Patents

Literature

306results about How to "Adjustable performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

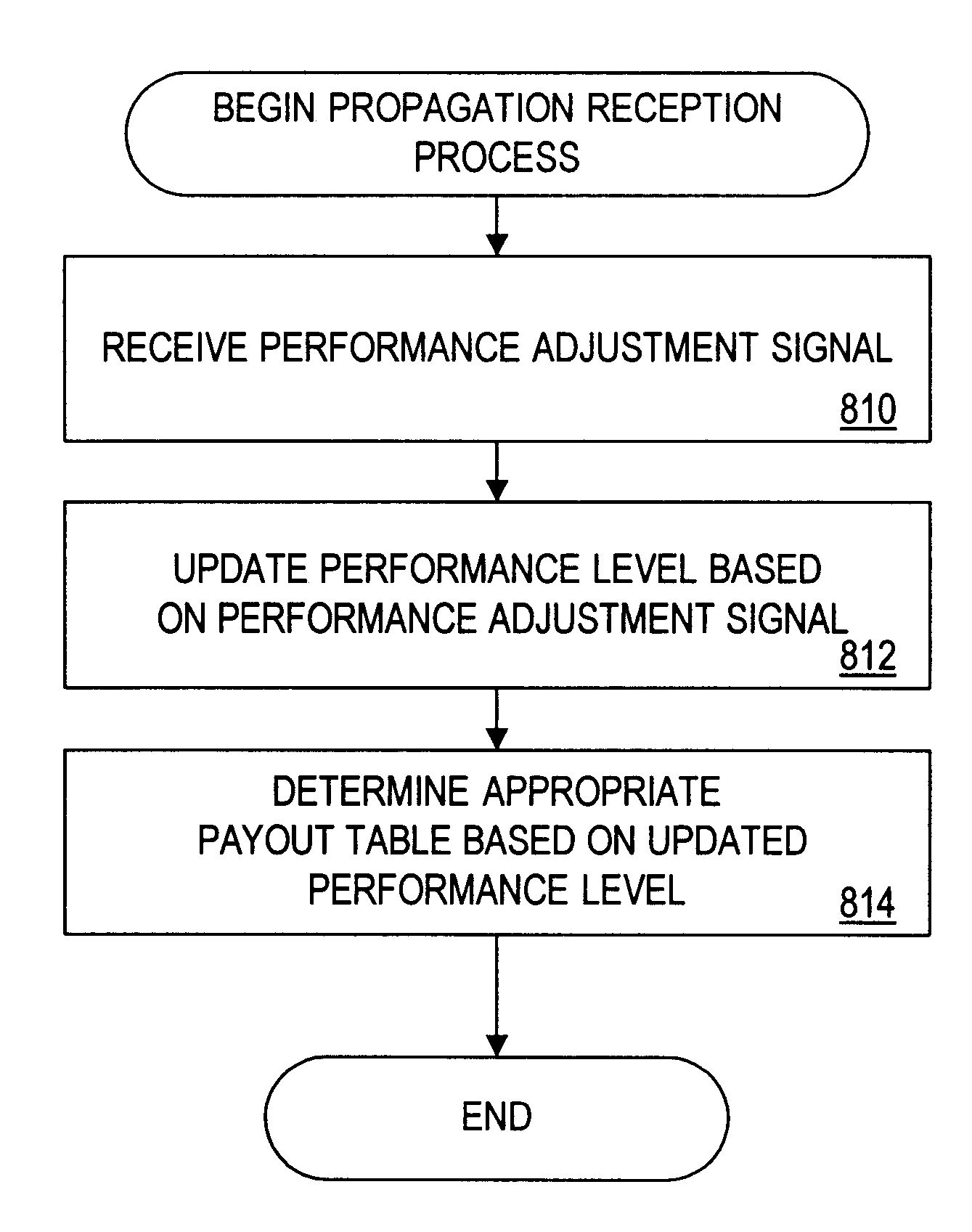

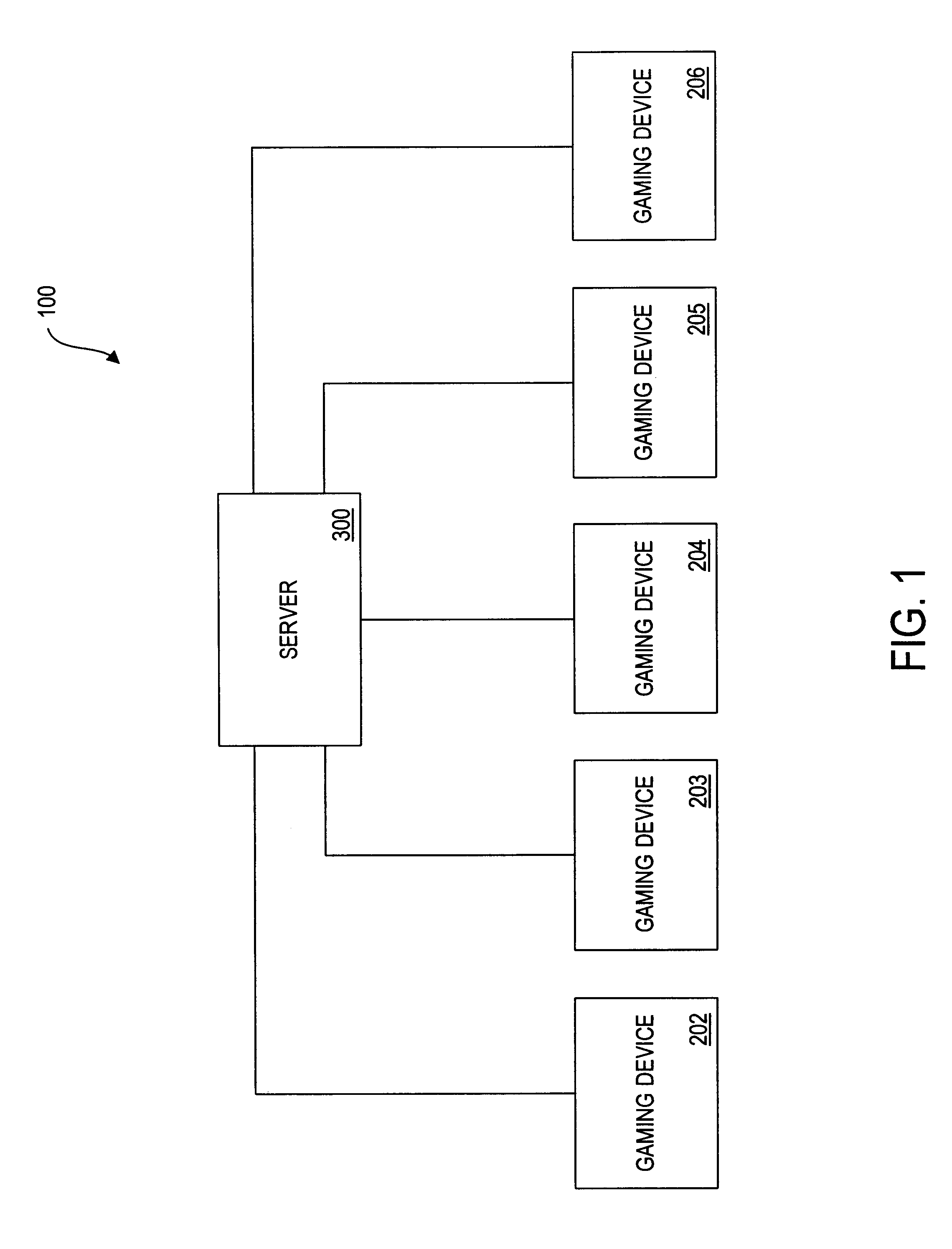

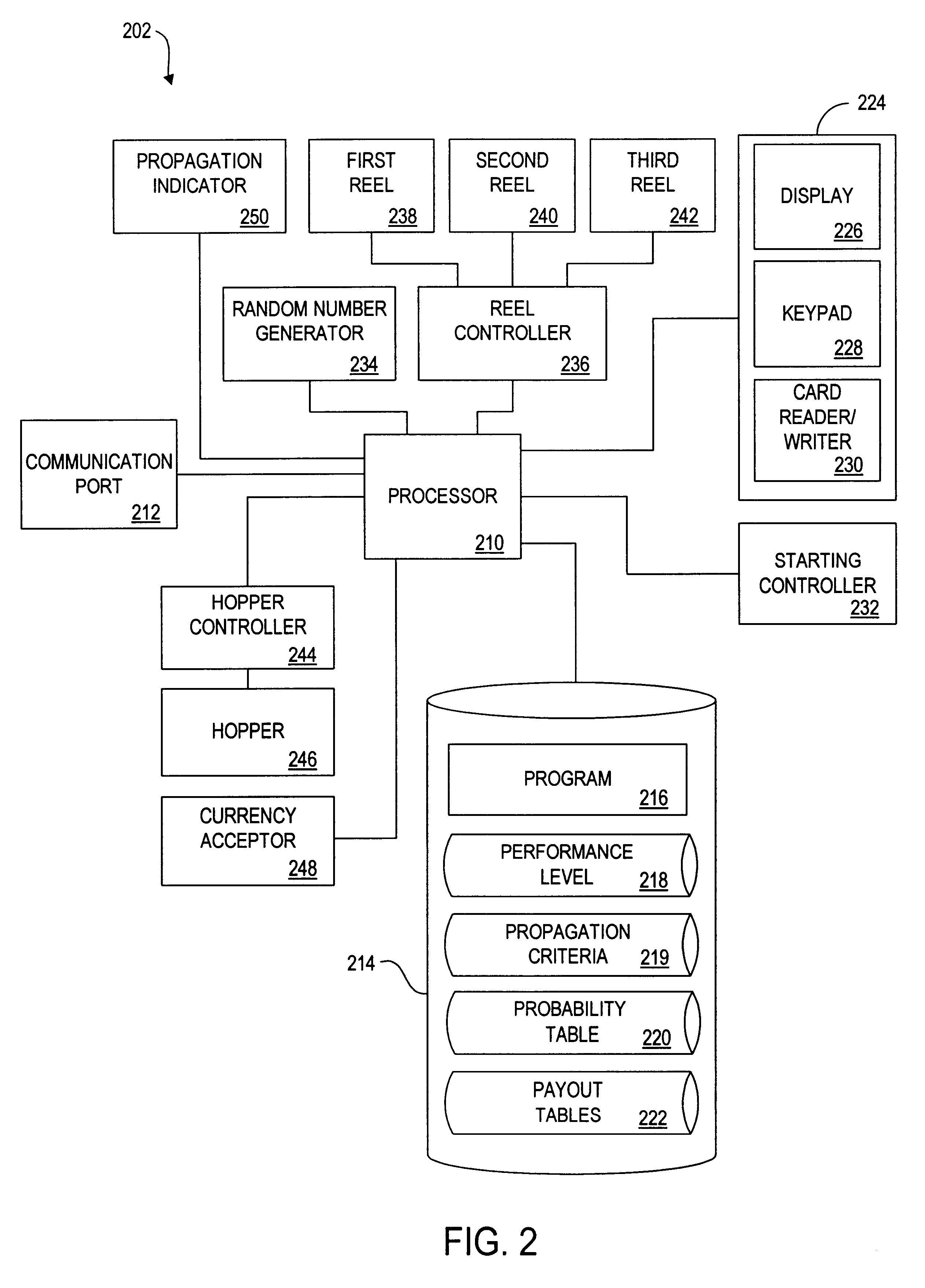

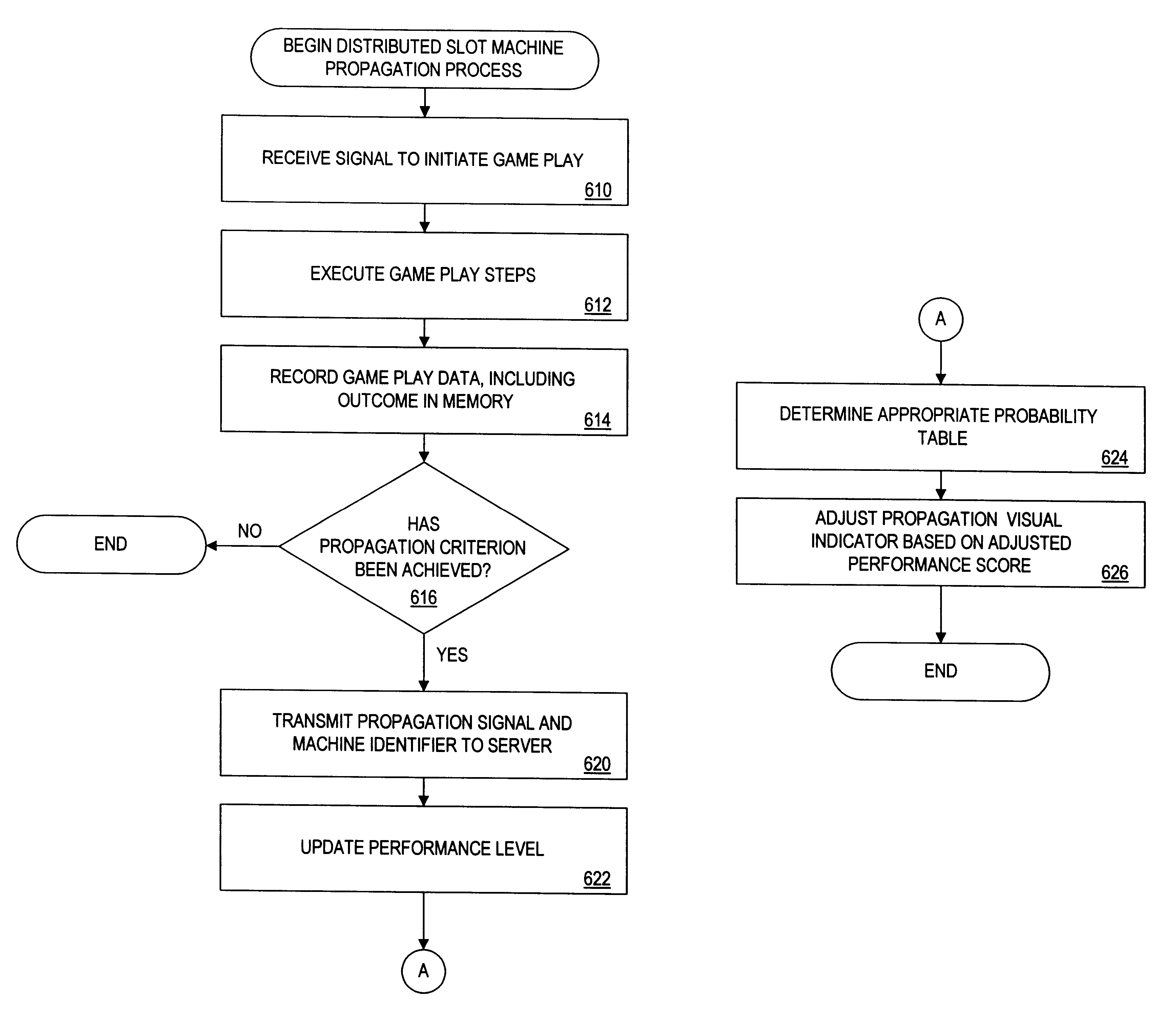

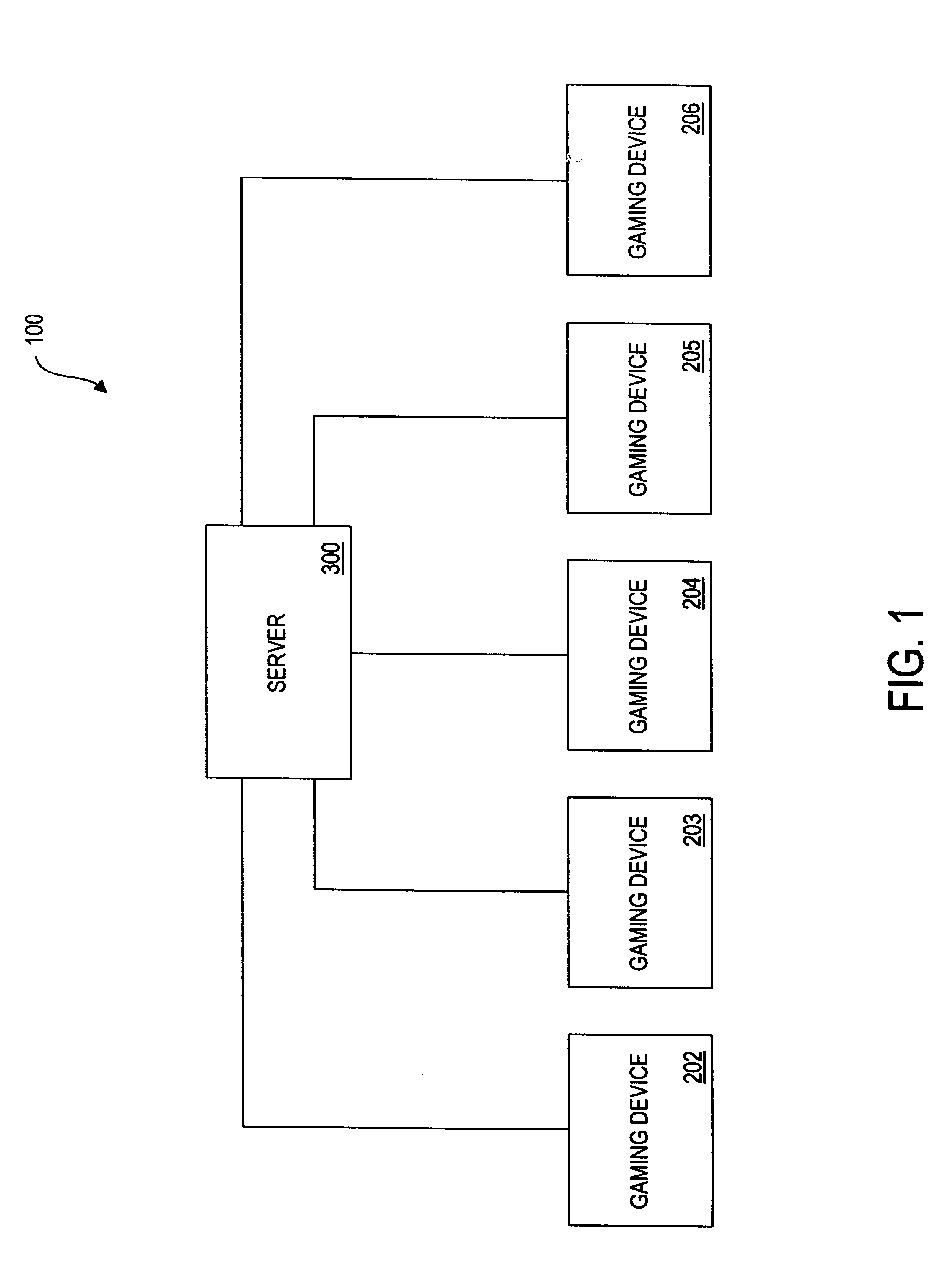

Electronic amusement device and method for propagating a performance adjustment signal

InactiveUS6648762B2Sure easyEncourages prolonged slot machine playCard gamesApparatus for meter-controlled dispensingGame playServer

