Patents

Literature

31 results about "Field homogeneity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Resonator system

ActiveUS7193418B2Improve efficiencySmall angleMagnetic measurementsElectric/magnetic detectionElectricityResonance

Owner:BRUKER SWITZERLAND AG

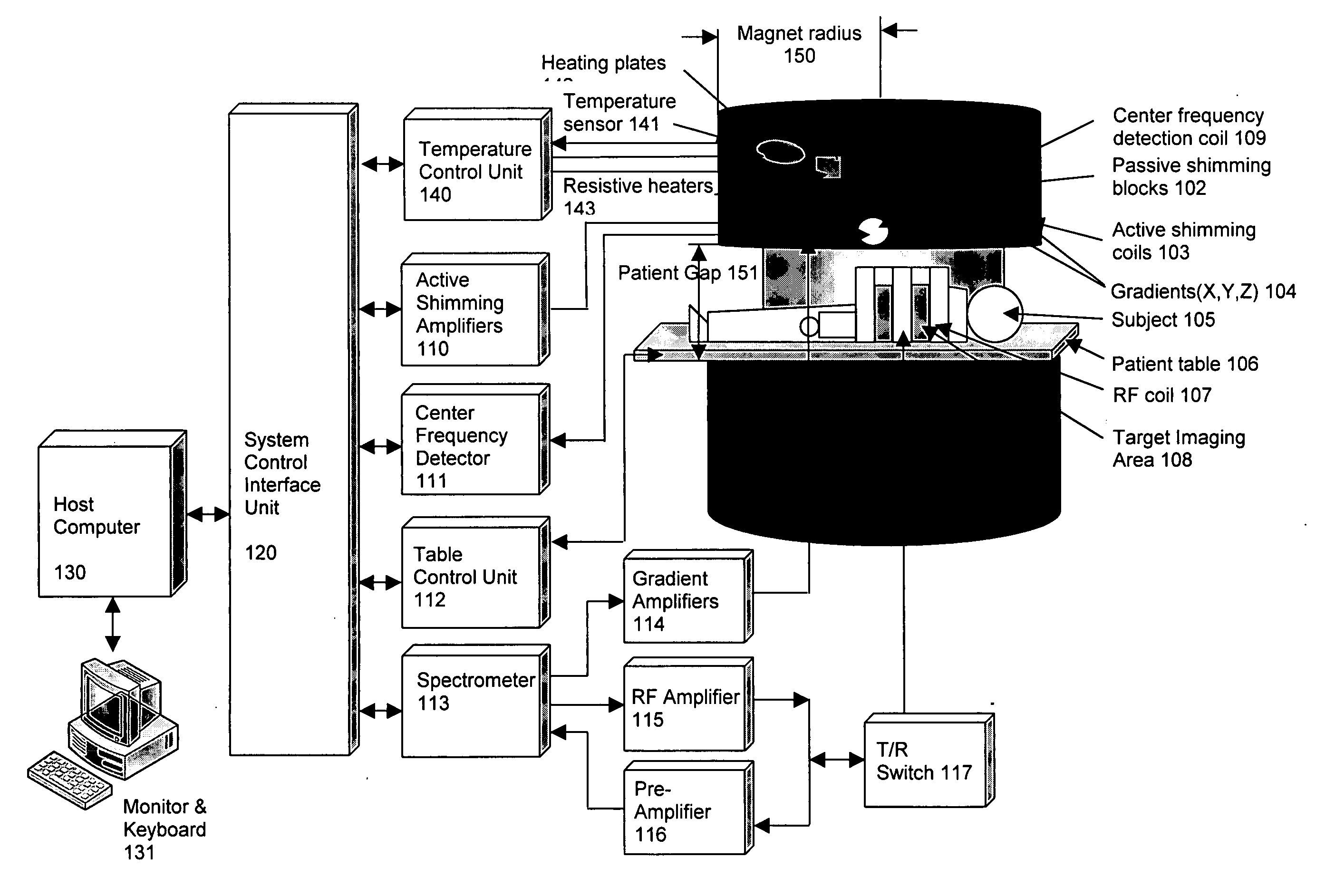

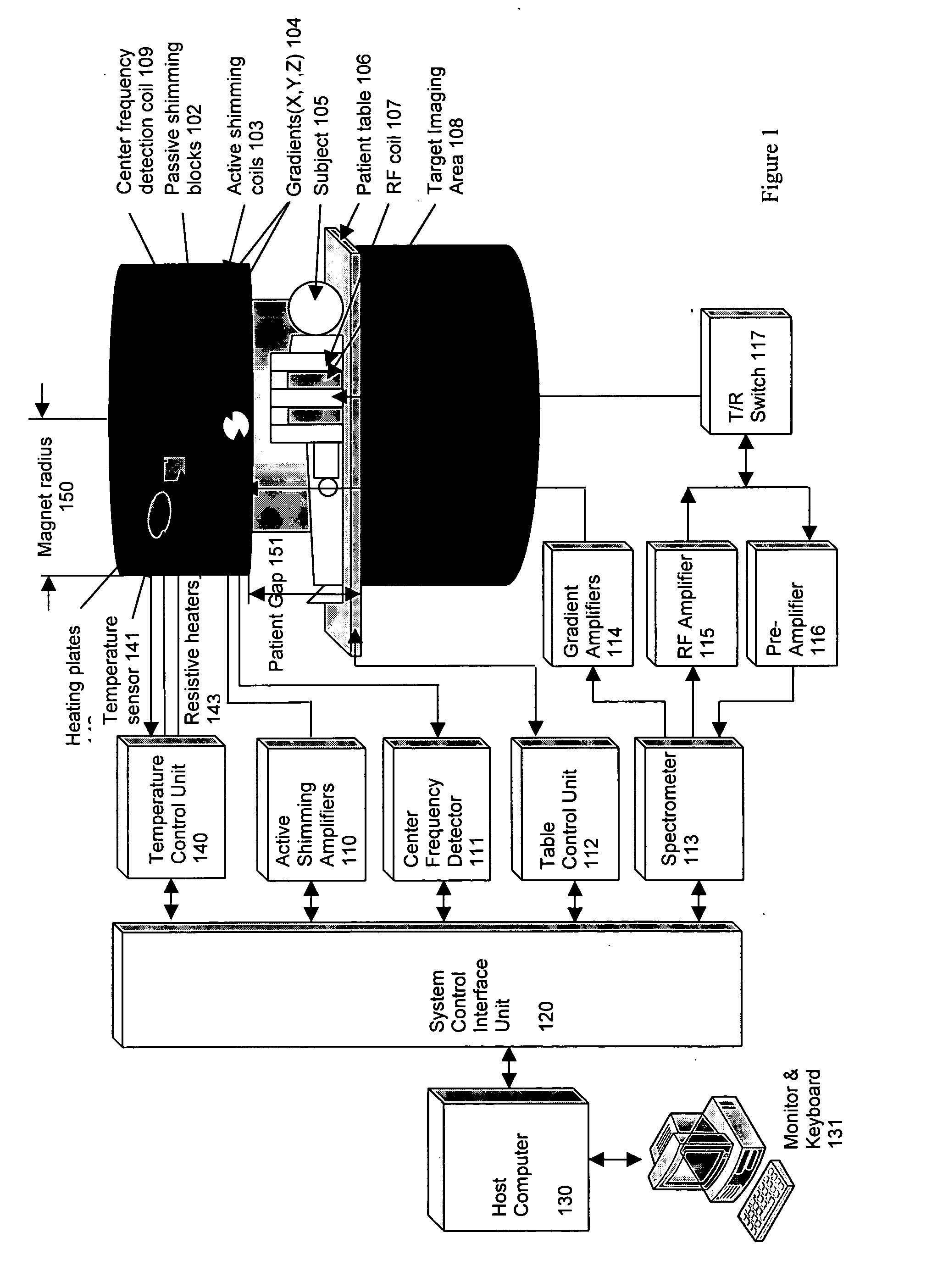

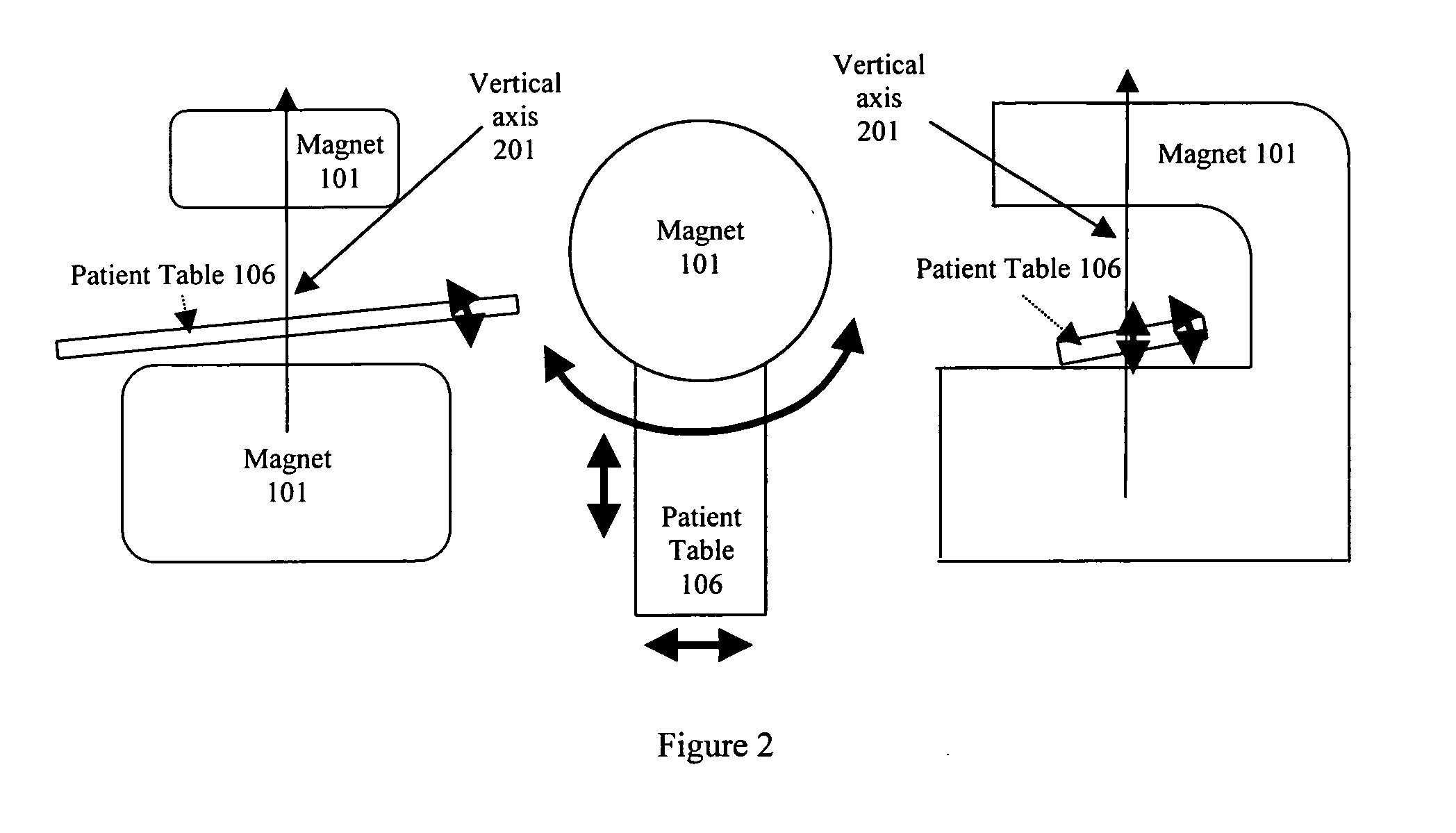

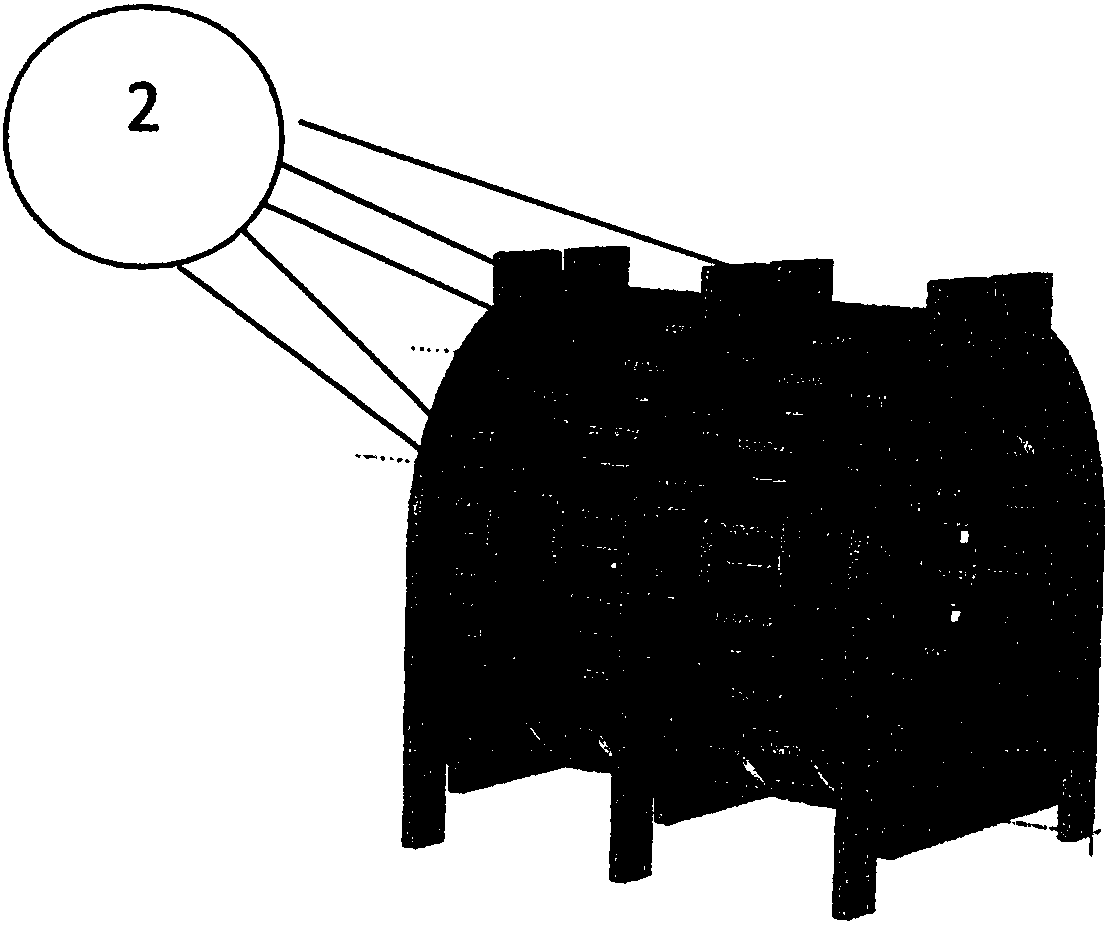

Method of using a small MRI scanner

InactiveUS20050154291A1Close accessMore accessDiagnostic recording/measuringSensorsCost effectivenessWhole body

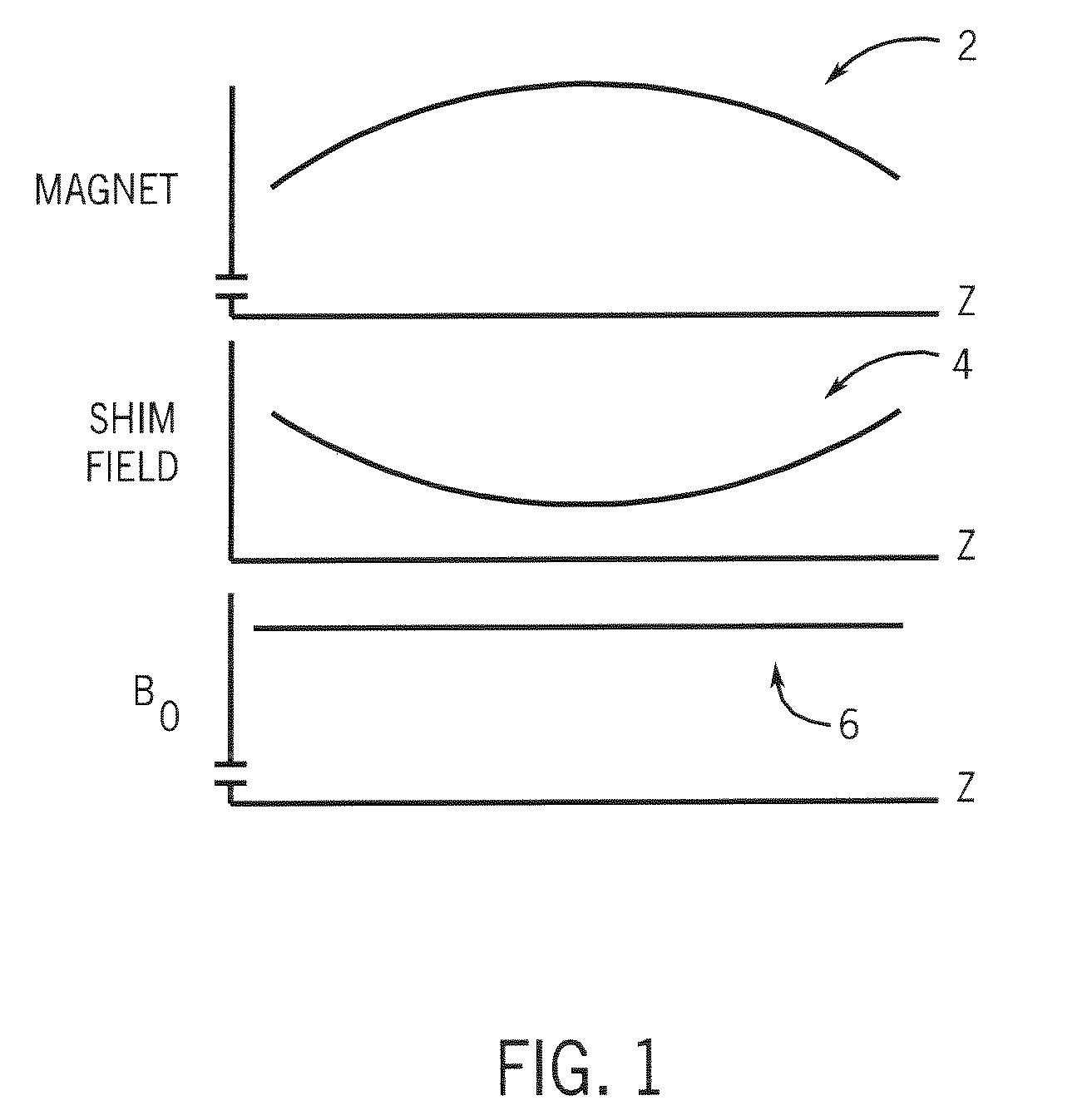

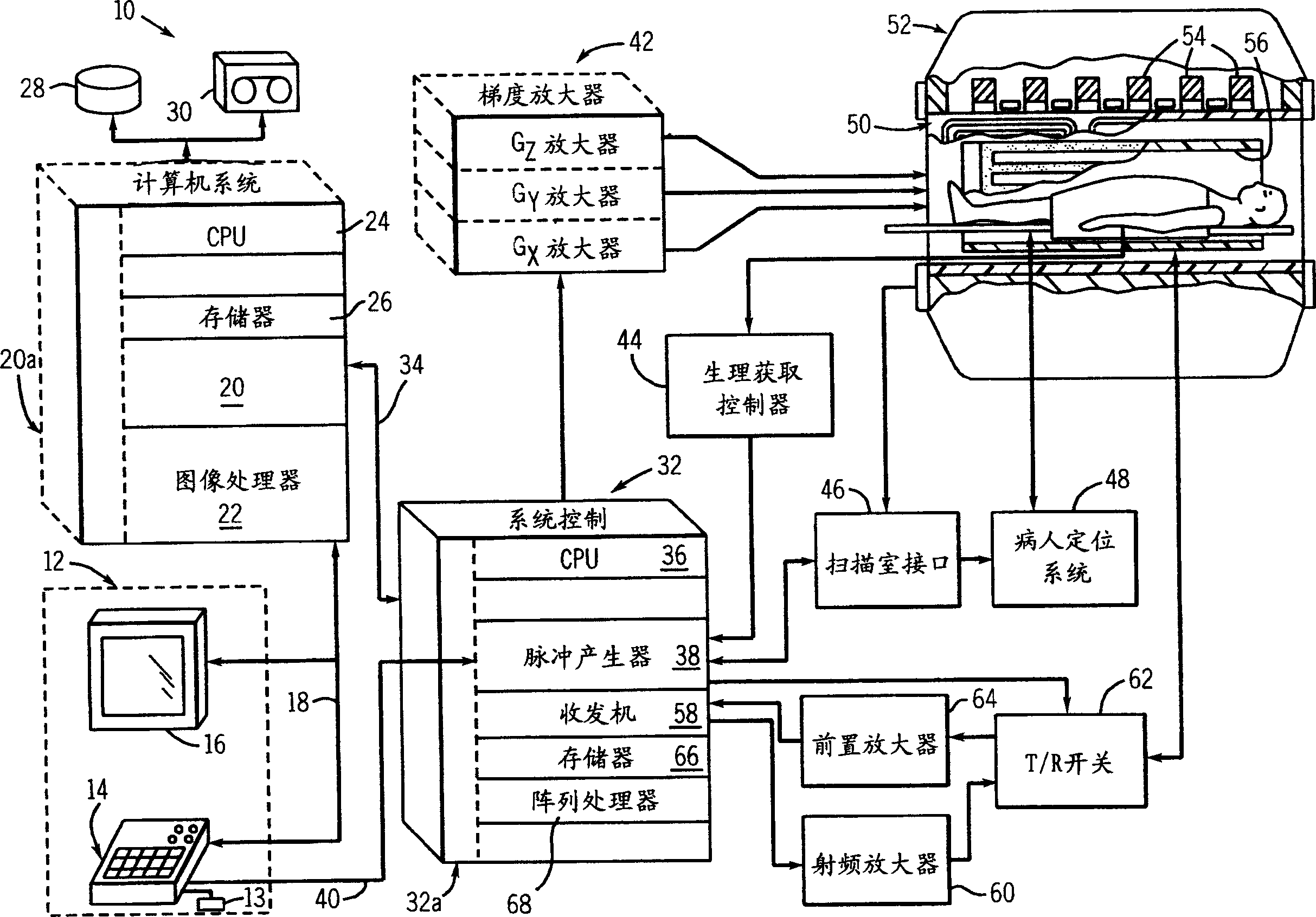

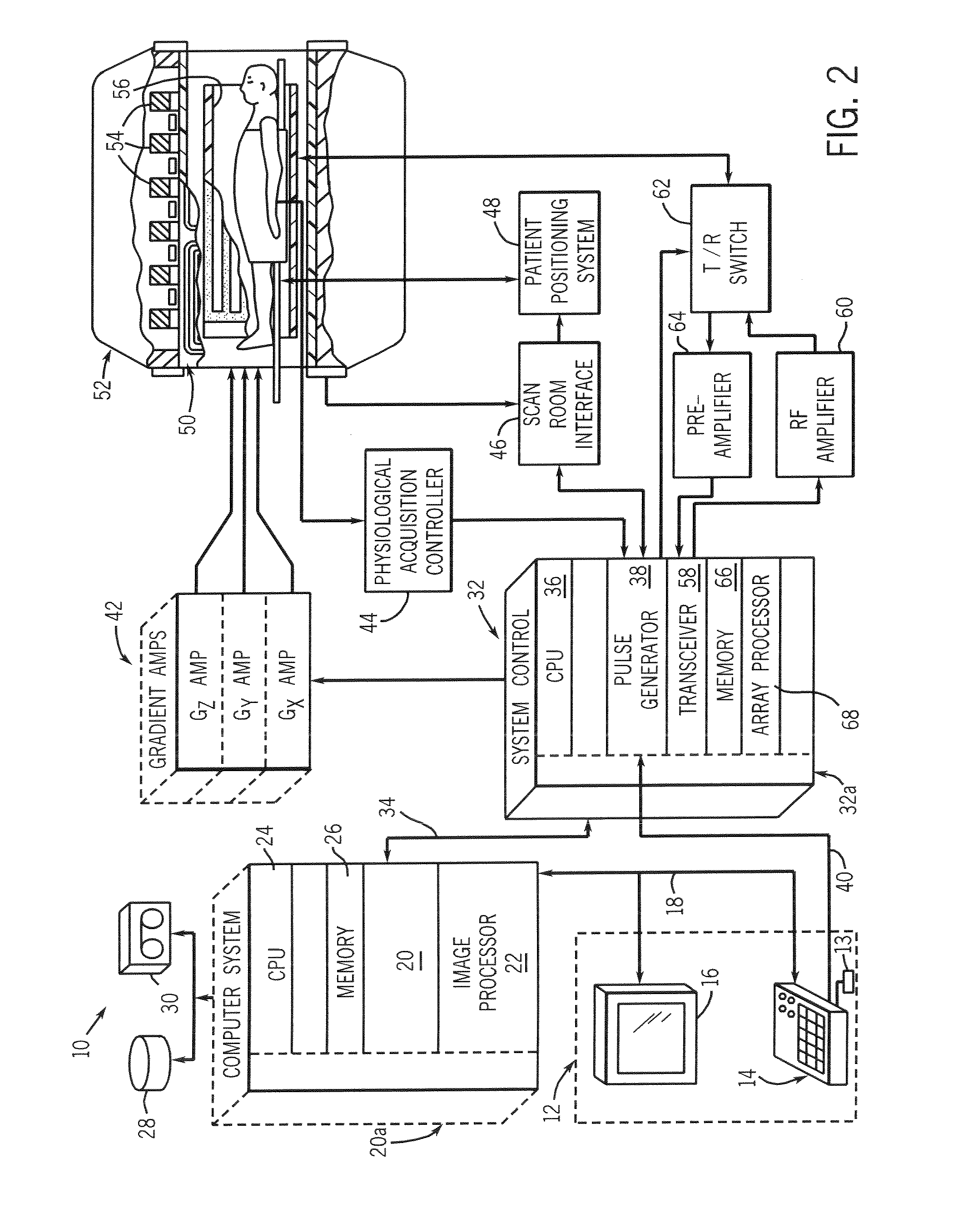

Multiple methods of performing whole body scans using a cost-effective small magnetic resonance imaging (MRI) system are disclosed. High magnetic field homogeneity of an open, small MRI is obtained by a combination of passive shimming and high order active shimming. A dynamic shimming while imaging (DSWI) method is provided to dynamically optimize field homogeneity for each scanned slab (slice) during imaging. Also provided is a method that scan a large subject volume only using a limited optimal imaging region of a magnet by continuously adjusting patient position and orientations with a 6 degrees of freedom patient table.

