Secondary-flow evaporation tube type combustion chamber structure

A combustion chamber and secondary flow technology, applied in the direction of combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problems of increased NOx emissions, long residence time of combustion products, high wall temperature, etc., and achieve the effect of reducing the probability of ablation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

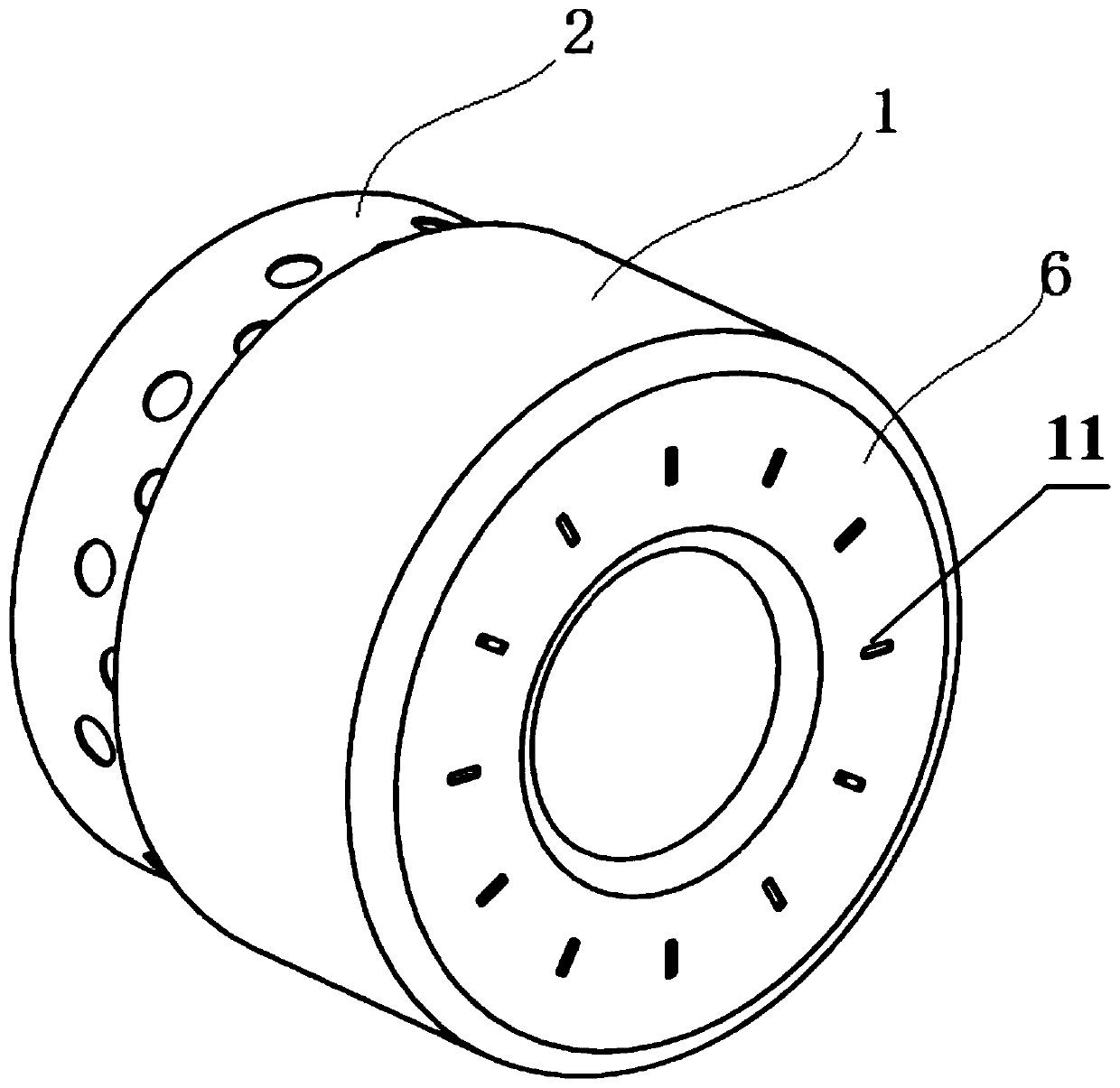

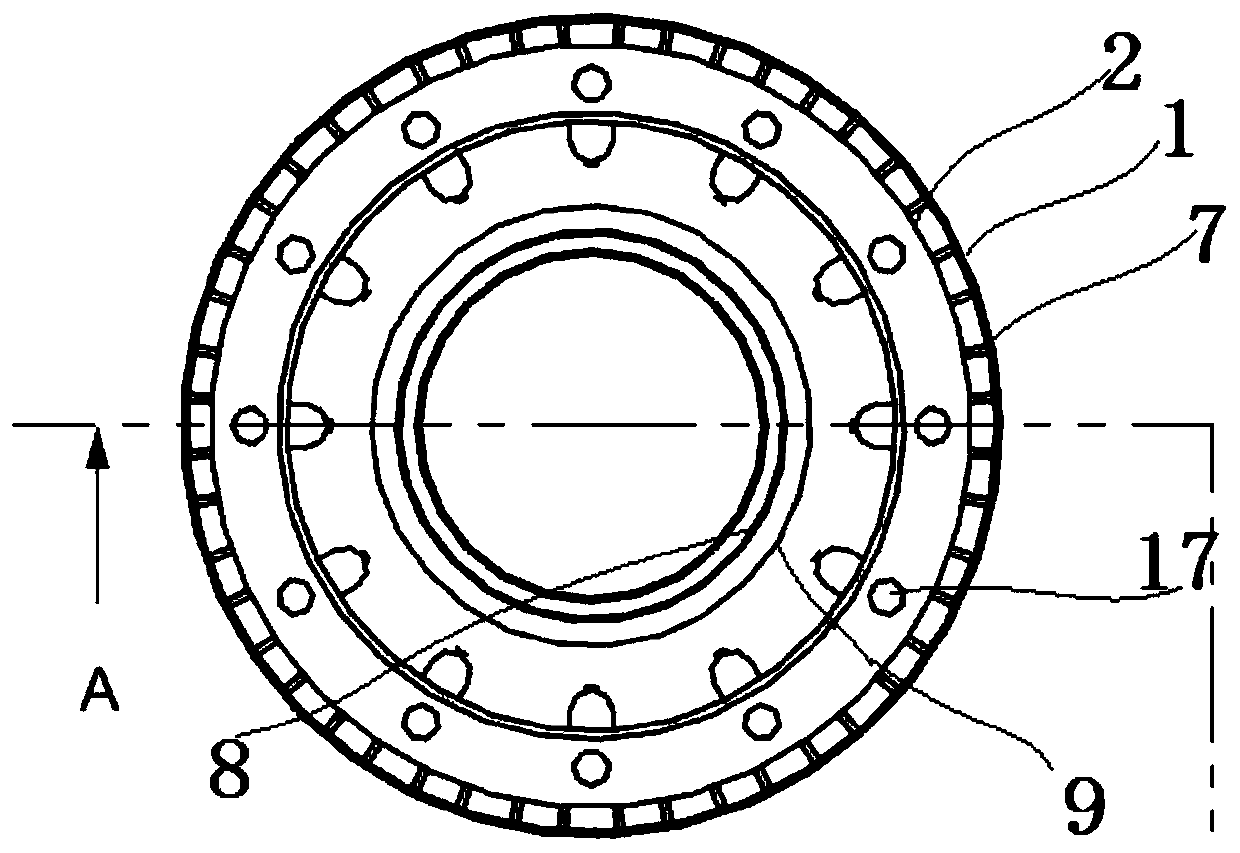