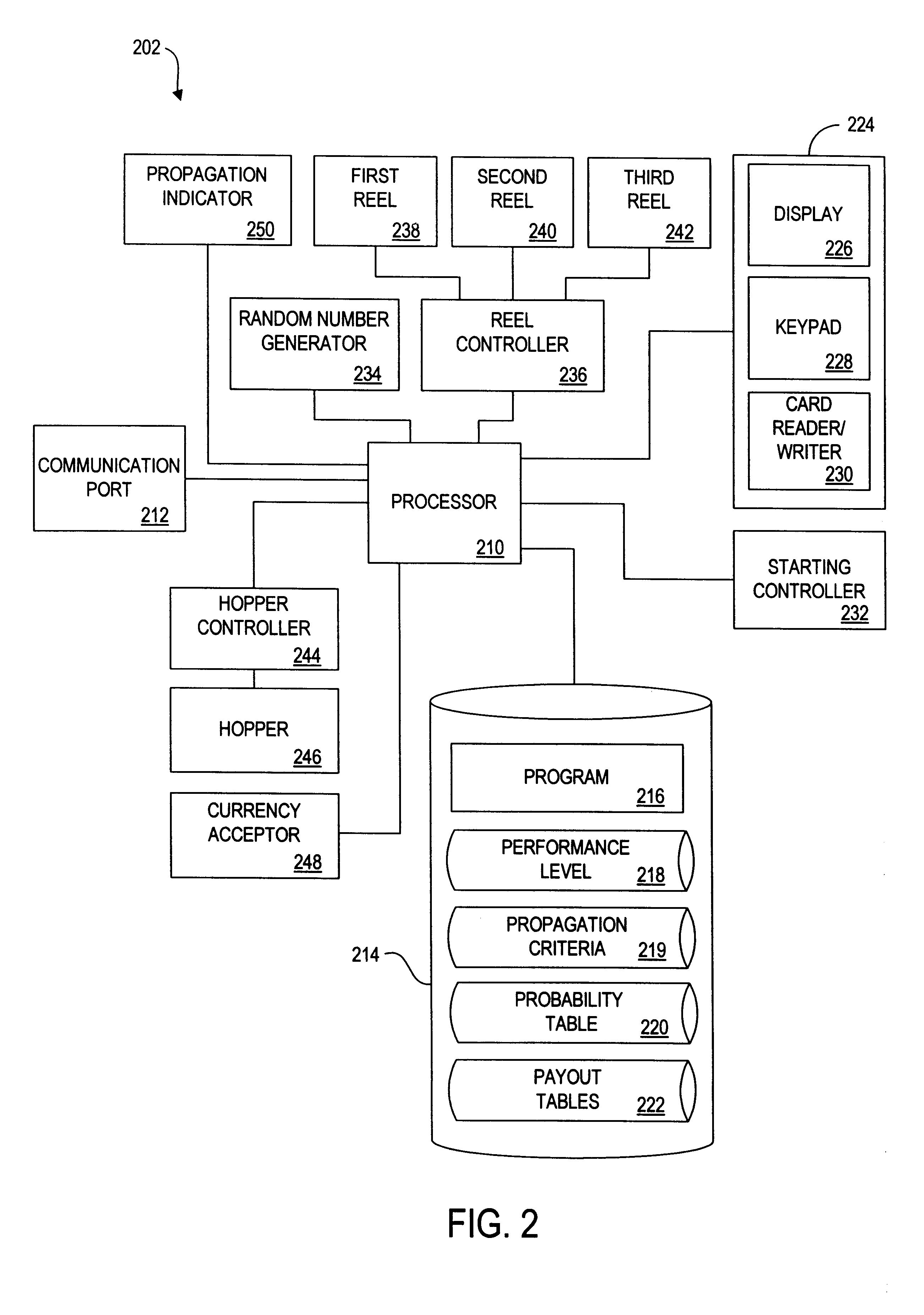

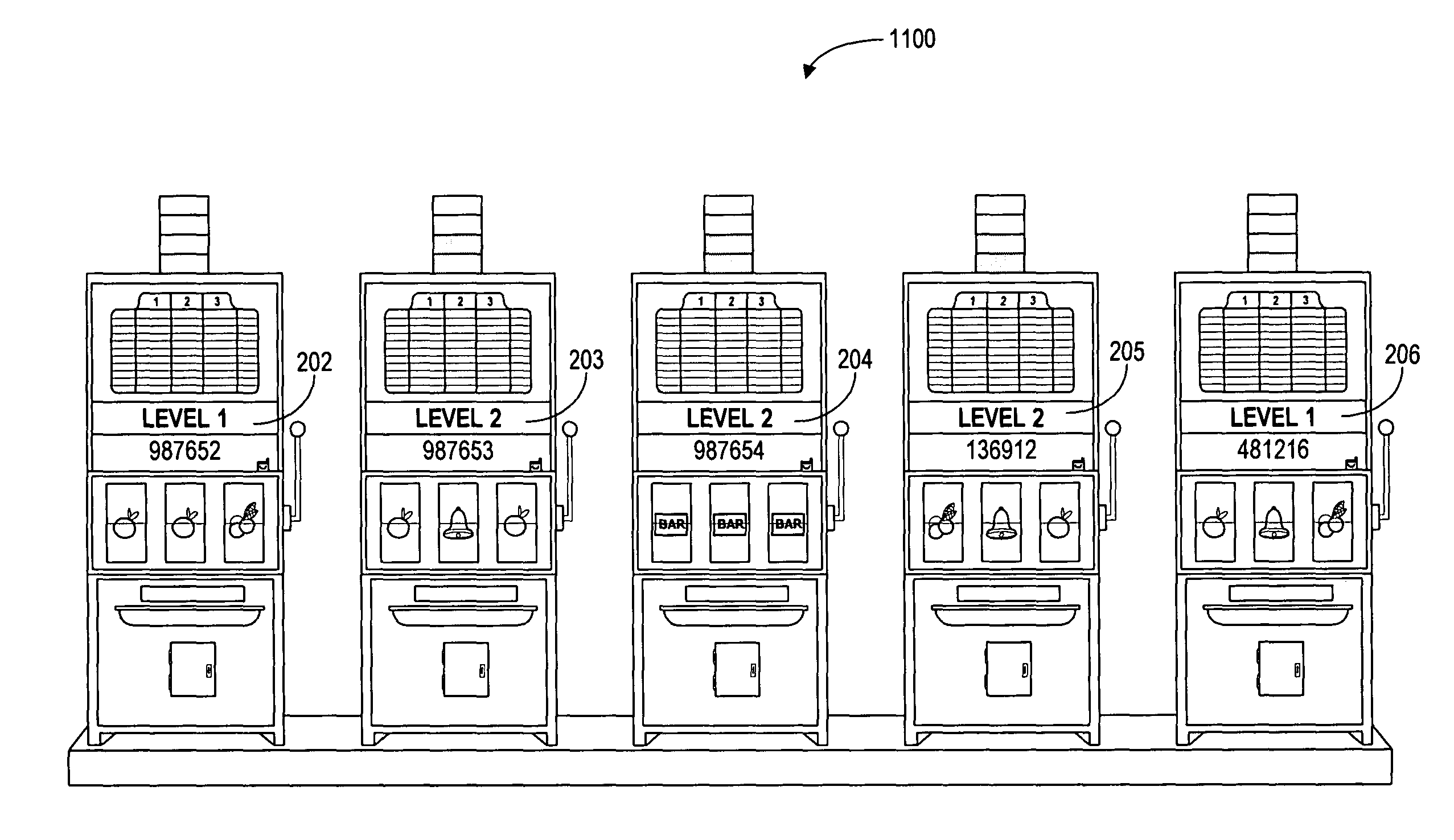

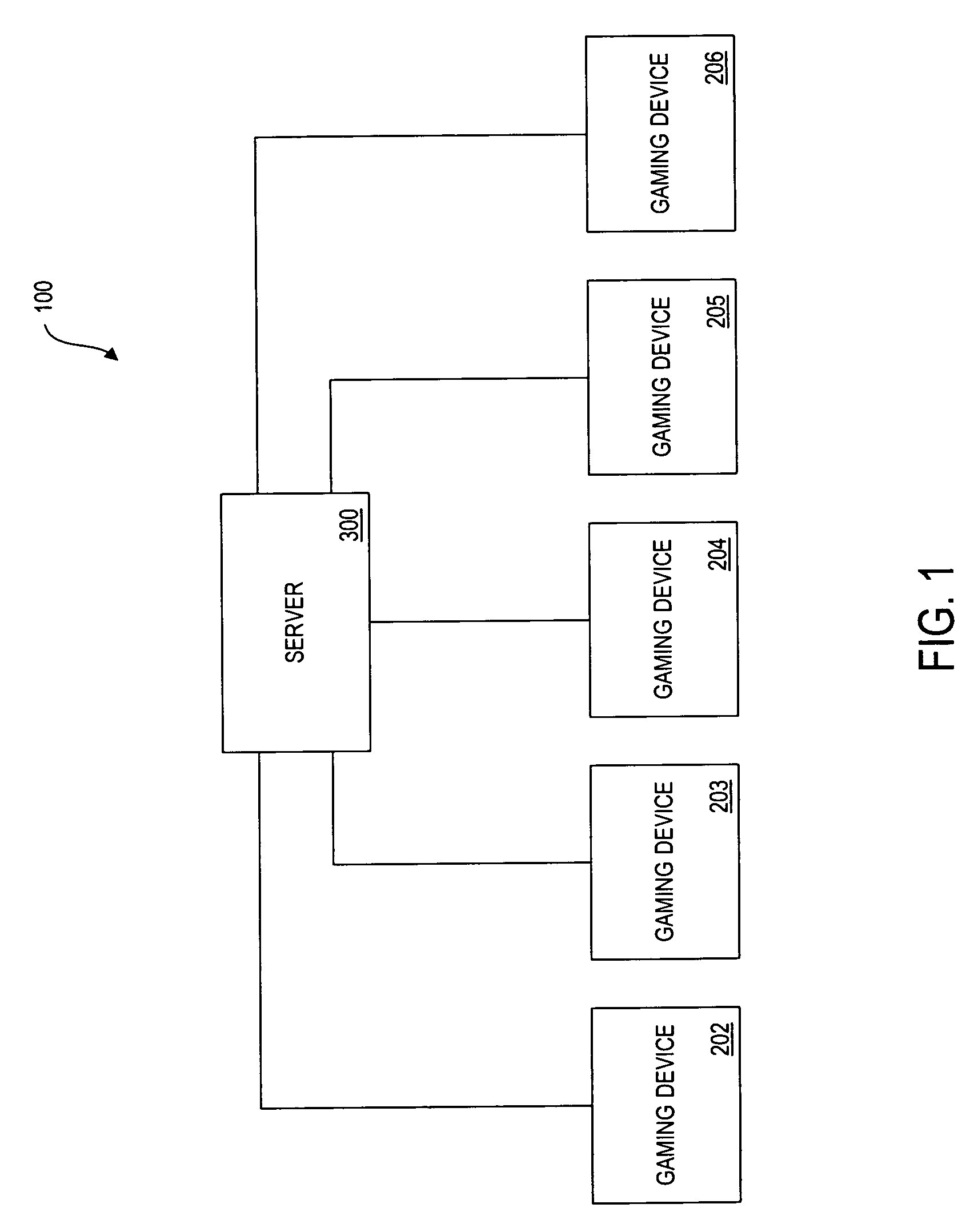

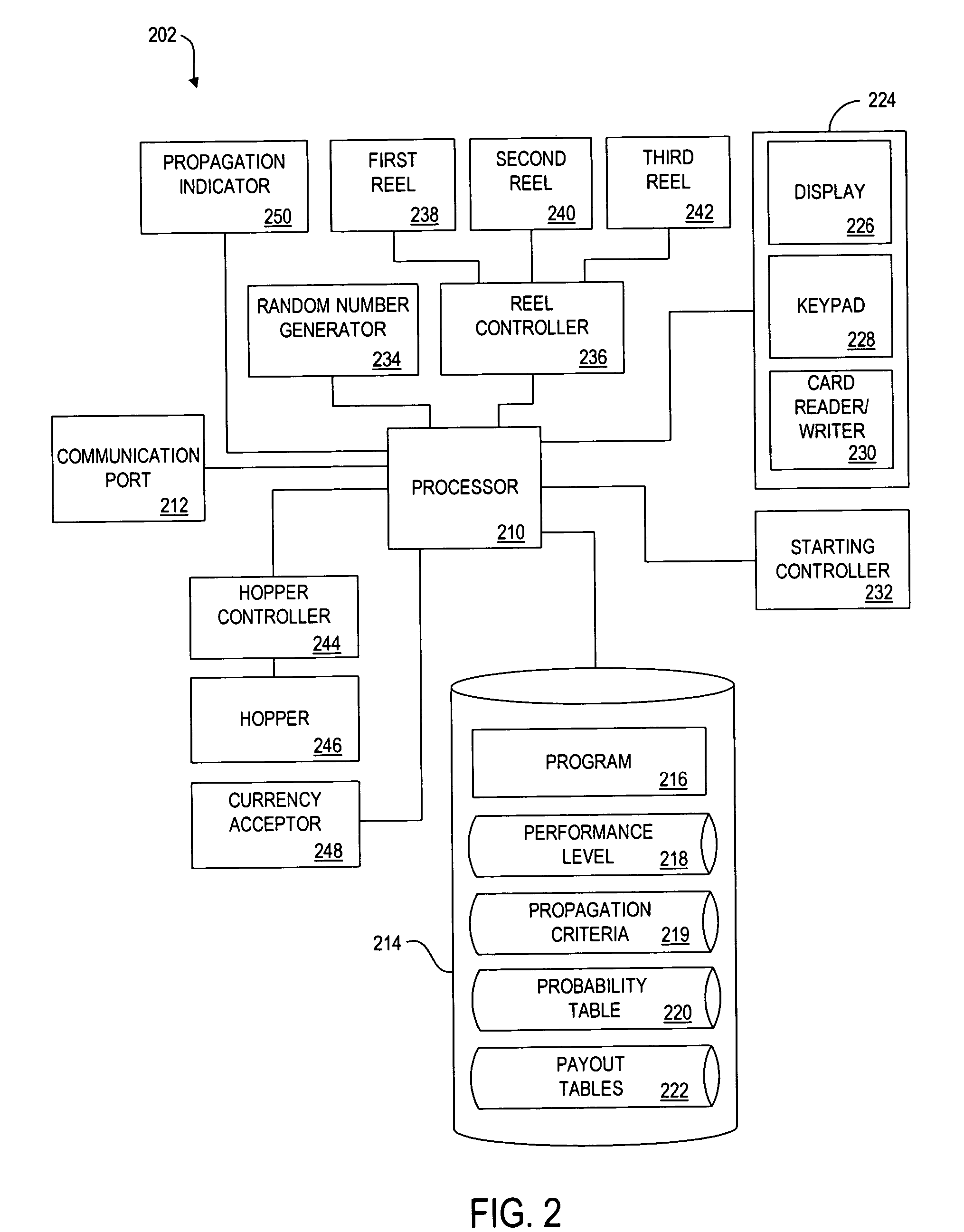

An electronic amusement device and a method for operating the device are disclosed. In accordance with one embodiment, a slot machine receives an initiation signal to initiate game play at the slot machine. The slot machine conducts a game in response to the initiation signal. The slot machine determines whether a propagation criteria has been achieved and outputs a propagation signal, indicating a performance adjustment, to at least one other slot machine. In accordance with a second embodiment, a slot machine that stores a performance level is disclosed. The slot machine receives a propagation signal indicating a performance adjustment, and the slot machine adjusts the performance level accordingly. A slot server and method for operating the server are also disclosed.

Owner:INVENTOR HLDG

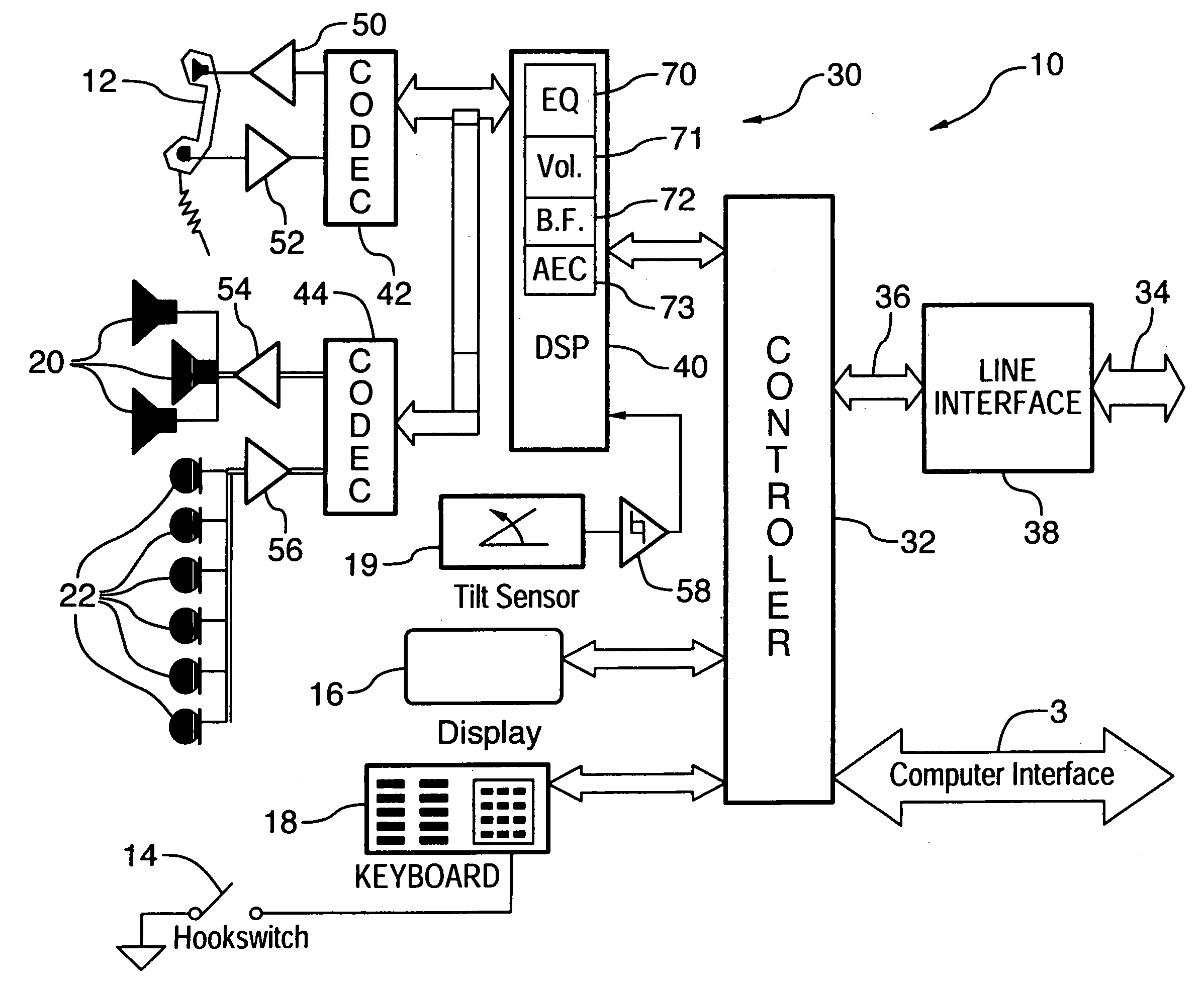

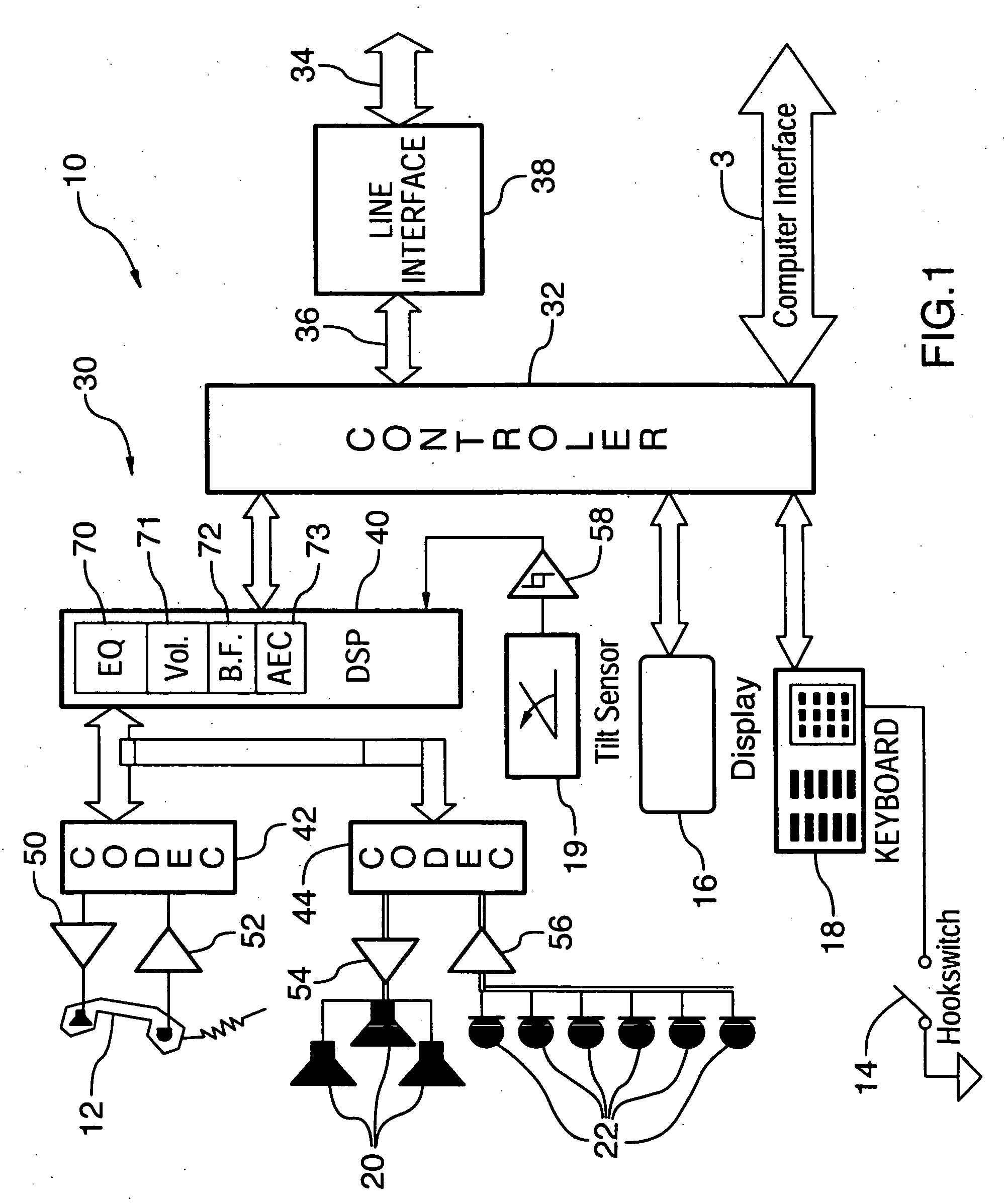

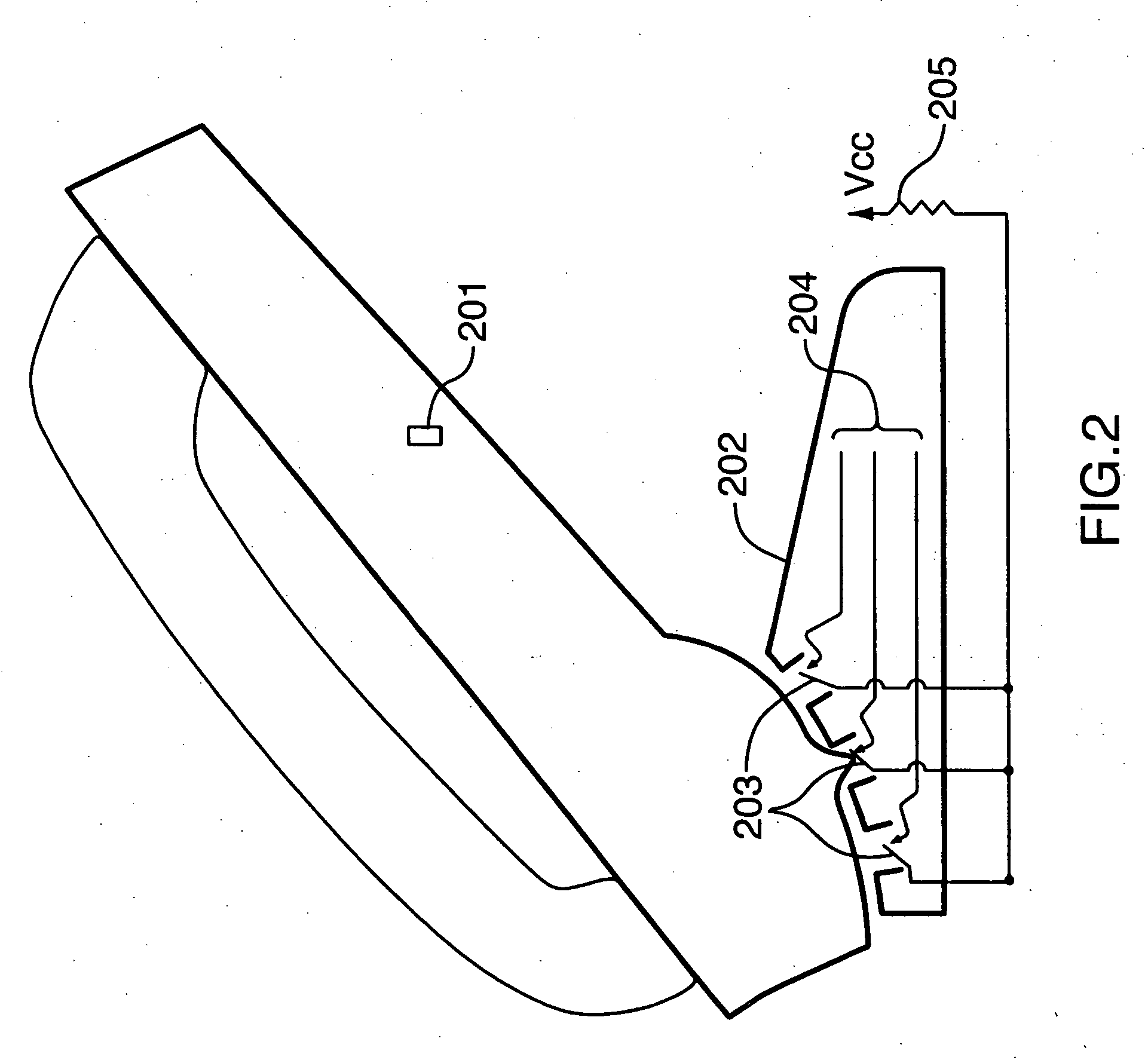

Method and apparatus for optimizing speakerphone performance based on tilt angle

ActiveUS20050201549A1Adjustable performanceEnhancing cancellationTwo-way loud-speaking telephone systemsSubstation speech amplifiersEngineeringLoudspeaker

According to the present invention, a tilt sensor is used to determine the tilt angle of a speakerphone and the surface on which it rests. This information is used to optimize both the receive and transmit signals for the chosen tilt angle. The information can also be used to adjust performance of any beamformer(s) where the speakerphone incorporates a microphone array or loudspeaker array. In one embodiment, vibrational data is provided by the tilt sensor for enhancing the receive signal and acoustic echo cancellation.

Owner:MITEL

Electronic amusement device and method for propagating a performance adjustment signal

InactiveUS6328648B1Encourages prolonged slot machine playAttracts attentionCard gamesApparatus for meter-controlled dispensingPerformance tuningControl theory

An electronic amusement device and a method for operating the device are disclosed. In accordance with one embodiment, a slot machine receives an initiation signal to initiate game play at the slot machine. The slot machine conducts a game in response to the initiation signal. The slot machine determines whether a propagation criteria has been achieved and outputs a propagation signal, indicating a performance adjustment, to at least one other slot machine. In accordance with a second embodiment, a slot machine that stores a performance level is disclosed. The slot machine receives a propagation signal indicating a performance adjustment, and the slot machine adjusts the performance level accordingly. A slot server and method for operating the server are also disclosed.

Owner:INVENTOR HLDG +1

Electronic amusement device and method for propagating a performance adjustment signal

InactiveUS20040127290A1Improve performanceSure easyCard gamesApparatus for meter-controlled dispensingControl theoryGame play

An electronic amusement device and a method for operating the device are disclosed. In accordance with one embodiment, a slot machine receives an initiation signal to initiate game play at the slot machine. The slot machine conducts a game in response to the initiation signal. The slot machine determines whether a propagation criteria has been achieved and outputs a propagation signal, indicating a performance adjustment, to at least one other slot machine. In accordance with a second embodiment, a slot machine that stores a performance level is disclosed. The slot machine receives a propagation signal indicating a performance adjustment, and the slot machine adjusts the performance level accordingly. A slot server and method for operating the server are also disclosed.

Owner:WALKER DIGITAL

Functional polymer nano composite material and preparation method and uses thereof

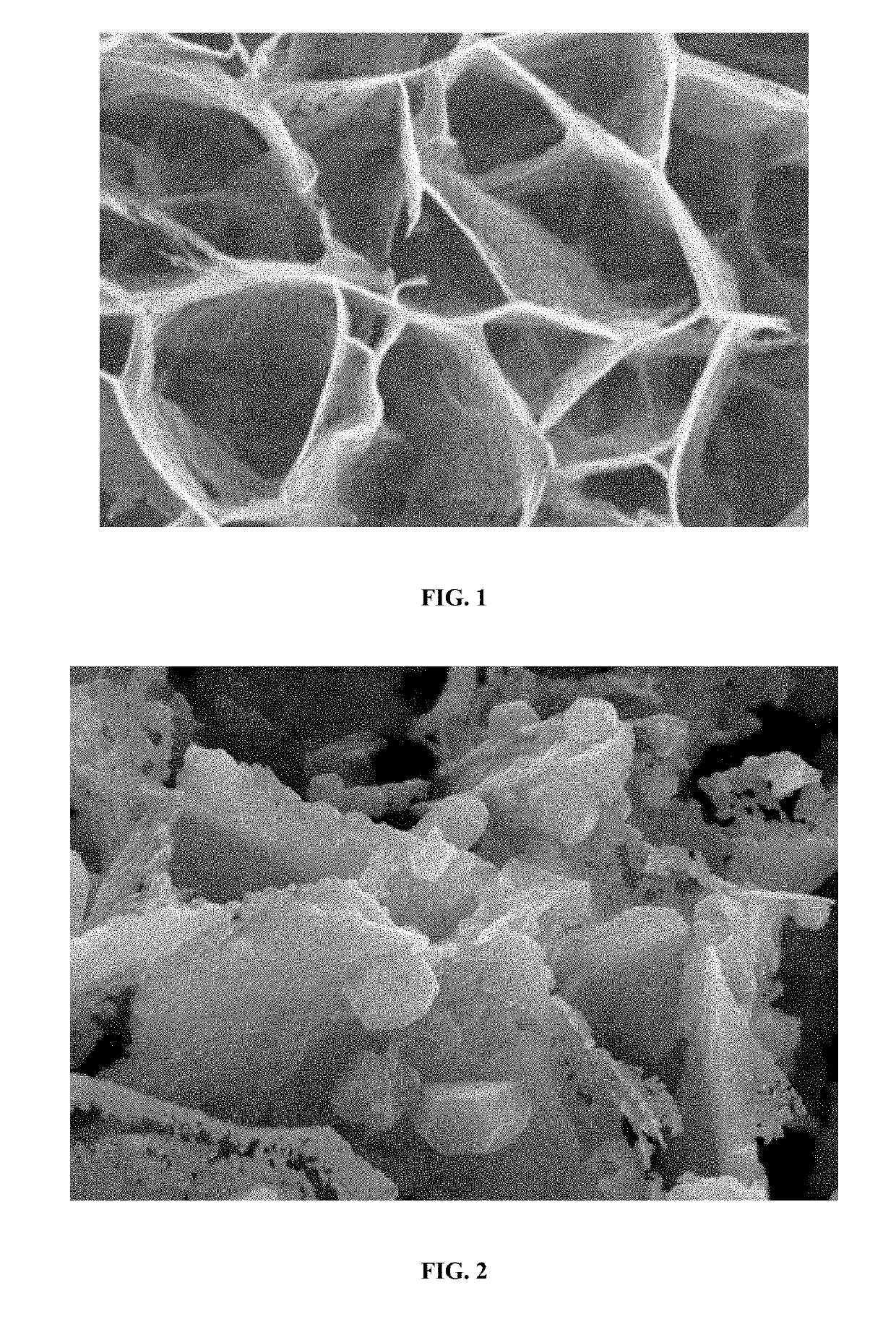

ActiveCN101161705AEvenly dispersedStable structureBiocideOther chemical processesEcological environmentPolymer solution

The present invention relates to a polymer nano-composite of the functional inorganic nano-particle with intermingle prepared by electrospinning method, and the use of the composite. The precursory sol of the functional inorganic nano-particle is prepared by the sol-gel method, and is mixed with the polymer solution to form spinning fluid, adding precursor of dopant if necessary, and then the mixed spinning fluid is sprayed on to the electric collecting board with the action of the electric field force by electrospinning method to obtain functional polymer nano-composite with intermingle. The equipment of the invention is simple, the operation is easy, the components, structure and characteristics of the composite is easy to control, the structure is stable, the inorganic nano-particle is dispersed uniformly. According to the difference of the functionality of the inorganic nano-particles, the composite can be used in conducting material, antistatic material, magnetic material, electrochromic material, photocatalysis and ecology environment material, antibiosis material and biomaterial.