Owner:ZHAO LEI +2

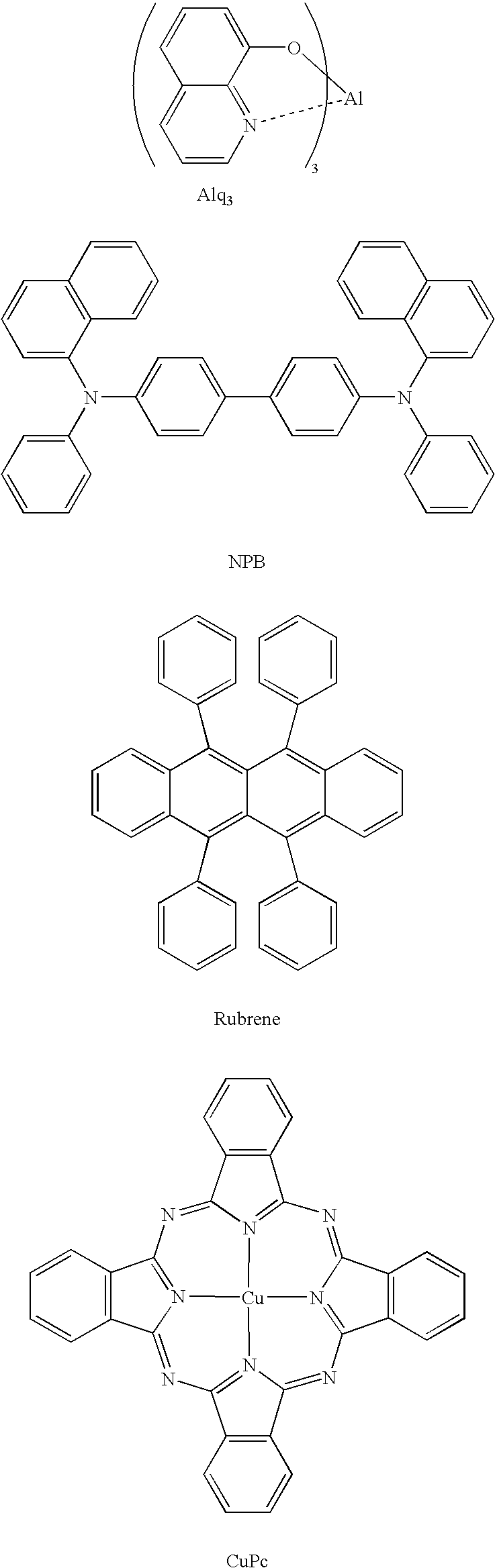

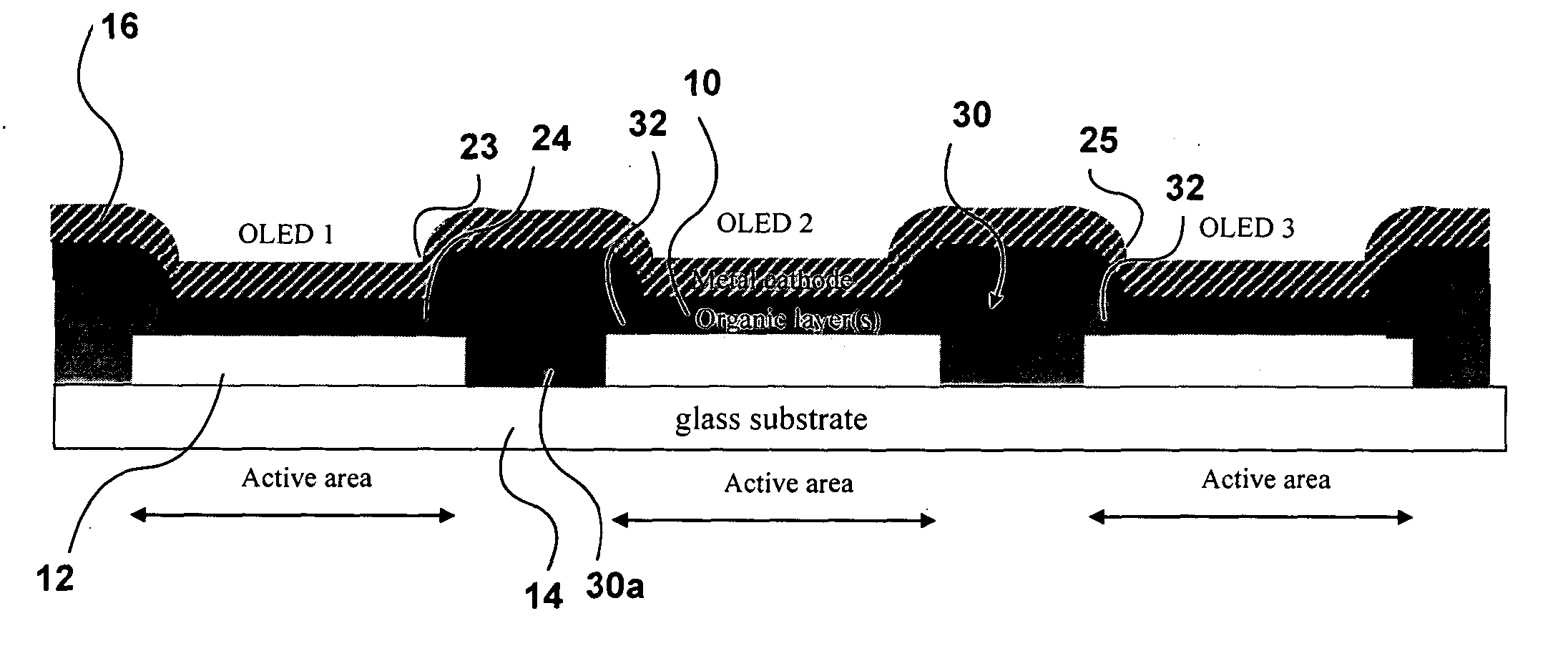

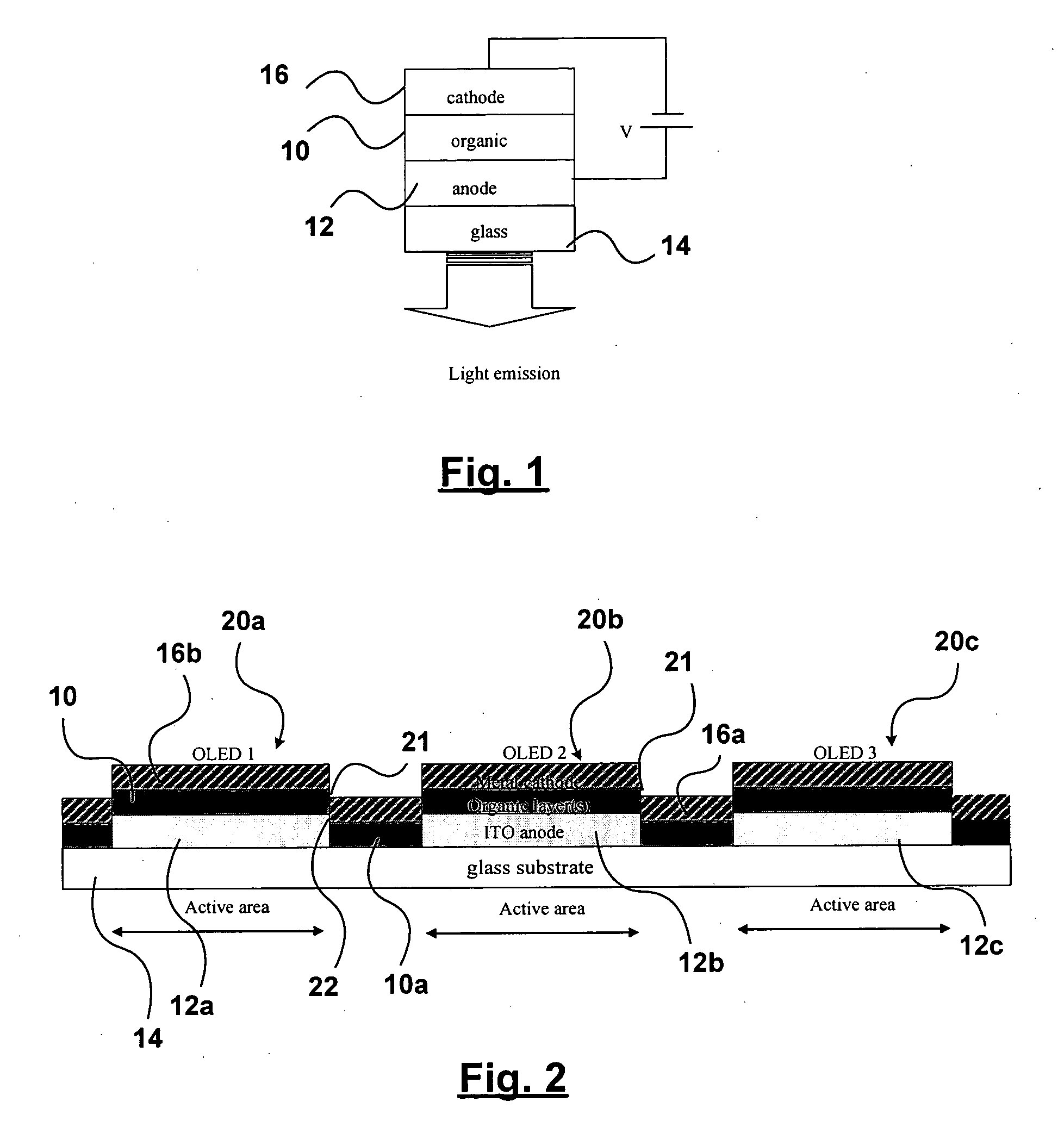

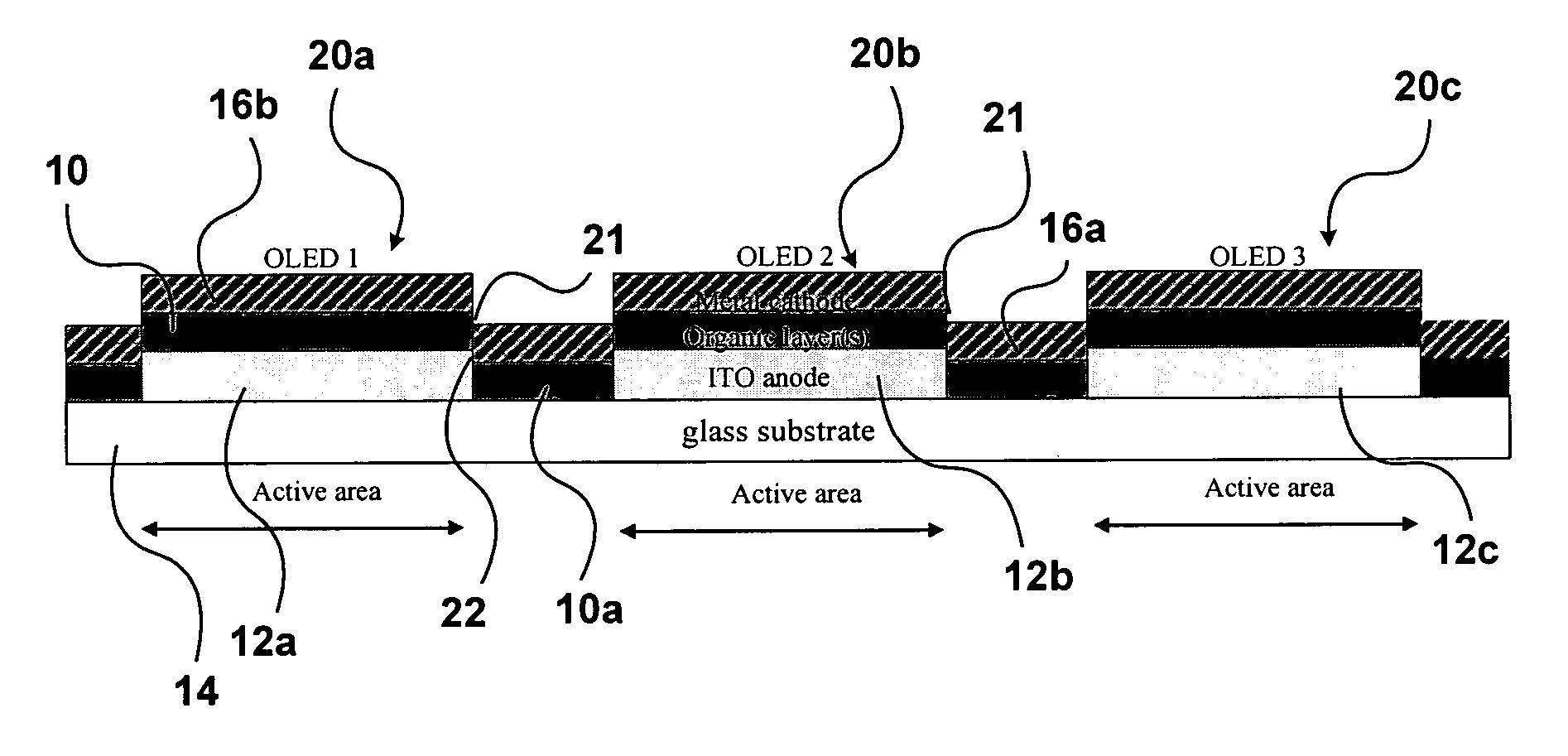

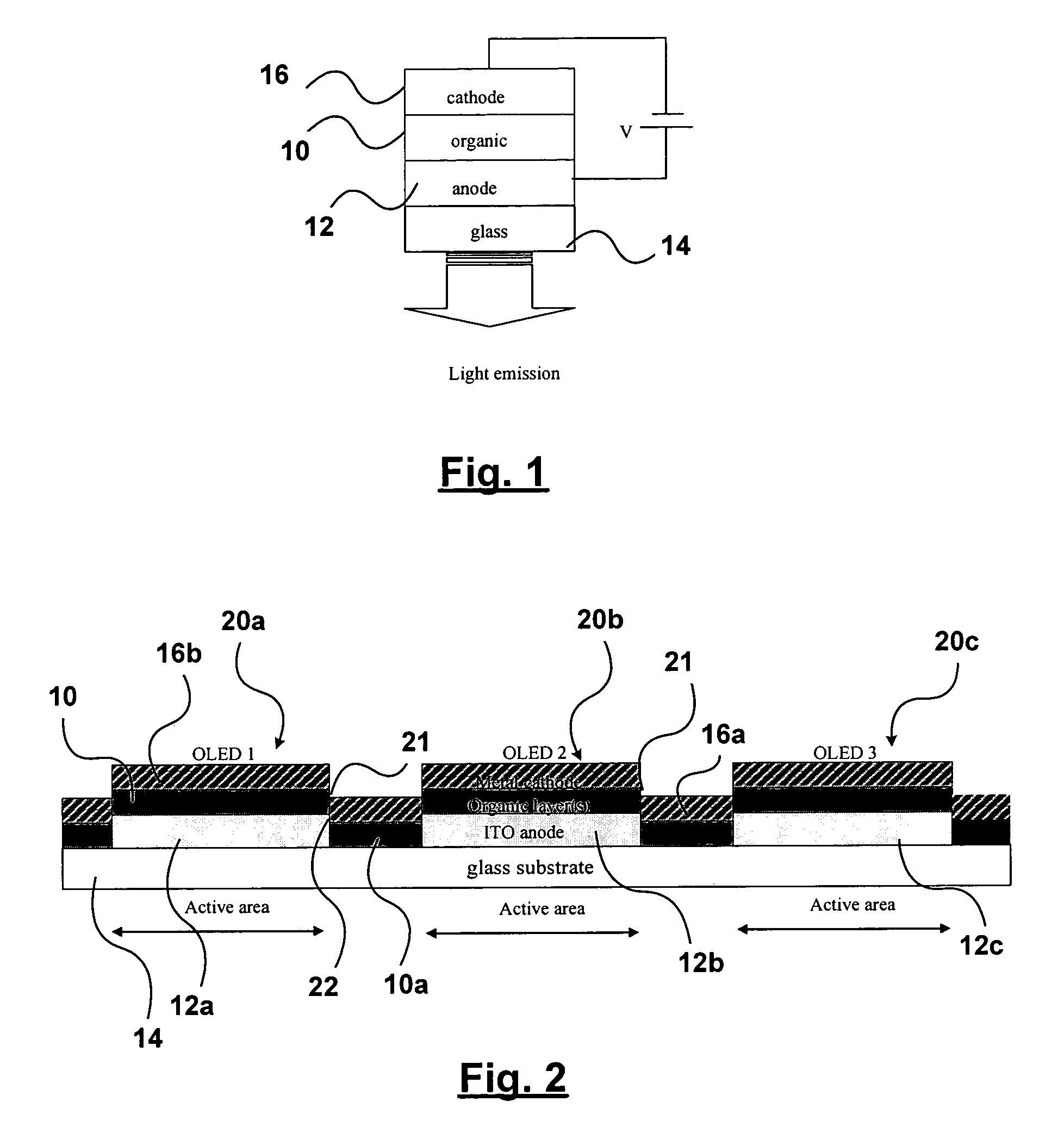

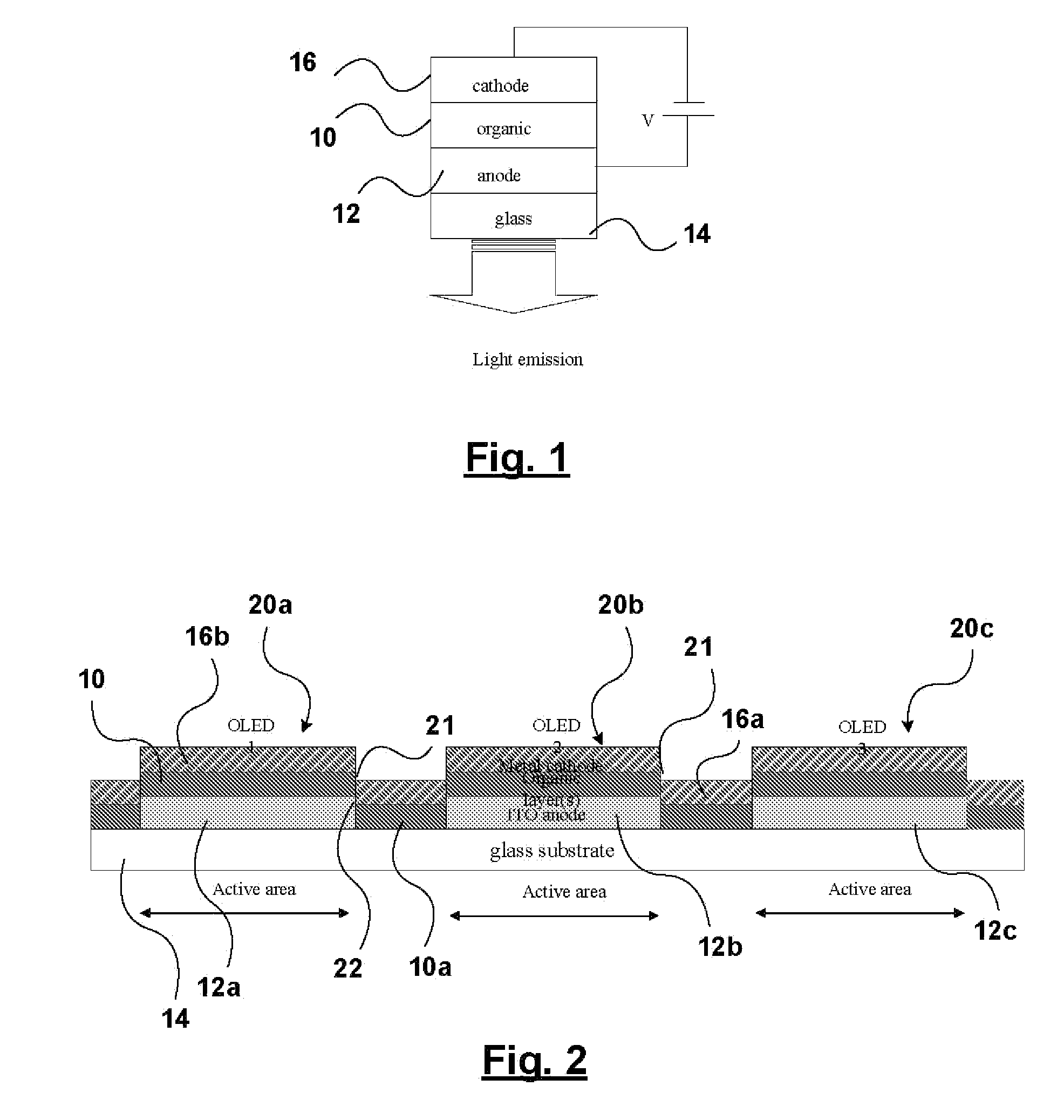

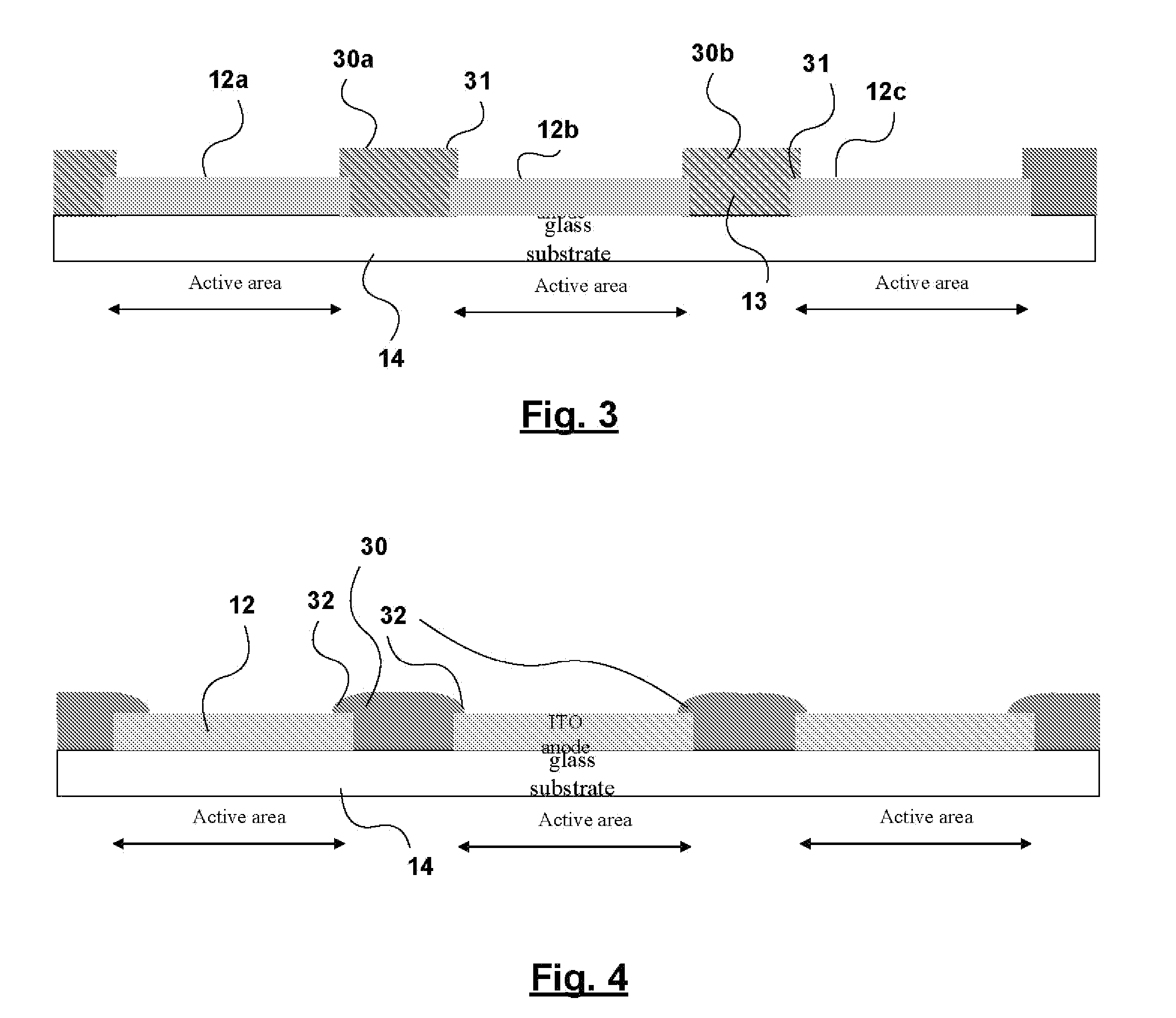

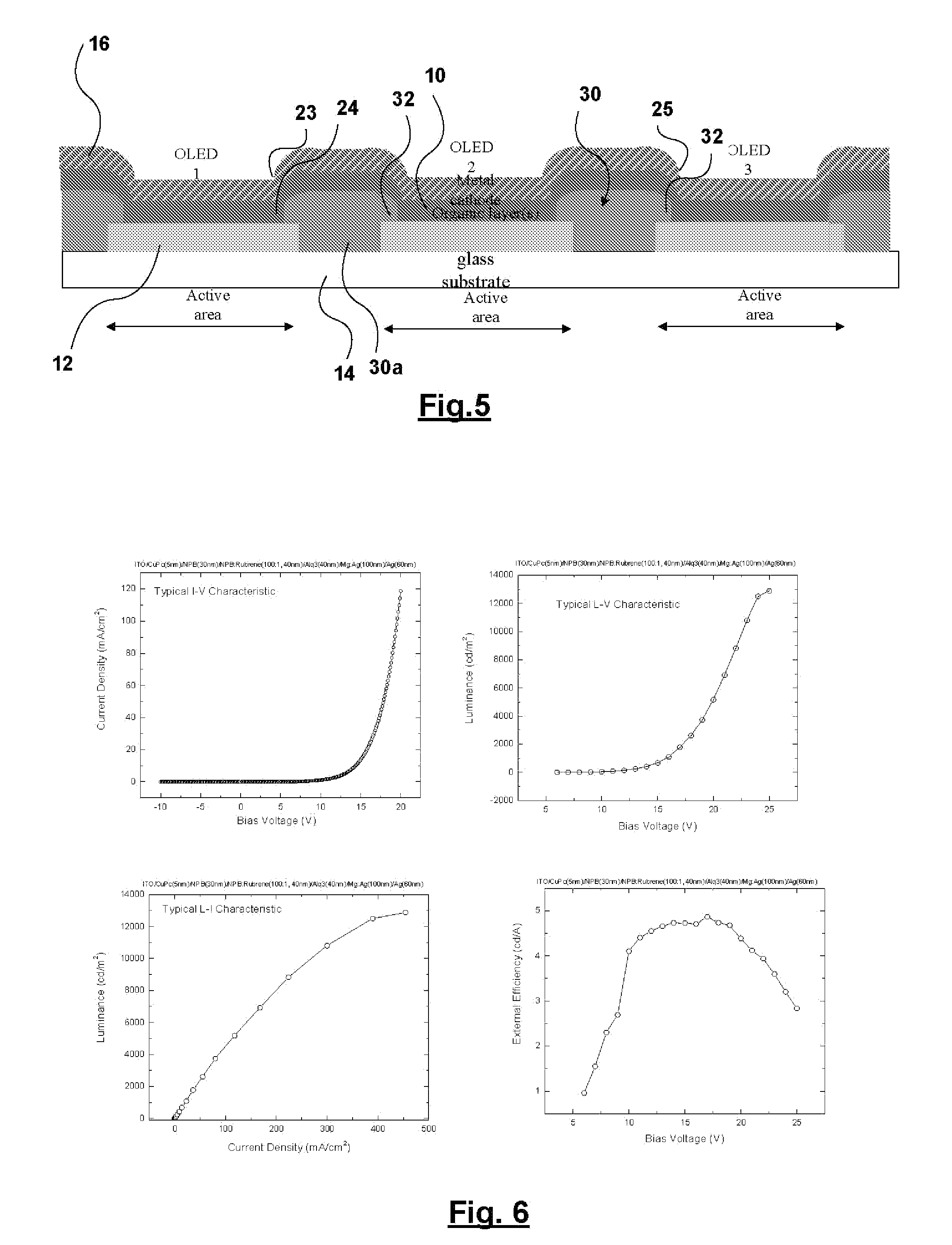

Photoresist mask/smoothing layer ensuring the field homogeneity and better step-coverage in OLED displays

InactiveUS20040075385A1Discharge tube luminescnet screensElectroluminescent light sourcesOrganic light emitting deviceComputational physics

A method of making an organic light emitting device (OLED) is disclosed wherein an inert insulating conformal smoothing layer is deposited over a protruding structure. The smoothing layer is patterned to expose portions of the structure underlying the smoothing layer and defining active regions of the device. The inert smoothing layer is treated, preferably by heat reflow, to taper the layer over the stepped edges of the structure on the exposed portions. Additional layers are then deposited over the smoothing layer and the exposed portions of the structure. The smoothing layer blunts all underlying layer edges and provides sloped edges wherever a step occurs from one layer to another. This effect results in a homogeneous field across the pixel and the continuity in the layers deposited after the photoresist layer.

Owner:NAT RES COUNCIL OF CANADA

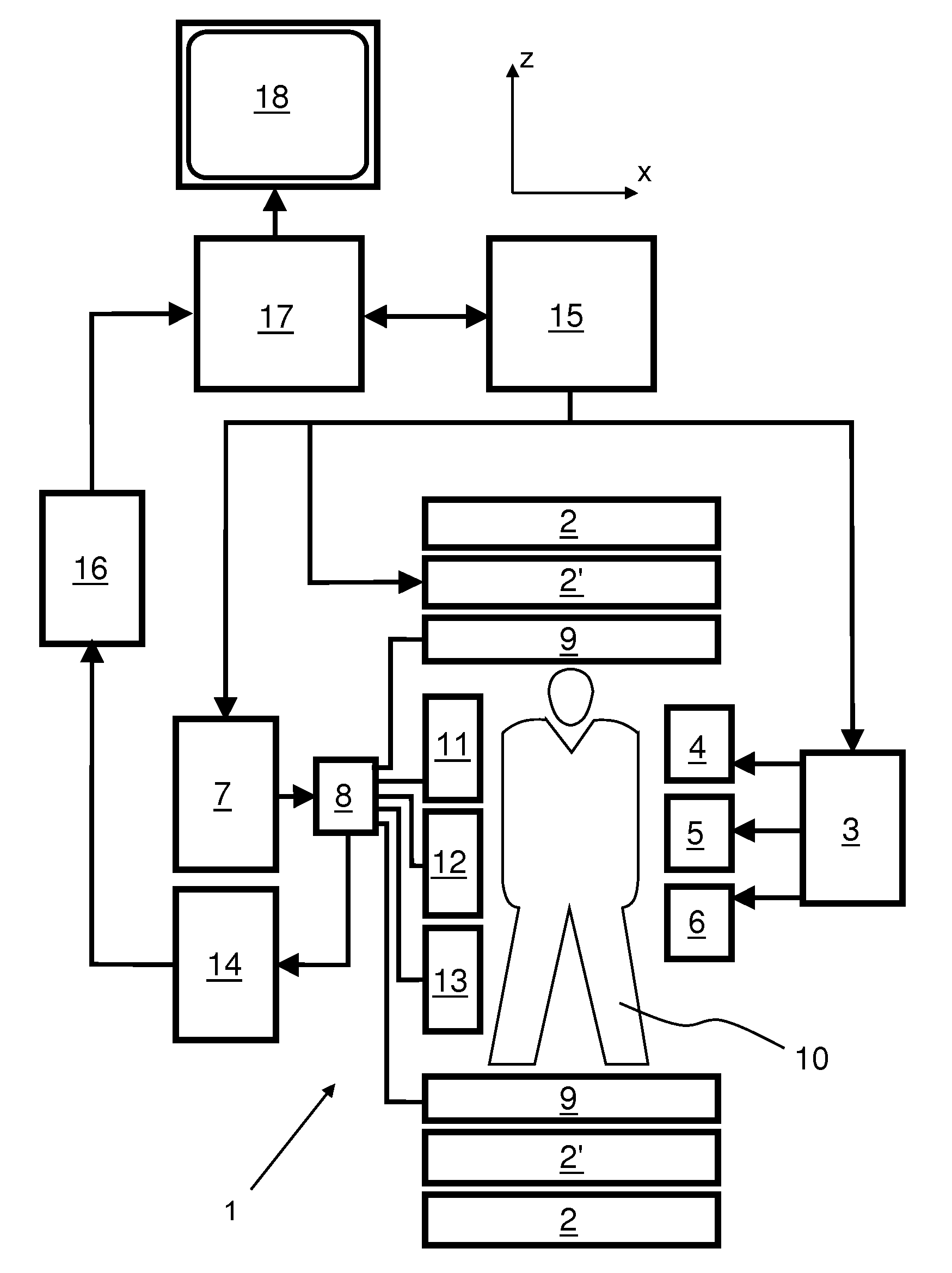

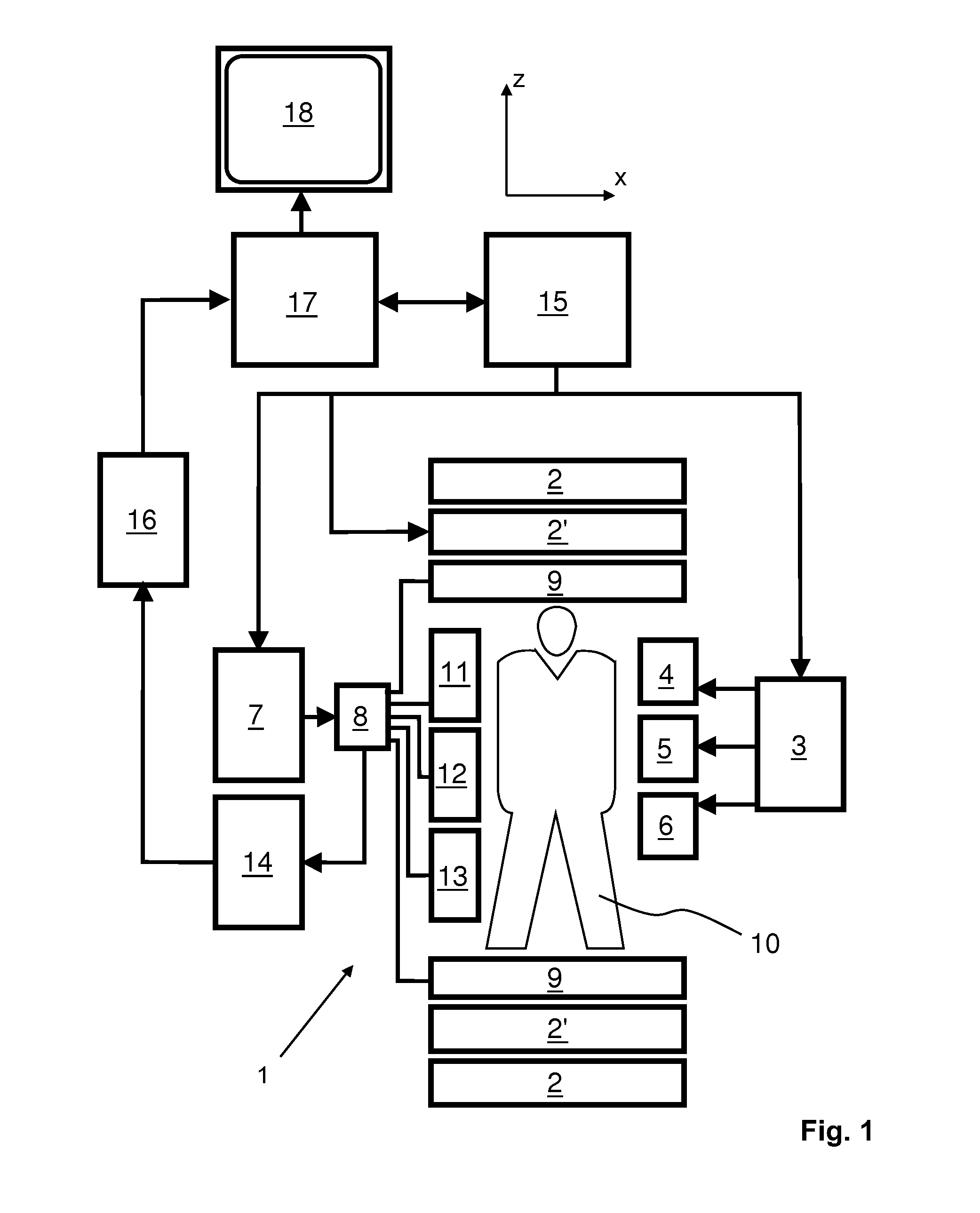

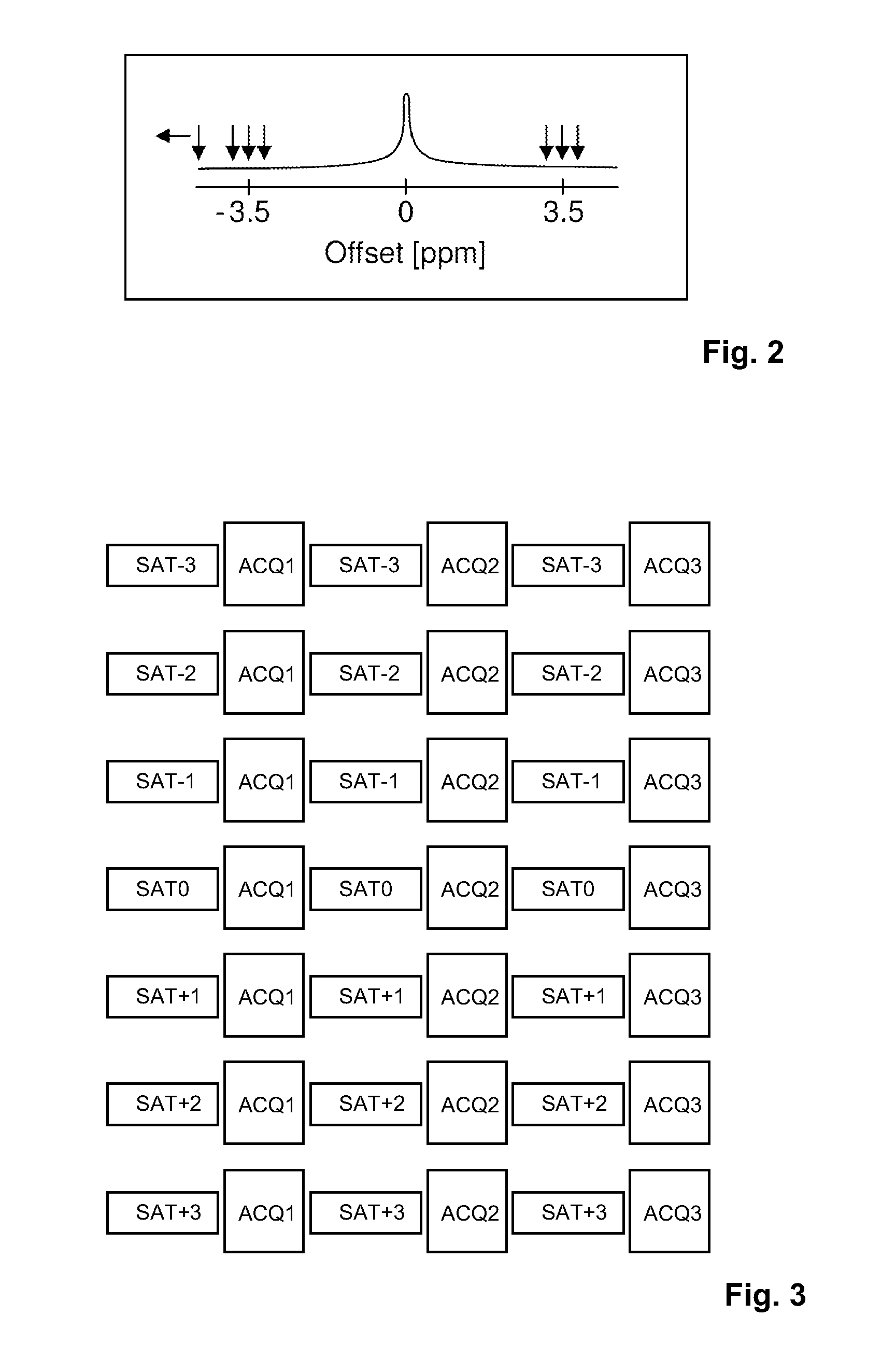

Mr imaging using apt contrast enhancement and sampling at multple echo times

ActiveUS20150051474A1Improved MR imaging techniqueHigh-quality and high contrast-to-noise MR imagingDiagnostic recording/measuringMeasurements using NMR imaging systemsMagnetic field gradientContrast enhancement

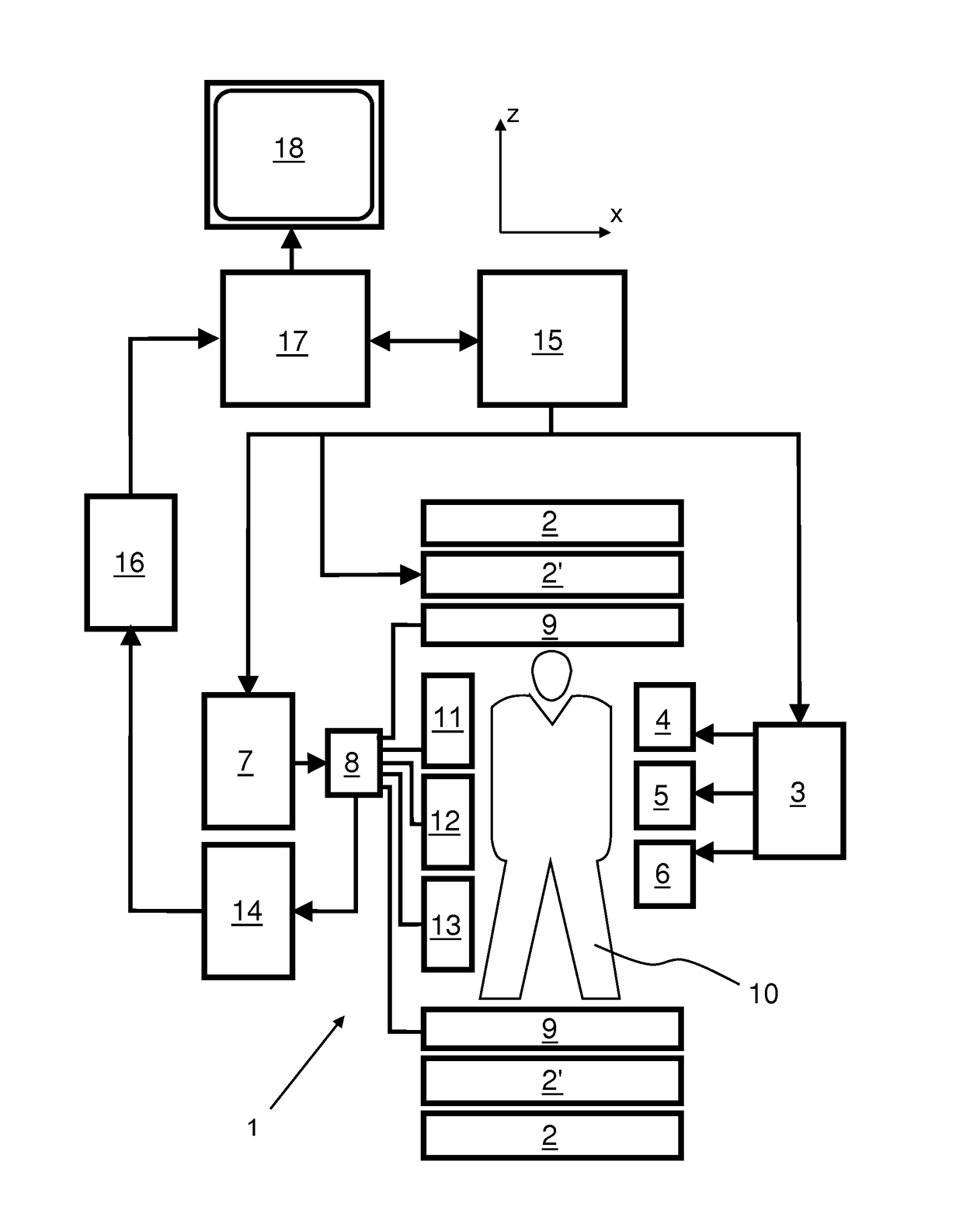

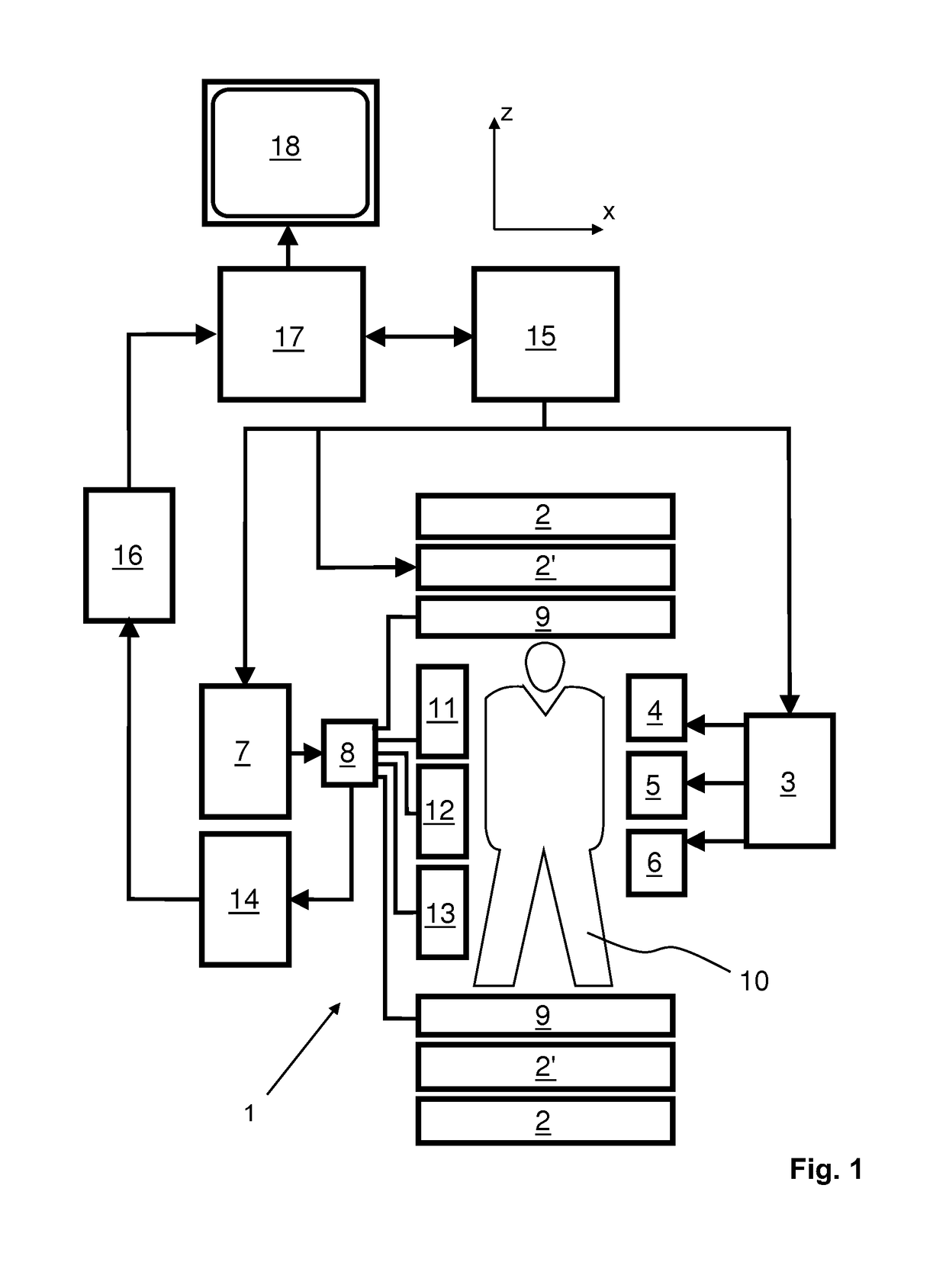

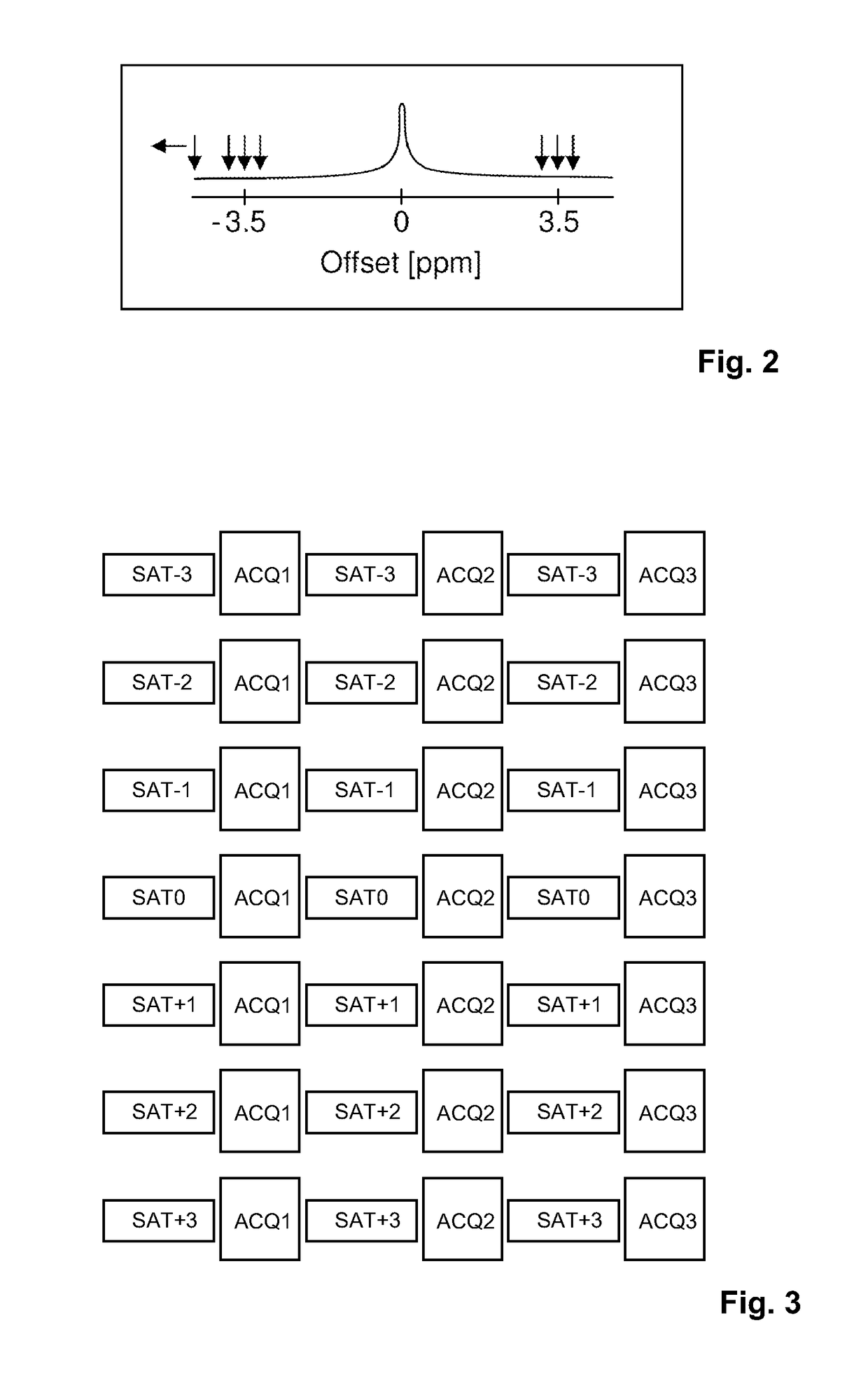

The invention relates to a method of CEST or APT MR imaging of at least a portion of a body (10) placed in a main magnetic field B0 within the examination volume of a MR device. The method of the invention comprises the following steps: •a) subjecting the portion of the body (10) to a saturation RF pulse at a saturation frequency offset; •b) subjecting the portion of the body (10) to an imaging sequence comprising at least one excitation / refocusing RF pulse and switched magnetic field gradients, whereby MR signals are acquired from the portion of the body (10) as spin echo signals; •c) repeating steps a) and b) two or more times, wherein the saturation frequency offset and / or a echo time shift in the imaging sequence are varied, such that a different combination of saturation frequency offset and echo time shift is applied in two or more of the repetitions; •d) reconstructing a MR image and / or B0 field homogeneity corrected APT / CEST images from the acquired MR signals. Moreover, the invention relates to a MR device (1) for carrying out the method of the invention and to a computer program to be run on a MR device.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

