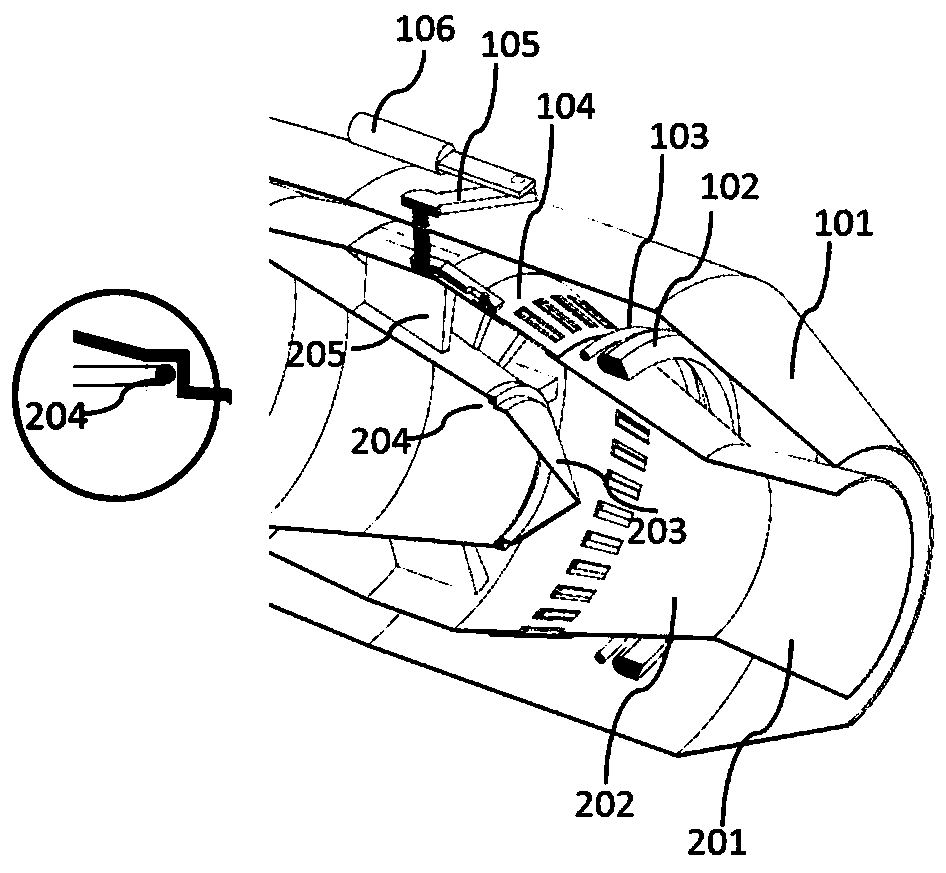

Afterburner integrated with stabilizer and worm wheel rear rectification support plate

InactiveCN102538010ASolve the technical problems of ablationImprove reliabilityContinuous combustion chamberEfficient propulsion technologiesCombustion chamberFuel oil

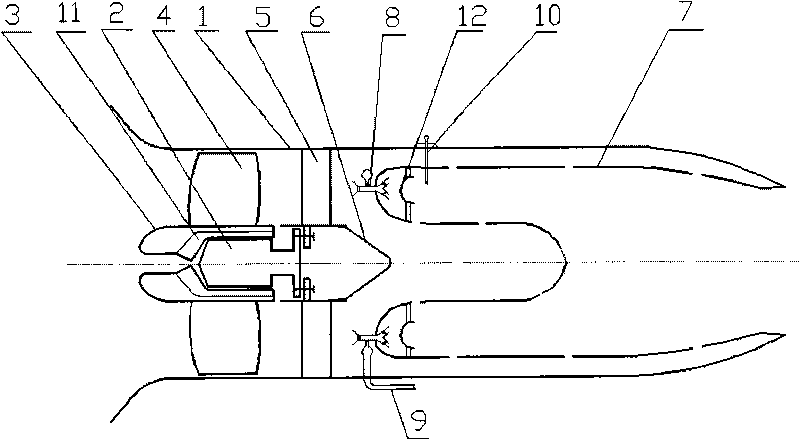

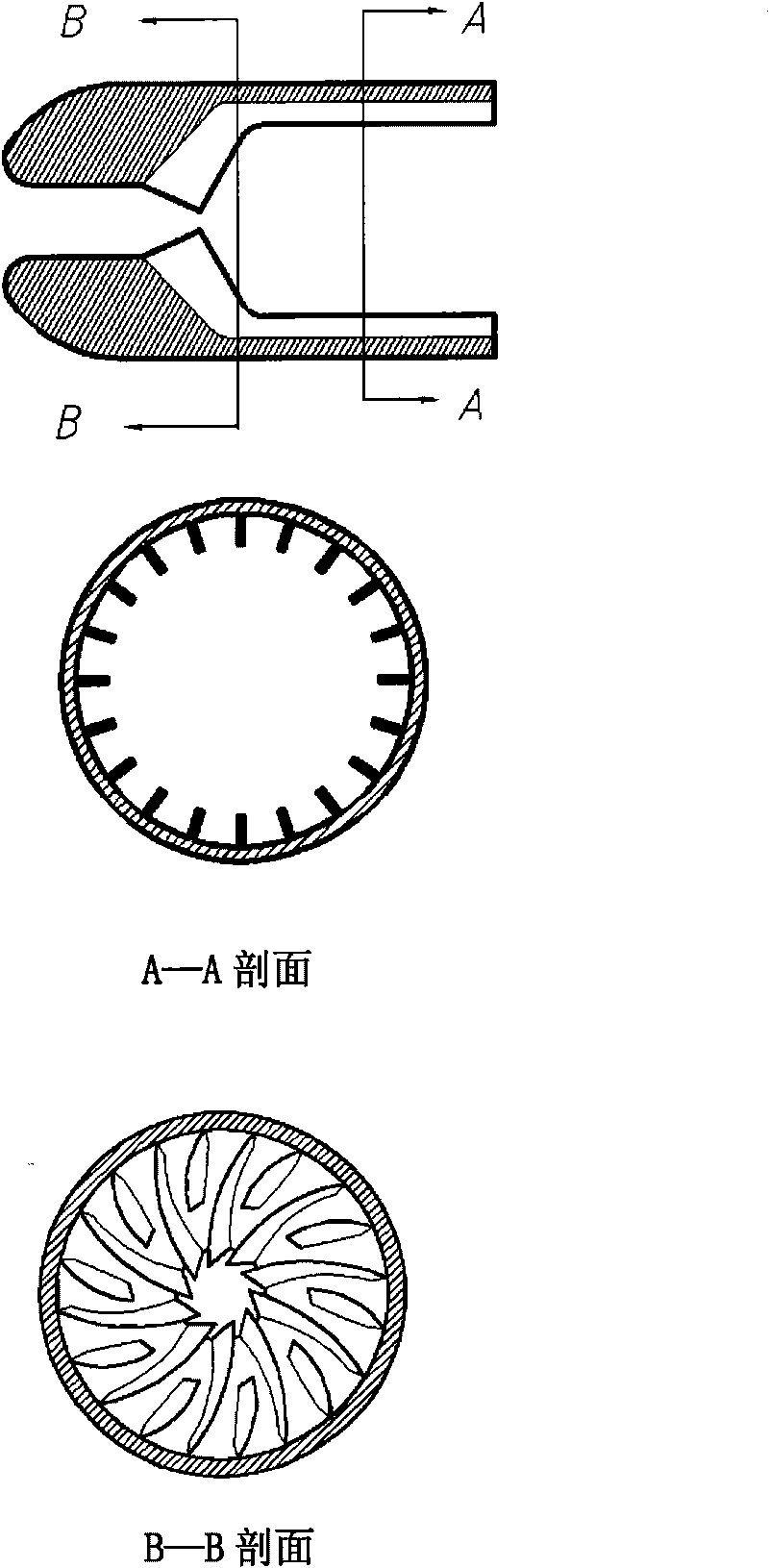

The invention discloses an afterburner integrated with a stabilizer and a worm wheel rear rectification support plate. A combustion part in the afterburner is integrated with a worm wheel rear load-bearing framework; the worm wheel rear rectification support plate is integrated with an inner culvert flame stabilizer, and cooling air is fed; a fuel oil supply pipe and a fuel oil nozzle are arranged in the rectification support plate; main fuel oil is transversely sprayed out from two sides of the support plate; and duty fuel oil is sprayed out from a groove on the rear surface of the stabilizer to form a duty flame. A pneumatic appearance of an outer culvert flame stabilizer is designed as a V-shaped bluff body, and the cooling air is fed into the outer culvert flame stabilizer; a fuel oil pipeline is arranged in the outer culvert flame stabilizer; the main fuel oil is transversely sprayed by a baffle plate nozzle; and the duty fuel oil is sprayed out from a groove on the rear surface of the outer culvert flame stabilizer. An annular flame stabilizer is arranged between the inner culvert flame stabilizer and the outer culvert flame stabilizer, so that functions of the stabilizer and a flame coupler are realized in a circumferential direction. The internal parts of the afterburner are integrated, so that the part utilization efficiency is improved, and the engine thrust-weight ratio is increased.

Owner:BEIHANG UNIV

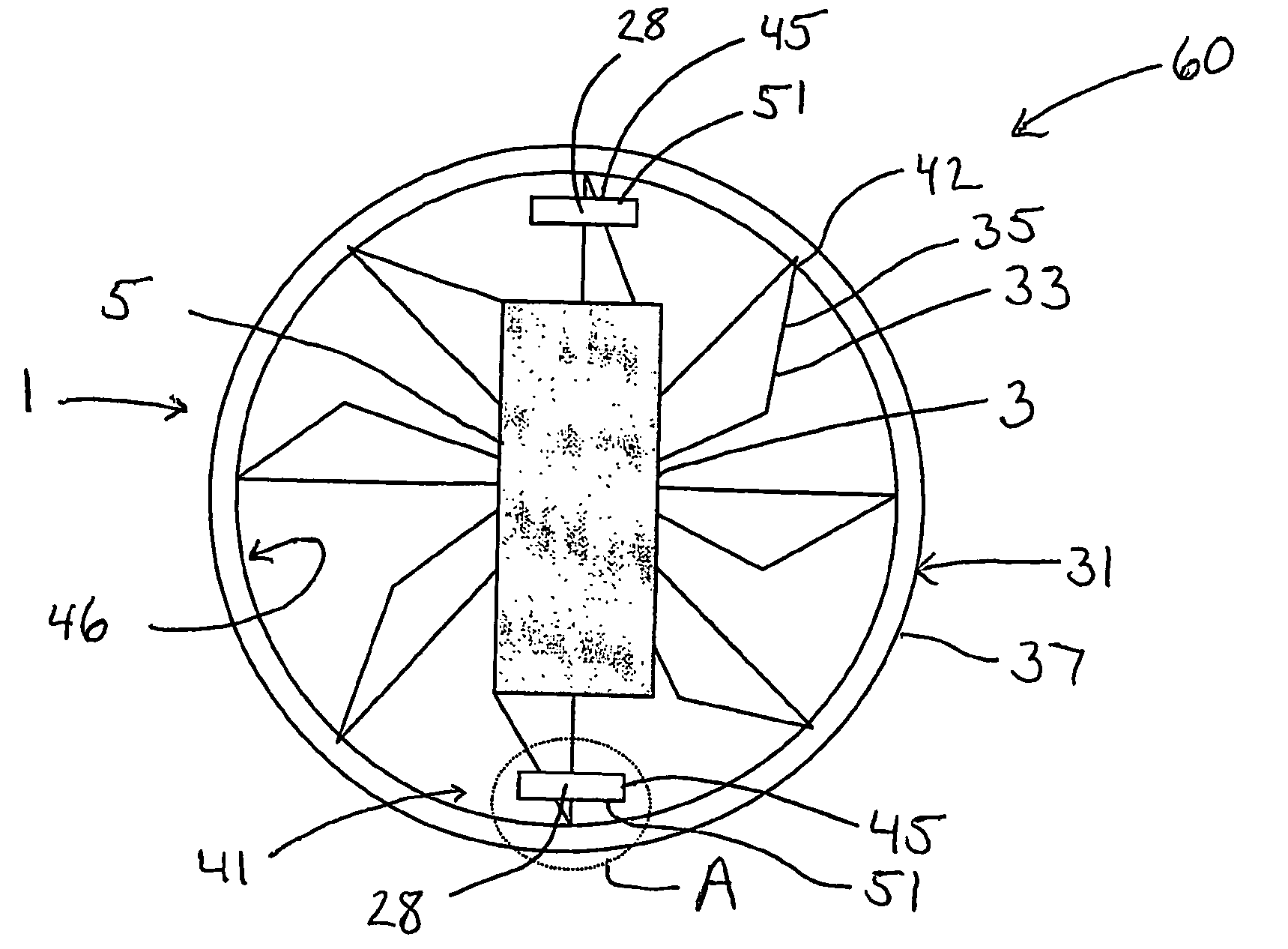

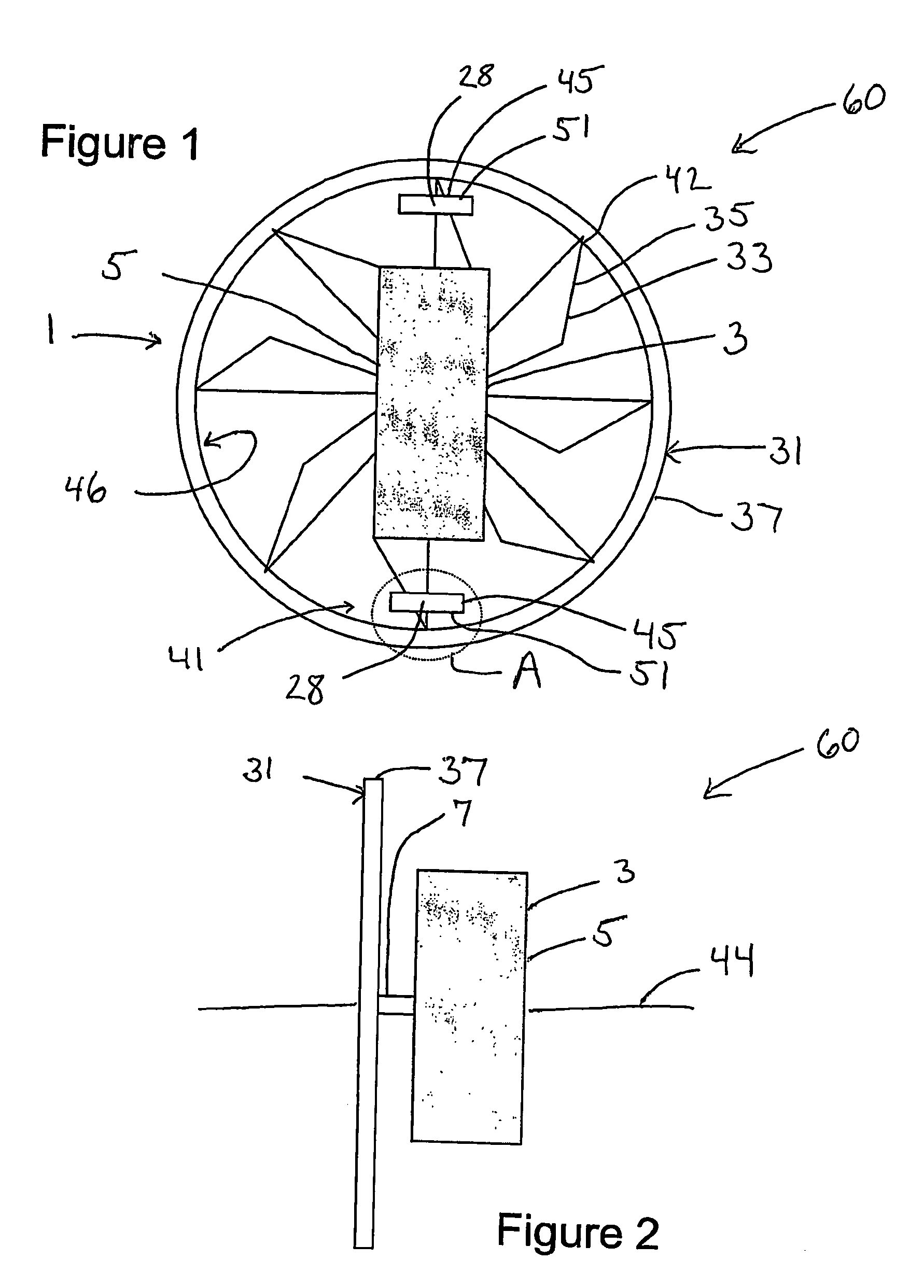

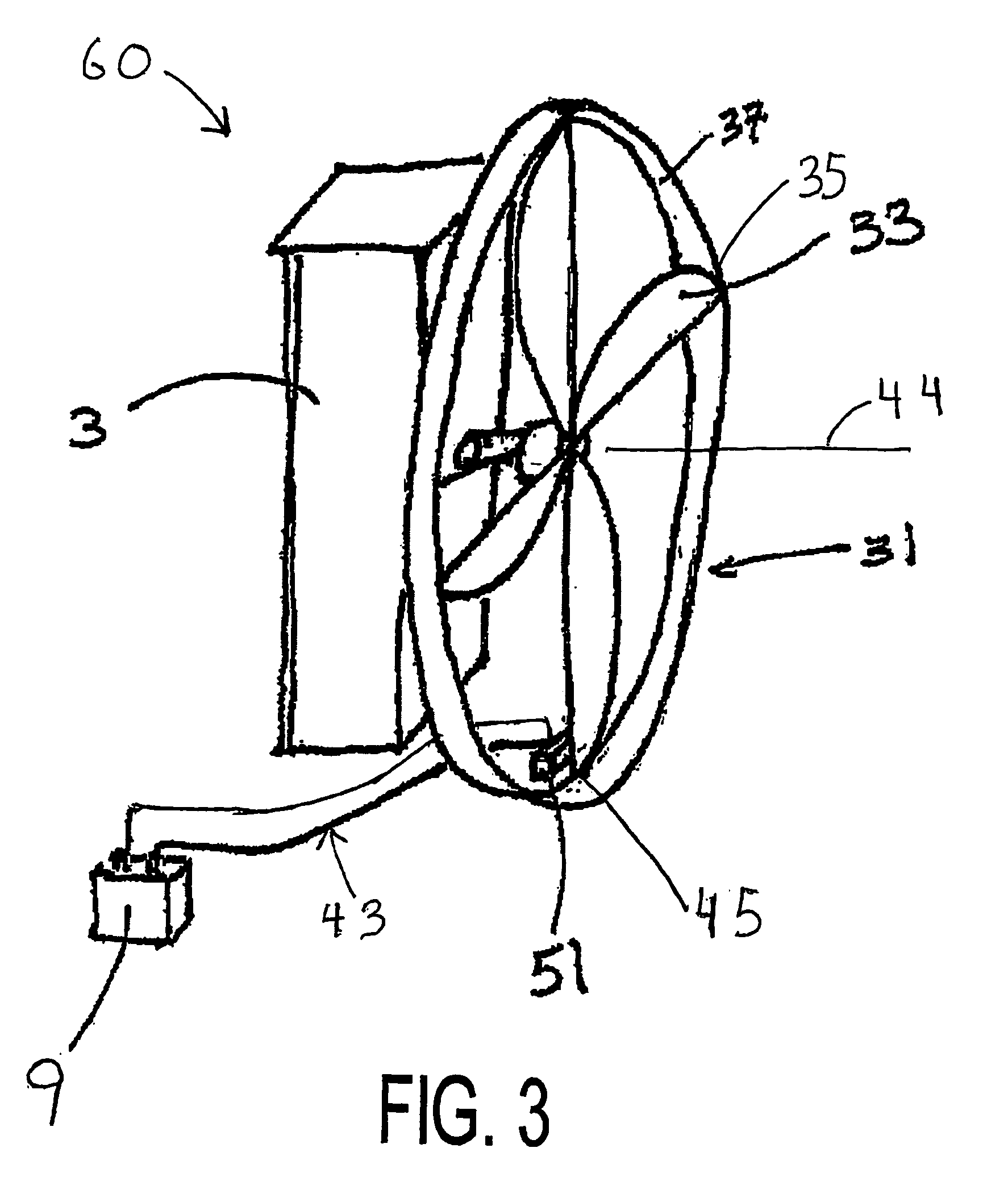

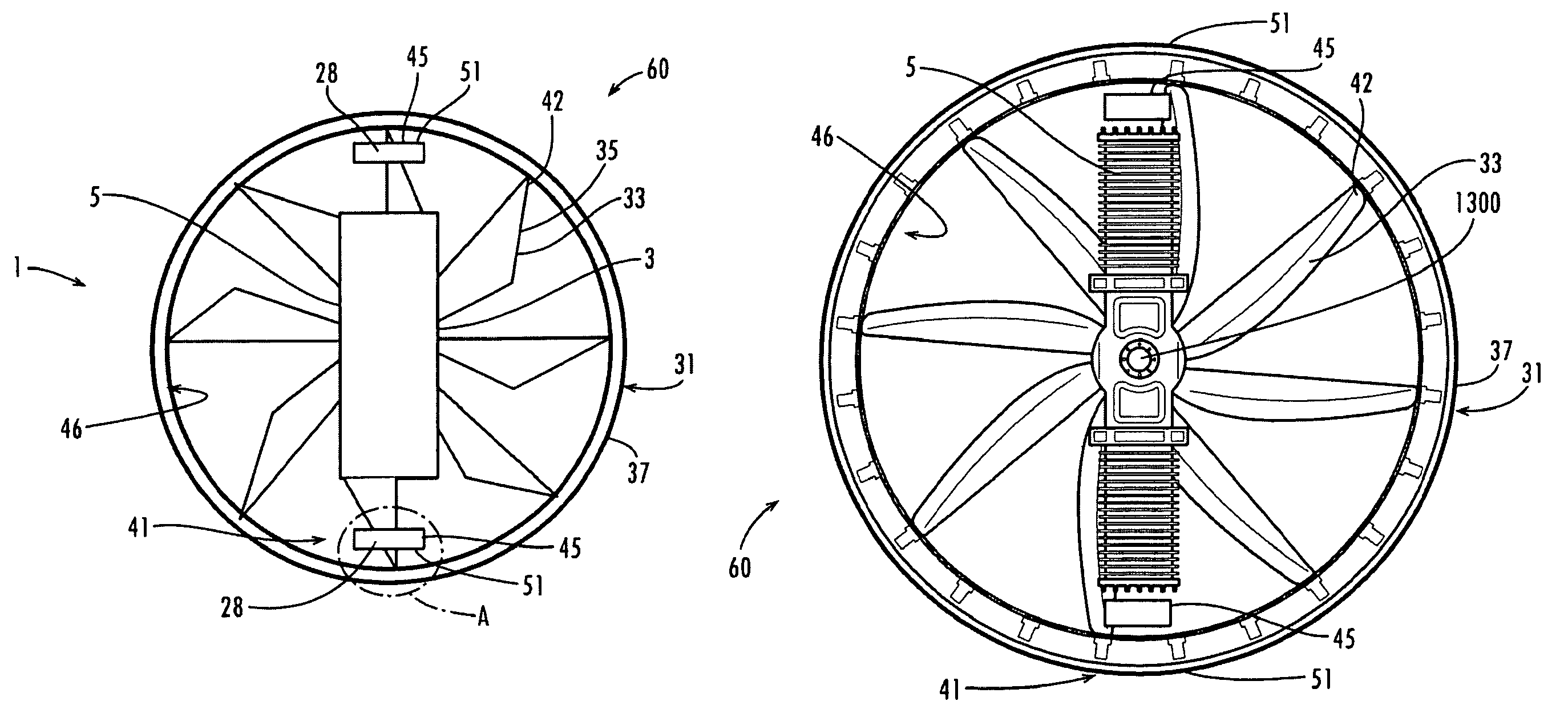

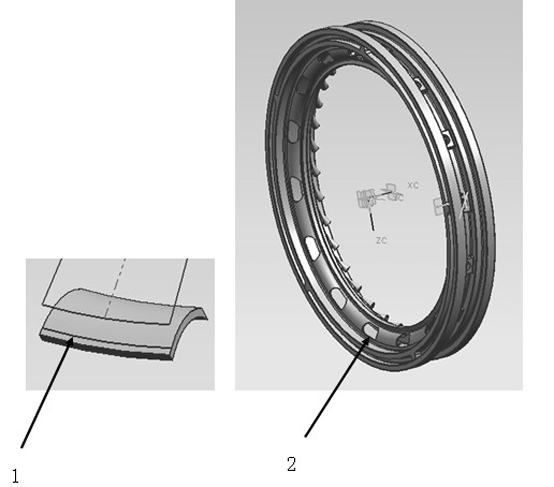

Ring generator

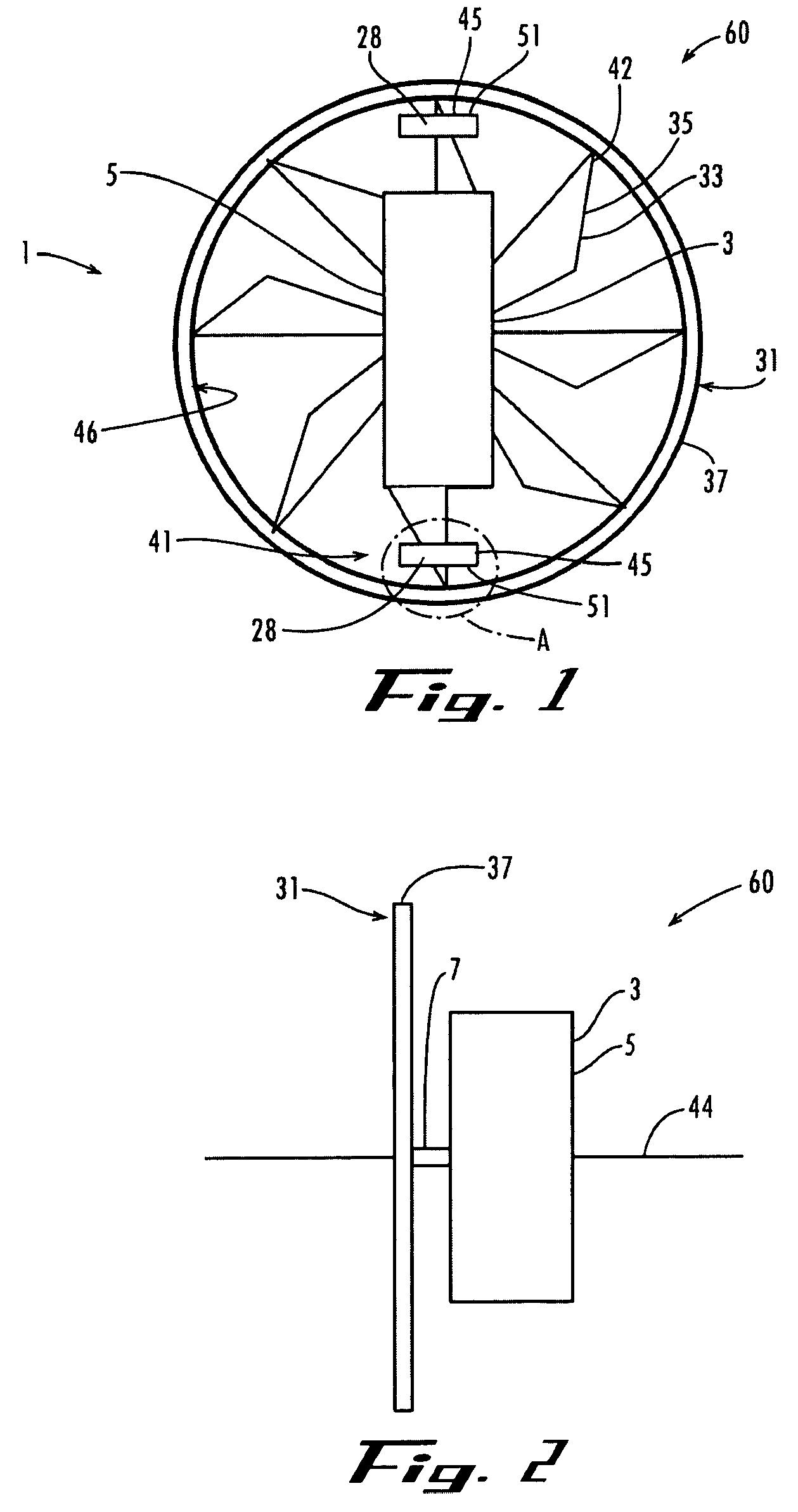

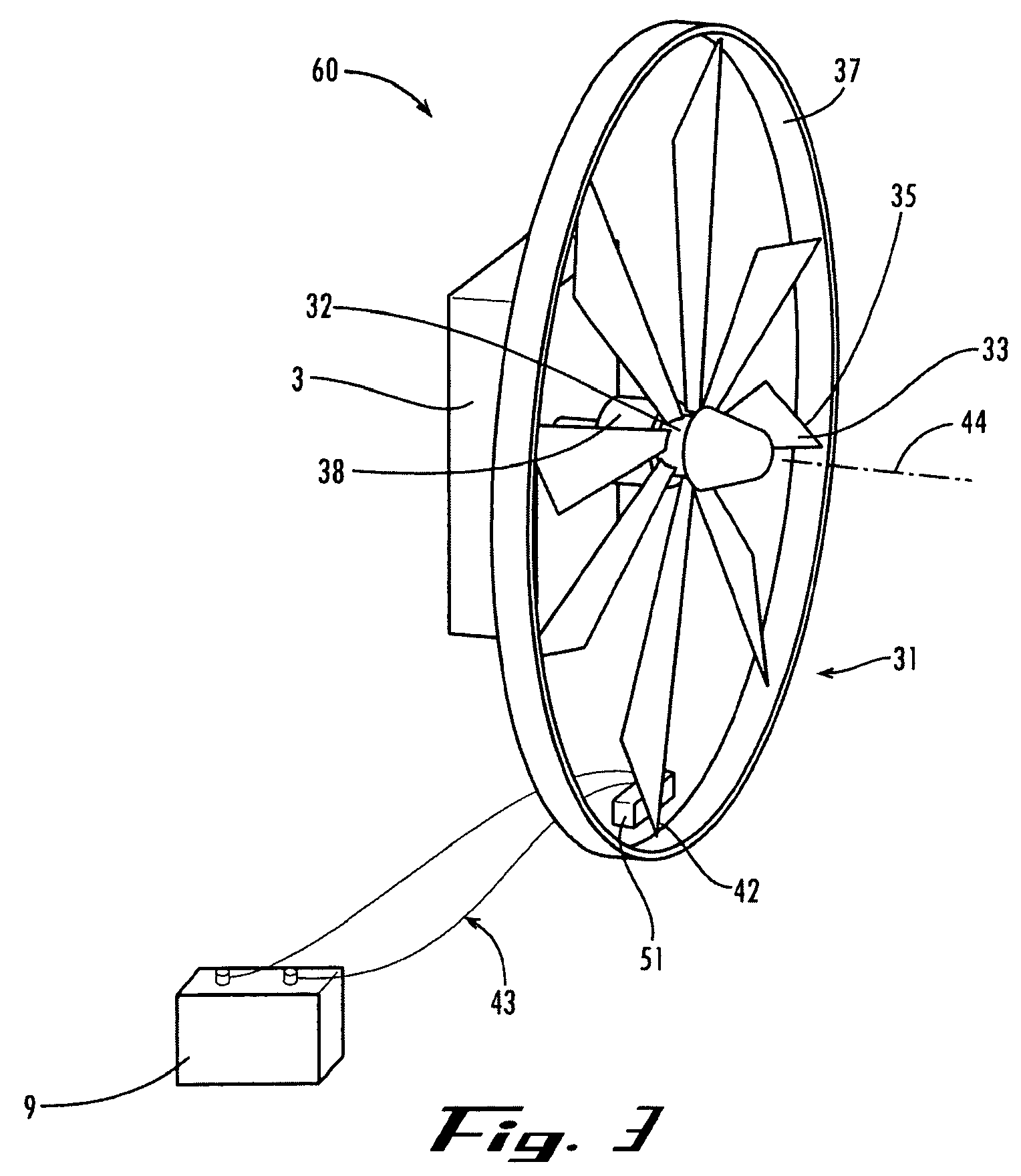

InactiveUS20060138777A1Minimal visibilityHigh weight ratioUnmanned aerial vehiclesRemote controlled aircraftCombustionFlight vehicle

The present invention is a rotary device that may be adapted for use as a propeller assembly and electrical generator for aerial vehicles or other vehicles intended for fluid media. In one example, the device includes a ring assembly having a plurality of centrally linked blades coupled to a rotatable common hub. Rotary motion of the ring assembly is facilitated by coupling it to an opposed cylinder, opposed piston, internal combustion. The ring assembly includes components of an electrical power generating system so that electrical power is produced from the rotation of the ring assembly.