Owner:INST OF CHEM CHINESE ACAD OF SCI

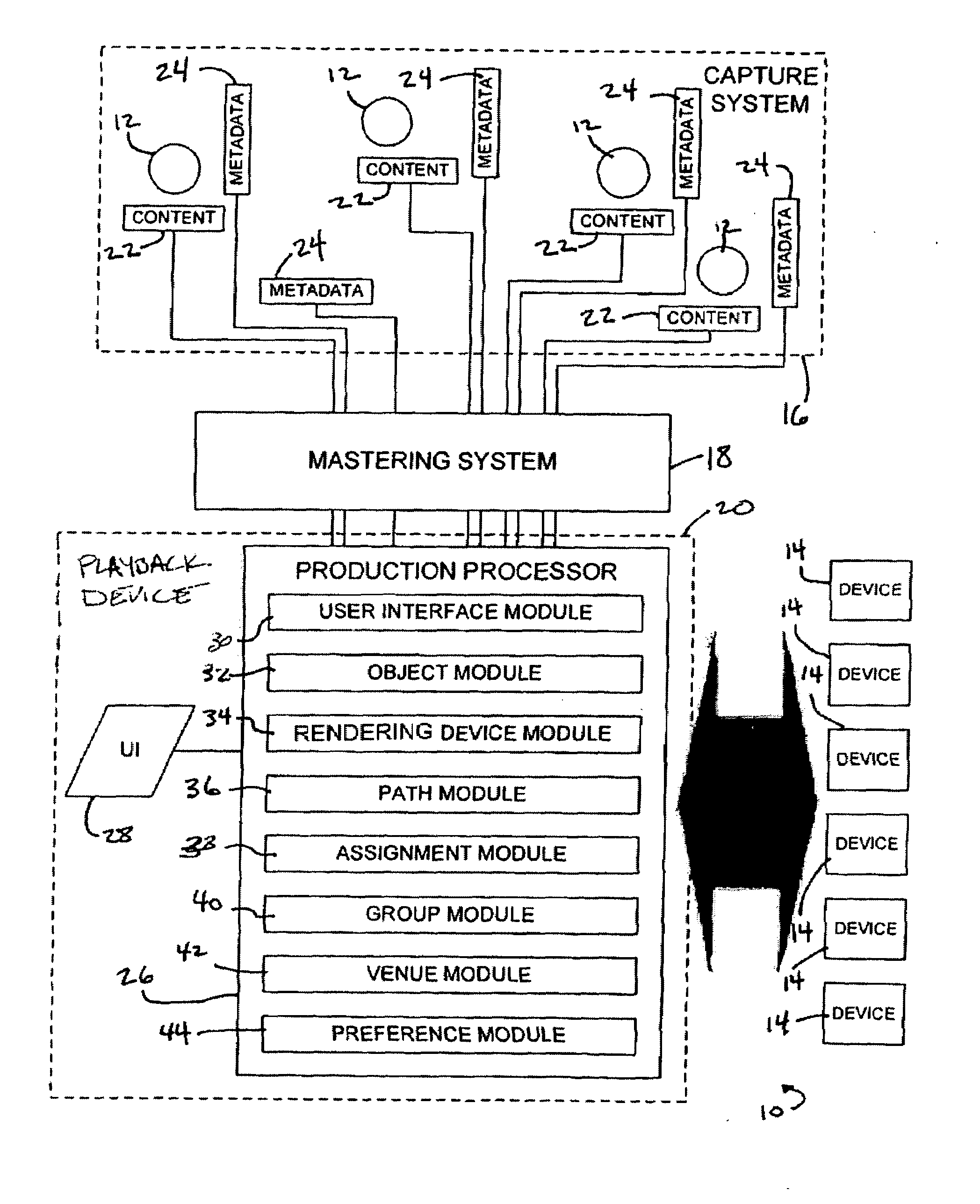

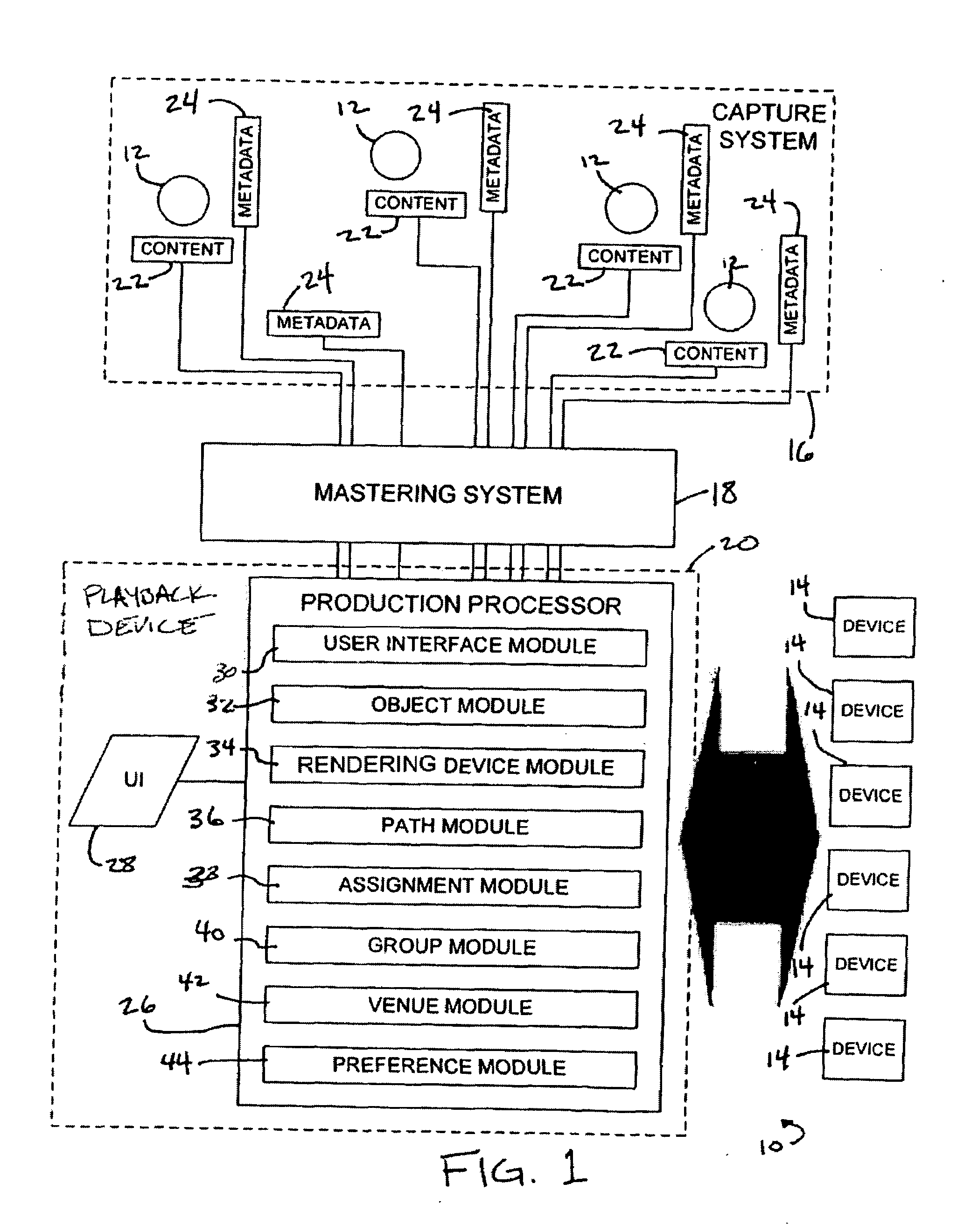

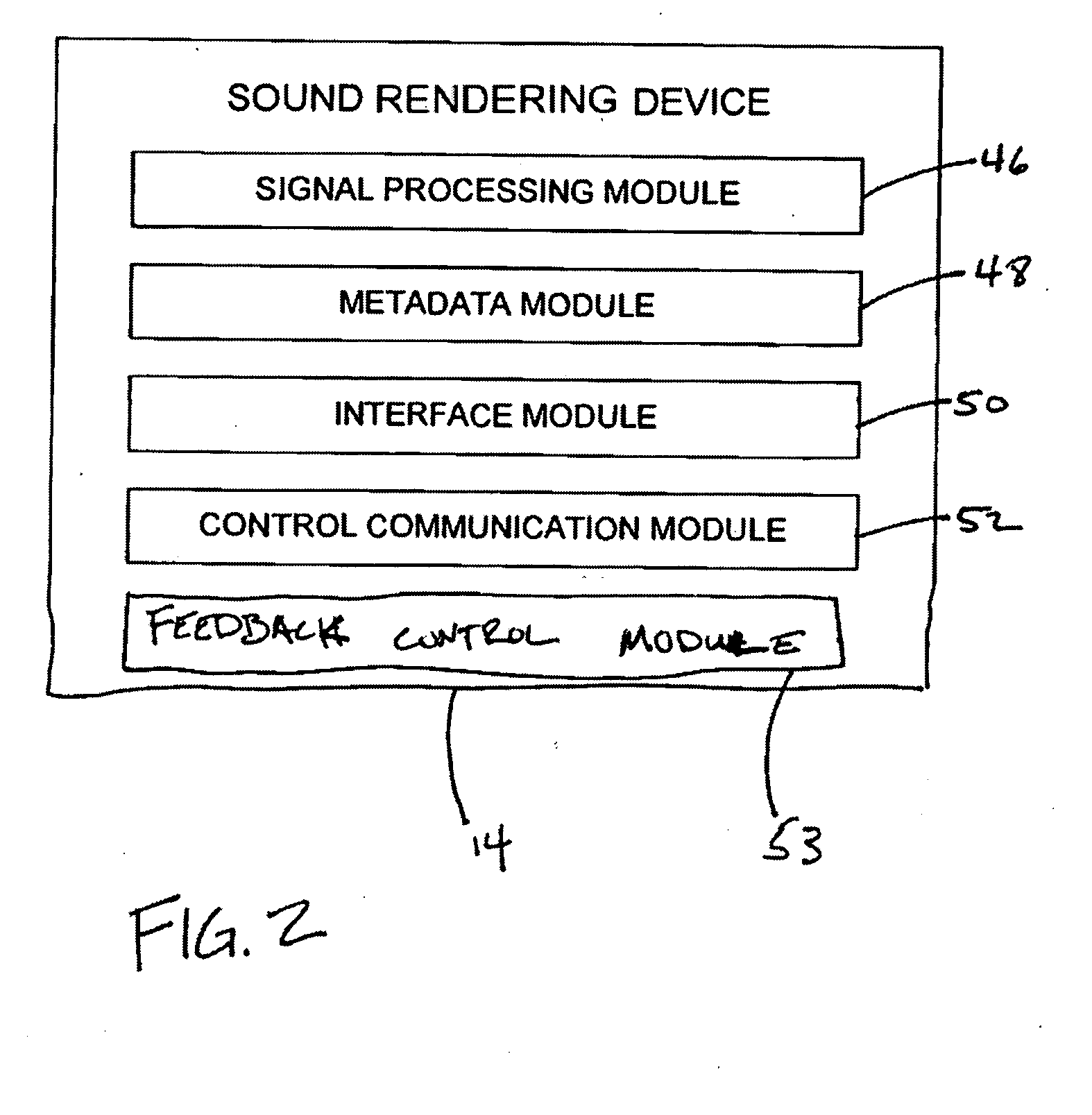

Playback Device For Generating Sound Events

InactiveUS20100223552A1Less-delay in signal pathIncrease productionStereophonic systemsInput/output processes for data processingSound sourcesSound production

A system configured to capture and / or produce a sound event generated by a plurality of sound sources. In particular, the system may be configured such that the capture, processing, and / or output for sound production of sound objects associated with separate ones of the sound sources may be controlled on an individual based. This discretized control over the sound objects may enhance various aspects of productions of the sound event by systems that do not capture, process and / or output sounds from different sound sources in a manner that maintains the discrete nature of the sound sources.

Owner:VERAX TECH

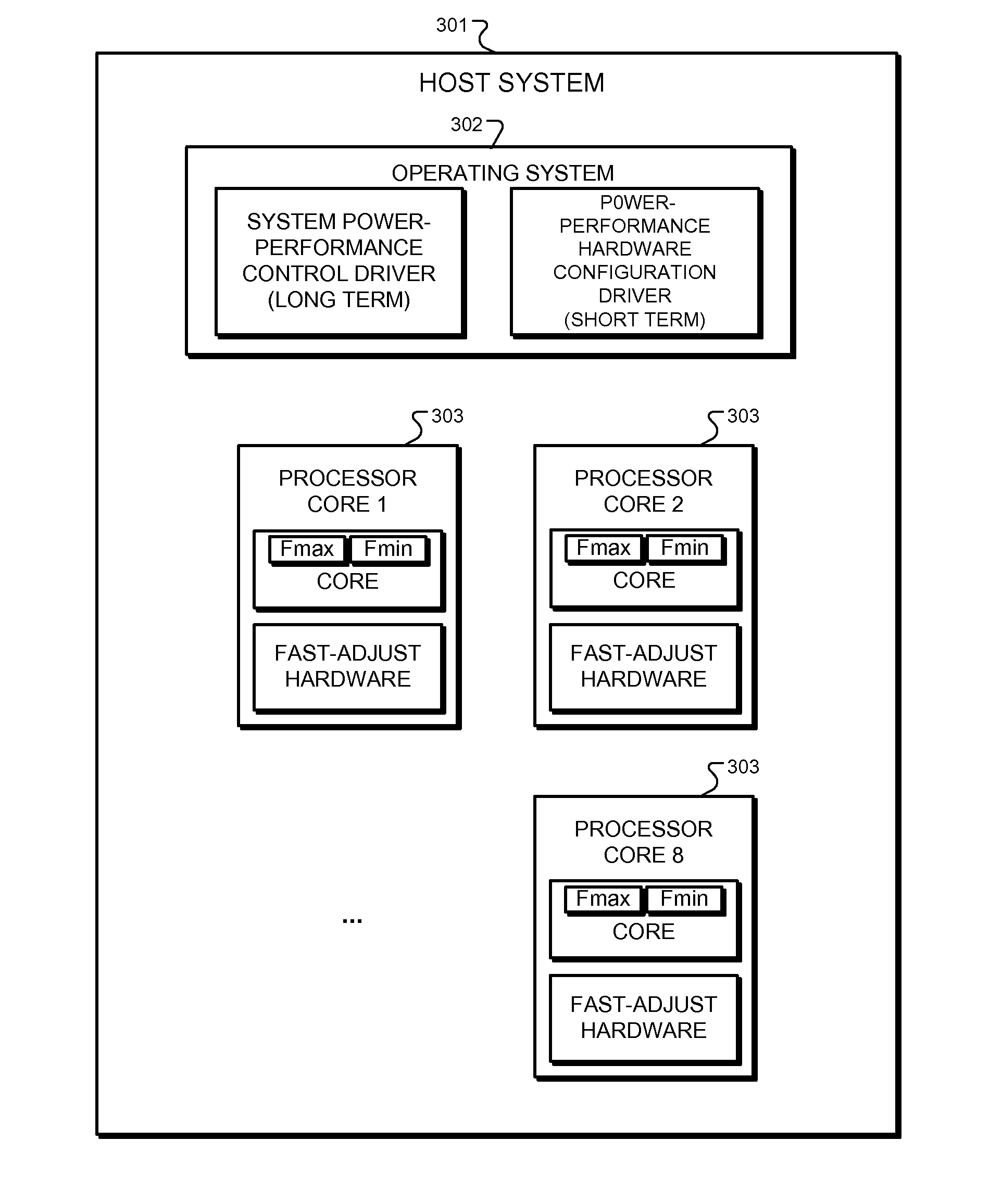

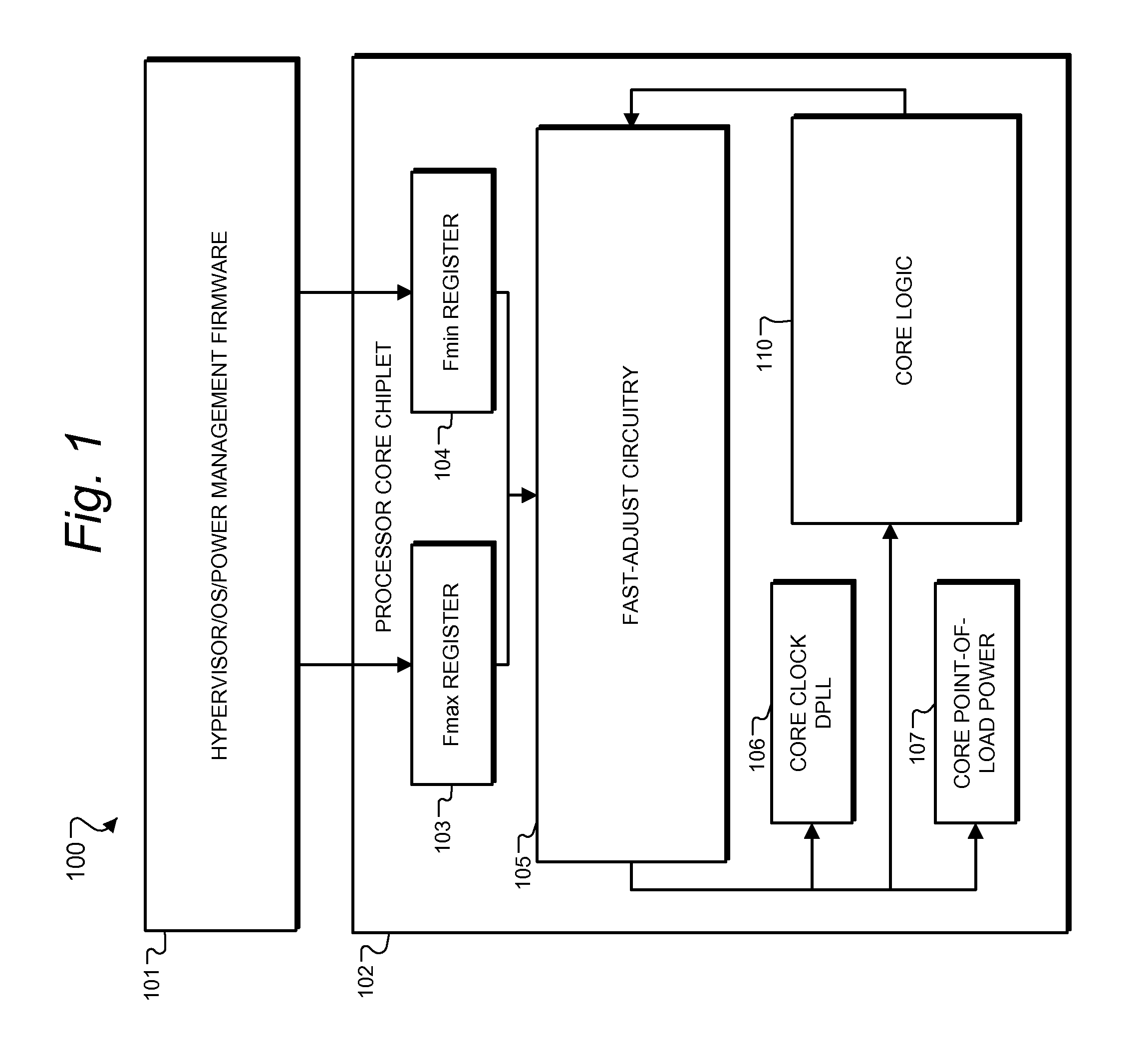

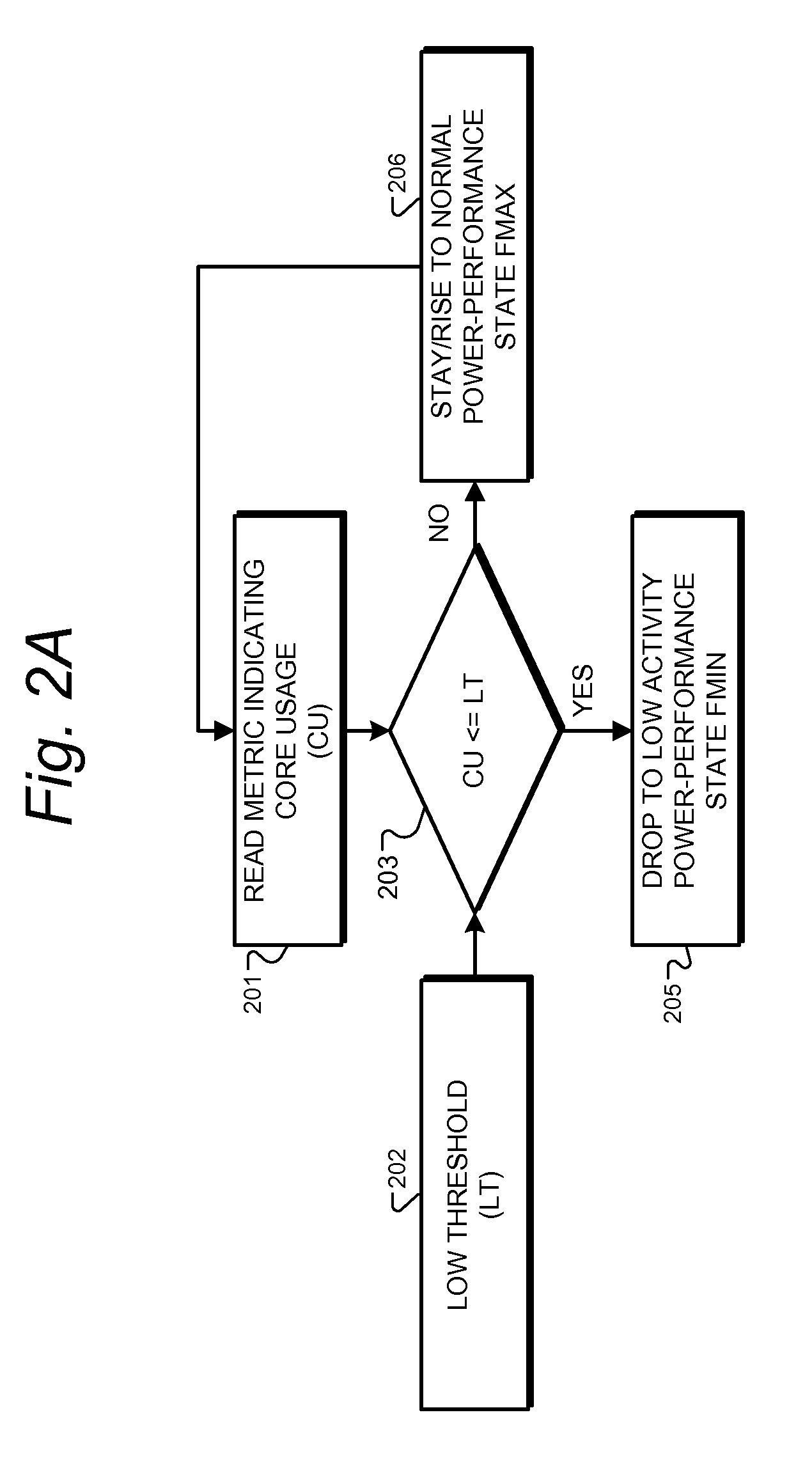

System and Method for Managing the Power-Performance Range of an Application

InactiveUS20100218029A1Improve power efficiencySacrificing performanceEnergy efficient ICTDigital computer detailsOperational systemProcessor register

Semiconductor device circuits and methods are provided for adjusting core processor performance based on usage metrics. Metric detection and adjustment are performed in digital logic hardware guided by registers providing maximum and minimum frequency settings, without intervening input from system software or firmware, thus greatly speeding the processor performance adjustment. Power-performance drivers provide applications or the operating system ability to specify maximum and minimum frequency requirements.

