Method for preparing transparent conductive film material

A transparent conductive film, zinc oxide film technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of low repeatability, complex preparation process, high cost, and improve light transmittance , the process is simple, the effect of high deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

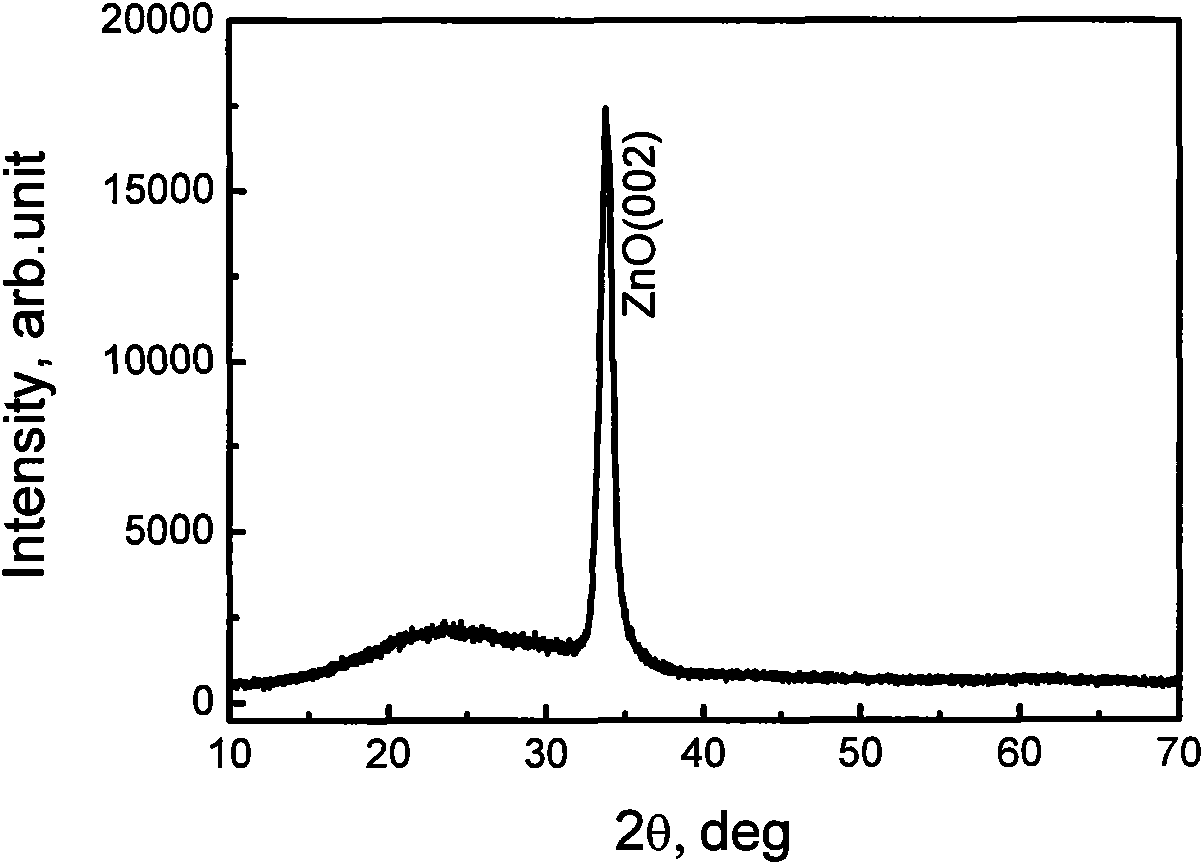

Embodiment 1

[0024] The Al-doped zinc oxide film was deposited by an intermediate frequency reactive magnetron sputtering system. The target materials were aluminum with a purity of 99.99% and zinc oxide with a purity of 99.99%. The double targets were co-sputtered and connected to the ALS-150R Hall ion source. The target and ion source are located around the vacuum chamber, the position is fixed, the substrate is placed in the center, and rotated at a speed of 40r / min, the distance between the center of the substrate and the target is 90mm. The background vacuum of the system is 5×10 -4 Pa, the working gas in the sputtering process is high-purity argon, the flow rate is 20 sccm, and the reaction gas is high-purity oxygen. Before coating, the ultra-clear glass substrate was ultrasonically cleaned in acetone for 30 minutes, then ultrasonically cleaned in alcohol for 10 minutes, then cleaned with deionized water and dried. Before the preparation, pre-sputter the aluminum metal target for 15...

