Solvent-free polyaspartic acid ester polyurea elastic waterproof paint

A technology of aspartic acid ester and waterproof coating, which is applied in the direction of polyurea/polyurethane coating, coating, etc., can solve the problems of poor surface effect, poor color retention and aging resistance of polyurea, low adhesion, etc., to achieve Convenient construction, excellent elongation at break, environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

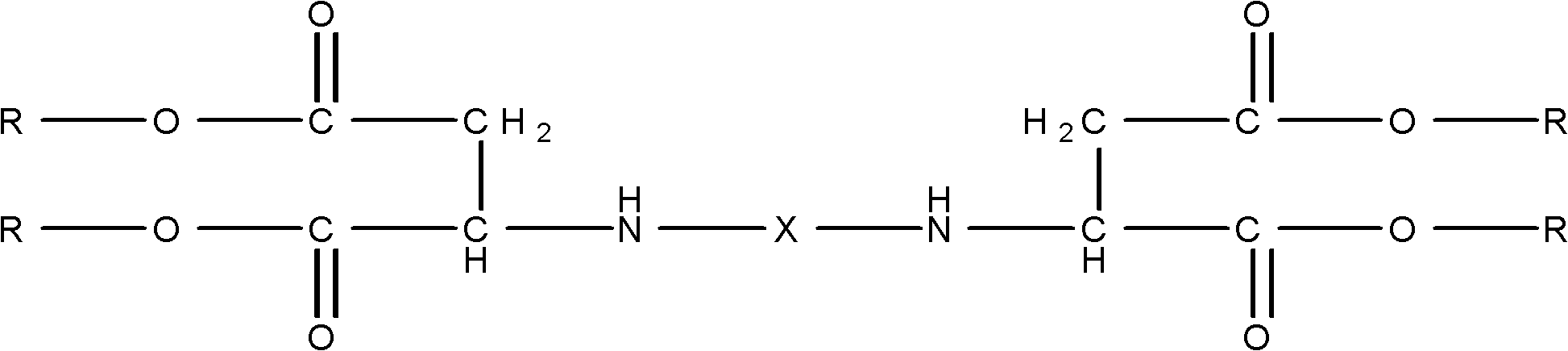

Method used

Image

Examples

Embodiment 1

[0021] A solvent-free polyaspartate polyurea elastic waterproof coating consists of two components. Component A is prepared from 34.8 parts of toluene diisocyanate (TDI) and 100 parts of polyoxypropylene diol with a molecular weight of 1000 to prepare a prepolymer with a content of 6.2% NCO, add 15 parts of diphenylmethane diisocyanate (MDI), and mix well. The NCO content is 9-11% of the A component.

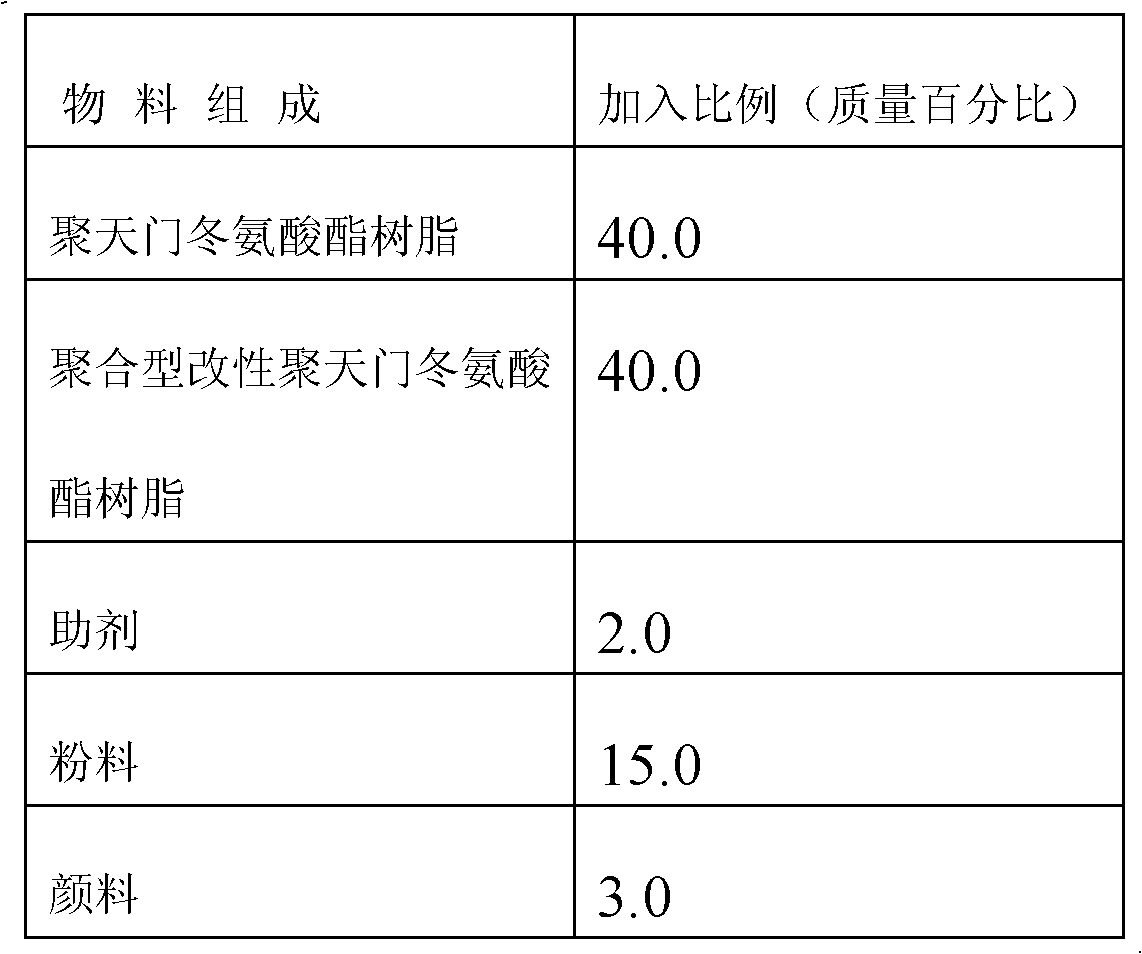

[0022] After component B of the coating is added accurately in sequence according to the formula, disperse on a high-speed disperser for at least 30 minutes;