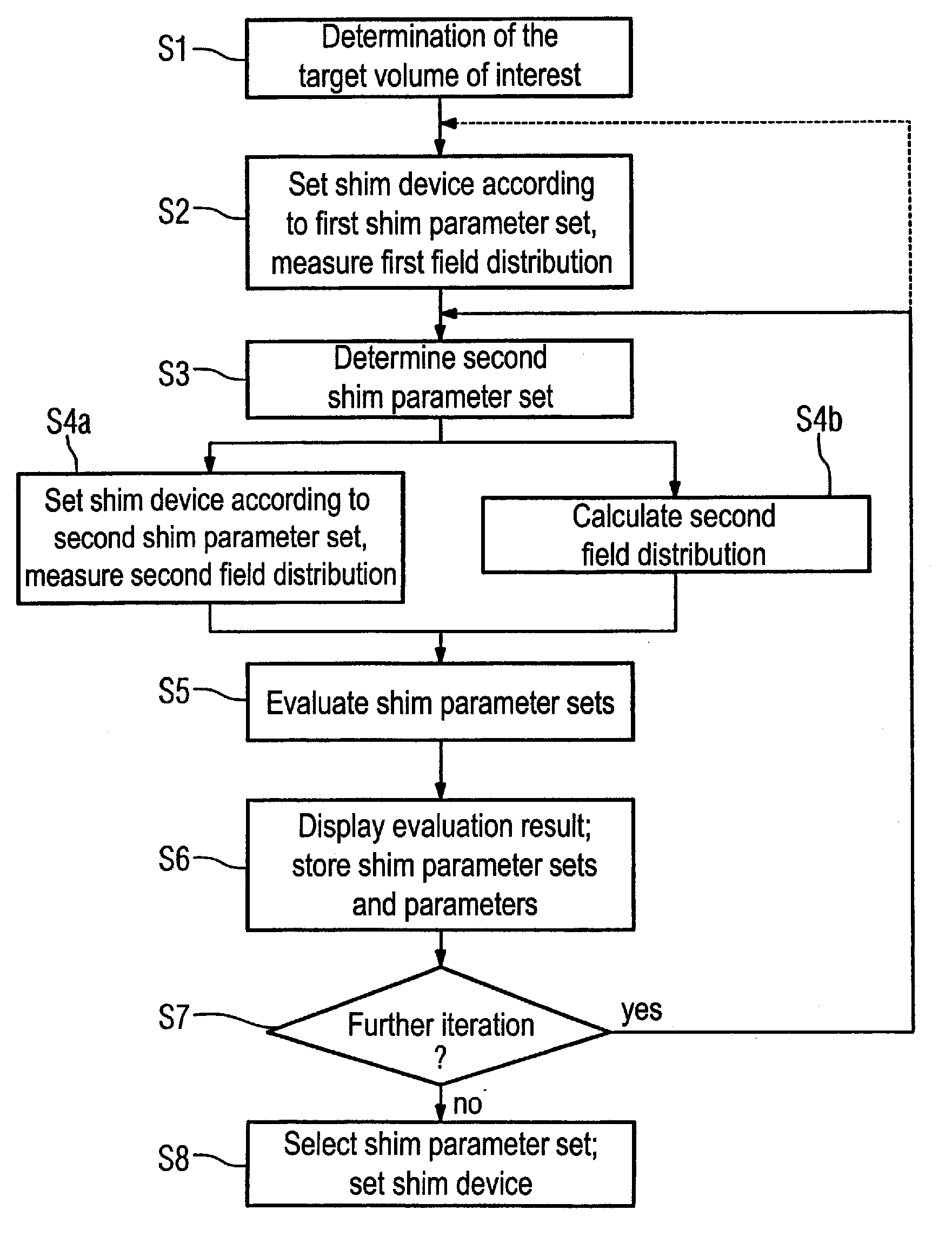

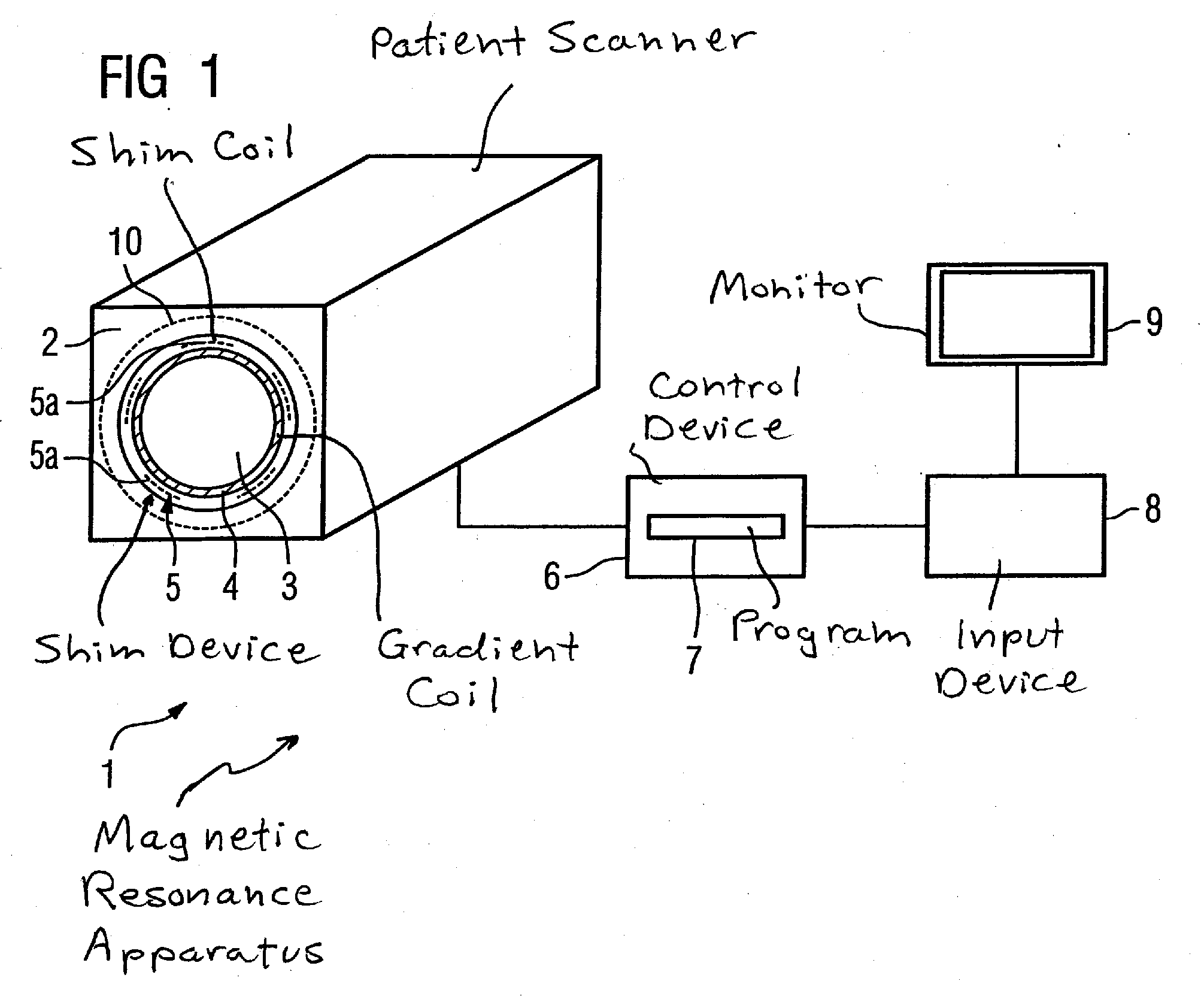

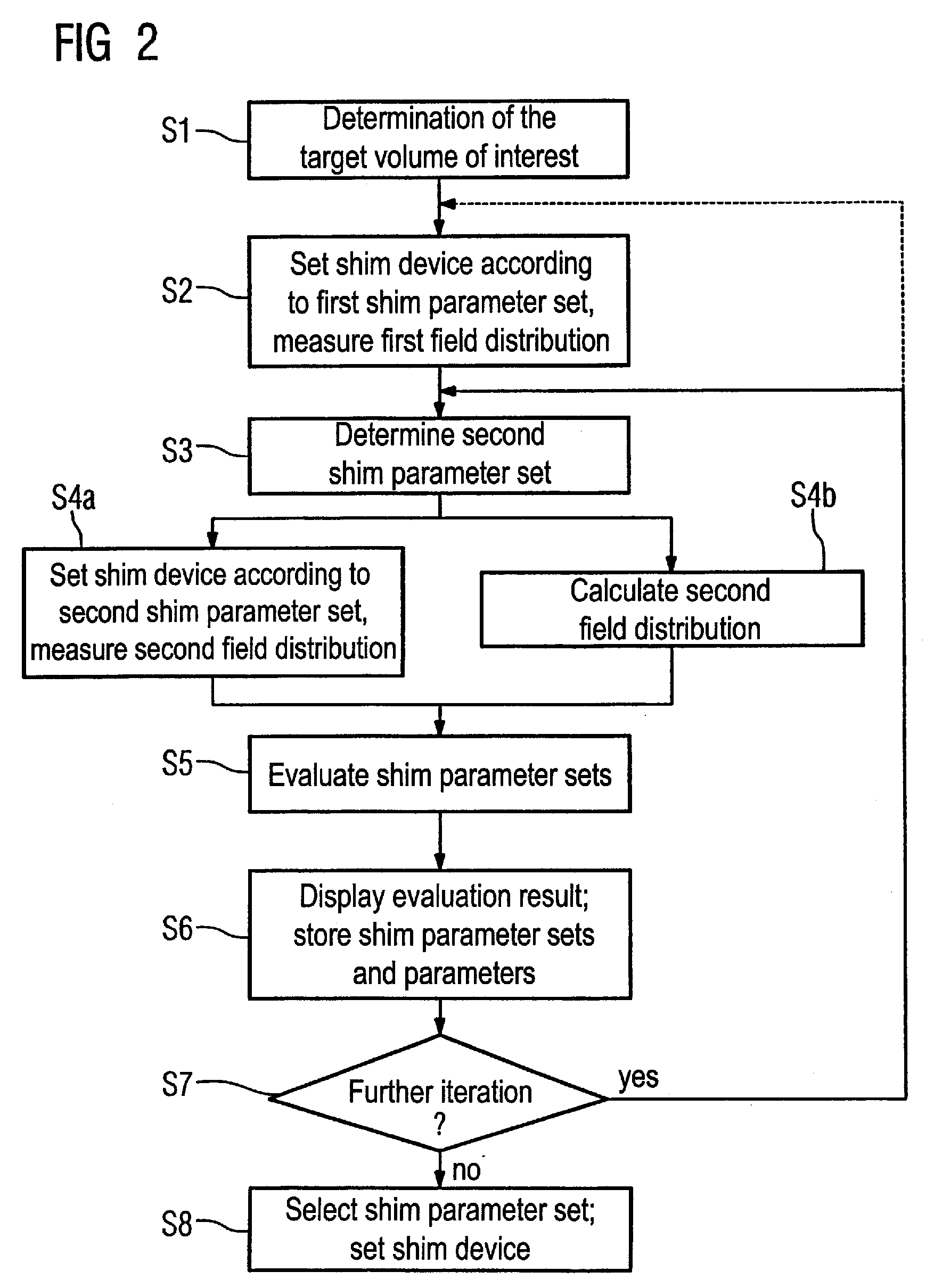

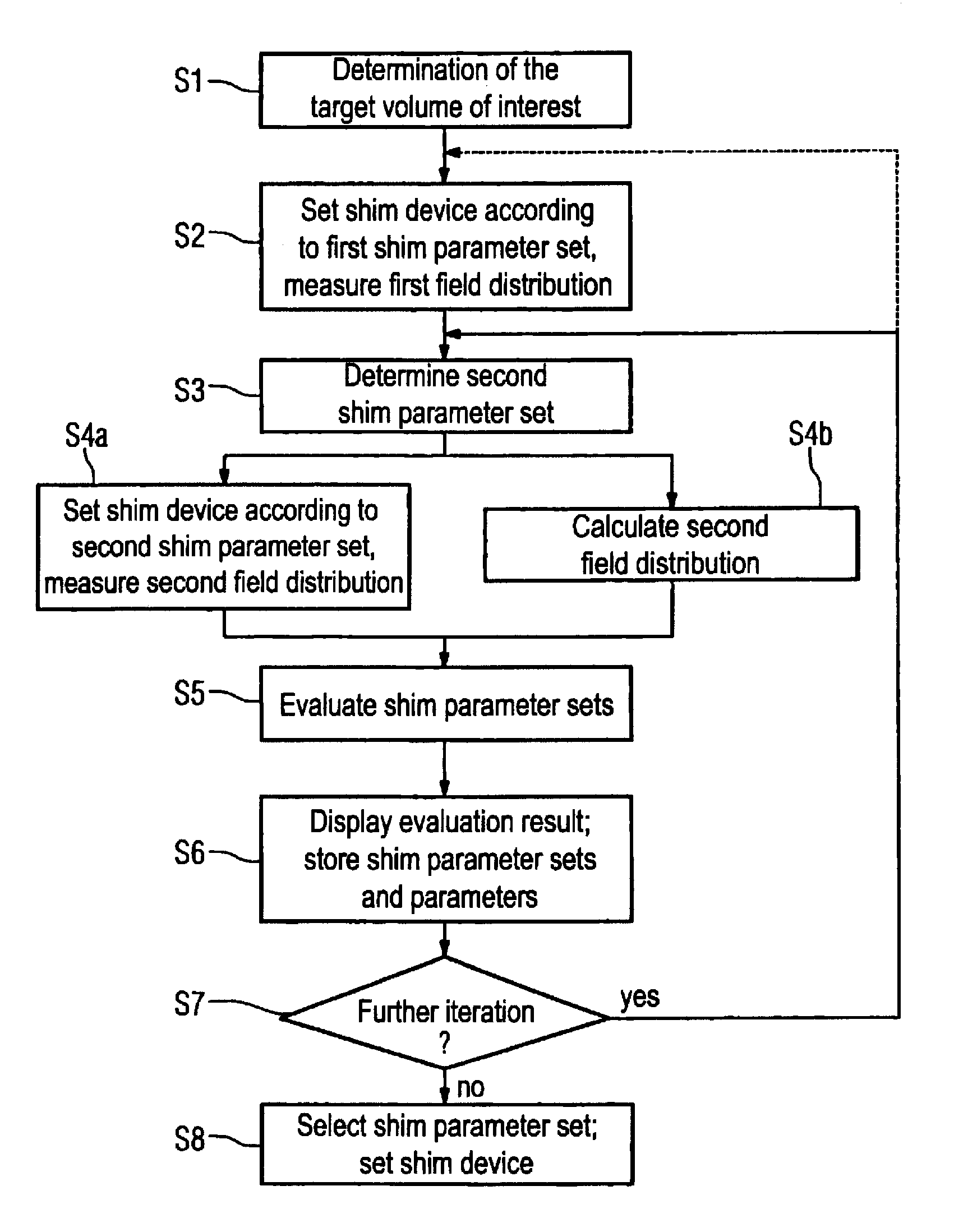

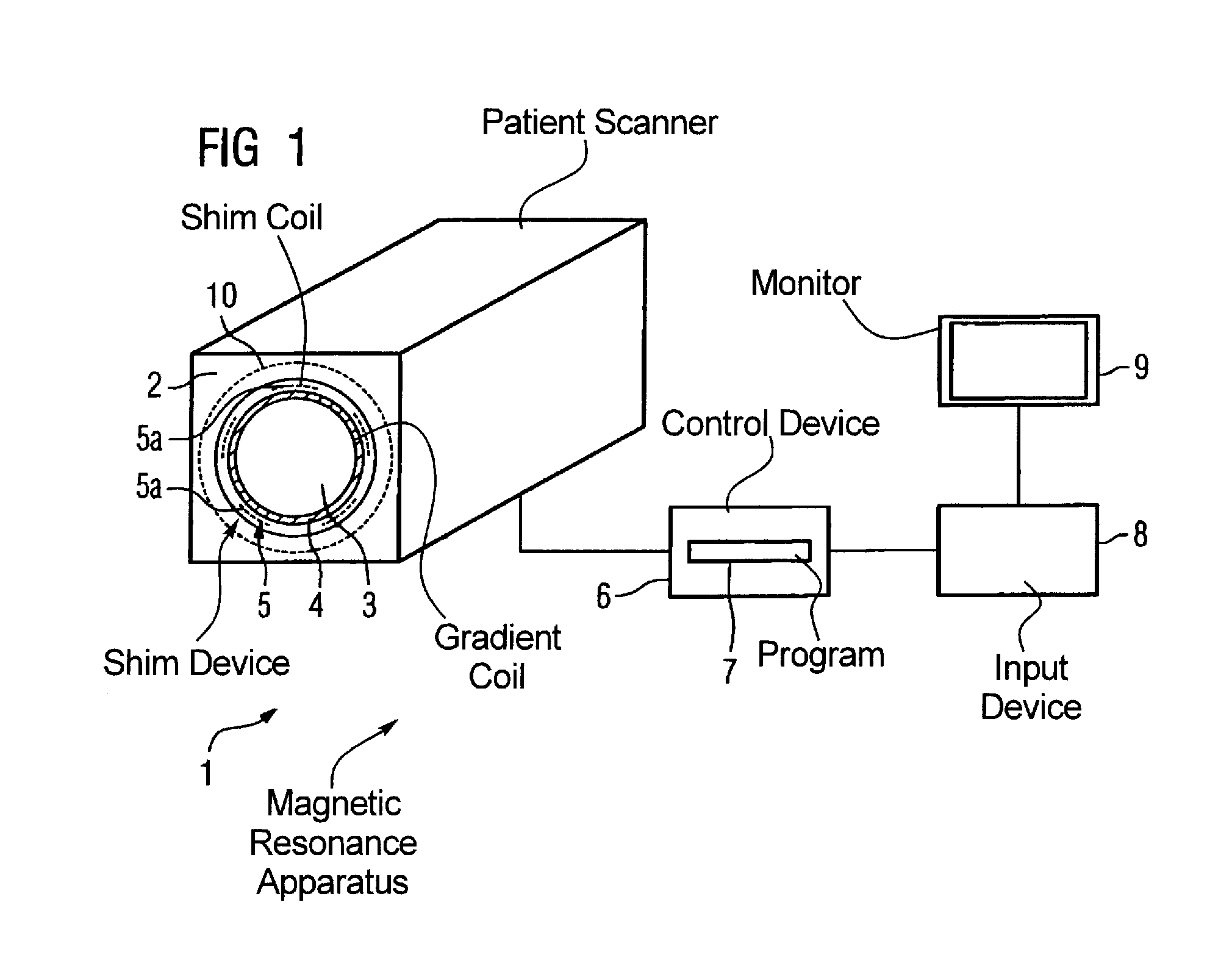

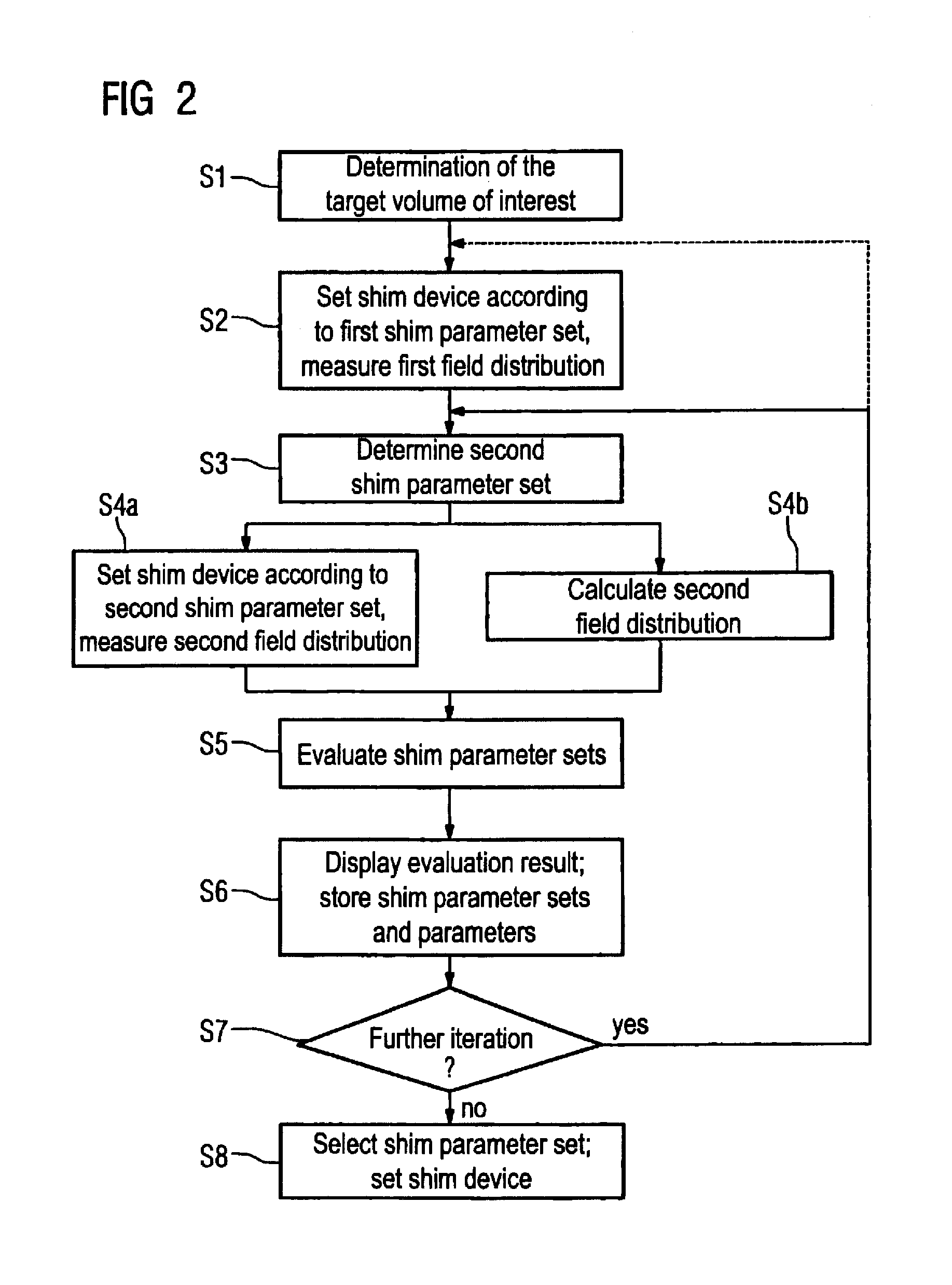

Method for determination and evaluation of a shim parameter set for controlling a shim device in a magnetic resonance apparatus

InactiveUS20080088307A1Improve field uniformityMeasurements using NMR imaging systemsBiological testingResonanceComputer science

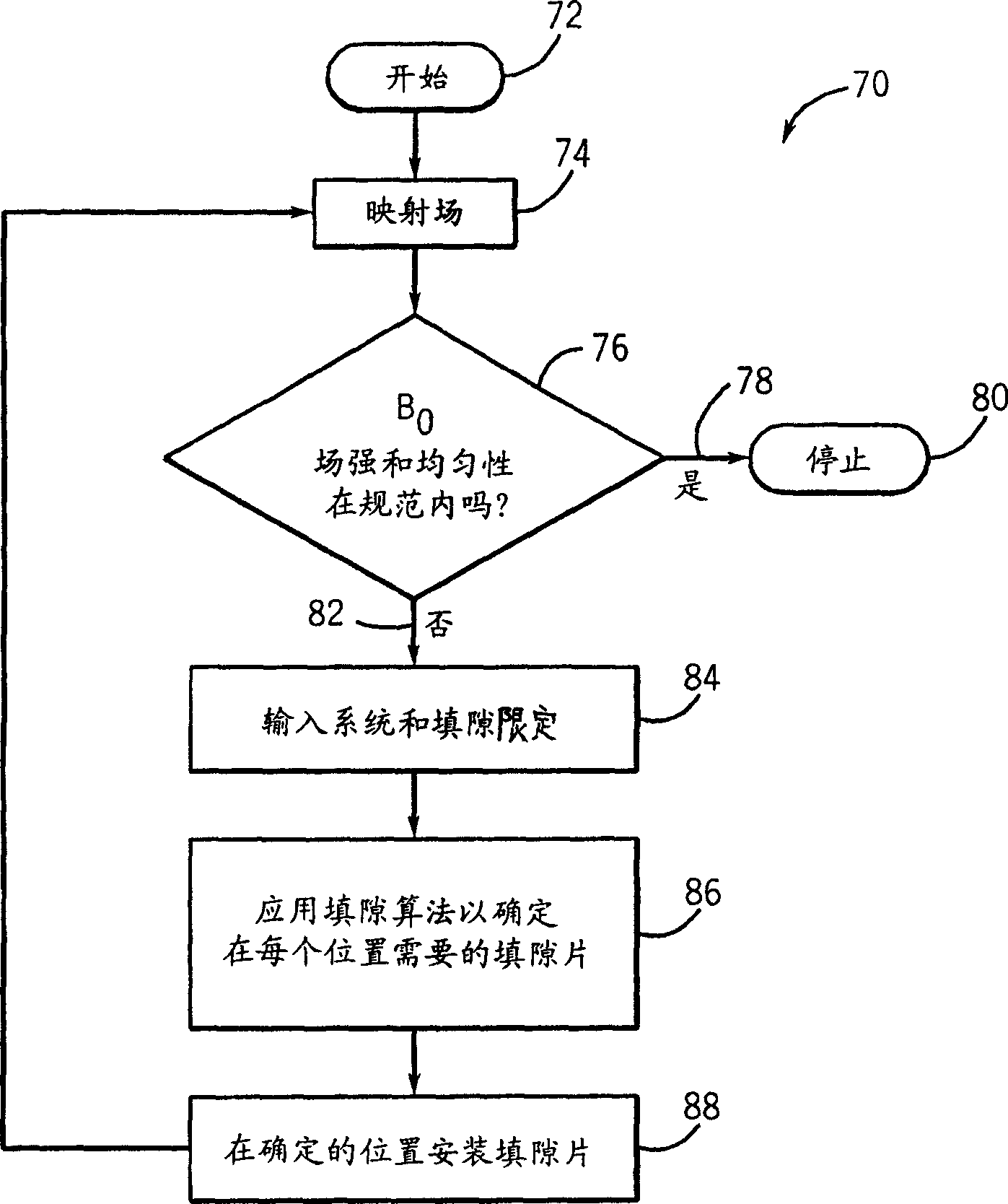

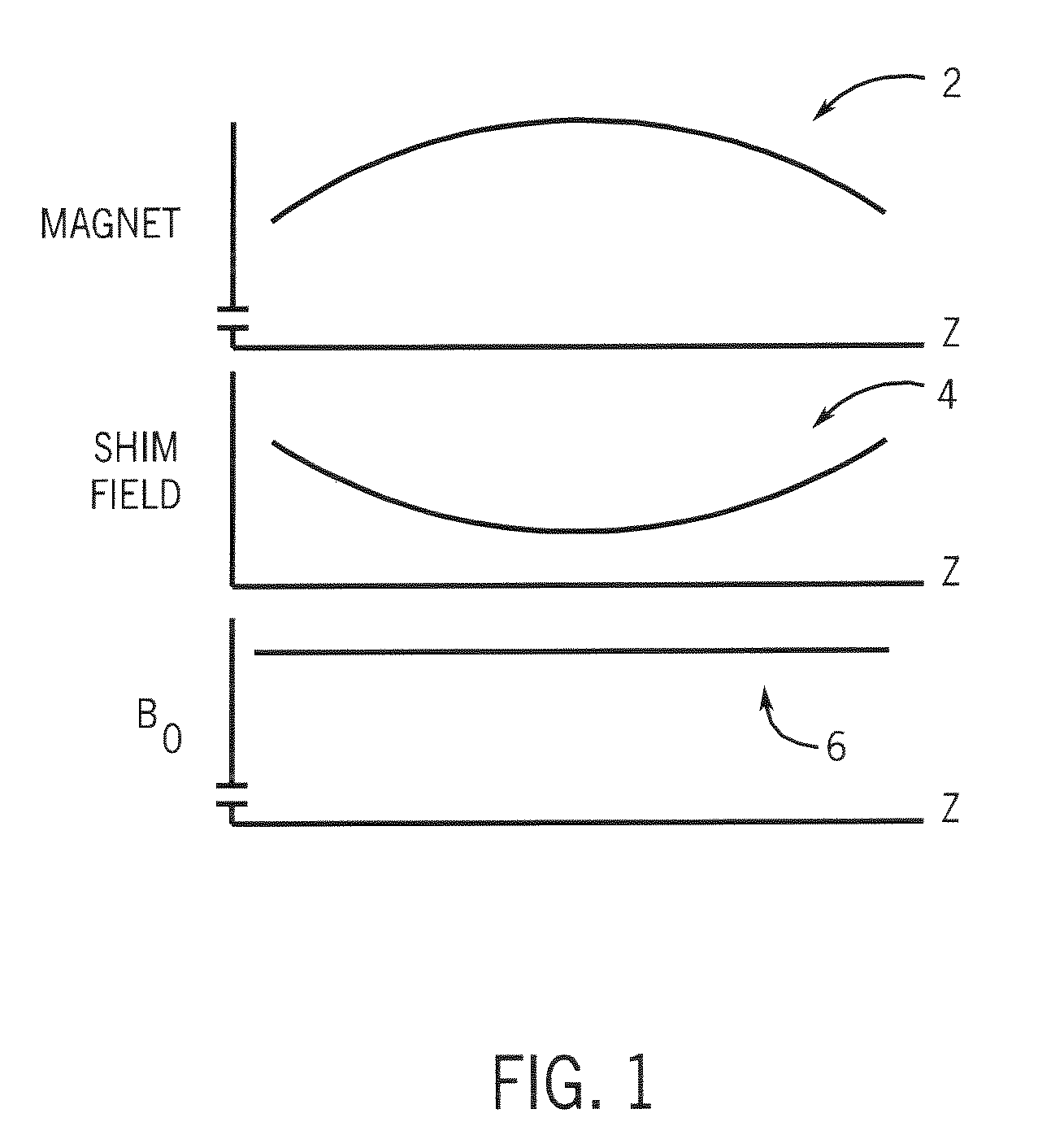

In a method for determination and evaluation of a shim parameter set for controlling a shim device in a magnetic resonance (MR) apparatus, the shim device is set using a first shim parameter set, a first field distribution is measured in a body region encompassing a target volume from which MR data are to be acquired, a second shim parameter set is determined using an algorithm for optimization of the field homogeneity in the target volume on the basis of the first shim parameter set and dependent on the first field distribution, a second field distribution is determined on the basis of the second shim parameter set, and the shim parameter sets are evaluated by indirect or direct comparison of the first field distribution and the second field distribution, in particular in the target volume.

