Preparation method of pine needle fibers

A fiber and pine needle technology, which is applied in the field of pine needle fiber preparation, can solve the problems of inconspicuous extract color, deterioration of fiber physical performance index, extract and fiber damage, etc., so as to improve immunity, good spraying effect, and guarantee The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

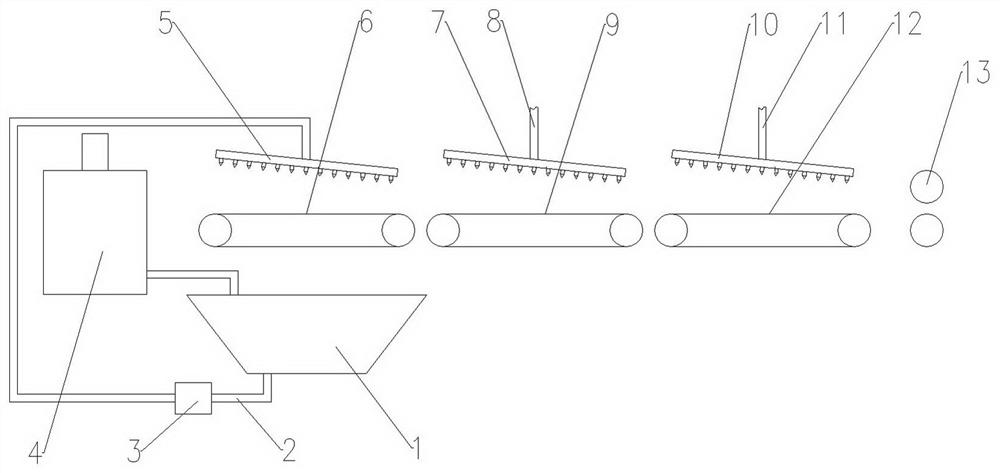

[0038] Example: as attached figure 1 Shown, a kind of preparation method of pine needle fiber, described preparation method comprises the following steps:

[0039] (1) Preparation of pine needle extract solution

[0040] Put the pine needle extract powder in deionized water at 50°C, add a dispersant, stir with an electric mixer for 1 hour, let it stand for precipitation, take the supernatant, and filter it twice with a 200-mesh filter to obtain pine needles with a solid content of 10%. Extract solution.

[0041] (2) Pengrun treatment of cationic viscose fiber

[0042] Wet the cationic viscose fiber with deionized water, spray it evenly on the surface of the fiber with a sprayer, and the temperature is 30°C to make the fiber absorb water evenly and expand the fiber. (3) Preparation of pine needle extract fiber

[0043] The cationic viscose fiber is loosened by an opener, and the viscose fiber after opening is placed on the first chain net 6 which rotates circularly. The fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com