Preparation method of artemisia annua fiber

A technology of Artemisia annua and fiber, applied in the field of preparation of Artemisia annua fiber, can solve problems such as damage, loss of extract, damage of extract, etc., and achieve the effects of reducing stocking pressure, short production cycle, bright and soft luster

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

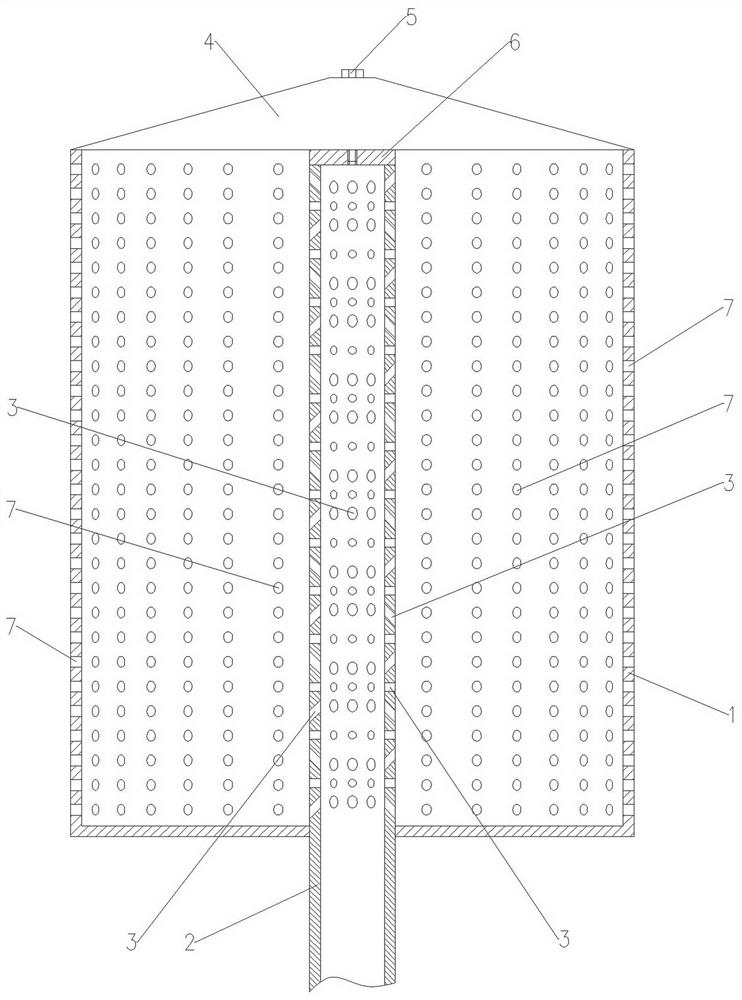

Image

Examples

Embodiment

[0032] Embodiment: a kind of preparation method of Artemisia annua fiber, it is characterized in that: described preparation method comprises the following steps:

[0033] (1) Preparation of Artemisia annua Extract Dispersion

[0034] Add Artemisia annua extract powder to 50-degree deionized water to dissolve, the weight ratio of Artemisia annua to water is 1:9. Then use a 500-mesh filter to pressurize and filter 3 times, and set aside.

[0035] (2) Preparation of reactive dye solution

[0036] The weight ratio of reactive red: reactive yellow: emerald blue is 0.11:0.6:0.2, and the three are added into 50-degree deionized water according to this ratio, stirred by electric power for 30 minutes, and set aside.

[0037] (3) Cationization of fibers

[0038] Add demineralized water, cationic modifier and caustic soda to viscose fiber, heat up to 80°C, keep warm for 30 minutes, neutralize with acid for 15 minutes, wash with water, and dry to obtain cationic viscose fiber.

[0039...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com