Owner:SIEMENS HEATHCARE GMBH

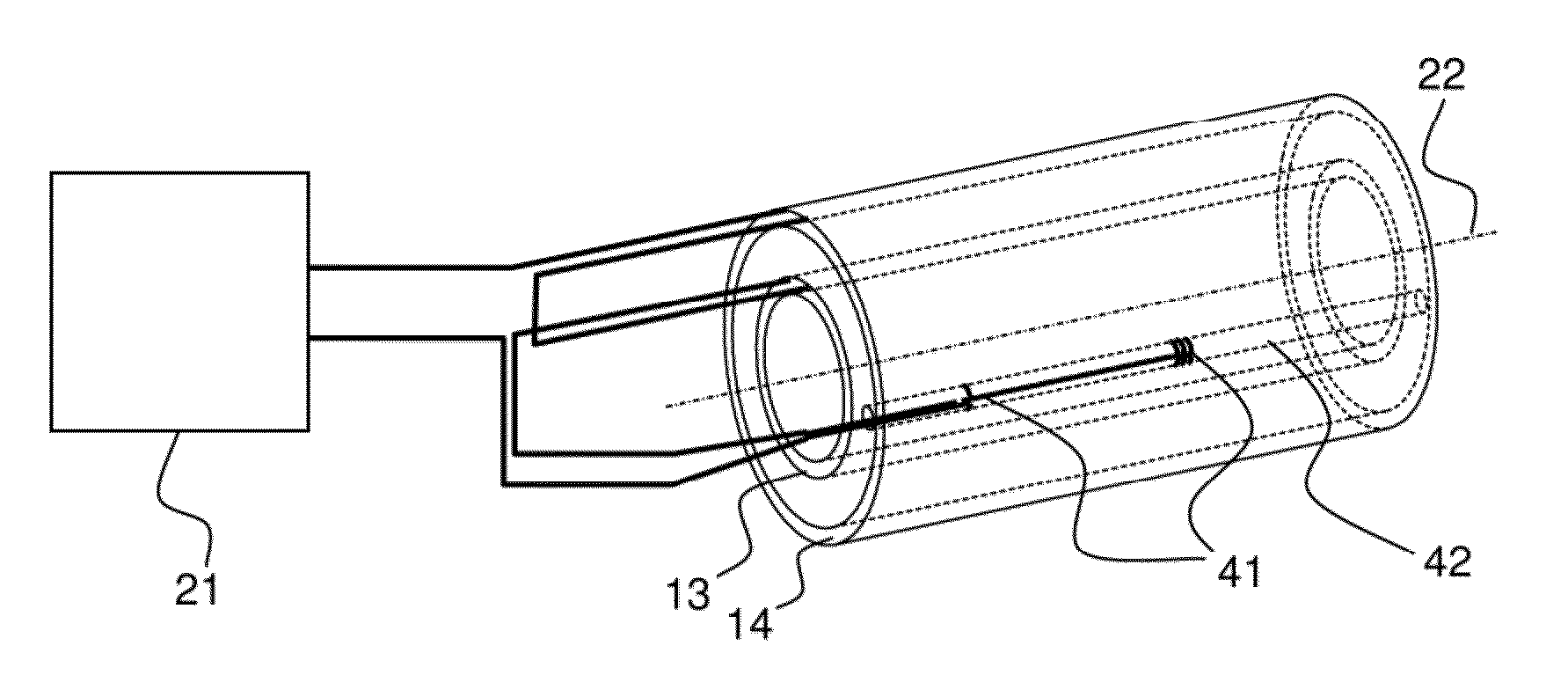

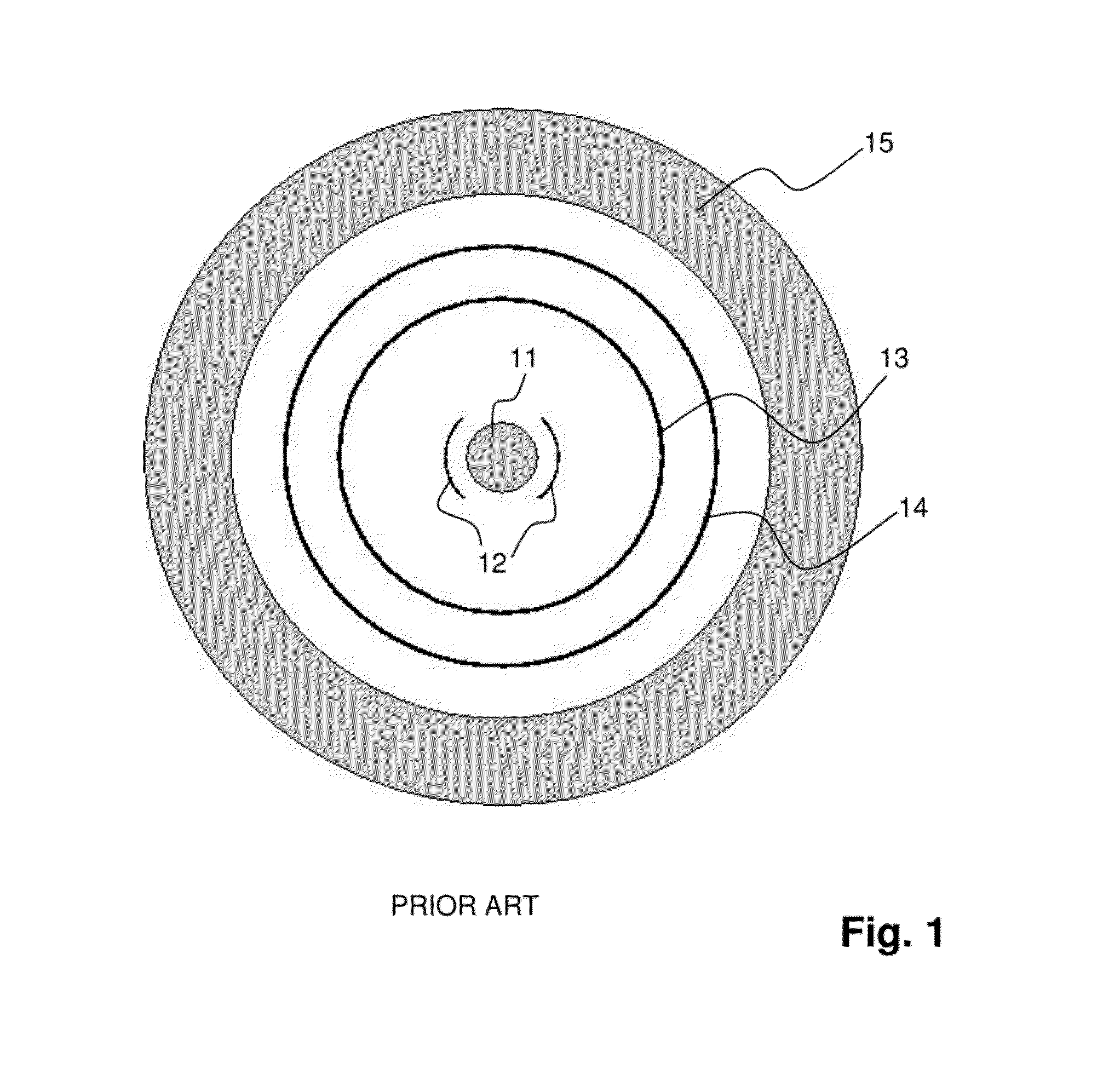

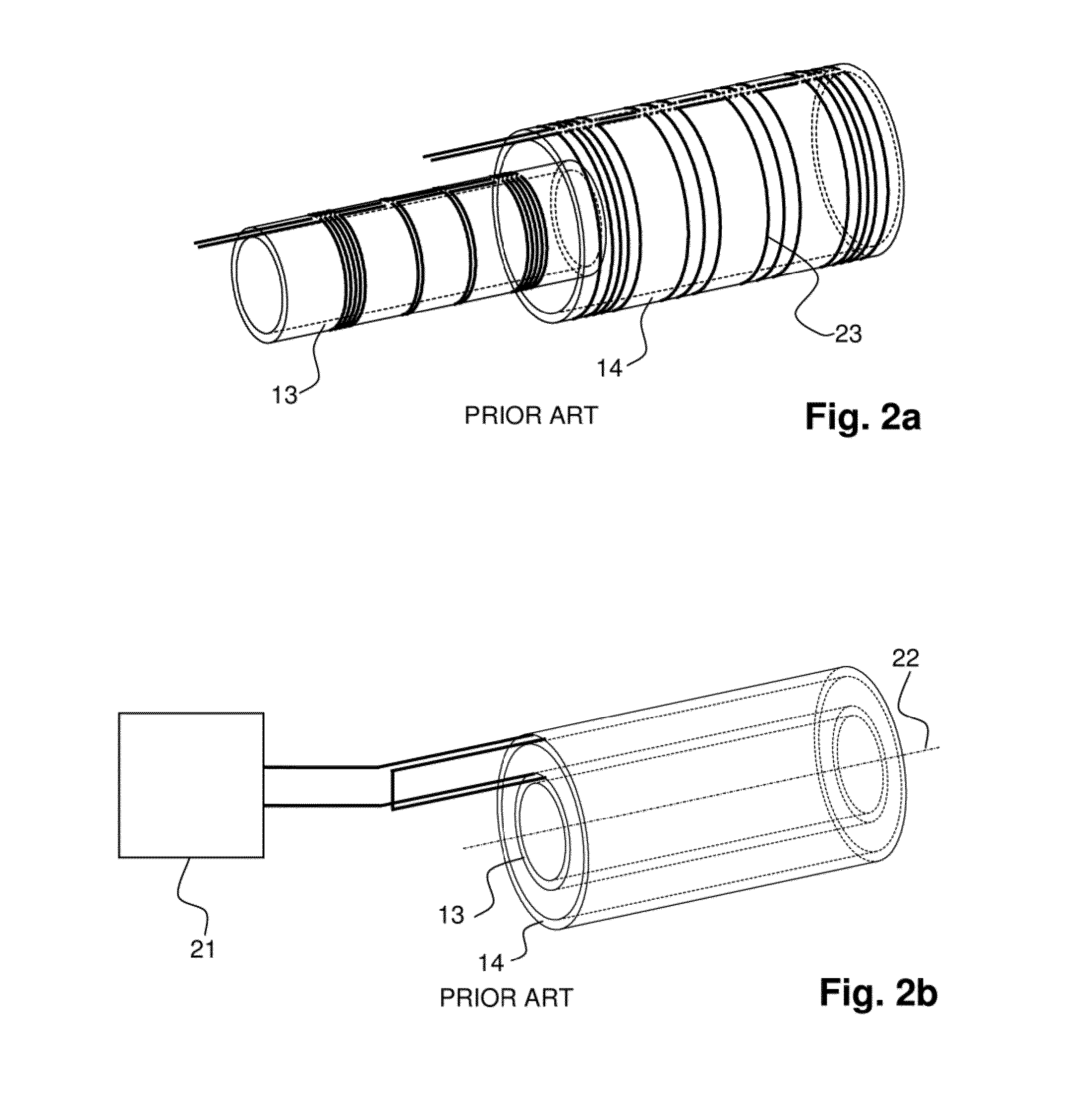

Gradient coil with correction windings and method for production thereof

ActiveUS20130229182A1Shorten the construction periodSufficiently accurate approximationMagnetic measurementsElectronic circuit testingMagnetic field gradientElectricity

In a coil arrangement for nuclear magnetic resonance comprising a main coil (13), a shielding coil (14), and at least one correction coil (41), the function of which consists in forming a magnetic field gradient with eddy current properties which are as good as possible, the main coil (13) and the shielding coil (14) are electrically connected in series with the correction coil (41). The deviations of the residual field from the desired design generated by production tolerances are thereby modified by the correction coil in such a fashion that the long-lasting eddy currents are suppressed. This either reduces the waiting time that must lapse after a gradient pulse before a predetermined field homogeneity is achieved or e.g. the deviations from the desired field are minimized in imaging applications.

Owner:BRUKER SWITZERLAND AG

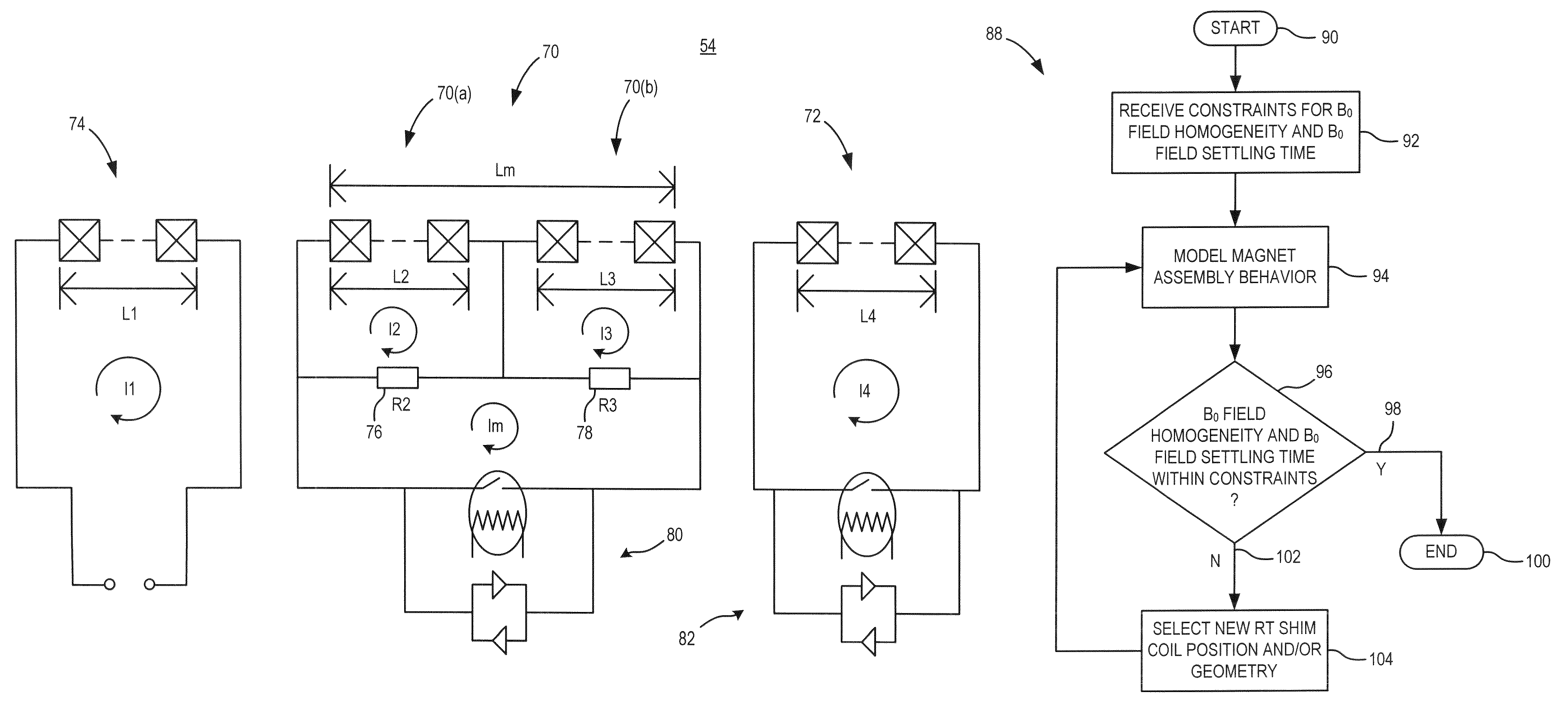

Method of designing a shim coil to reduce field settling time

ActiveUS7570141B2Reduce Flux LeakageImpact settling timeMagnetic measurementsMagnetsRoom temperatureEngineering

A shim coil design technique determines a position and a geometry of a room temperature (RT) shim coil to provide both a desired field homogeneity and a desired B0 field setting time. The simultaneous satisfaction of both field homogeneity and field settling time is achieved without a reduction of flux leakage from the shim coil, modification of main magnet protection circuitry, and without necessarily decoupling of the shim coil from the overall main magnet.

Owner:GENERAL ELECTRIC CO

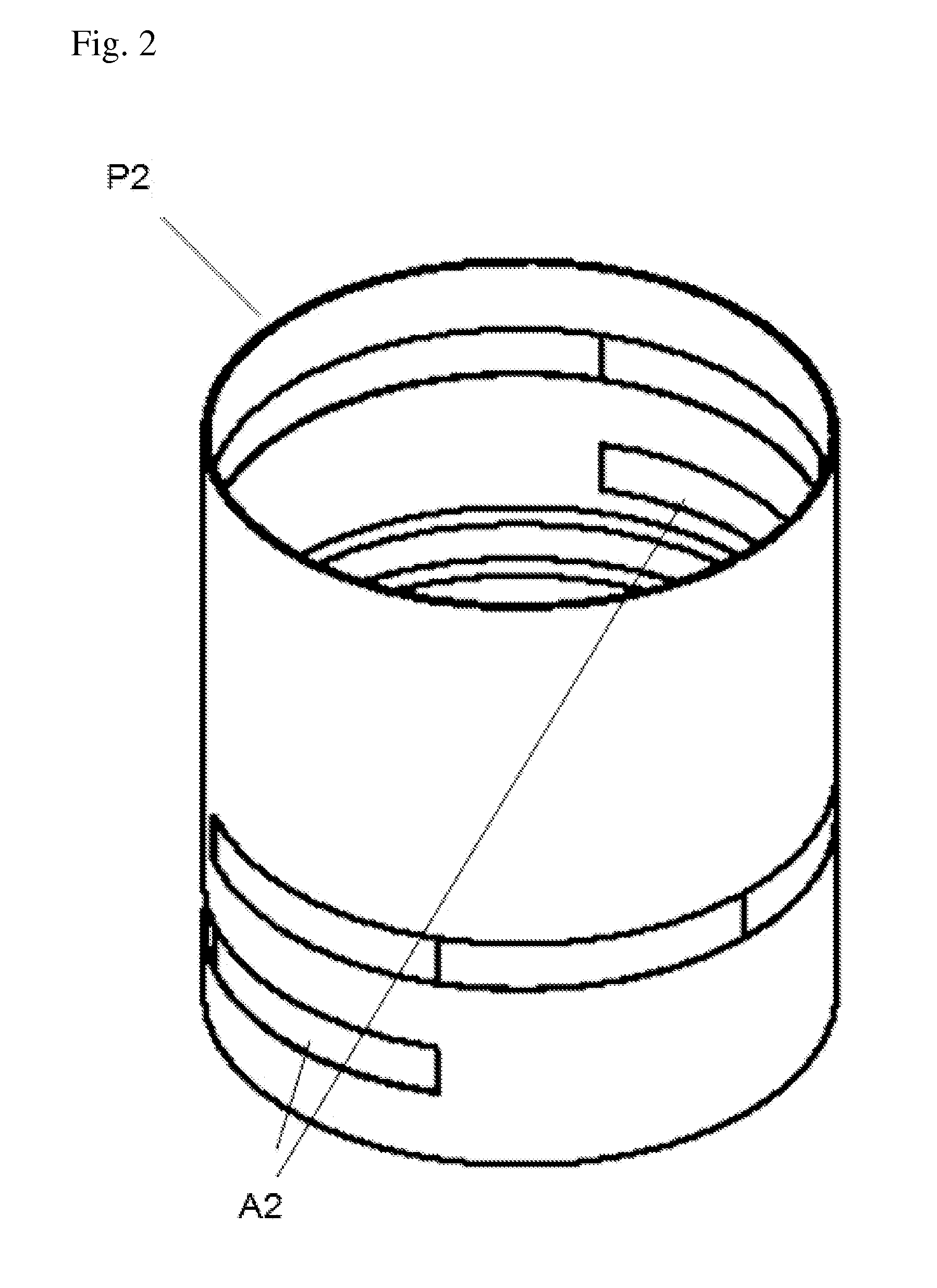

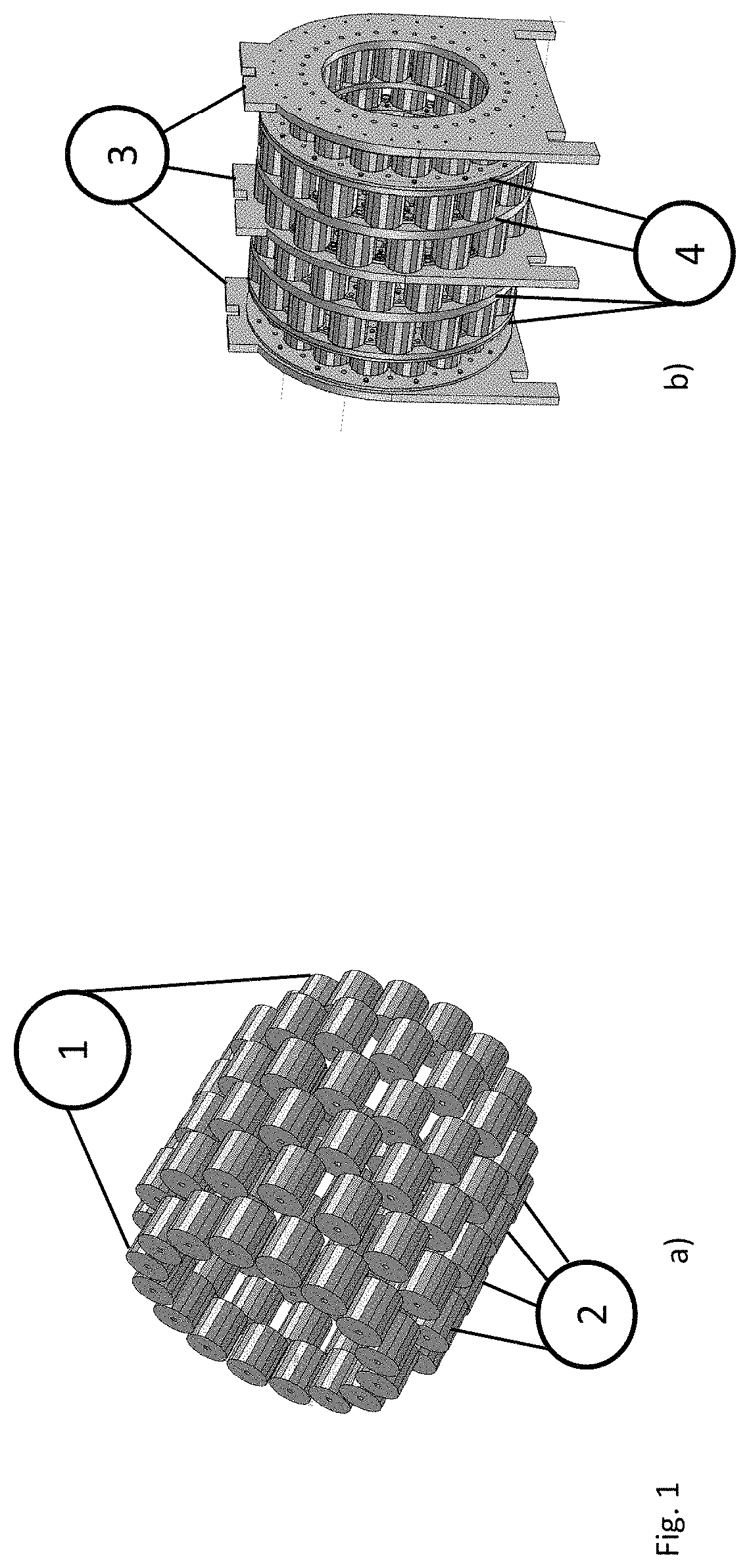

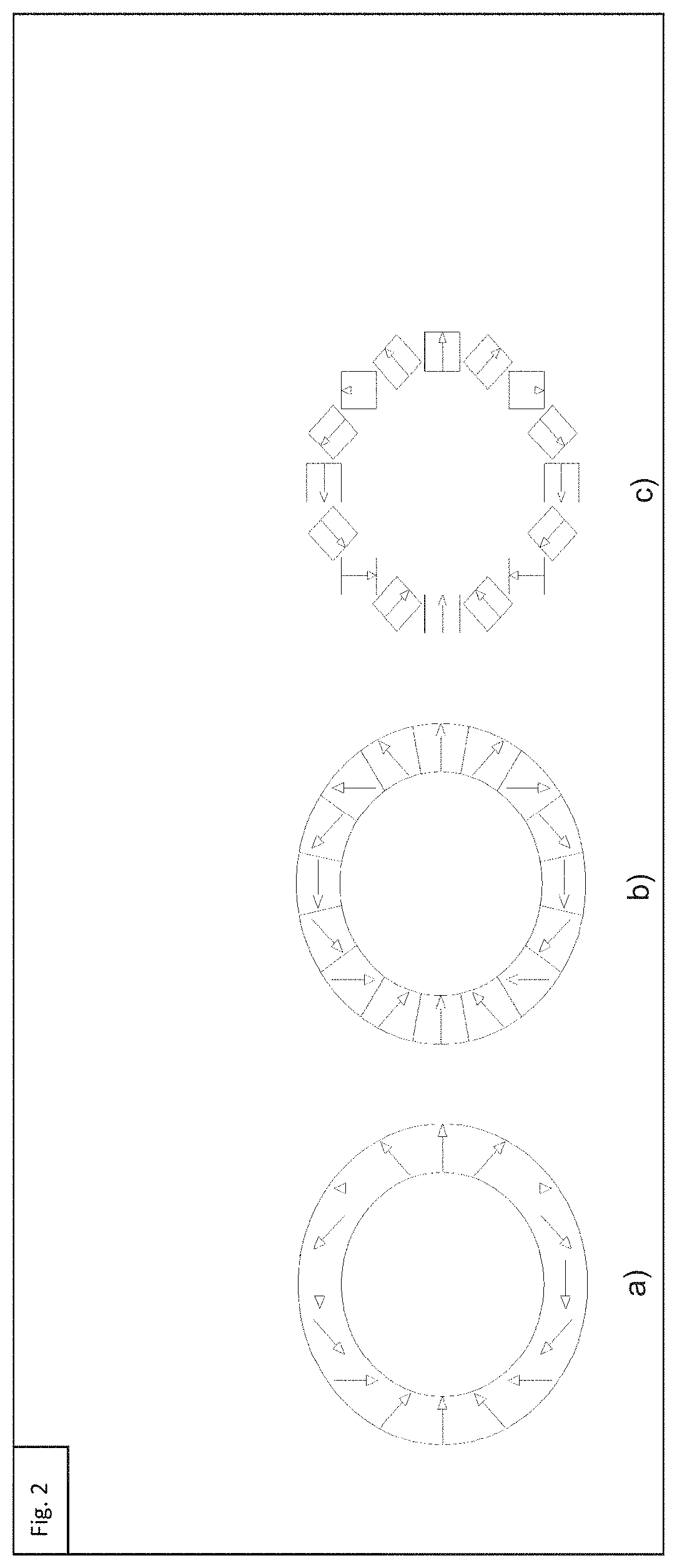

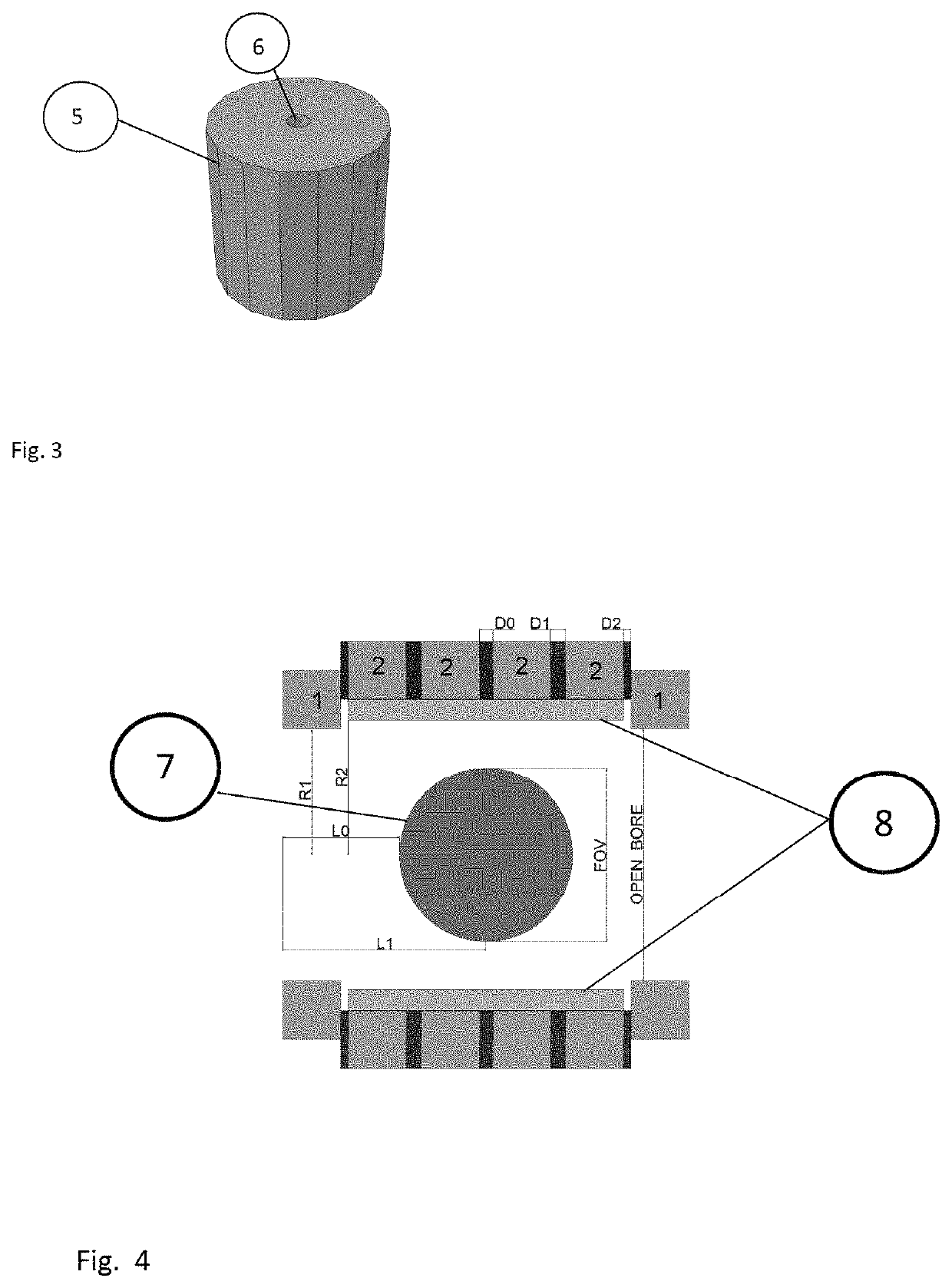

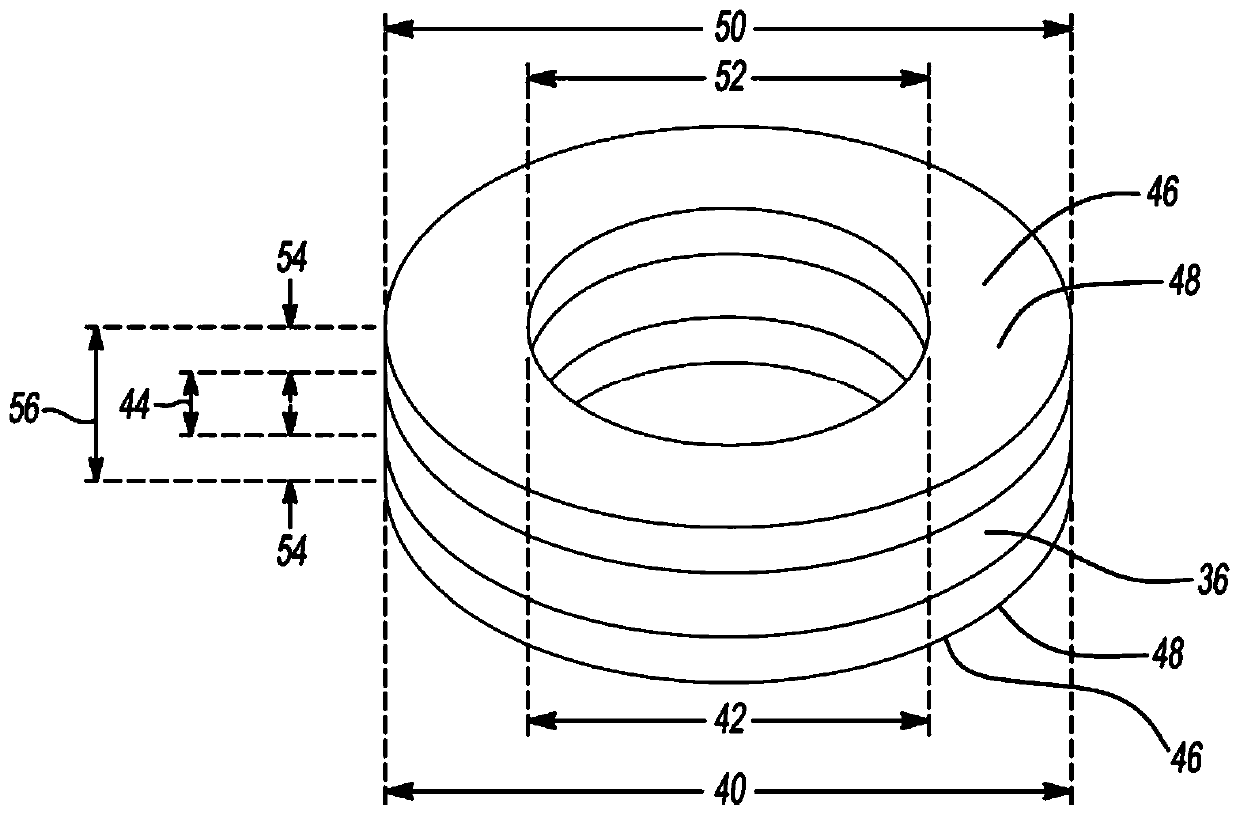

Magnet assembly for MRI comprising cylindrical rings of halbach type

ActiveCN108139453AAccurate knowledge of magnetizationMagnetic measurementsMagnetsMagnetizationCondensed matter physics

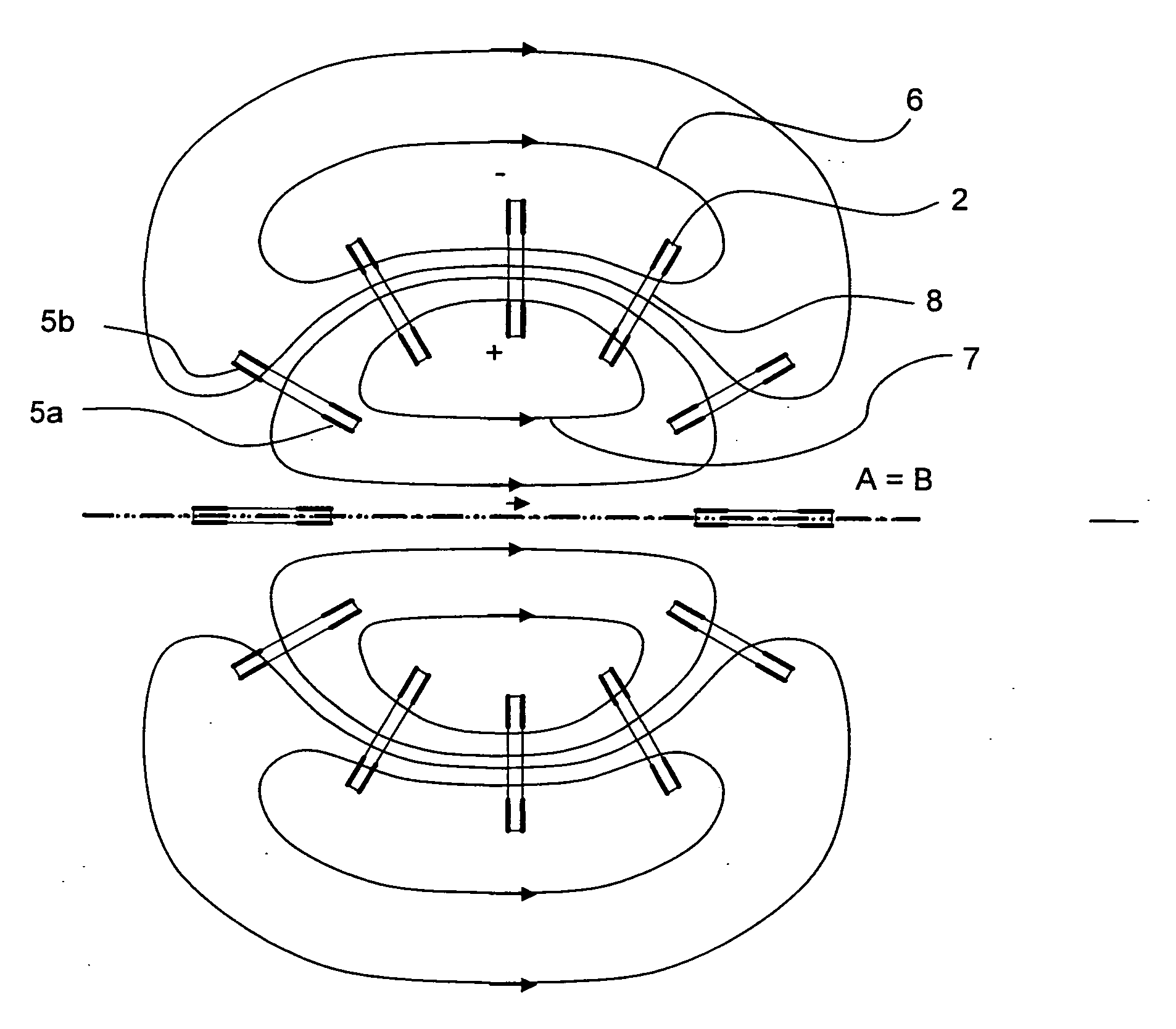

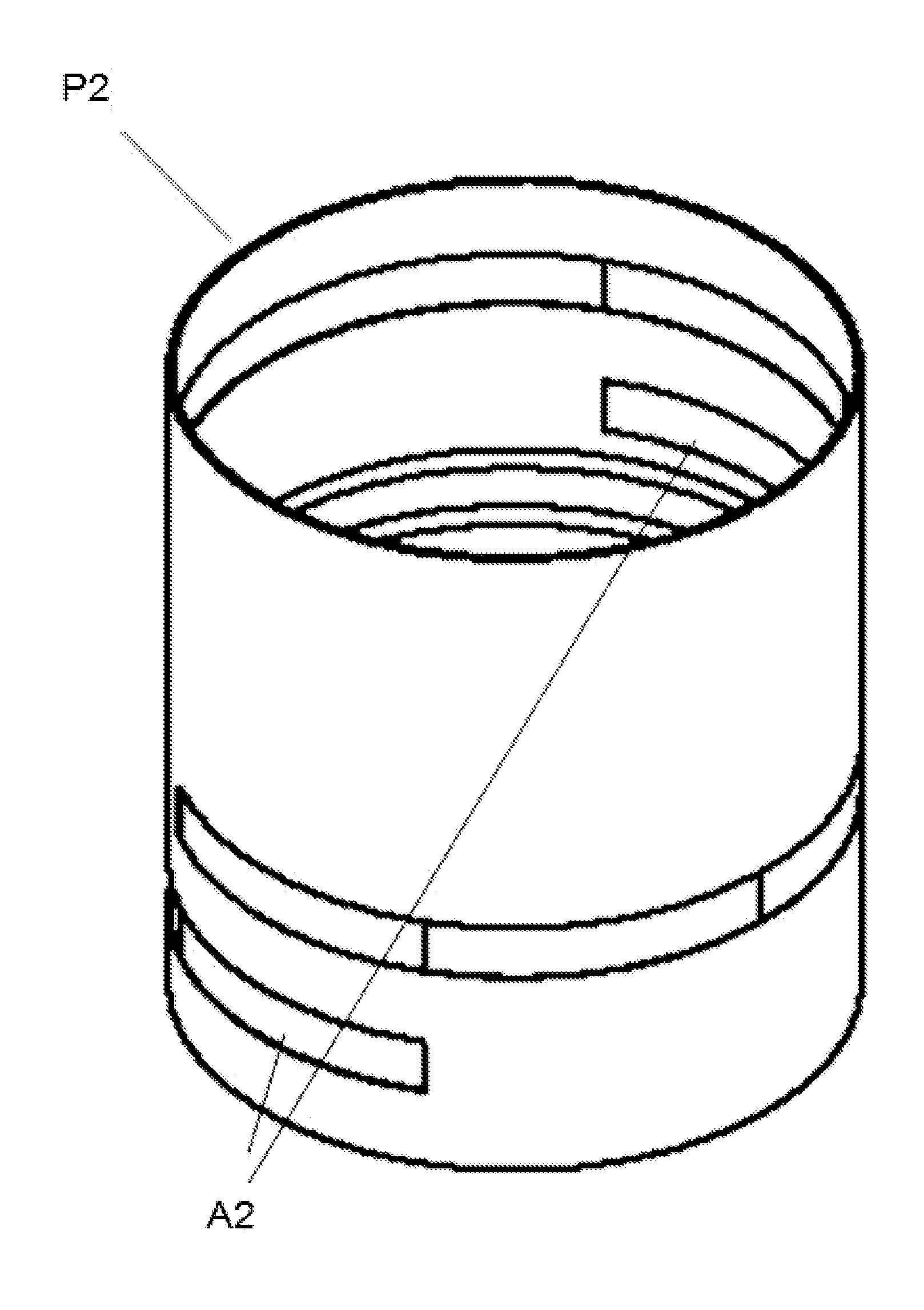

The present invention identifies the construction methods and the techniques that allow to obtain a magnetic field of the field homogeneity required for the use in magnetic resonance imaging (MRI), inthe order of 20 parts per million (ppm) in the area of interest (such techniques in the following will be indicated with the word "shimming"). The peculiarity of the described constructive method isto obtain a homogeneous field region, usable for the MRI analysis, of linear dimensions equal to about 40% of the linear dimensions of the magnet. The shimming technique involves the use of conditioned magnetic material and allows to control accurately the magnetization of the corrective elements while using a material that inherently has a large spread in the magnetization value. The result is alow weight and small magnet suitable for MRI for dedicated clinical applications such as the analysis of the peripheral joint, the analysis of the ocular region, veterinary applications.

