Edge covering rubber for new energy automobile battery, and manufacturing method thereof

A technology of new energy vehicles and manufacturing methods, applied in the field of rubber processing, can solve problems such as shortened service life and poor mechanical properties, and achieve the effect of maintaining practical life and good tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] An edge-wrapping rubber used for new energy vehicle batteries, comprising the following components according to the weight distribution ratio:

[0031] 101 parts of methyl vinyl silicone rubber, 6 parts of cerium-containing polysiloxane, 0.7 parts of 2,5-dimethyl-2,5-bis, 2 parts of tert-butyl peroxy, 4 parts of bis-pentasulfide 2 parts, white carbon black 2 parts.

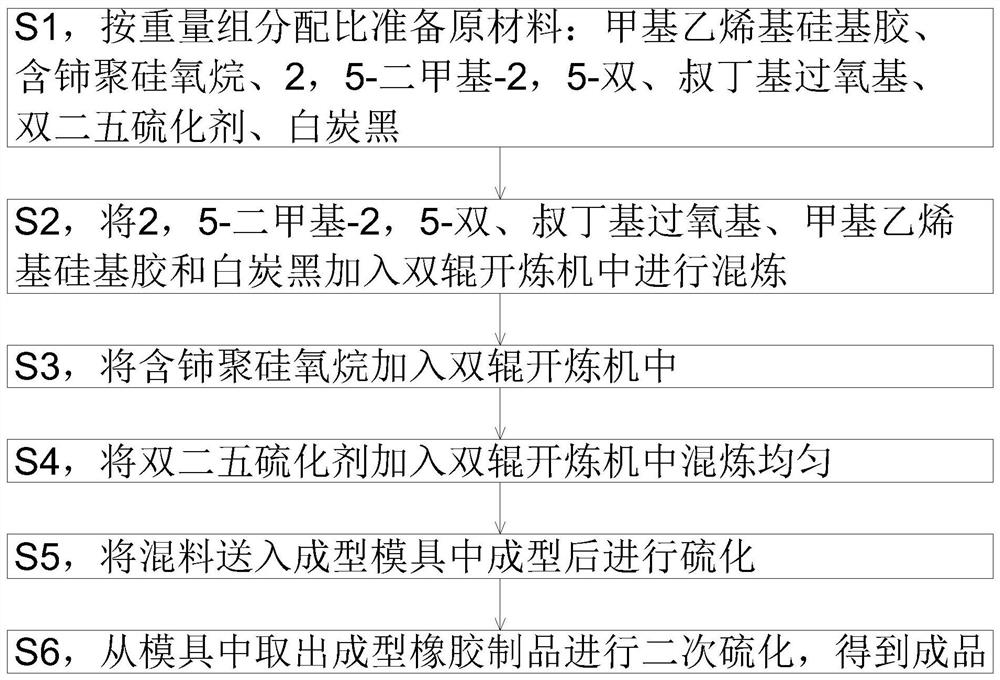

[0032] A method for manufacturing edge-wrapping rubber for new energy vehicle batteries, comprising the following steps:

[0033] S1, prepare raw materials according to weight group ratio: methyl vinyl silicone rubber, cerium-containing polysiloxane, 2,5-dimethyl-2,5-bis, tert-butyl peroxy, bis-pentasulfide agent, white carbon black;

[0034] S2, adding 2,5-dimethyl-2,5-bis, tert-butyl peroxy, methyl vinyl silicon-based glue and white carbon black into a two-roll mill for mixing;

[0035] S3, adding cerium-containing polysiloxane into the double-roll mill;

[0036] S4, adding the bis-2-5 vulcanizing age...

Embodiment 2

[0051] An edge-wrapping rubber used for new energy vehicle batteries, comprising the following components according to the weight distribution ratio:

[0052] 115 parts of methyl vinyl silicone rubber, 10 parts of cerium-containing polysiloxane, 1.2 parts of 2,5-dimethyl-2,5-bis, 3.8 parts of tert-butyl peroxy, 6 bis-pentasulfurizing agents parts, 4 parts of white carbon black.

[0053] A method for manufacturing edge-wrapping rubber for new energy vehicle batteries, comprising the following steps:

[0054] S1, prepare raw materials according to weight group ratio: methyl vinyl silicone rubber, cerium-containing polysiloxane, 2,5-dimethyl-2,5-bis, tert-butyl peroxy, bis-pentasulfide agent, white carbon black;

[0055] S2, adding 2,5-dimethyl-2,5-bis, tert-butyl peroxy, methyl vinyl silicon-based glue and white carbon black into a two-roll mill for mixing;

[0056] S3, adding cerium-containing polysiloxane into the double-roll mill;

[0057] S4, adding the bis-2-5 vulcanizi...

Embodiment 3

[0072] An edge-wrapping rubber used for new energy vehicle batteries, comprising the following components according to the weight distribution ratio:

[0073] 118 parts of methyl vinyl silicone rubber, 14 parts of cerium-containing polysiloxane, 1.8 parts of 2,5-dimethyl-2,5-bis, 4 parts of tert-butyl peroxy, 9 parts of bis-pentasulfide Parts, 4.2 parts of white carbon black.

[0074] A method for manufacturing edge-wrapping rubber for new energy vehicle batteries, comprising the following steps:

[0075] S1, prepare raw materials according to weight group ratio: methyl vinyl silicone rubber, cerium-containing polysiloxane, 2,5-dimethyl-2,5-bis, tert-butyl peroxy, bis-pentasulfide agent, white carbon black;

[0076] S2, adding 2,5-dimethyl-2,5-bis, tert-butyl peroxy, methyl vinyl silicon-based glue and white carbon black into a two-roll mill for mixing;

[0077] S3, adding cerium-containing polysiloxane into the double-roll mill;

[0078] S4, adding the bis-2-5 vulcanizing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com