An evaporating tube type compact combustion chamber

A technology of evaporating tubes and combustion chambers, which is applied in the field of combustion systems of micro-miniature aero-engines, can solve the problems of low air film coverage, limited cooling effect, and large flow loss, and achieve optimized jet flow field, improved efficiency, and stable combustion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

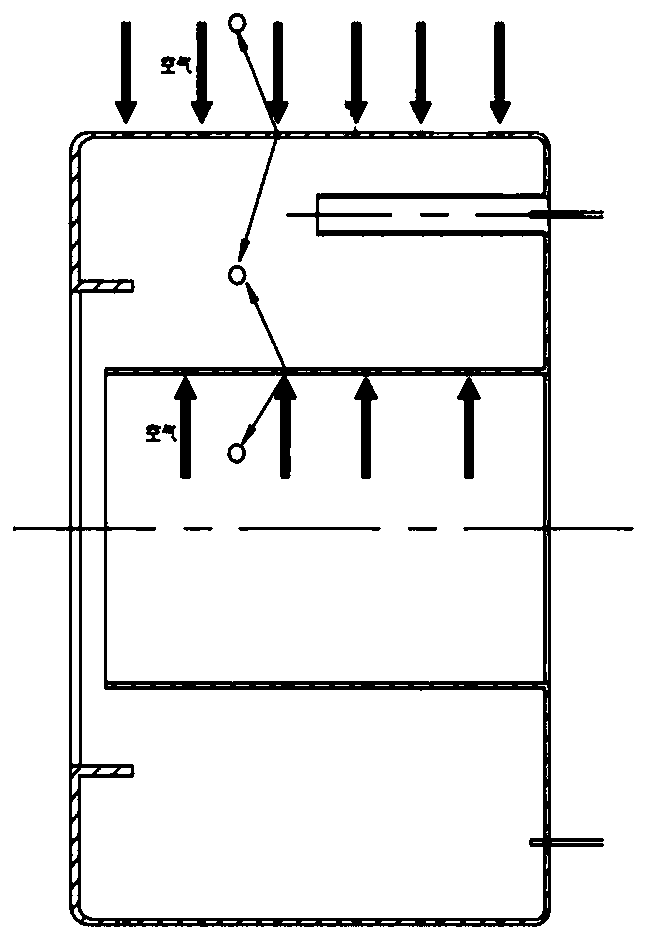

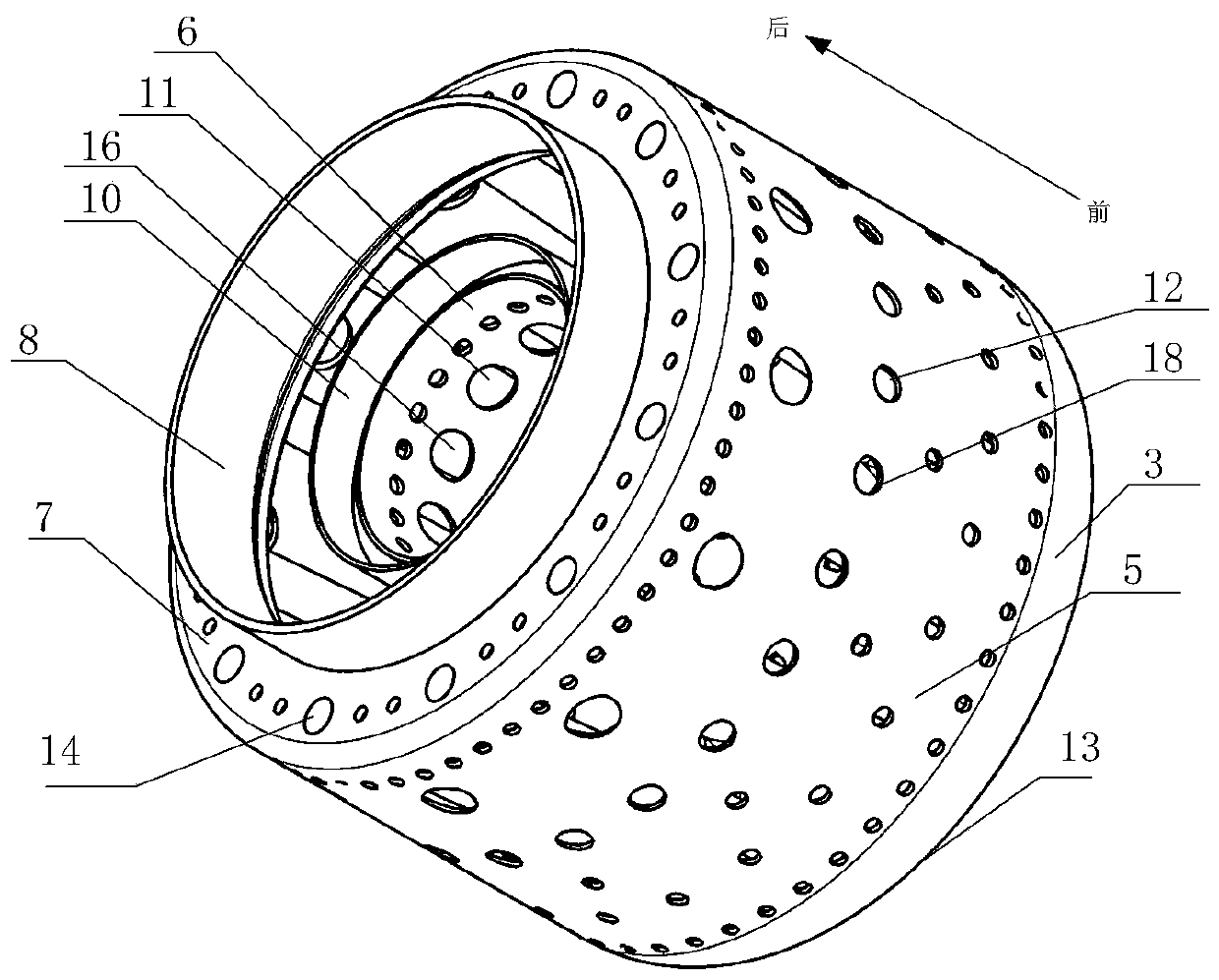

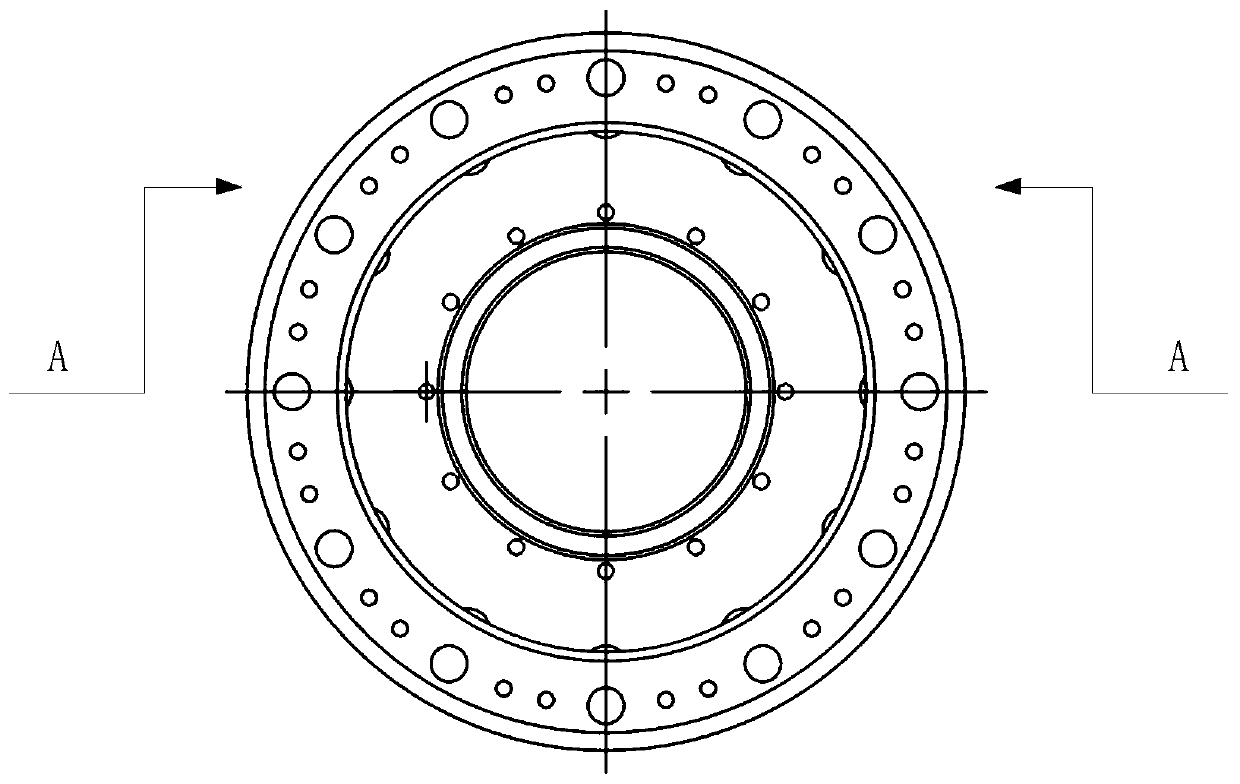

[0035] see figure 2 and image 3 , the invention discloses an evaporating tube type compact combustion chamber; the combustion chamber includes an outer wall 5 and an inner wall 6, both of which are cylindrical structures, and the diameter of the cylindrical barrel formed by the inner wall 6 is smaller than that of the cylindrical barrel formed by the outer wall 5 The diameter of the barrel, the height of the cylindrical barrel formed by the inner wall 6 is smaller than the height of the cylindrical barrel formed by the outer wall 5, the front end of the outer wall 5 and the front end of the inner wall 6 are connected by a curved wall surface 3, the curved wall surface 3 protrudes to the outside, and the curvature of the curved wall surface 3 2π / 3~π, that is, the degree of the curved wall surface 3 is 120°~180°, so that the incoming air fits t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com