Owner:安东内洛索特奎

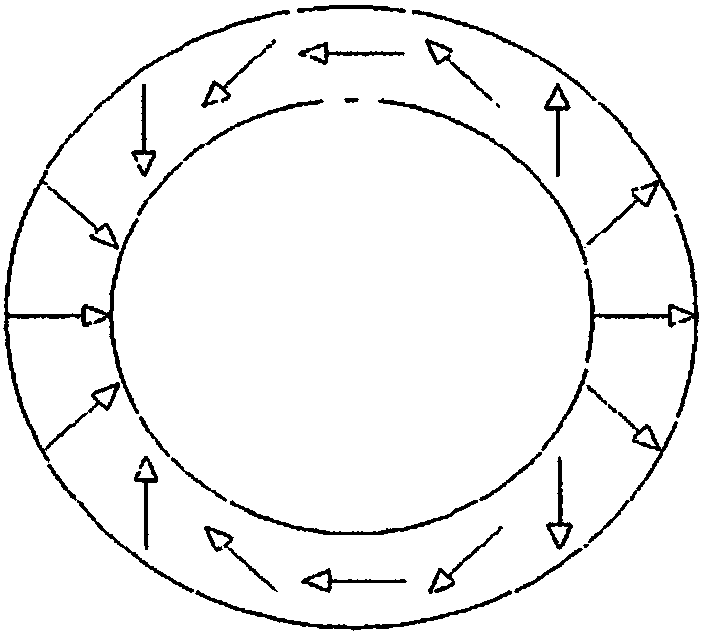

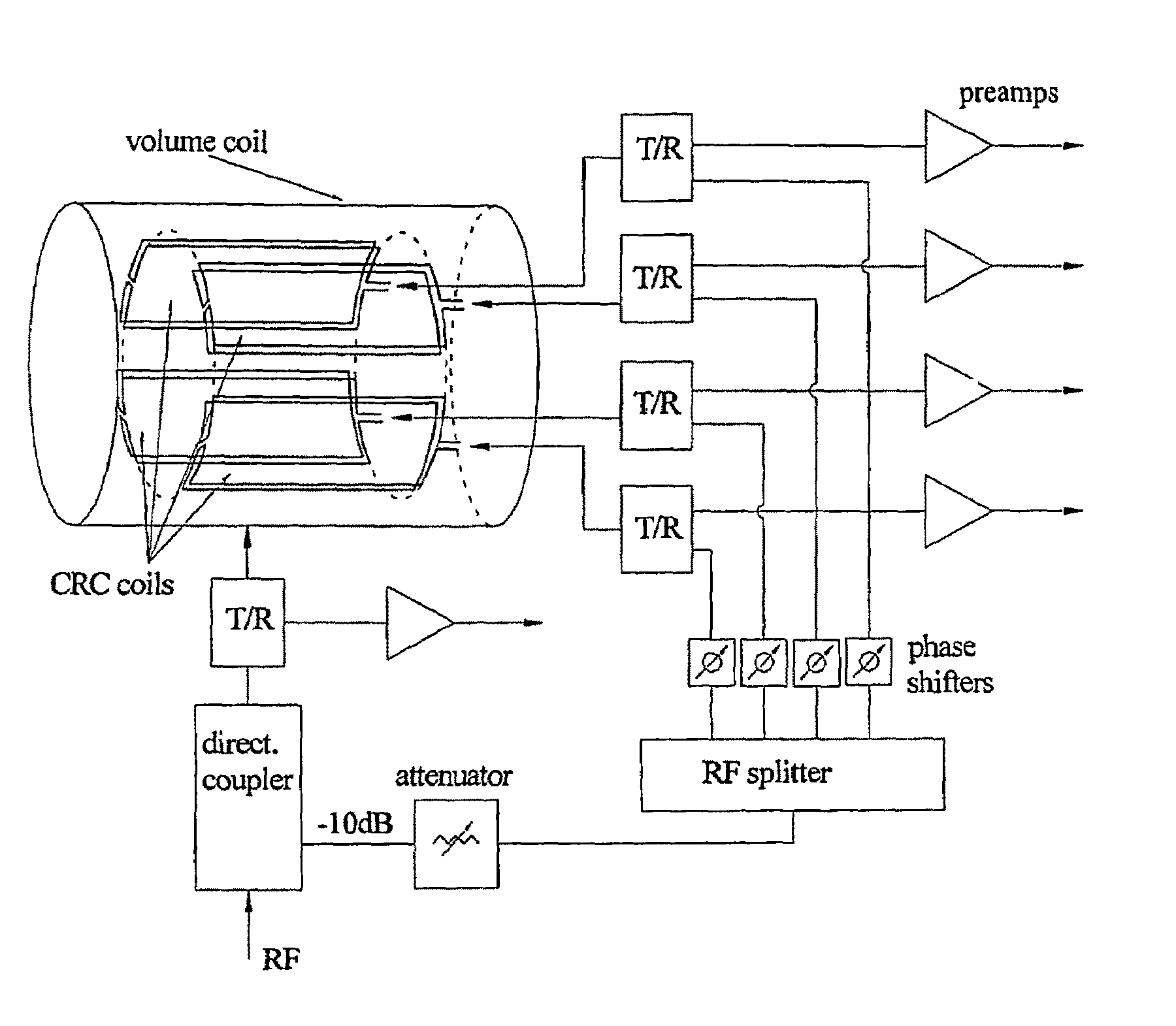

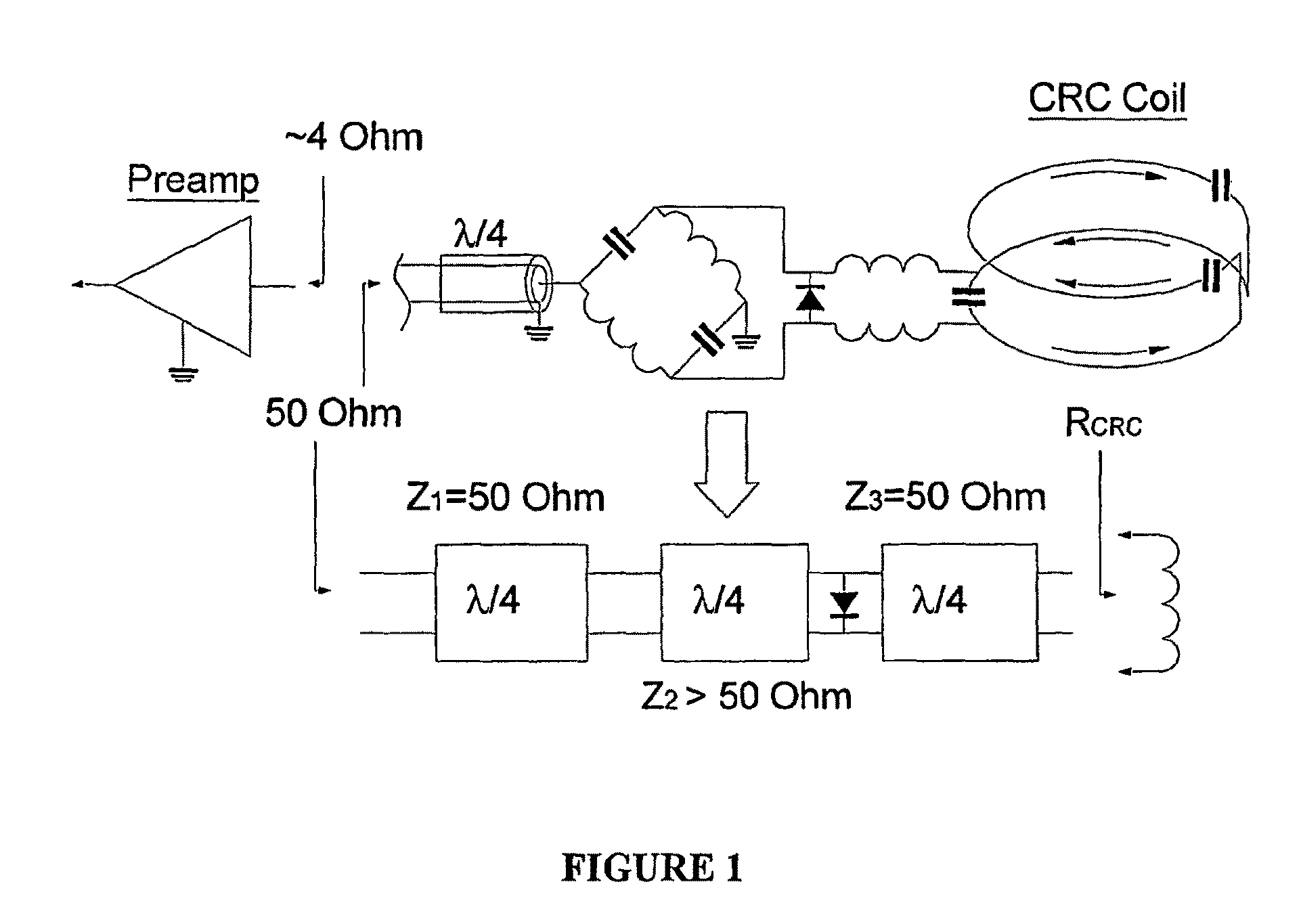

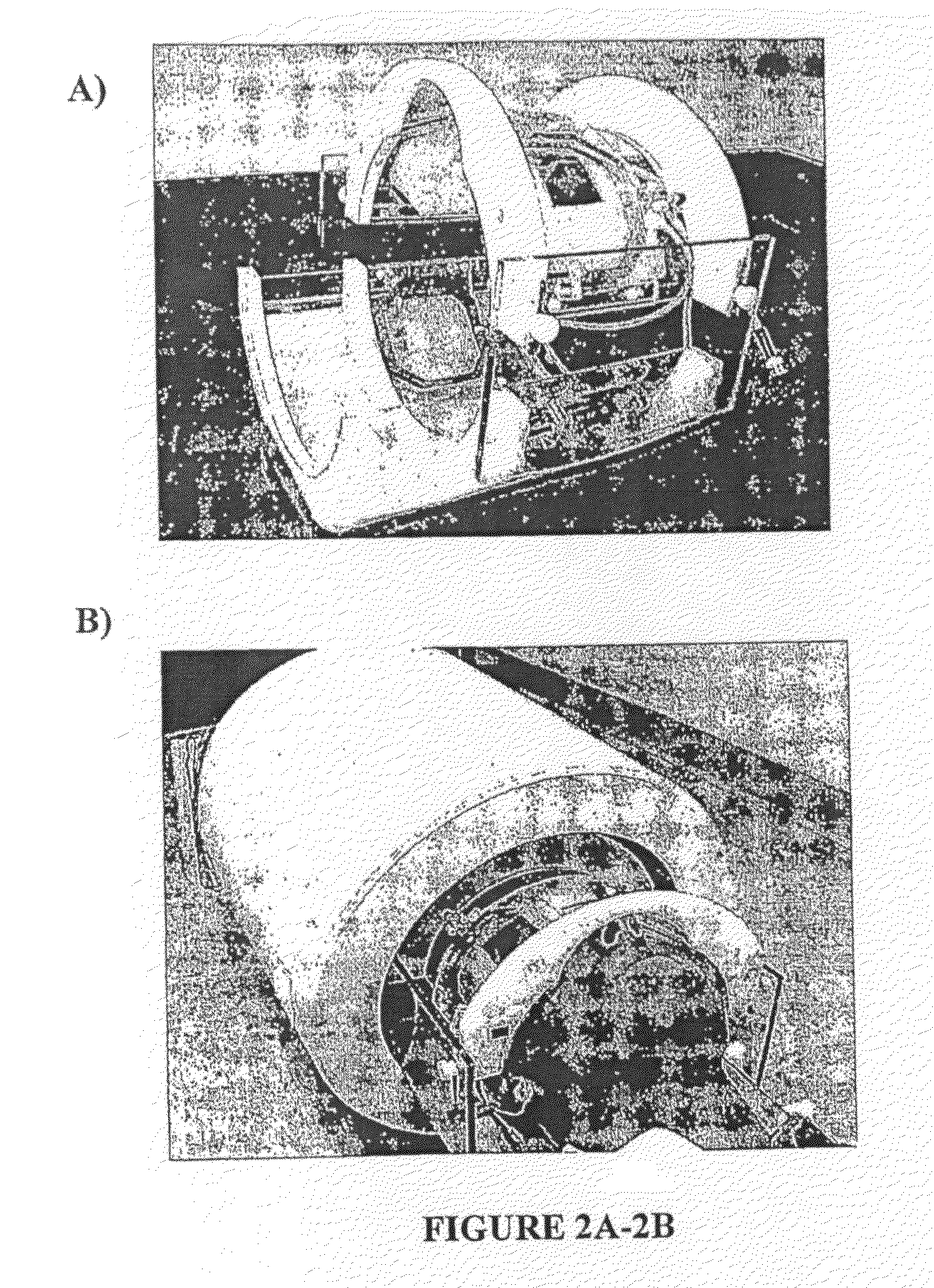

Surface coil arrays for simultaneous reception and transmission with a volume coil and uses thereof

InactiveUS8030926B2Improve signal-to-noise ratioImprove the uniformity of the magnetic fieldMagnetic measurementsElectric/magnetic detectionSignal-to-noise ratio (imaging)Surface coil

This invention provides arrays of counter rotating current surface coils for simultaneous reception and transmission with a volume coil for improved signal-to-noise ratio and radio frequency field homogeneity for in particular high-field (4-8 T) imaging of deep body regions, such as central brain structures.

Owner:ALBERT EINSTEIN COLLEGE OF MEDICINE OF YESHIVA UNIV

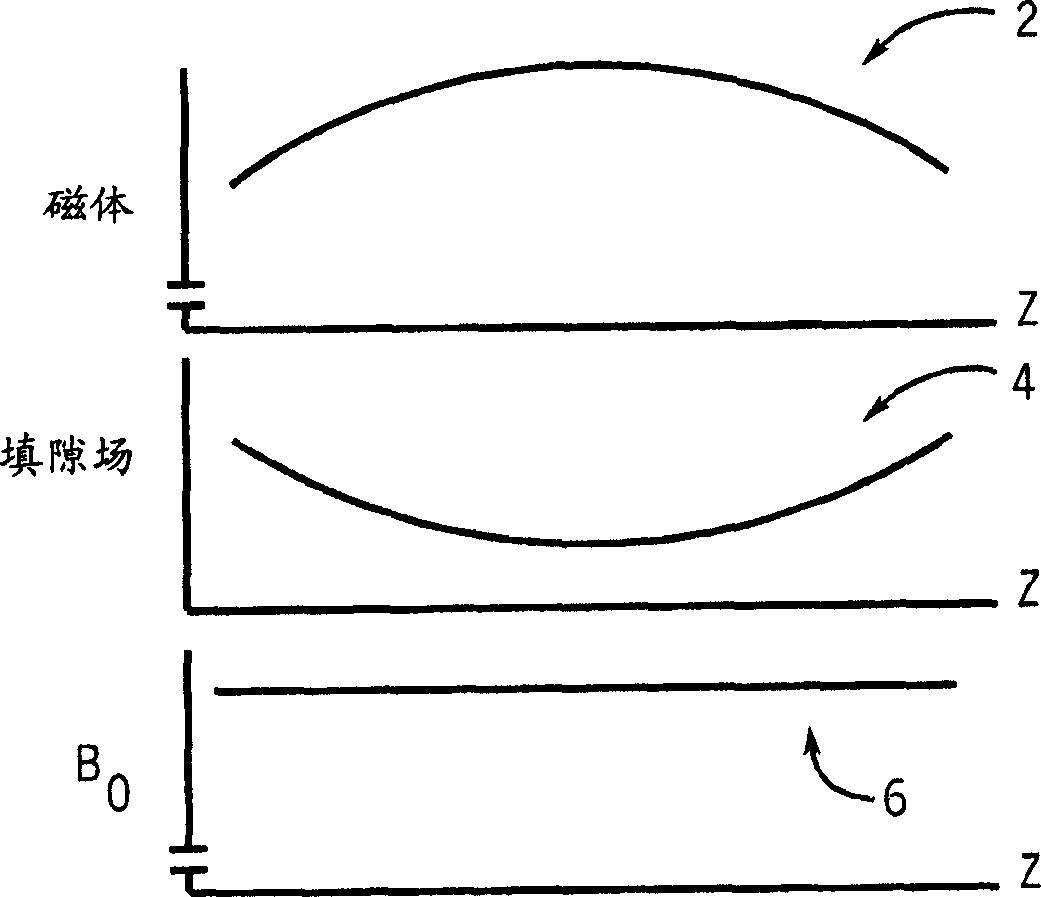

Method of magnetic field contarolled gap filling

InactiveCN1534306AReduce unevennessSmall inhomogeneity to establish desired B0 field strengthMagnetic measurementsDiagnostic recording/measuringEngineeringGap filling

The present invention is directed to a method of shimming a magnet assembly of an MR imaging system such that a desired B0 field strength may be created with minimal inhomogeneities therethrough. With this method, sufficient shimming of the magnet assembly may be achieved without requiring mechanical variations to the magnet assembly after the magnet assembly has been assembled. The invention analyzes variations from the desired B0 field and inhomogeneities at a number of target points along the magnet assembly or B0 field. A comparison is then made at each point to determine a shimming or weighting factor such that the desired overall B0 field strength and targeted field homogeneity is achieved. Active and / or passive shim elements may then be incorporated into the magnet assembly at each target point to achieve the desired overall field strength and minimum overall field homogeneity.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