Owner:ADVANCED PROPULSION TECH

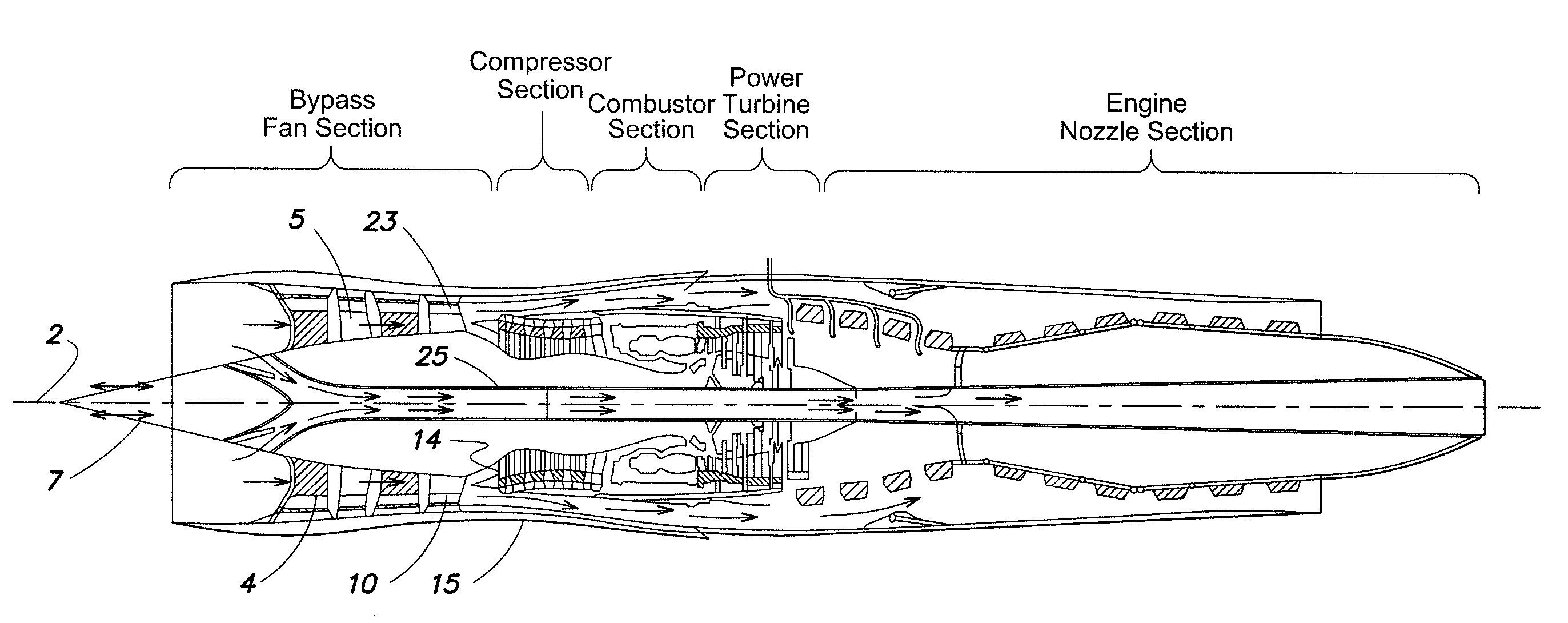

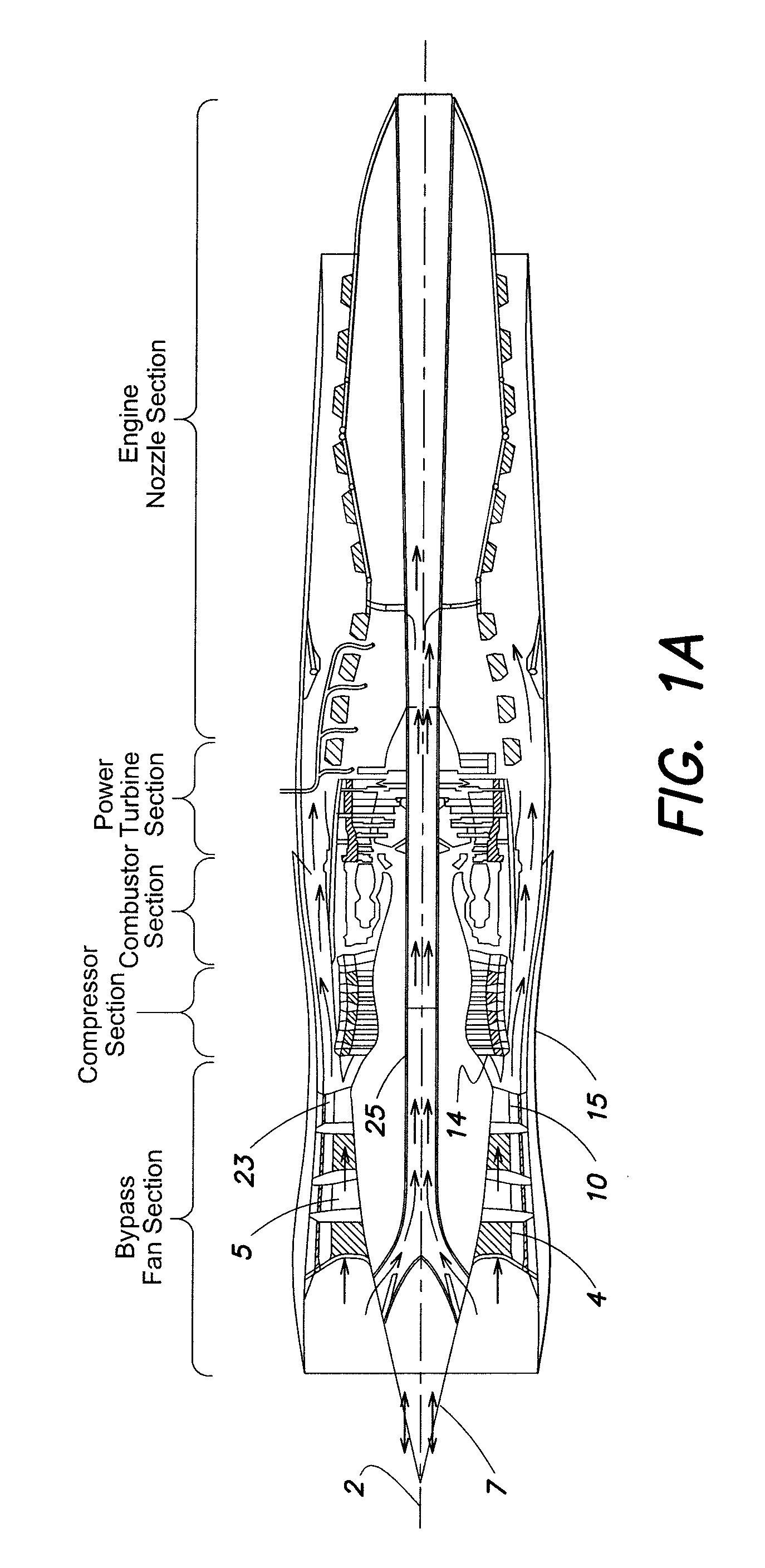

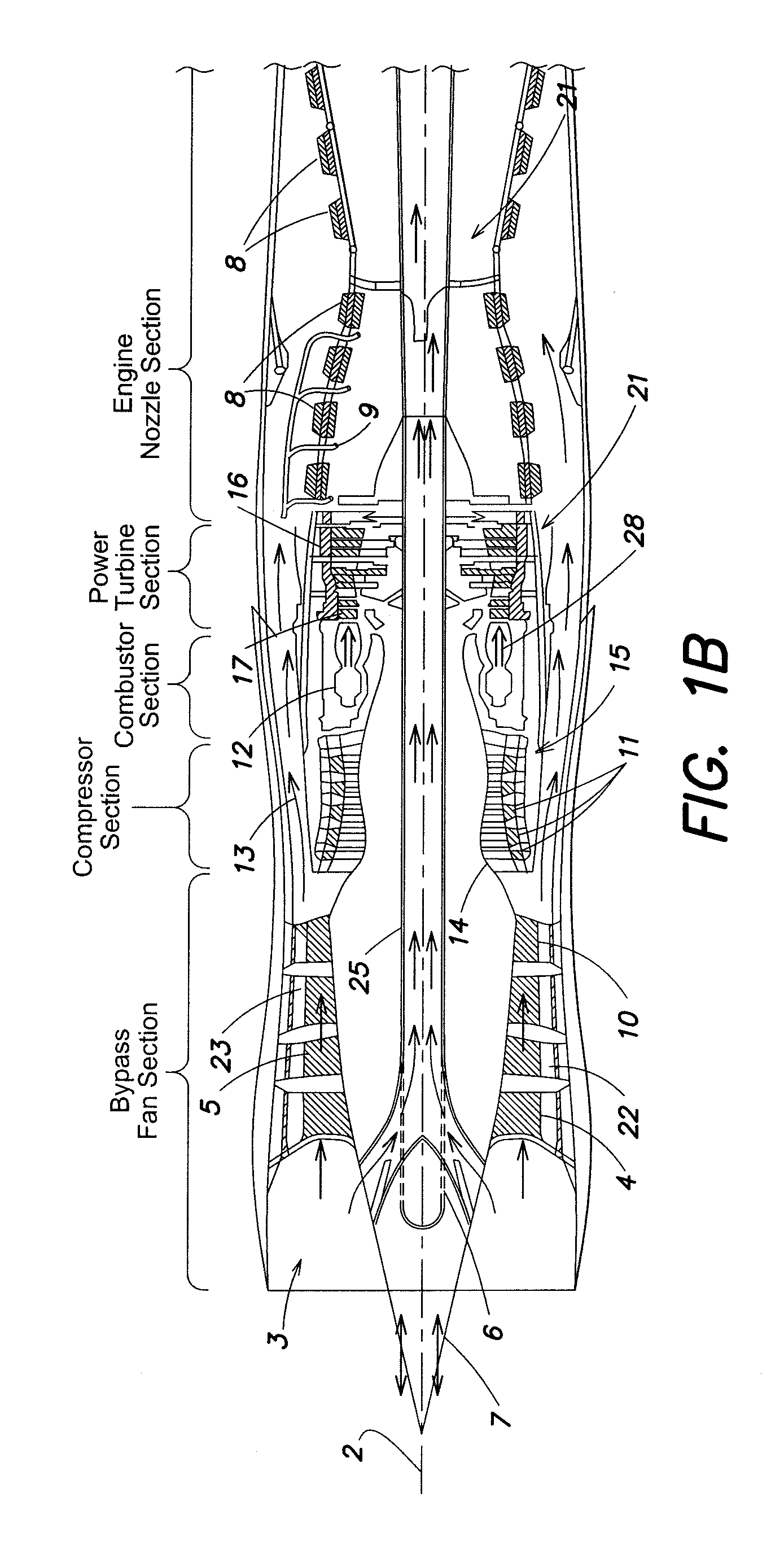

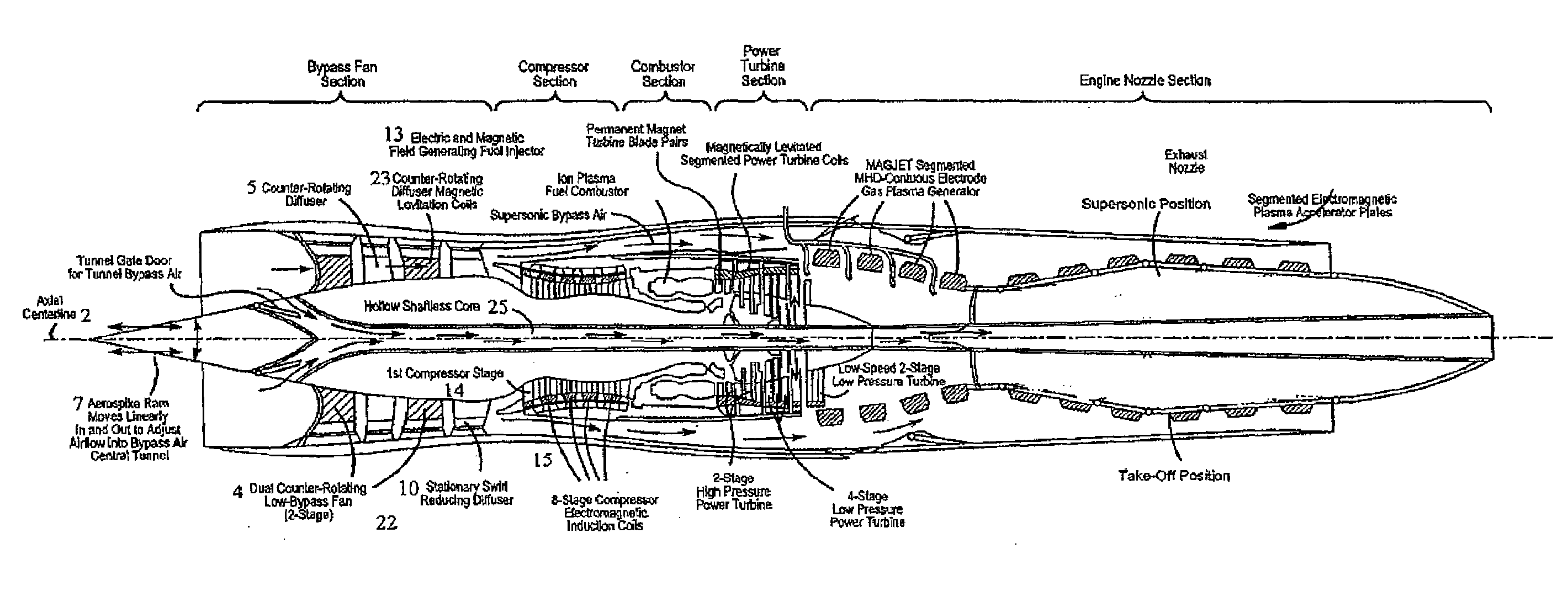

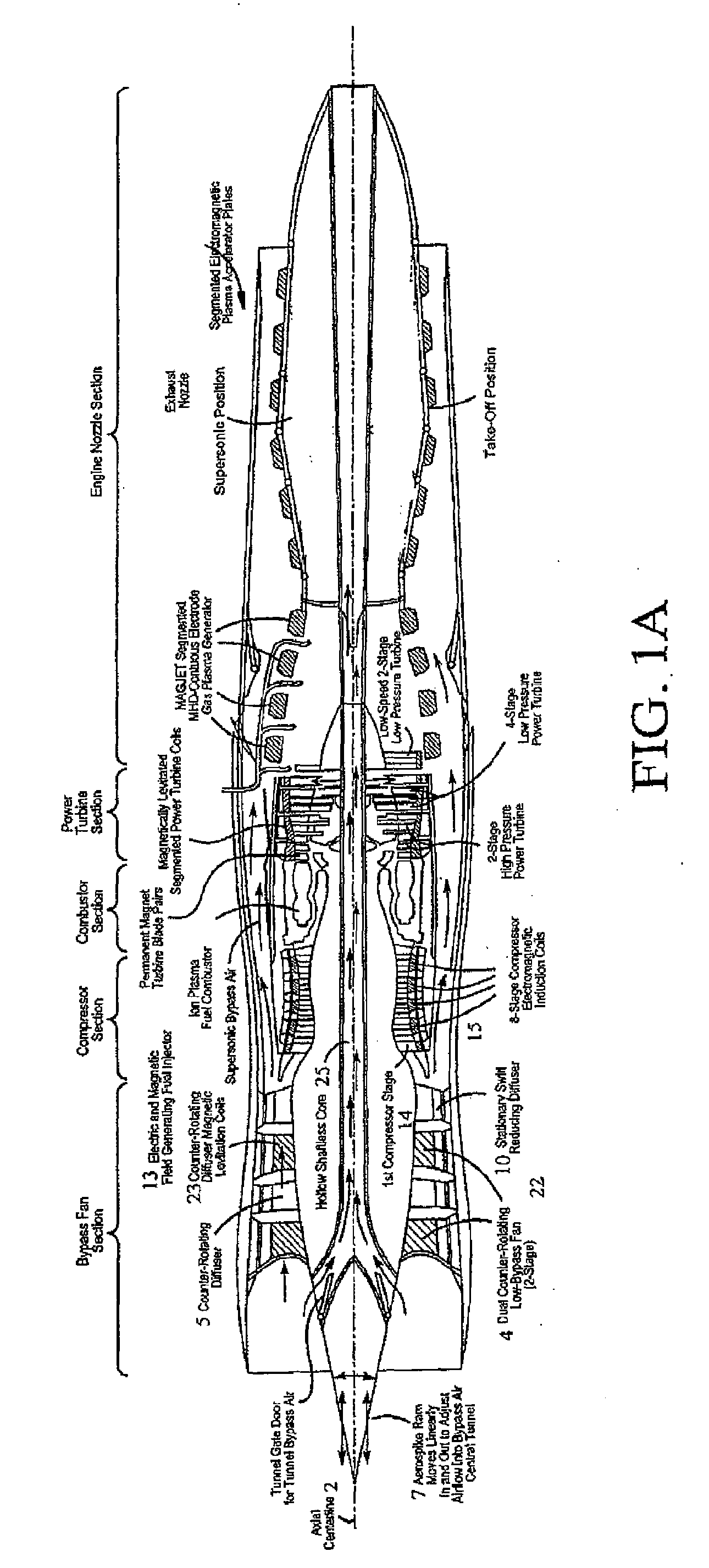

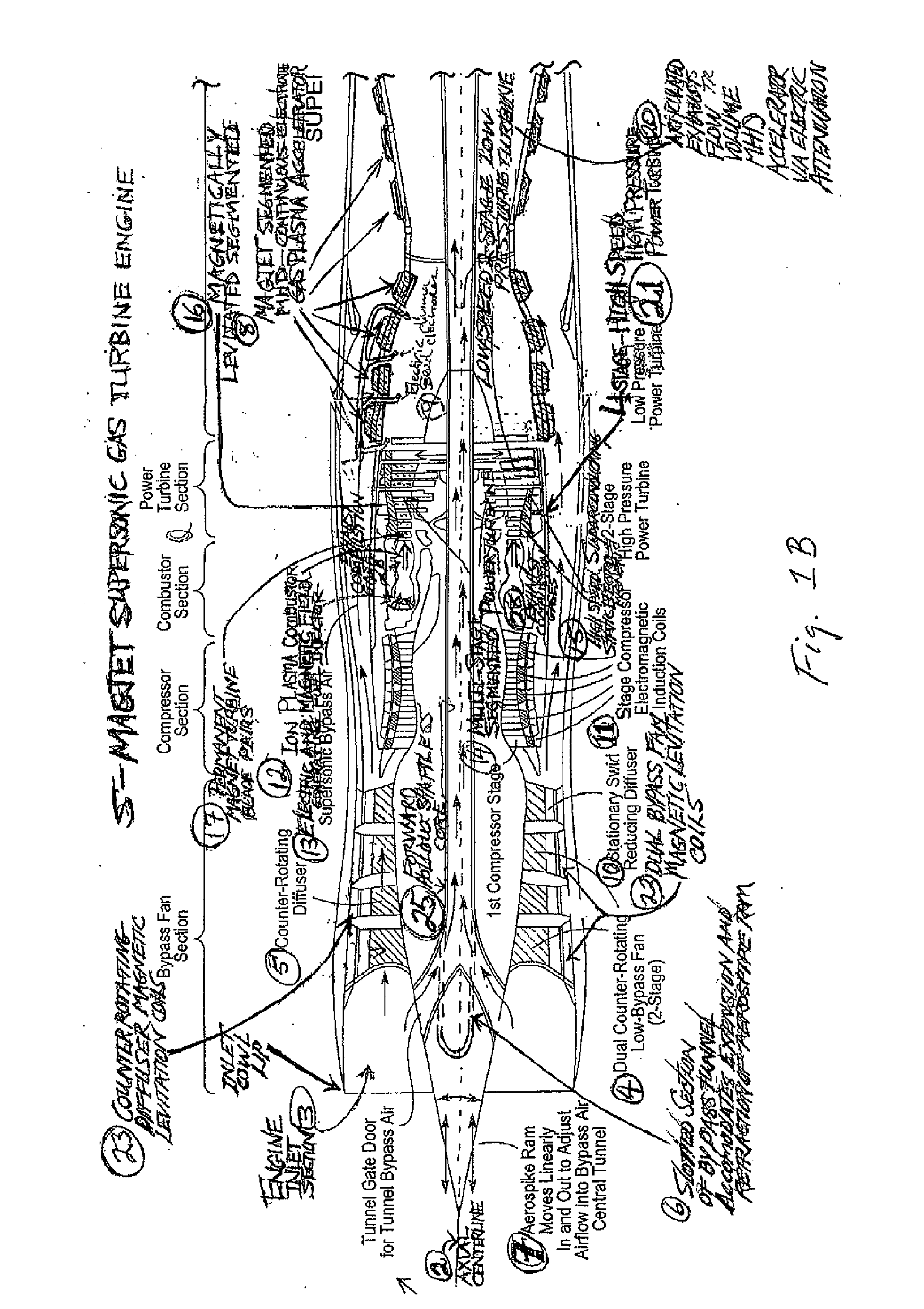

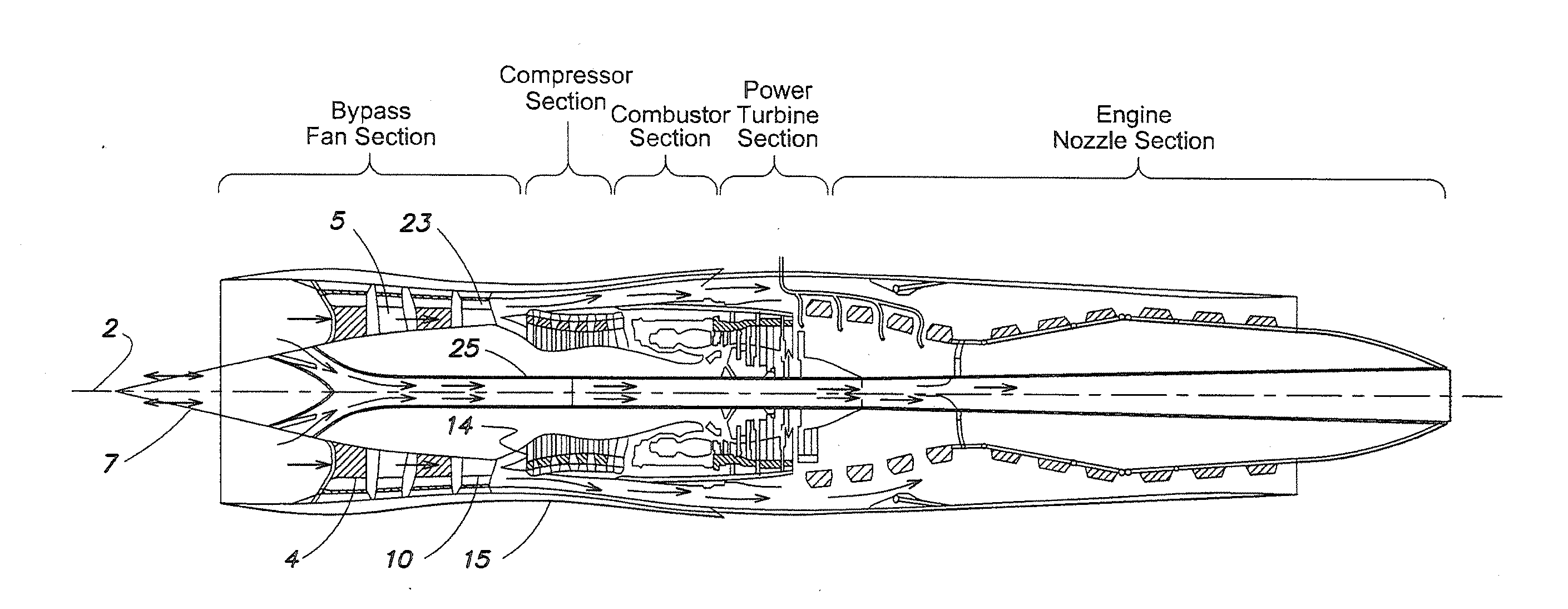

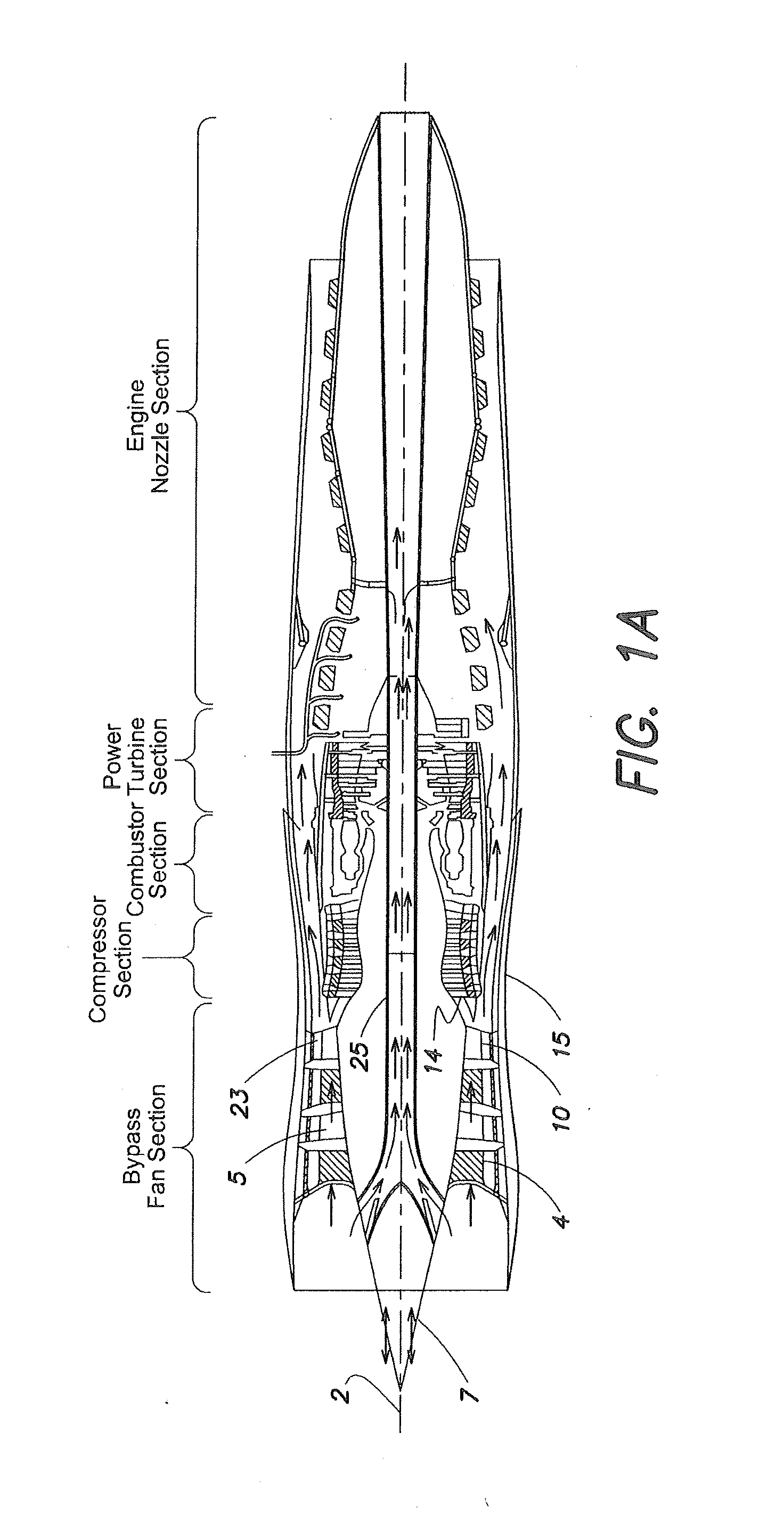

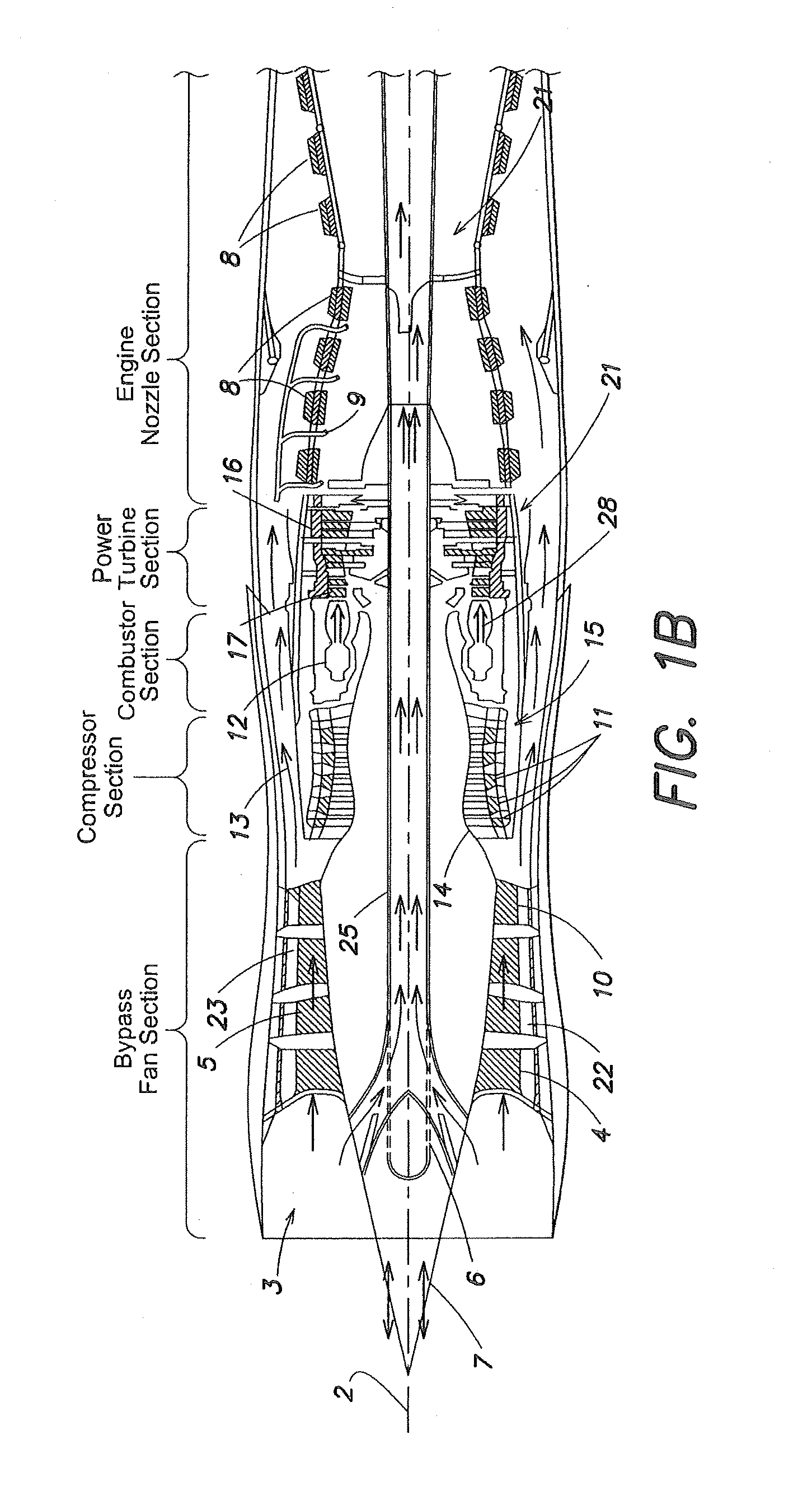

Magnetic advanced generation jet electric turbine

ActiveUS8365510B2Maximizes propulsion efficiencyImprove combustionGas turbine plantsEnergy production using magneto-hydrodynamic generatorsAviationElectric power system

