Active rotary airflow field test system

A test system and rotary technology, applied in aerodynamic tests, climate sustainability, machine/structural component testing, etc., can solve the problems of consuming material, financial and manpower, high cost, and large floor space. Achieve the effect of improving experimental accuracy and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

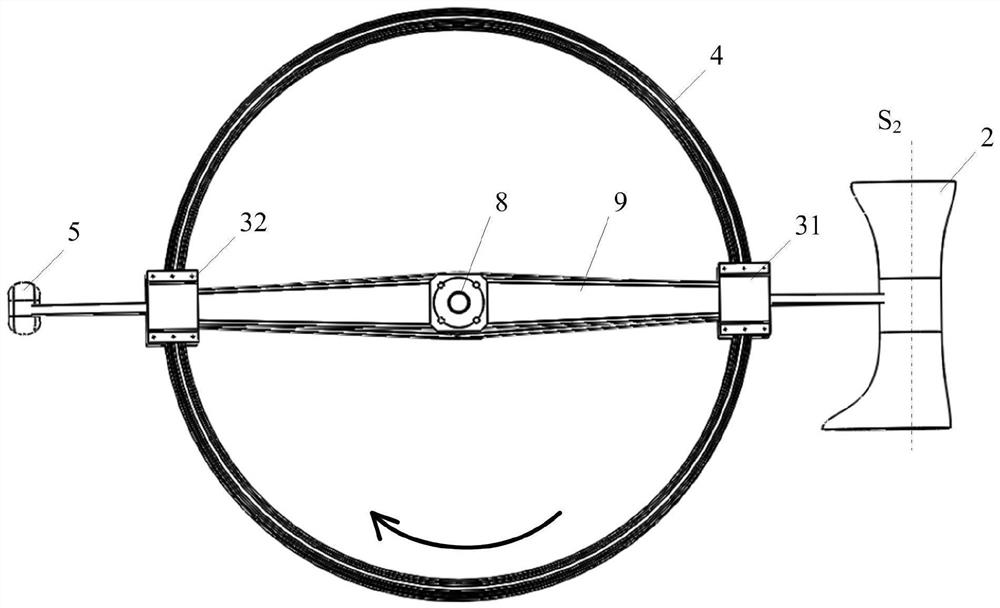

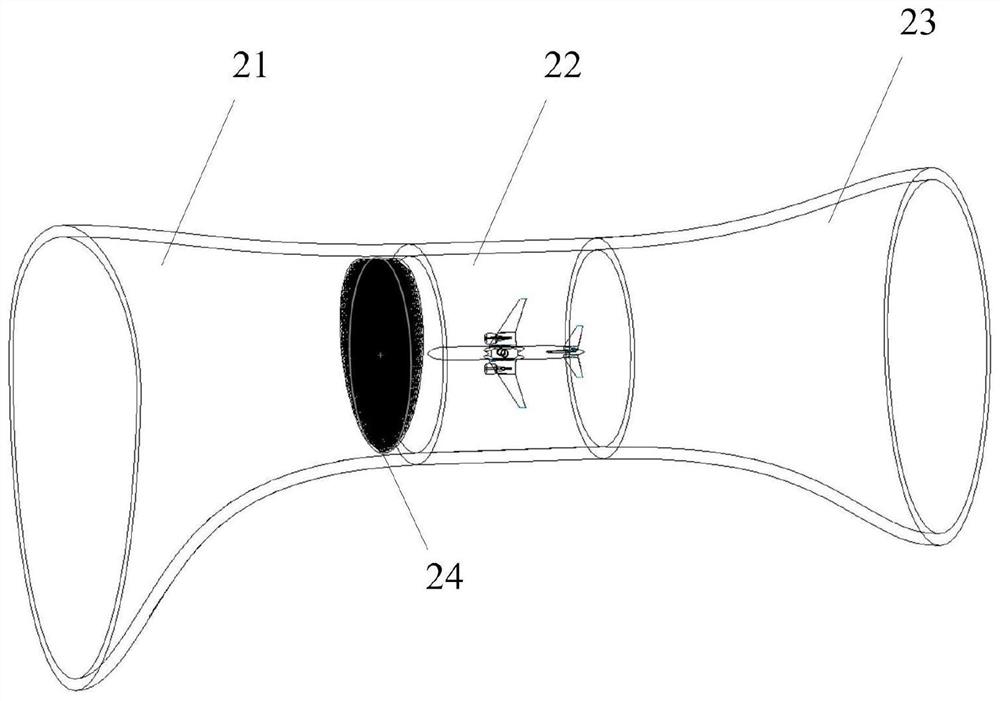

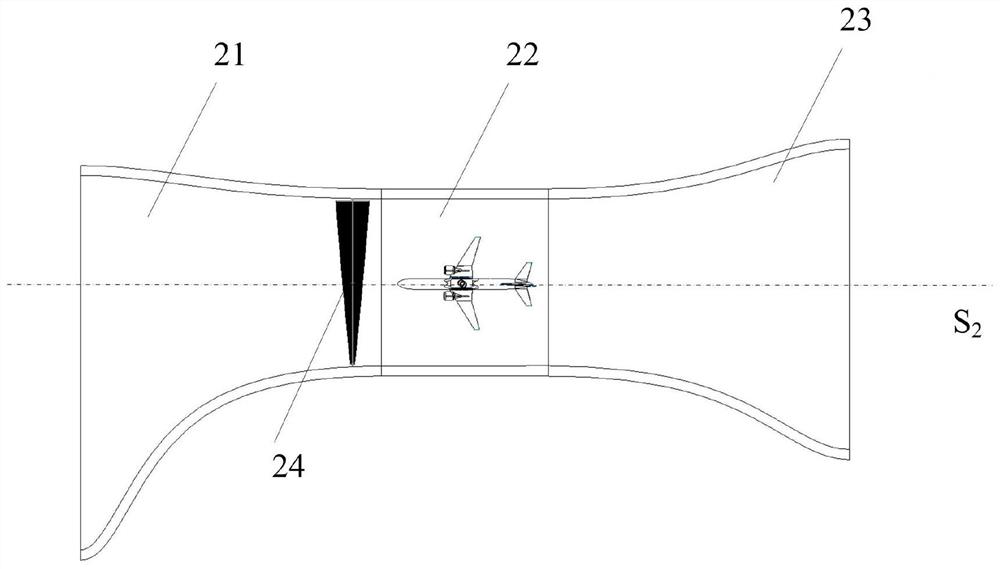

[0043] see figure 1 , The first specific embodiment of the present invention provides an active rotating airflow field test system, the system mainly includes a flow-equalizing duct 2 and a rotating mechanism. The current equalizing acceleration duct 2 is used to place the test product and provide a test environment for the test product; the rotating mechanism is used to control the current equalizing acceleration duct 2 around the central axis L0 (ie figure 1 The central axis of the rotating main shaft 8 in the center) rotates to make the current uniform acceleration duct 2 and the test product inside move at high speed through the method of circular drive, forming a relative test speed.

[0044] Specifically, see Figure 1 to Figure 4 , The flow equalizing acceleration duct 2 includes a constriction section 21 , a test section 22 and a diffusion section 23 connected in sequence. in:

[0045] The cross-sectional area of the constriction section 21 decreases gradually alo...

no. 2 Embodiment

[0068] See Figure 9 , the second specific embodiment of the present invention provides an active rotary airflow field test system, which differs from the above-mentioned first specific embodiment only in that the first circular guide rail 41 and the second circular guide rail 42 are respectively provided with a second Two sliding tables 32, each second sliding table 32 is respectively provided with a dynamic balancing device 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com