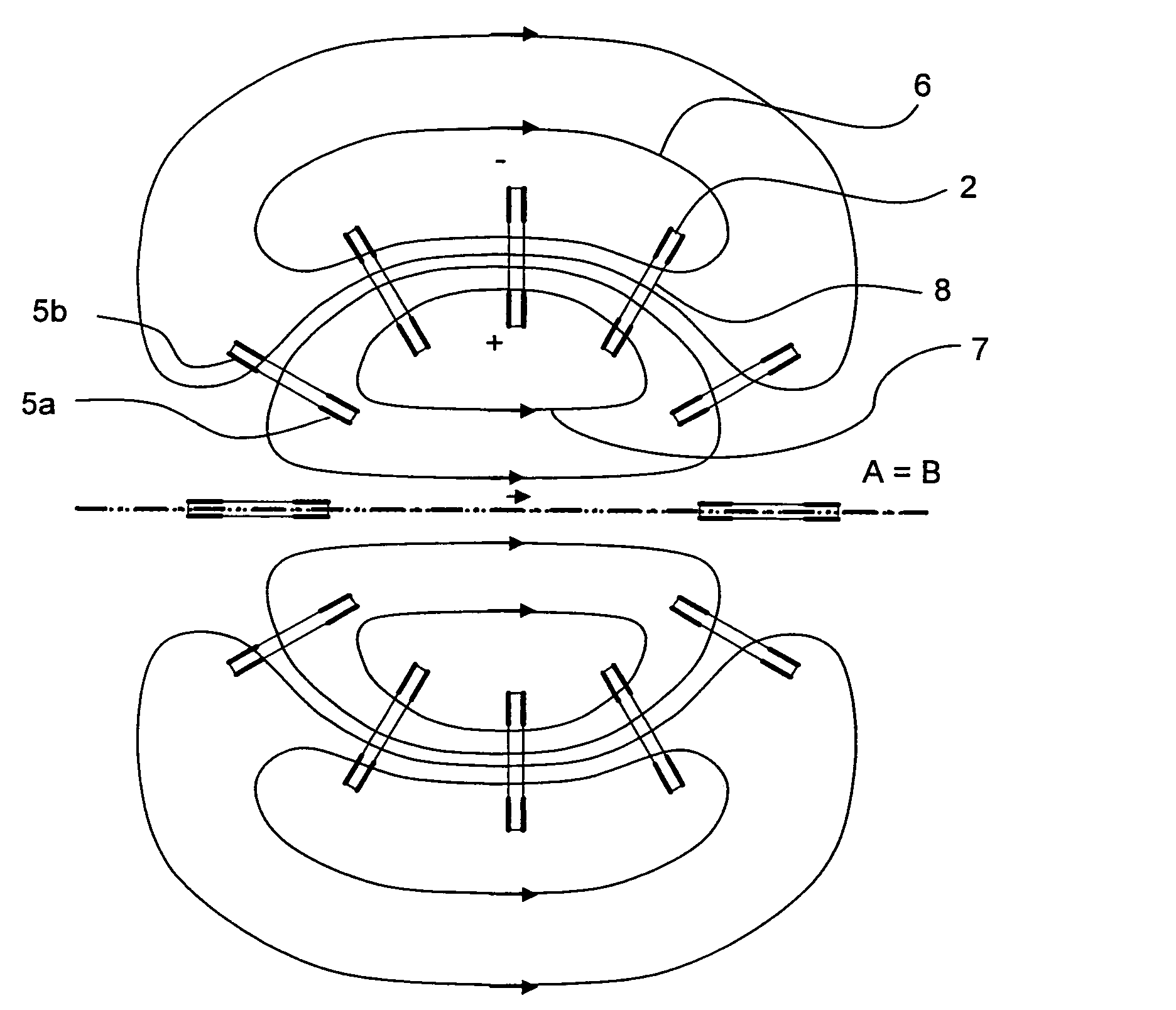

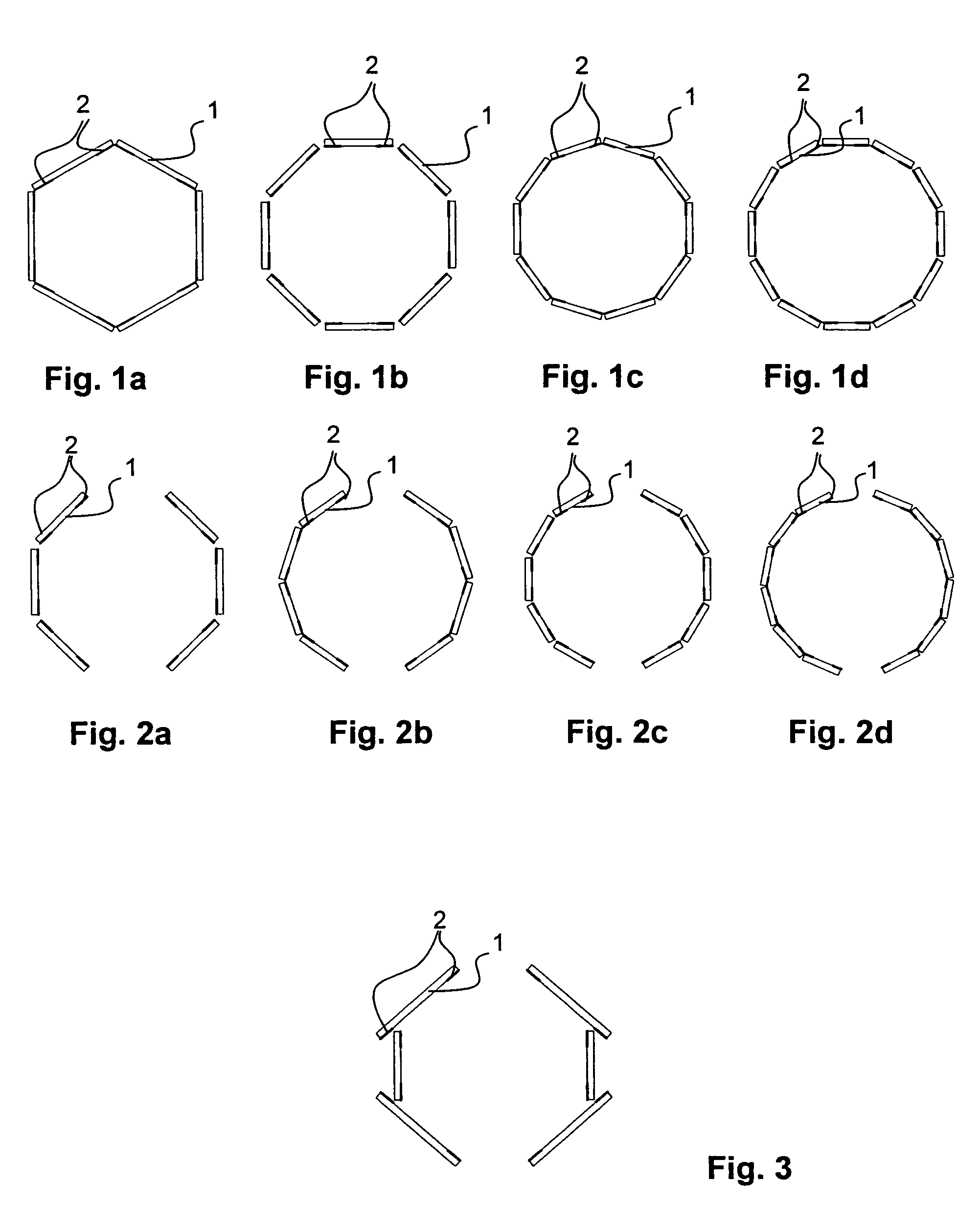

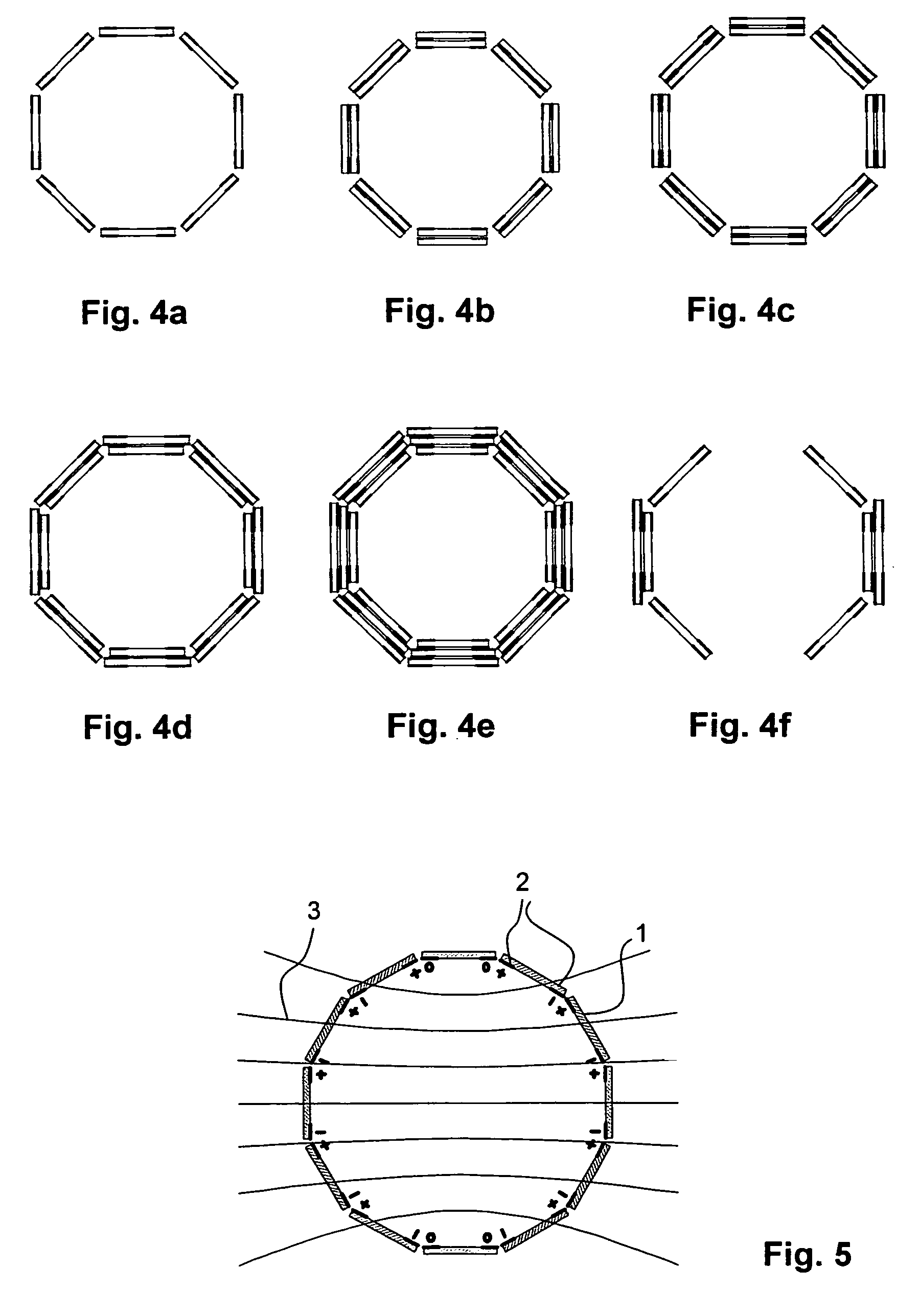

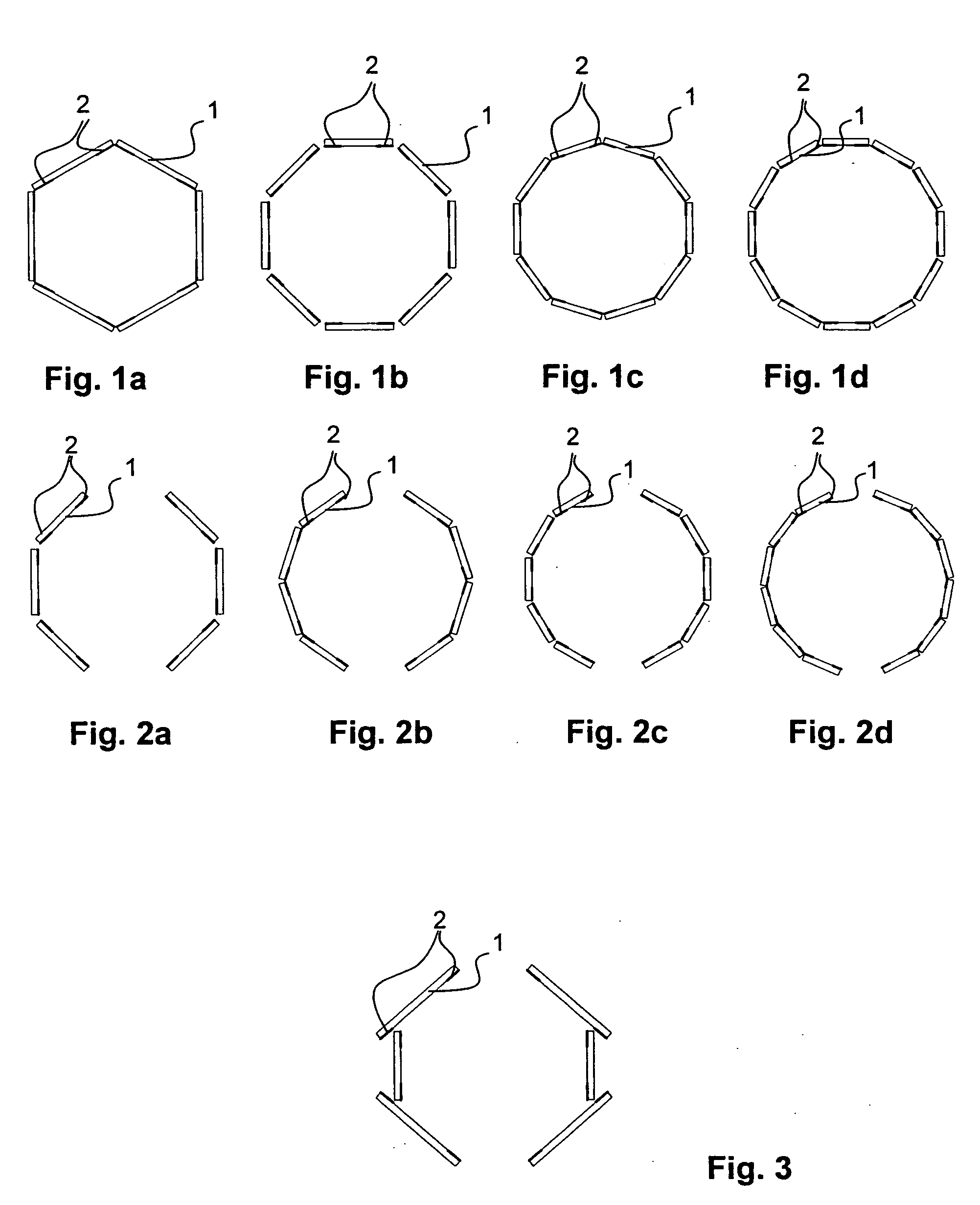

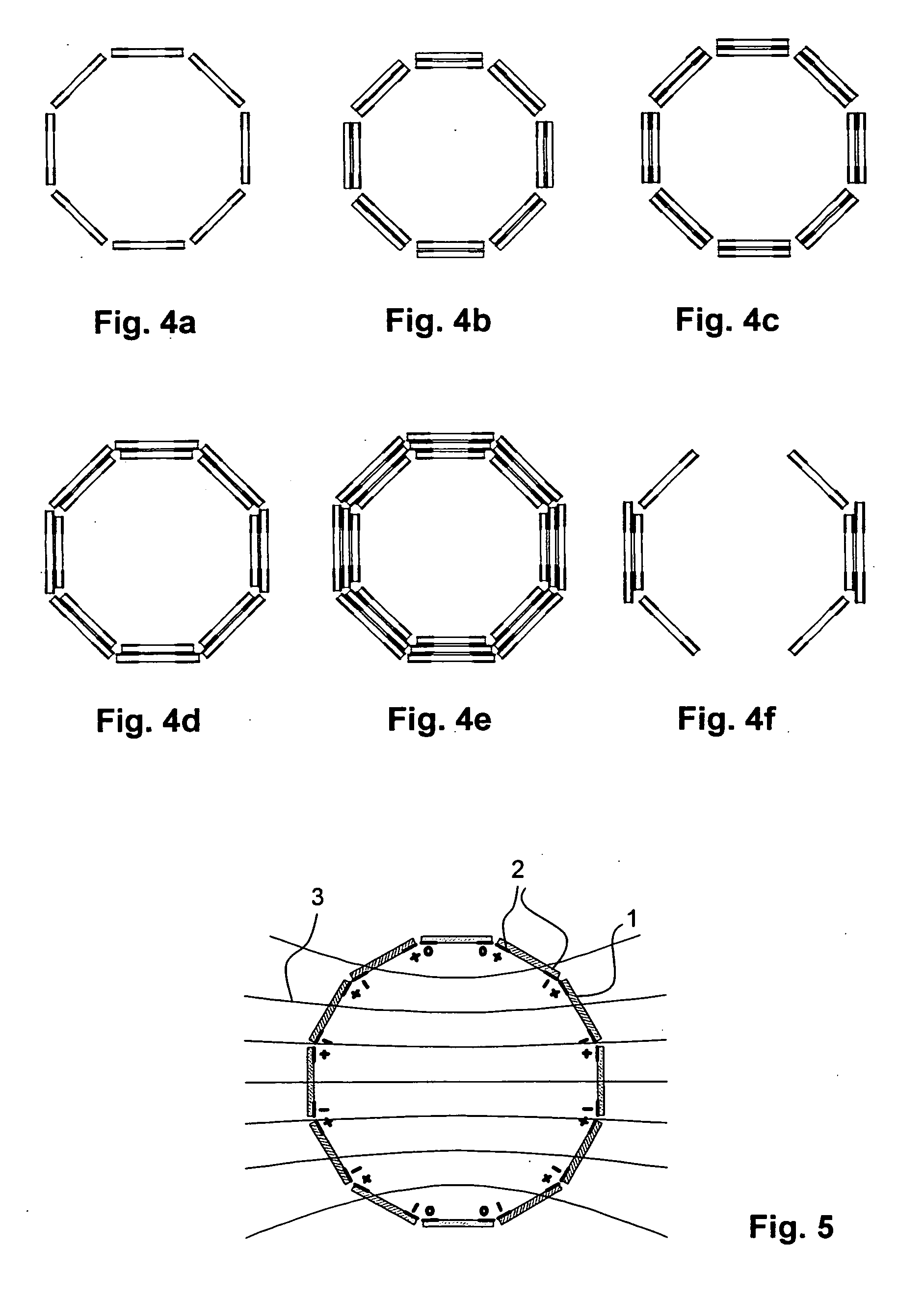

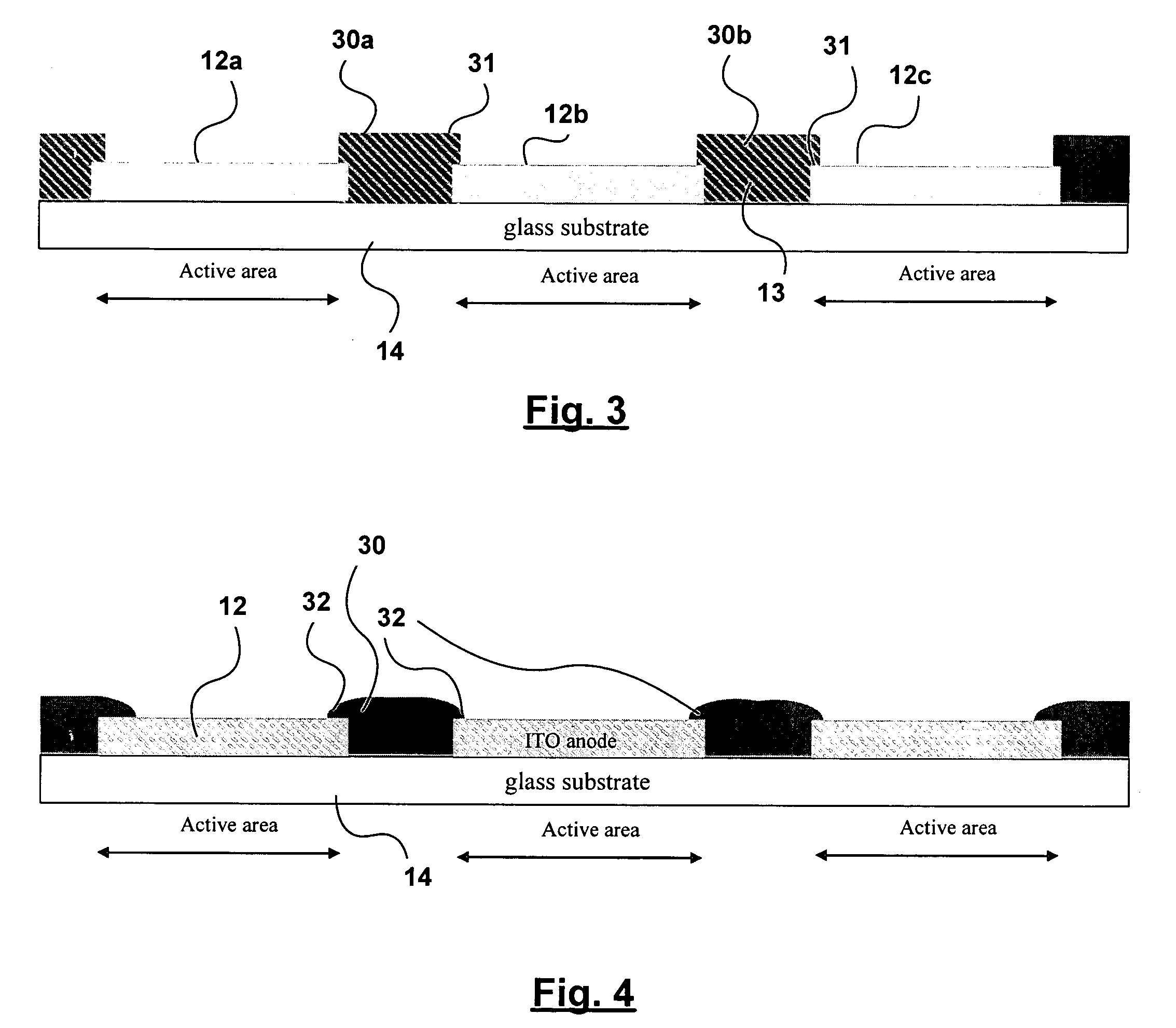

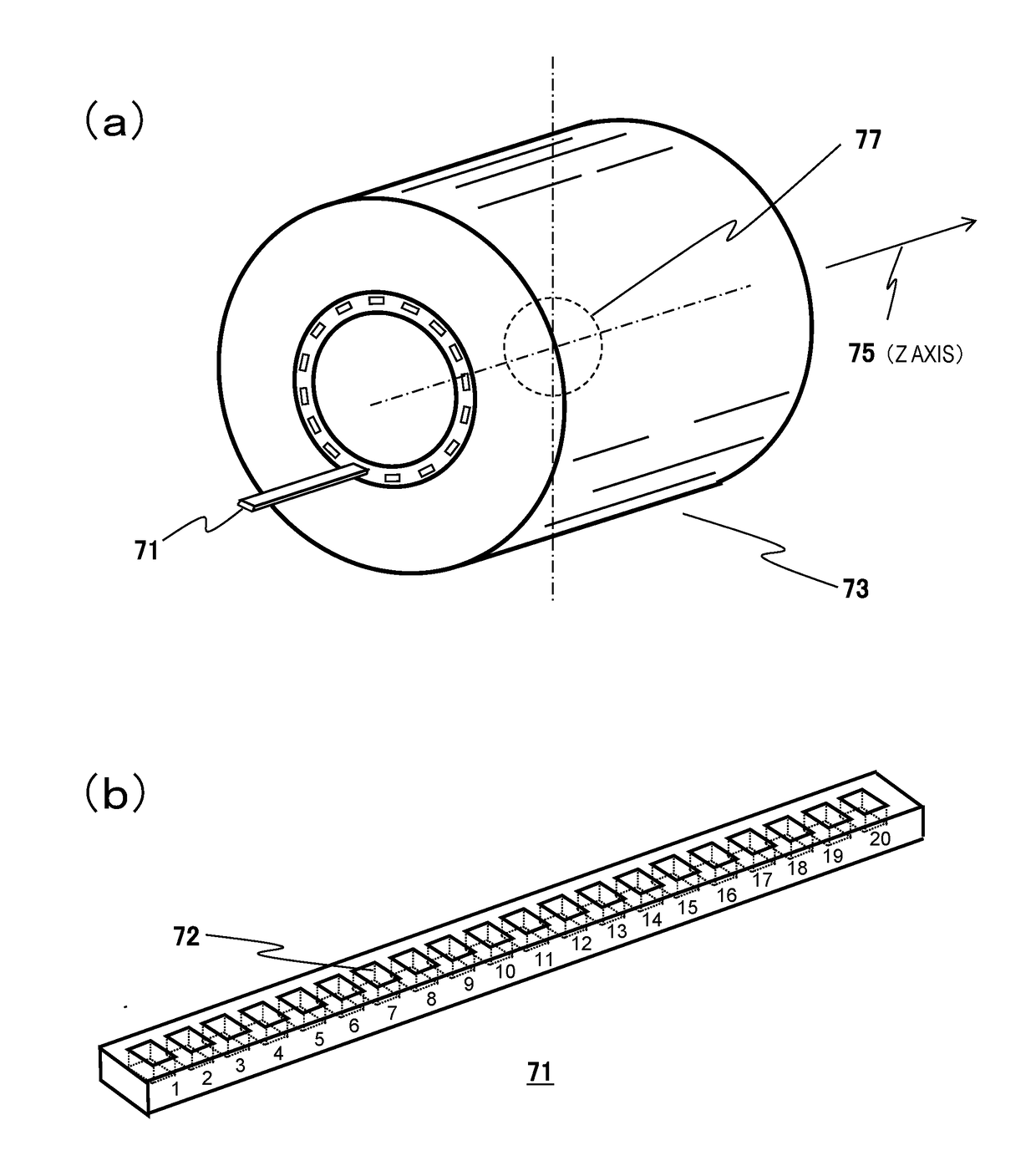

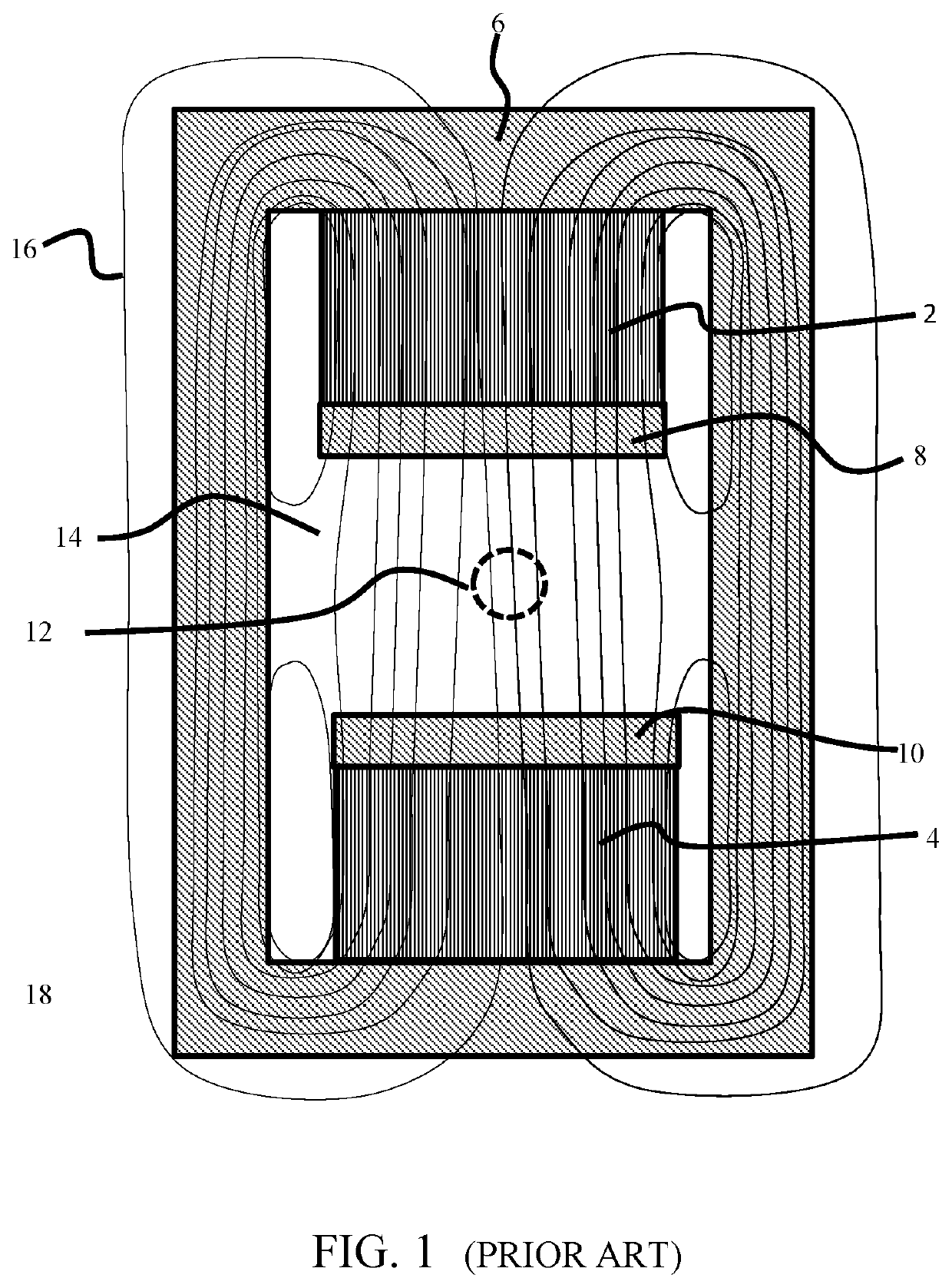

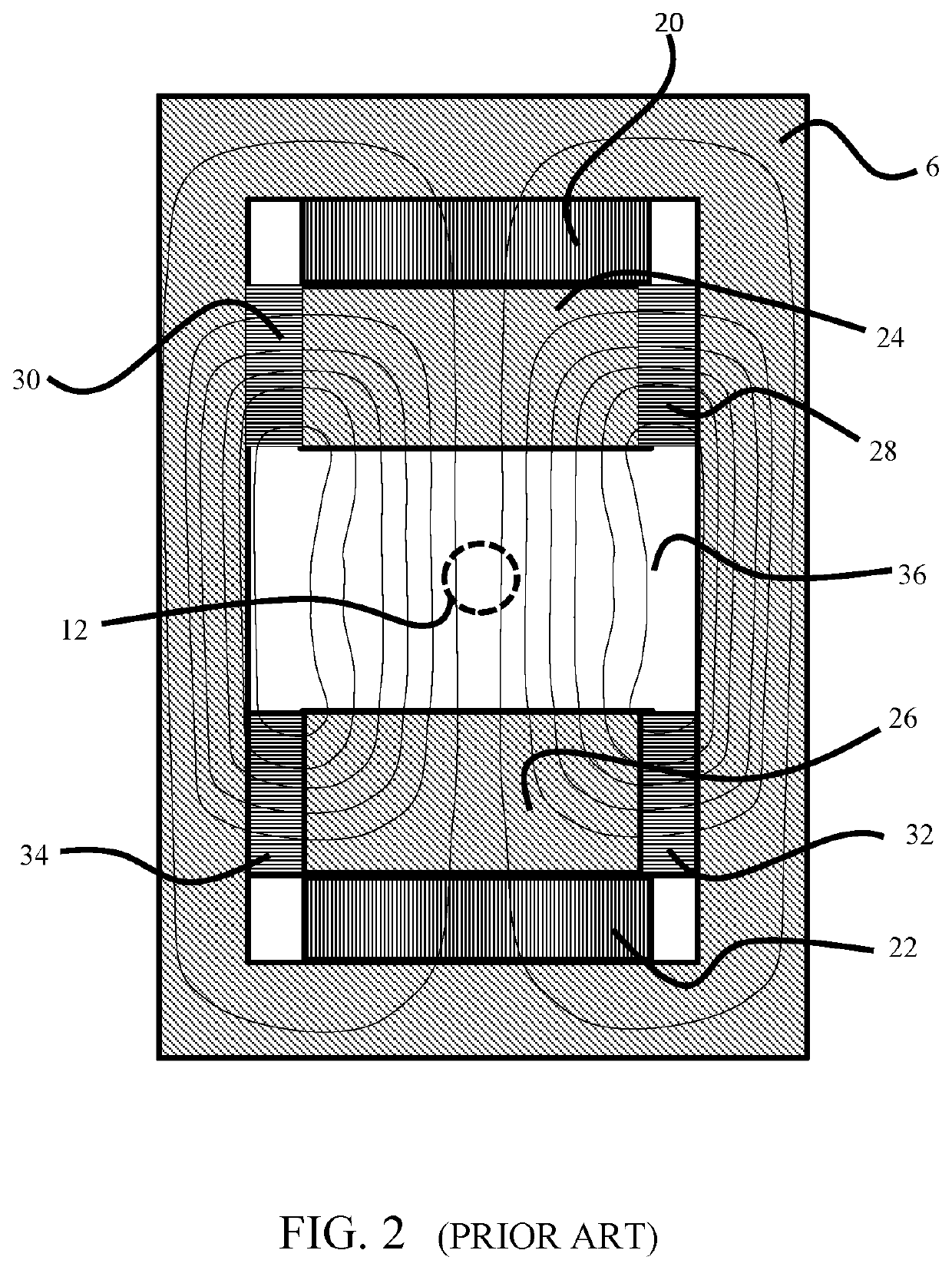

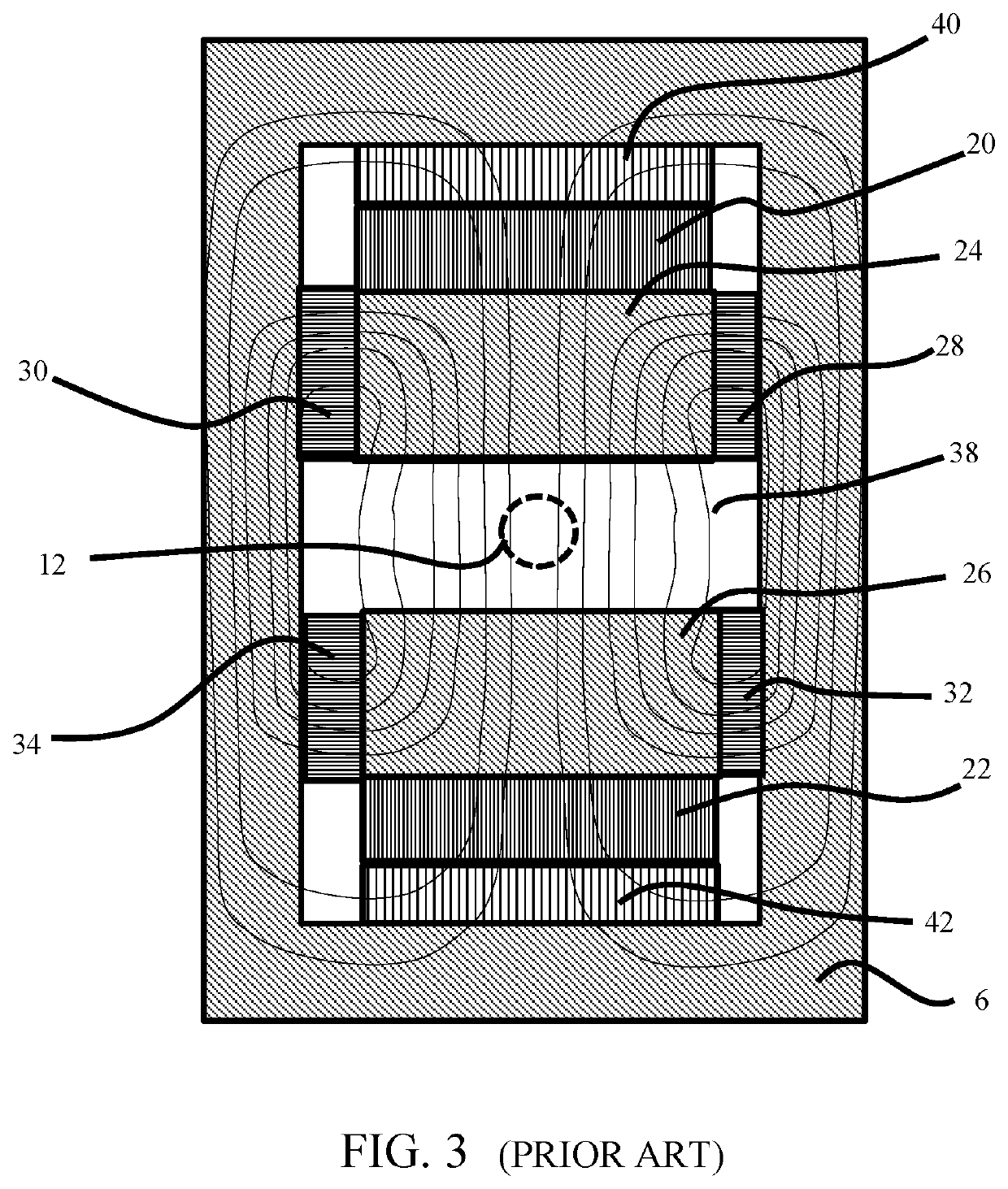

Resonator system

ActiveUS20060017440A1Improve efficiencySmall angleMagnetic measurementsElectric/magnetic detectionResonanceDielectric substrate

A resonator system for generating a radio frequency (RF) magnetic field in a volume under investigation of a magnetic resonance (MR) arrangement, comprises a number N of individual resonators (2) which surround the volume under investigation and which are each disposed on a flat dielectric substrate (1) around a z-axis, wherein the individual resonators (2) have windows (8) through each of which one individual RF field is generated in the volume under investigation in single operation of the individual resonators (2) and, through cooperation among the individual resonators (2), a useful RF field (7) is generated in the volume under investigation, wherein a remote RF field (6) is asymptotically generated far outside of the resonator system, and the spatial distribution of the useful RF field (7) is substantially mirror-symmetrical relative to a first plane A which contains the z-axis, and that of the asymptotic remote RF field (6) is substantially mirror-symmetrical relative to a second plane B which contains the z-axis, the useful RF field (7) extending substantially parallel to the first plane A in the volume under investigation, wherein the number of individual resonators (2) is N>4 and wherein, during operation of the resonator system at at least one point in time, the substrate plane of at least one individual resonator (2) subtends an angle of more than 40° with respect to the direction of the useful RF field (7) in the volume under investigation, and at least one further individual resonator (2) subtends an angle of less than 40° with respect to the direction of the useful RF field (7) in the volume under investigation, is characterized in that the first plane A is not rotated about the z-axis relative to the second plane B or is rotated by less than 360° / (N+1). The inventive resonator system realizes a resonator system with improved field homogeneity and full quadrature suitability, high quality factor and large efficiency using straightforward constructional measures.

Owner:BRUKER SWITZERLAND AG

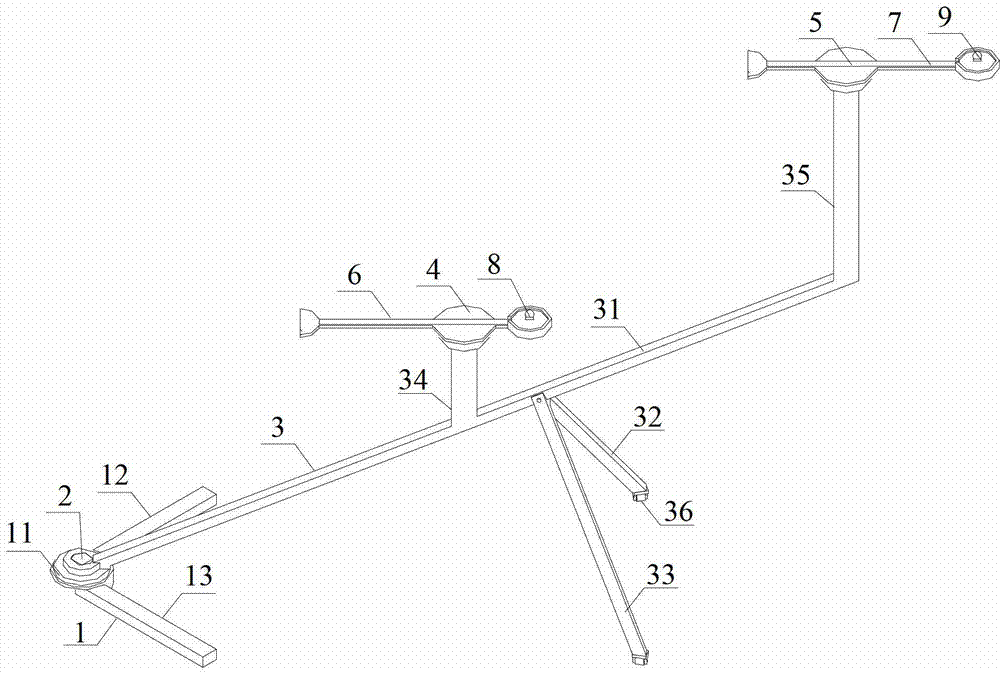

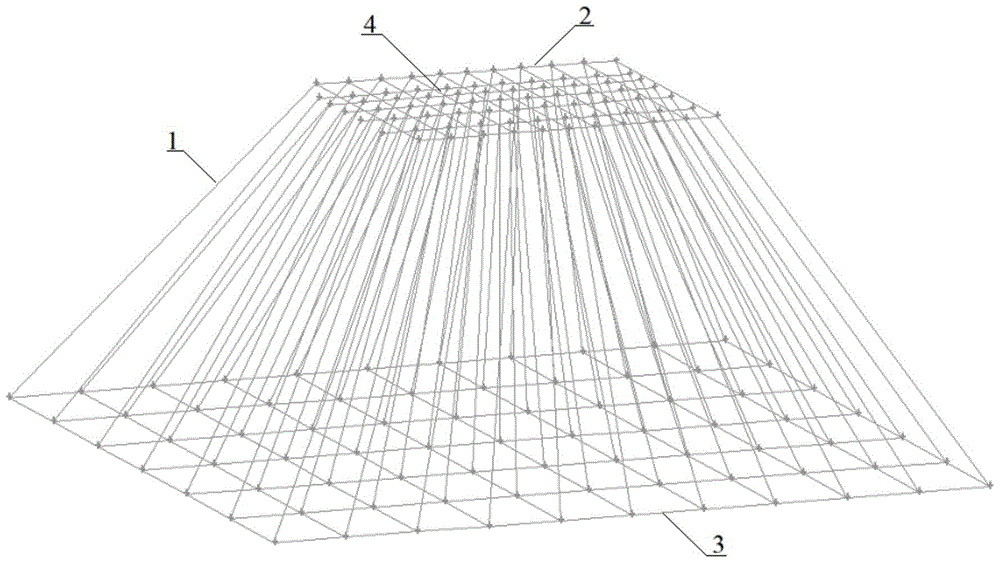

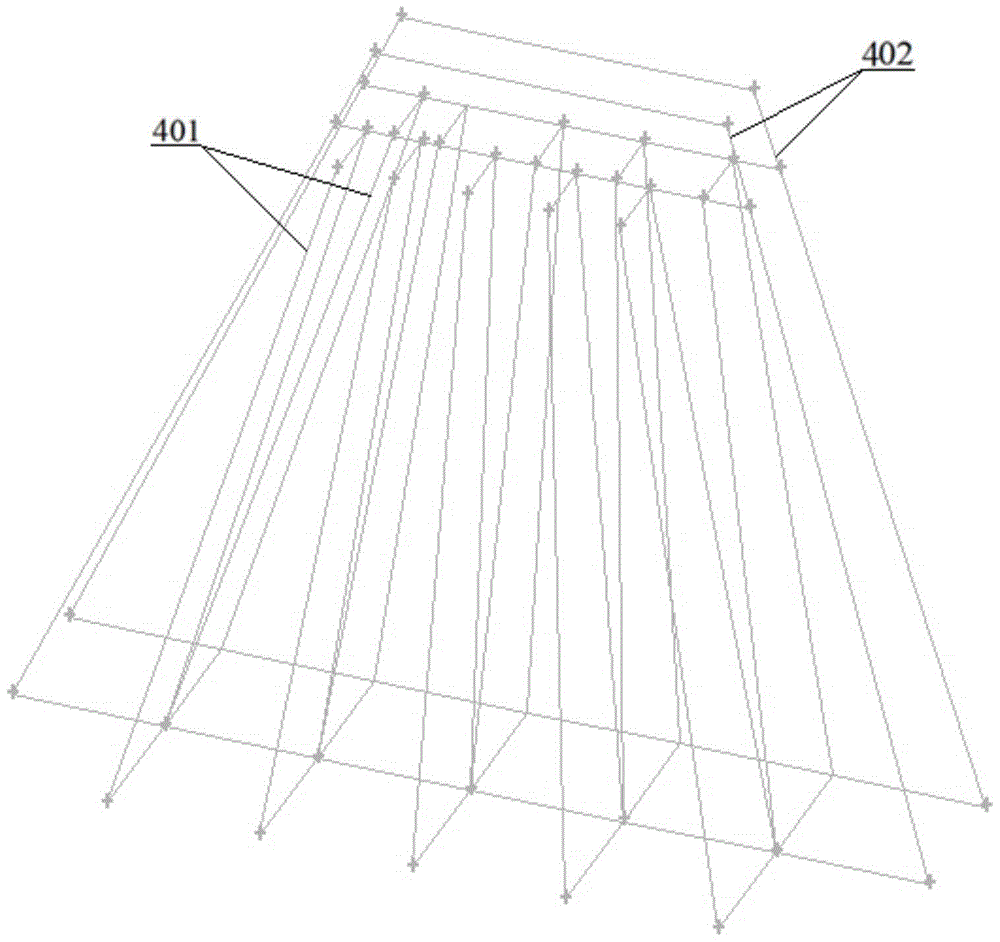

Supporting device for correcting uniformity of transient electromagnetic field

InactiveCN102829296AAdjustable positionAdjustable angleStands/trestlesEngineeringElectromagnetic field

The invention discloses a supporting device for correcting uniformity of a transient electromagnetic field. The supporting device comprises a base (1), a rotating shaft (2), a main frame (3), a first rotating plate (4), a second rotating plate (5), a first probe fixing device (6) and a second probe fixing device (7), wherein the base (1) comprises a fixing plate (11), a first base arm (12) and a second base arm (13), and the main frame (3) comprises a test rod (31), a first supporting rod (32), a second supporting rod (33), a first vertical column (34) and a second vertical column (35). When a supporting frame is adopted by a system for correcting the uniformity of the transient electromagnetic field, the supporting frame can be used for supporting and fixing a probe and also can be used for adjusting the position and angle of the probe. The supporting frame has high precision in adjusting the position and angle of the probe. The supporting frame is low in cost and is convenient to use.

Owner:BEIJING INST OF RADIO METROLOGY & MEASUREMENT

Method for determination and evaluation of a shim parameter set for controlling a shim device in a magnetic resonance apparatus

In a method for determination and evaluation of a shim parameter set for controlling a shim device in a magnetic resonance (MR) apparatus, the shim device is set using a first shim parameter set, a first field distribution is measured in a body region encompassing a target volume from which MR data are to be acquired, a second shim parameter set is determined using an algorithm for optimization of the field homogeneity in the target volume on the basis of the first shim parameter set and dependent on the first field distribution, a second field distribution is determined on the basis of the second shim parameter set, and the shim parameter sets are evaluated by indirect or direct comparison of the first field distribution and the second field distribution, in particular in the target volume.

Owner:SIEMENS HEALTHCARE GMBH

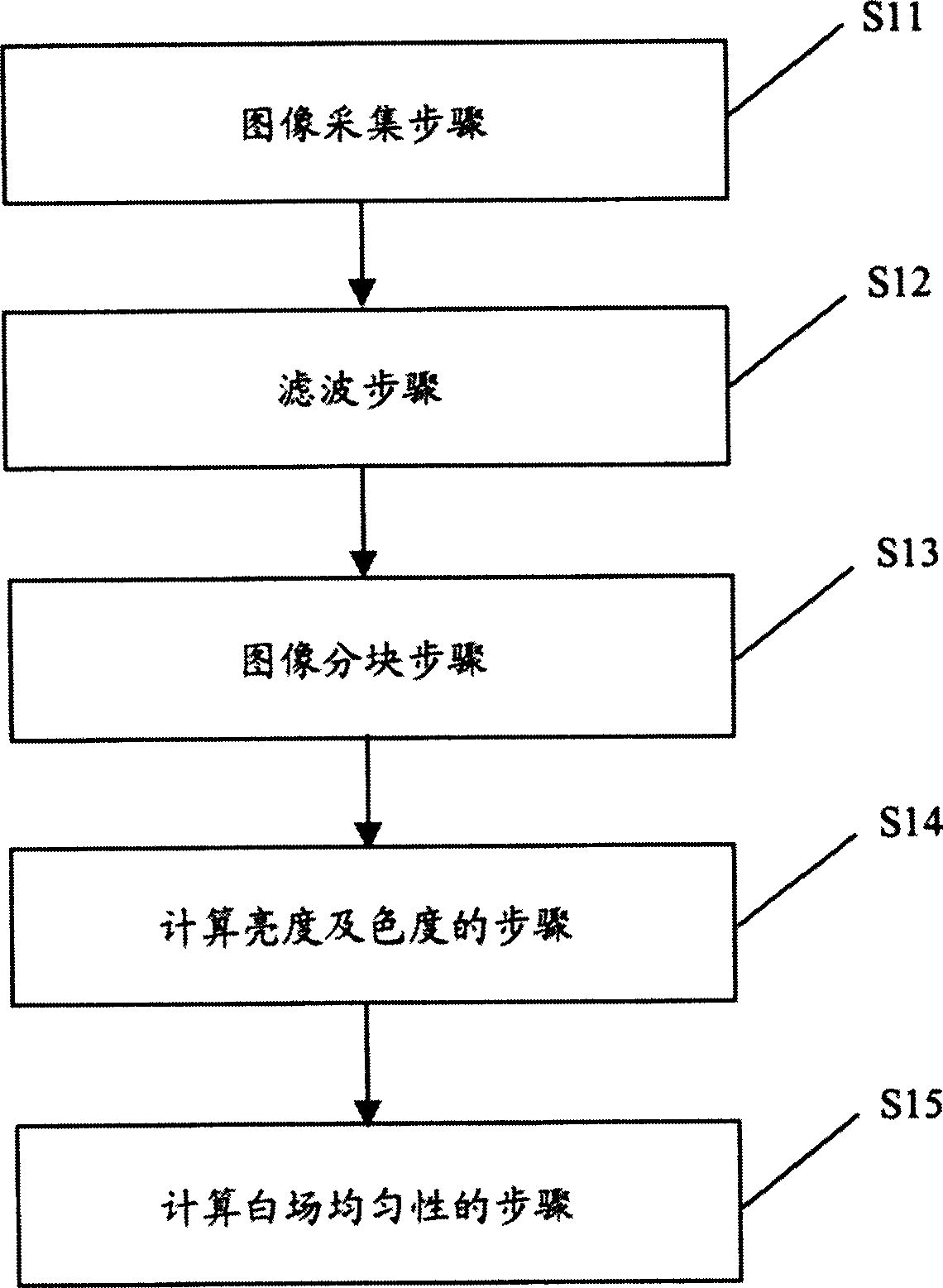

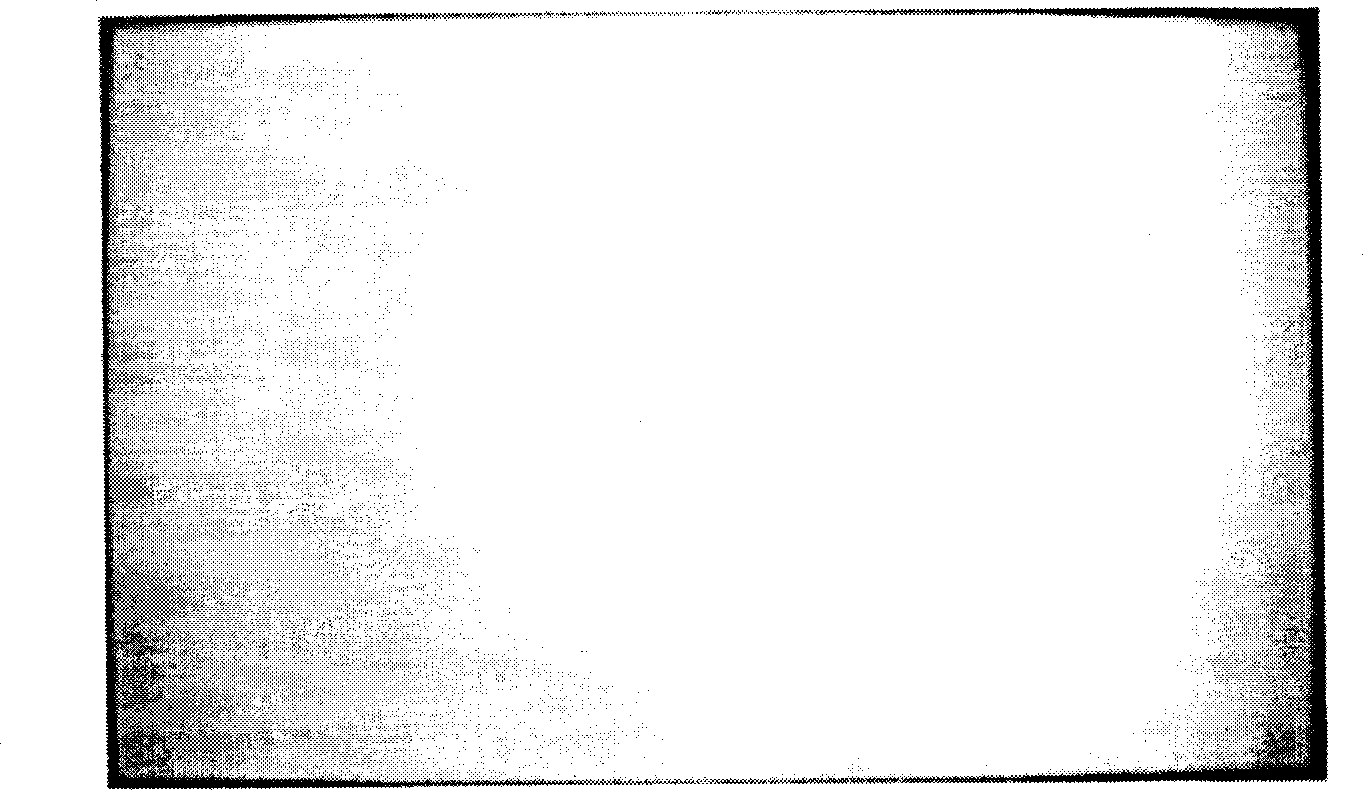

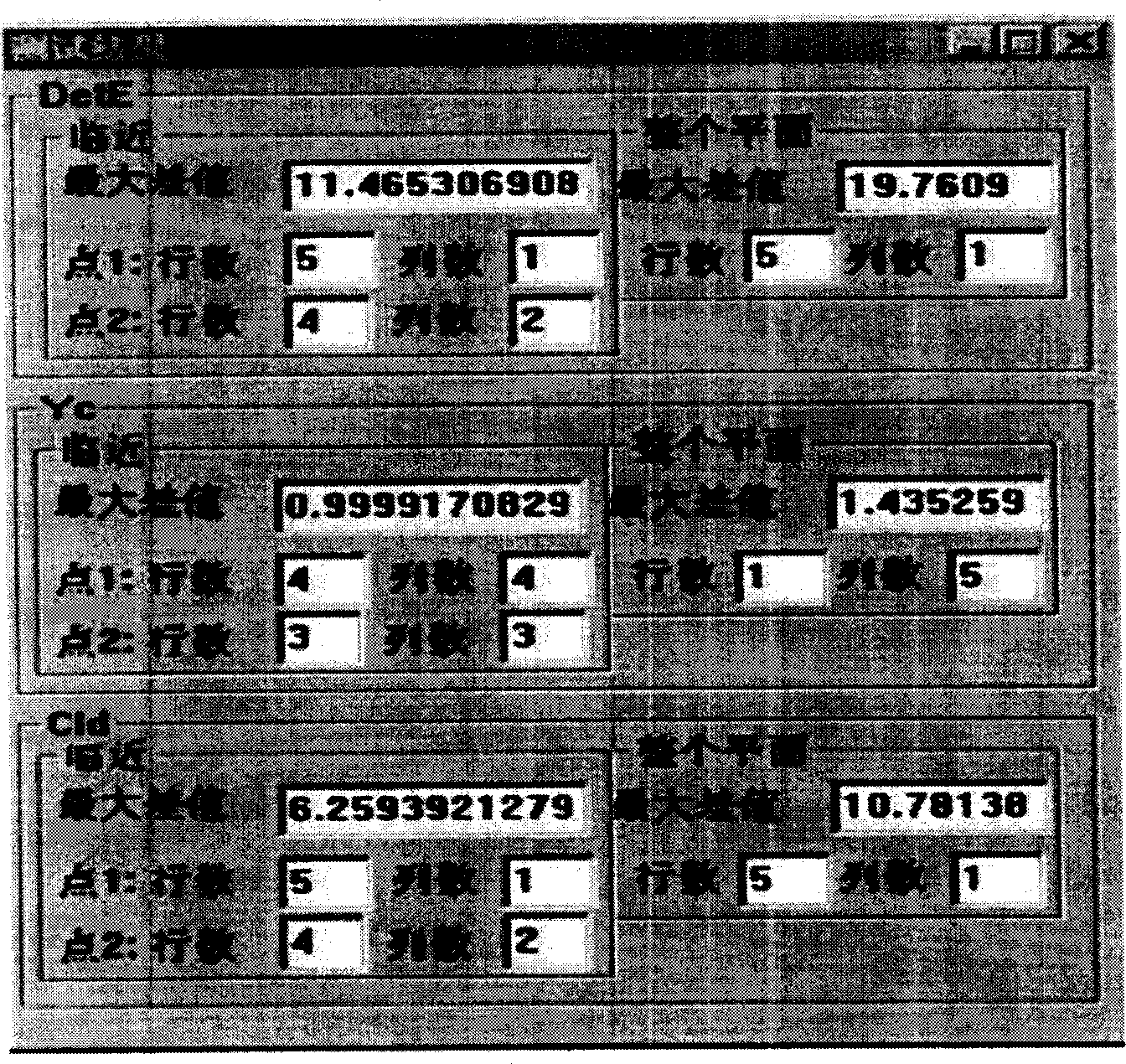

Chromatic display unit white field homogeneity testing method and system

The invention discloses a homogeneity test method for homogeneity of color display, which comprises: collecting image with image collector, filtering with mean value average filter device, partitioning image with image partition device, calculating lightness and colority and homogeneity of white field by opposite device. This invention decides the homogeneity of white field for whole screen with uniform standard instead of manual decision to avoid test error and ensure consistency.