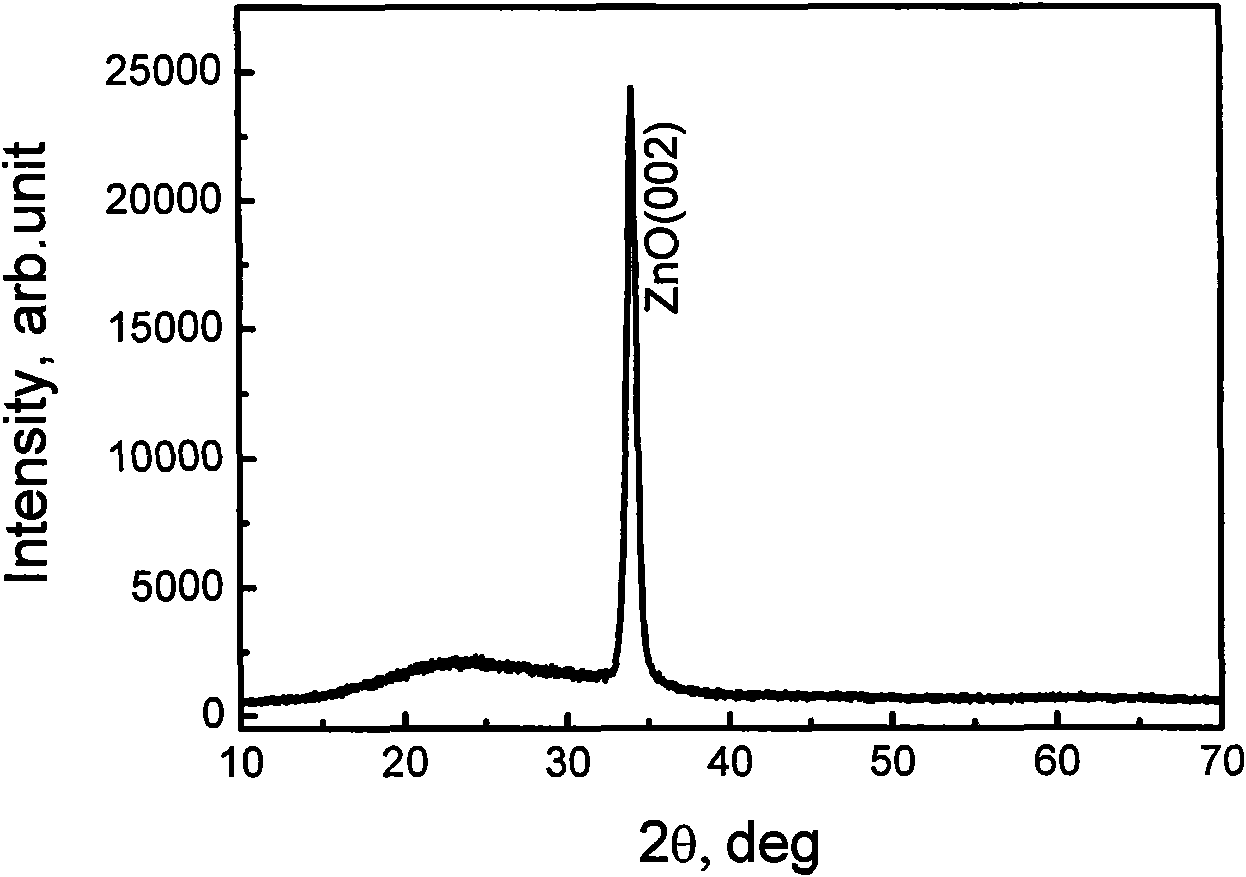

Embodiment 2

[0029] The Al-doped zinc oxide film was deposited by an intermediate frequency reactive magnetron sputtering system. The target materials were aluminum with a purity of 99.99% and zinc oxide with a purity of 99.99%. The double targets were co-sputtered and connected to the ALS-150R Hall ion source. The target and the ion source are located around the vacuum chamber, the position is fixed, the substrate is placed in the center, rotated at a speed of 50r / min, and the distance between the center of the substrate and the target is 100mm. The background vacuum of the system is 1×10 -4 Pa, the working gas in the sputtering process is high-purity argon, the flow rate is 15 sccm, and the reaction gas is high-purity oxygen. Before coating, the ultra-clear glass substrate was ultrasonically cleaned in acetone for 30 minutes, then ultrasonically cleaned in alcohol for 10 minutes, then cleaned with deionized water and dried. Before the preparation, pre-sputter the aluminum metal target f...