Owner:IBM CORP

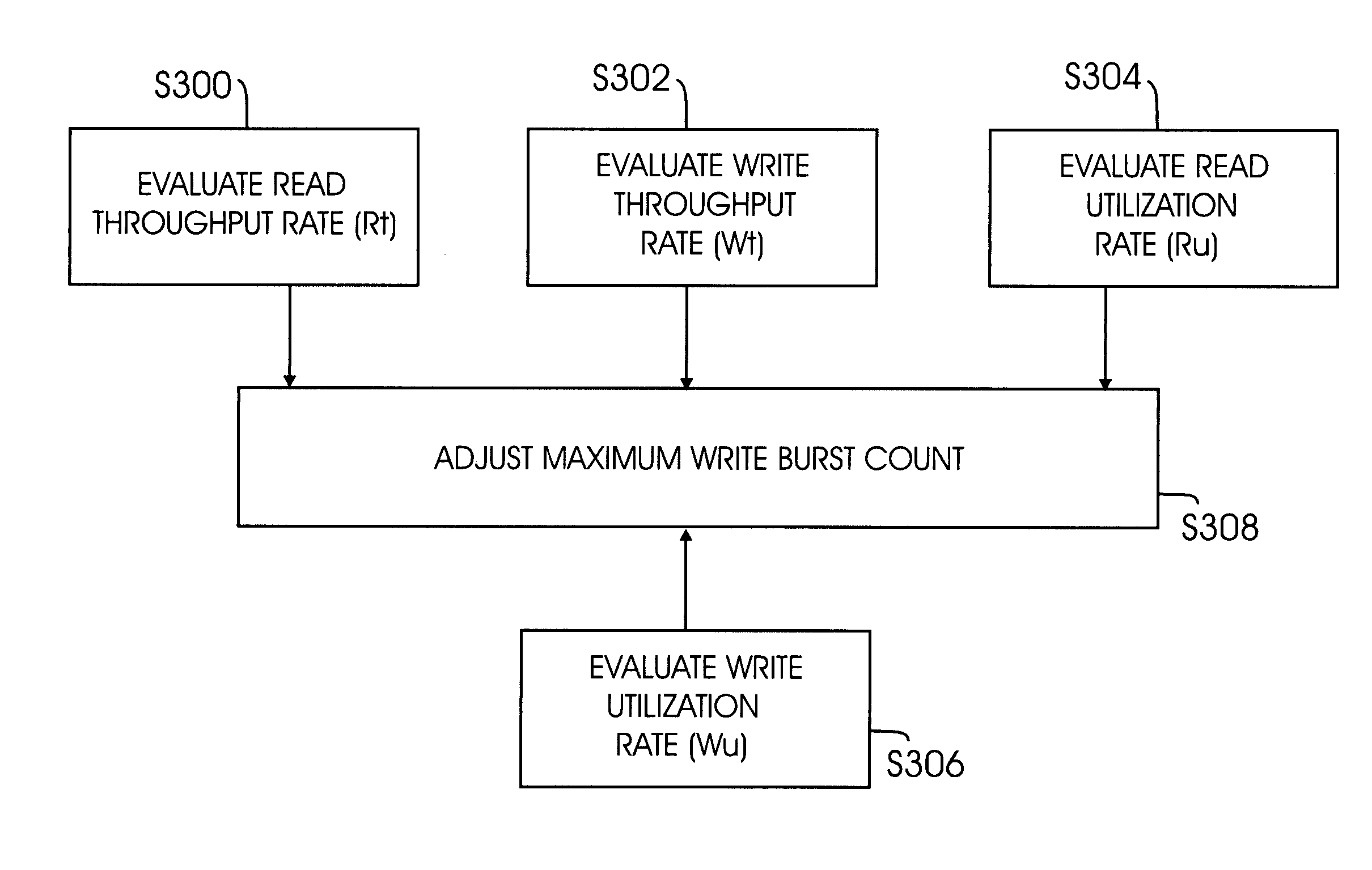

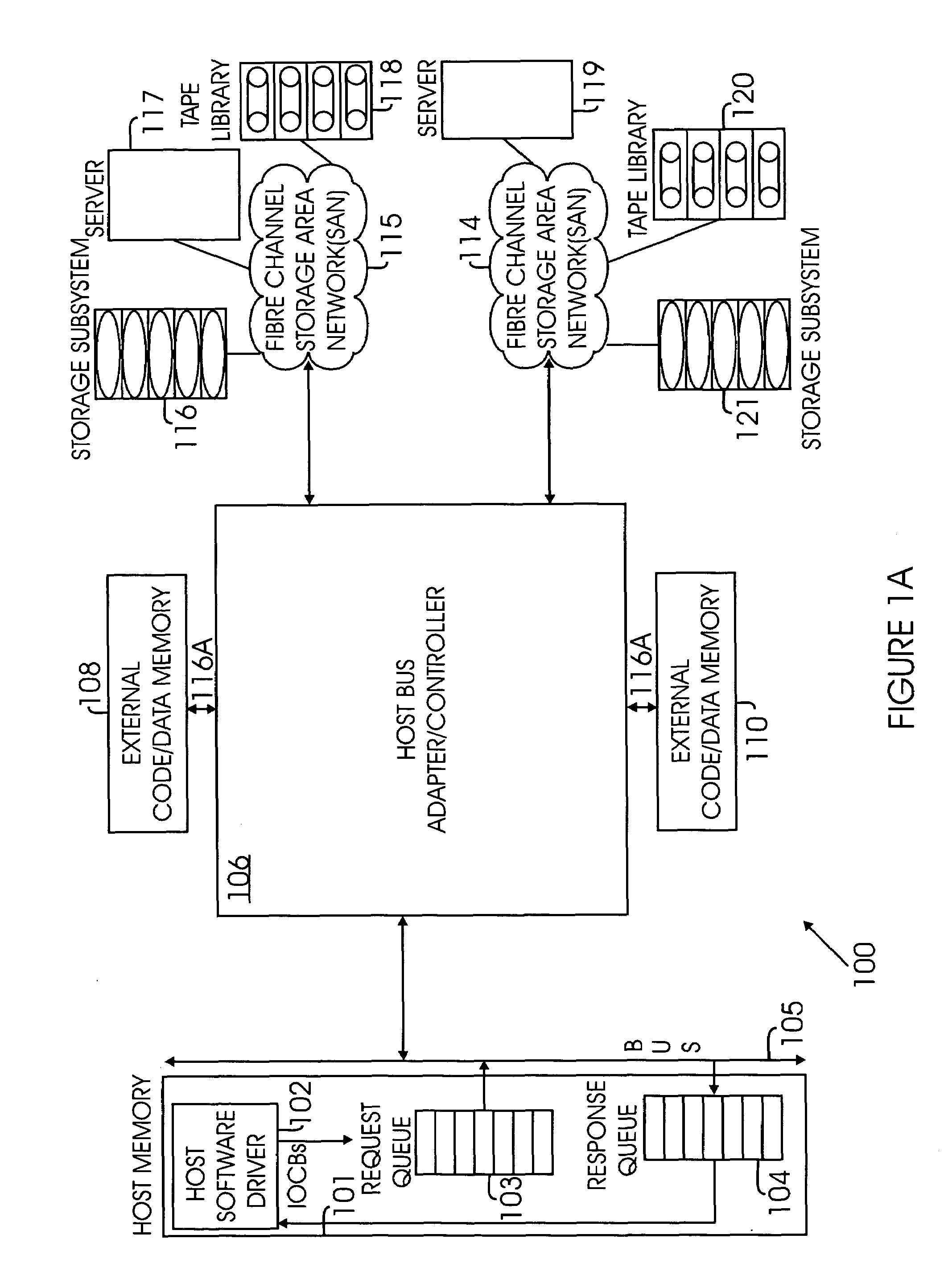

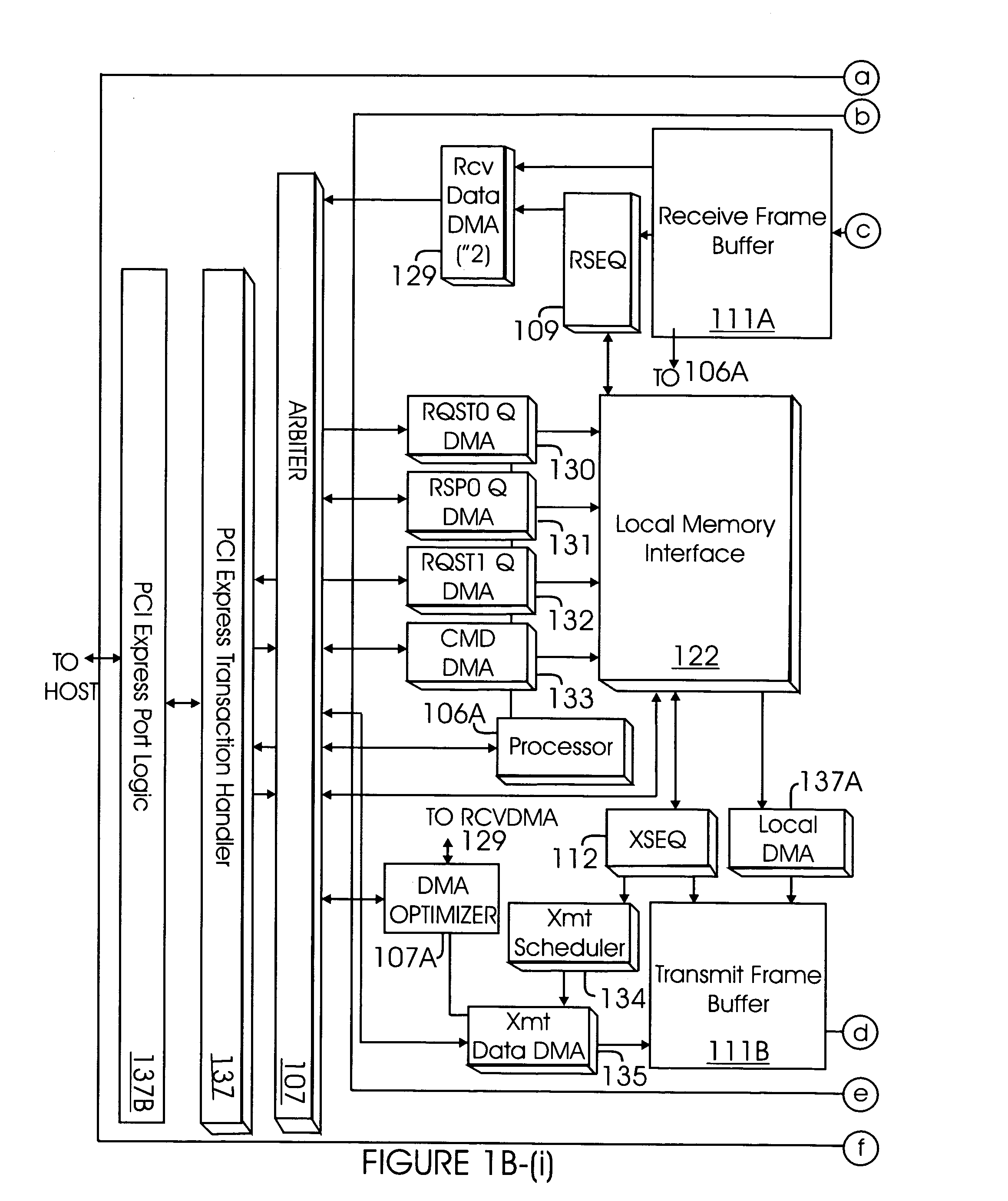

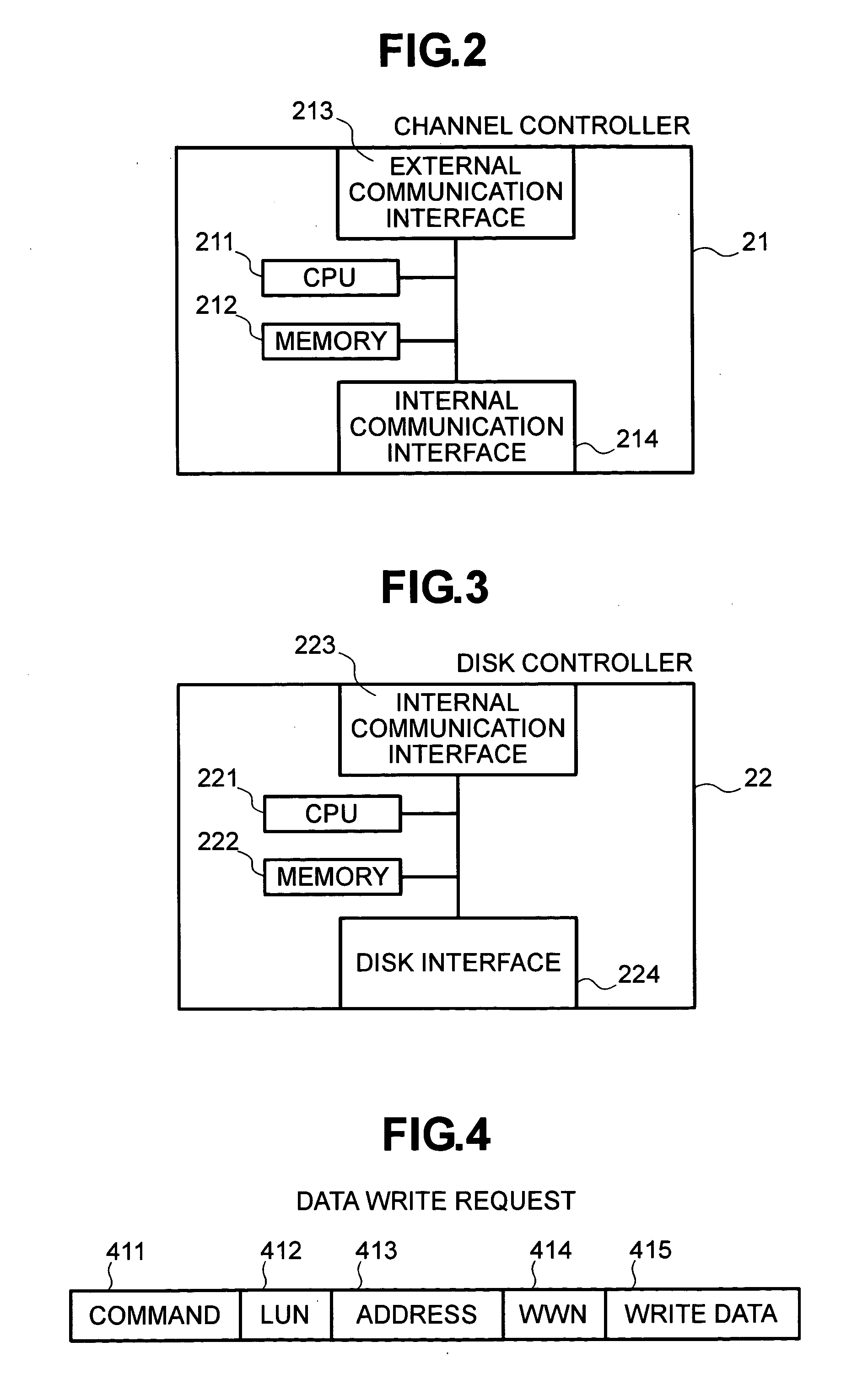

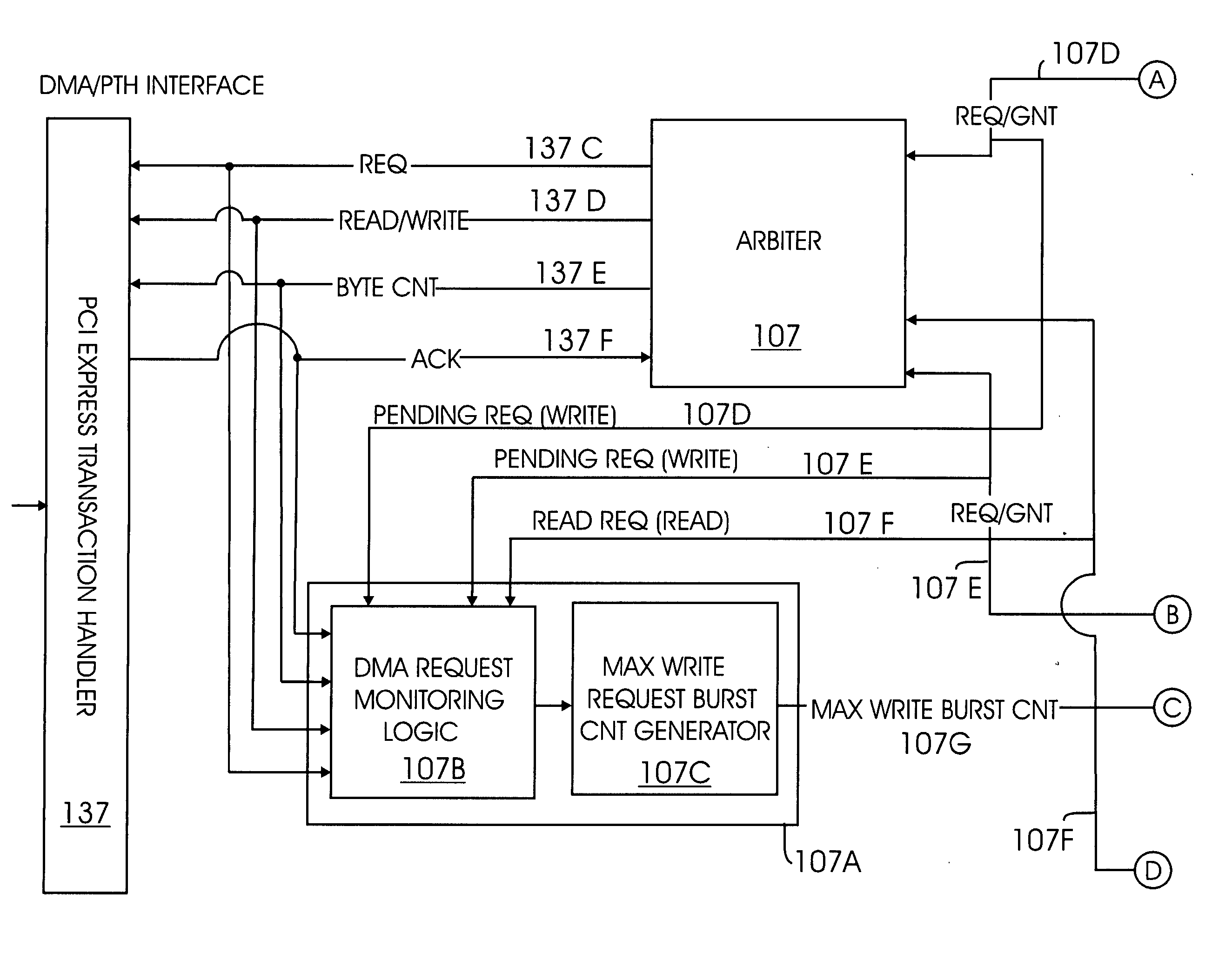

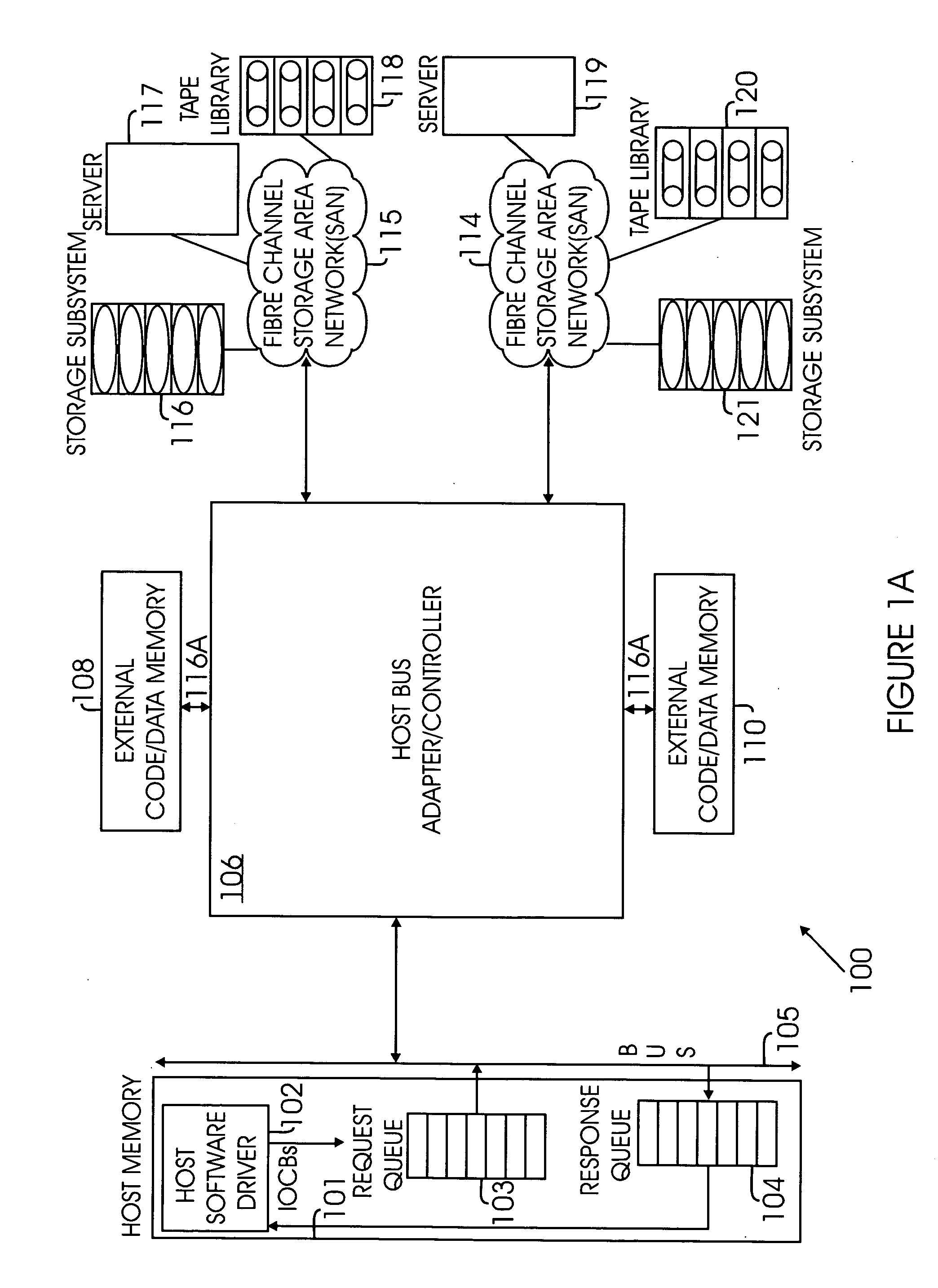

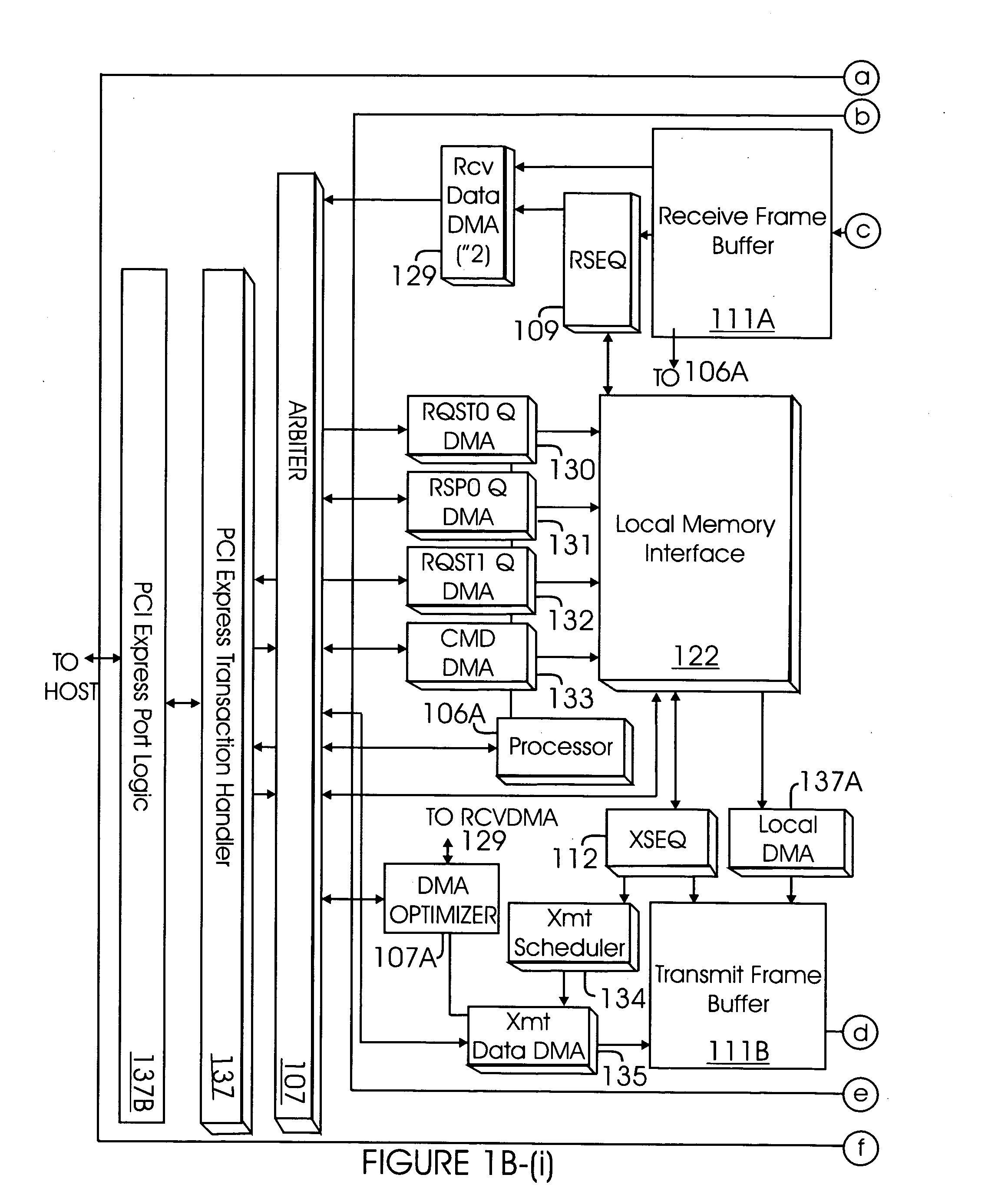

Method and system for DMA optimization in host bus adapters

InactiveUS7398335B2Optimize the writing processAdjustable performanceMultiple digital computer combinationsInput/output processes for data processingMaximum burst sizeBurst count

Method and system for optimizing DMA request processing is provided. The system includes a HBA that uses a dynamic DMA maximum write burst count sizing to optimize processing of write and read requests, wherein the HBA includes a DMA optimizer module that selects a certain write burst size to adjust performance when read and write DMA requests are being utilized. The DMA optimizer module can toggle between write and read request priority based on a maximum write request burst size. A shorter maximum write burst size provides more opportunity to issue read requests and a larger maximum burst size provides a better write request performance. The method includes, evaluating a read request throughput rate; evaluating a write request throughput rate; evaluating a read request utilization rate; evaluating a write request utilization rate; and adjusting a maximum write burst size.

Owner:MARVELL ASIA PTE LTD

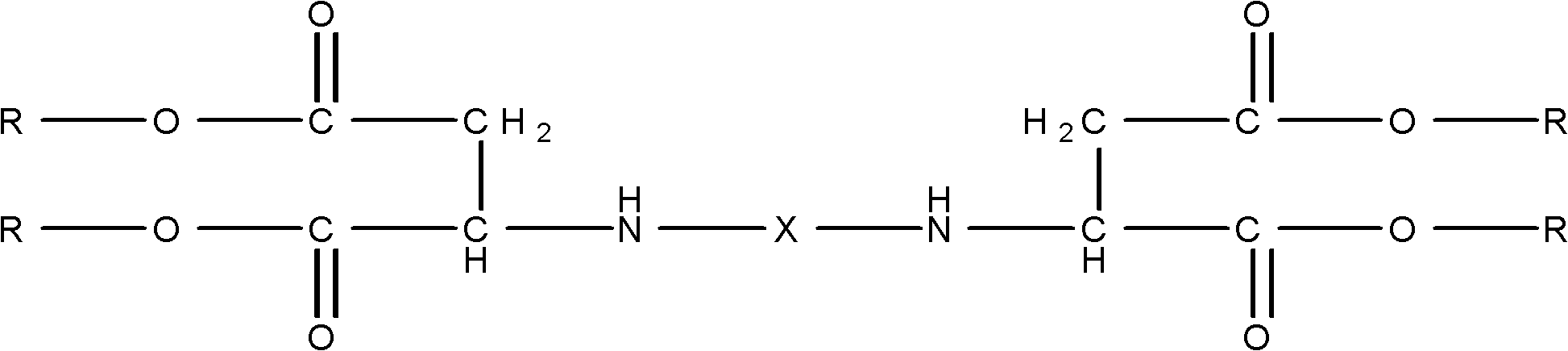

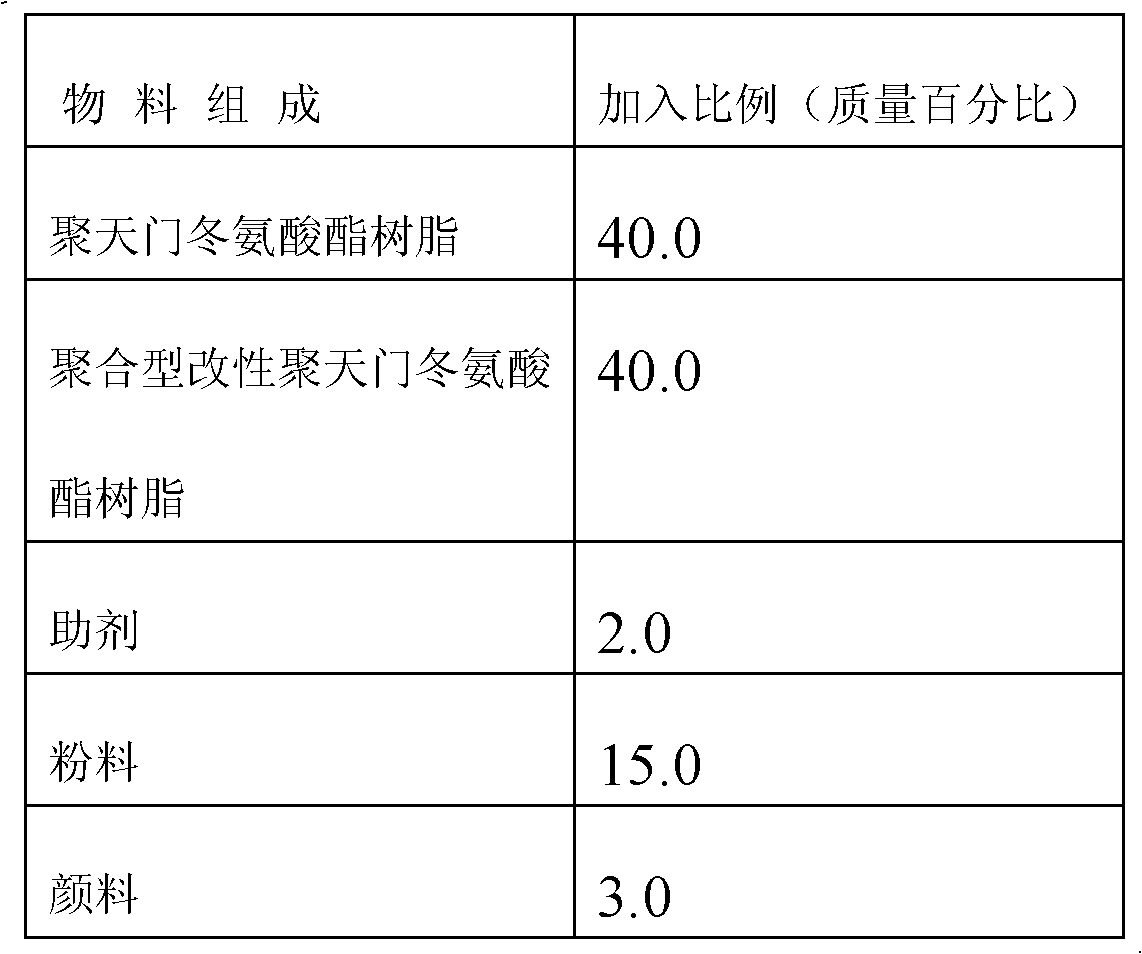

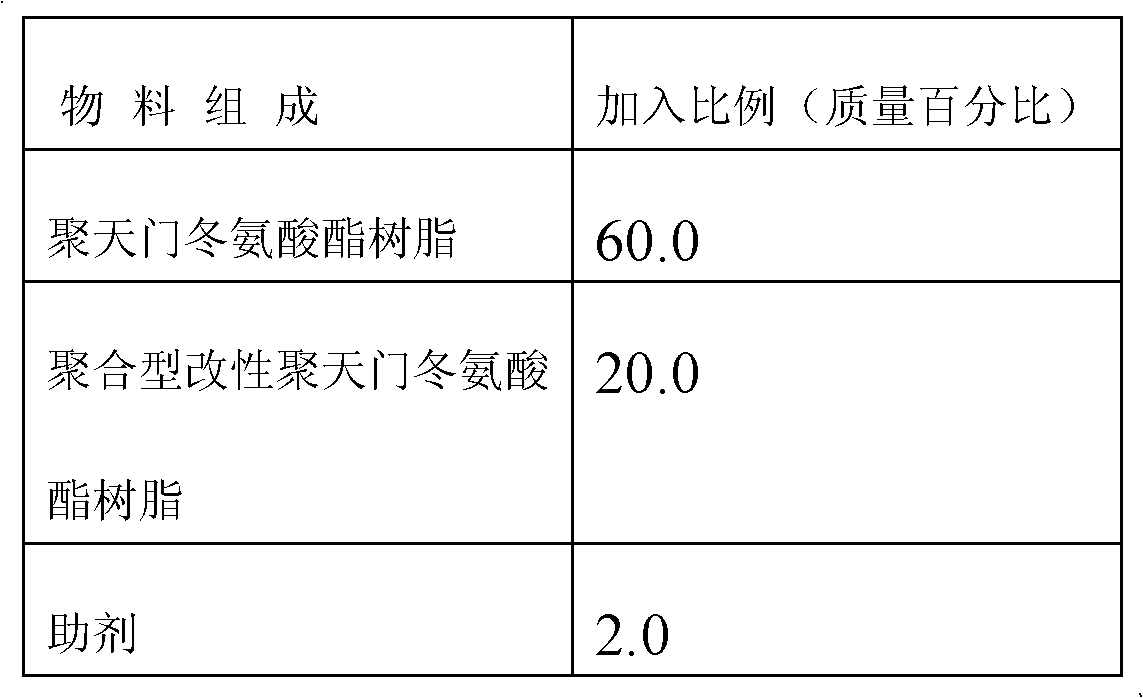

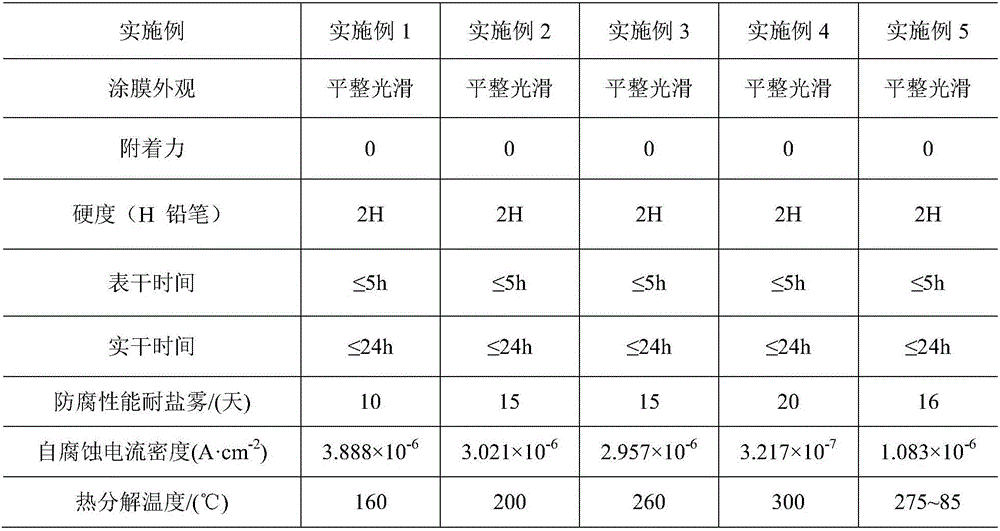

Solvent-free polyaspartic acid ester polyurea elastic waterproof paint

ActiveCN103031045AGood elongation at breakEasy constructionPolyurea/polyurethane coatingsSolventIsocyanate

The invention relates to paint and a preparation method thereof and discloses solvent-free polyaspartic acid ester polyurea elastic waterproof paint. The solvent-free polyaspartic acid ester polyurea elastic waterproof paint is composed of a component A and a component, wherein the component A comprises 2%-35% of polyisocyanate and 65%-98% of end seal isocyanate prepolymer by weight percent; and the component B comprises 20%-60% of polyaspartic acid ester, 10%-40% of polymeric modified poly aspartic acid ester, 5%-30% of stuffing and a small amount of additives by weight percent. Compared with the polyurea paint processed by the polyaspartic acid ester, the solvent-free polyaspartic acid ester polyurea elastic waterproof paint processed by raw materials has the advantages that the construction is convenient, a special large-scale spraying device is not needed, the gelation time is prolonged, the surface drying time is shortened, the tensile strength is enhanced, the elongation at break is increased, and the elastic coating film hardness is increased, does not have a solvent, is environment-friendly and harmless to a human body.