Owner:SHANGHAI NOVEL COLOR PICTURE TUBE

Photoresist mask/smoothing layer ensuring the field homogeneity and better step-coverage in OLED displays

InactiveUS7086917B2Simplified slopingOvercome difficultiesElectroluminescent light sourcesSolid-state devicesOrganic light emitting deviceComputational physics

A method of making an organic light emitting device (OLED) is disclosed wherein an inert insulating conformal smoothing layer is deposited over a protruding structure. The smoothing layer is patterned to expose portions of the structure underlying the smoothing layer and defining active regions of the device. The inert smoothing layer is treated, preferably by heat reflow, to taper the layer over the stepped edges of the structure on the exposed portions. Additional layers are then deposited over the smoothing layer and the exposed portions of the structure. The smoothing layer blunts all underlying layer edges and provides sloped edges wherever a step occurs from one layer to another. This effect results in a homogeneous field across the pixel and the continuity in the layers deposited after the photoresist layer.

Owner:NAT RES COUNCIL OF CANADA

Method of designing a shim coil to reduce field settling time

ActiveUS20070126541A1Reduce Flux LeakageImpact settling timeMagnetic measurementsMagnetsRoom temperatureEngineering

A shim coil design technique determines a position and a geometry of a room temperature (RT) shim coil to provide both a desired field homogeneity and a desired B0 field setting time. The simultaneous satisfaction of both field homogeneity and field settling time is achieved without a reduction of flux leakage from the shim coil, modification of main magnet protection circuitry, and without necessarily decoupling of the shim coil from the overall main magnet.

Owner:GENERAL ELECTRIC CO

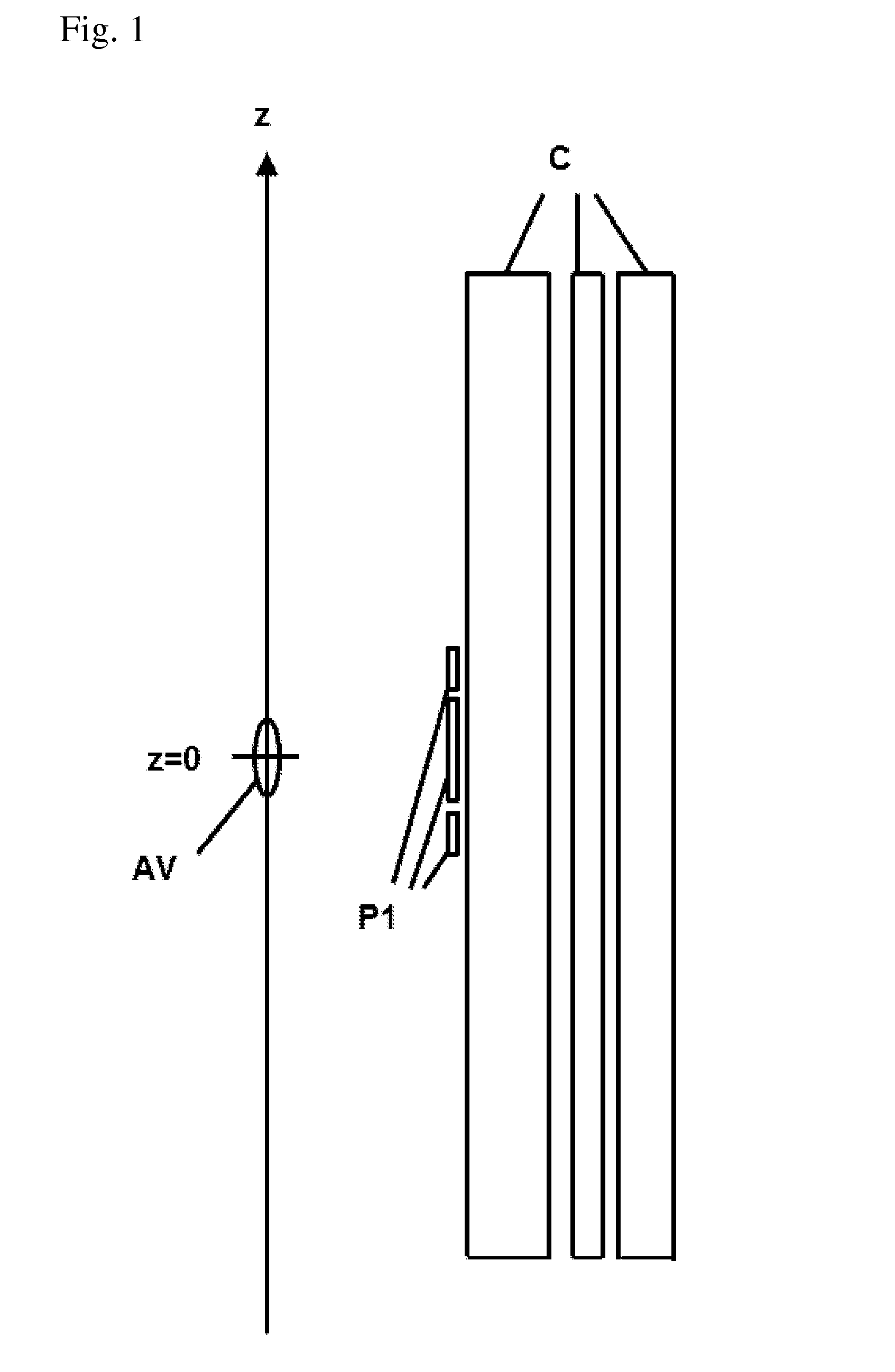

Magnet configuration with a superconducting magnet coil system and a magnetic field forming device for magnetic resonance spectroscopy

InactiveUS20140125342A1Improve field uniformityEasy to assembleMagnetic property measurementsSuperconductor device manufacture/treatmentSpherical harmonicsSuperconducting Coils

A magnet assembly has a field shaping device (P1) that is cylindrically symmetric with respect to the z-axis and made of magnetic material. At least parts of the field shaping device have a radial distance from the z-axis of less than 80 millimeters and compensate for at least one of the inhomogeneous field parts An0·zn of the magnet coil system. The field shaping device has one or more non cylindrically symmetric recesses, which are constituted such that at least a coefficient Anm or Bnm in the magnetic field expansion of the magnet assembly according to the spherical harmonic functions is reduced by at least 50%. In this way, the field homogeneity of the working volume can be substantially increased in a simple manner and without increasing the volume of the magnet assembly, wherein only a few iterations are required to optimize the magnet assembly.

Owner:BRUKER BIOSPIN

Photoresist mask/smoothing layer ensuring the field homogeneity and better step-coverage in OLED displays

InactiveUS20060220545A1Simplified slopingOvercome difficultiesDischarge tube luminescnet screensElectroluminescent light sourcesOrganic light emitting deviceComputational physics

A method of making an organic light emitting device (OLED) is disclosed wherein an inert insulating conformal smoothing layer is deposited over a protruding structure. The smoothing layer is patterned to expose portions of the structure underlying the smoothing layer and defining active regions of the device. The inert smoothing layer is treated, preferably by heat reflow, to taper the layer over the stepped edges of the structure on the exposed portions. Additional layers are then deposited over the smoothing layer and the exposed portions of the structure. The smoothing layer blunts all underlying layer edges and provides sloped edges wherever a step occurs from one layer to another. This effect results in a homogeneous field across the pixel and the continuity in the layers deposited after the photoresist layer.

Owner:NAT RES COUNCIL OF CANADA

MR imaging using apt contrast enhancement and sampling at multiple echo times

ActiveUS9766313B2Enhance the imageHigh-quality and high contrast-to-noise MR imagingDiagnostic recording/measuringSensorsMagnetic field gradientFrequency offset

Owner:KONINK PHILIPS ELECTRONICS NV

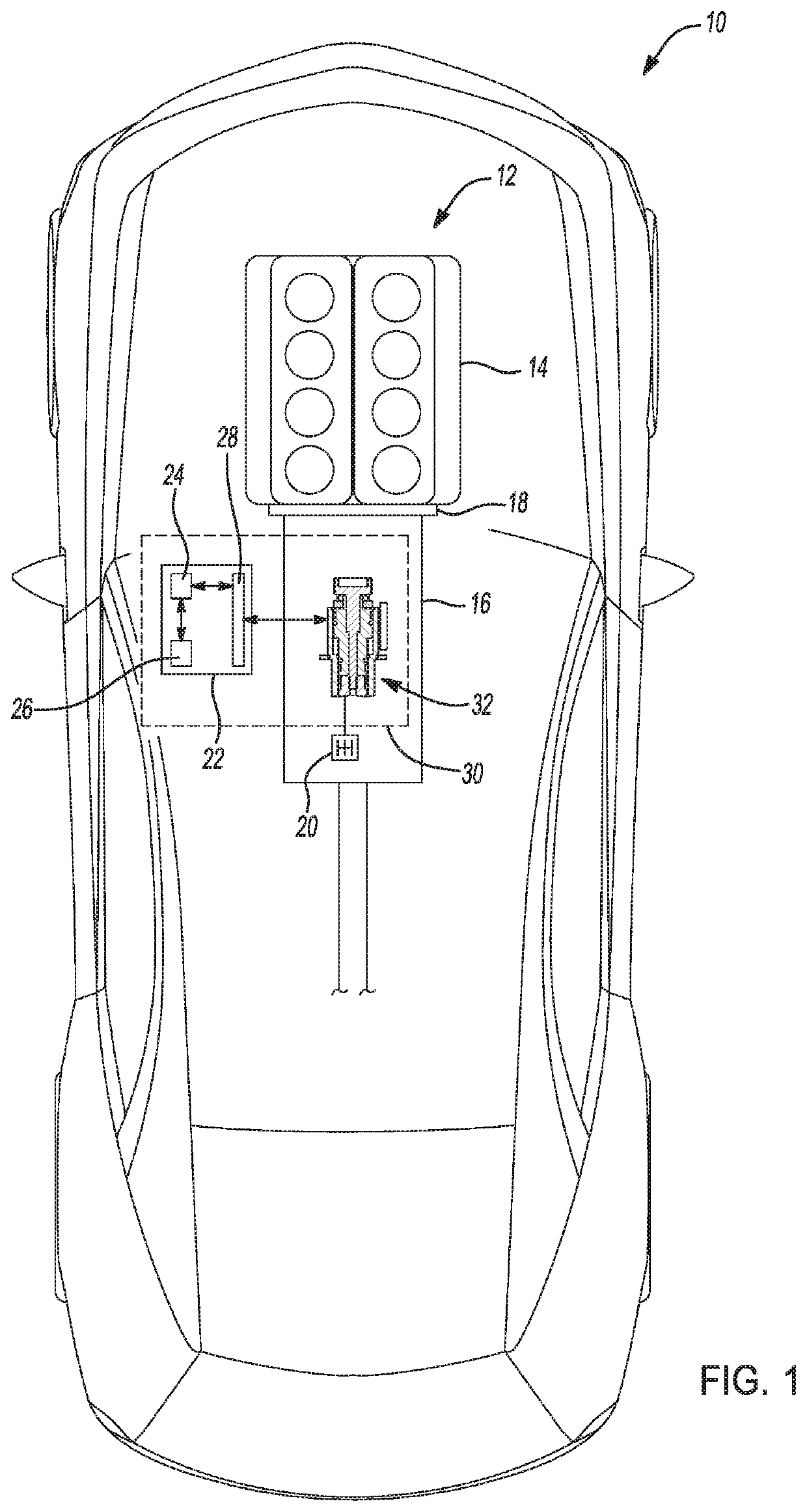

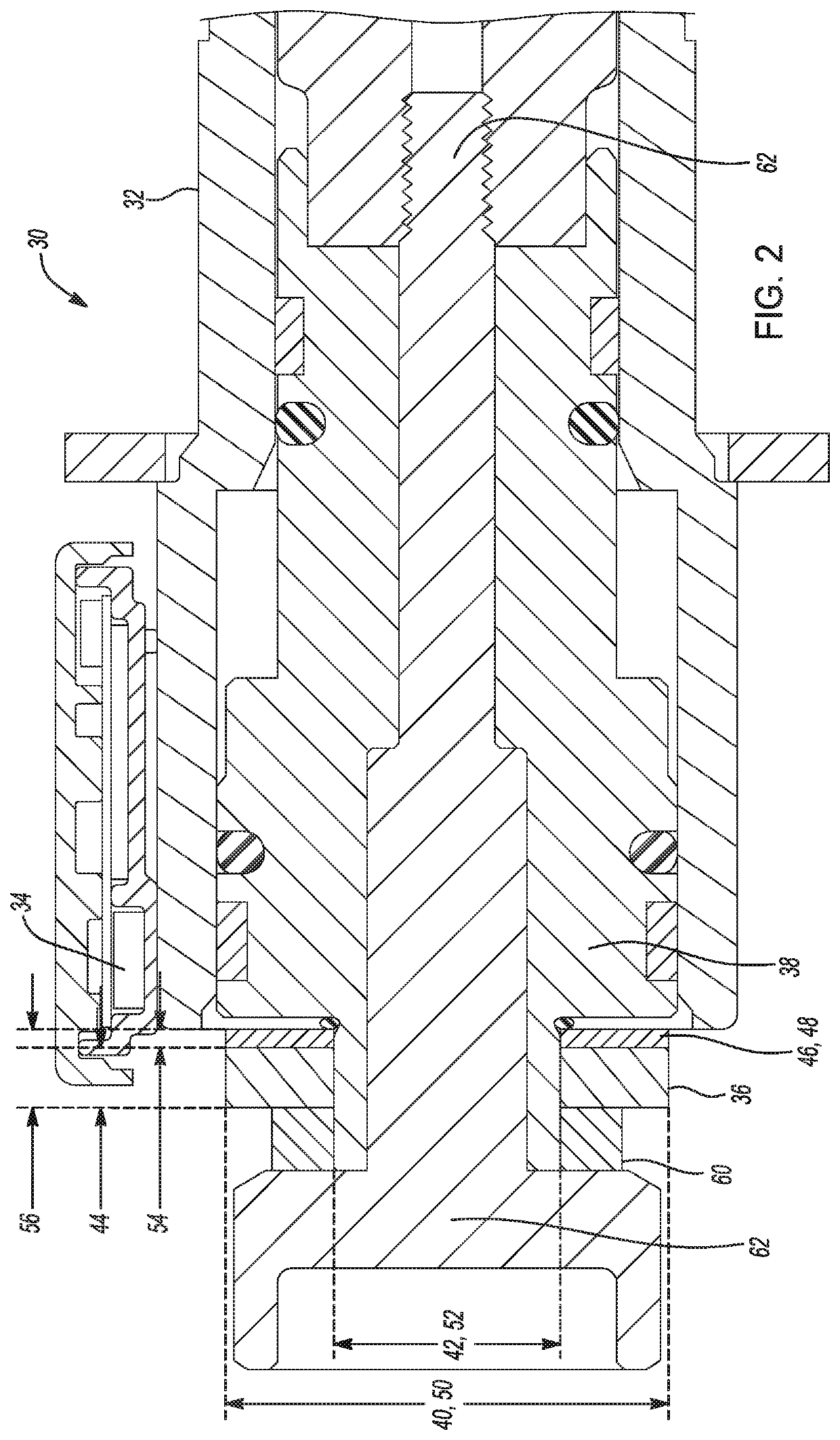

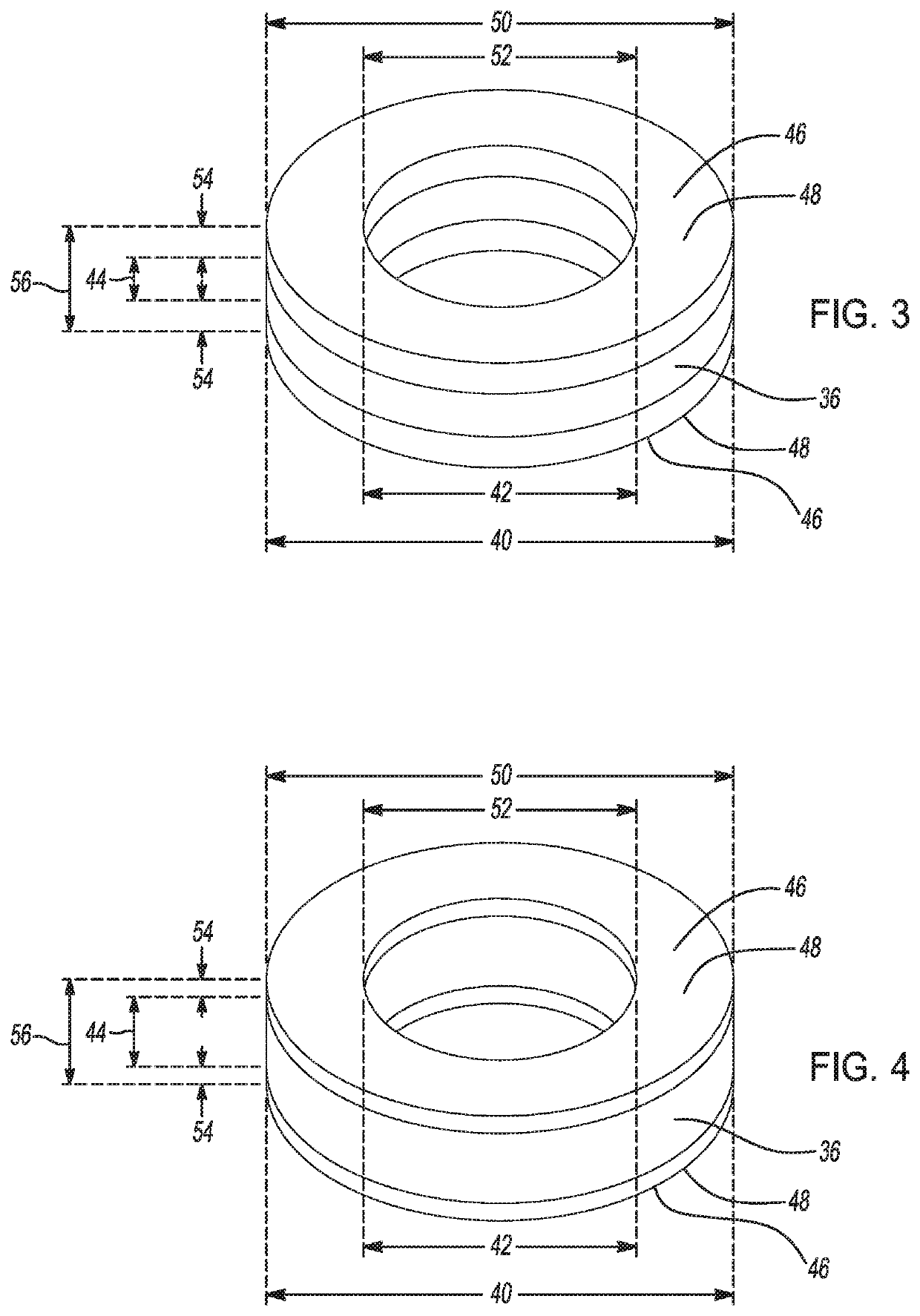

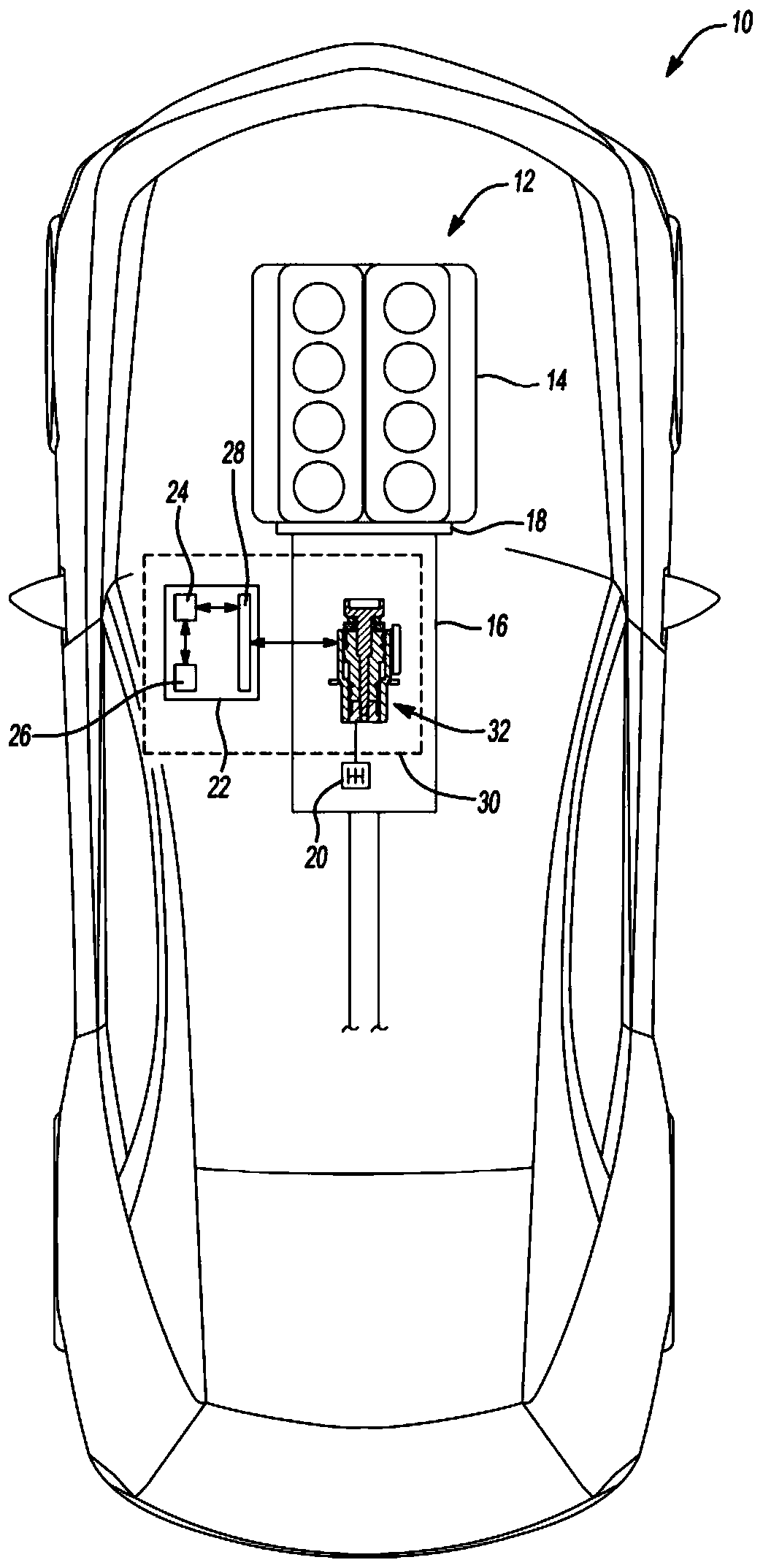

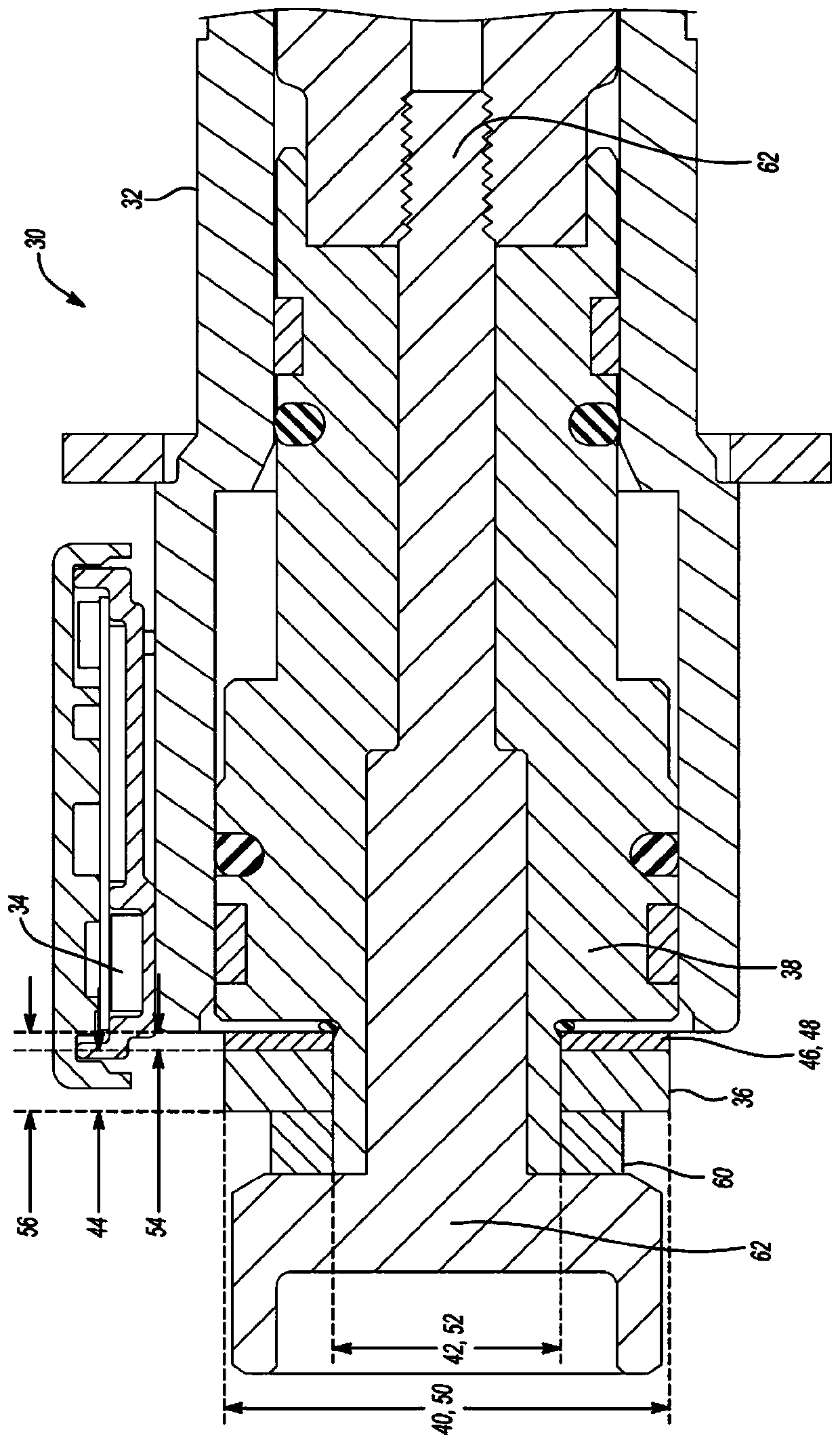

Robust magnet field homogeneity and detected signal-to-noise for transmission park position sensor applications

ActiveUS10527158B1Component with highReduce rotationGearing controlConverting sensor output electrically/magneticallyElectronic transmissionMotorized vehicle

An electronic transmission range selection (ETRS) system for a motor vehicle transmission includes an ETRS housing disposed on the transmission, the ETRS housing having a magnetic field sensor in communication with a transmission controller; and a magnetic field source including a magnet component and a high magnetic permeability component. The magnetic field source disposed on a transmission selector shaft, the magnetic field source detectable by the magnetic field sensor at a plurality of predetermined positions along a movement path of the transmission selector shaft; and the magnetic field sensor detecting magnetic flux generated by the magnetic field source, and communicating magnetic field source position information to the controller. The high magnetic permeability component homogenizes the magnetic flux generated by the magnet component and the controller generates an electronic transmission mode signal based on the magnetic field source position information.

Owner:GM GLOBAL TECH OPERATIONS LLC

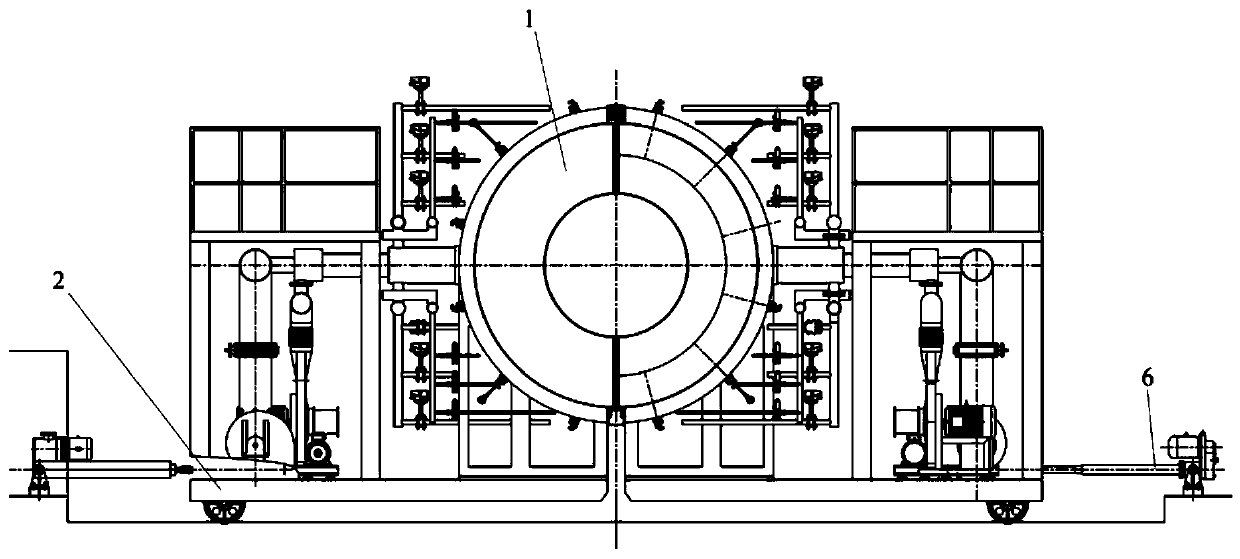

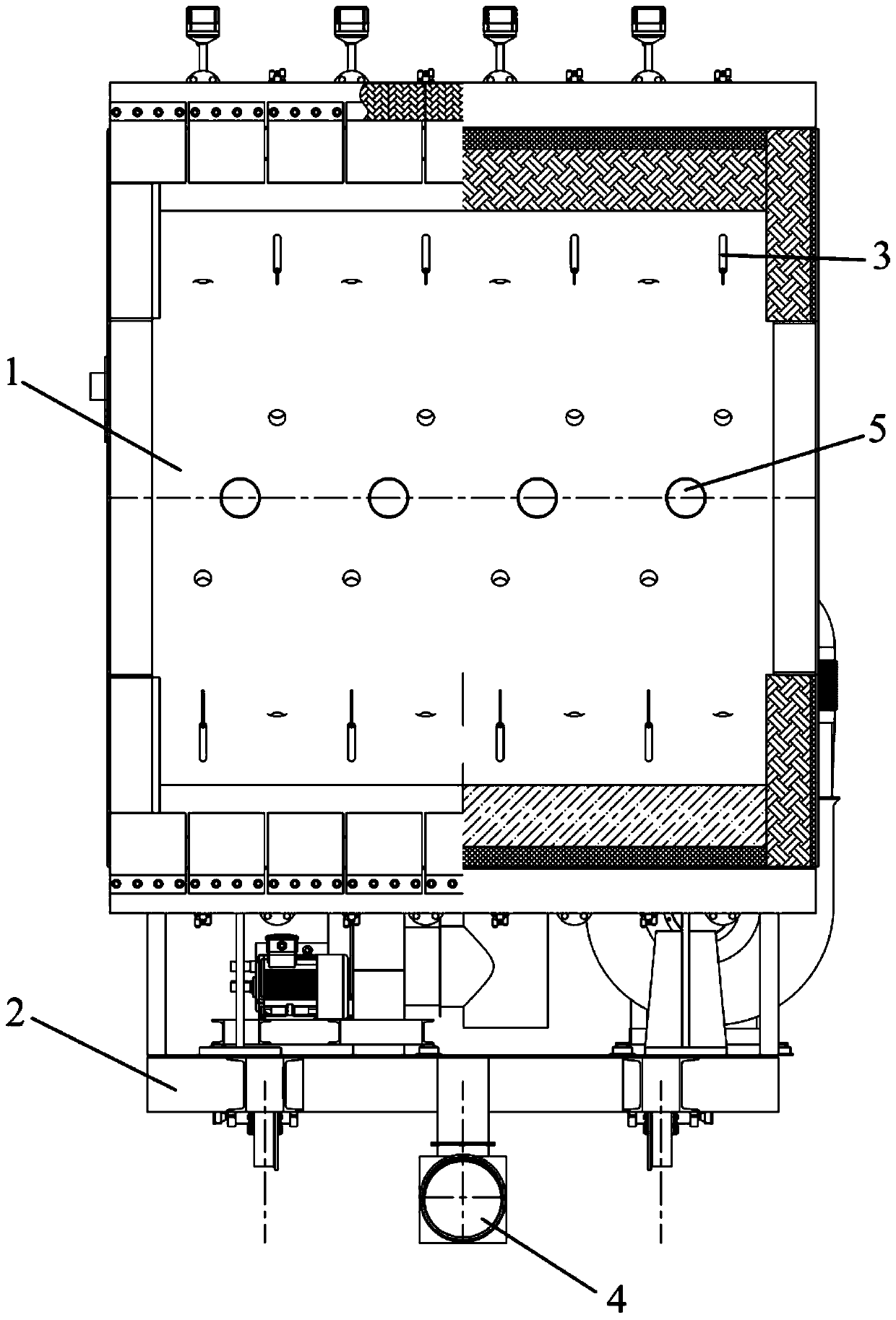

Flat flame nozzle type differential temperature heat treatment furnace

PendingCN110241295AGuaranteed temperature uniformityImprove uniformityFurnace typesIndirect carbon-dioxide mitigationCombustion systemCombustion

The invention relates to a flat flame nozzle type differential temperature heat treatment furnace, belongs to the technical field of differential temperature heat treatment, and solves the problem that it is difficult to ensure high quality heating of continuous rolling mill bearing rollers with roller bodies in different specifications. The flat flame nozzle type differential temperature heat treatment furnace comprises two half furnace structures in the same structural size; each half furnace structure comprises a furnace body, a trolley, a combustion system and a smoke exhaust system; each furnace body is arranged on the corresponding trolley; the furnace bodies of the two half furnace structures can be combined into a cylindrical furnace wall with the end faces being a ring; the combustion systems penetrate into the furnace bodies, and flat flame nozzles are arranged on the inner surfaces of the furnace bodies; the axes of the flat flame nozzles are perpendicular to the inner surfaces of the furnace bodies; smoking ports of the smoke exhaust systems are arranged on the furnace wall of the furnace bodies; and a heat exchange structure is arranged between an exhaust pipe and an air intake pipe. By means of the flat flame nozzle type differential temperature heat treatment furnace, stable control over the roller body axial temperature field homogeneity during heating of the bearing rollers is achieved, the roller body hardness uniformity index of the bearing rollers reaches the higher level, and the product quality yield is improved.

Owner:TIANJIN HEAVY EQUIP ENG RES +1

Magnet assembly for MRI comprising cylindrical rings of halbach type

ActiveUS10732240B2High error rateMagnetic measurementsPermanent magnetsUniform fieldMagnet resonance imaging

Construction methods and techniques allow for a magnetic field of the field homogeneity required for the use in magnetic resonance imaging (MRI), in the order of 20 parts per million (ppm) in the area of interest (such techniques in the following will be indicated with the word “shimming”). The peculiarity of the constructive method is to obtain a homogeneous field region, usable for the MRI analysis, of linear dimensions equal to about 40% of the linear dimensions of the magnet. The shimming technique involves the use of conditioned magnetic material and allows accurate control of the magnetization of the corrective elements while using a material that inherently has a large spread in the magnetization value. The result is a low weight and small magnet suitable for MRI for dedicated clinical applications such as the analysis of the peripheral joint, the analysis of the ocular region, and veterinary applications.