Supersonic Magnetic Advanced Generation Jet Electric Turbine (S-MAGJET) described herein, and a subsonic derivative, MAGJET, integrate a gas power turbine, superconducting electric power and propulsion generation, and magnetic power flux field systems along with an ion plasma annular injection combustor which utilizes alternative petroleum-based fuel and combustion cycles to create a hybrid turbine turbomachine for aerospace propulsion. The propulsion unit is able to achieve a dramatic increase in horsepower, combustion and propulsion efficiency, and weight reduction. In addition, the turbomachinery structures may be disposed within an exo-skeleton architecture that achieves an increase in thrust to weight ratio with a concomitant increase in fuel efficiency and power generation over traditional gas turbine technology today. The engine continuously adjusts the temperature, pressure and mass airflow requirements using an electromagnetic power management system architecture. Engine performance may be controlled across the entire desired flight envelope, whether subsonic, transonic or supersonic flight conditions.

Owner:SONIC BLUE AEROSPACE

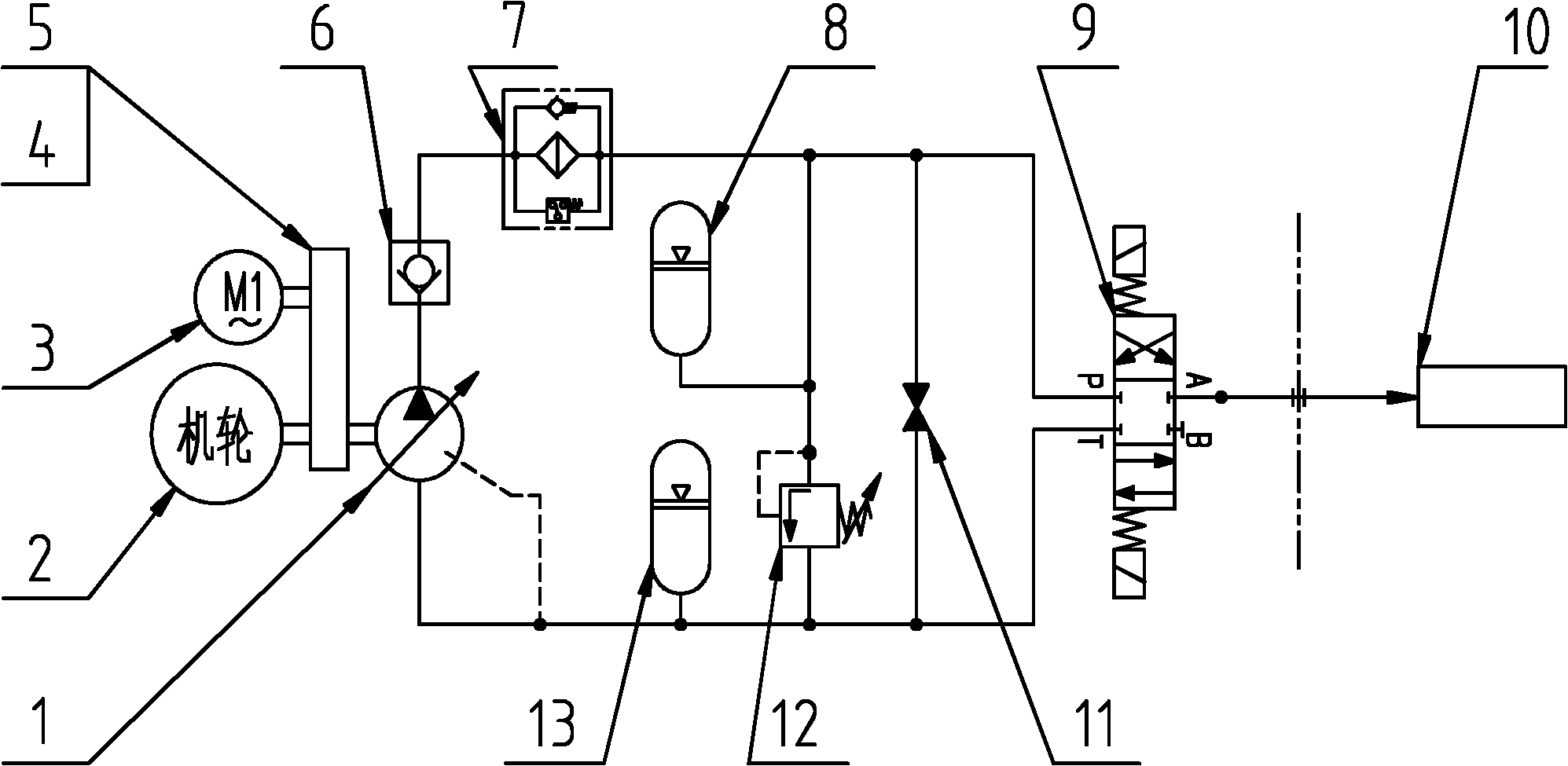

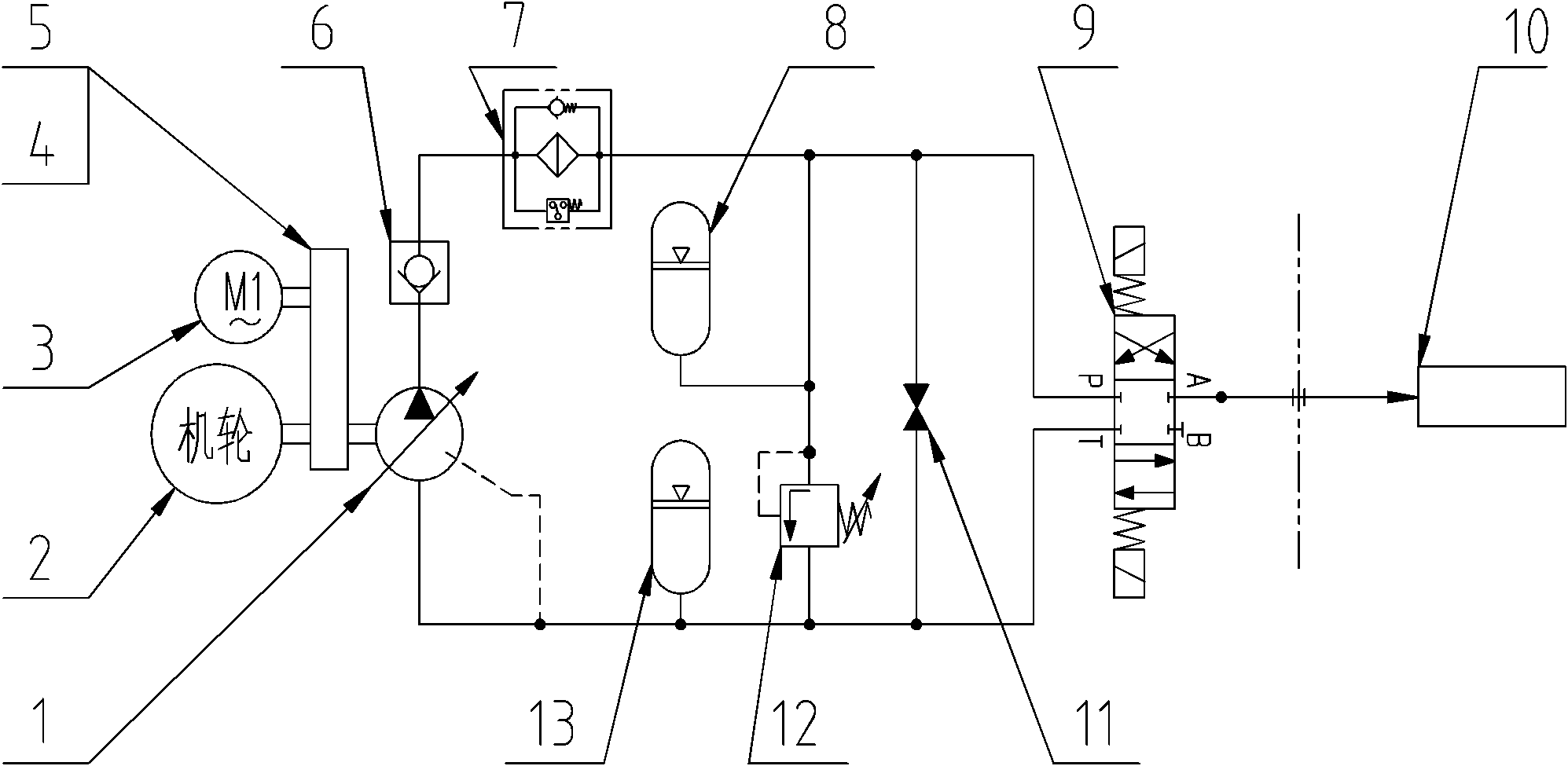

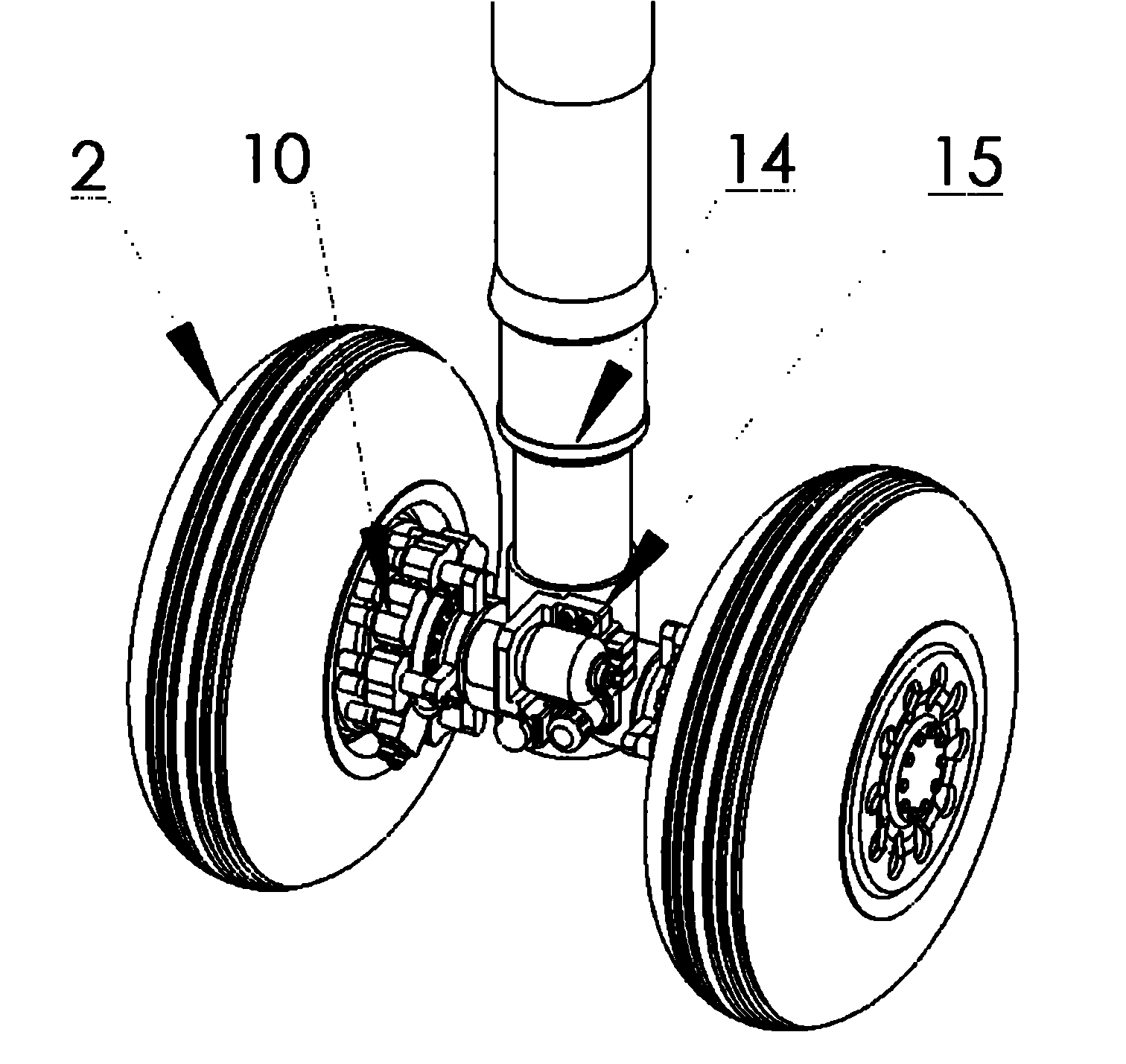

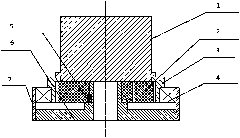

Self-energy feeding type brake device for airplanes

ActiveCN102092472ALayout benefitsSimple structureAircraft braking arrangementsReduction driveFuel tank

The invention discloses a self-energy feeding type brake device for airplanes, belonging to the technical field of an airplane brake system, comprising a hydraulic pump, an auxiliary motor, a reducer, an electromagnetic clutch, a one-way valve, a high pressure oil filter, an energy accumulator, a brake valve, a by-pass valve, an overflow valve and an oil tank, wherein an input shaft of the hydraulic pump is connected with wheel shafts of airplane wheels via the electromagnetic clutch and the reducer; the electromagnetic clutch and the reducer are connected with the auxiliary motor; an oil suction port of the hydraulic pump is connected with the oil tank; an oil outlet of the hydraulic pump is sequentially connected with the one-way valve and the high pressure oil filter; then the oil passage is divided into three parallel branch oil passages; the first branch oil passage is sequentially connected with the energy accumulator and the overflow valve; the second branch oil passage is connected with the by-pass valve; the third branch oil passage is connected with a brake pressure servo valve; the three branch oil passages are gathered to enter into the oil tank; and the brake valve isconnected with a brake actuator via the oil passage. The brake device adopts an integral structure design and electrical interfaces, and directly converts the energy after the airplane lands into theenergy needed by the brake device for anti-skidding braking.

Owner:BEIHANG UNIV

Magnetic advanced generation jet electric turbine

ActiveUS20110138765A1Improve combustion efficiencyImprove propulsion efficiencyGas turbine plantsEnergy production using magneto-hydrodynamic generatorsAviationFuel efficiency

Supersonic Magnetic Advanced Generation Jet Electric Turbine (S-MAGJET) described herein, and a subsonic derivative, MAGJET, integrate a gas power turbine, superconducting electric power and propulsion generation, and magnetic power flux field systems along with an ion plasma annular injection combustor which utilizes alternative petroleum-based fuel and combustion cycles to create a hybrid turbine turbomachine for aerospace propulsion. The propulsion unit is able to achieve a dramatic increase in horsepower, combustion and propulsion efficiency, and weight reduction. In addition, the turbomachinery structures may be disposed within an exo-skeleton architecture that achieves an increase in thrust to weight ratio with a concomitant increase in fuel efficiency and power generation over traditional gas turbine technology today. The engine continuously adjusts the temperature, pressure and mass airflow requirements using an electromagnetic power management system architecture. Engine performance may be controlled across the entire desired flight envelope, whether subsonic, transonic or supersonic flight conditions. With bypass fan(s), compressor stages and turbine segments controlled electrically in a shaftless turbine design, the S-MAGJET maximizes the propulsion efficiencies over a broader range of operating conditions compared to current art of turbine technology and at much higher thermodynamic and aerodynamic efficiencies.

Owner:SONIC BLUE AEROSPACE

Ring generator

InactiveUS7728446B2Minimal visibilityHigh weight ratioUnmanned aerial vehiclesRemote controlled aircraftCombustionFlight vehicle

The present invention is a rotary device that may be adapted for use as a propeller assembly and electrical generator for aerial vehicles or other vehicles intended for fluid media. In one example, the device includes a ring assembly having a plurality of centrally linked blades coupled to a rotatable common hub. Rotary motion of the ring assembly is facilitated by coupling it to an opposed cylinder, opposed piston, internal combustion. The ring assembly includes components of an electrical power generating system so that electrical power is produced from the rotation of the ring assembly.

Owner:ADVANCED PROPULSION TECH

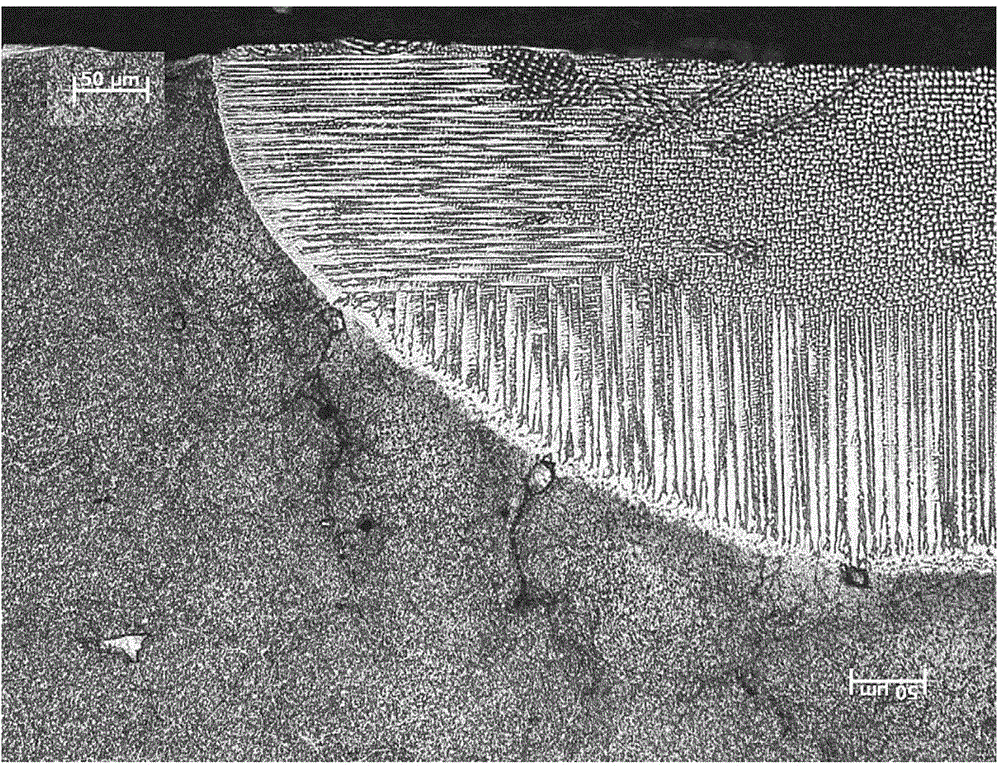

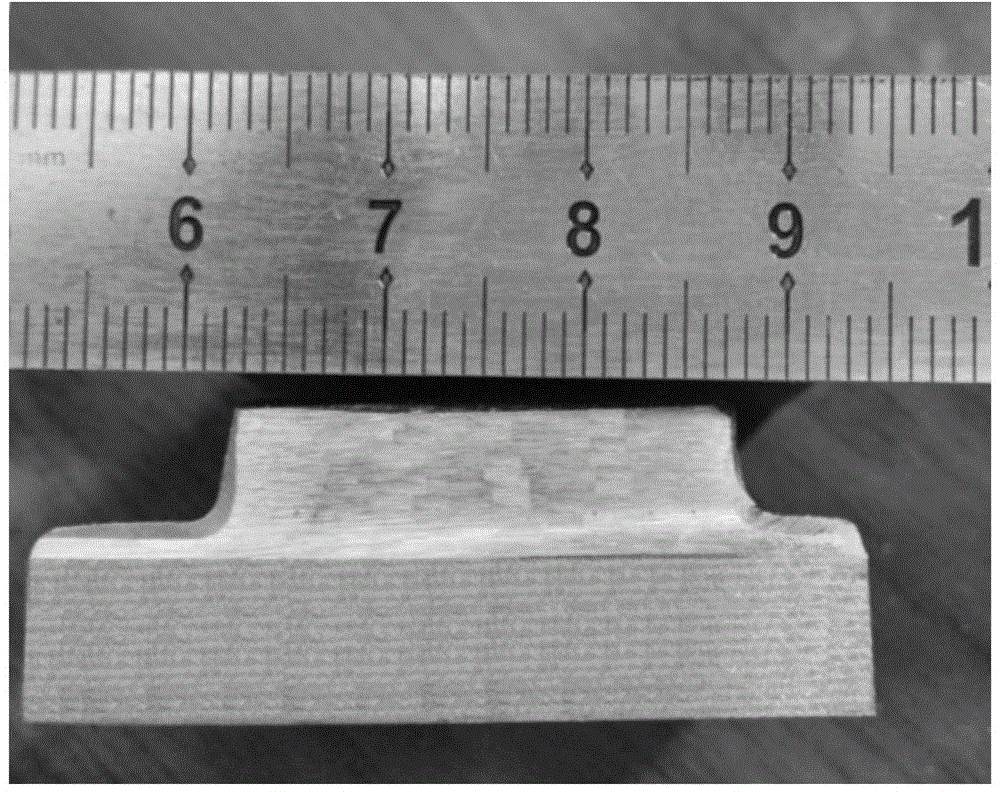

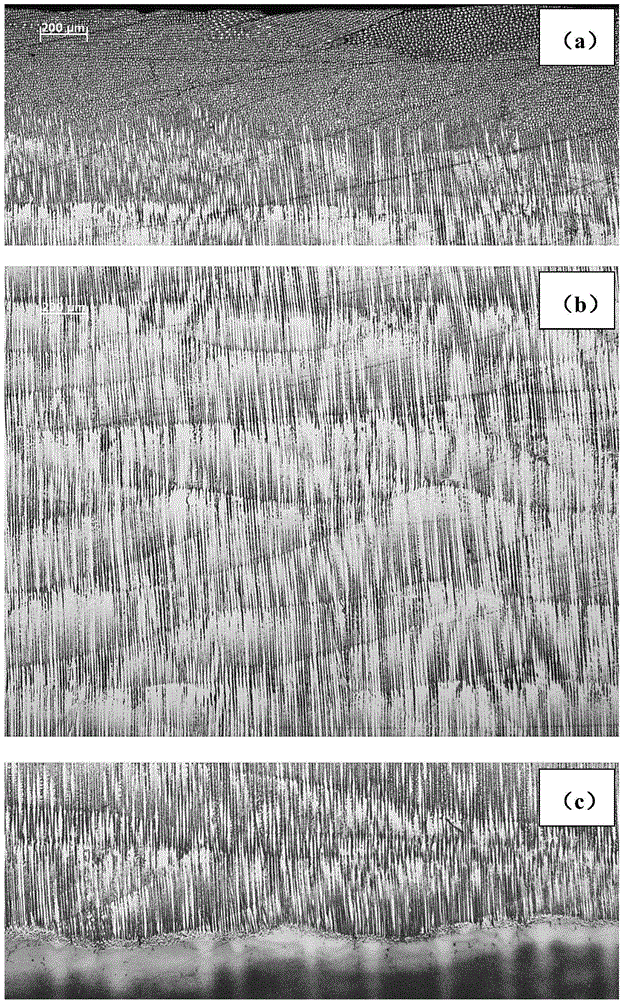

Method for preparing single crystal high temperature alloy block material through laser 3D printing

InactiveCN104947175ASmall dendritesIncrease thrust-to-weight ratioPolycrystalline material growthFrom solid stateSingle crystal superalloySingle crystal

The invention discloses a method for preparing a single crystal high temperature alloy block material through laser 3D printing and belongs to the technical fields of single crystal solidification and laser rapid forming. The method for preparing the single crystal high temperature alloy block material through the laser 3D printing comprises the following steps: firstly cutting a base material used for the laser 3D printing from a single crystal high temperature alloy material, then preheating the cut base material, carrying out surface remelting on the cut base material, and then observing a remelting microscopic structure; and based on a remelting technique, preparing the single crystal high temperature alloy block material through the laser 3D printing under the conditions that the base material is preheated to 0-800 DEG C, laser power is 200-500w, scanning speed is 30-3000mm / min, and powder feeding rate is 0.3-30g / min. The single crystal high temperature alloy prepared through the laser 3D printing can be used for developing a single crystal blade repairing technology and can also be used for developing a new single crystal high temperature alloy blade process.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

