Temperature-resistant silica gel leather and preparation method thereof

A technology of silica gel and leather, applied in coatings, devices for coating liquid on the surface, etc., can solve problems that hinder the research of flame-retardant leather, and achieve the effects of shortening vulcanization time, long-lasting subjectivity, and convenient operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

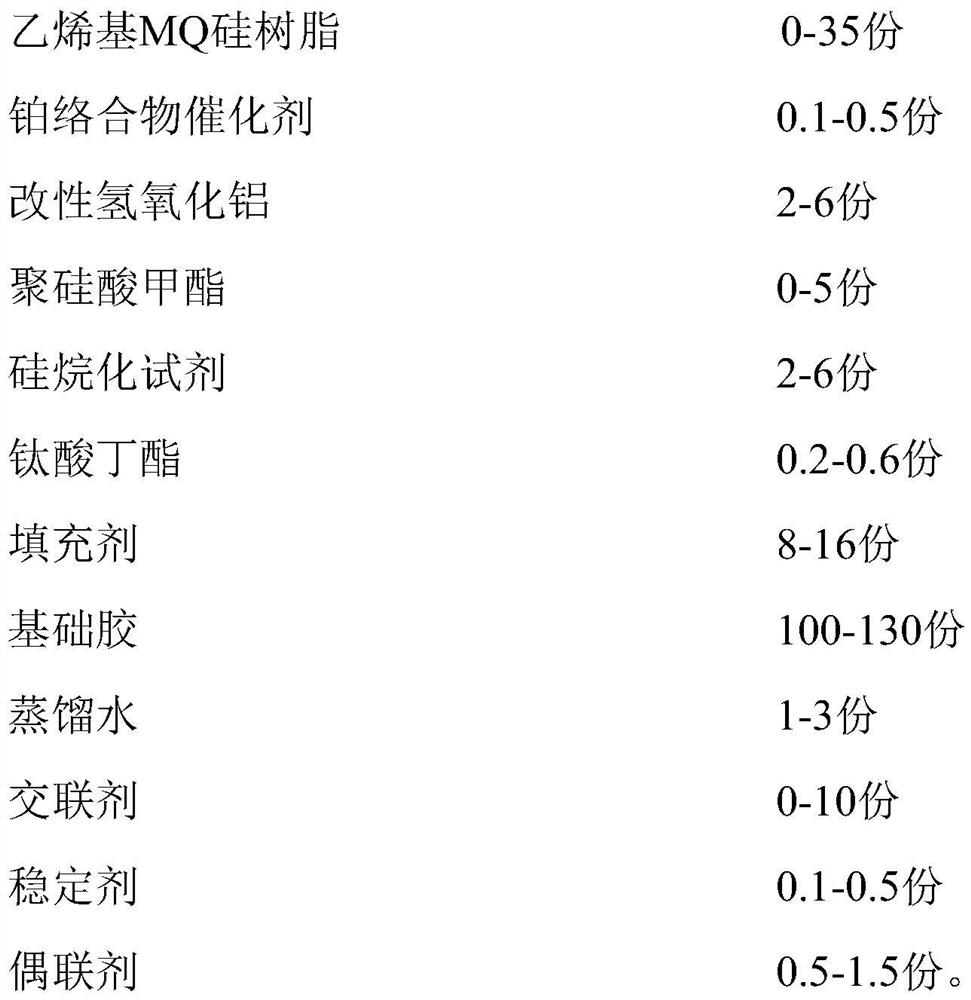

[0032] A heat-resistant silicone leather, comprising a textile base cloth and a finish layer coated on the textile base cloth, the finish layer is made of a silica gel material, and the silica gel material includes the following raw materials in parts by weight:

[0033]

[0034]

[0035] The platinum complex catalyst is a platinum-tetravinyltetramethylcyclotetrasiloxane complex with a Pt mass fraction of 2.0%; the base glue is made of α, ω-divinyl polydimethylsiloxane alkane and polymethylvinylsiloxane in a weight ratio of 1:0.3; the viscosity (25°C) of the α, ω-divinylpolydimethylsiloxane is 600 000mPa·s, and the The viscosity (25°C) of polymethylvinylsiloxane is 1000mPa·s; the viscosity (25°C) of the vinyl MQ silicone resin is 300mPa·s, and the vinyl content is 5.4%.