Owner:SOTGIU ANTONELLO

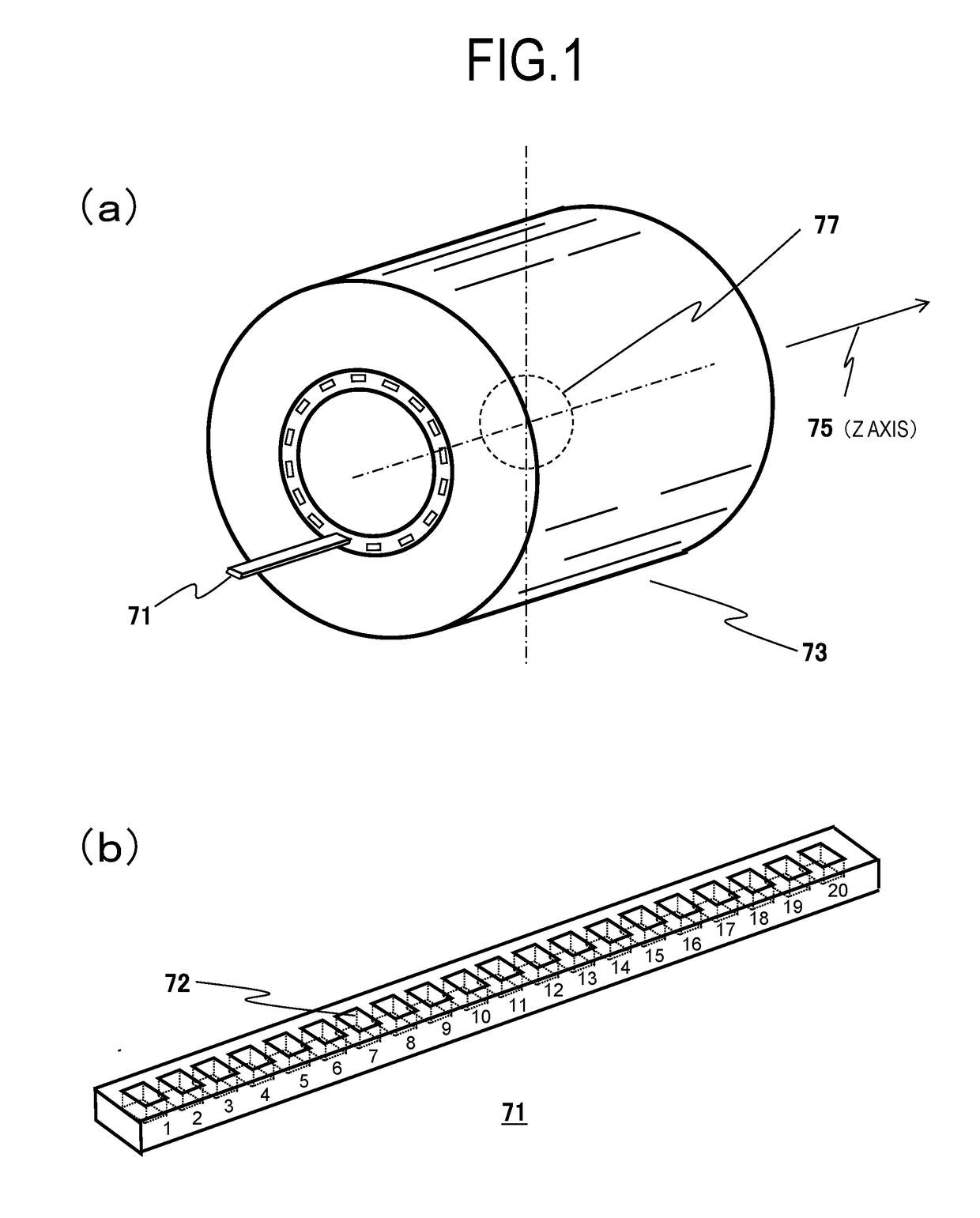

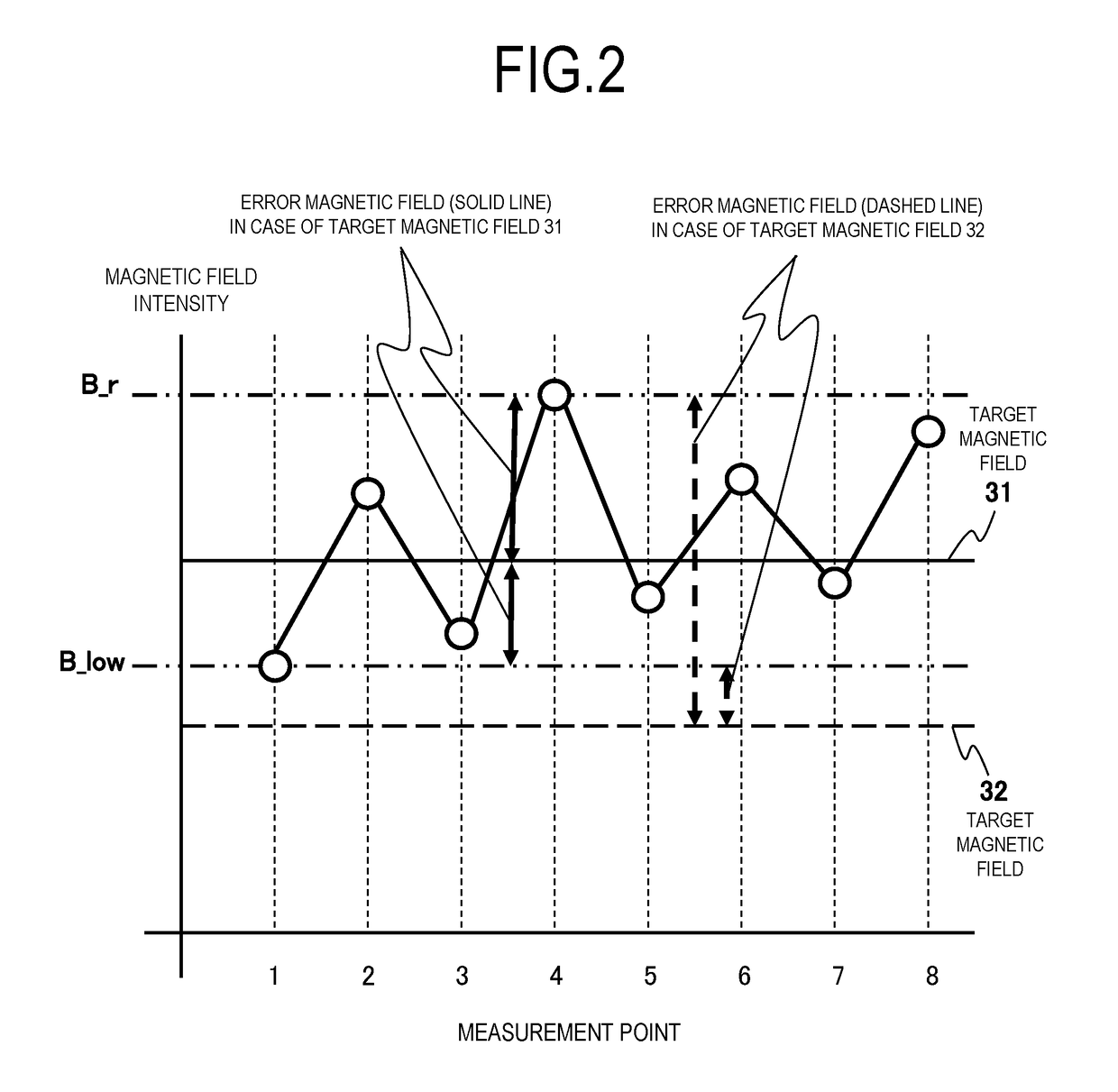

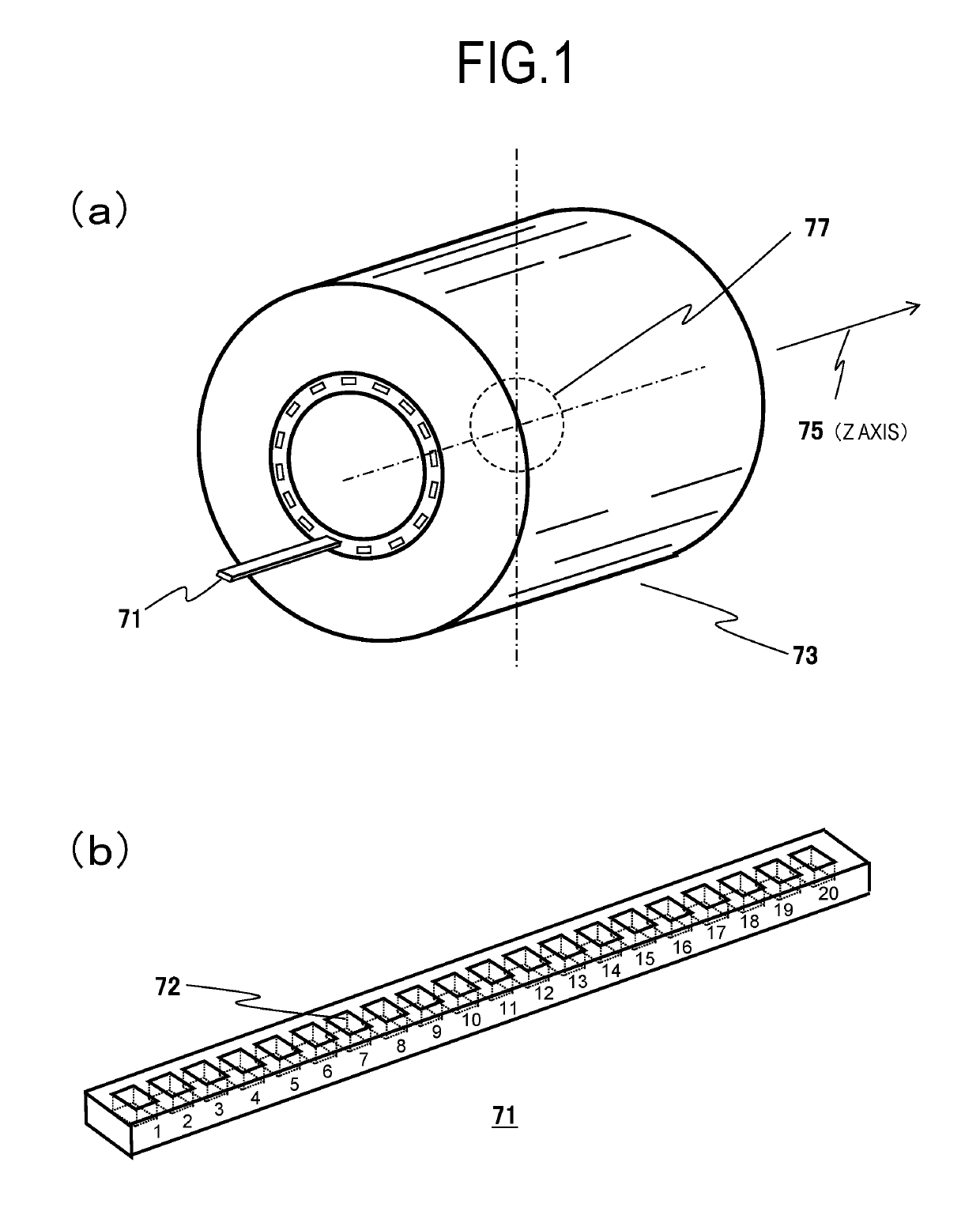

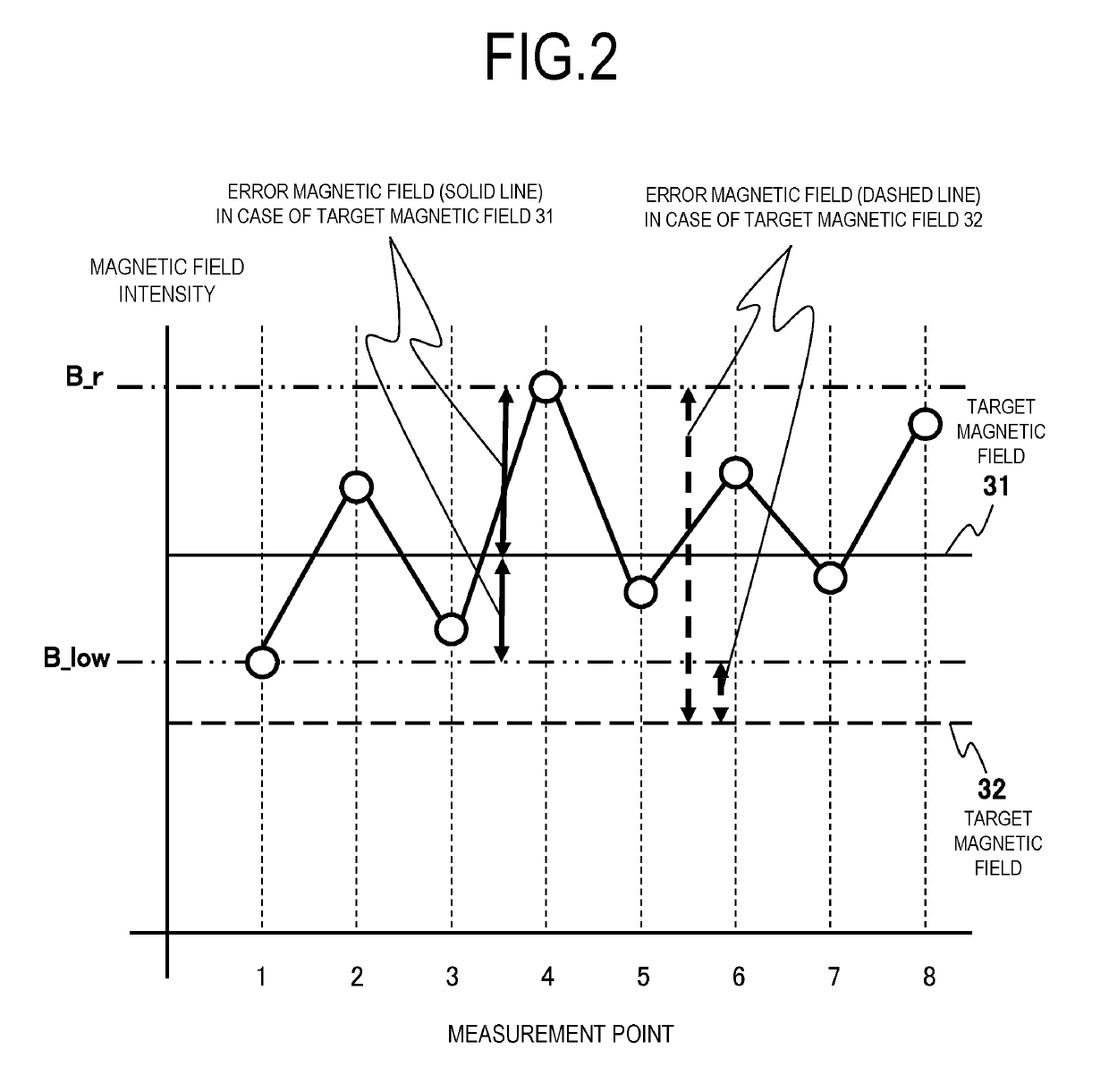

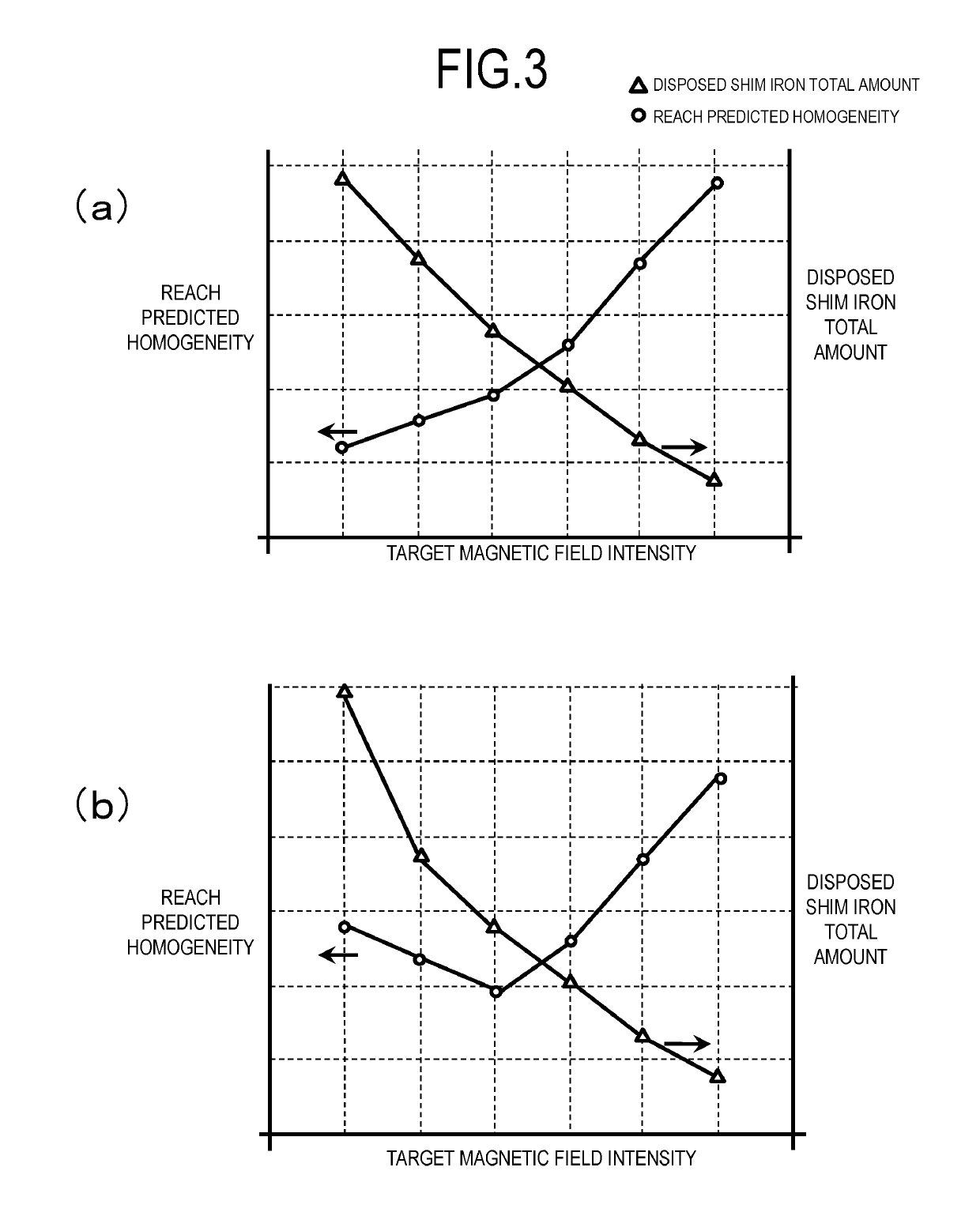

Magnetic field homogeneity adjustment method, magnetic field homogeneity adjustment program and magnetic field homogeneity adjustment device

ActiveUS20180284205A1Adjustable performanceMagnetic measurementsDiagnostic recording/measuringLimit valueField homogeneity

Even if there is a restriction in an amount of magnetic pieces which can be disposed at each position in a shim tray, a distribution of a static magnetic field is measured so that an error magnetic field between the distribution of the static magnetic field and a target magnetic field is calculated, and respective reachable magnetic field homogeneities in a case where the magnetic pieces are disposed at one or more of the plurality of positions in the shim tray are calculated while changing the target magnetic field. The target magnetic field is selected in which an amount of magnetic pieces at each of the positions in the shim tray is equal to or less than a predetermined upper limit value, and the reachable magnetic field homogeneity is equal to or less than a predetermined value.

Owner:FUJIFILM HEALTHCARE CORP

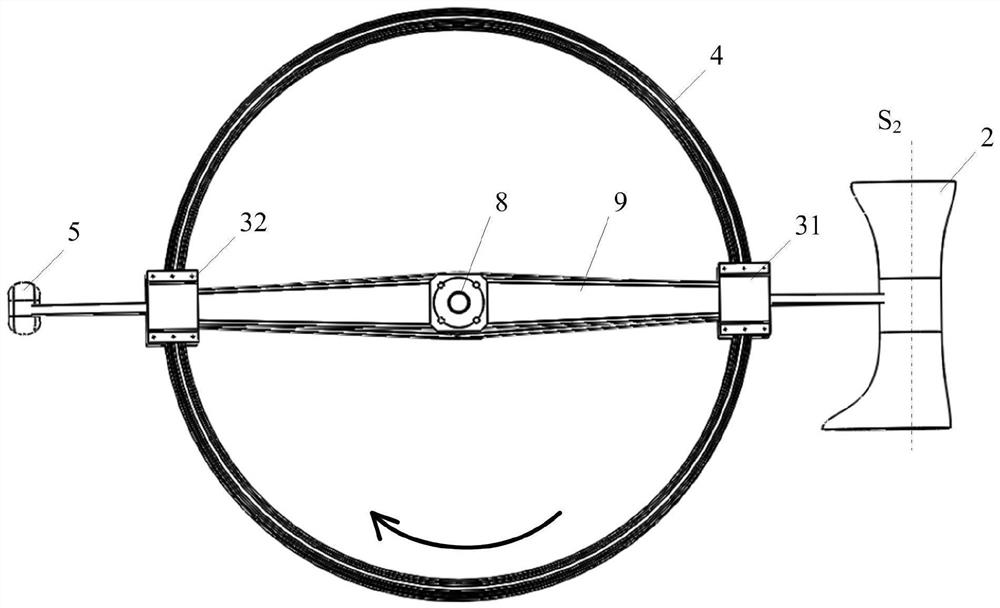

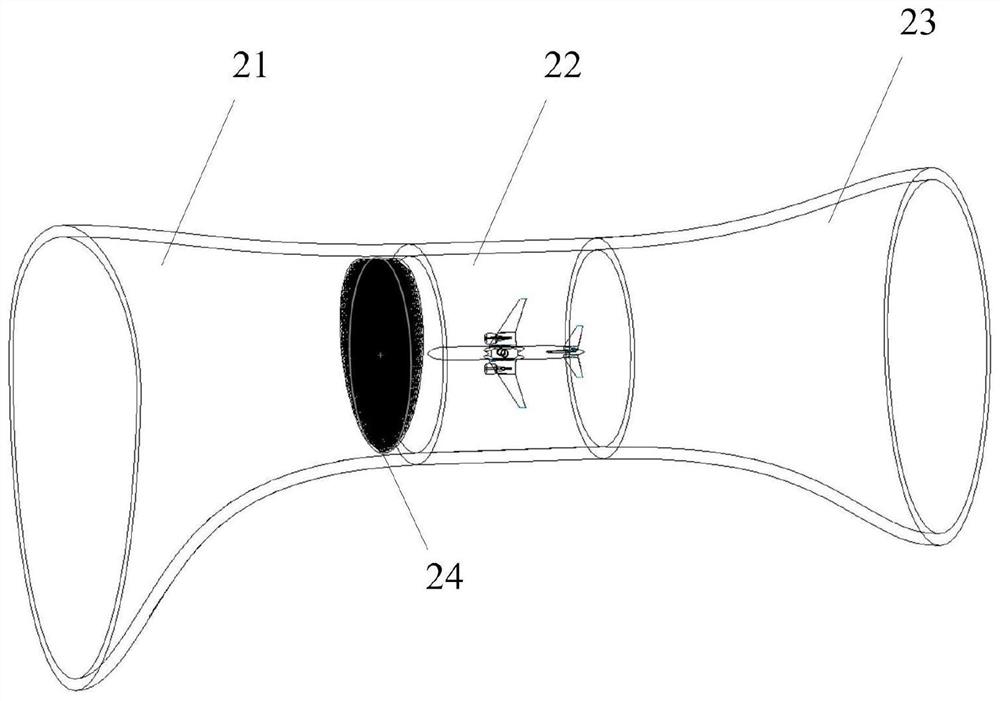

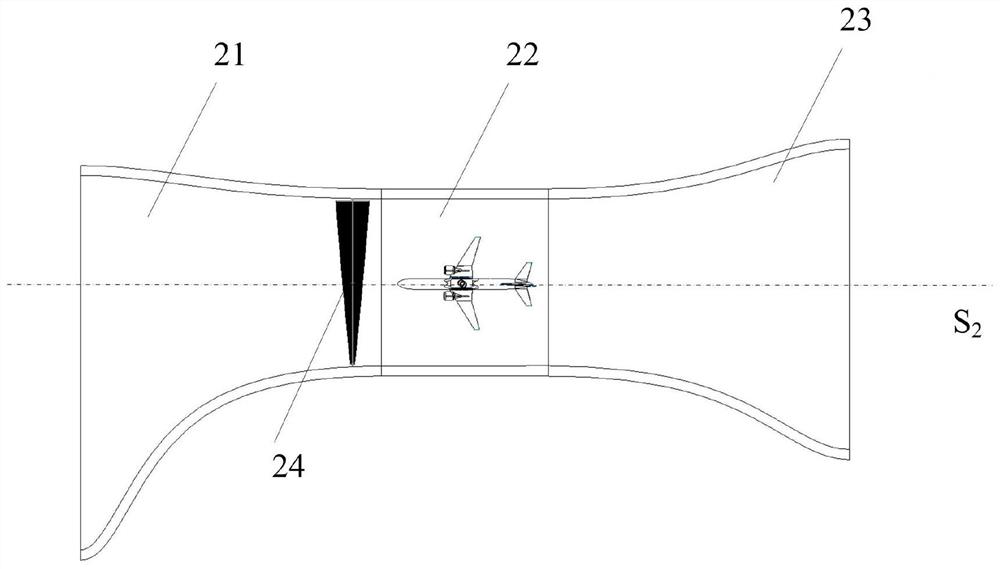

Active rotary airflow field test system

ActiveCN113551864AEnsure flow field homogeneityCompensates for speed differences between inner and outer ringsAerodynamic testingRenewable energy source integrationKineticsHoneycomb

The invention relates to the technical field of experimental fluid mechanics and aerodynamics and discloses an active rotation type airflow field test system. The system comprises a flow equalizing acceleration duct and a rotation mechanism, in the flow equalizing acceleration duct, the cross section area of a contraction section is gradually reduced along the air inlet direction; the test section is of a cylindrical ventilation structure and is used for placing a test object; the sectional area of the diffusion section is gradually increased in the air inlet direction; the contraction section, the test section and the diffusion section are symmetrical structures taking the first reference surface as a symmetrical central surface; in the contraction section, a distance from the midpoint of the air inlet inner side edge to the second reference surface is the maximum value a of the distance from any point in the air inlet inner side edge to the second reference surface, a distance from the midpoint of the air inlet outer side edge to the second reference surface is the maximum value b of the distance from any point in the air inlet outer side edge to the second reference surface, and b is smaller than a. In the active rotary airflow field test system, the flow field homogeneity in the test section is ensured through the flow-equalizing acceleration duct (and the asymmetric honeycomb device) with a specific structure.

Owner:CHONGQING UNIV

Magnetic field homogeneity adjustment method, magnetic field homogeneity adjustment program and magnetic field homogeneity adjustment device

ActiveUS10267877B2Adjustable performanceDiagnostic recording/measuringSensorsLimit valueField homogeneity

Owner:FUJIFILM HEALTHCARE CORP

A Method of Airflow Uniform Distribution Based on Numerical Calculation of Flow Field

InactiveCN103914614BReduce flow rate deviationPracticalSpecial data processing applicationsEngineeringChannel width

The invention discloses an airflow uniform distribution method based on numerical calculation of the flow field. A trapezoidal honeycomb structure diversion grid is arranged in a conventional bell mouth, and the airflow passes through the diversion grid from a narrower section channel to a wide section channel, combined with the flow field Numerical simulation of the flow field distribution of the air flow through the diversion grid, and obtain the flow distribution of each grid, and then obtain the deviation of the air flow of each grid channel from the average flow, and increase or decrease according to the size of the deviation For the entrance cross-sectional area of the trapezoidal grid, the numerical simulation calculation of the flow field is carried out again. After several repetitions, the gas flow rate of each grid can be close to the same, so that the flow field of the wide-section channel can be evenly distributed. Utilizing the air flow uniform distribution method based on the numerical calculation of the flow field described in the present invention can reduce the flow velocity deviation on the target section to a very low range, and meet the needs of some engineering occasions that require high flow field uniformity. The method is effective and feasible.

Owner:SOUTHEAST UNIV

Robust magnet field homogeneity and detected signal-to-noise for transmission park position sensor applications

InactiveCN110848377AGearing controlConverting sensor output electrically/magneticallyElectronic transmissionMotorized vehicle

An electronic transmission range selection (ETRS) system for a motor vehicle transmission includes an ETRS housing disposed on the transmission, the ETRS housing having a magnetic field sensor in communication with a transmission controller; and a magnetic field source including a magnet component and a high magnetic permeability component. The magnetic field source disposed on a transmission selector shaft, the magnetic field source detectable by the magnetic field sensor at a plurality of predetermined positions along a movement path of the transmission selector shaft; and the magnetic fieldsensor detecting magnetic flux generated by the magnetic field source, and communicating magnetic field source position information to the controller. The high magnetic permeability component homogenizes the magnetic flux generated by the magnet component and the controller generates an electronic transmission mode signal based on the magnetic field source position information.

Owner:GM GLOBAL TECH OPERATIONS LLC

Calculation of plate shadow for eliminating central bright spot in color picture tube

InactiveCN100361259CSmall sizeEliminate the central bright spotNon-emitting electrodes manufactureGroove widthBright spot

The calculation method for eliminating central bright spot in color picture tube, and especially raising the white field homogeneity and the corner-to-center brightness ratio of color picture tube includes the following steps: to calculate groove width D in terms of the expression of D=a0+a1X2+a2X4+a3Y2+a4X2Y2+a5X4Y2+a6Y4+a7X2Y4+a8X4Y4 and to calculate bridge width B of the expression of B=b0+b1X2+b2X4+b3Y2+b4X2Y2+b5X4Y2+a6Y4+a7X2Y4+a8X4Y4. The improved expressions for D and B result in reduced D and B, mild transition from the central part to peripheral in the plate shadow, eliminating central bright spot in color picture tube, and raised overall picture quality of the color picture tube.

Owner:CAIHONG GRP ELECTRONICS CO LTD +1

Dynamic stabilization of magnetic fields

ActiveUS11204405B1Stabilize fieldPermanent magnetsTransformers/inductances detailsNMR - Nuclear magnetic resonanceControl signal

An apparatus and method for dynamically stabilizing the fields in a permanent magnet assembly, including a nuclear magnetic resonance machine. One or more magnetically active elements affect the fields of the magnet assembly. A mechanism controls and changes the position(s) of the magnetically active element(s) to affect and adjust the magnetic field strength in the working volume of the assembly. A sensor provides a control signal indicating the status of the magnetic field strength, and an algorithm is executed for determining, based on the signal, the manner in which the adjustment should be made. The adjustment may be continuous and dynamic, and stabilization of the field may occur during operation of the permanent magnet assembly. The adjustments of the position of the magnetically active element stabilize the field without unduly degrading the field homogeneity, even for high homogeneity magnets.

Owner:MCDOWELL ANDREW F

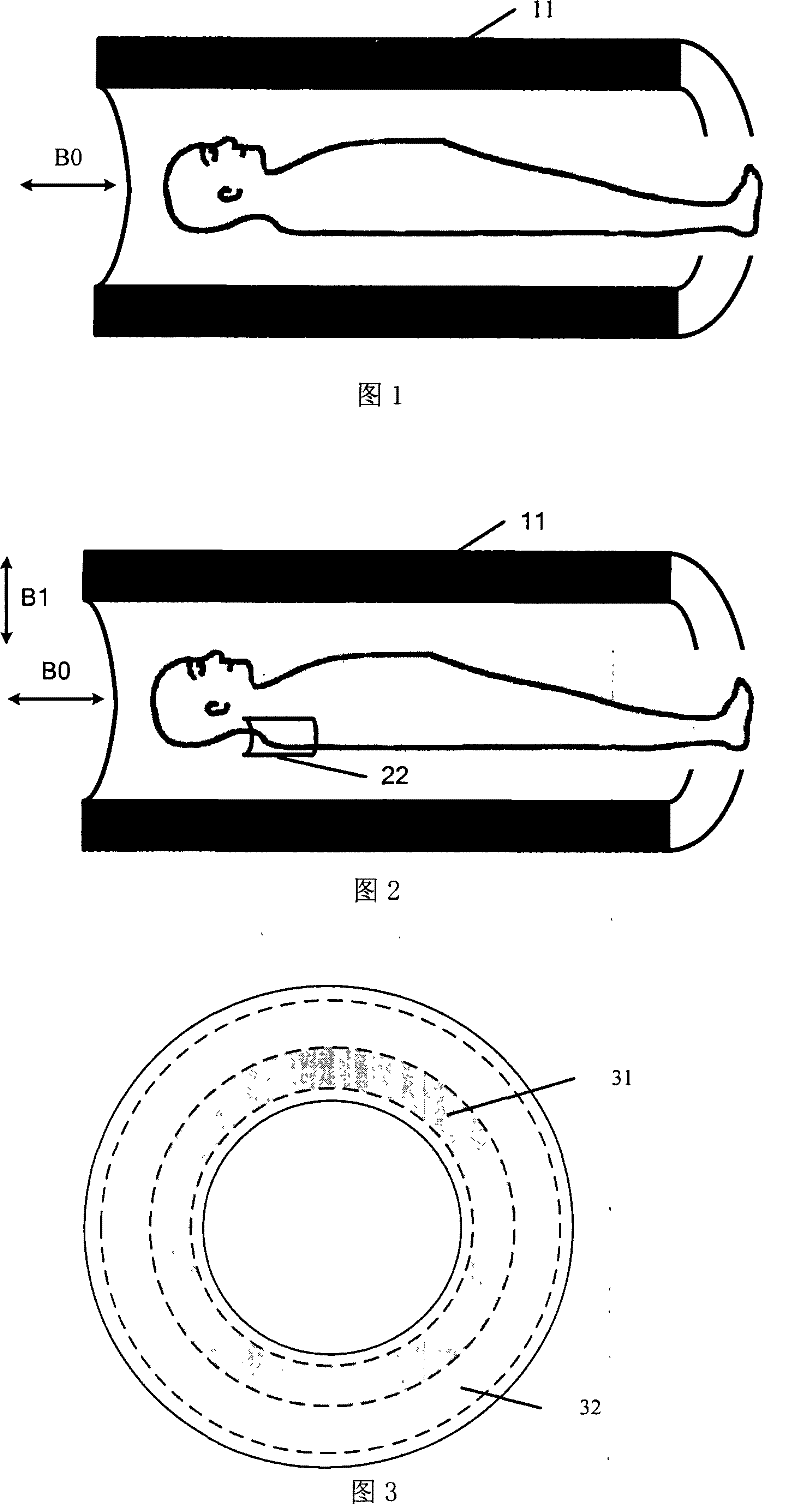

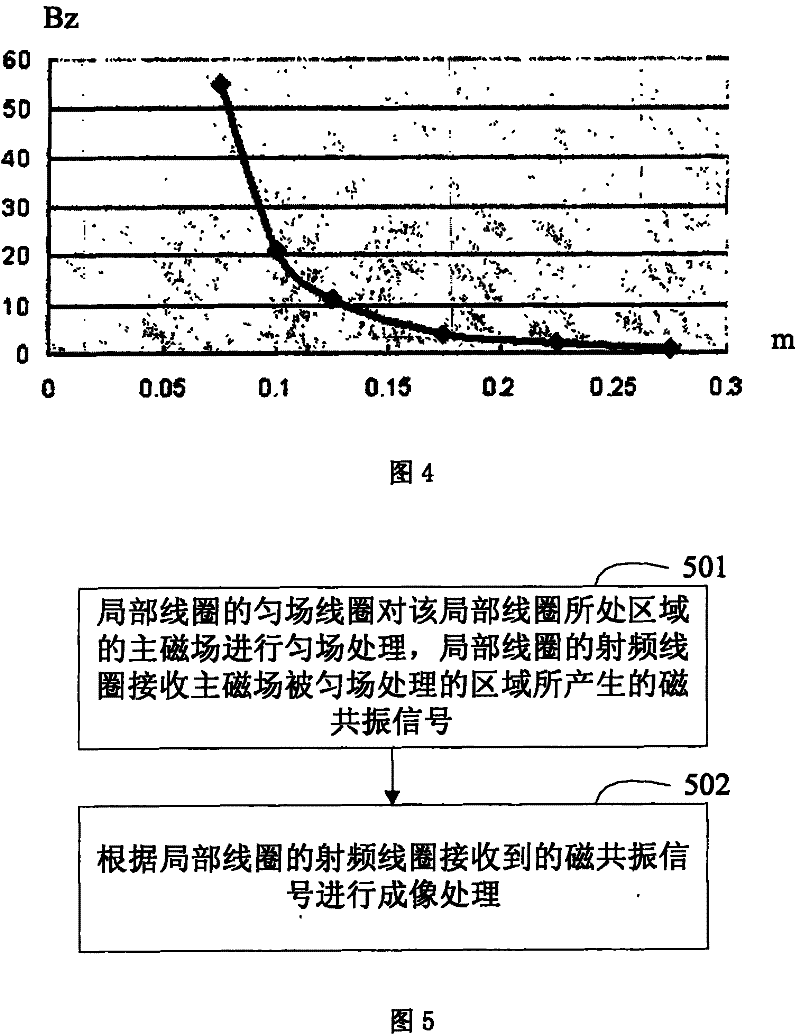

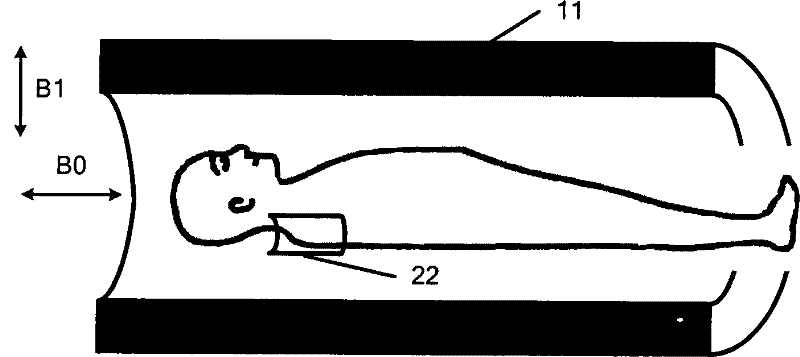

Partial coil in magnetic resonance equipment, the magnetic resonance equipment and imaging method

ActiveCN101452065BImprove local imaging qualityImprove the uniformity of the main magnetic fieldMagnetic property measurementsDiagnostic recording/measuringImaging qualityAcoustics

The present invention discloses a partial coil in a magnetic resonance device. The partial coil according to the invention is composed of a first coil and a second coil, wherein the second coil executes a field homogenizing procession to the area in which the partial coil is. The main field homogeneity of the area is increased. Furthermore the magnetic field generated by the first coil which receives the magnetic resonance signal and magnetic field generated by the second coil that executes the field homogenizing procession are not parallel, thereby the first coil and the second coil do not couple with each other for preventing the capability effect between the first coil and the second coil, and the partial imaging quality of area in which the partial coil is can be increased. Furthermore, the partial coil is installed on certain areas with inferior field homogenizing effect, such as area which is non-homocentric to the main magnetic field, and the effect for increasing the partial imaging quality is especially evident.

Owner:SIEMENS HEALTHINEERS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com