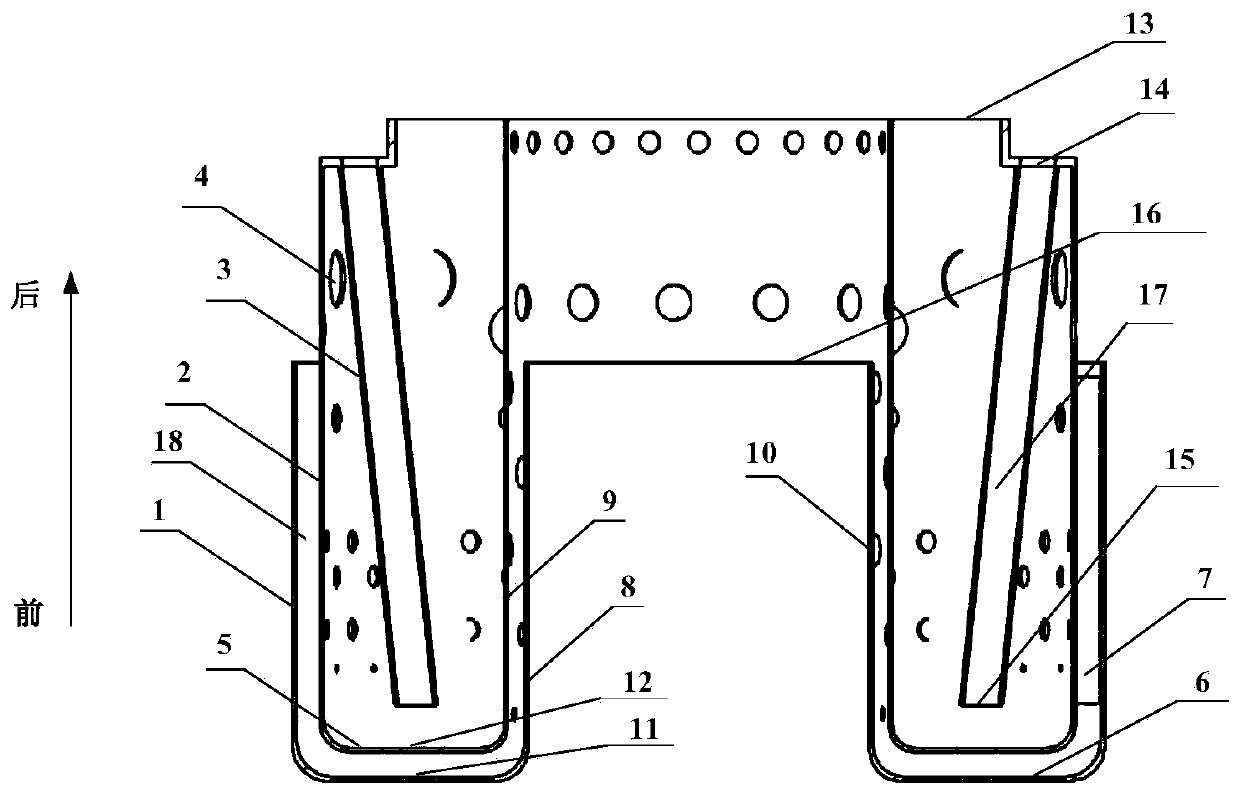

[0030] The present invention is described in further detail below in conjunction with accompanying drawing:

[0031] see Figure 1 to Figure 5 As shown, a secondary flow evaporating tube type combustion chamber structure includes a combustion chamber body 3 and a baffle plate 18. The combustion chamber body 3 includes an outer wall surface 2 of the combustion chamber, an inner wall surface 9 of the combustion chamber, a front wall surface 5 of the combustion chamber and a rear wall surface of the combustion chamber. The end wall surface 13 forms a flame cylinder between the combustion outer wall surface 2 and the combustion inner wall surface 9; the combustion outer wall surface 2, the combustion chamber wall surface 9 and the combustion chamber front end wall surface 5 are all provided with air film holes, and there is a circle outside the combustion chamber wall surface 2 Baffle 18, baffle 18 comprises baffle outer wall 1, baffle front end wall 6, baffle inner wall 8 and baf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com