Owner:SHENZHEN FEIYANG JUNYAN TECH DEV

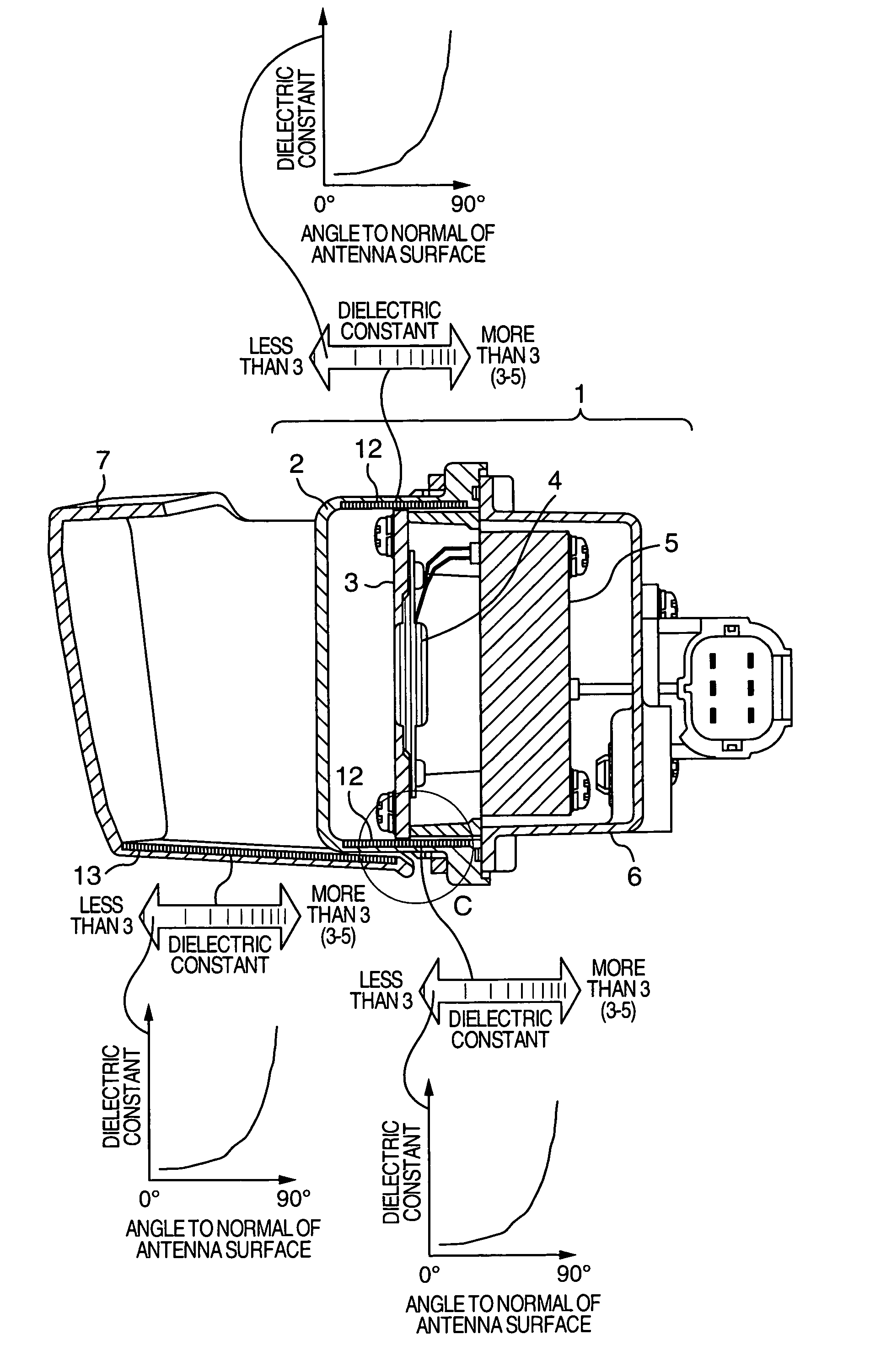

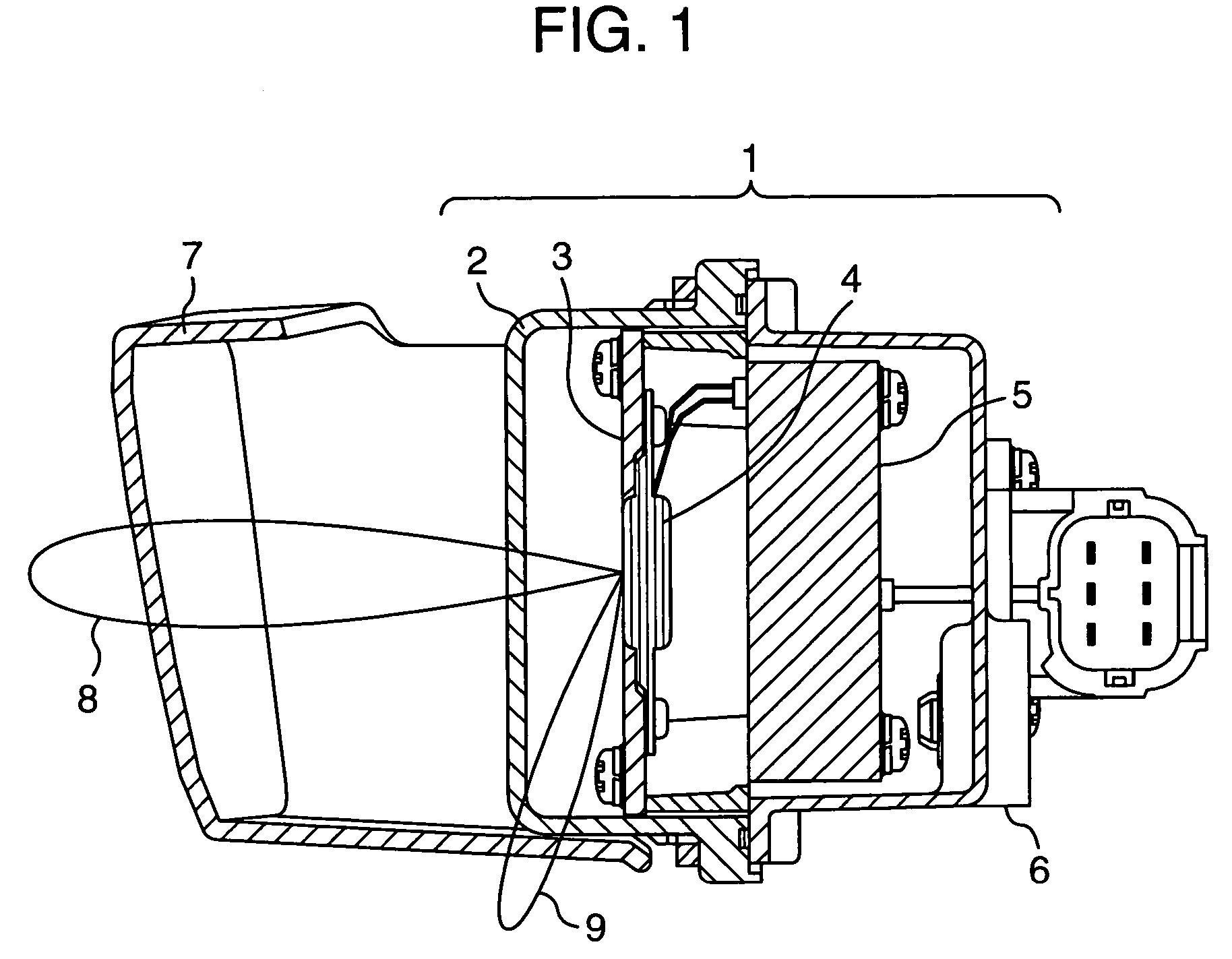

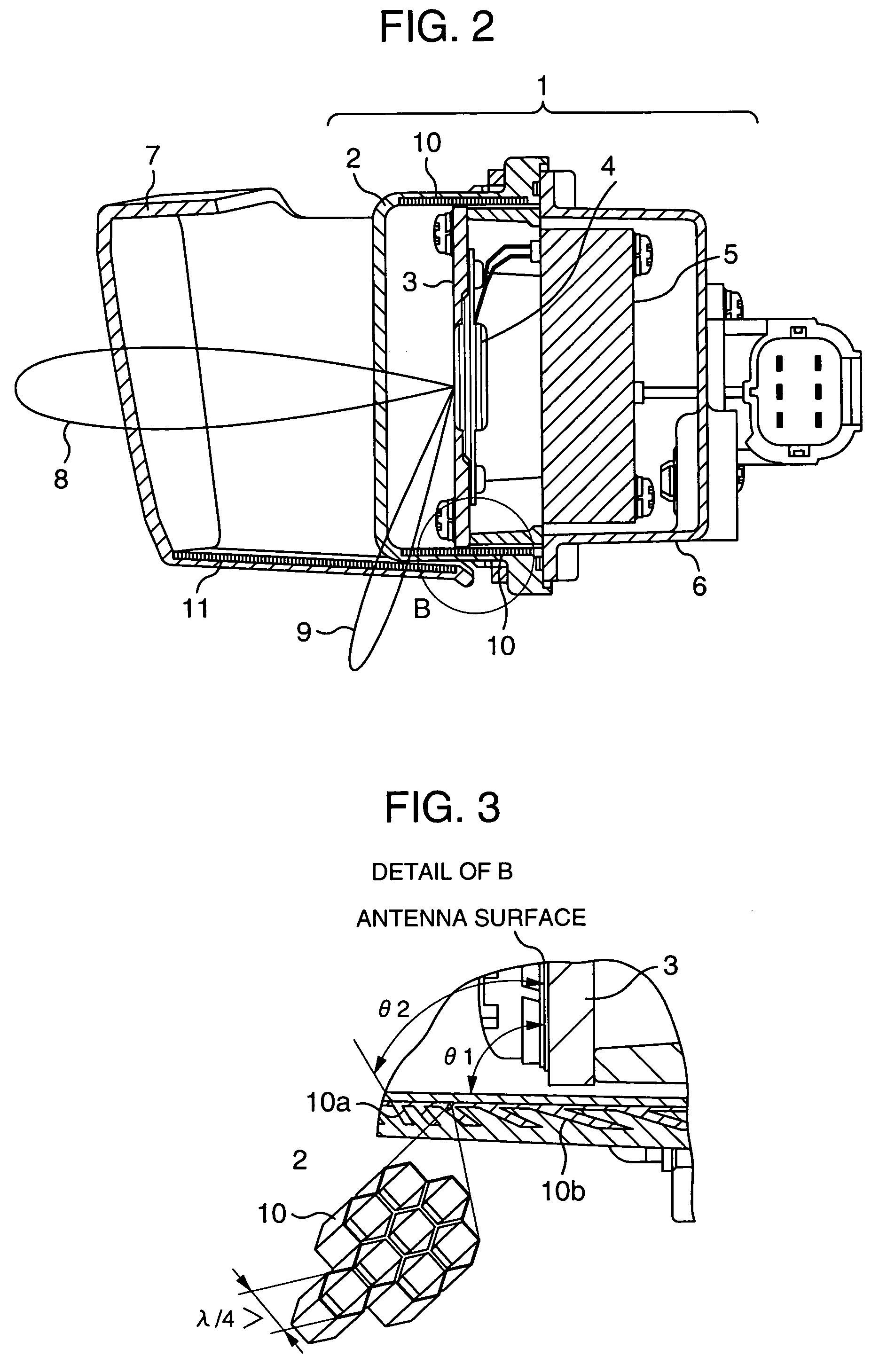

Millimeter wave-radar and method for manufacturing the same

InactiveUS7126525B2Maximum performanceAdjustable performanceRadiating element housingsRadio wave reradiation/reflectionRadomeDielectric

A millimeter-wave radar has a radome or radar cover including a layer, the dielectric constant of which is a greater than that of the other portion without the layer, or including a magnetic loss layer in an appropriate position with respect to the antenna. The dielectric constant of the radome or radar cover can be made higher in a portion corresponding to the side of the antenna than in a portion corresponding to the front of the antenna.

Owner:HITACHI LTD

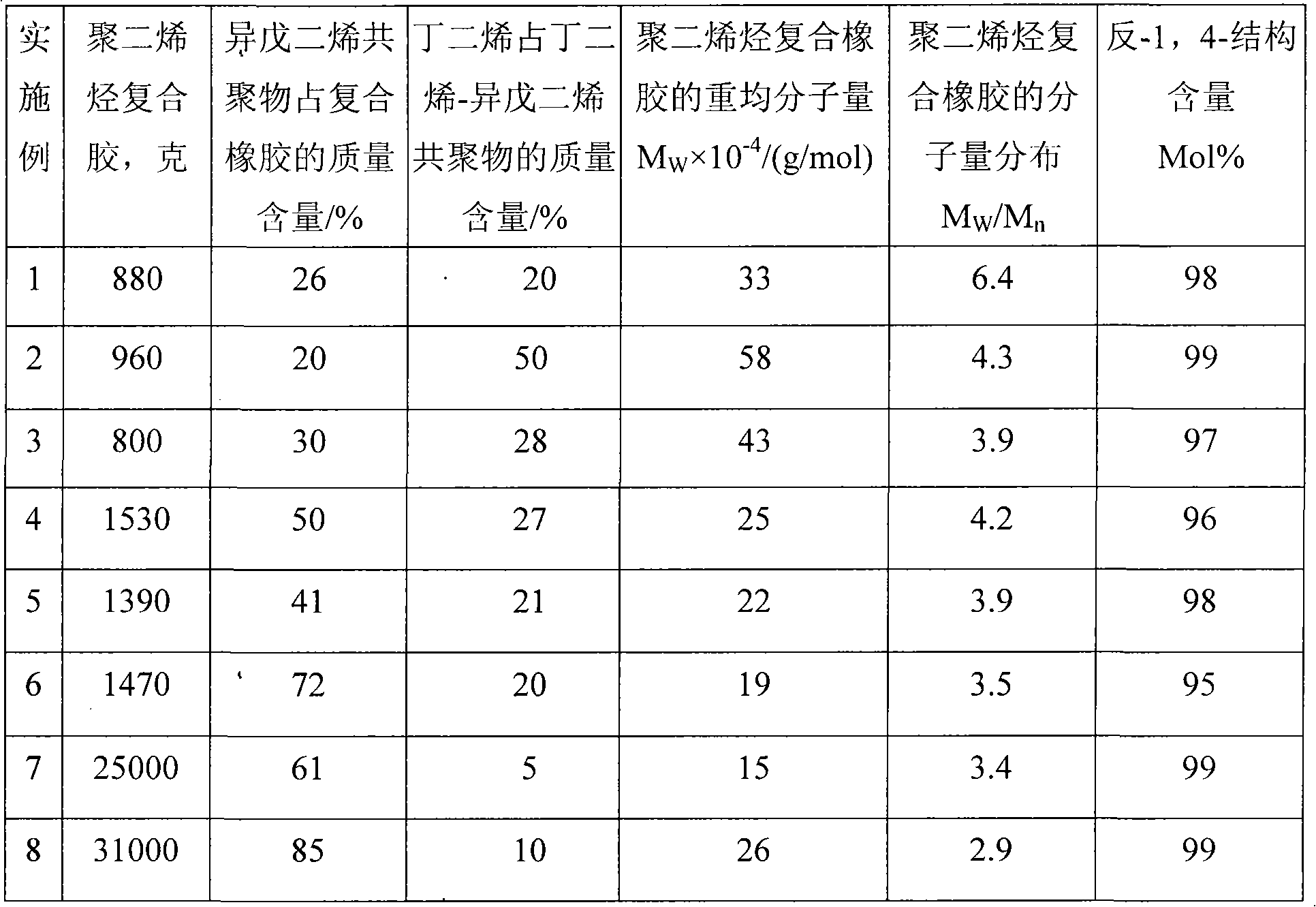

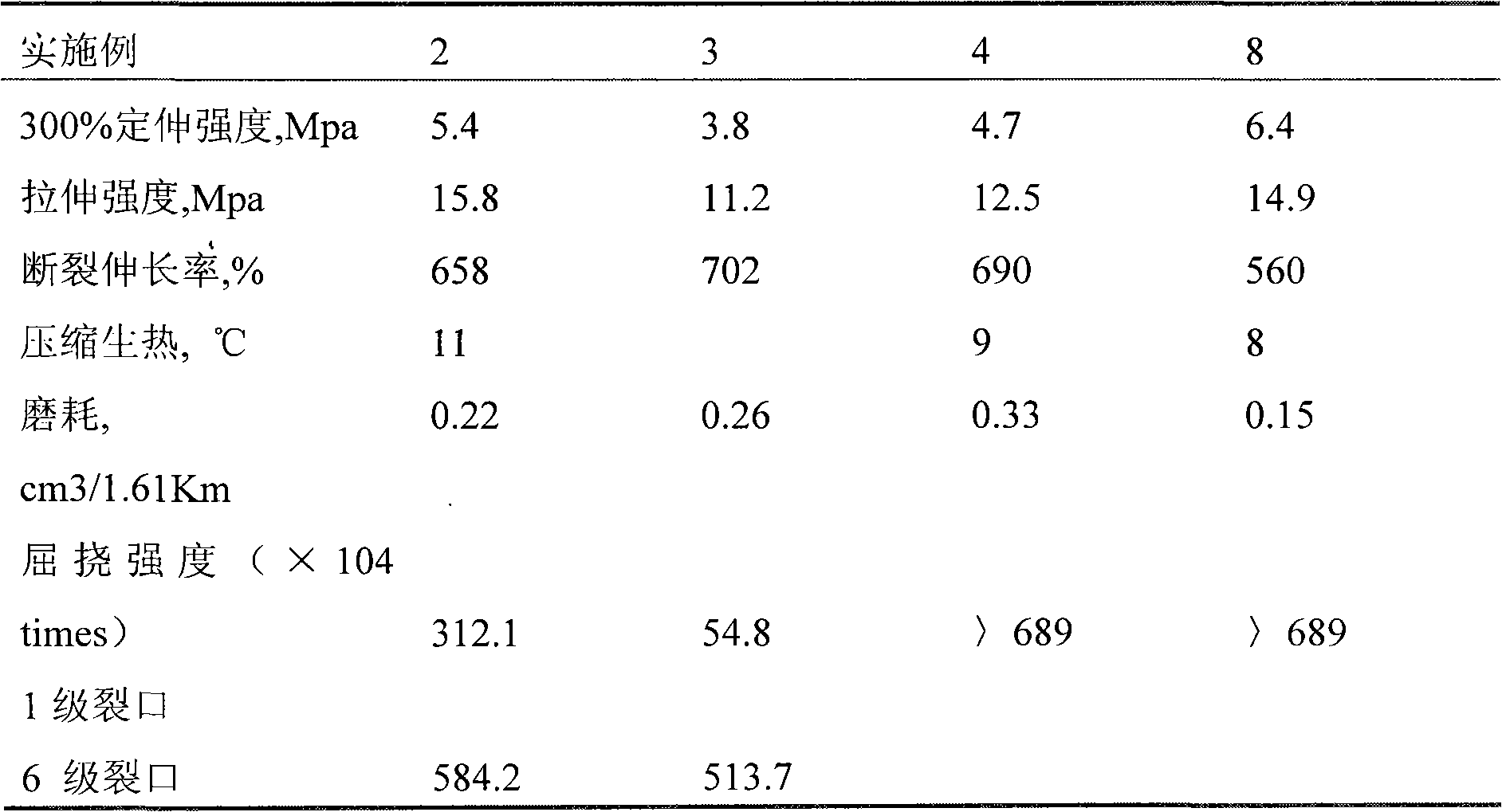

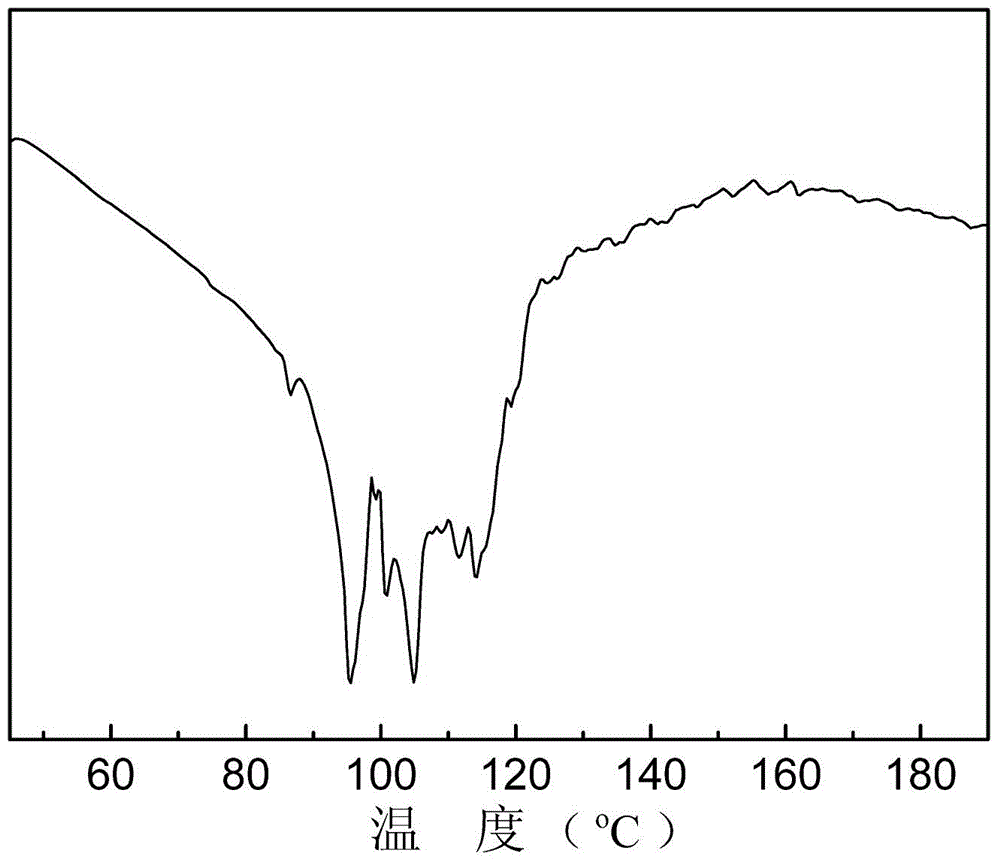

Trans-1,4-polydialkene composite rubber and preparation methods thereof

The invention relates to a polydialkene composite rubber of trans-1,4- structure and preparation methods thereof. The composite rubber consists of 10 to 80 mass percent of trans-1,4-polyisoprene and 20 to 90 mass percent of trans-1,4-butadiene-isoprene copolymer, wherein over 90 percent of structural units of all dialkenes in the composite rubber have trans-1,4-structures. The first preparation method comprises the following steps of: homopolymerizing isoprene to obtain trans-1,4-polyisoprene by adopting a Ziegler-Natta catalysis system consisting of MgCl2 supported titanium and organic aluminum compound, and then adding butadiene to synthesize the trans-butadiene-isoprene copolymer. The second preparation method comprises the following steps of: adding mixed monomers of butadiene and isoprene into a polymerization device at the same time, performing copolymerization to obtain the butadiene-isoprene copolymer of the trans-1,4-structure, and continuously polymerizing the isoprene to obtain the trans-1,4-polyisoprene after the butadiene with high polymerization speed is completely consumed. The used polymerization device is a stirring reaction kettle or a screw extruder. The composite rubber has excellent performance such as low rolling resistance, low generated heat, abrasion resistance, particularly fatigue break increment resistance and the like, and is suitable for dynamically used rubber products such as tyres, vibration absorption materials and the like.

Owner:SHANDONG HUAJU POLYMER MATERIALS CO LTD

No-shrinkage grouting filler with adjustable performance

The present invention belongs to the field of building material, and is especially one kind of no-shrinkage grouting filler with adjustable performance. The no-shrinkage grouting filler is hydraulic mixture comprising Portland cement and fly ash or silica fume as cementing material, quartzite, water reducing agent, expanding agent, water loss reducing agent, early settling preventing agent and early contract preventing agent. It has high flowability, no settling, no weeping, micro plastic expansion, no shrinkage, no cracking, adjustable performance, and no plastic settling and other excellent performance, and may be applied widely in installing large precise equipment, large area leveling, emergency repair engineering, etc.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

