Injectable silk fibroin-alginate double cross-linking hydrogel and preparation method and use method thereof

A technology of alginate and hydrogel, applied in medical science, prosthesis, etc., can solve the problem of not being able to prepare injectable silk fibroin-alginate hydrogel, and achieve good biodegradability and gelation speed Fast, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Preparation of solution A silk fibroin protein solution: cut silkworm cocoons into pieces, add 0.05 mol / L Na 2 CO 3 Aqueous solution with a bath ratio of 1:200, heated to boiling and kept for 60 min to remove sericin on the surface of silk. After washing and drying, the silk fibroin was dissolved in CaCl 2 / EtOH / H 2 O (substance ratio: 1 mol:2 mol:8 mol) dissolved in the system, placed in running water and dialyzed for 3 days to remove ethanol and free Ca in the solution 2+ , prepare 10 mL of silk fibroin protein solution with a mass concentration of 1 wt% with deionized water, stir and add 0.0451 g of CaCl 2 .

[0040] Preparation of solution B modified alginate solution: Dissolve alginate, prepare 10 mL of alginate solution with a mass concentration of 2 wt% in deionized water, add a cross-linking agent 1-ethyl - 0.0052 g of 3-(3-dimethylaminopropyl) carbodiimide (EDC), 0.0016 g of N-hydroxysuccinimide (NHS), the pH of the solution was 7.0, stirred, and aged for ...

Embodiment 2

[0043] Preparation of solution A: Prepare 10 mL of silk fibroin protein solution with a mass concentration of 1 wt% according to the method described in Example 1, stir and add 0.0618 grams of CaCl 2 .

[0044] Preparation of Solution B: Prepare according to the steps described in Example 1.

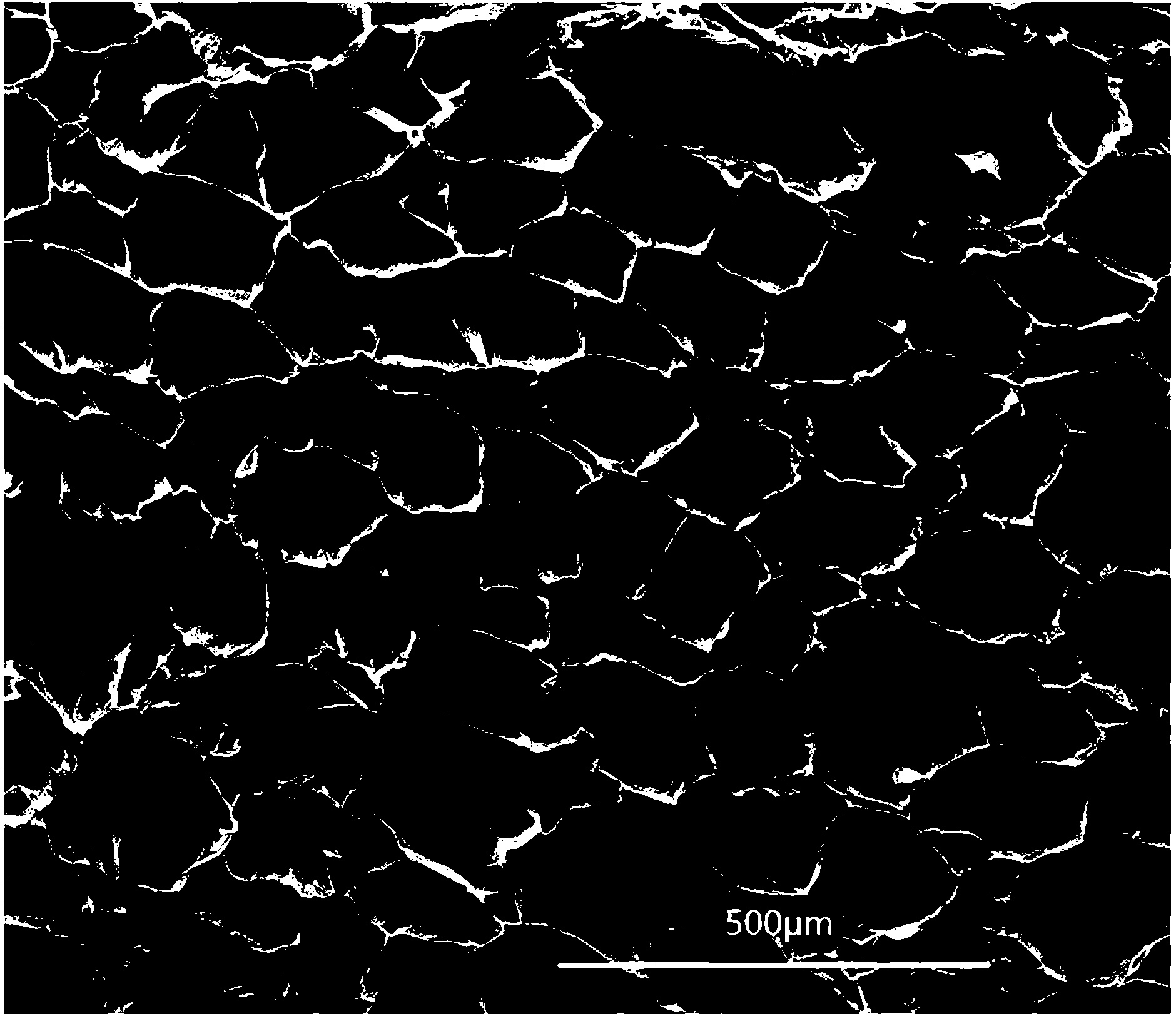

[0045] Cross-linking: according to the steps described in Example 1, a double-cross-linked hydrogel with amino and carboxyl covalent cross-linking and metal ion cross-linking was prepared. As the concentration of calcium ions increases, the gelation time of the obtained hydrogel decreases to 100 s; the cell size of the hydrogel decreases, and the cell distribution is uniform; the elastic modulus increases to 700-900Pa, and the water swelling rate decreases. Small, the degradation rate is reduced.

Embodiment 3

[0047] Preparation of Solution A: Follow the steps described in Example 1.

[0048] Preparation of solution B: Prepare 10 mL of alginate solution with a mass concentration of 2 wt% as described in Example 1, and add a cross-linking agent 1-ethyl-3-(3-dimethylammonia Propyl) carbodiimide (EDC) 0.0104 g, N-hydroxysuccinimide (NHS) 0.0031 g, solution pH 7.0, stirred, and aged for 100 min.

[0049] Crosslinking: Proceed as described in Example 1.

[0050] Increasing the concentration of carboxyl-activated cross-linking agent increases the gelation time of the obtained hydrogel to 240 s, increases the elastic modulus, decreases the water swelling rate of the hydrogel, and decreases the degradation rate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com