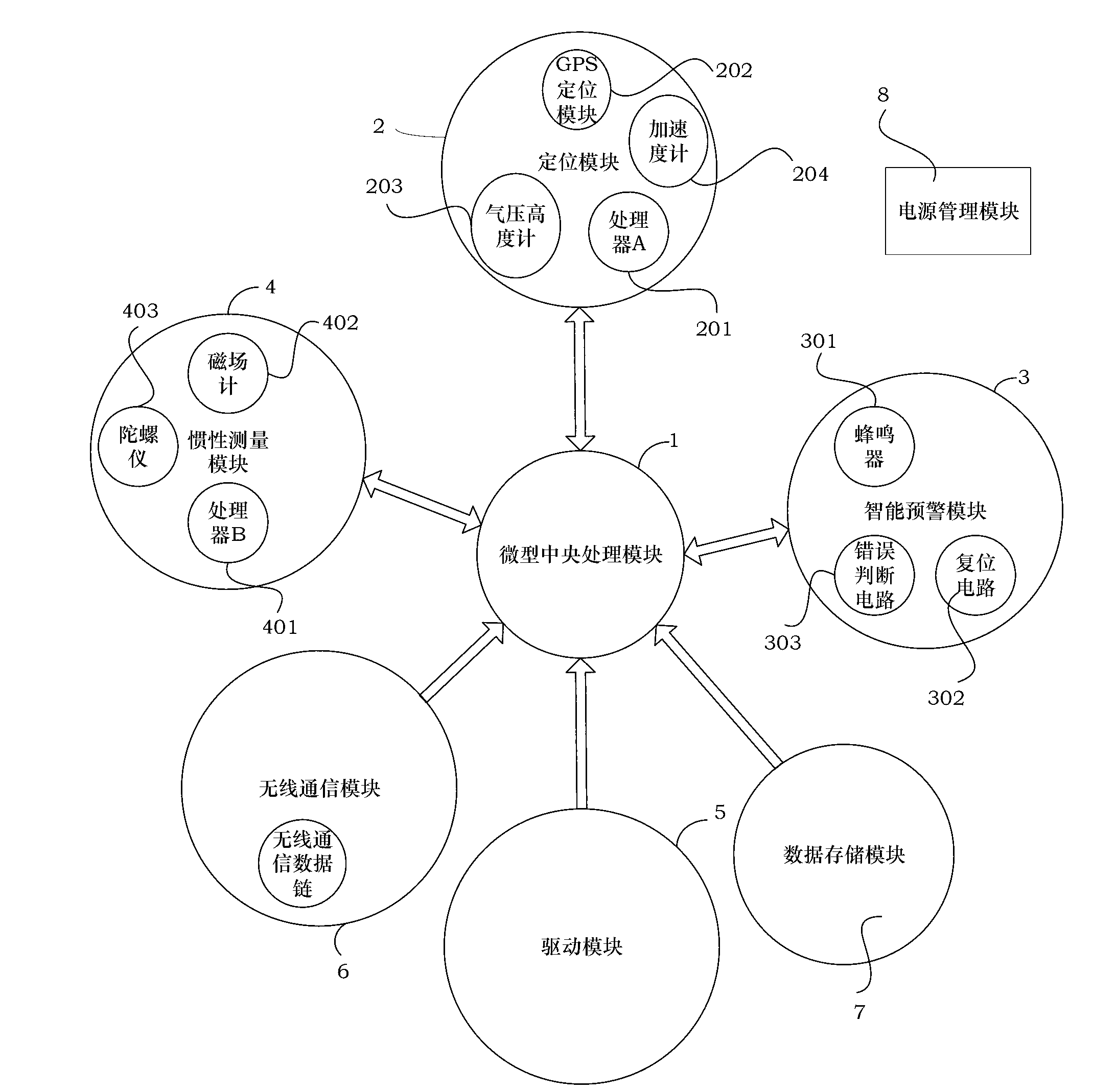

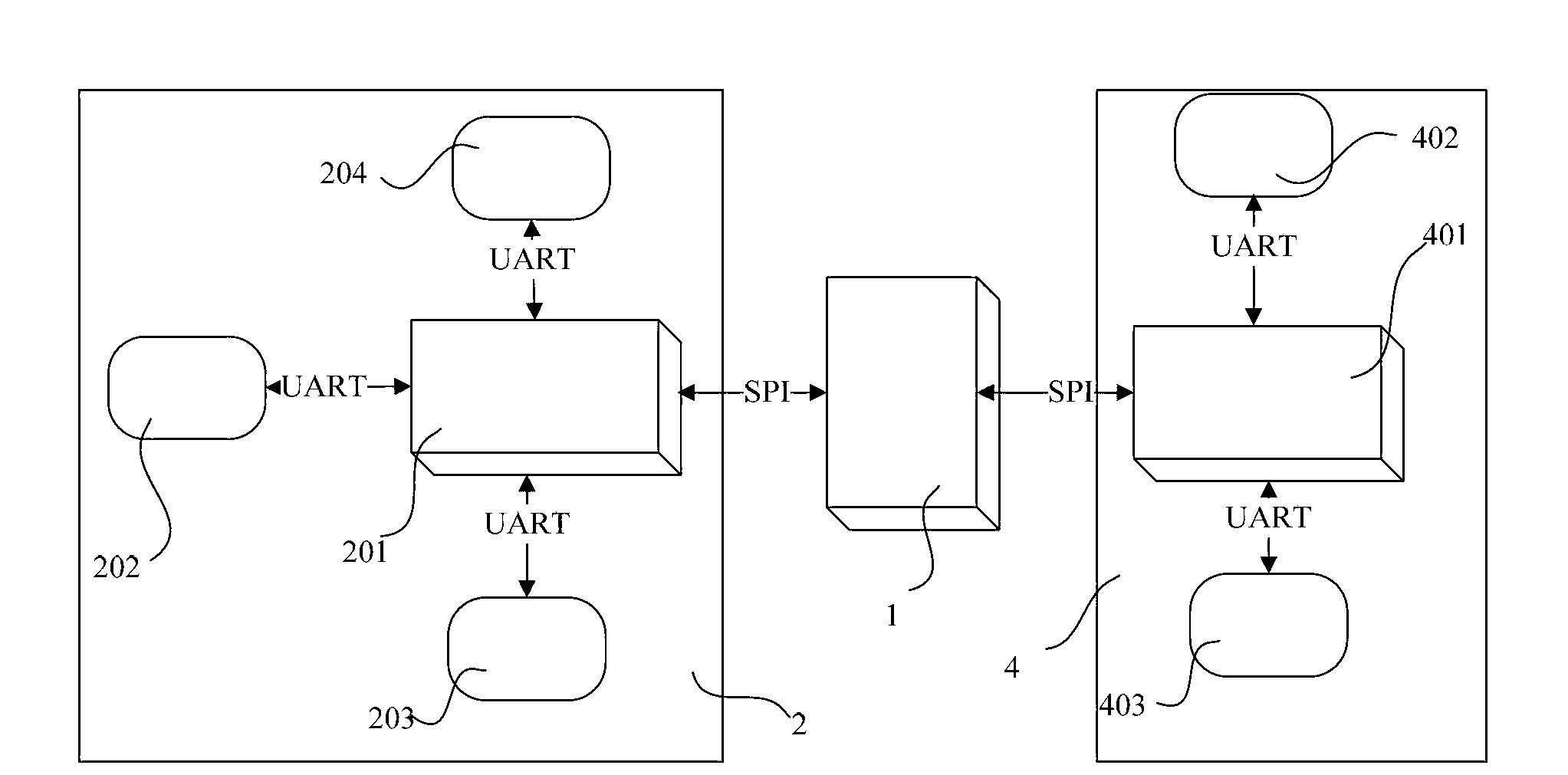

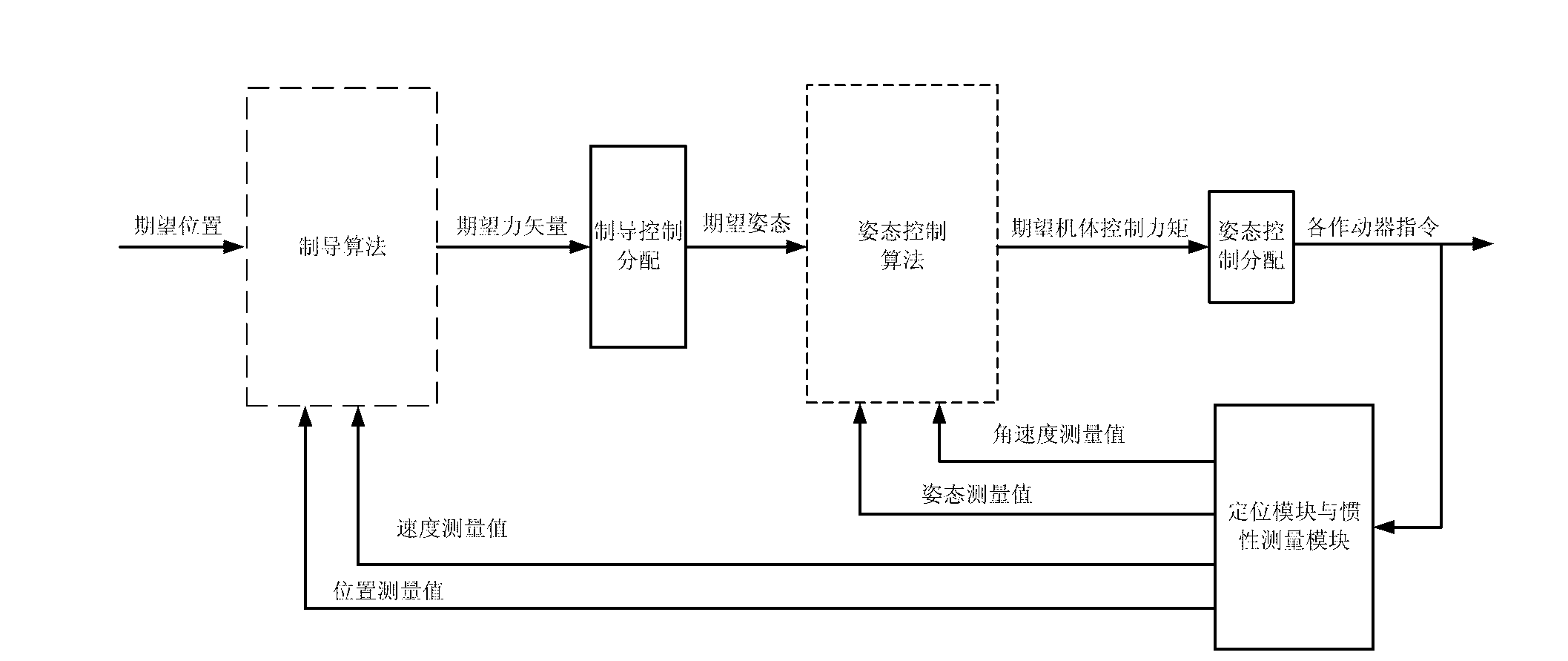

Integration flight control system for miniature flying robot

ActiveCN103057712ATimely notificationRealize the communication functionAircraft power plantsAttitude controlComputer module

The invention discloses an integration flight control system for a miniature flying robot. The integration flight control system comprises a miniature central processing module, a positioning module, an inertia measurement module, an intelligent early warning module, a driving module, a wireless communication module, a data storage module and a power management module, wherein the miniature central processing module is in charge of management of each module and running of a control algorithm; the positioning module is used for measuring position and speed information of the flying robot and transmitting the information to the miniature central processing module; the inertia measurement module is used for measuring gesture and angular speed information of the flying robot; the intelligent early warning module monitors a flight state of the flying robot so as to timely send out early warning; the driving module drives actuation of the flying robot according to instructions of the miniature central processing module; the wireless communication module is in charge of data communication between the flying robot and a ground station system; the data storage module is in charge of storage of data in the flight process; and the power management module is in charge of power supply to the whole system. The integration flight control system can integrate guidance and attitude control functions, has the advantages of being high in integration, light in weight, small in size and strong in functions and the like, and can effectively improve thrust-weight ratio and efficiency of the miniature flying robot.

Owner:BEIHANG UNIV

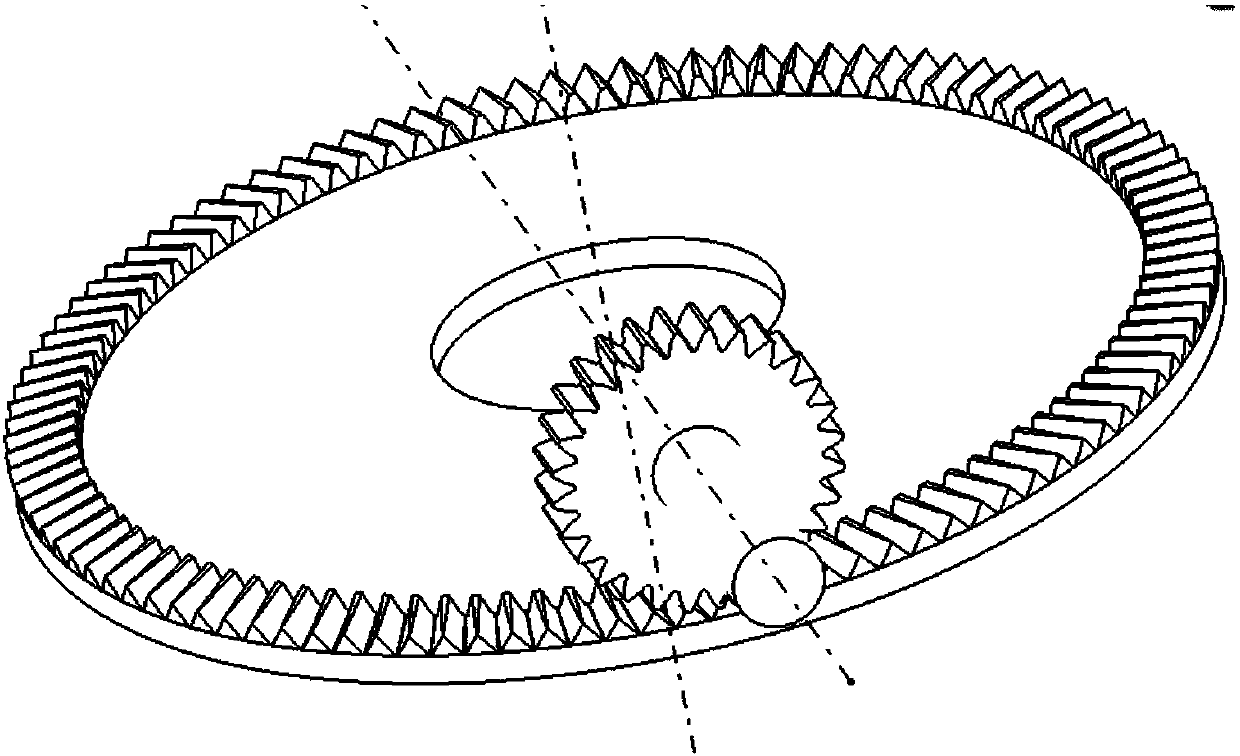

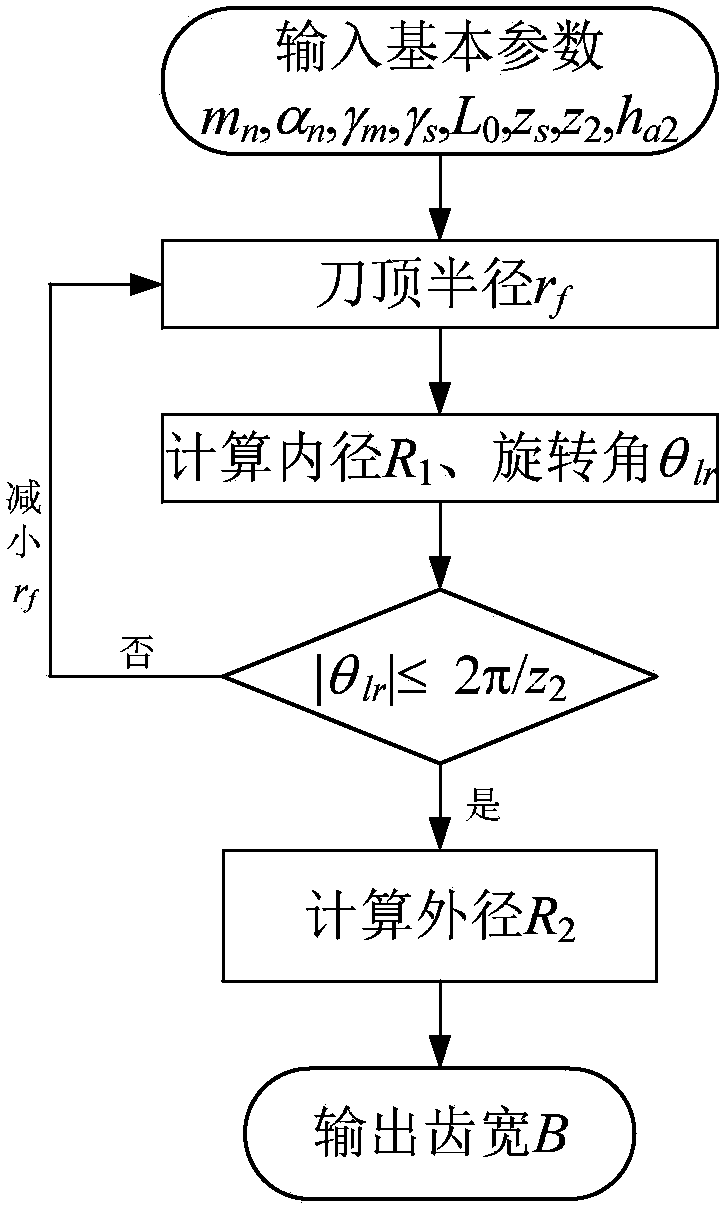

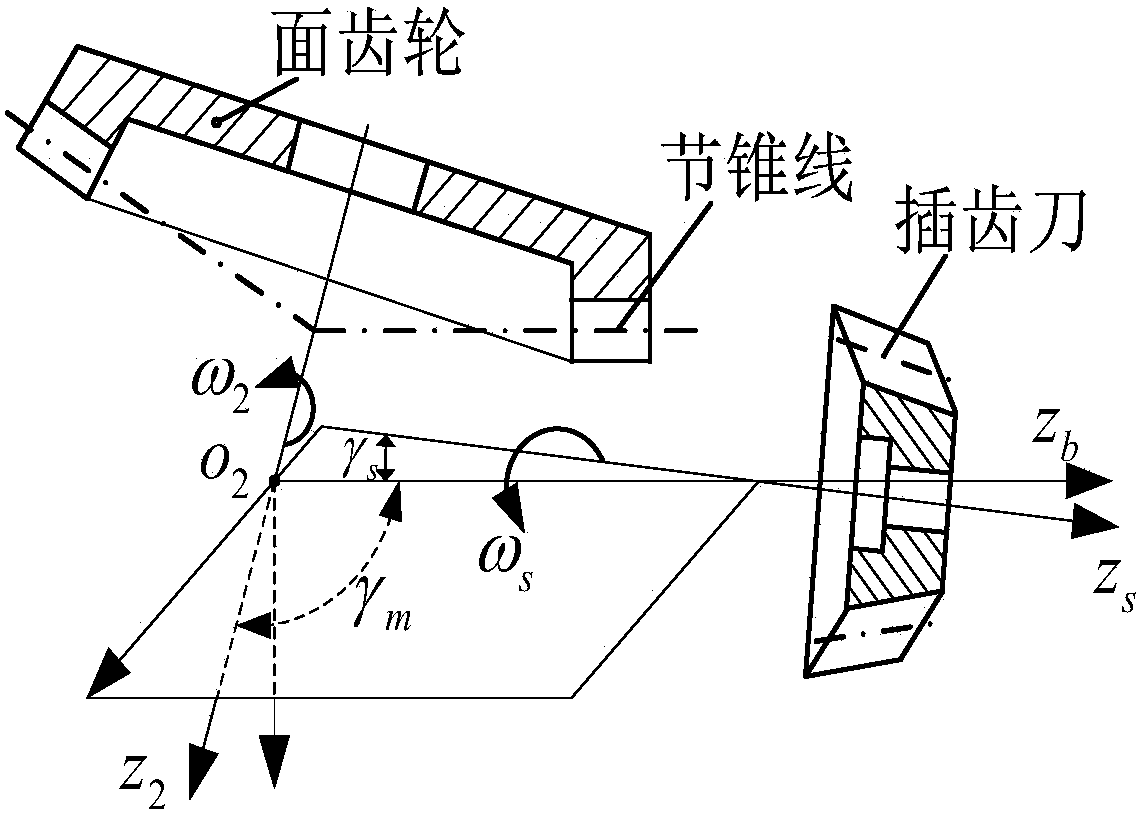

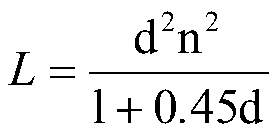

Skew line tooth surface gear transmission pair and tooth width geometric design method

InactiveCN105156637AReduce weightIncrease thrust-to-weight ratioPortable liftingGearing elementsAviationGeometric design

The invention discloses a skew line tooth surface gear transmission pair and a tooth width geometric design method. The skew line tooth surface gear transmission pair adopts an alternating axis transmission form composed of involute spur gears and skew line tooth surface gears. Each skew line tooth surface gear is formed by spreading straight tooth involute slotting cutters in a staggered mode; the skew line tooth surface gears can only mesh with the straight tooth cylindrical gears and can not mesh with the skewed tooth cylindrical gears with helix angle; and the tooth trace is approximate to a skew line and forms an oblique angle with the radius direction, thereby being very suitable for the demands of design diversification for aviation compact space. The method illuminates the gear shaping principle of the skew line gear and skew line tooth surface gear, and deduces the tooth surface equation of the skew line tooth surface gear. The margin line of the involute slotting cutters is utilized to calculate the position of the tangent point of the internal end tooth root. The condition that the outer end tooth top tooth thickness is equal to zero is utilized to obtain the sharpening condition. The condition of avoiding secondary cutting of the tooth root is combined with determine the cutter top fillet radius, thereby finally obtaining the tooth width of the skew line tooth surface gear.