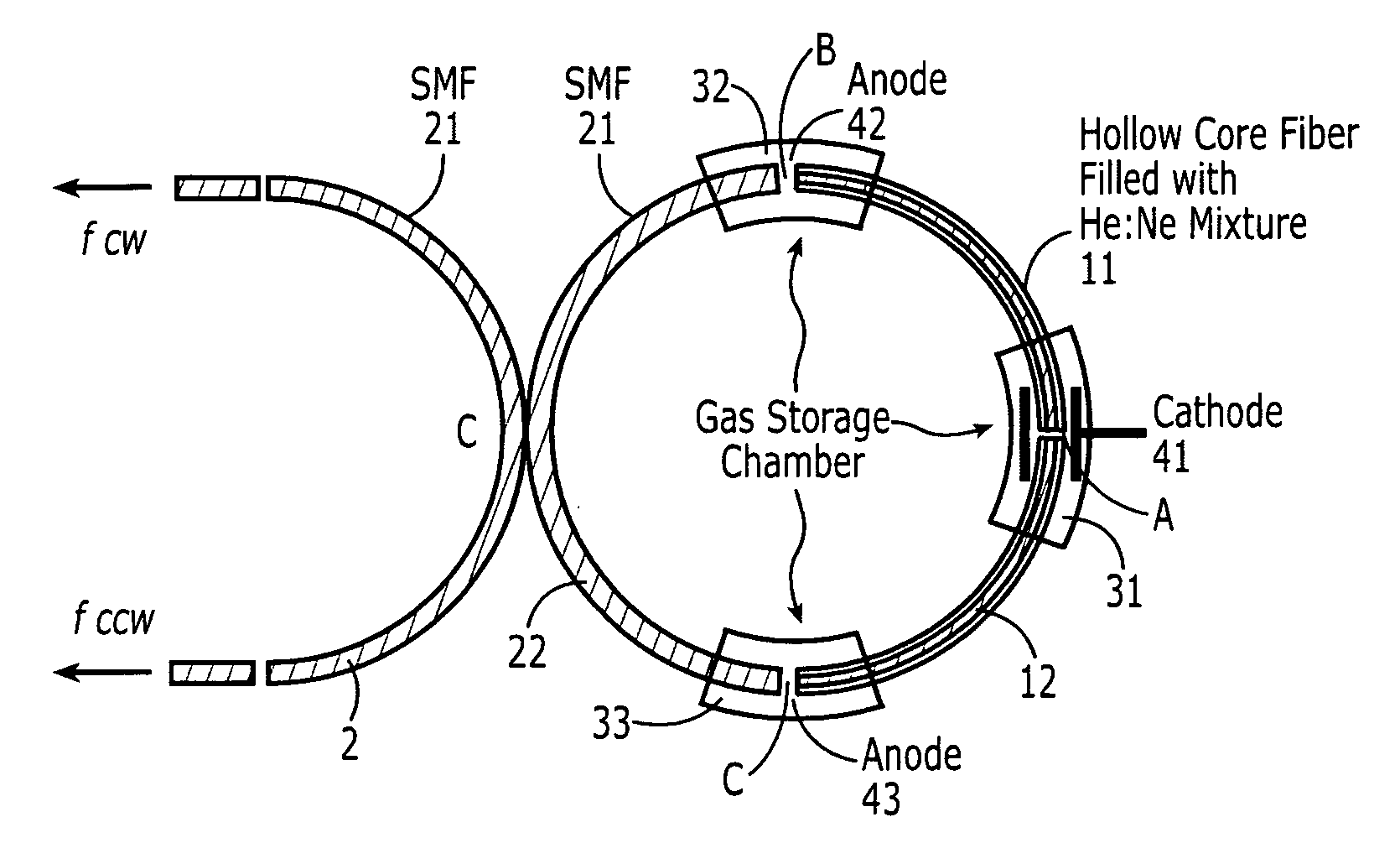

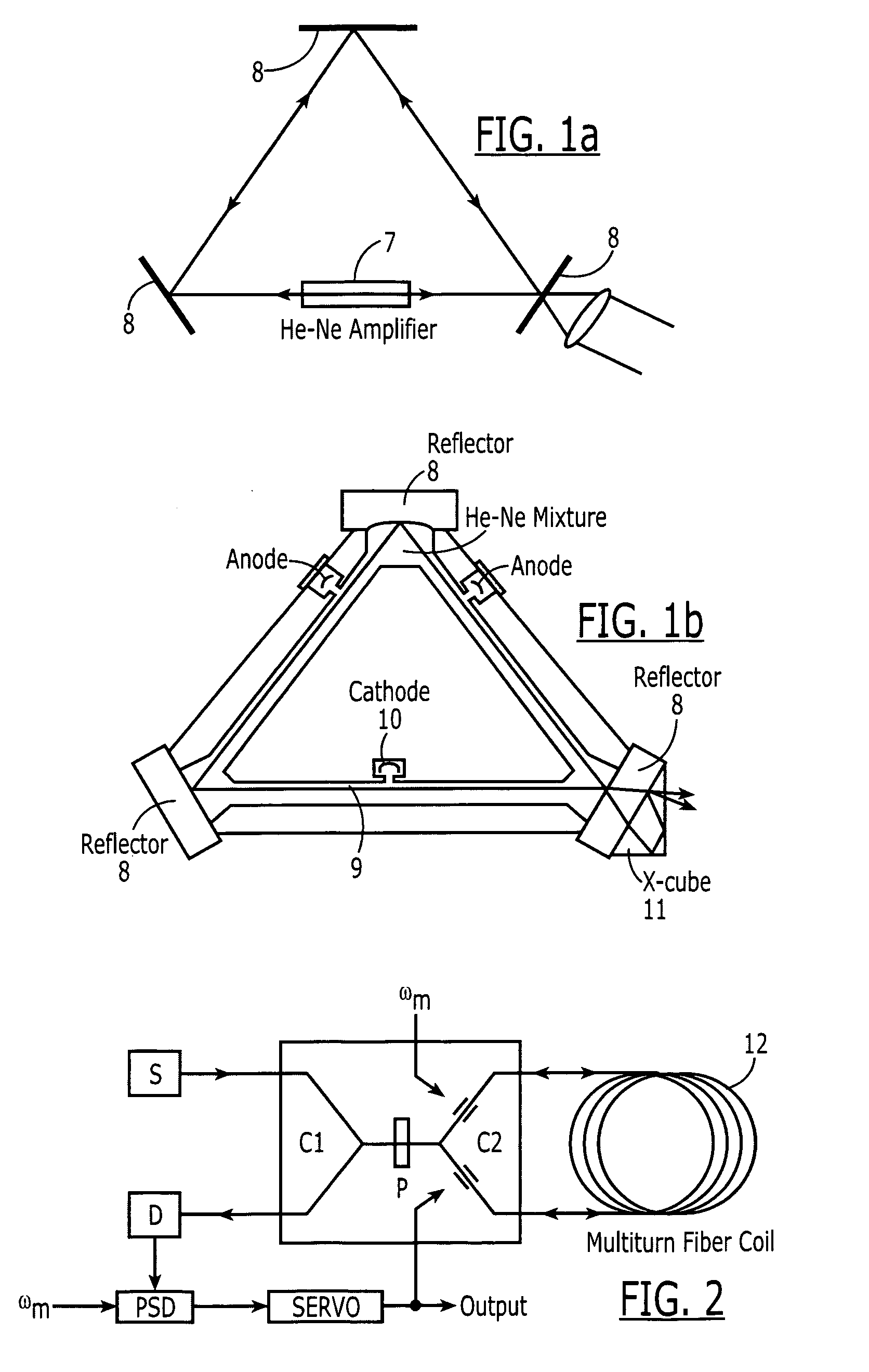

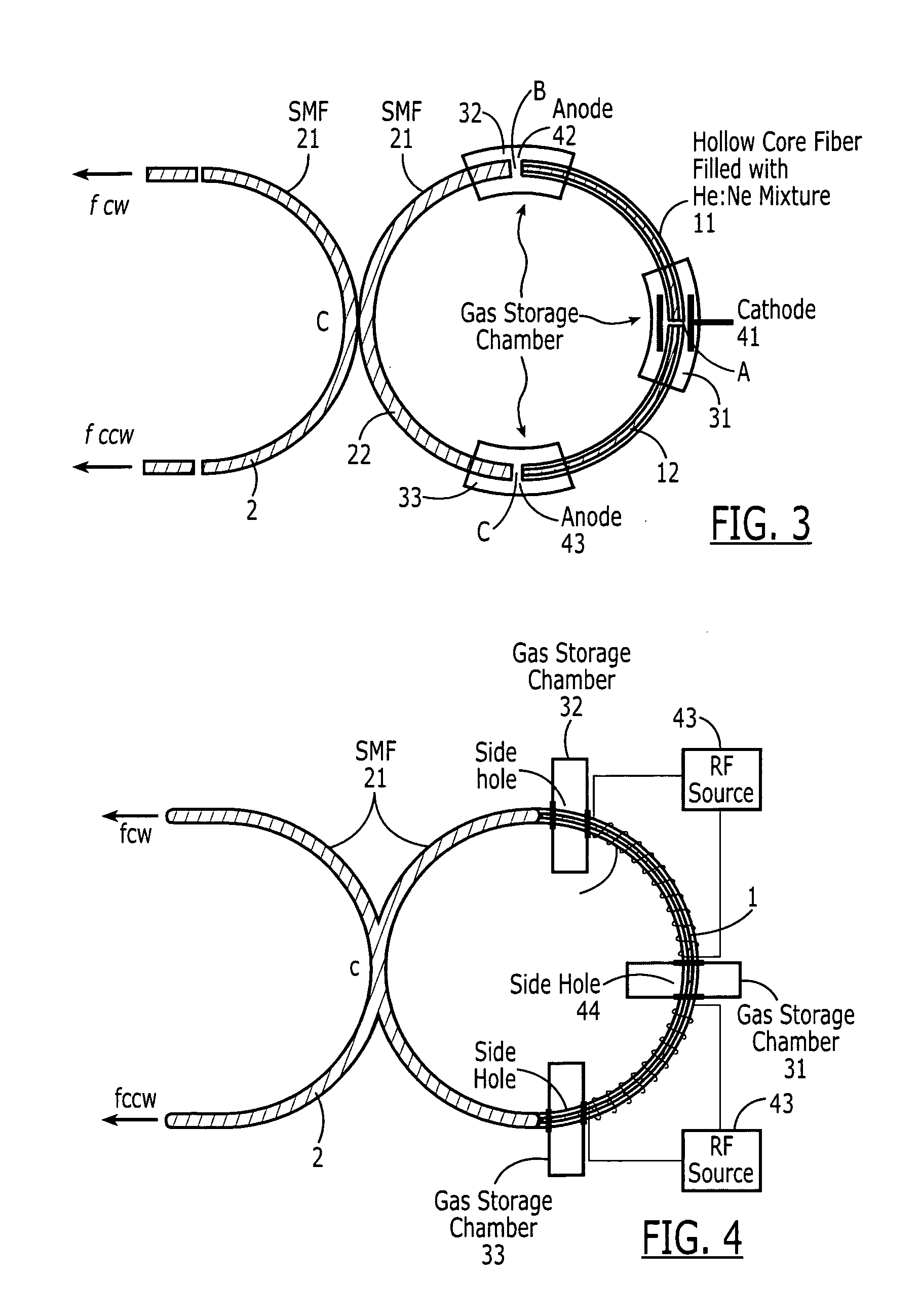

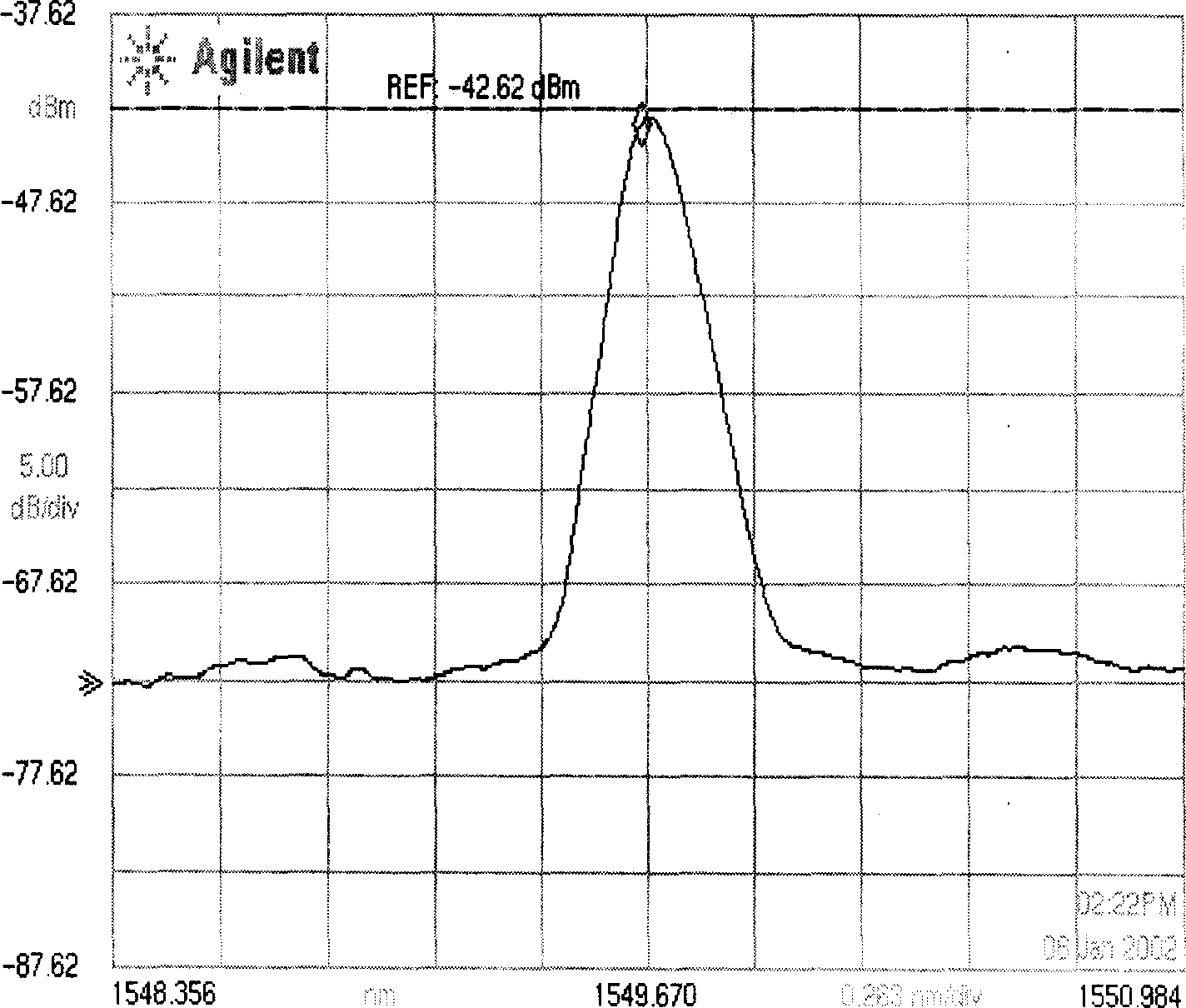

Fiber gas lasers and fiber ring laser gyroscopes based on these gas lasers

InactiveUS20080094636A1Good amplification performanceSimple structureLaser using scattering effectsSpeed measurement using gyroscopic effectsFiber couplerGyroscope

This invention discloses to a type of fiber gas lasers and fiber ring laser gyroscopes based on these fiber gas lasers. The fiber gas lasers comprise of excitation gases, optical resonator and excitation source, etc. The optical resonator is made by connecting two selected arms of a single mode fiber coupler to the two ends of hollow-core fiber to form a ring resonator. The hollow-core of the fiber is filled with excitation gases to act as gain medium. The fiber laser is simple to construct, lower cost, and has adjustable size and good amplification performance. The fiber ring laser gyroscopes based on this novel type of gas lasers can be applied on robotics, automobile navigation, etc.

Owner:THE HONG KONG POLYTECHNIC UNIV

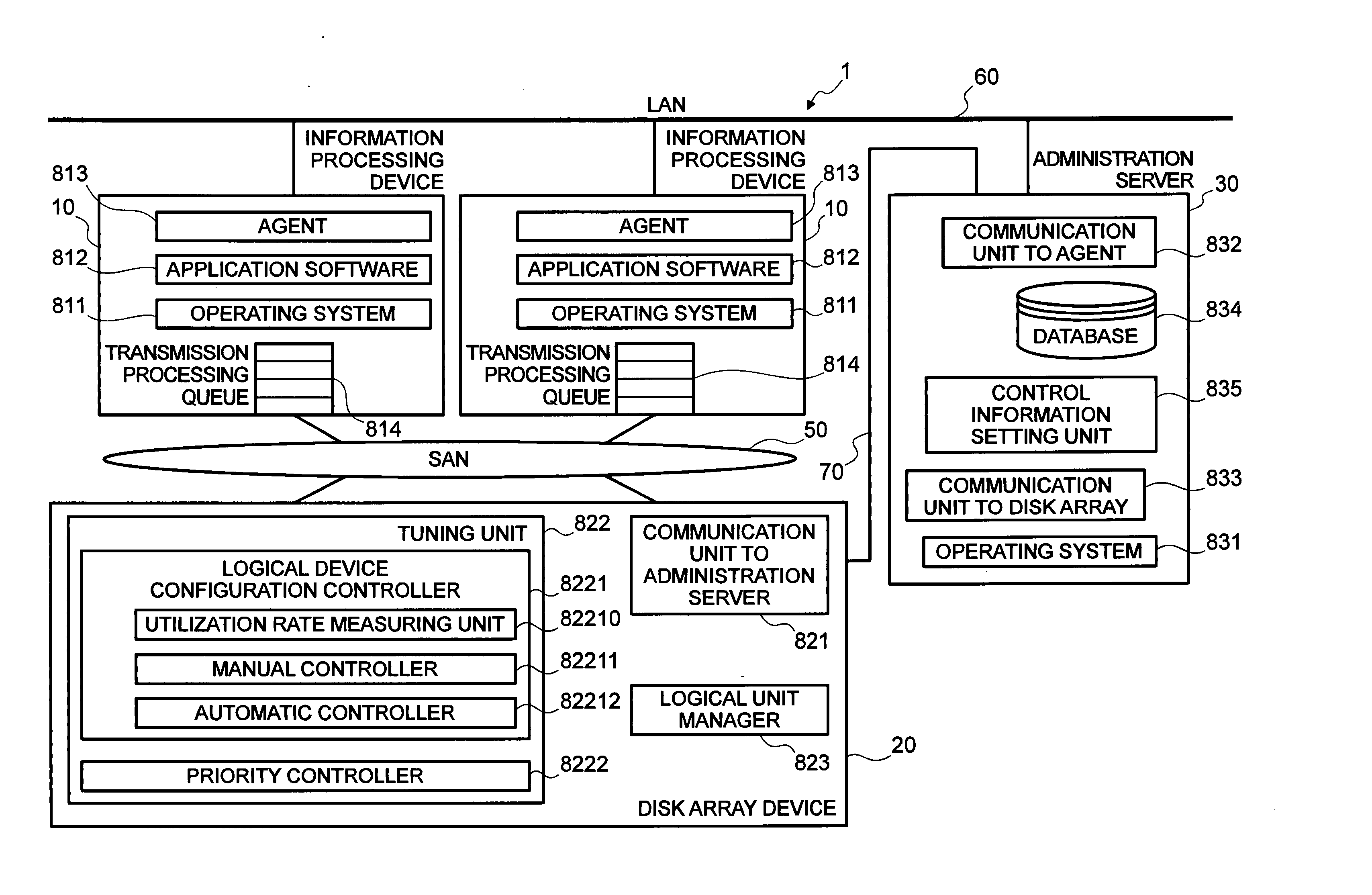

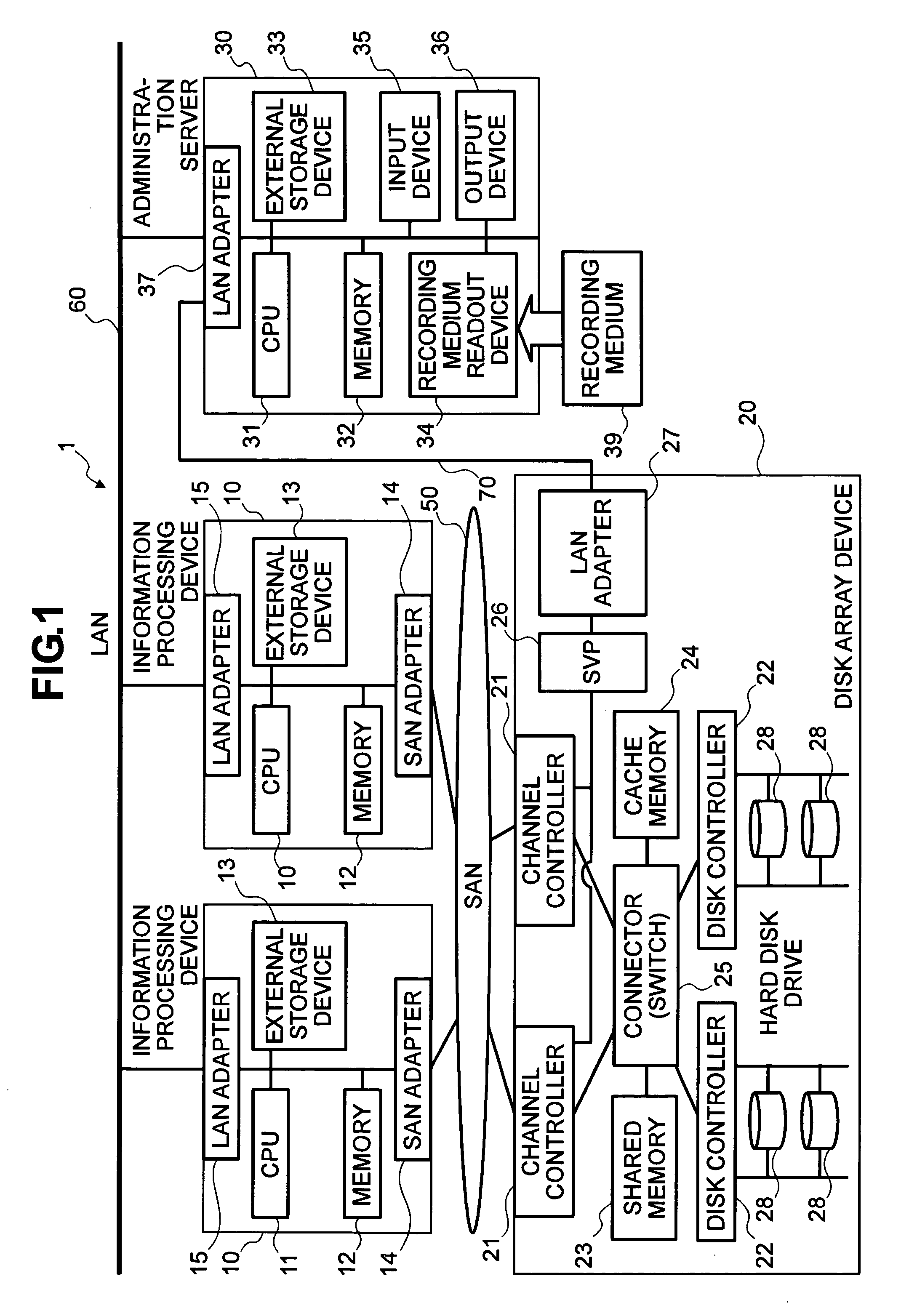

Storage system, storage control device, and control method for storage system

InactiveUS20050125426A1Improve performanceAdjustable performanceInput/output to record carriersDigital data processing detailsInformation processingData shipping

Provided is storage system comprising a plurality of first information-processing devices; a storage control device which is communicatively connected with the first information-processing devices via a first communication network, to receive a data input / output request transmitted from an information-processing device, and to read or write data from or to a storage device according to the data input / output request; and a second information-processing device communicatively connected with the first information-processing devices and the storage control device, wherein each of the first information-processing devices transmits processing status data relating to data input / output requests being processed to the second information-processing device; the second information-processing device receives the processing status data and transmits the storage control device a message which relates to performance adjustment of the storage control device for the first information-processing devices, and is determined according to the processing status data; and the storage control device executes processing related to performance adjustment of the first information-processing devices according to the message.

Owner:HITACHI LTD

Method for preparing carbon nanometer tube composites by sol and gel method

InactiveCN1644494AAvoid reunionGood compatibilityPigment treatment with macromolecular organic compoundsSolubilityEpoxy

Production of carbon nanometer tube composite by sol-gel method is carried out by surface modifying the carbon nanometer tube to obtain acidified carbon nanometer tube by strong acid oxide, reacting acidified carbon nanometer tube with acylating agent to prepare active carbon nanometer tube containing acyl halide perssad, sesquioxosilane with azyl, chlorine, and epoxy etc. active perssad as end group reacting with acidified or acyl halide perssad contained carbon nanometer tube, and obtaining sesquioxosilane stem grafted carbon nanometer tube. Its advantages include good solubility in organic solvent, good dispersiveness to plastic and coating, good compatibility for high performance membrane material, high strength material and wave absorbing material.

Owner:EAST CHINA NORMAL UNIV

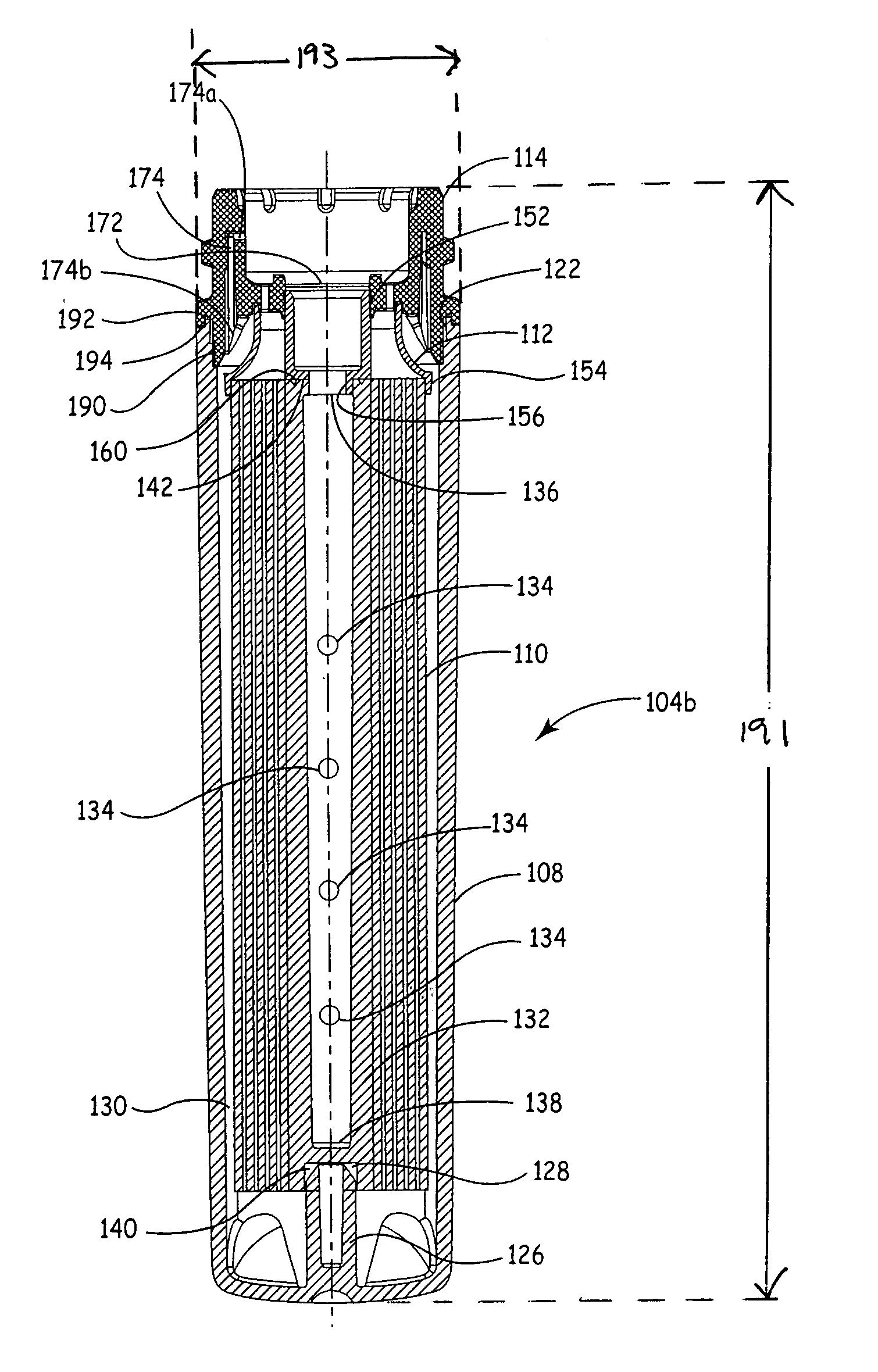

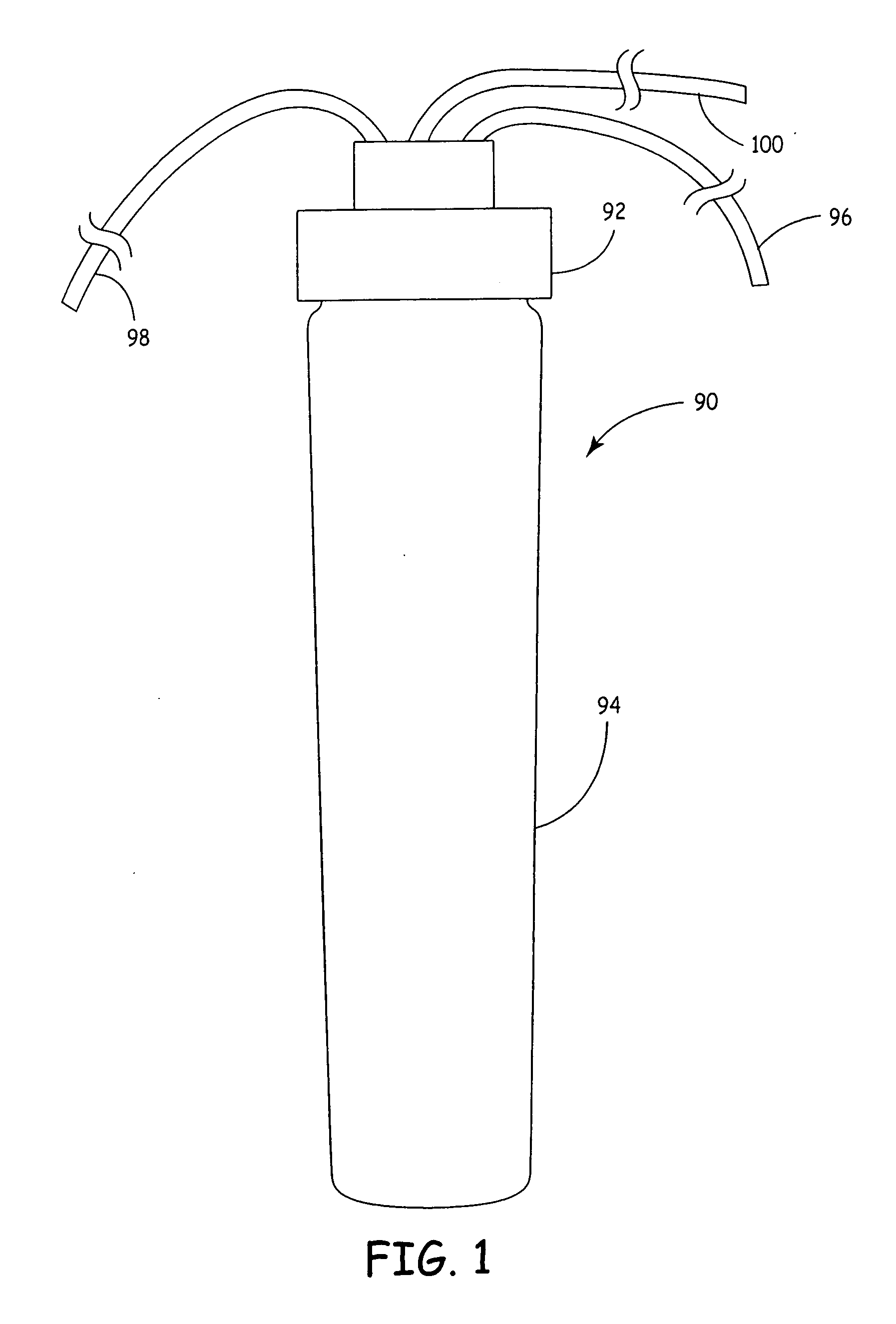

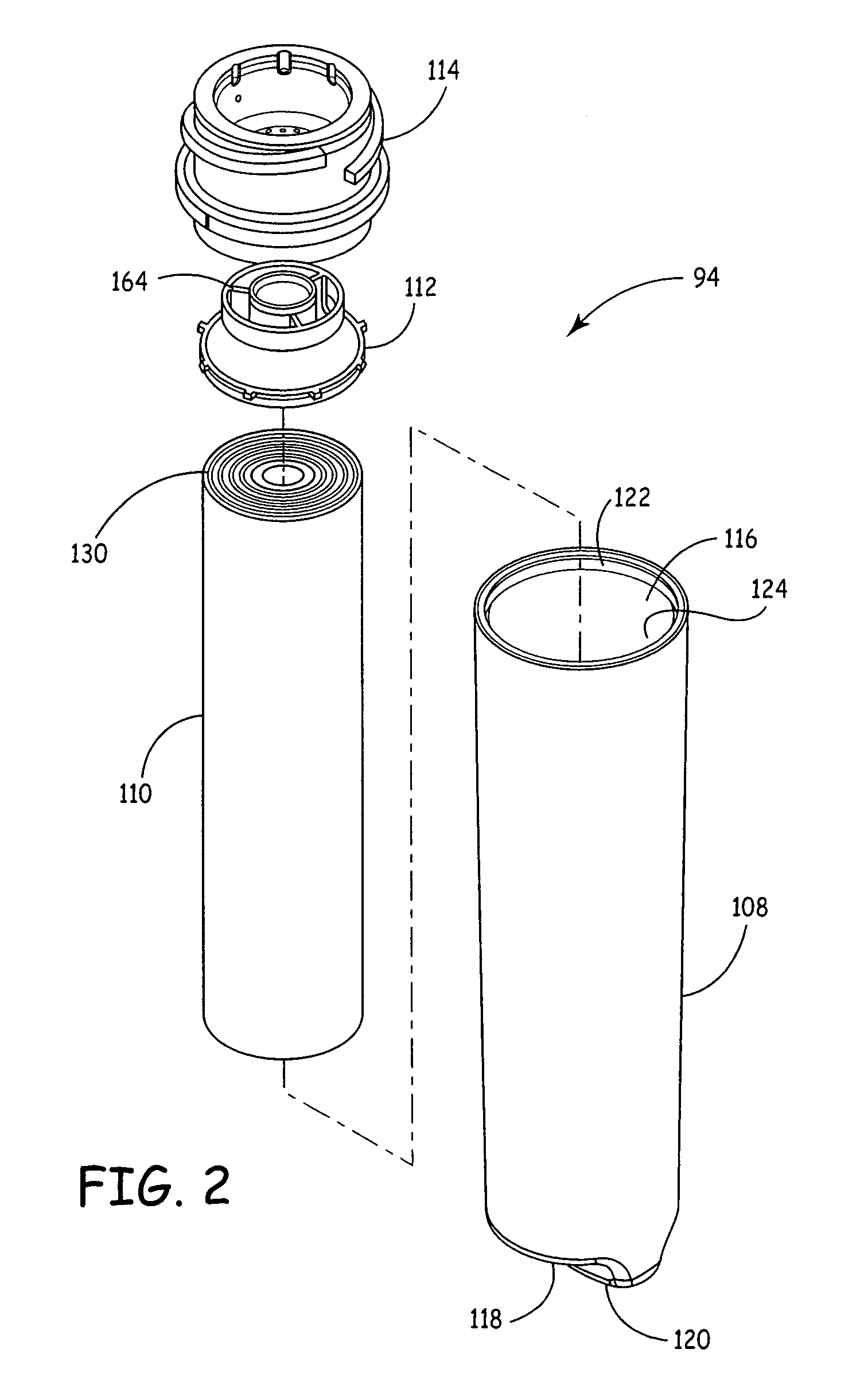

Crossflow filtration system with quick dry change elements

InactiveUS20050173319A1For quick replacementFiltering characteristics of the crossflow filtration system can be adjustablyUltrafiltrationSedimentation separationMicrofiltration membraneUltrafiltration

A crossflow filtration system including at least one quick dry change crossflow filtration cartridge designed to rotatably interface with a manifold assembly. The quick dry change crossflow filtration cartridge can comprise a membrane element, for example an ultrafiltration membrane, microfiltration membrane, nanofiltration membrane or high-flux reverse osmosis membrane element enclosed within a housing. The quick dry change cartridge includes an inlet stream, a permeate stream and a concentrate stream. The manifold assembly includes three similar flow paths; an inlet stream, a permeate stream and a concentrate stream. When engaged, the cartridge and manifold assembly define continuous inlet flow paths, permeate flow paths and concentrate flow paths that connect across the interface. Thus, all of the connections to the water filtration system can be made onto the manifold, and the resulting connected system is compact and easy to connect.