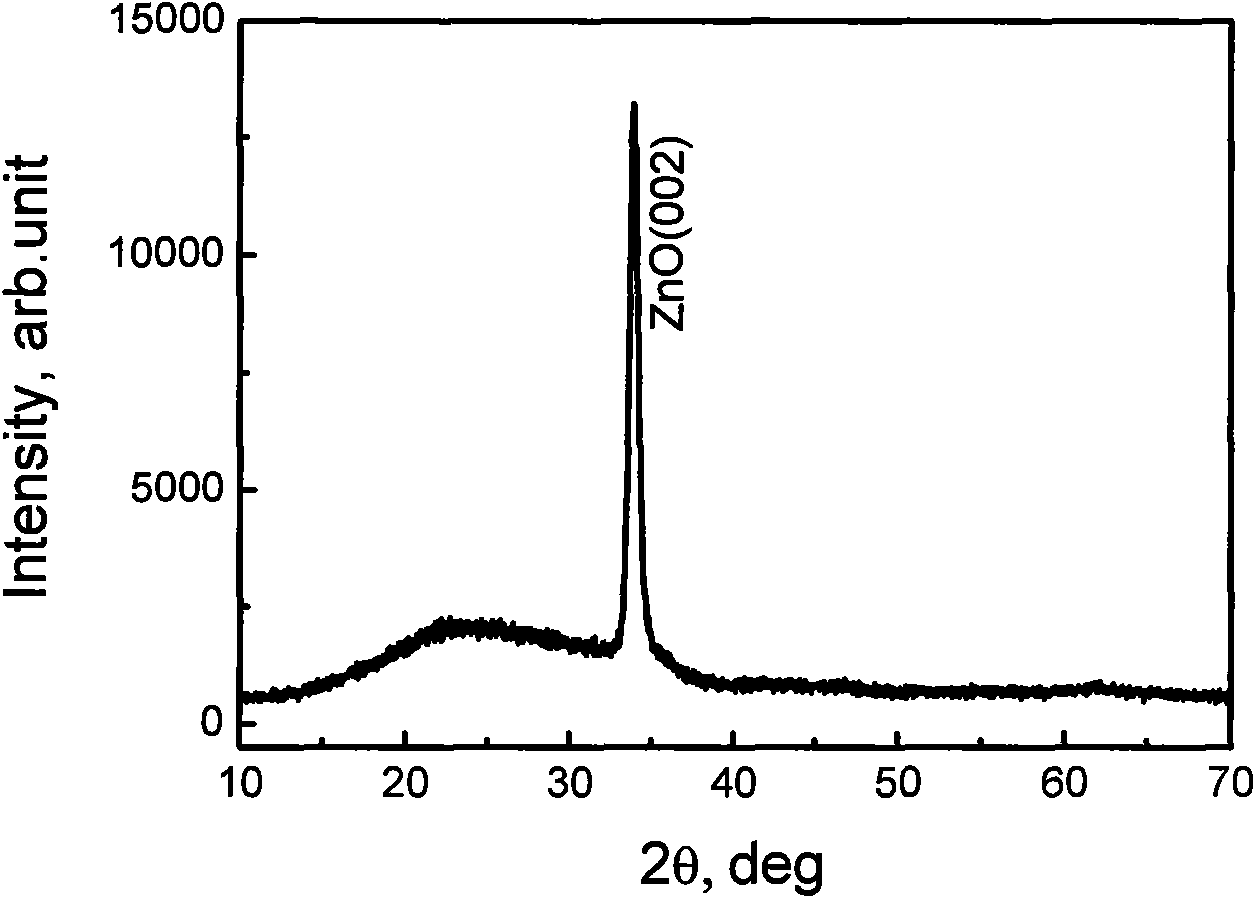

Embodiment 3

[0034] The Al-doped zinc oxide film was deposited by an intermediate frequency reactive magnetron sputtering system. The target materials were aluminum with a purity of 99.99% and zinc oxide with a purity of 99.99%. The double targets were co-sputtered and connected to the ALS-150R Hall ion source. The target and ion source are located around the vacuum chamber, the position is fixed, the substrate is placed in the center, and rotated at a speed of 30r / min, the distance between the center of the substrate and the target is 90mm. The background vacuum of the system is 1×10 -4 Pa, the working gas in the sputtering process is high-purity argon, the flow rate is 10 sccm, and the reaction gas is high-purity oxygen. Before coating, the ultra-clear glass substrate was ultrasonically cleaned in acetone for 20 minutes, then ultrasonically cleaned in alcohol for 10 minutes, then cleaned with deionized water and dried. Before the preparation, pre-sputter the aluminum metal target for 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com