Owner:CHANGAN UNIV

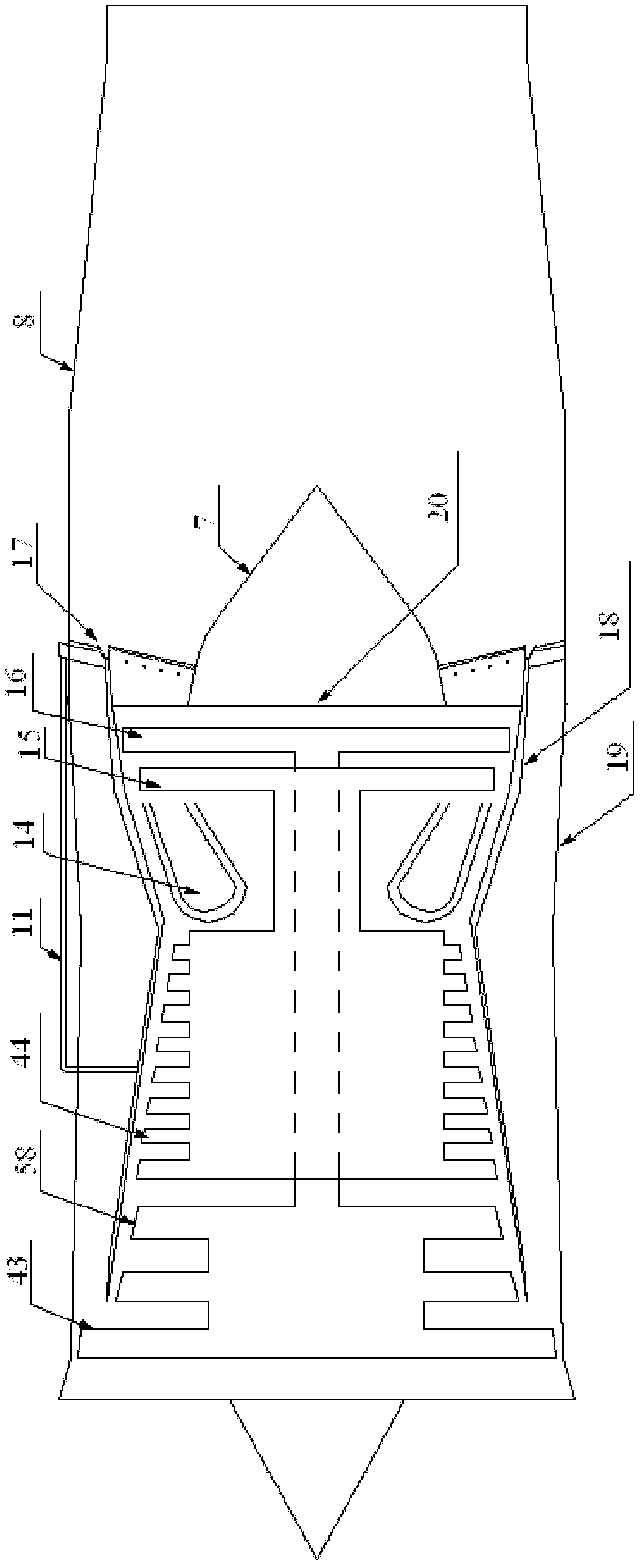

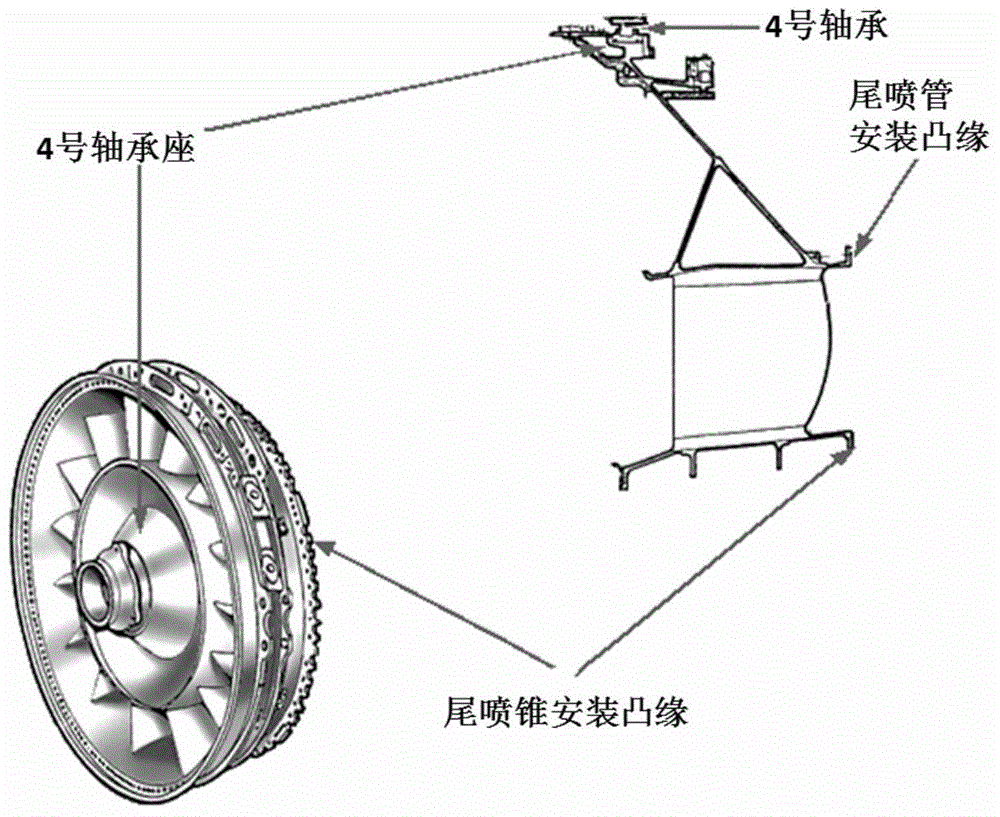

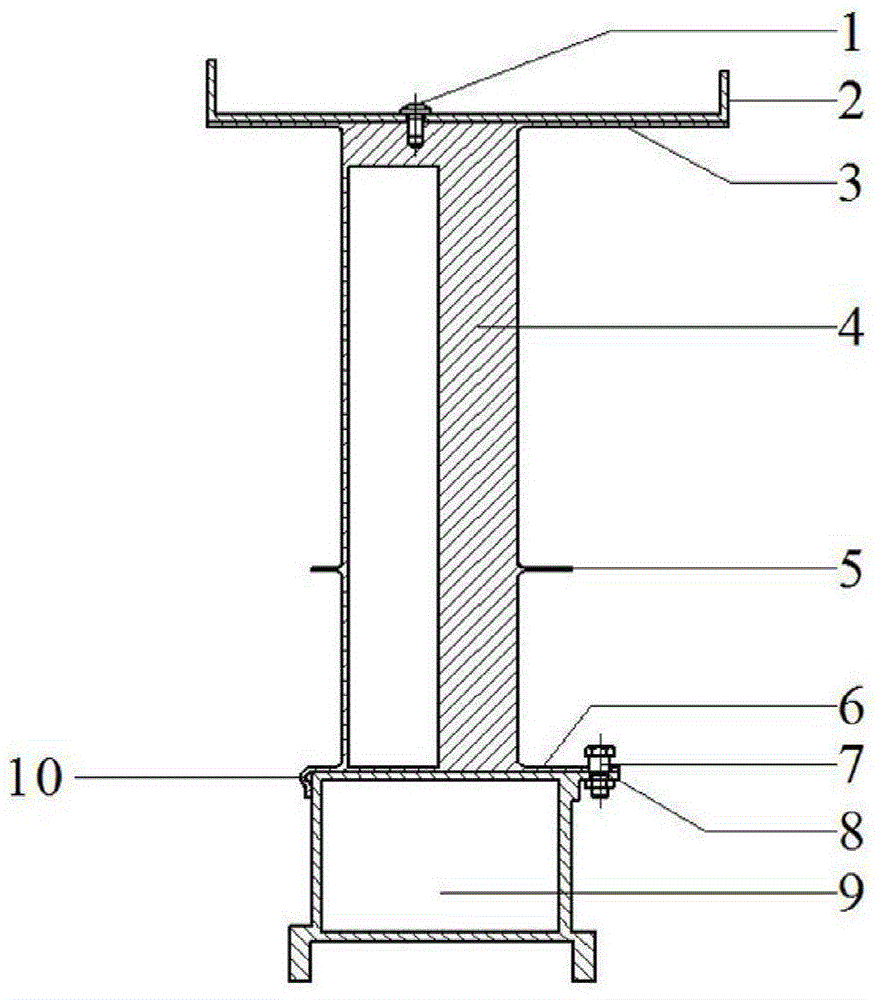

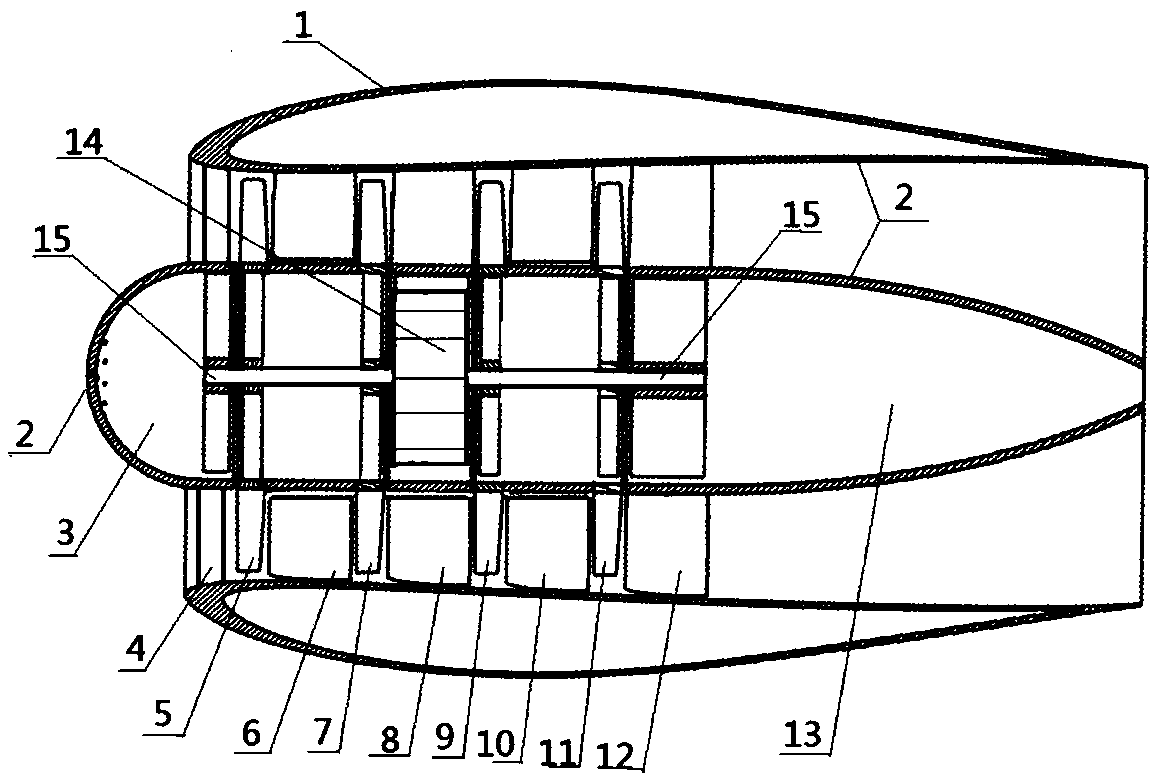

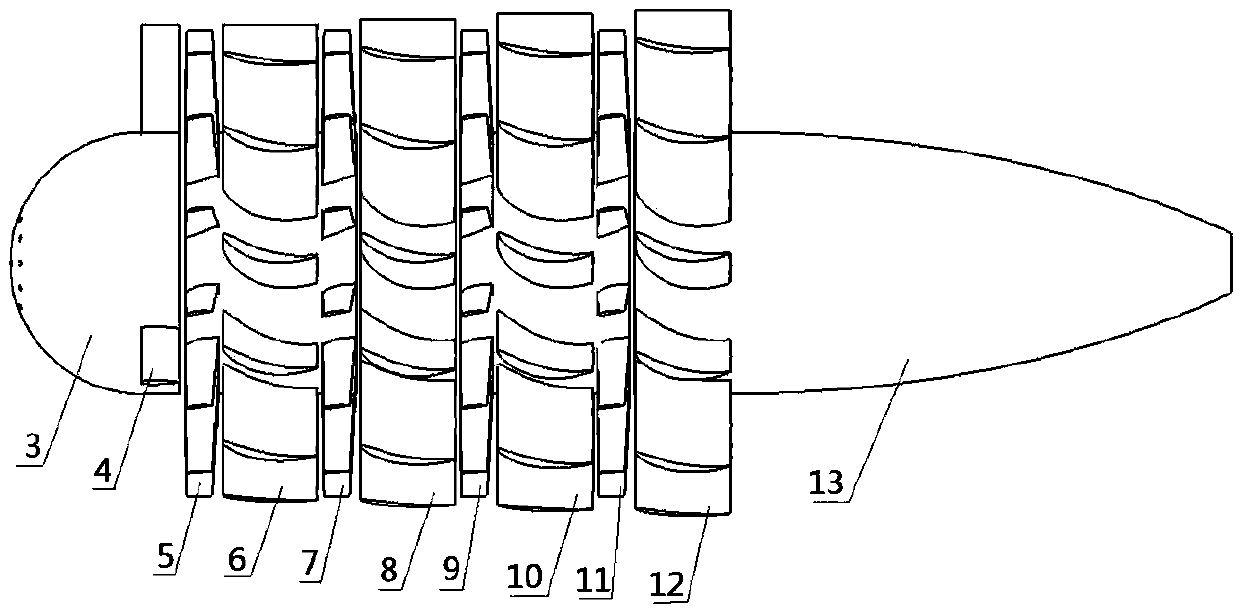

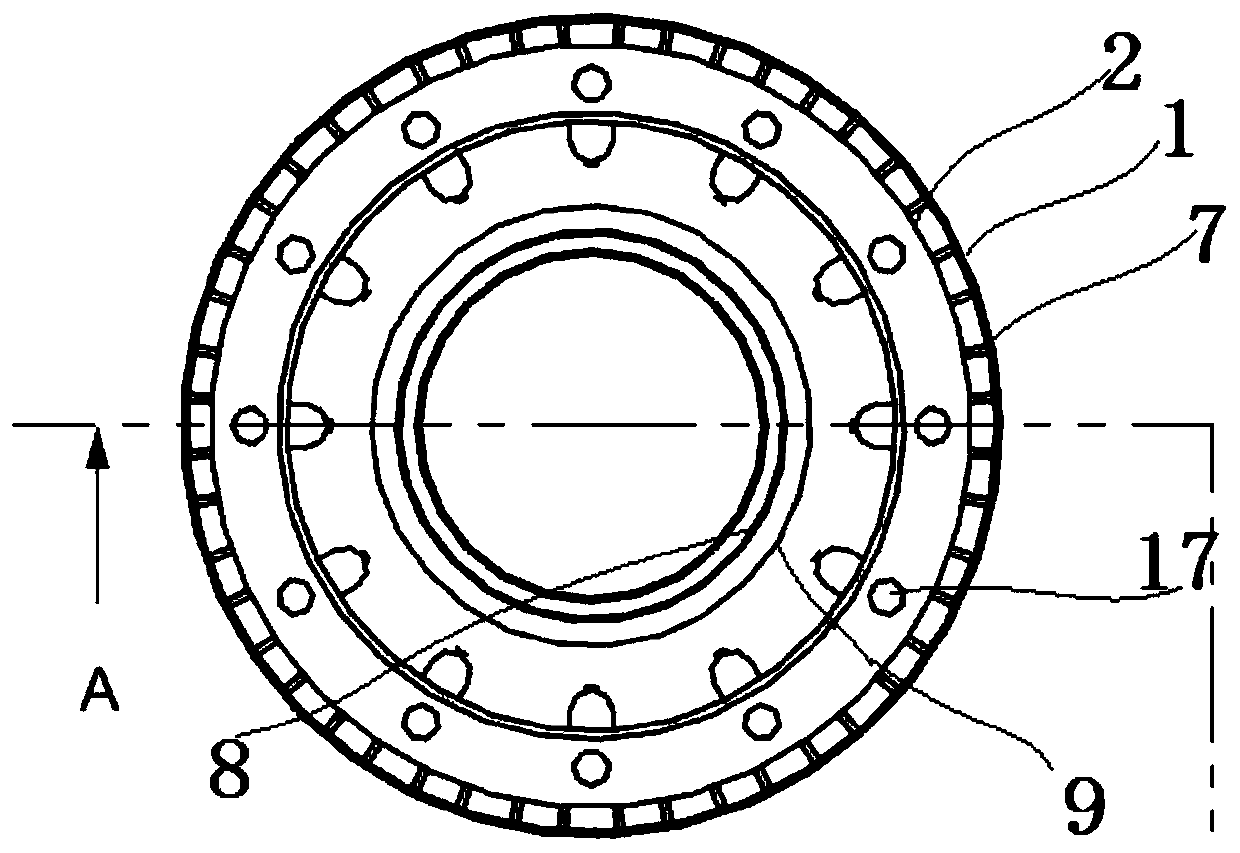

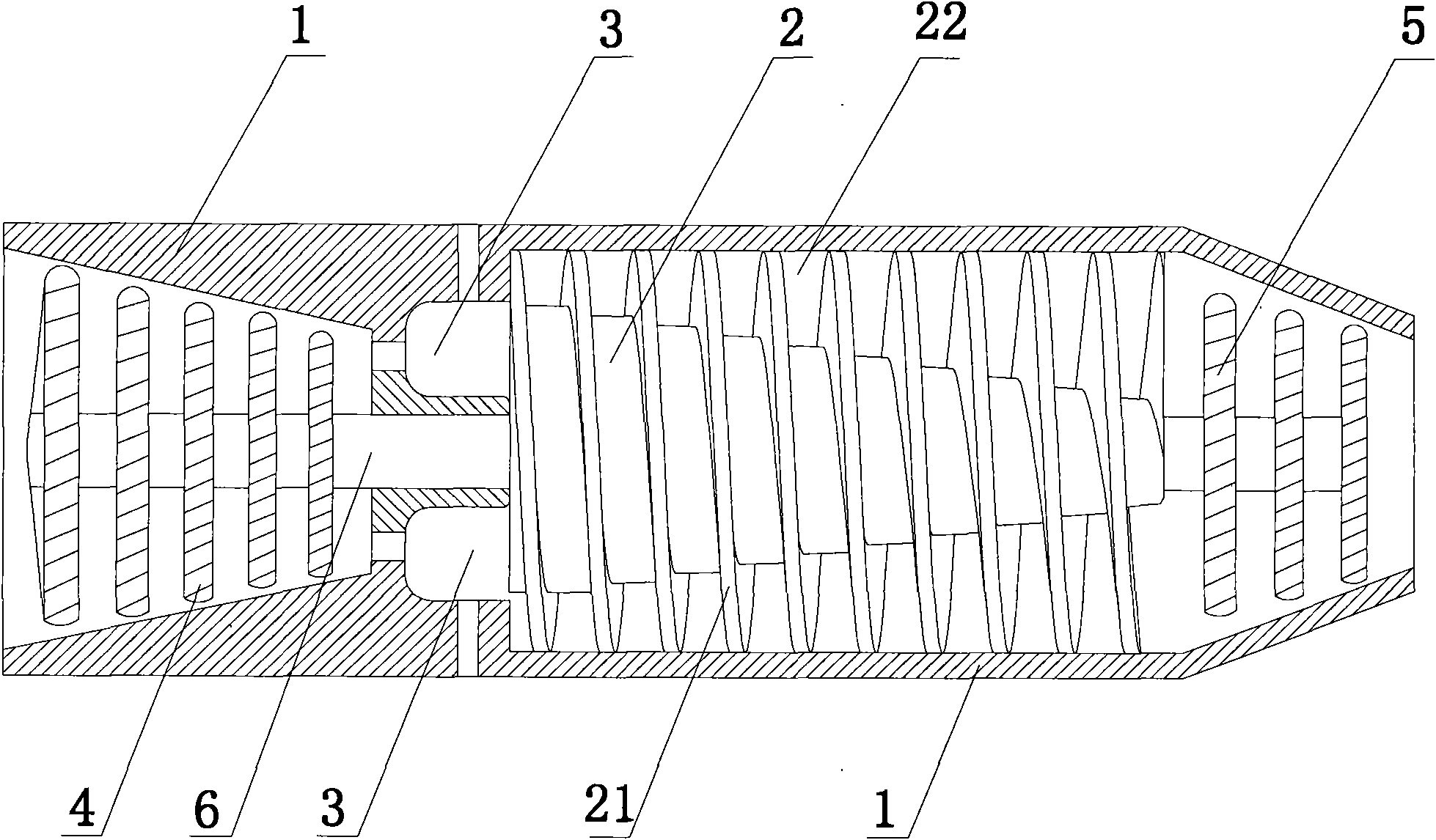

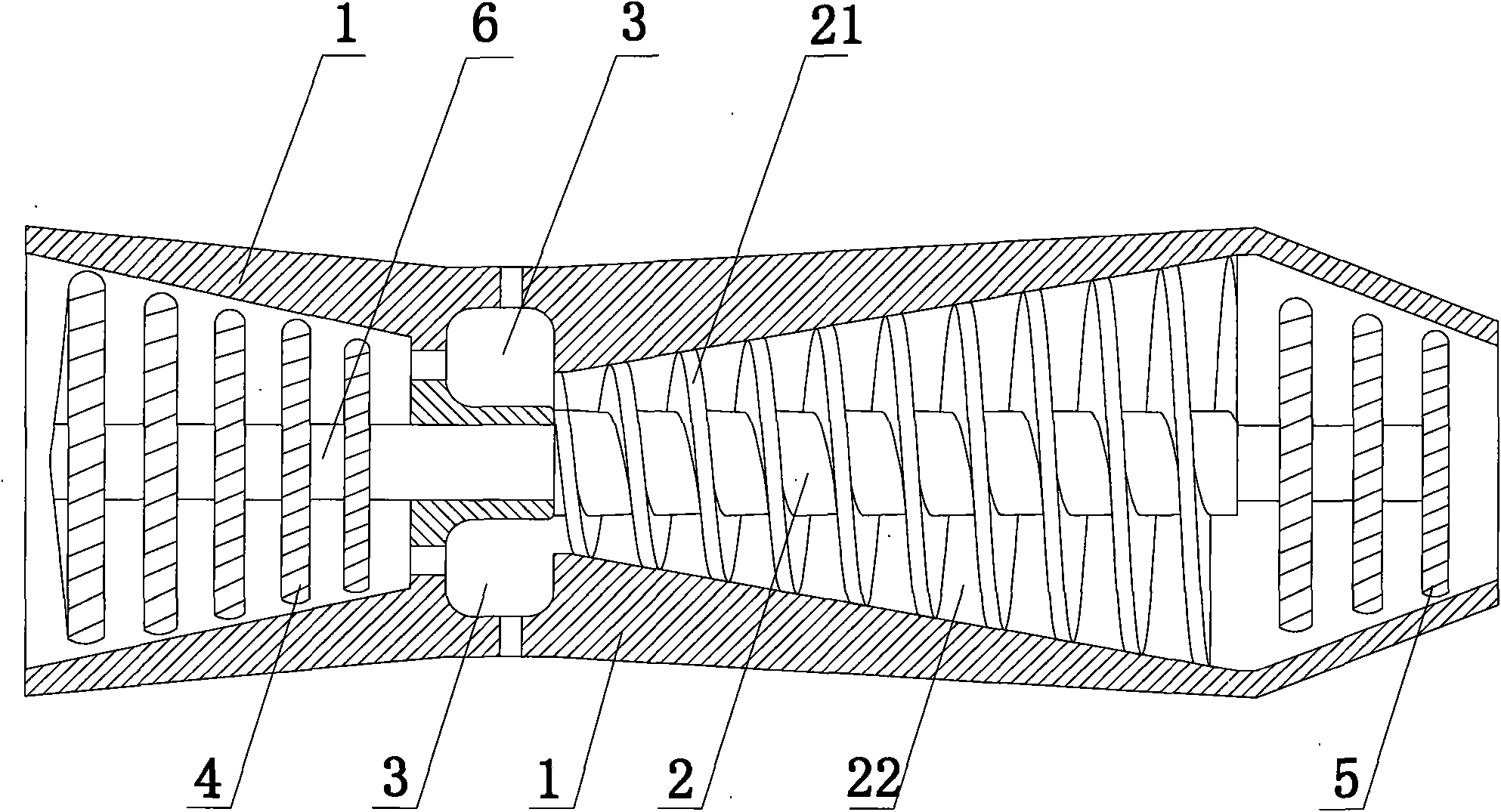

Turbine rear force bearing case integrally connected to rectification blade cascade

InactiveCN105317559ADoes not affect Morph CoordinationThe structure does not need to be substantially modifiedGas turbine plantsJet propulsion plantsUltimate tensile strengthTurbine

The invention relates to a turbine rear force bearing case and rectification blade cascade integrally-connecting structure, wherein the shape of the turbine rear force bearing case part is the same as the conventional turbine rear force bearing case, and the difference and the characteristics comprise that a rectification blade structure is arranged among the outer ring, the inner ring and the support plate of the conventional turbine rear force bearing case, the blade structure comprises a blade upper edge plate, blades, a blade flow channel plate, a blade lower edge plate and a blade lower edge front end baffle, the blade upper edge plate is fixed on the force bearing case outer ring through a radial screw, the rear end of the blade lower edge plate is axially and circumferentially positioned on the flange of the rear end of the force bearing case inner ring through a special radial bolt, and a gas flow channel is formed among the blade flow channel plate, the blades, the blade upper edge plate and the force bearing support plate. According to the present invention, under the premise of no substantial change of the turbine rear force bearing case structure, and no influence on the rear force bearing case strength, the deformation coordination and the support stiffness, the integration of the turbine rear force bearing case and the rectification blade cascade is achieved.

Owner:BEIHANG UNIV

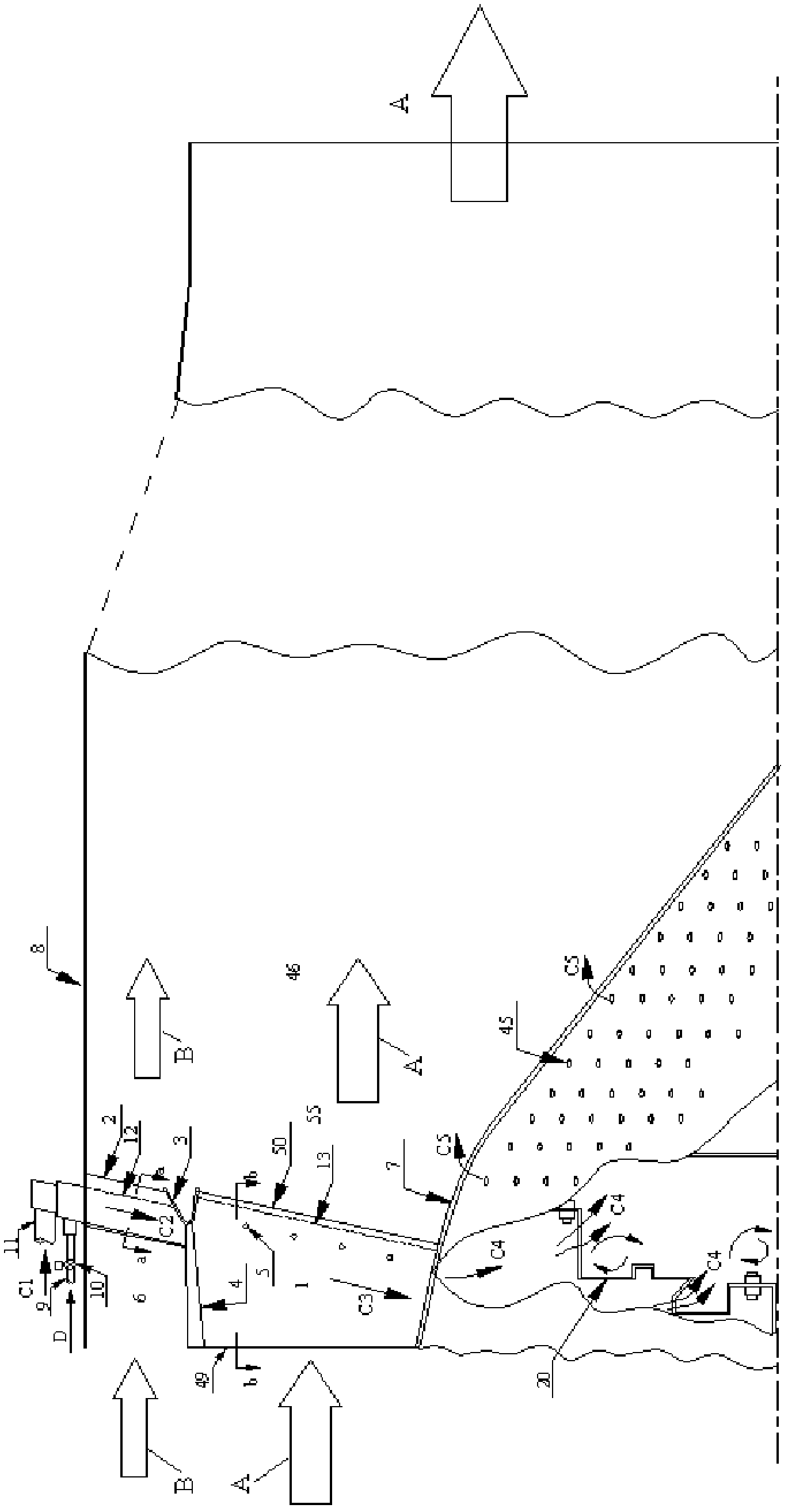

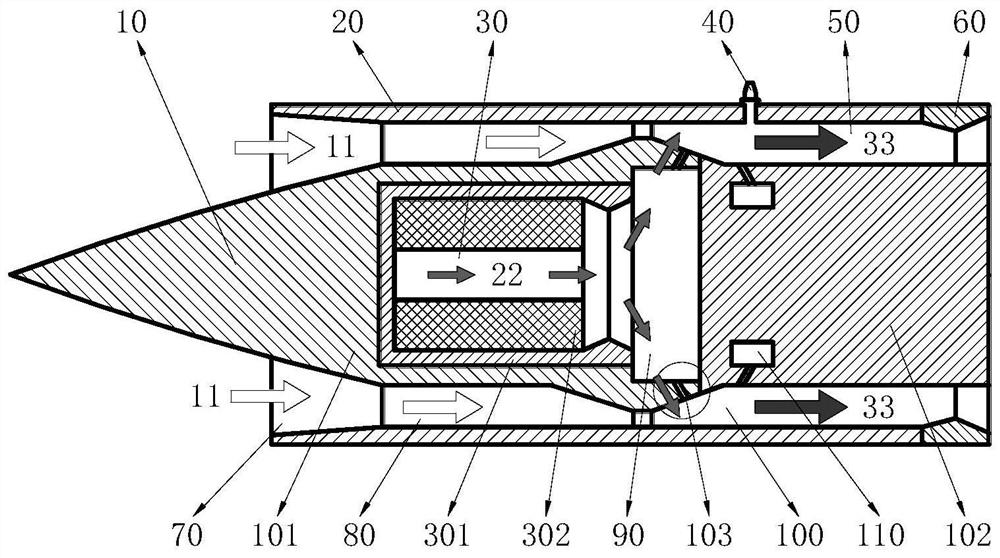

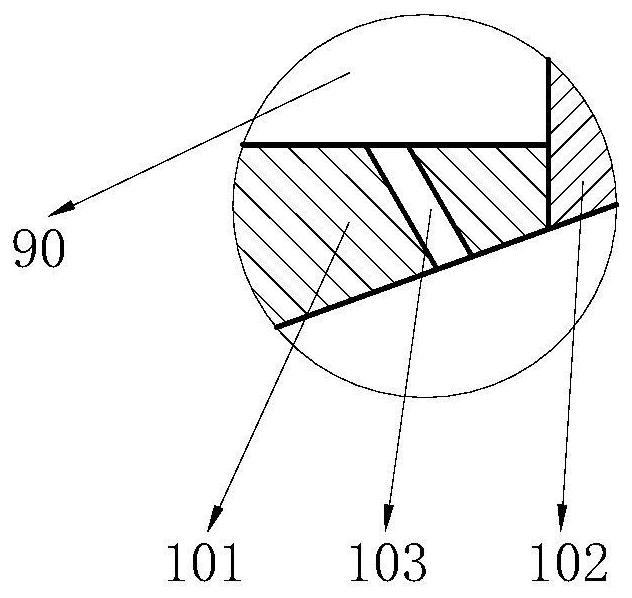

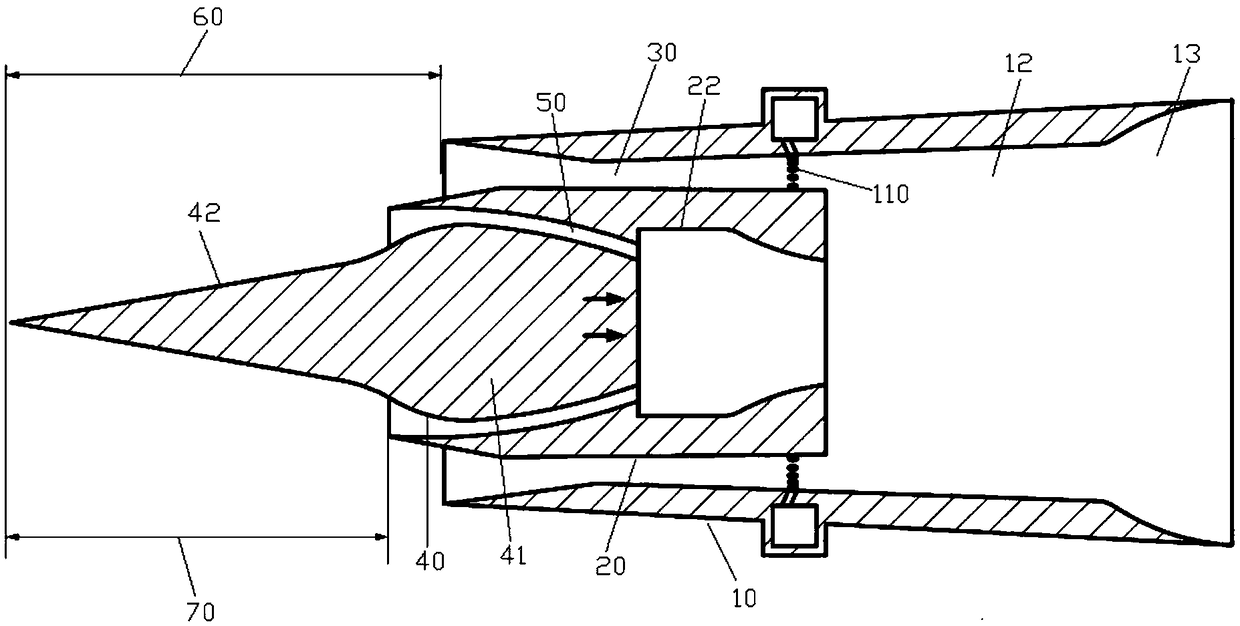

Solid rocket ramjet based on detonation combustion

ActiveCN112879178AImprove work efficiencyImprove convenienceGas turbine plantsIntermittent jet plantsRamjetCombustion chamber

The invention discloses a solid rocket ramjet based on detonation combustion. The solid rocket ramjet comprises an outer shell, an inner core, an air inlet channel, an isolation section channel, a detonation combustion channel, a gas generator, a flow stabilizing ring cavity, a main fuel injection system, a rotary detonation combustion chamber, a tail spray pipe and other structures, wherein the air inlet channel, the isolation section channel and the detonation combustion channel are formed between the inner wall of the outer shell and the outer wall of the inner core; air captured by the air inlet channel is decelerated and pressurized in an isolation section and then enters the rotary detonation combustion chamber; the front portion of the inner core is of a hollow structure, the gas generator is arranged in the inner core, an oxygen-deficient solid propellant is combusted in the gas generator and forms fuel-rich gas, and the fuel-rich gas enters an expansion section of the isolation section channel through a main fuel injector, is fully mixed with fresh air and then is sprayed into the ring cavity of the rotary detonation combustion chamber; and the rotary detonation combustion chamber is provided with an ignition device, the tail spray pipe is installed at an outlet, chemical energy is converted into kinetic energy, and thrust is generated. The solid rocket ramjet has higher combustion efficiency and work performance.

Owner:NANJING UNIV OF SCI & TECH

Magnetic advanced generation jet electric turbine

InactiveUS20140060005A1Maximizes propulsion efficiencyImprove combustionWind motor controlCombination enginesMagnetic tension forceAviation

Supersonic Magnetic Advanced Generation Jet Electric Turbine (S-MAGJET) described herein, and a subsonic derivative, MAGJET, integrate a gas power turbine, superconducting electric power and propulsion generation, and magnetic power flux field systems along with an ion plasma annular injection combustor which utilizes alternative petroleum-based fuel and combustion cycles to create a hybrid turbine turbomachine for aerospace propulsion. The propulsion unit is able to achieve a dramatic increase in horsepower, combustion and propulsion efficiency, and weight reduction. In addition, the turbomachinery structures may be disposed within an exoskeleton architecture that achieves an increase in thrust to weight ratio with a concomitant increase in fuel efficiency and power generation. The engine continuously adjusts the temperature, pressure and mass airflow requirements using an electromagnetic power management system architecture. Engine performance may be controlled across the entire desired flight envelope, whether subsonic, transonic or supersonic flight conditions.

Owner:SONIC BLUE AEROSPACE

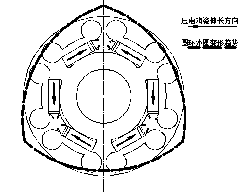

Lightweight high efficiency low noise duct type four-level electric fan propeller

ActiveCN105366060ALarge thrustReduce volumeAircraft power plant componentsEfficient propulsion technologiesLow noiseAviation

The invention discloses a lightweight high efficiency low noise duct type four-level electric fan propeller, and belongs to the aviation propulsion technical field; the propeller employs a brushless DC motor two motor shafts on two sides of the motor; the motor shaft on one side is fixed on a head cover, and the motor shaft on the other side is fixed on a tail cover; a first level fan, a first level flow deflector, a second level fan, a second level flow deflector, a third level fan, a third level flow deflector, a fourth level fan and a fourth level flow deflector are arranged in sequence from the head cover to the tail cover; the airflow passing the inner side of the engine are pressurized for four times; in addition, the inner wall of a nacelle and the outer wall of a radome are respectively provided with a noise reduction liner. The propeller is small in size, high in propulsion efficiency, can reduce operation noises, can reduce propeller weight, thus reducing making cost and maintenance cost, reducing harmful gas discharge, and improving propeller thrust weight ratio.