Owner:3M INNOVATIVE PROPERTIES CO

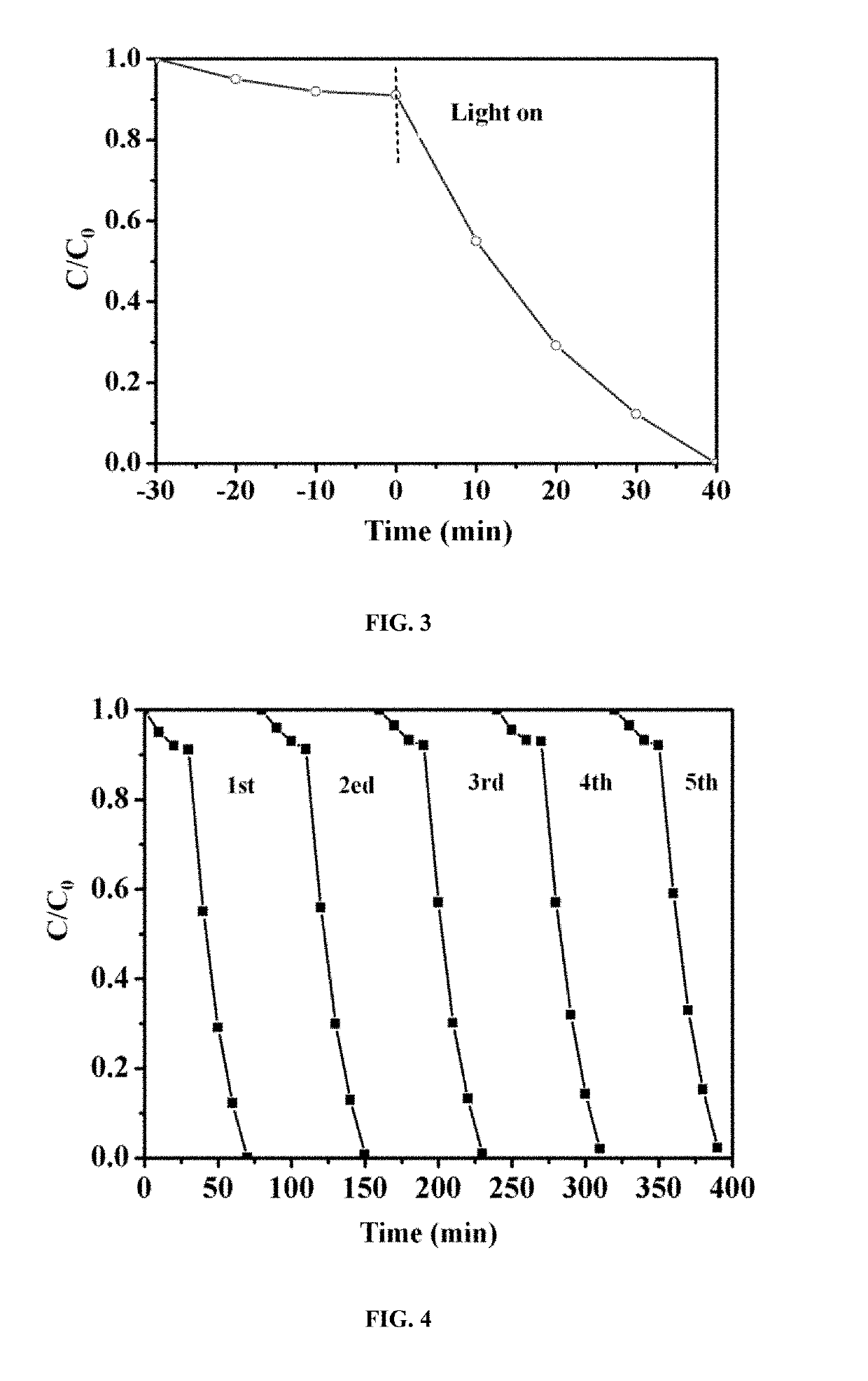

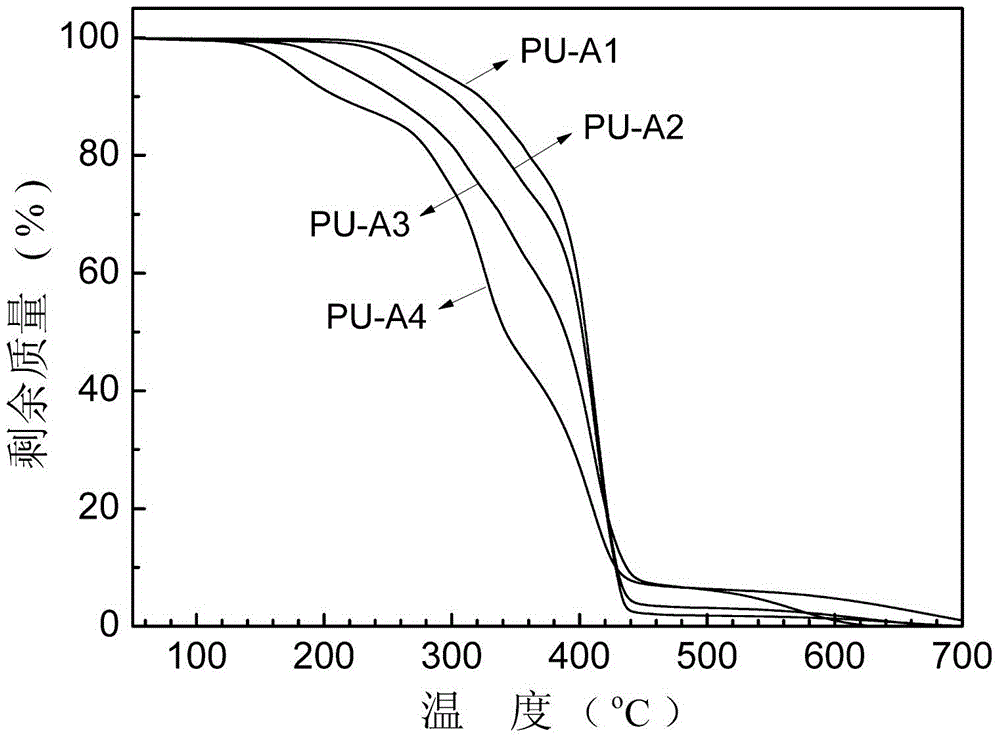

Loaded multifunctional catalysis composite material, preparation method thereof and application of composite material to catalytic removal of water pollutants

ActiveUS20190329236A1Promote full accessReduce recombination rateMaterial nanotechnologyWater/sewage treatment by irradiationPhoto catalysisNickel

The invention discloses a loaded multifunctional catalysis composite material, a preparation method thereof and an application of the composite material to catalytic removal of water pollutants. The preparation method includes the steps: preparing a zinc oxide nano-sheet loaded nickel foam (Ni@ZnO) composite material by an electro-deposition method; compounding molybdenum disulfide micro-nano particles on ZnO porous nano-sheets by an electro-deposition method to obtain Ni@ZnO / MoS2. The composite material Ni@ZnO / MoS2 combines the advantages of components such as nickel foam, the zinc oxide nano-sheets and molybdenum disulfide from the point of material performances, high catalytic degradation activity and recycled performances are achieved, photo-catalysis and electro-catalysis are combined from the point of material application, and the catalytic activity of the composite material is improved by the aid of synergistic effects of photo-catalysis and electro-catalysis.

Owner:SUZHOU UNIV

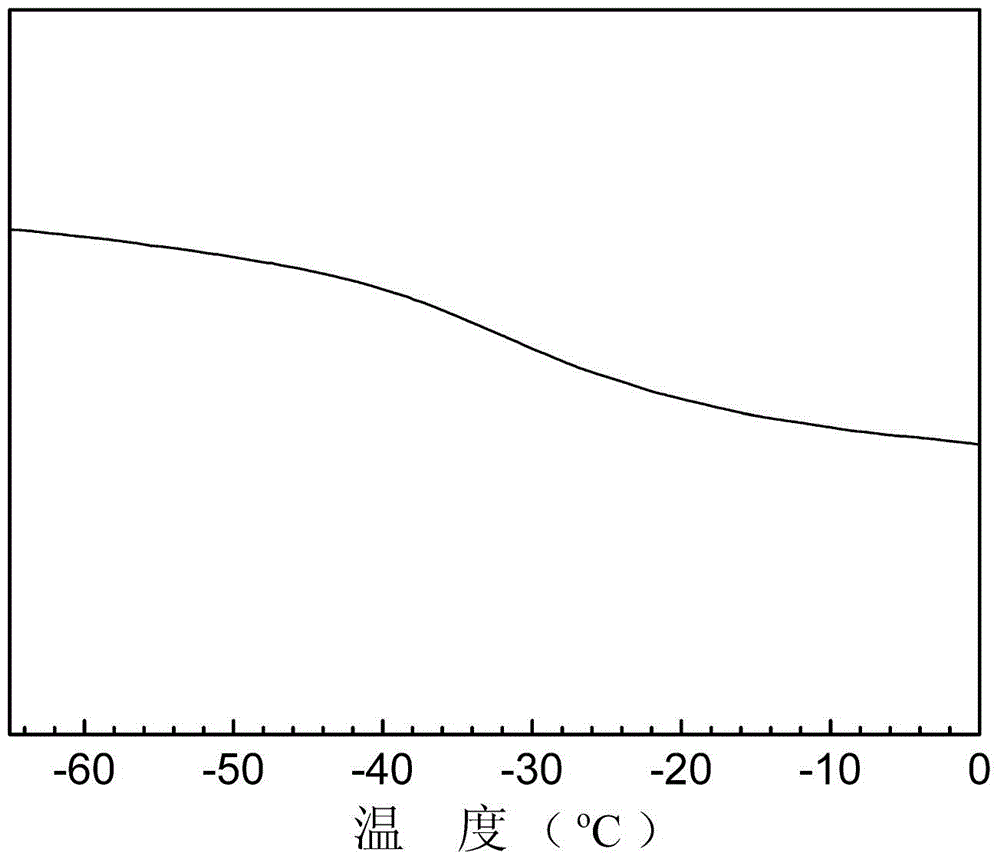

Solvent type polyurethane structure adhesive and preparation method thereof

InactiveCN104893644ADouble curing effectPlay the effect of curing cross-linkingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesCross-linkPolyurethane adhesive

The invention discloses a method for preparing a solvent type polyurethane structure adhesive. The method is characterized in that an isocyanate solidifying agent sealed by a sealing agent and a polyurethane prepolymer at the sealed end of hydroxyl group are mixed to obtain a polyurethane adhesive, or the polyurethane prepolymer sealed by the sealing agent and a trihydroxy compound are mixed, or the polyurethane prepolymer sealed by the sealing agent and the isocyanate solidifying agent sealed by the sealing agent are mixed to be added into an adsorbing filling material to obtain the polyurethane adhesive. When in use, the adhesive is heated and unsealed to obtain the isocyanate solidifying agent or polyurethane prepolymer containing NCO, and reacts with polyurethane prepolymer or the trihydroxy compound to obtain cross-linked and cured polyurethane. The adhesive can be stably stored at the room temperature, can be heated to obtain reaction type bi-component when in construction, and is different from the conventional bi-component solvent type polyurethane which wastes time in the processes of metering, mixing and the like, the construction process is simple, the performance adjustment of the single component polyurethane system is realized, and the unsealed unsealing agent cannot overflow.

Owner:UNIV OF SCI & TECH OF CHINA

Thermoplastic elastomer toughened epoxy resin, its preparation and its application

ActiveCN102516717AAdjustable elasticAdjustable plasticityOther chemical processesAnti-corrosive paintsElastomerPolymer science

The invention relates to a thermoplastic elastomer toughened epoxy resin, its preparation and its application, which belongs to the technical field of changing the physical index of epoxy resin. The raw materials possess the following weight proportion: 1) 100 parts of epoxy resin, 2) 15-40 parts of curing agent, 3) 2-20 parts of thermoplastic elastomer, 4) 5-100 parts of compatilizer and 0.5-5 parts of auxiliary agent; the compatilizer employs one or more selected from rosin and modified rosin, petroleum resin, coumarone indene resin, aromatic oil, naphthenic oil and solvent oil, the auxiliary agent employs one or more selected from calcium stearate, zine stearate and EBS. The method of the invention solves the compatibility of the thermoplastic elastomer and epoxy resin, and effectively improves the brittleness of epoxy resin, the property of a solidified substrate is capable of adjusting, and the manufacturability is capable of adjusting; the product of the invention has the advantages of environmental protection, good security and good economic applicability.

Owner:云南交投集团公路建设有限公司 +1

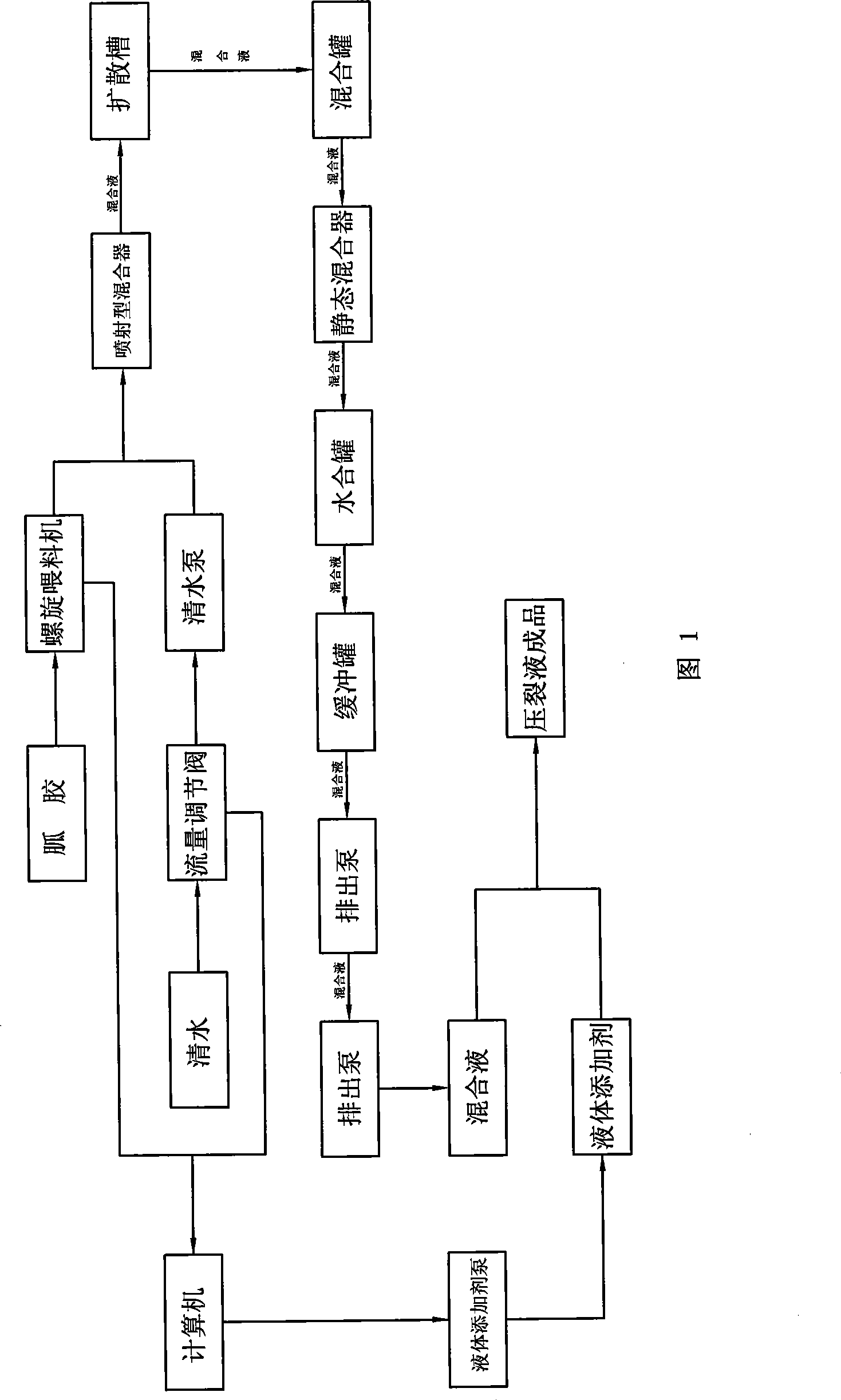

Continuous compounding method for fracturing fluid

The invention discloses a fracturing fluid continuous mixing method, comprising the steps as follows: guar gum is input into an injection-typed mixer which can automatically adjust the flux by a precise spiral feeding machine; the feeding quantity of the guar gum is adjusted by the rotation speed of the precise spiral feeding machine; the blanking quantity of the spiral feeding machine is controlled by a computer which can continuously read the difference value of an electronic balance within unit time, adjusts the rotation speed of the spiral feeding machine according to the flux and proportion of the external clean water and keeps the given liquid mixing ratio; the method is applicable to continuous mixing in-situ, the mixed fracturing fluid has good quality, the hydration speed of the liquid is fast, the labor intensity of workers is reduced, the cost payout is saved and the environmental pollution is reduced.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

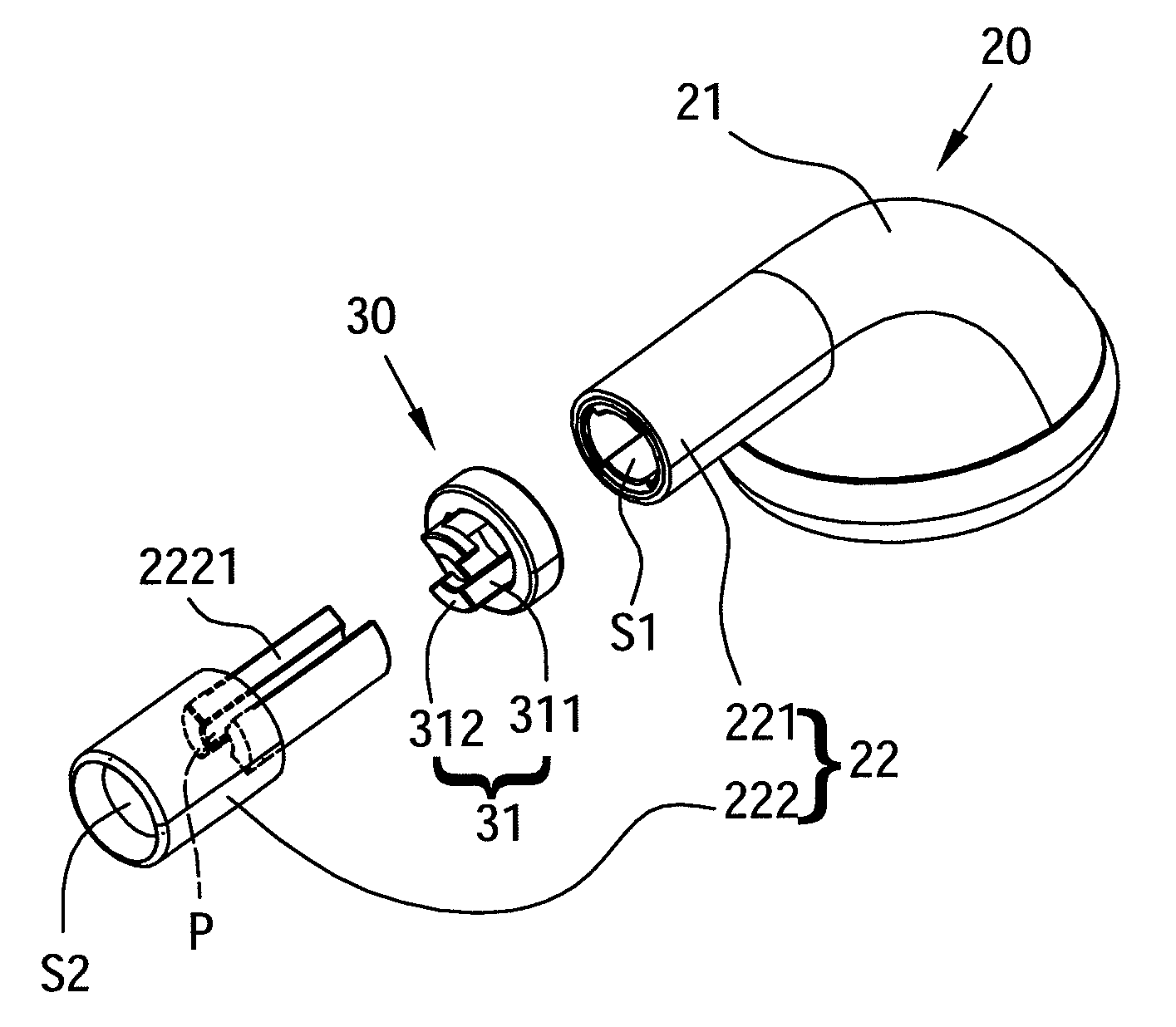

Earphone device with bass adjusting function

InactiveUS8532325B2Express the intrinsic tone quality characteristics of musicIncrease volumeIntra aural earpiecesFrequency/directions obtaining arrangementsEngineeringHeadphones

Owner:MERRY ELECTRONICS CO LTD

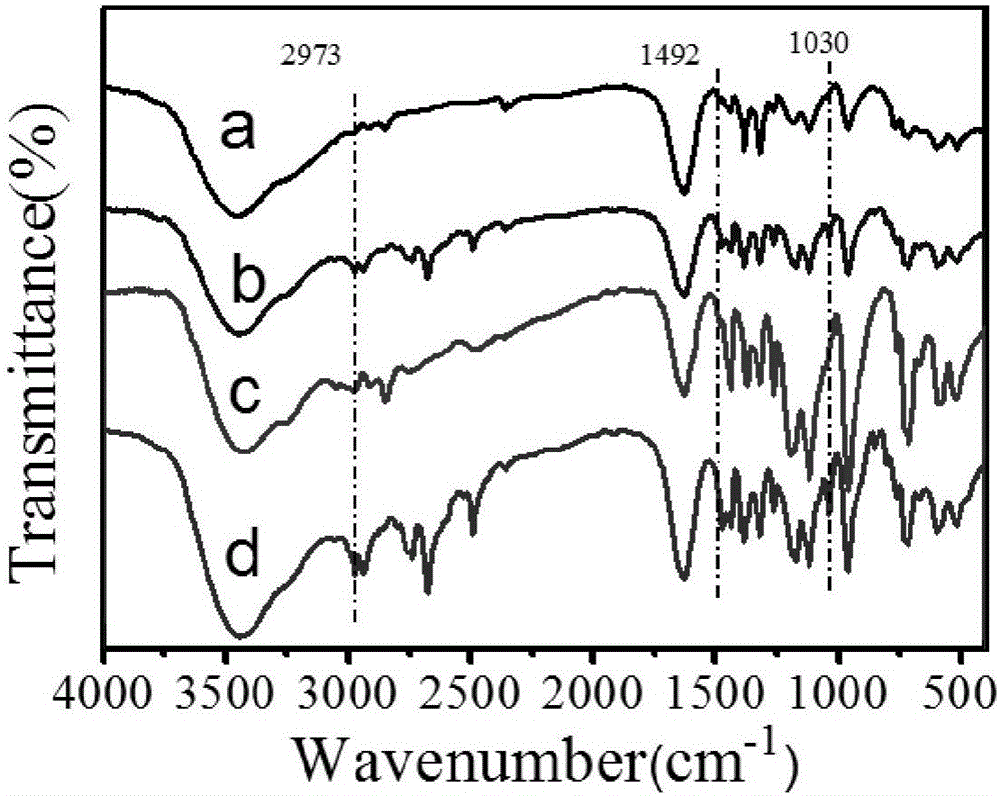

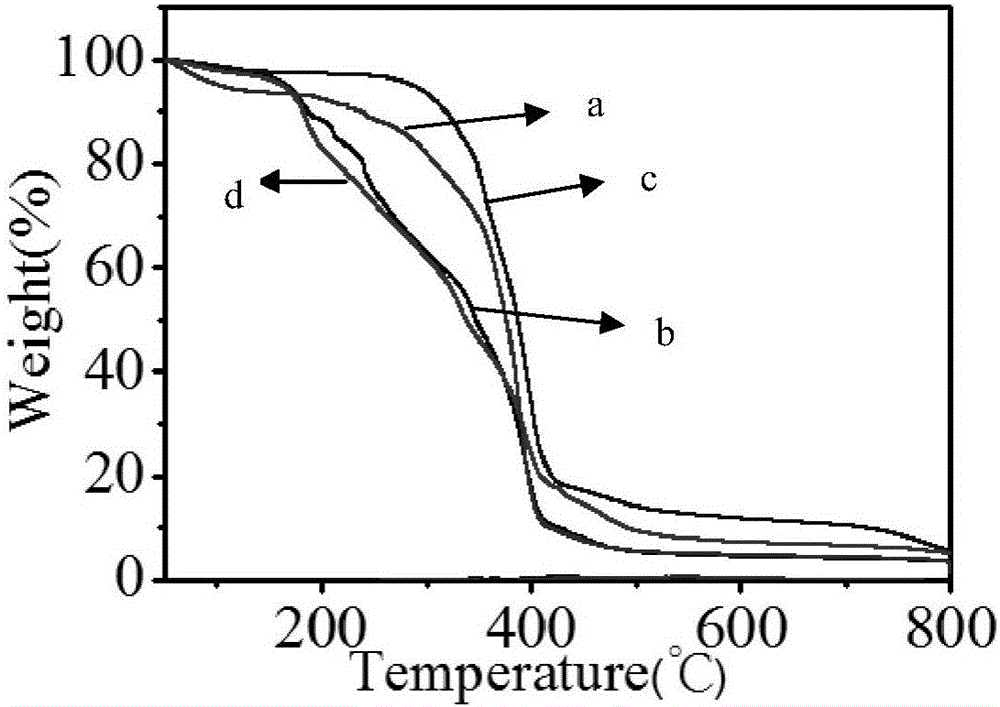

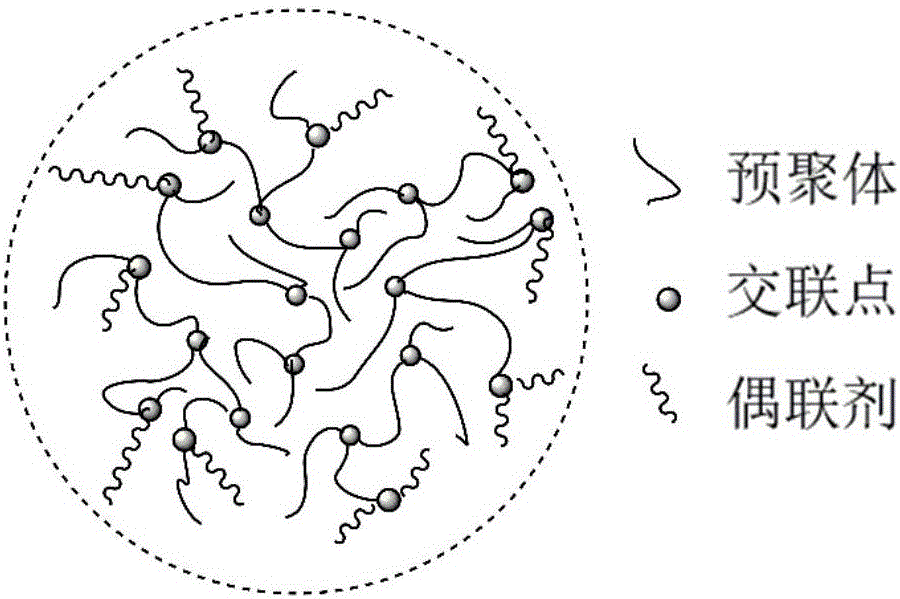

Phosphorus-containing network structure flame retardant

The invention relates to a network structure flame retardant. A phosphorus-containing macromolecular network structure flame retardant is developed aiming at the defects that the existing small-molecule flame retardant is easy to volatilize and emigrate, polymer flame retardants are less in types and the application field is limited. The preparation method comprises the following steps: preparing linear prepolymers, namely changing reaction conditions so as to obtain the linear prepolymers of different polymerization degrees; adding trifunctional cross-linked components so as to obtain a macromolecular flame retardant of different network structures; and finally, obtaining the final product through functional group end capping. According to the product, the problems of volatilization and transfer of the small-molecule flame retardant is improved, and the thermal decomposition behavior of the flame retardant can be regulated by changing the structure and reaction degree, so that products suitable for different polymer matrixes can be obtained. The raw materials used in the invention are wide in source and low in price, the polymerization process is mild in conditions and easy to produce, and the flame retardant is controllable in structure and can be independently taken as an intumescent flame retardant or serve as a charring agent or can be compounded with other flame retardants.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method and system for DMA optimization in host bus adapters

InactiveUS20060112199A1Optimize the writing processAdjustable performanceMultiple digital computer combinationsInput/output processes for data processingMaximum burst sizeBurst count

Method and system for optimizing DMA request processing is provided. The system includes a HBA that uses a dynamic DMA maximum write burst count sizing to optimize processing of write and read requests, wherein the HBA includes a DMA optimizer module that selects a certain write burst size to adjust performance when read and write DMA requests are being utilized. The DMA optimizer module can toggle between write and read request priority based on a maximum write request burst size. A shorter maximum write burst size provides more opportunity to issue read requests and a larger maximum burst size provides a better write request performance. The method includes, evaluating a read request throughput rate; evaluating a write request throughput rate; evaluating a read request utilization rate; evaluating a write request utilization rate; and adjusting a maximum write burst size.

Owner:MARVELL ASIA PTE LTD

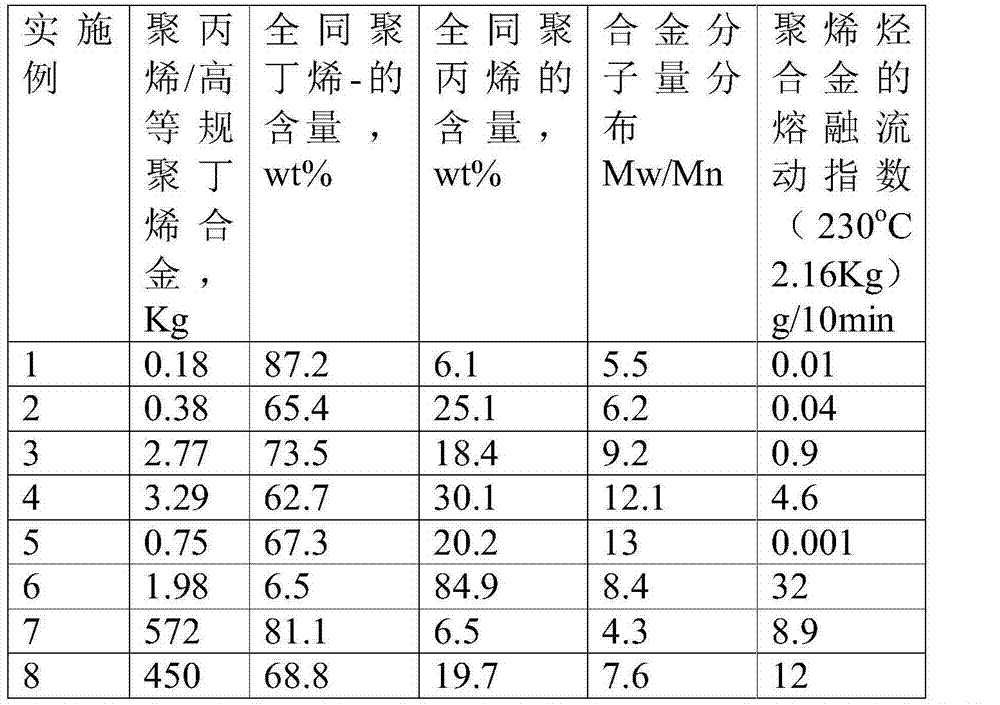

High isotactic polypropylene alloy material and preparation method thereof

The invention discloses a high isotactic polypropylene alloy material and a preparation method thereof. The material contains 5-98.9 parts by weight of polybutylene, 1-80 parts by weight of polypropylene and 0.1-15 parts by weight of propylene-butene copolymer; the isotacticity of the high isotactic polypropylene is larger than 85%, and the smelting point of the high isotatic polypropylene is 115-129 DEG C; the isotacticity of the high isotactic polypropylene is larger than 85%, and the smelting point of the high isotactic polypropylene is 155-169 DEG C; the propylene-butene copolymer contains a random copolymer and a segmented copolymer of propylene-butene. The preparation method uses a titanium / vanadium supported catalyst and adopts a multistage sequential polymerization manner and specifically comprises the steps of carrying out propylene polymerization or butane-1 polymerization, then initiating butane-1 polymerization or propylene polymerization, and respectively carrying out propylene polymerization or butane-1 polymerization, and so on to synthesize the high isotactic polypropylene alloy material. The material is a powdery or spherical product, and has the advantages of excellent impact resistance, thermal creep resistance and low shrinking percentage of polybutylene, high modulus, high surface hardness and fast setting of polypropylene, and the like.