[0036] Each part of the modified aluminum hydroxide is prepared through such steps as:

[0037] S1. In parts by weight, weigh 30 parts of aluminum hydroxide micropowder and 1 part of ethyl acetate into...

Embodiment 2

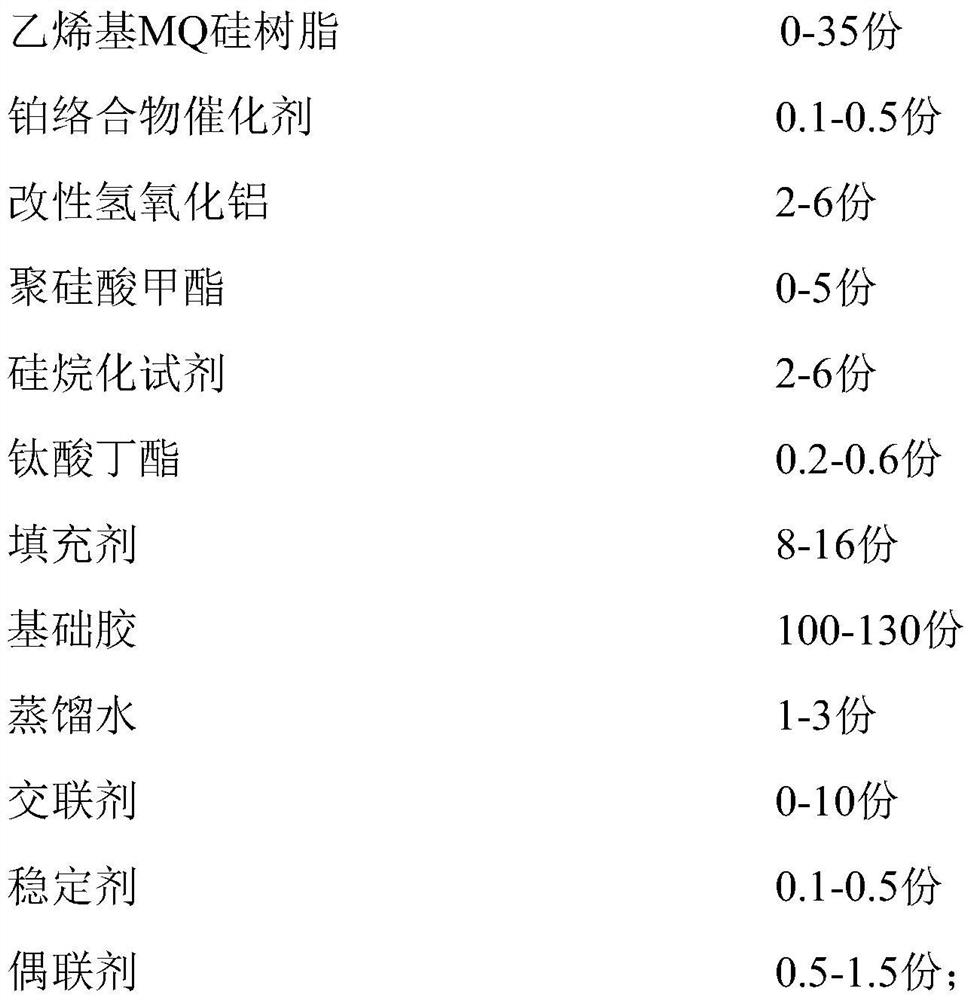

[0048] A heat-resistant silicone leather, comprising a textile base cloth and a finish layer coated on the textile base cloth, the finish layer is made of a silica gel material, and the silica gel material includes the following raw materials in parts by weight:

[0049]

[0050] The platinum complex catalyst is a platinum-tetravinyltetramethylcyclotetrasiloxane complex with a Pt mass fraction of 2.0%; the base glue is α, ω-divinyl polydimethylsiloxane The viscosity (25°C) of the α,ω-divinyl polydimethylsiloxane is 600 000mPa·s; the viscosity (25°C) of the vinyl MQ silicone resin is 300mPa·s, and the vinyl content is 5.5 %.

[0051] Each part of the modified aluminum hydroxide is prepared through such steps as:

[0052] S1. In parts by weight, weigh 33 parts of aluminum hydroxide fine powder and 1.5 parts of ethyl acetate into the reaction device, heat to 85°C, and stir at a speed of 250r / min for 25min, and obtain mixture A after cooling, and set aside;

[0053] S2. In pa...