[0023] The formula is as follows:

[0024]

[0025] Mix the dispersed A component and B component according to the ratio of NCO equivalent and NH equivalent respectively, and then make a board for testing. The coating thickness is 0.5-0.6mm, and the testing standard GB / T23446-2009 (spray polyurea waterproof material) And GB / T19250 (polyurethane waterproof coating), the test results are as follows;

[0026] ...

Embodiment 2

[0029] A solvent-free polyaspartate polyurea elastic waterproof coating consists of two components. Component A is prepared from 34.8 parts of toluene diisocyanate (TDI) and 100 parts of polyoxypropylene diol with a molecular weight of 1000 to prepare a prepolymer with an NCO content of 6.2%, adding 7.5 parts of a HDI trimer with an NCO content of 21% and 7.5 parts of diphenyl Methyl methane diisocyanate (MDI), after mixing evenly, the A component with NCO content of 9-11% is prepared.

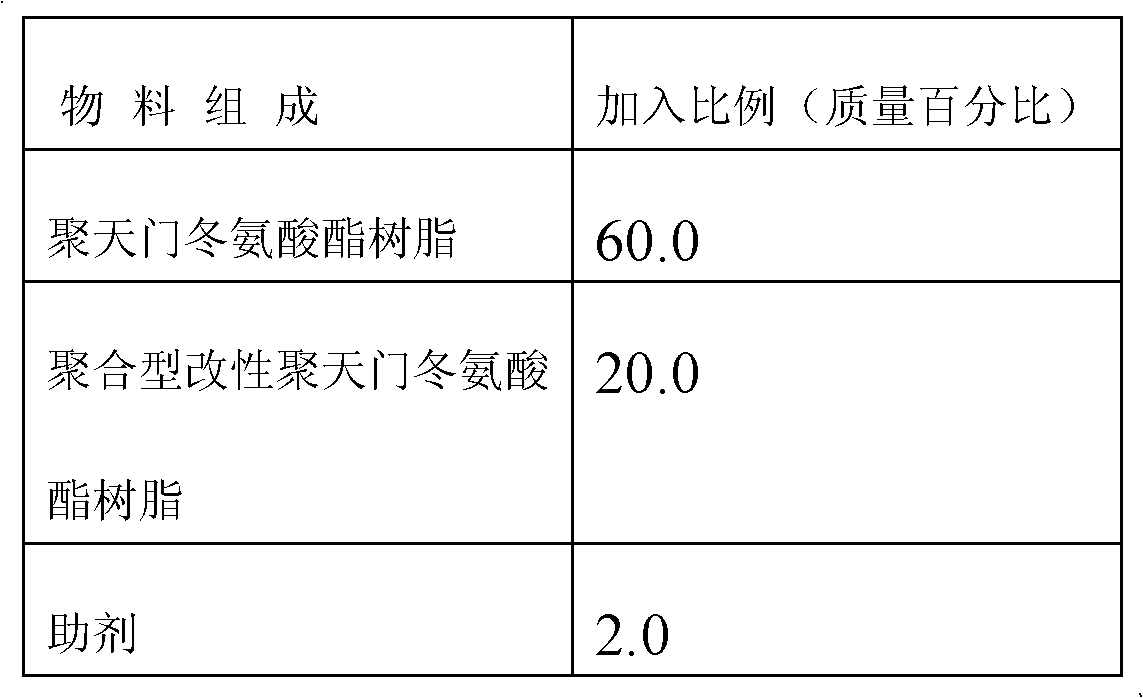

[0030] After component B of the paint is accurately added in sequence according to the formula, disperse on the high-speed disperser for at least 30 minutes;

[0031] The formula is as follows

[0032]

[0033]

[0034] Mix the dispersed components A and B according to the ratio of NCO equivalent and NH equivalent respectively, and then make a board for testing. The coating thickness is 0.5-0.6mm, and the testing standard GB / T23446-2009 (spray polyurea waterproof material) And GB / T1925...

Embodiment 3

[0037] A solvent-free polyaspartate polyurea elastic waterproof coating consists of two components. Component A is prepared from 44.4 parts of isophorone diisocyanate (IPDI) and 100 parts of polyoxypropylene diol with a molecular weight of 1000 to prepare a prepolymer with an NCO content of 5.8%, add 36 parts of dicyclohexylmethane diisocyanate, and mix well A component A with an NCO content of 11.0% was prepared.

[0038] After component B of the paint is accurately added in sequence according to the formula, disperse on the high-speed disperser for at least 30 minutes;

[0039] The formula is as follows:

[0040] Material composition

[0041] Mix the dispersed components A and B according to the ratio of NCO equivalent and NH equivalent respectively, and then make a board for testing. The coating thickness is 0.5-0.6mm, and the testing standard GB / T23446-2009 (spray polyurea waterproof material) And GB / T19250 (polyurethane waterproof coating), the test results ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tear strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com