Owner:BEIHANG UNIV

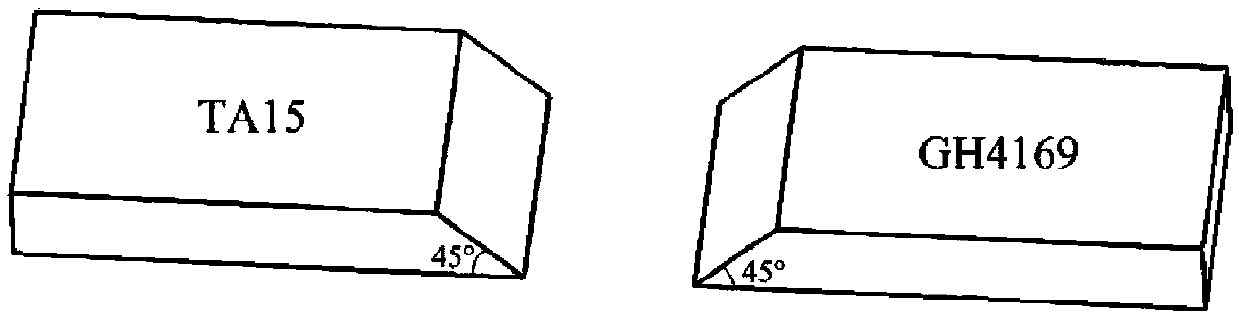

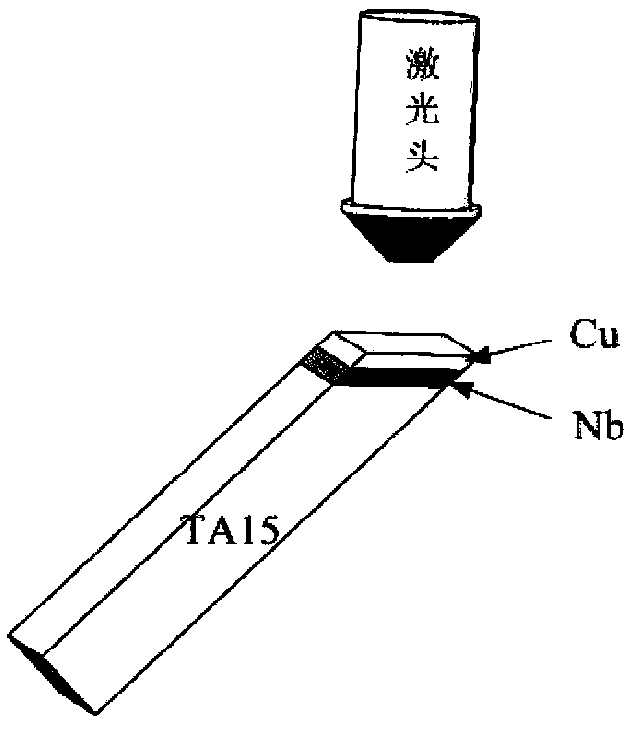

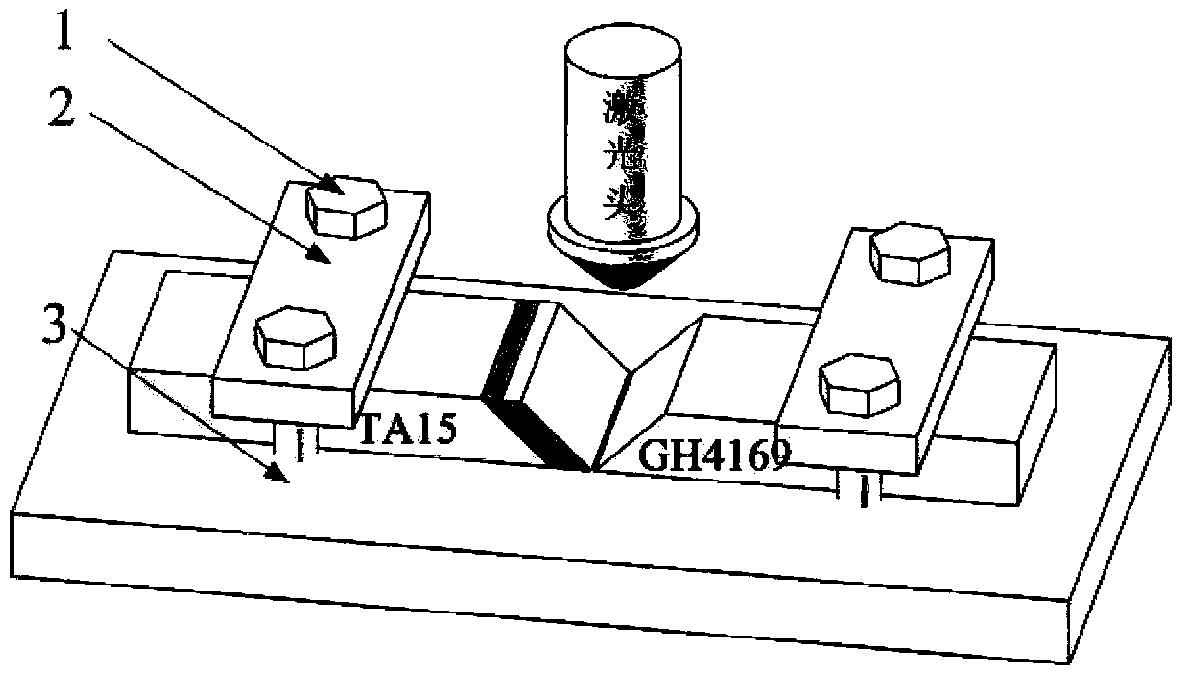

Manufacturing method for titanium alloy and nickel-base superalloy laser additive connection

ActiveCN109570765AImprove organizationAchieve preparationAdditive manufacturing apparatusWelding/soldering/cutting articlesStress reliefTitanium alloy

The invention relates to a manufacturing method for titanium alloy and nickel-base superalloy laser additive connection. The method comprises the following steps of (1) using to-be-connected workpieces of a titanium alloy and a superalloy for preparing a 45-degree groove through a machining manner, cleaning the groove, and then cleaning through anhydrous acetone, so that no oil stains and other impurities exist on the surface of the groove; (2) forming Nb with the thickness being 0.5 to 1mm on the surface of the titanium alloy groove through a laser additive manufacturing method, then formingCu with the thickness being 0.5 to 1mm on the Nb, and using Nb / Cu as a connection transition layer; (3) installing the to-be-connected workpieces of the titanium alloy and the nickel-base superalloy onto a laser additive connection tool fixture, and using nickel-base superalloy powder for carrying out laser additive connection; and (4) adopting a vacuum heat treatment furnace for carrying out overall stress relief annealing treatment. During the laser additive connection process, through the Nb / Cu transition layer, an intermetallic compound can be effectively prevented from being produced between the titanium alloy and the nickel-base superalloy, the generation of cracks is avoided, and the effective connection of the titanium alloy and the nickel-base superalloy is realized.

Owner:SHENYANG POLYTECHNIC UNIV

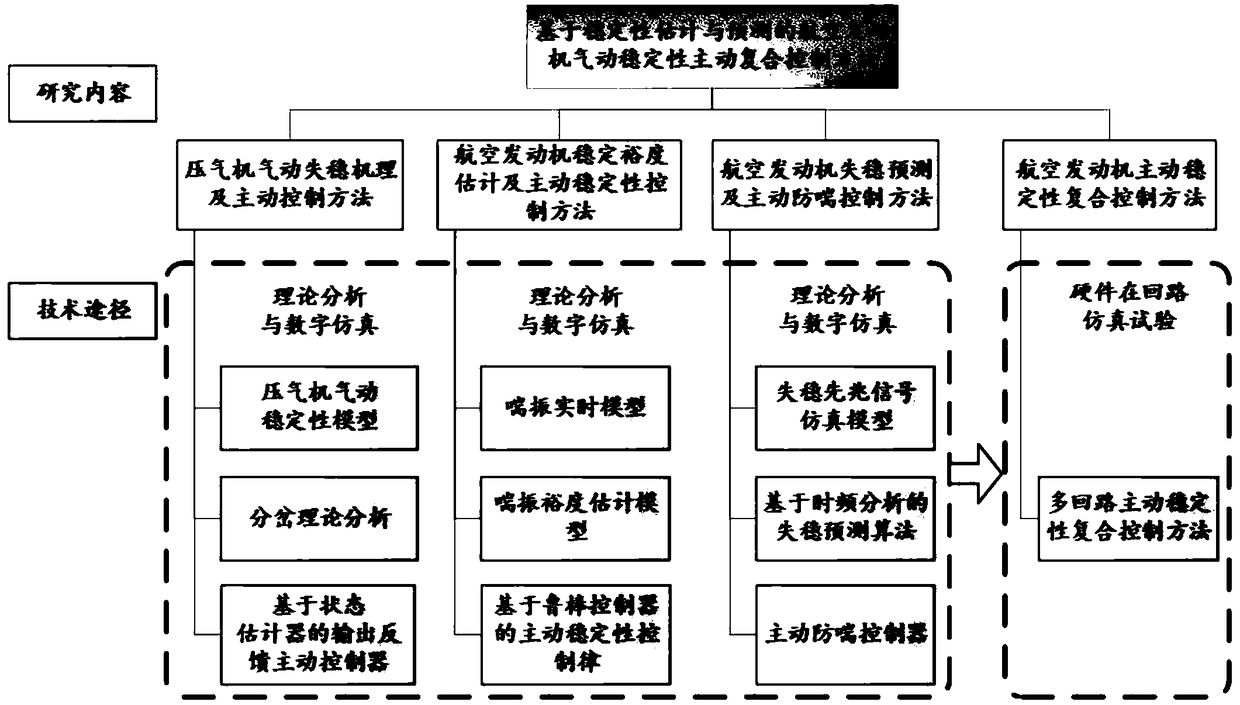

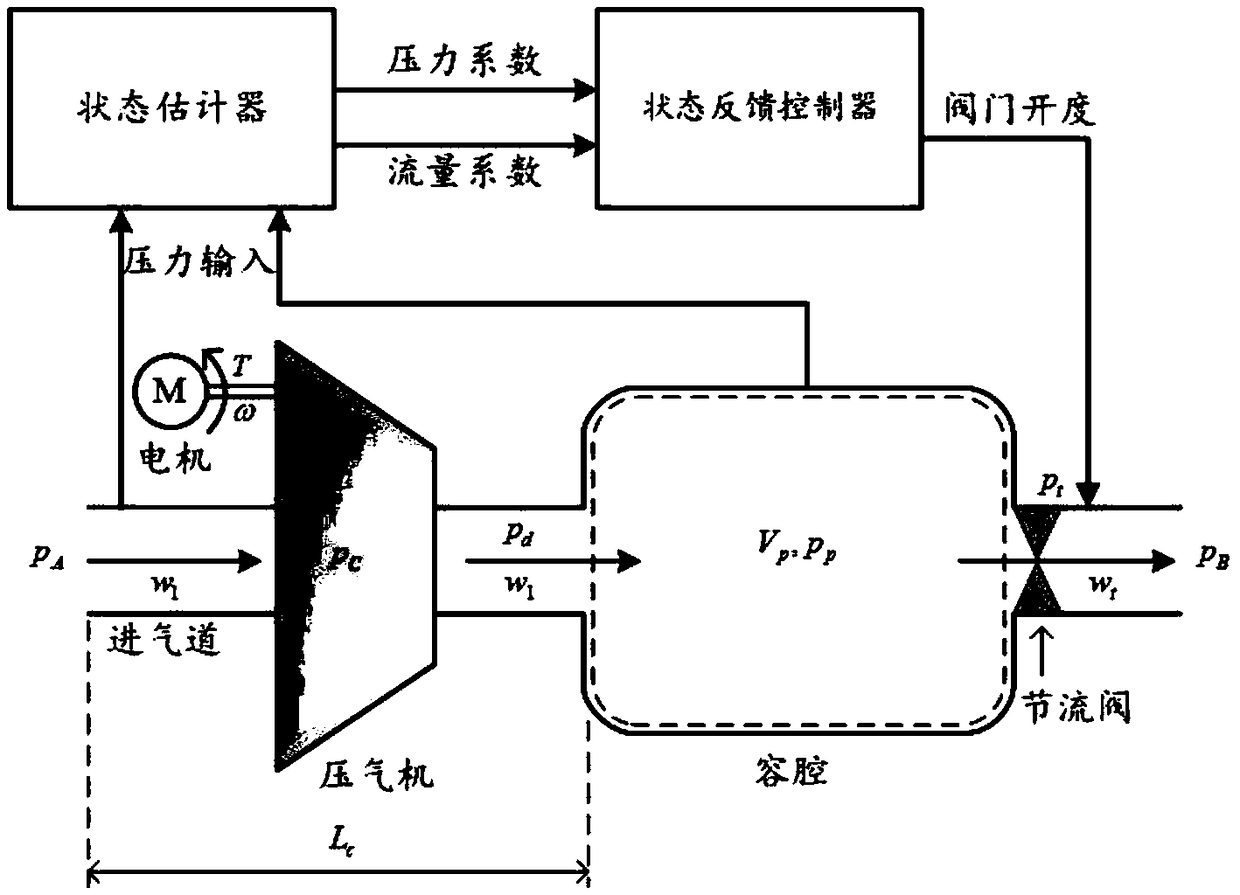

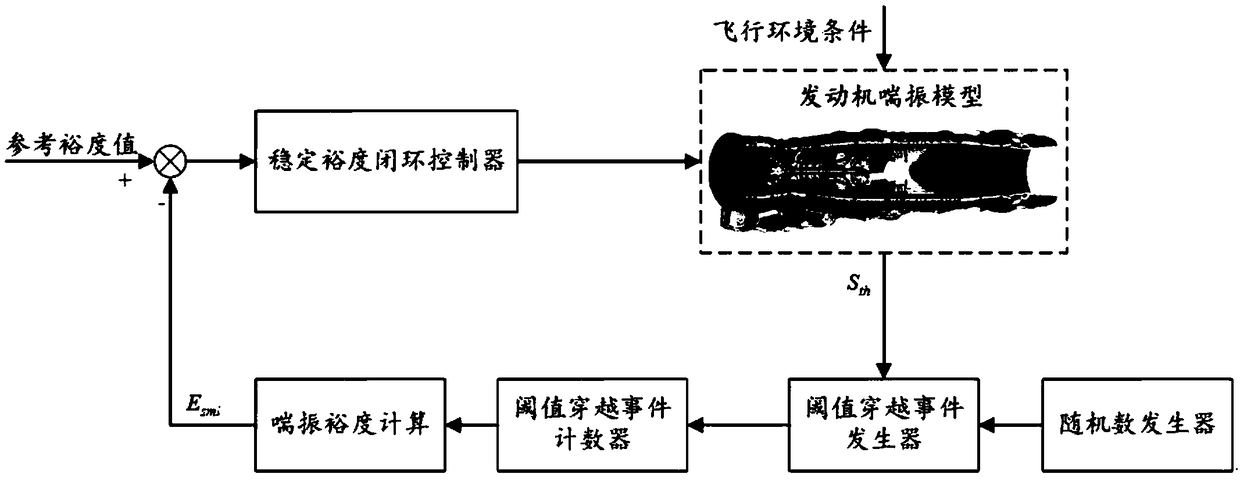

Aero-engine aerodynamic stability active composite control method based on stability estimation and prediction

InactiveCN109184913AReduce the number of compressor stagesIncrease thrust-to-weight ratioGas turbine plantsEngine componentsSurge controlInstability

The invention discloses an aero-engine aerodynamic stability active composite control method based on stability estimation and prediction. The active composite control method comprises (1) a gas compressor pneumatic instability mechanism and an active control method, (2) an aero-engine stability margin estimation and active stability control method, (3) an aero-engine instability prediction and active anti-surge control method, and (4) an aero-engine active stability composite control method. Aiming at the aero-engine aerodynamic stability problem, the aero-engine aerodynamic stability is improved from three different aspects of gas compressor part stability extension, residue stability margin utilization and active anti-surge, an adjustment and control strategy and algorithm with the surge margin dynamically adjusted and controlled along with the application requirements and suitable for the aero-engine active stability control feature and engineering application background is obtained, and the actual use requirements are met.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Electric fuel oil jet propeller

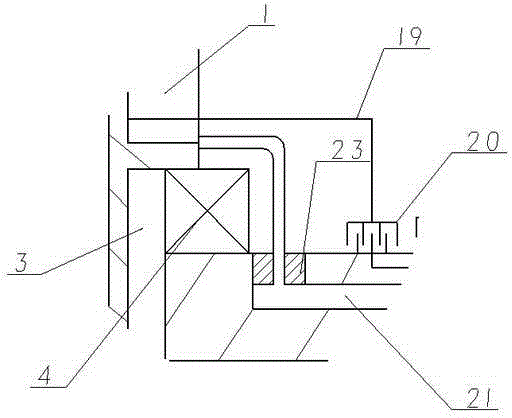

InactiveCN101725431AIncrease thrust-to-weight ratioReduce volumeJet propulsion plantsCombustion chamberElectric machine

The invention discloses an electric fuel oil jet propeller which comprises an air inlet, a fan, a motor, an air deflector, a combustion chamber and a tailpipe with the thrust of 1-50kg. The electric fuel oil jet propeller is characterized in that fan blades are fixed on a fan hub which is fixed on an outer rotor direct-current motor rotor; the motor is fixed on an air deflector inner support ring through a bolt; an air deflector outer ring is embedded on the inner wall of a ducted casing; a heat insulation shield is arranged at the rear end of the air deflector inner support ring; the combustion chamber is arranged at the middle-rear end of the ducted casing; a pneumatic fuel oil nozzle ring is arranged at the front section of the combustion chamber and communicated with an oil pipeline; a falcate flame stabilizer is arranged at the rear end of the pneumatic fuel oil nozzle ring; an igniter is arranged at the rear end of the falcate flame stabilizer, passes through the combustion chamber and the ducted casing and is fixed on the outer wall surface of the ducted casing; and the inner wall of the ducted casing adopts a heat insulation coating. The propeller can be used as main power of small and middle size delivery tools and has simple structure, small size, light weight and large working thrust.