Embodiment 3

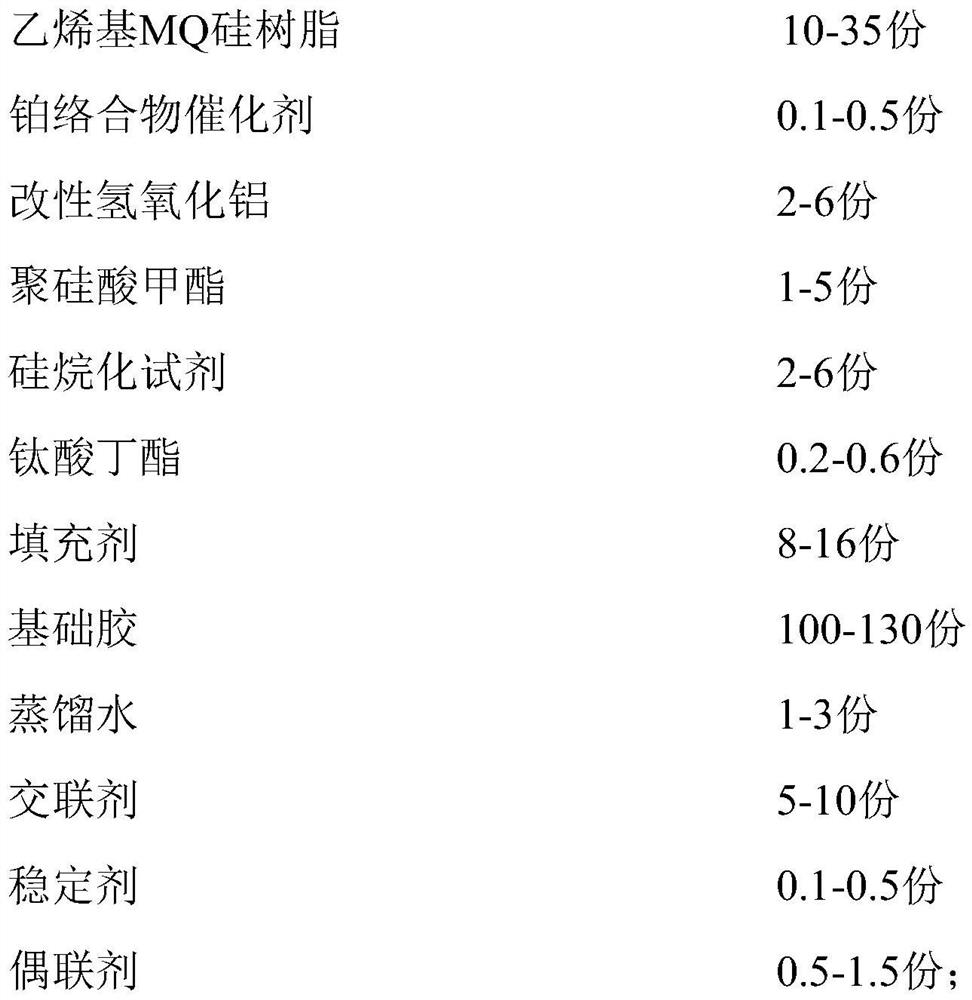

[0063] A heat-resistant silicone leather, comprising a textile base cloth and a finish layer coated on the textile base cloth, the finish layer is made of a silica gel material, and the silica gel material includes the following raw materials in parts by weight:

[0064]

[0065] The platinum complex catalyst is a platinum-tetravinyltetramethylcyclotetrasiloxane complex with a Pt mass fraction of 2.0%; the base glue is α, ω-divinyl polydimethylsiloxane The viscosity (25°C) of the α,ω-divinyl polydimethylsiloxane is 600 000mPa·s; the viscosity (25°C) of the vinyl MQ silicone resin is 300mPa·s, and the vinyl content is 5.6 %.

[0066] Each part of the modified aluminum hydroxide is prepared through such steps as:

[0067] S1. In parts by weight, weigh 35 parts of aluminum hydroxide micropowder and 2 parts of ethyl acetate into the reaction device, heat to 90 ° C, and stir at a speed of 300 r / min for 30 min, and obtain mixture A after cooling, and set aside;

[0068] S2. In ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com