Elastic compound metal heat interface material and preparation method thereof

A technology of thermal interface materials and composite metals, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problem of high cost, achieve low cost, small interface thermal resistance, and ensure the effect of mechanical and physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

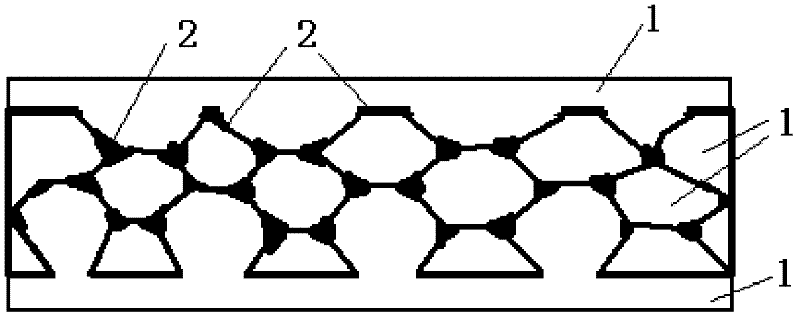

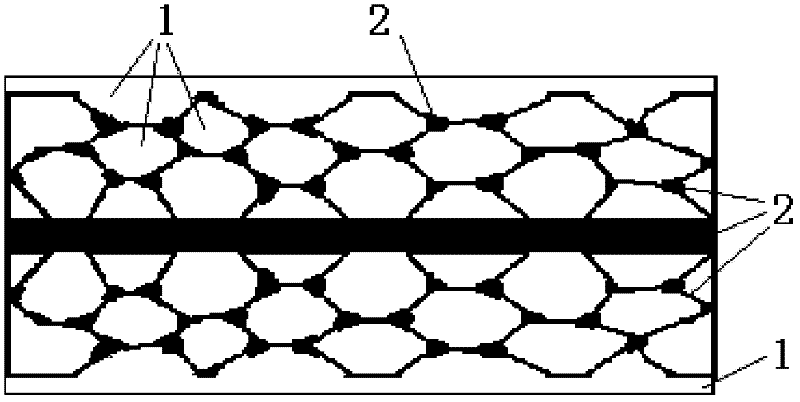

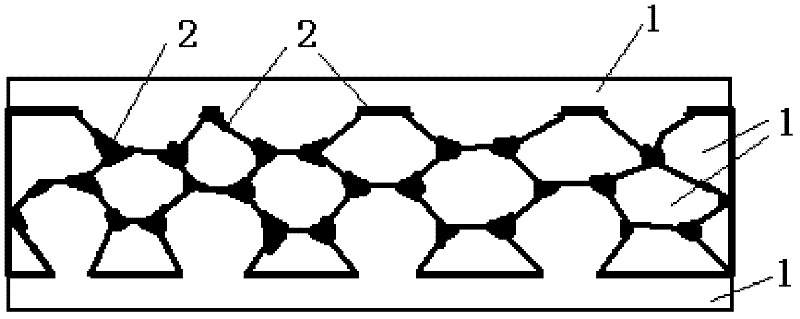

[0022] An elastic composite metal thermal interface material is composed of indium and a through-hole porous metal sheet. The indium is filled inside the through-hole porous metal and covers the upper and lower surfaces of the through-hole porous metal sheet.

[0023] The through-hole porous metal sheet is one of sheet-like porous copper, porous silver, porous zinc, porous titanium, porous magnesium, porous aluminum, and porous gold. The thickness of the through-hole porous metal sheet is 60-200 microns, for example, can be selected as 80 microns, 120 microns, 150 microns, 160 microns, 180 microns, 190 microns, the porosity of the through-hole porous metal (so-called porosity refers to the Volume as a percentage of the apparent total volume of the porous metal) is 30%-95%, for example, it can be 35%, 40%, 50%, 60%, 70%, 80%, 90%, and the pore size is 100 nanometers to 30 microns, For example, 200 nanometers, 400 nanometers, 600 nanometers, 800 nanometers, 1 micrometer, 5 micro...

Embodiment 2

[0026] An elastic composite metal thermal interface material, which is composed of indium and porous copper sheets with through holes. The thickness of the porous copper sheets is 160 microns, the porosity is 90%, and the pore diameter is 5 microns. Indium is filled in the porous copper sheets through the holes. Inside, there is almost no gap in the through-hole porous copper, and the upper and lower surfaces of the through-hole porous metal sheet are covered, and the thickness of indium on the upper and lower surfaces is 2-10 microns. An anti-oxidation layer palladium or the like may be provided on the surface of the through-hole porous copper sheet, which is deposited by electroplating. This thermal interface material is applied by conventional methods, and its interface thermal resistance is less than 10mm due to the good interface contact 2 K / W (measured by ASTM-D5470 standard).

Embodiment 3

[0028] A method for preparing the elastic composite metal thermal interface material, the first step is to prepare a through-hole porous metal sheet, the thickness of the through-hole porous metal sheet is 60-200 microns, for example, it can be selected as 80 microns, 120 microns, or 150 microns , 160 microns, 180 microns, 190 microns, the porous metal sheet with through holes is one of sheet-like porous copper, porous silver, porous zinc, porous titanium, porous magnesium, porous aluminum, and porous gold. The preparation method adopts one of dealloying, sol-gel method, sintering method and the like. The porosity of the obtained through-hole porous metal (the so-called porosity refers to the percentage of the volume of the pores in the apparent total volume of the porous metal) is 30%-95%, for example, it can be 35%, 40%, 50%, 60%, 70%, 80%, 90%.

[0029] In this scheme, the specific steps of preparing the through-hole porous metal sheet by the dealloying method are as follo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com