Owner:NANCHANG HANGKONG UNIVERSITY +1

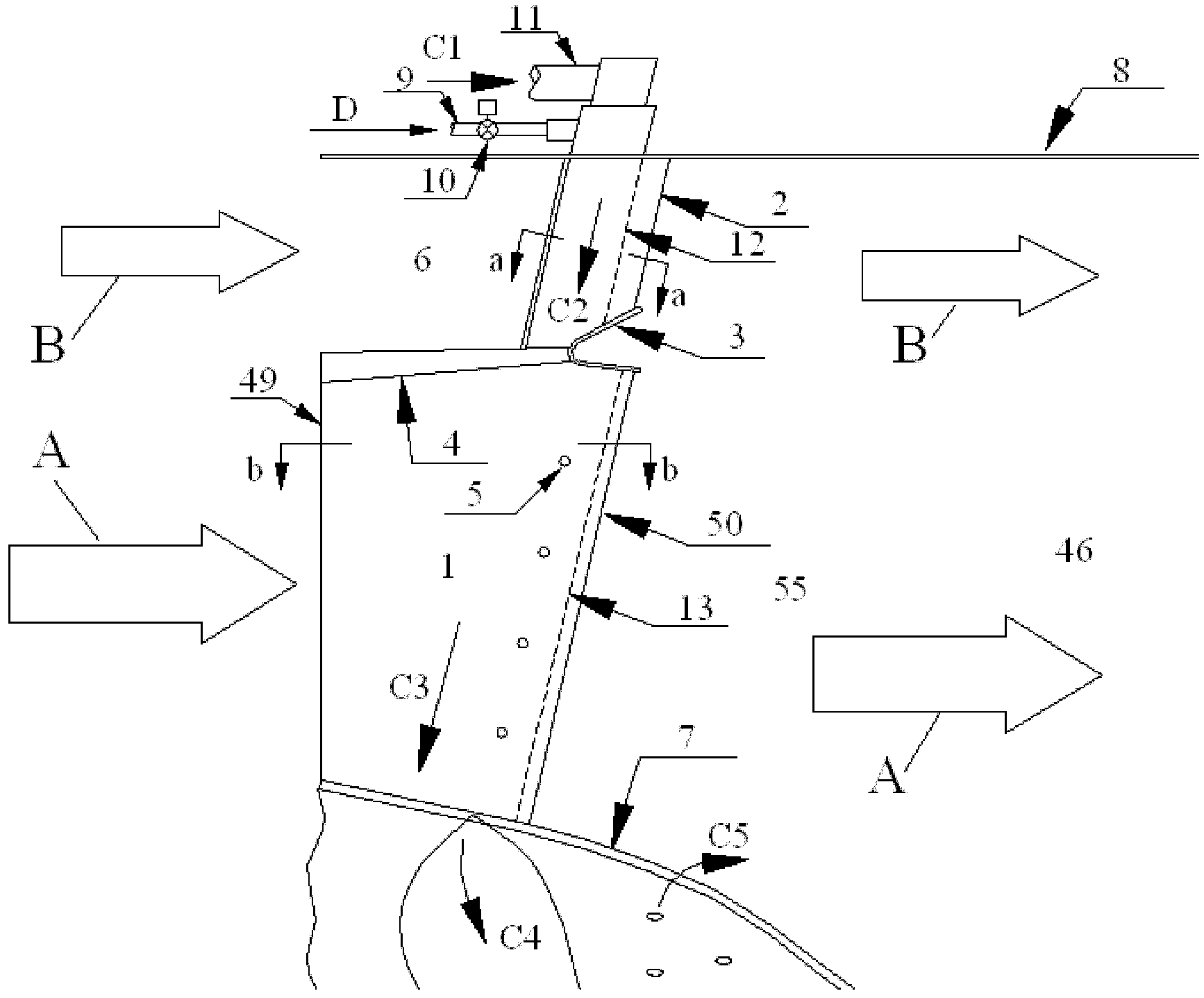

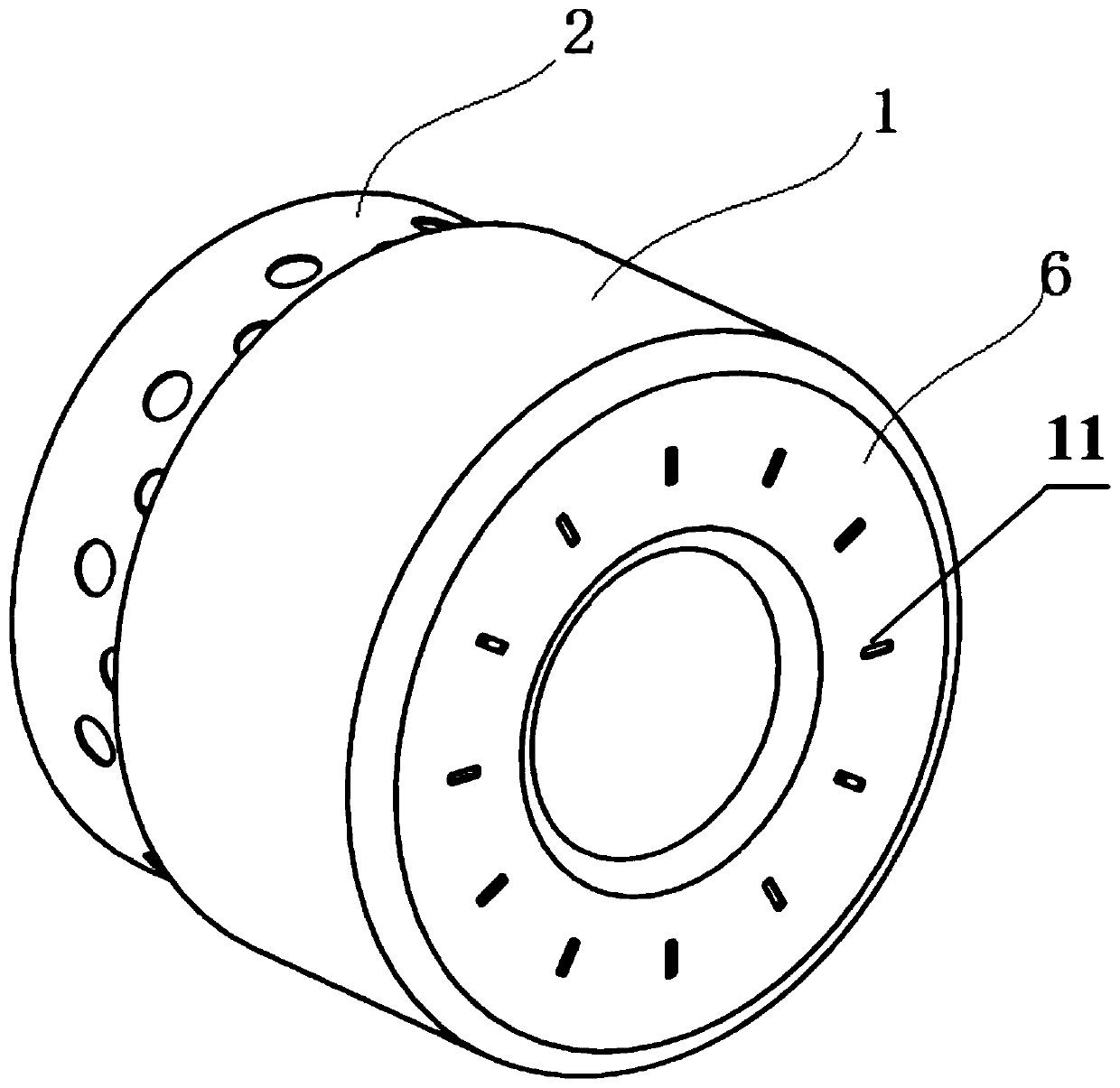

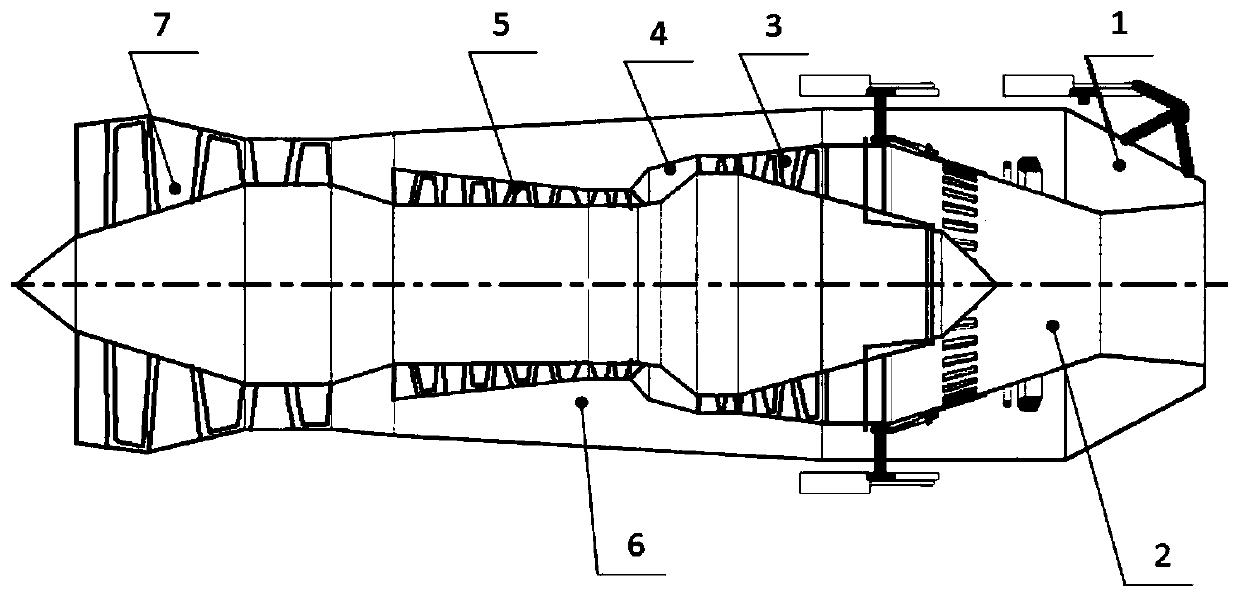

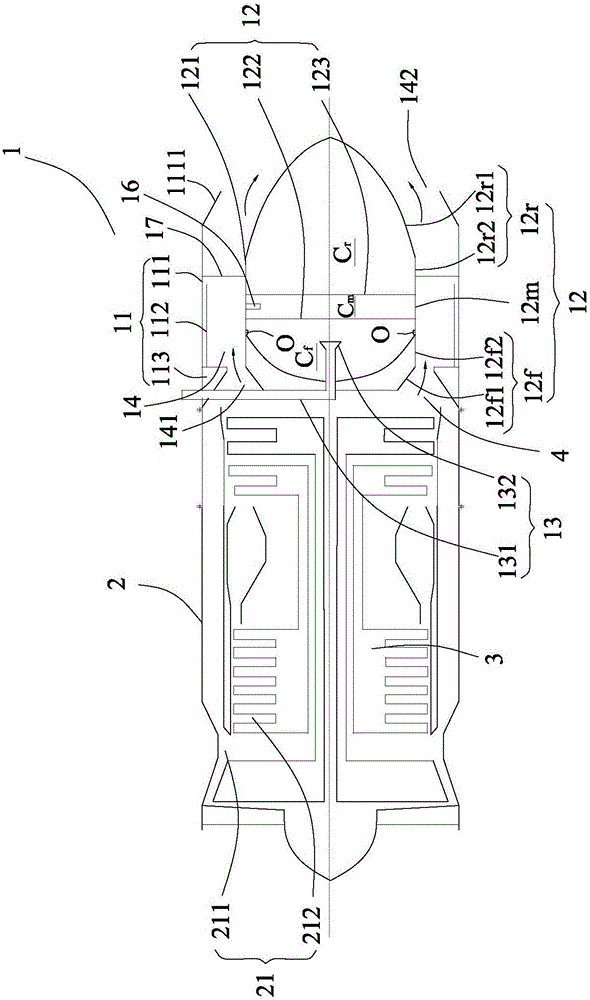

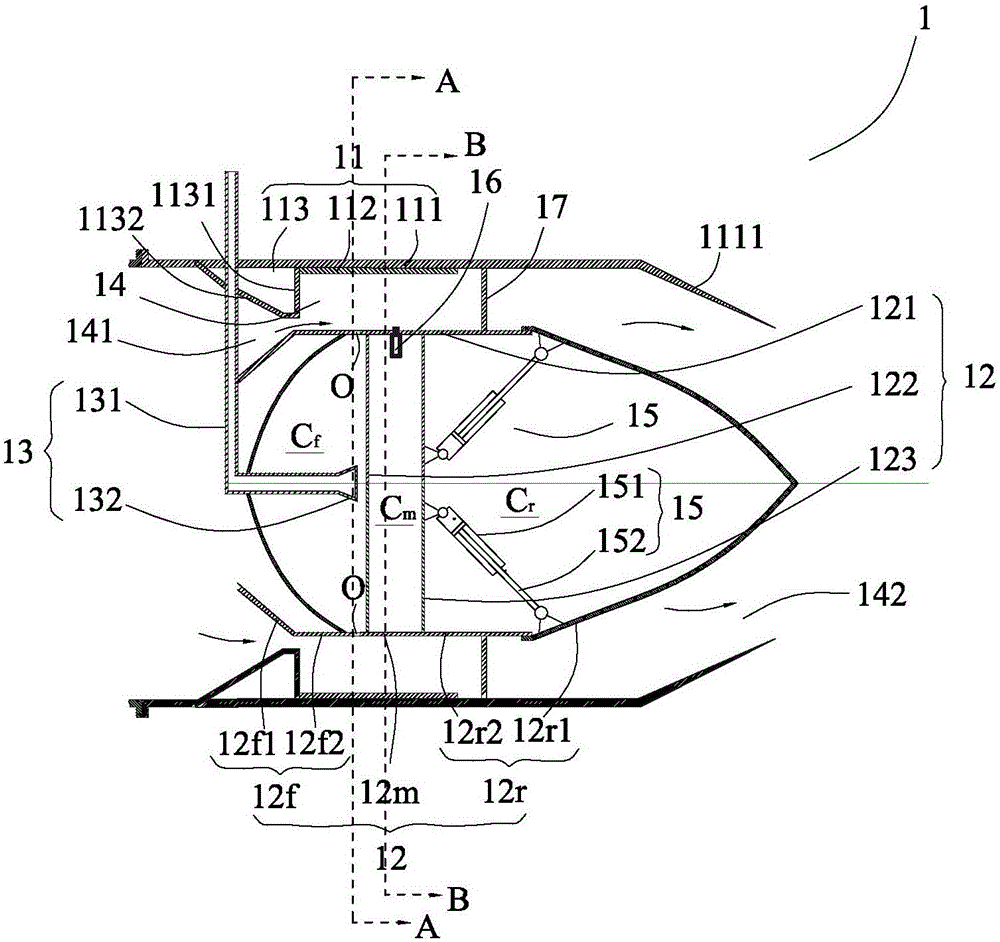

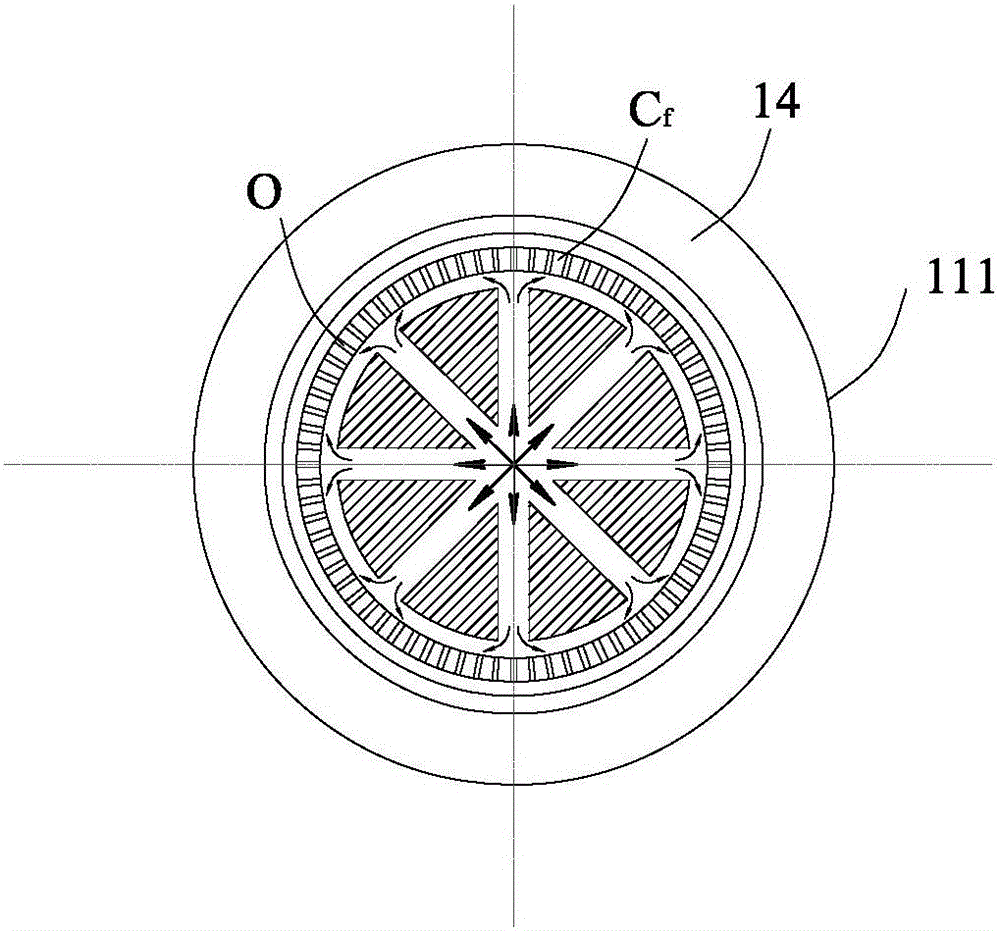

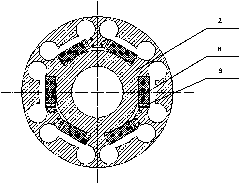

Contra-rotating outer framework water-air dual-purpose engine

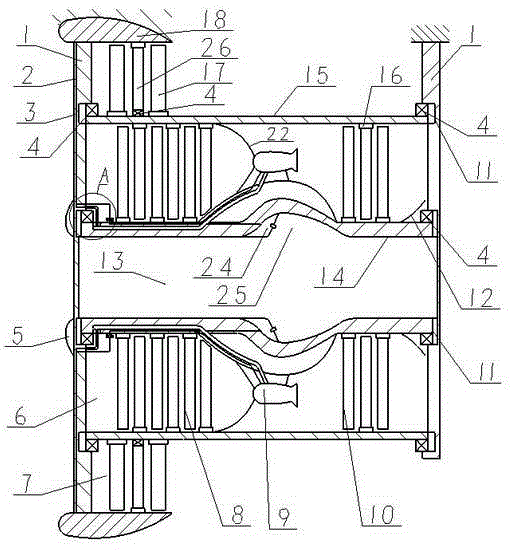

InactiveCN104481696AReduce the size of the axial structureIncrease thrust-to-weight ratioGas turbine plantsReactive propulsion thrust deviceAbsolute rotationCombustion chamber

The invention discloses a contra-rotating outer framework water-air dual-purpose engine. The engine mainly structurally comprises a supporting frame, an oil electric pipeline, a front thrust bearing, a peripheral bearing, a radome, an inner duct, an outer duct, a gas compressor, a ring-shaped combustion chamber, a worm wheel, a rear thrust bearing, a convergent tail spray tube, a central duct, an inner rotor, an outer rotor, a blade tongue-and-groove, a fan, an engine cover, a power transmission circuit, a conductive slide ring, an oil conveying pipeline, a convergent channel, a rotary joint, a metal fuel cavity, a metal-water reaction combustion chamber and a fan stator blade. The gas compressor and the worm wheel of the engine are not provided with a stator blade, and an outer frame rotor and an inner rotor are in counter rotating in an air working state, so that the gas compressor and the worm wheel can realize counter rotating, the absolute rotation speed of the rotor is lowered when the engine efficiency is improved, the axial dimension of the engine is shortened and the structure weight is reduced. When the engine works in water, the ring-shaped combustion chamber does not work, the inner and outer rotors are static, and power is produced by the metal-water reaction combustion chamber, so that water-spraying propulsion is realized.

Owner:NANCHANG HANGKONG UNIVERSITY

Secondary-flow evaporation tube type combustion chamber structure

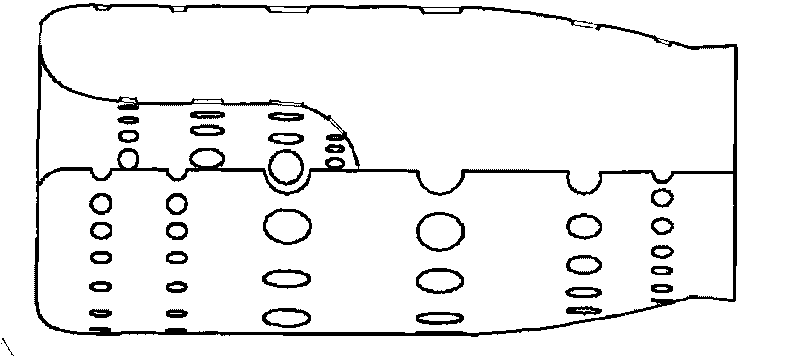

ActiveCN111023155AReduce the chance of ablationSmall sizeContinuous combustion chamberCombustion chamberMechanical engineering

The invention discloses a secondary-flow evaporation tube type combustion chamber structure. A combustion chamber body and a baffle plate are adopted, wherein the front end of the combustion chamber body is shaped like a cylinder, and the upper end of the baffle plate is provided with an annular groove; the baffle plate is additionally arranged on an outer wall surface of a combustion chamber, andair film holes are formed in the annular cylindrical barrel wall and the groove wall of the annular groove, so that the reverse air flow of a secondary flow in a casing is heated and heated again after being injected by a primary air flow at the head of the combustion chamber and mixed; and then the combustion flame temperature field is more uniform, the heat transfer of the fin reinforced wall surface enables the temperature of the wall surface to be effectively decreased, the uniformity of the flow field is optimized, the combustion efficiency is improved, and the emission of pollutants such as NOx is greatly reduced while fuel is saved. The annular cylindrical outer wall and the inner wall of the annular groove are connected through fins to form an integrated forming structure, the overall weight of the device is reduced, the outline size of the combustion chamber is decreased, the thrust ratio of an engine is effectively increased, and the maneuverability of the engine is increased; and the using number of connecting parts between structural members is decreased at the same time, and the overall performance is improved.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

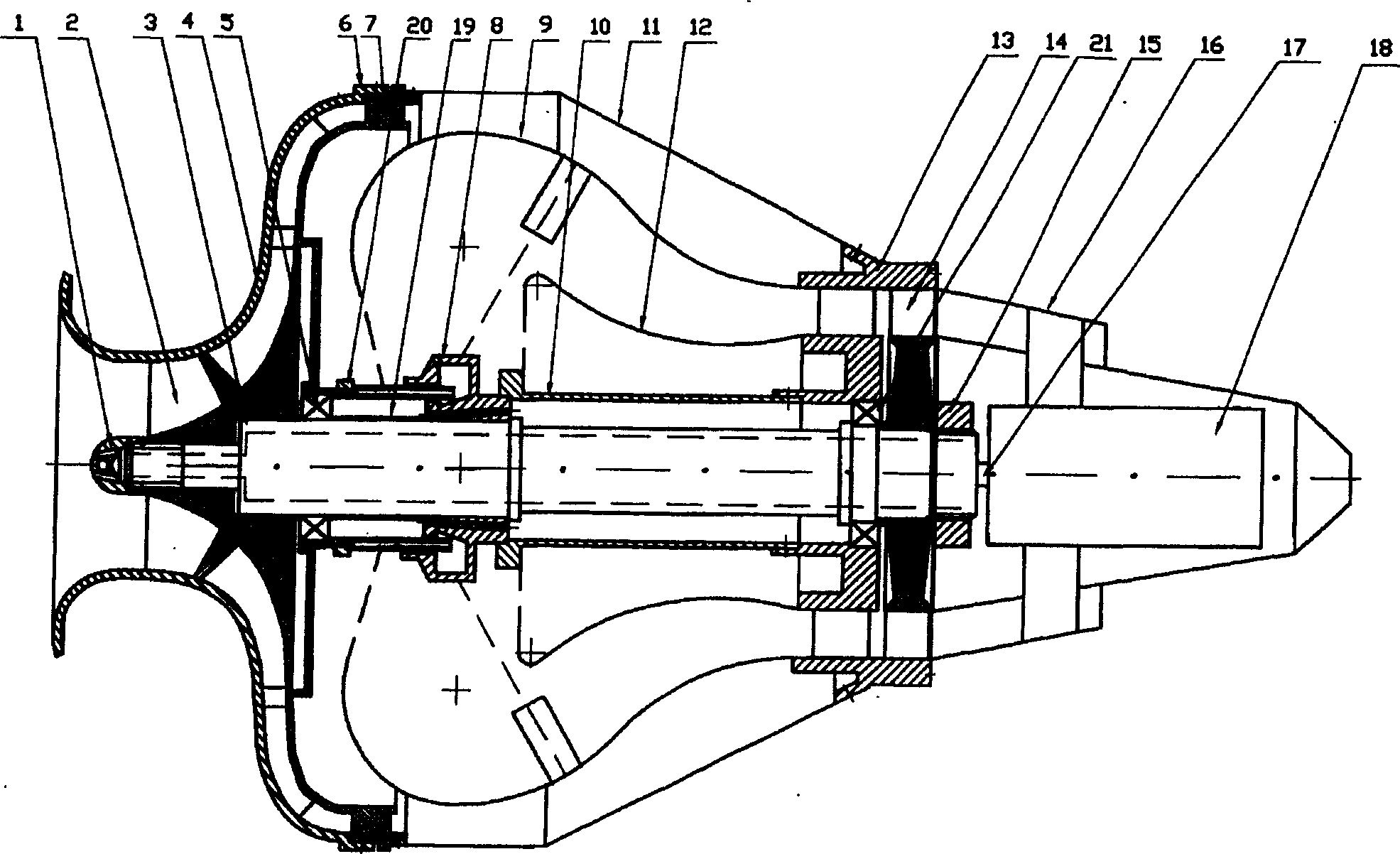

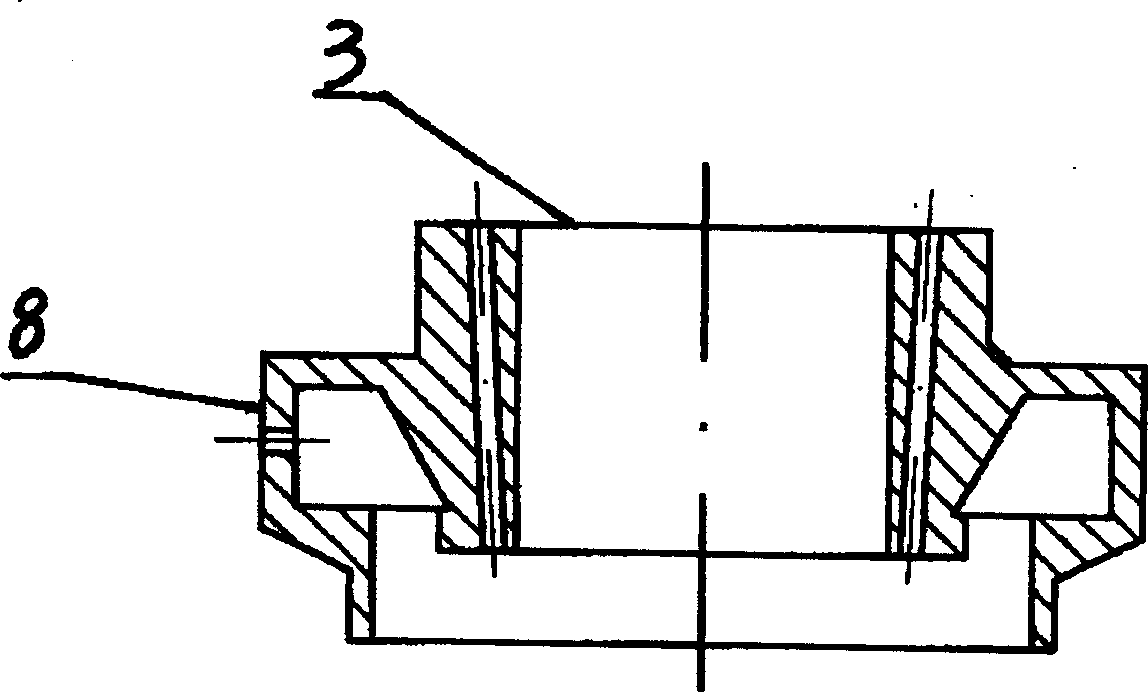

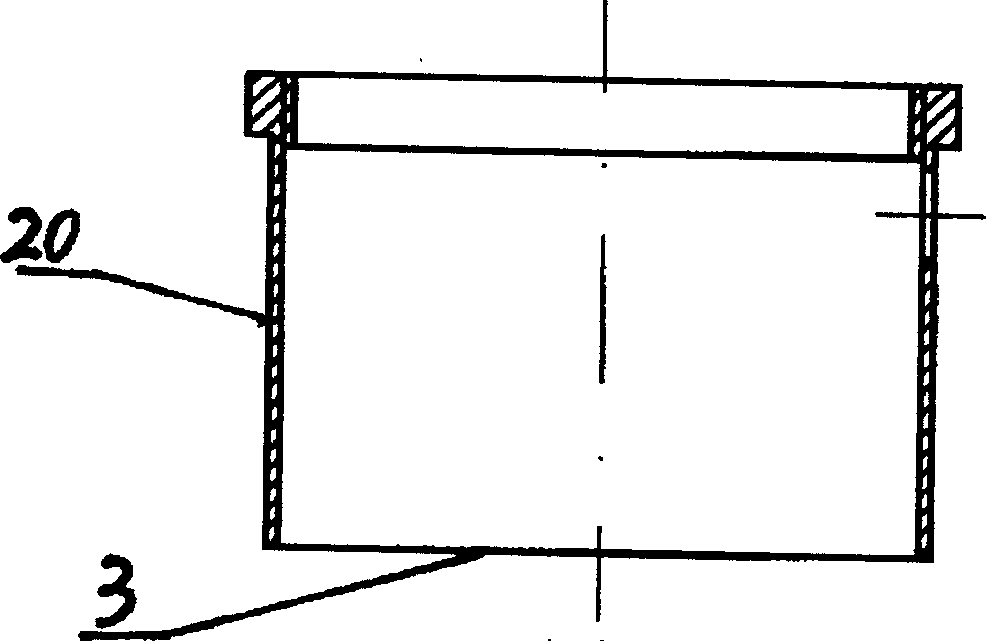

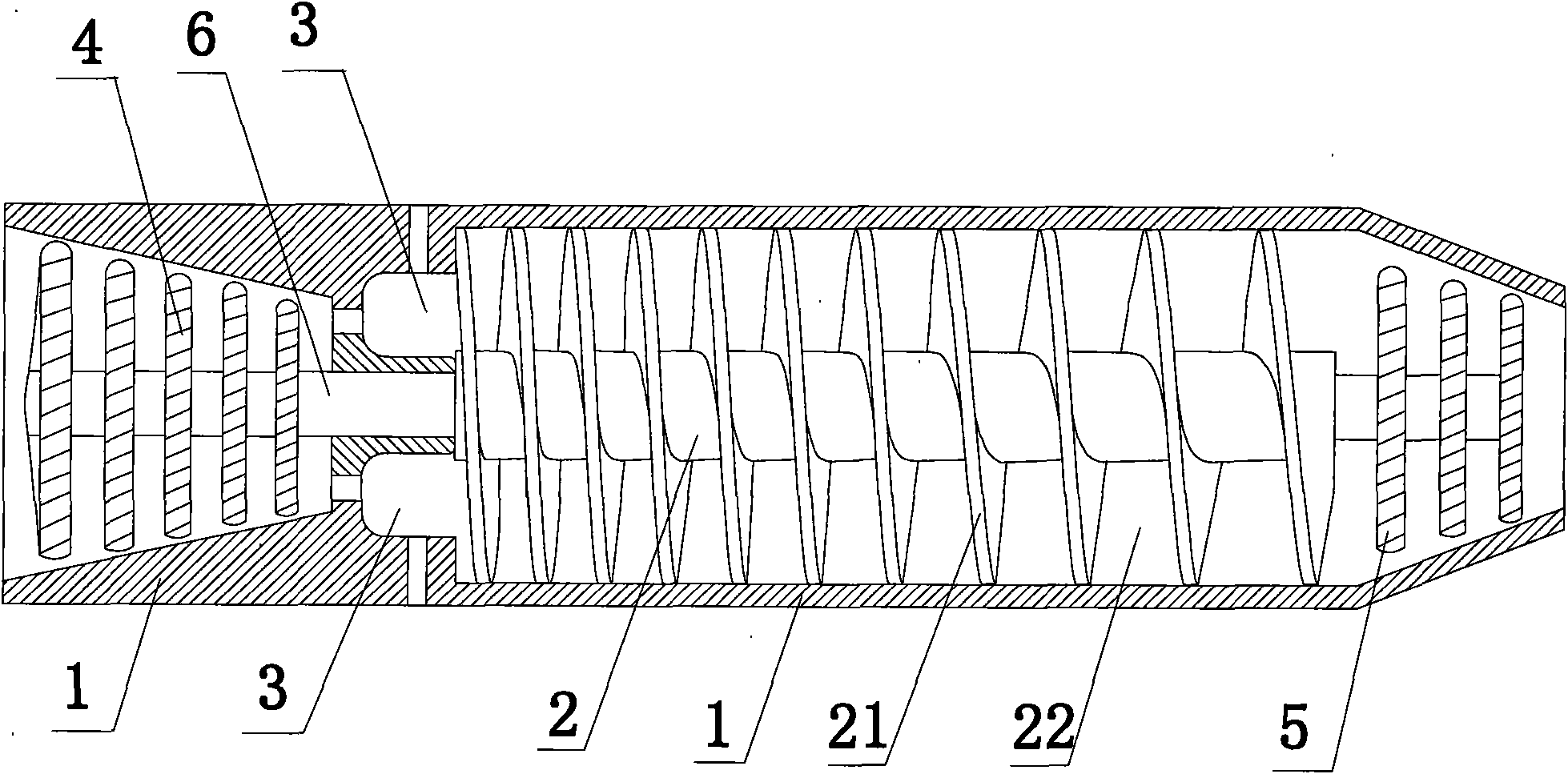

Miniature turbine jet engines

InactiveCN1490514AHigh degree of automationIncrease thrust-to-weight ratioJet propulsion plantsCombustion chamberCentrifugal compressor

A miniature turboject engine with 10-30 kg of propulsive force is composed of air inlet channel, compressor, combustion chamber and exhaust system. The front and back nuts, rotor of centrifugal compressor, oil thrower and turbo rotor are installed on the shaft of engine. It has also the flame barrel, tail jet nozzle, shaft couple and DC motor. Its advantages are simple structure, small size and light weight.

Owner:BEIHANG UNIV

Turbofan engine

ActiveCN109854379AShorten the lengthRealize control areaGas turbine plantsJet propulsion plantsAviationCombustion chamber

The invention discloses a turbofan engine and belongs to the technical field of design of an aero turbofan engine. The engine comprises a second afterburner (2) and a first afterburner (1), wherein the second afterburner (2) comprises an afterburner inner spraying pipe and a main force exerting cavity; the afterburner inner spraying pipe is fixedly connected with the back end of an inner cylinder;the main force exerting cavity is positioned in the afterburner inner spraying pipe; a through hole is formed in the afterburner inner spraying pipe; the first afterburner (1) comprises an afterburner outer spraying pipe and an auxiliary force exerting cavity; the afterburner outer spraying pipe is fixedly connected with the back end of an outer cylinder; the auxiliary force exerting cavity is positioned between the afterburner outer spraying pipe and the afterburner inner spraying pipe; the first afterburner (1) also comprises a baffle; the baffle is controlled by an adjusting mechanism to close or open the through hole in the afterburner inner spraying pipe; and the opening section of the tail end of the afterburner outer spraying pipe is adjustable. The length and the weight of the afterburner are reduced by adjusting the afterburning condition of the main force exerting cavity and the auxiliary force exerting cavity.