Owner:QINGDAO UNIV OF SCI & TECH +1

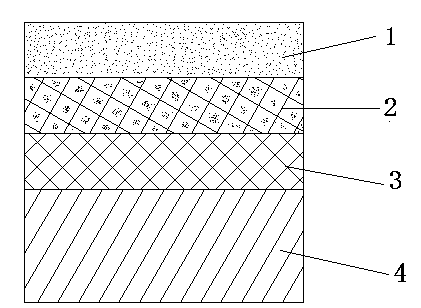

Penetration brazing preparation method of high-content wolfram carbide gradient wear-resisting coating

The invention provides a penetration brazing preparation method of a high-content wolfram carbide gradient wear-resisting coating, comprising the following steps: sequentially sticking a plurality of layers metal wire net flexible compound cloth containing wolfram carbide WC or wolfram carbide-cobalt WC-Co and nickel-chromium alloy powder Ni-Cr on a metal base body by using an epoxy resin binding agent; and carrying out penetration brazing in a vacuum furnace. Compared with the prior art, the Rockwell hardness of a researched coating with the WC content of 70% is HRC64-70 and the wear resistance is obviously improved.

Owner:NANCHANG INST OF TECH

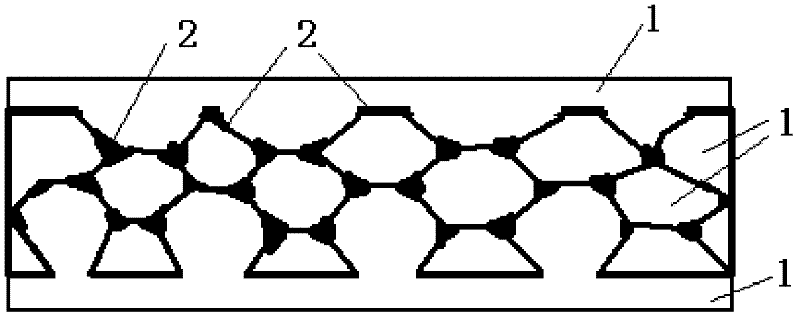

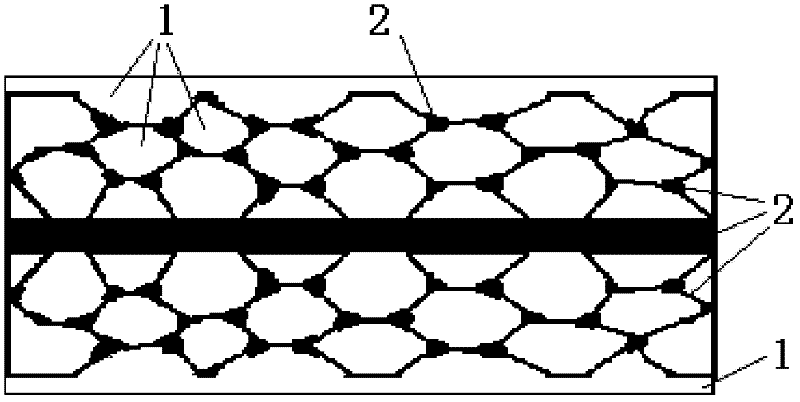

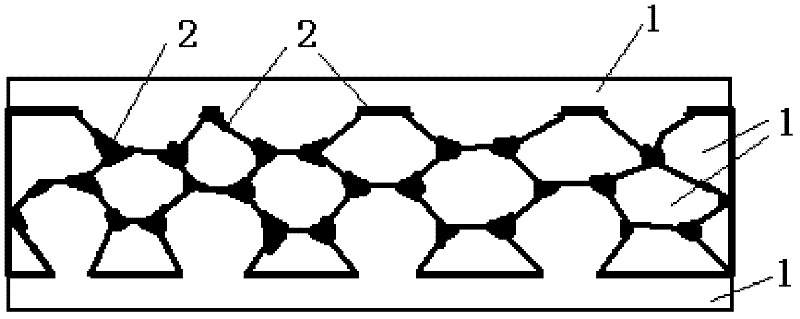

Elastic compound metal heat interface material and preparation method thereof

The invention belongs to the technical field of a heat interface material and discloses an elastic compound metal heat interface material. The elastic compound metal heat interface material is formed by compounding indium and a through-hole porous metal sheet, wherein the indium is filled in the through-hole porous metal sheet and covers the upper and lower surfaces of the through-hole porous metal sheet. The invention also discloses a preparation method of the elastic compound metal heat interface material. The method comprises the following steps: preparing the through-hole porous metal sheet at first; adding a proper amount of indium; heating for smelting indium so that smelted indium fills in the through-hole porous metal sheet and covers the upper and lower surfaces of the through-hole porous metal sheet; and finally cooling, thereby obtaining the elastic compound metal heat interface material. The two surfaces of the through-hole porous metal sheet are both through-hole porous metal and the middle core of the through-hole porous metal sheet is a metal solid. The compound material of the through-hole porous metal sheet and indium has higher elasticity and flexibility in the direction vertical to a mounting surface, so that the compound material can be quickly filled in bigger gaps caused by heat sink and an uneven silicon surface, the interface can be completely filled and the heat resistance of the interface can be kept.

Owner:SOUTHEAST UNIV

Injectable silk fibroin-alginate double cross-linking hydrogel and preparation method and use method thereof

The invention relates to injectable silk fibroin-alginate double cross-linking hydrogel which comprises a solution A: a silk fibroin solution and a solution B: a modified alginate solution, wherein the solution A comprises the following components in parts by weight: 1.0*10<-1>-3.0 parts of silk fibroin, 1.4*10<-3>-2.0*10<-3> part of a divalent metal ion cross-linking agent, and the balance of water containing 1-5wt% of silk fibroin; the solution B comprises the following components in parts by weight: 5.0*10<-1>-4.0 parts of alginate, 2.5*10<-3>-4.0*10<-1> part of a carboxyl activating cross-linking agent and the balance of water containing 1-5wt% of alginate. By adopting a double cross-linking method of covalent cross-linking and ion cross-linking, the double cross-linking hydrogel is quick to polymerize in situ and has an application prospect in the fields such as engineering stents, drug controlled release and regenerative medicines. The invention further provides a preparation method and a use method of the double cross-linking hydrogel.

Owner:GUANGXI NORMAL UNIV

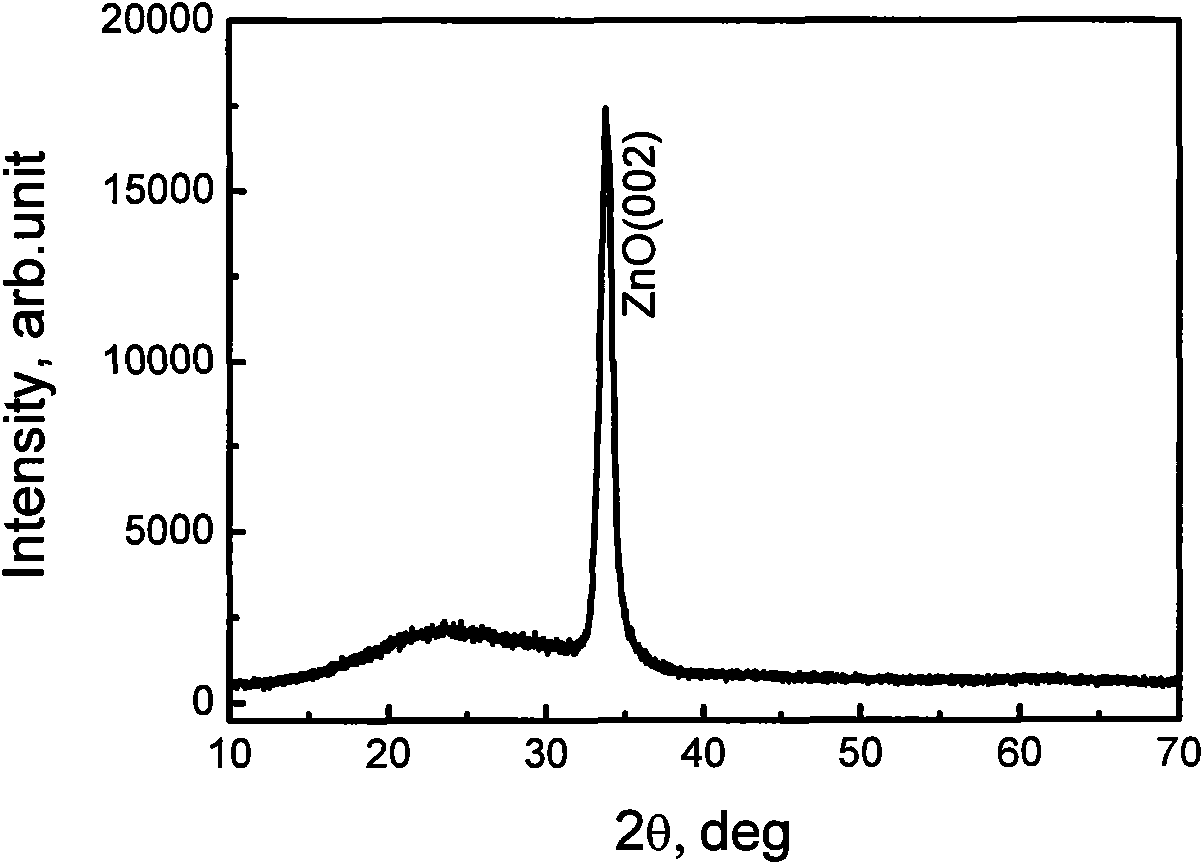

Oxidized graphene/waterborne polyurethane acrylate composite emulsion and preparation method and application thereof

InactiveCN106632878AImprove mechanical propertiesHigh solid contentFireproof paintsAnti-corrosive paintsPolyesterPolymer science

The invention discloses oxidized graphene / waterborne polyurethane acrylate composite emulsion and a preparation method and an application thereof. The preparation method comprises the following steps: using an in-situ polymerization method, and using vinyl monomer as a continuous phase, and using polyester polyol, diisocyanate, a hydrophilic chain extender, and an inner-crosslinking agent as raw materials for preparing a polyurethane prepolymer and vinyl monomer mixture, end-capping by vinyl, neutralizing by antalkali, and adding aqueous dispersion containing polymerizable surfmer and the oxidized graphene for dispersing in high speed, and then dripping a water-soluble initiator and an outer-crosslinking agent, enabling the vinyl monomer to polymerize with the polyurethane, the oxidized graphene and double-bond-contained surface active monomer, and preparing the oxidized graphene / waterborne polyurethane acrylate composite emulsion. The oxidized graphene / waterborne polyurethane acrylate composite emulsion is used for not only improving the heat resistance of the coating effectively, but also improving the surface salt fog resistance and antiseptic property of the coating. The preparation process of the product is simple, the raw materials can be easily obtained, and the product is easy to promote and apply in the actual industry.

Owner:SHAANXI UNIV OF SCI & TECH

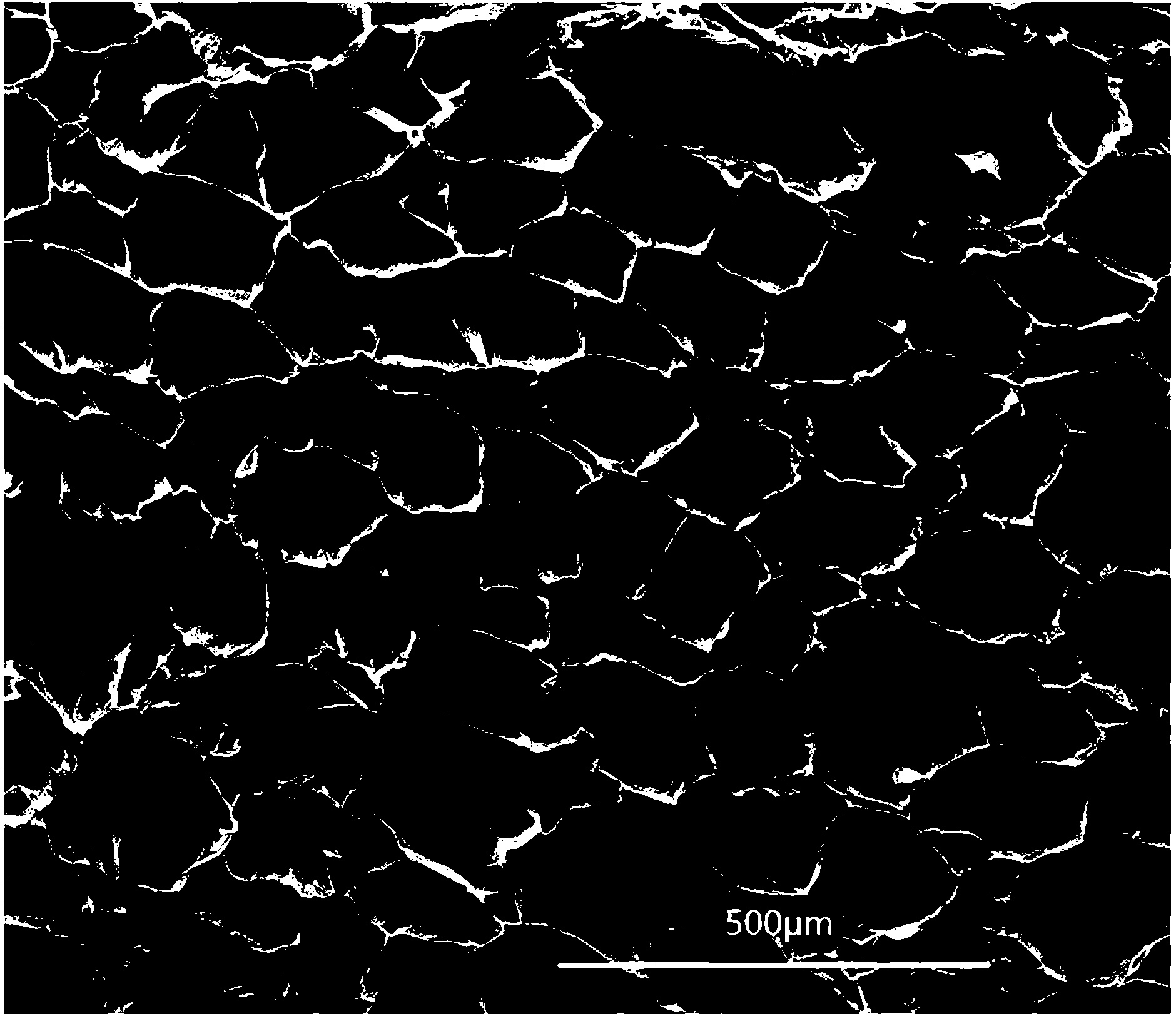

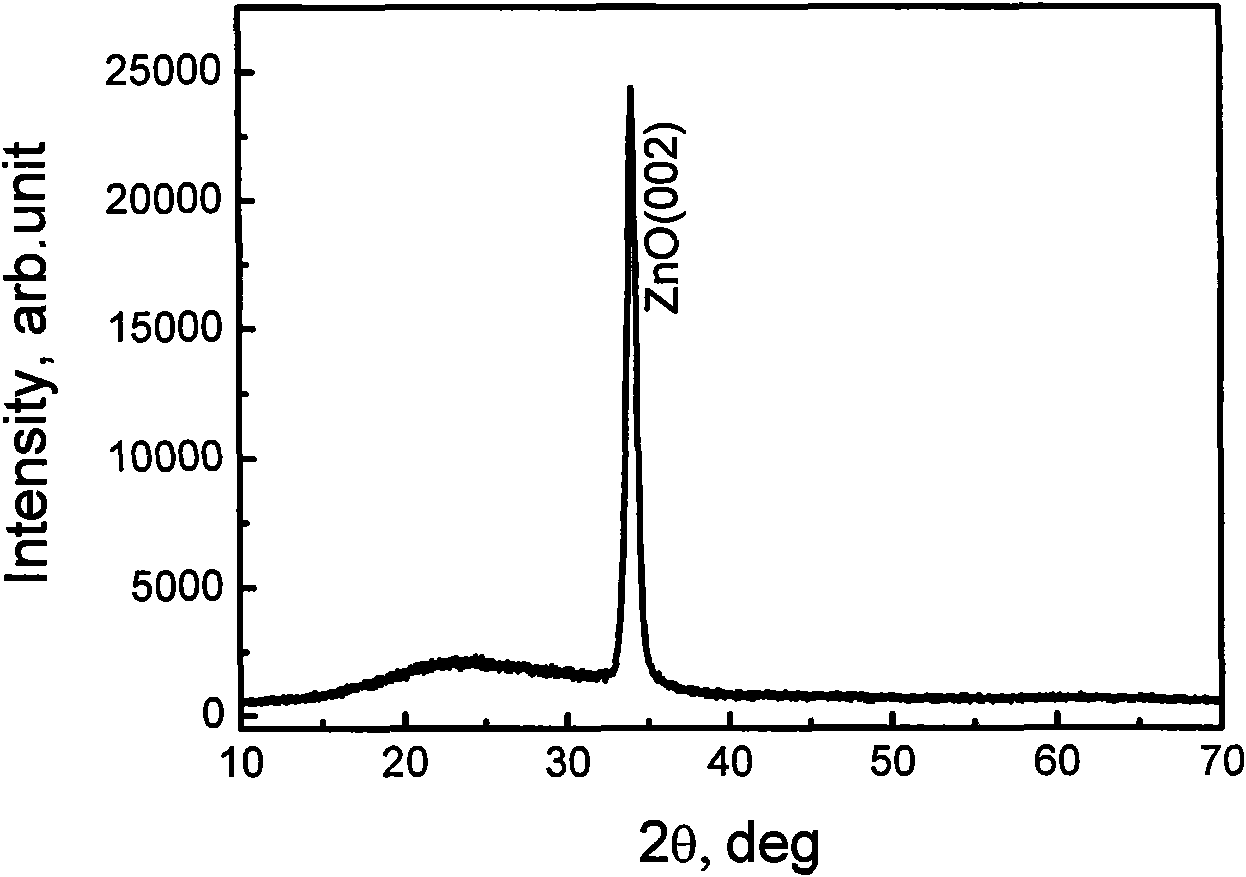

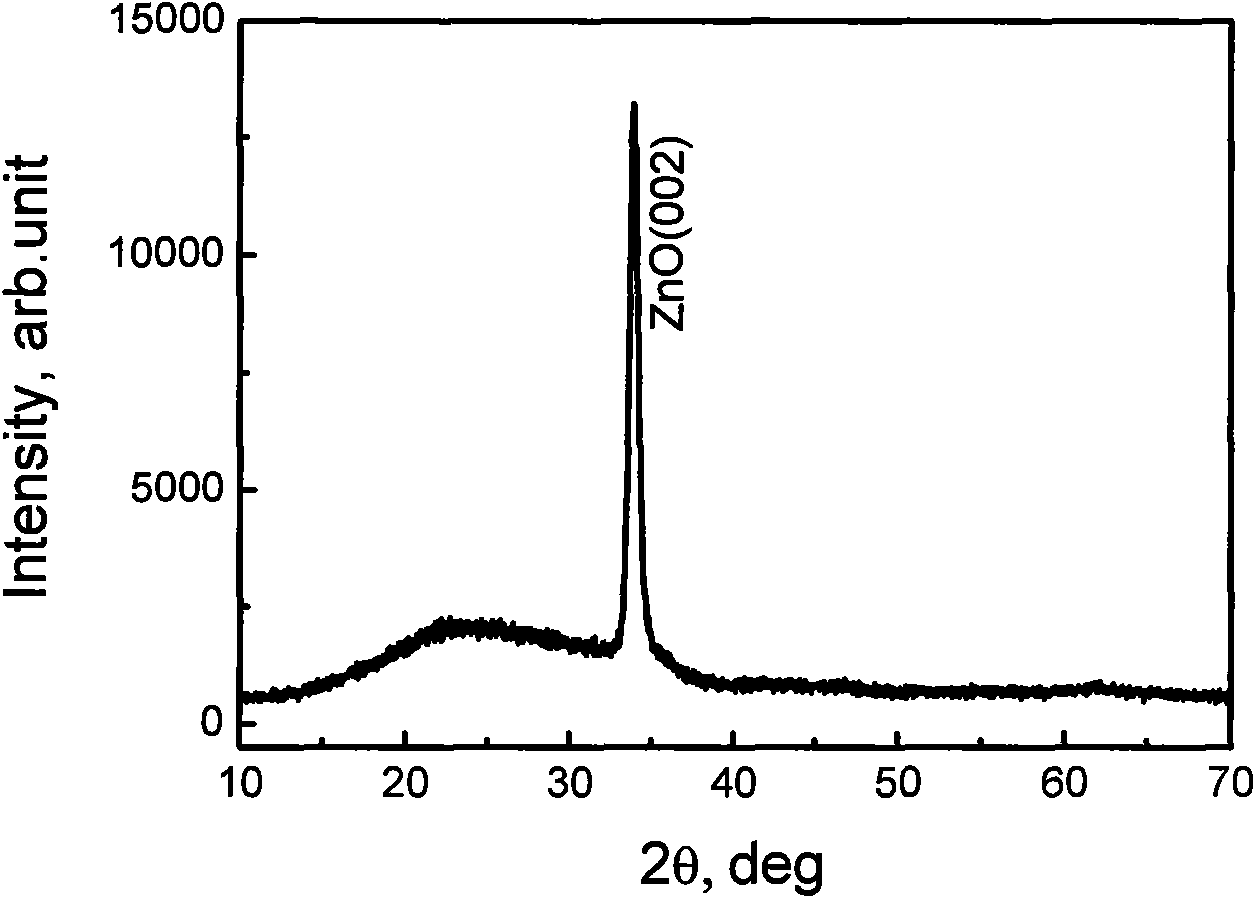

Method for preparing transparent conductive film material

InactiveCN101619445AIncrease deposition rateImprove the suede structureVacuum evaporation coatingSputtering coatingLow temperature depositionOxygen

The invention provides a method for preparing a transparent conductive film material and relates to the preparation of the conductive film material. The invention adopts a medium-frequency reaction magnetic control sputtering system, washing and etching are carried out in a plasma by controlling a basal body before preparation, a metal Al target with higher purity and a ZnO target with high purity are adopted in the preparation process to carry out double-target co-sputtering, the double-target co-sputtering is aided by the plasma, a plasma etching technique is carried out after the preparation is finished, and the problem that the transparent conductive film with higher light transmittance and lower resistivity can not be obtained by low-temperature sedimentation is solved by controlling oxygen loss. The invention is simple and easy, effectively solves the problem that the proportion of metal elements is uncontrollable, has no pollution and simple technology, can use the prior ITO production line, can realize industrialized production without upgrading and reconstructing and has important research value and extensive application prospect, and all the raw materials are relatively common.

Owner:UNIV OF SCI & TECH BEIJING

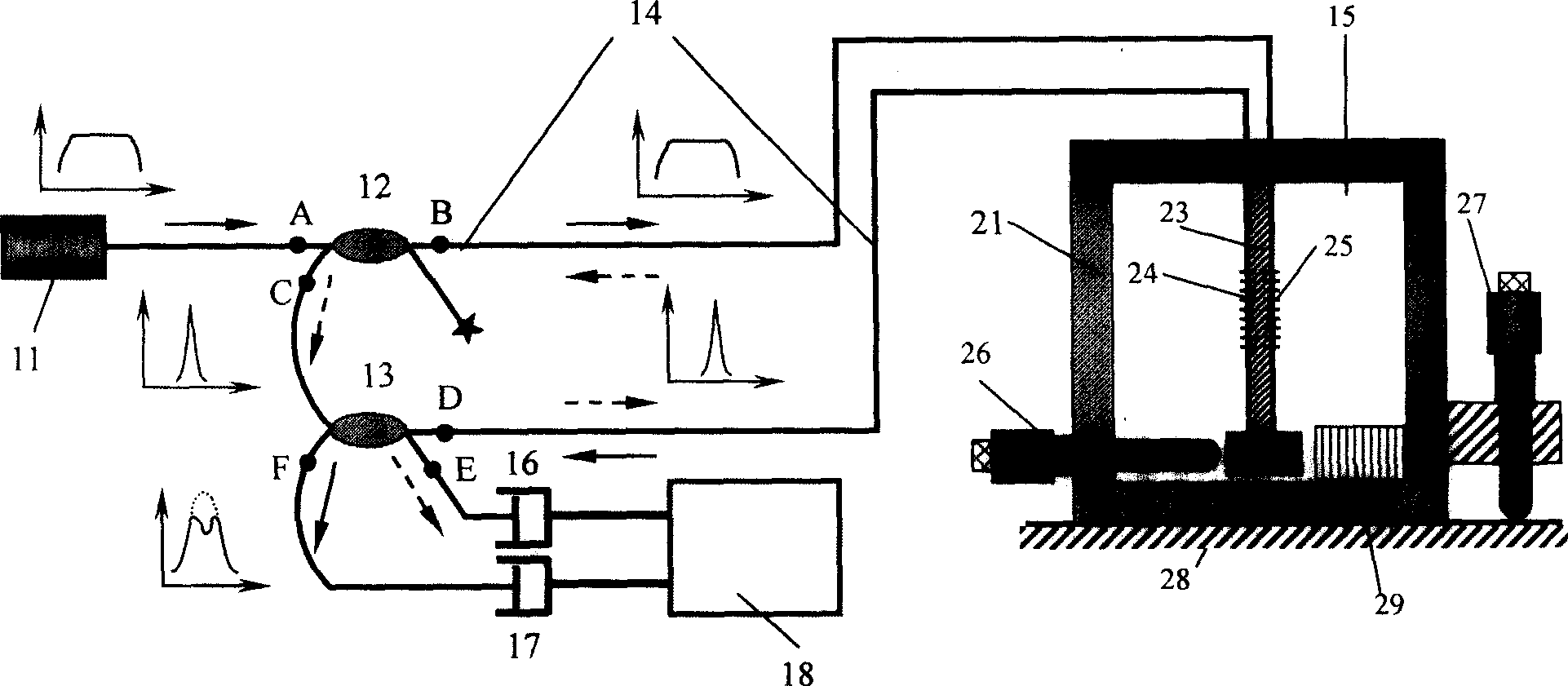

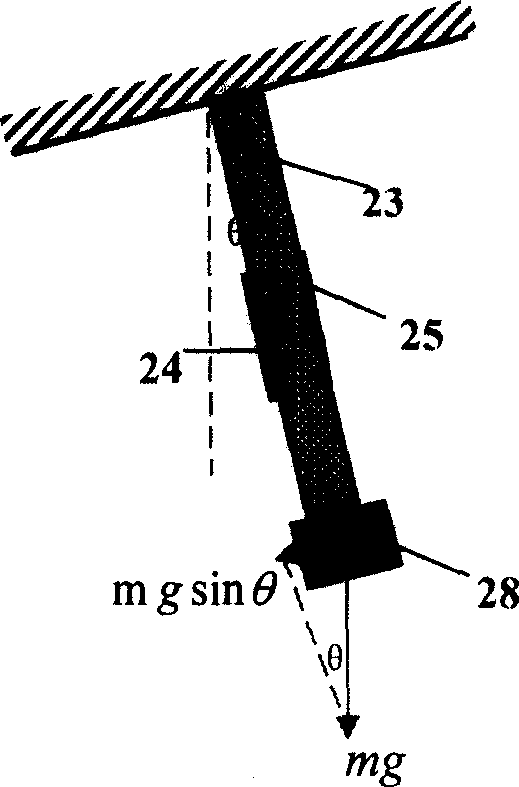

Optical fiber grating multi-parameter comprehensive sensing experimental apparatus

InactiveCN1605835ASimple structureNovel structureConverting sensor output opticallyCantilevered beamGrating

The present invention is multi-parameter comprehensive fiber grating sensing experiment instrument as one kind of physical and detection technology teaching instrument. The instrument includes measuring unit, sensing unit and fiber coupling link. The sensing unit includes frame, equal-thickness isosceles triangle cantilever beam fixed inside the frame, gravitational pendulum fixed to the bottom of the cantilever beam, two fiber gratings with the same parameters adhered symmetrically on two sides of the cantilever beam, micro displacement meter fixed horizontally to one side of the frame, micro obliquity meter fixed vertically on the other side of the frame and electromagnetic coil fixed inside the bottom of the frame. The instrument may be used in detecting current, obliquity, vibration and displacement, performing various fiber experiment, etc. and is suitable for use in relevant teaching experiments.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com