Owner:AECC SHENYANG ENGINE RES INST

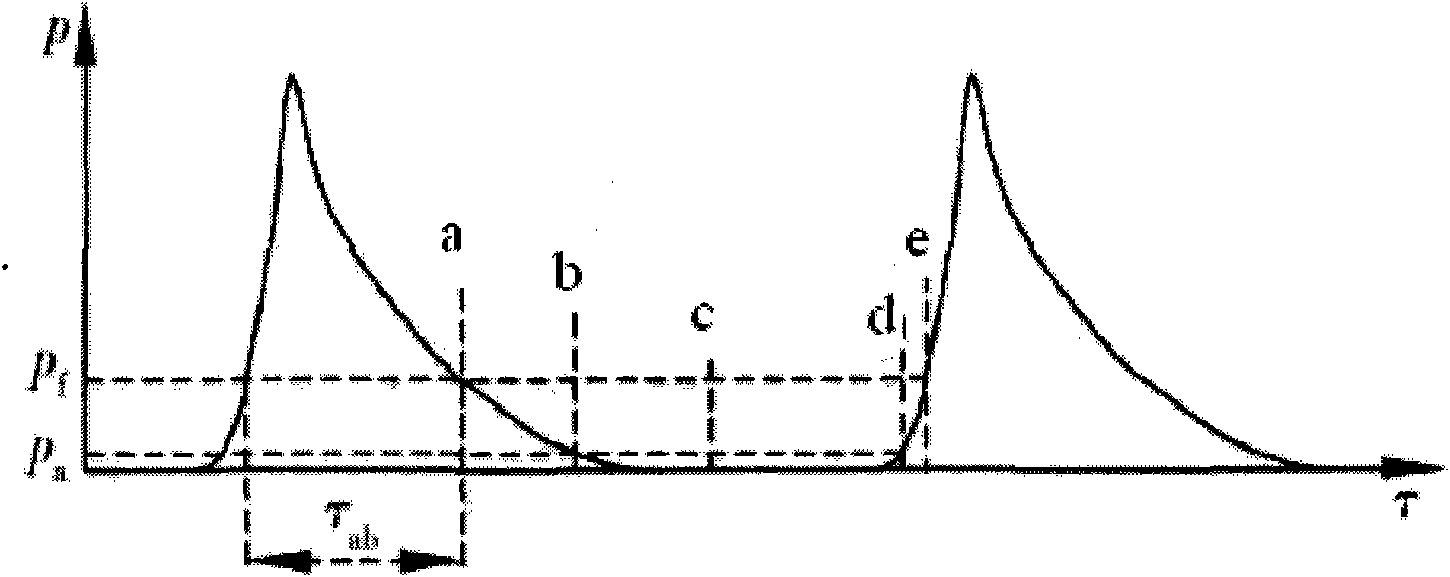

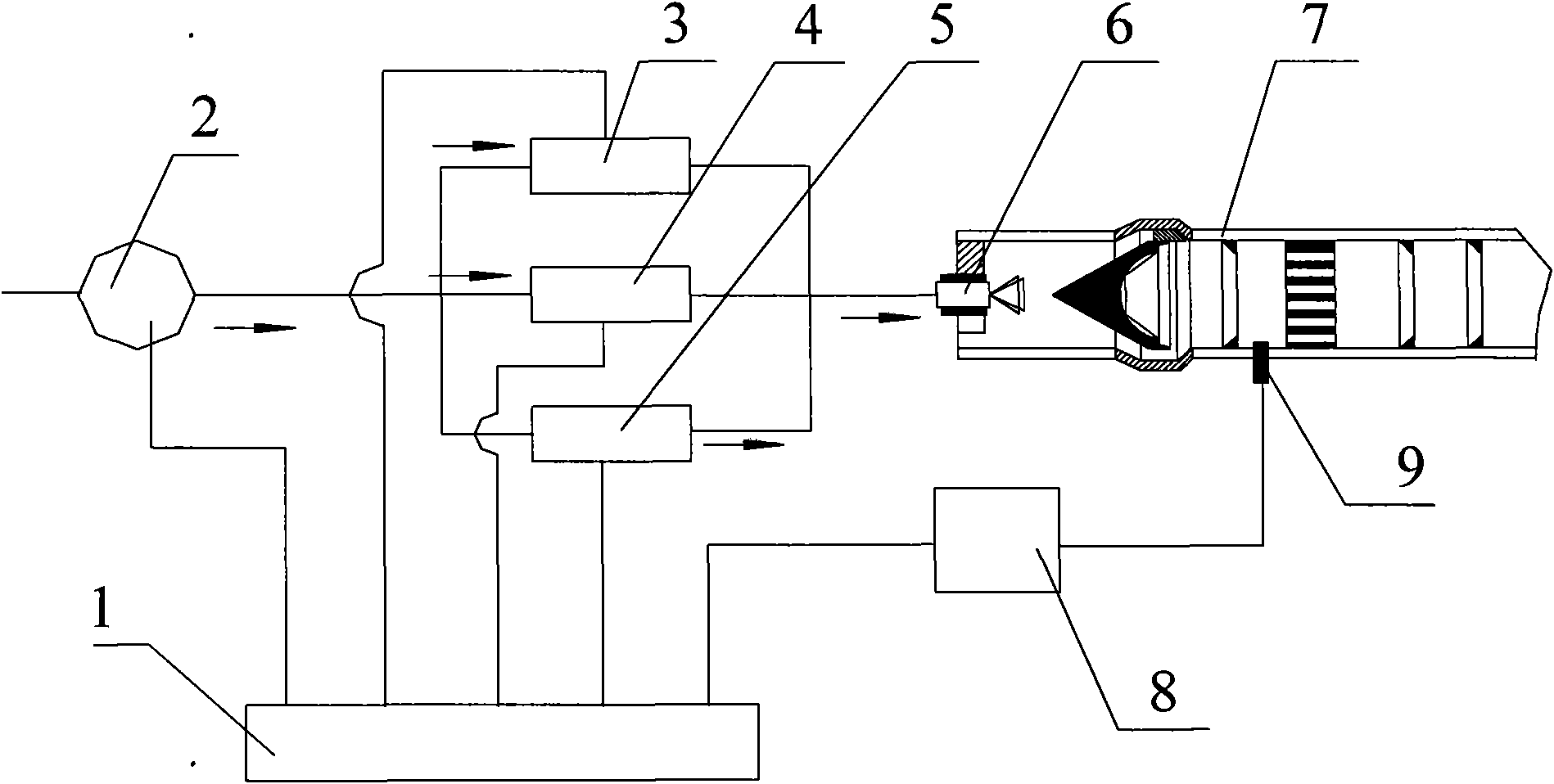

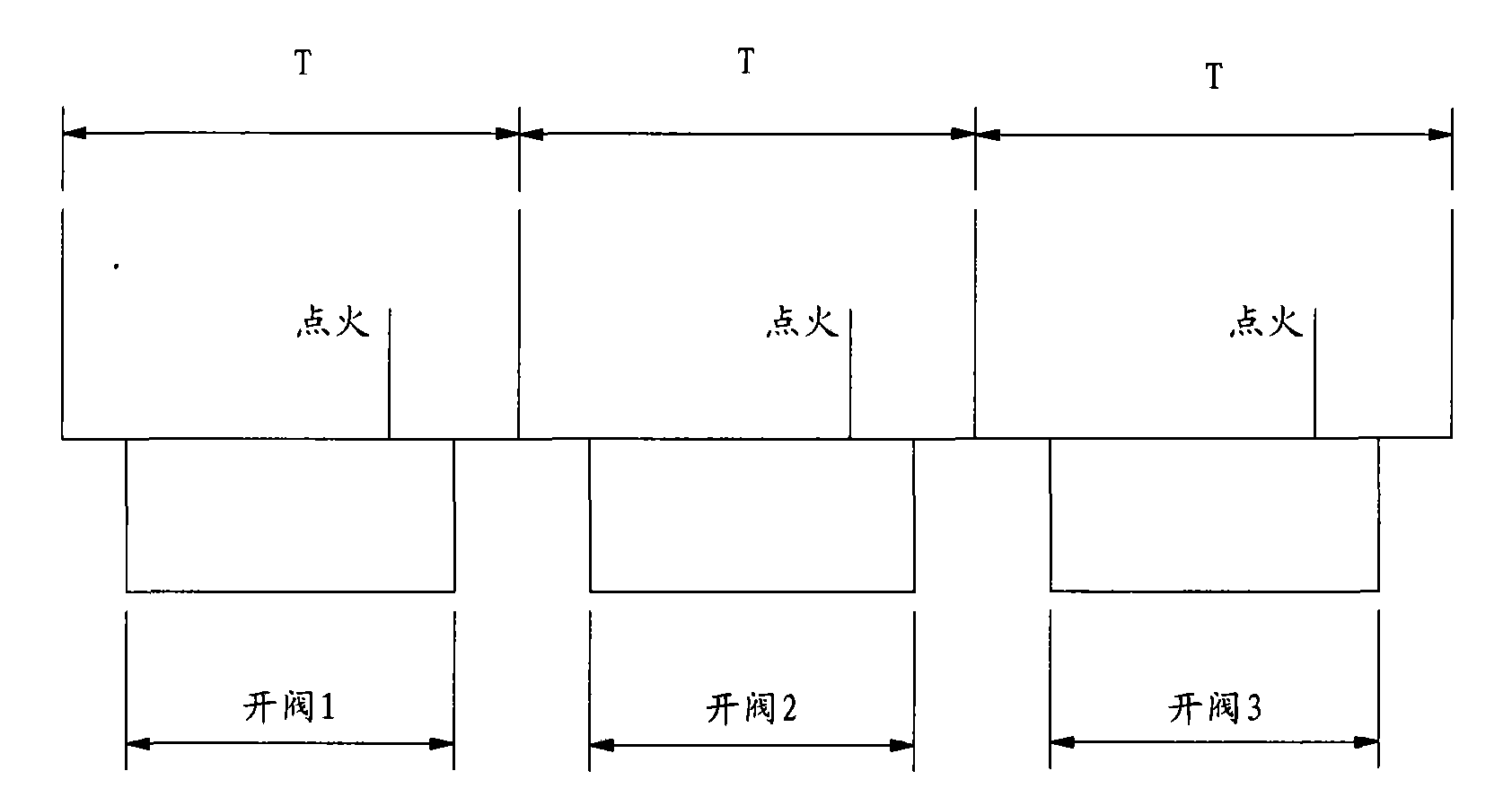

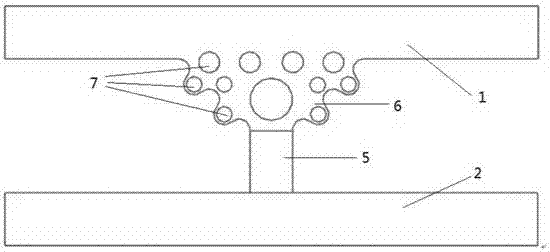

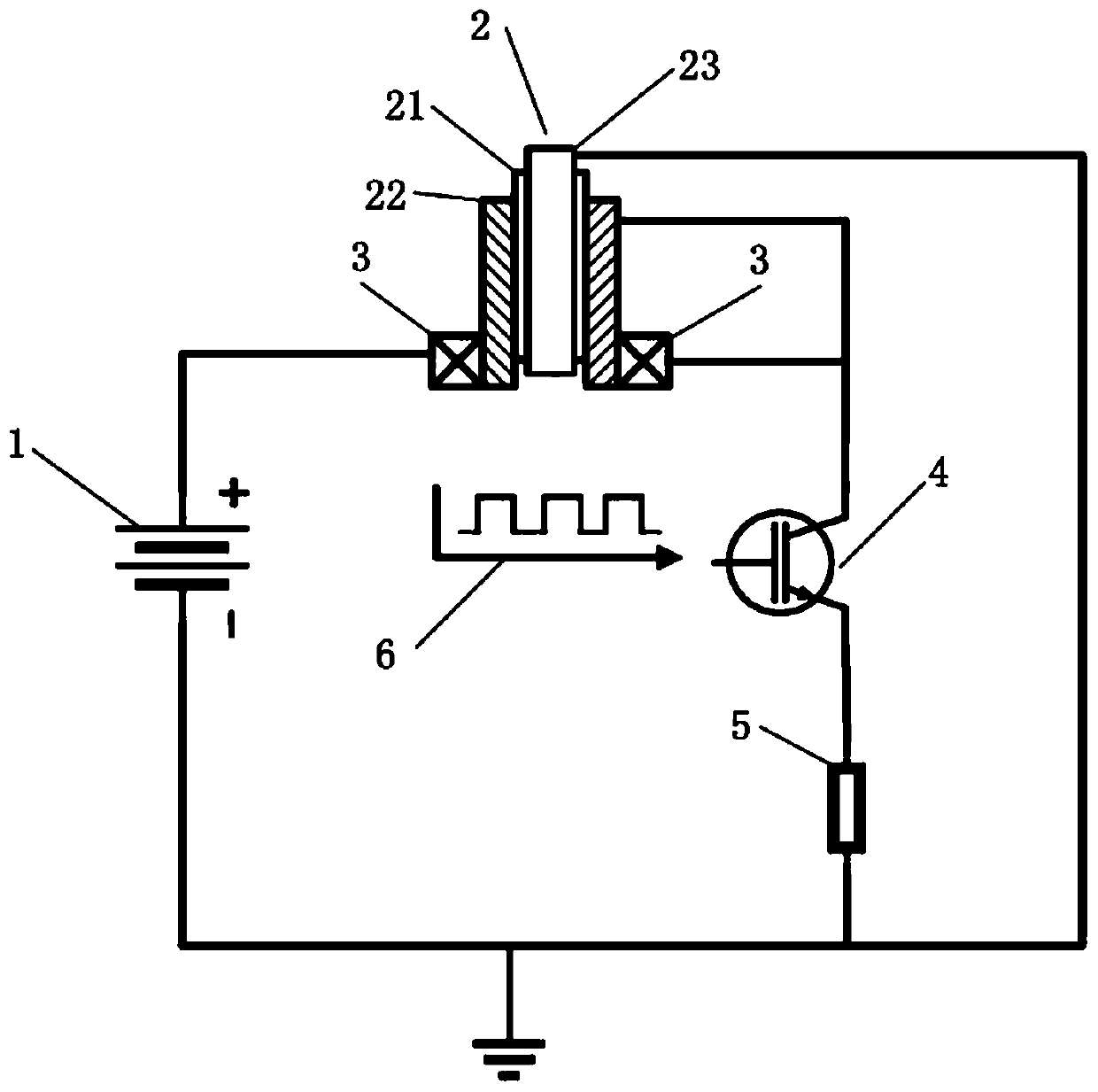

Pulse detonation engine (PDE) magnetic valve high frequency oil supply and ignition system

The invention discloses a pulse detonation engine (PDE) magnetic valve high frequency oil supply and ignition system, comprising a controller, an oil pump, a plurality of magnetic valve branches connected in parallel, a pulse detonation engine (PDE), a nozzle and a spark plug arranged at the head part of the PDE, an ignition power supply connected with the spark plug via a wire, wherein the controller is respectively connected with the oil pump, the multiple magnetic valve branches connected in parallel and the ignition power supply via wires; and the upstream of the multiple magnetic valve branches connected in parallel is connected with the oil pump through an oil pipe, and the downstream thereof is connected with the nozzle via an oil pipe. The invention can enhance oil supply and ignition frequency, control intermittent supply of fuel oil actively, improve fuel oil atomization evaporation and mixing properties, shorten DDT distance and time, reduce oil consumption, increase thrust-weight ratio, and is adaptable to urgent development demands of the PDE.

Owner:PEKING UNIV

Double-combustion-chamber ramjet and hypersonic aerocraft

ActiveCN108708788AImprove thermal cycle efficiencyExcellent thrust performanceTurbine/propulsion fuel flow conduitsGas turbine plantsRamjetCombustion chamber

The invention discloses a double-combustion-chamber ramjet and a hypersonic aerocraft. The double-combustion-chamber ramjet comprises an outer shell; and the outer shell is a hollow cylinder with twocommunicating ends. The double-combustion-chamber ramjet further comprises a center shell; the center shell is arranged in a shaft hole of the outer shell, and is connected with the outer shell; a gapbetween the center shell and the outer shell forms an outer drainage channel; a cavity between the back end surface of the center shell and the inner wall of the outer shell forms a knocking chamber;and a tail spraying pipe communicates with the knocking chamber. The double-combustion-chamber ramjet further comprises a center cone; the back body of the center cone extends into the center shell,and is connected with the center shell; a gap between the center cone and the center shell forms a center drainage channel; a cavity between the back end surface of the center cone and the inner wallof the center shell forms a sub-combustion chamber; and the sub-combustion chamber is connected with a fuel source, and communicates with the knocking chamber. Multiple outer nozzles are formed in theouter wall of the outer shell; and the two ends of the outer nozzles communicate with the fuel source and the outer drainage channel. And / or multiple inner nozzles are formed in the outer wall of thecenter shell; and the two ends of the inner nozzles communicate with the fuel source and the outer drainage channel respectively.

Owner:NAT UNIV OF DEFENSE TECH

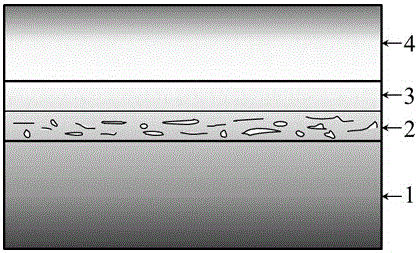

Thermal barrier coating with two bonding layers and preparation method of thermal barrier coating

ActiveCN106119760AReduce vertical stressRelieve high temperature thermal expansionMolten spray coatingPorous layerSand blasting

The invention discloses a thermal barrier coating with two bonding layers. The thermal barrier coating comprises a high-temperature alloy matrix, wherein a first bonding layer, a second bonding layer and a surface ceramic layer are deposited above the matrix in sequence; and the first bonding layer is of a multiporous laminated structure, and the second bonding layer is of a compact structure. A preparation method of the thermal barrier coating comprises the following steps: (1) grinding and performing sand blasting treatment on the surface of the high-temperature alloy matrix; (2) depositing a porous layer, which is the first bonding layer, with the porosity of 10 to 30 percent on the surface of the matrix by adopting gas shield protection plasma spraying; (3) depositing a compact layer, which is the second bonding layer, on the surface of the porous layer by adopting hypersonic flame spraying, low-pressure plasma spraying or cold spraying; and (4) depositing the surface ceramic layer on the surface of the second bonding layer by adopting atmospheric plasma spraying. The thermal barrier coating with the two bonding layers can both ensure that alpha-Al2O3 is continuously generated on the surfaces of the bonding layers and further relieve thermal expansion mismatch between the matrix and the ceramic layer, so that the service life of the thermal barrier coating is prolonged.

Owner:XI'AN PETROLEUM UNIVERSITY

Method for making guide vane inner ring by opening process window

InactiveCN102019347AShorten the processing cycleImprove performanceFoundry mouldsFoundry coresWaxSpray nozzle

The invention relates to the technical field of precision casting, in particular to a method for making a guide vane inner ring by opening a process window. The method comprises the following steps of: designing a computer model of the guide vane inner ring by a UG solid modeling method; firing with a laser rapid forming machine; performing combination, sticking and wax-welding on a fixture with a fixing tenon; performing size detection and local trimming on the wax piece to finish the manufacturing of a wax mould; assembling the wax mould into a pouring system; smearing a mixed coating consisting of silica sol and fused corundum on the surface of the wax mould; dewaxing and sintering to obtain a shell of the pouring system; pouring on a vacuum furnace to obtain an integral mother casting of the guide vane inner ring; opening 14 process windows in 15 mm*20 mm on the annular thin wall of the integral mother casting of the guide vane inner ring; welding 15 through holes of the outer ring and 35 nozzle holes of the inner ring on the integral mother casting of the inner ring; and welding a 15 mm*20 mm blocker on the process window to obtain the final product.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Afterburner and turbine engine

ActiveCN105698219ASolve combustion instabilityImprove efficiencyGas turbine plantsExplosive combustion chamberAutomotive engineeringCombustion chamber

The invention provides an afterburner and a turbine engine. The afterburner comprises an outer cylinder assembly, a center body assembly, an oil way assembly, an annular combustion chamber and an igniter; the center body assembly comprises a front body, a middle body and a rear body, wherein the front body is located at the axial front end of the afterburner and forms a gas inlet, accepting entry of oxygen-containing gas, of the annular combustion chamber with the outer cylinder assembly, the middle body is located behind the front body along the axis and is connected to the front body and integrated with the front body, and the rear body is located behind the middle body in the axial direction, is arranged in the middle body in a slid and sleeved mode and forms a gas outlet of the annular combustion chamber with the outer cylinder assembly; the igniter is arranged at the corresponding part, forming the annular combustion chamber with the outer cylinder assembly, of the center body assembly and is used for igniting fuel gas formed by fuel and the oxygen-containing gas entering the annular combustion chamber, then rotation and knocking combustion of the fuel gas are realized, and therefore the problem that combustion of the afterburner is instable is solved, the heat efficiency of combustion is improved, and the power capability of working media is improved.

Owner:清航空天(浙江)科技有限公司

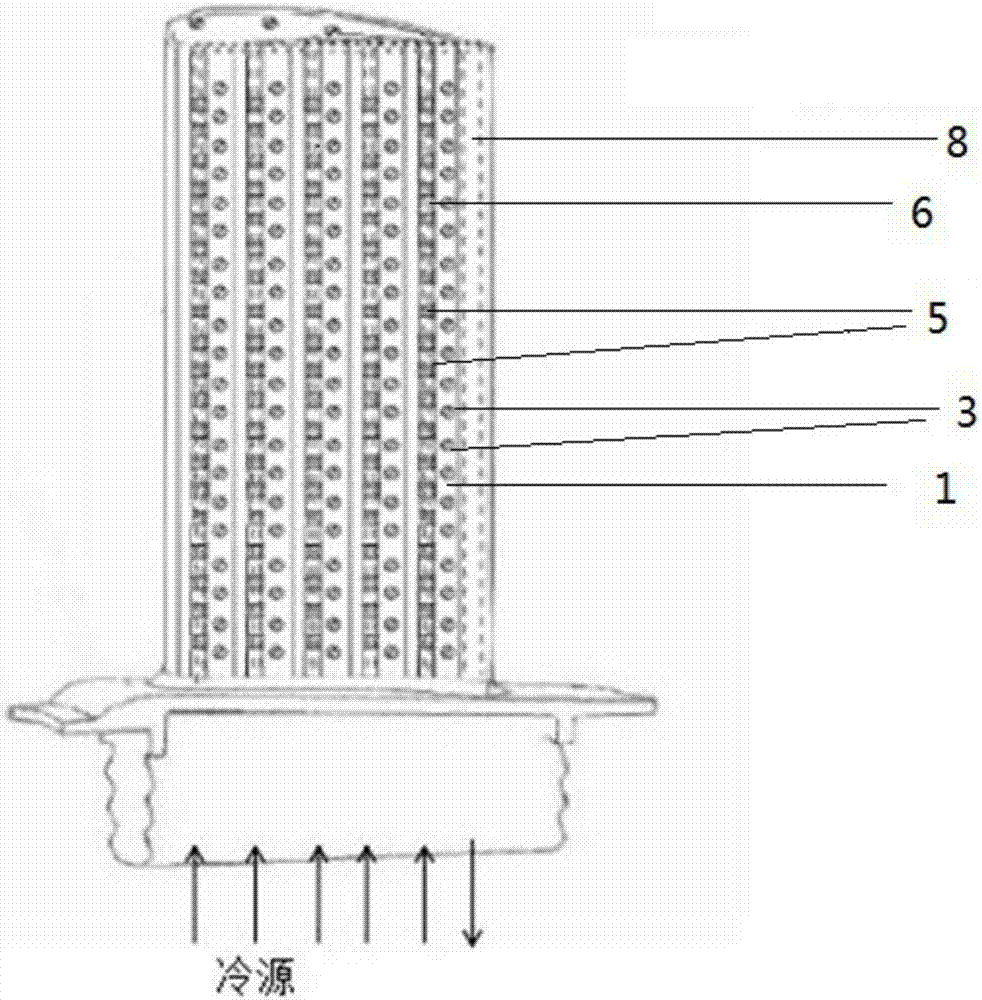

Gas-liquid coupling turbine blade cooling unit

ActiveCN107060892AImprovement of double shell type "shock/air film/disturbance" composite cooling structureReduce the temperatureBlade accessoriesMachines/enginesTurbine bladeEngineering

Based on an existing double-layer shell type impact / gas film / turbulent flow composite cooling structure, the invention discloses a gas-liquid coupling turbine blade cooling unit. The gas-liquid coupling turbine blade cooling unit comprises a plurality of mutually independent cooling subunits. Each cooling subunit comprises a cold gas wall, a hot gas wall, a plurality of impact holes formed in the cold gas wall, a plurality of gas film holes formed in the hot gas wall, a plurality of turbulent flow columns located between the cold gas wall and the hot gas wall, and a collecting table connected with the cold gas wall and the turbulent flow columns, wherein the cold gas wall and the hot gas wall are arranged oppositely, the upper surface of the collecting table is connected with the inner surface of the cold gas wall, the lower surface of the collecting table is connected with the turbulent flow columns, and at least one cold source pipeline penetrating through the collecting table longitudinally is arranged in the collecting table. Further, in the cooling subunits, the side walls of the collecting tables are smoothly connected with the inner surfaces of the cold gas walls and the side walls of the turbulent flow columns to form a smooth hook face structure together. Through the gas-liquid coupling turbine blade cooling unit, a liquid cooling path is added, and the overall temperature of a turbine is further lowered.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Micro-cathode arc propulsion system

ActiveCN110486243AReduce quality problemsReduce volumeCosmonautic propulsion system apparatusMachines/enginesInsulation layerInductor

The invention discloses a micro-cathode arc propulsion system. The micro-cathode arc propulsion system comprises an inductor, a power supply treating unit and a thruster, wherein the inductor is charged under the power-on condition and is used for forming a backward voltage after charging is finished and power is powered off, the power supply treating unit is connected with the inductor and is used for controlling the inductor to be powered on or powered off, the thruster is arranged inside the inductor and is connected with the power supply treating unit and the inductor, when the inductor forms the backward voltage, a pulse voltage is formed between a cathode and the anode of the thruster, the thruster breaks down an insulation layer under the action of the pulse voltage, meanwhile, thecathode is subjected to vapor formation to form plasma, and the plasma is led out under a magnetic field formed by the inductor to form reaction thrust. According to the system, the thruster is arranged in the inductor, the magnetic field formed when the inductor is powered on is used as the magnetic field for guiding and accelerating ions, an excitation circuit of the thruster is omitted, the total mass and total size of the micro-cathode arc thruster propulsion system are reduced, so that the thrust-weight ratio of the thruster is improved.

Owner:HARBIN INST OF TECH

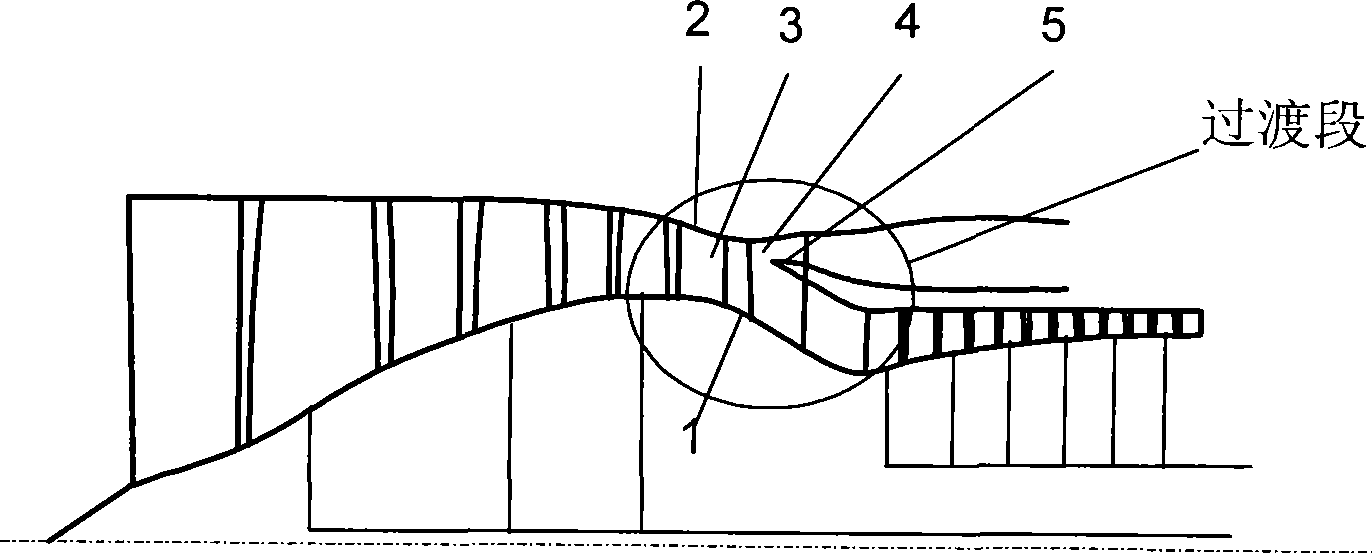

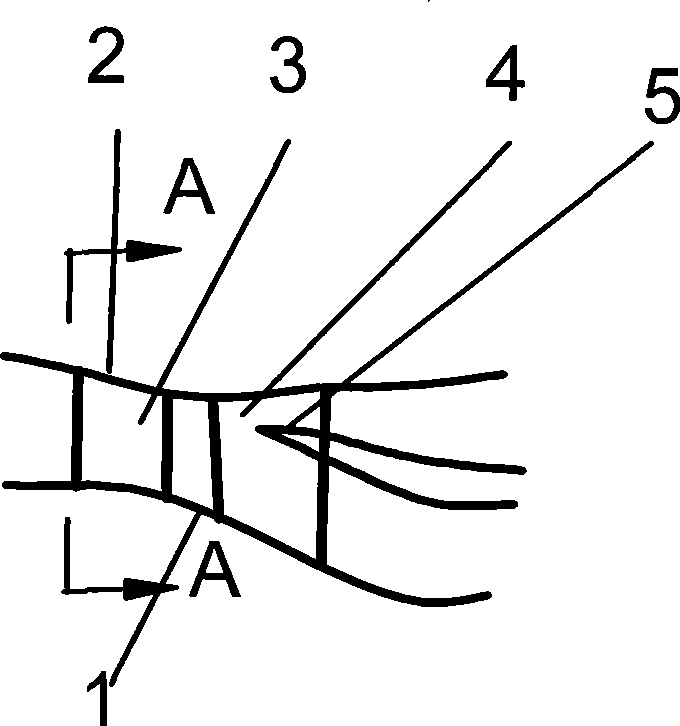

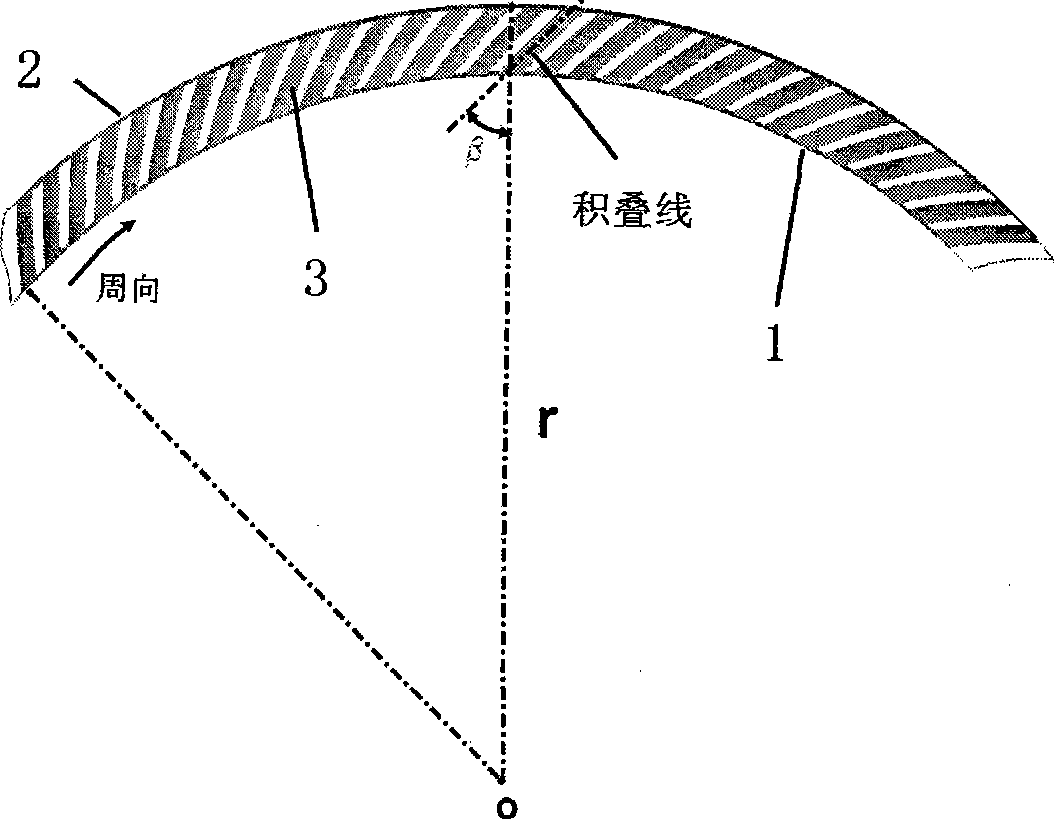

Method for restraining flow separation in transition section by utilizing guide vane

The invention relates to a method for inhibiting flow separation in a transition section of a compression system of an engine of a low-bypass aerial turbofan by using a guide vane. The method comprises the following steps: placing the guide vane at a first curved conduit on the inner wall of a transition section of an air compressor, and forming a vane force with gradient opposite to that of the prior pressure at the curved conduit of the transition section through changing a peripheral included angle of a laminated line and a radial line of the guide vane, so as to reduce pressure gradient of the flow direction at the curved conduit, and inhibit the flow separation in the transition section. Because the method can inhibit the flow separation in the transition section, the method can increase bending degree of the transition section, so as to reduce the length of the transition section. At the same time, because the guide vane is placed in the transition section, the method saves space occupied by the prior guide vane, and is favorable for reducing the length of the whole air compressor. The length of the transition section is estimated to be shortened by about 20 percent by adopting the method and the method contributes to the thrust mass ratio of the engine by about 1 percent.

Owner:廊坊智驰动力科技有限公司

Laminating type piezoelectric brake adopting flexible amplifying structure and working method thereof

InactiveCN103994159AEasy to install precisionLarge displacement and forceDrum brakesBrake actuating mechanismsElectromagnetic interferenceCeramic

The invention discloses a laminating type piezoelectric brake adopting a flexible amplifying structure and a working method thereof. The piezoelectric brake comprises a non-rotation part, a brake support, a circular ring, a key, a brake disk and a rotating part, wherein the brake support, the circular ring, the key, the brake disk and the rotating part are installed in the non-rotation part. The circular ring is located in the non-rotation part, the inner circle of the circular ring and the brake support are connected through the key and located, and the inner circle of the brake disk and the outer circle of the circular ring are in clearance fit. The rotating part is installed on the circular ring and fixedly connected with the brake disk. The laminating type piezoelectric brake adopting the flexible amplifying structure further comprises laminating piezoelectric ceramic embedded in the circular ring, a wedge arranged on one side of the laminating piezoelectric ceramic and used for providing the pretightening force, and an isosceles triangle displacement amplifying structure used for amplifying and controlling extension displacement of the laminating piezoelectric ceramic. The laminating type piezoelectric brake adopting the flexible amplifying structure has the advantages of being small in size, easy to process, assemble and use, fast in response, easy to control and the like, and electromagnetic interference is avoided.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Spiral type thrust engine

InactiveCN101576021AIncrease working fluid temperatureIncrease thrust-to-weight ratioHot gas positive displacement engine plantsSpiral bladeMaterial requirements

The invention discloses a spiral type thrust engine, relating to a hot air variable capacity type engine device. The spiral type thrust engine comprises an engine shell and a high pressure refrigerant generating device, and also comprises a spiral type thrust generator fixedly arranged inside the engine shell. The spiral type thrust generator comprises a core shaft and a spiral blade which is fixedly arranged at the lateral side of the core shaft, takes the shaft as a rotating shaft, goes forward along the axis direction spirally and extends from the front end to the back end of the core shaft. The whole spiral blade forms a spiral type variable capacity quality guide groove which extends from the front end surface to the back end surface of the core shaft and communicates the front end surface with the back end surface on the core shaft, wherein the cross-sectional area of the groove is gradually increased from front to back in equivalent ratio difference and the front opening of the groove is communicated with a refrigerant output end thereof. The invention provides a spiral type thrust engine which adopts a new thrust generating mode, can generate thrust directly and has simple structure, long service life, easy manufacture, low material requirements, low cost and smaller energy consumption.

Owner:胡巍

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com