Phosphorus-containing network structure flame retardant

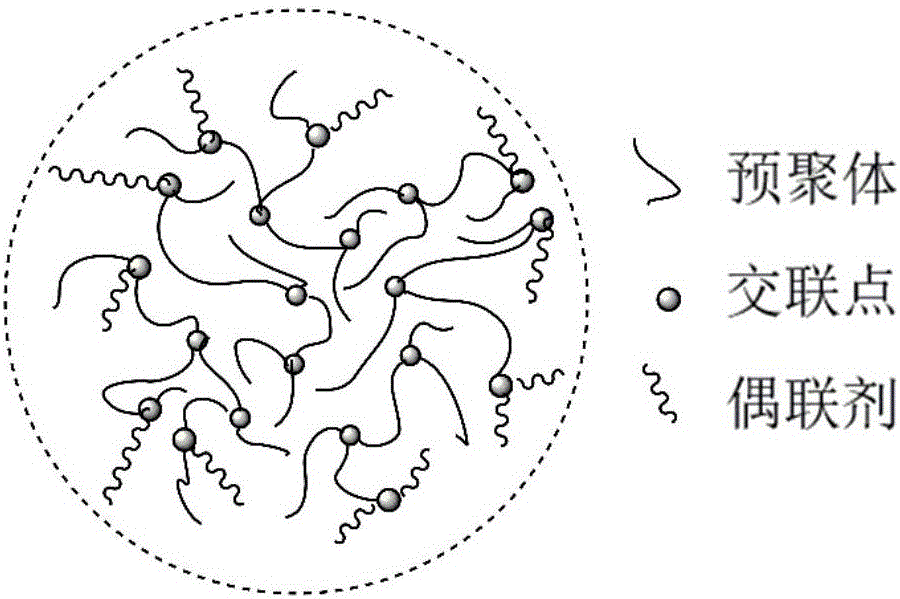

A network structure and flame retardant technology, which is applied in the field of network structure flame retardants containing phosphorus elements, can solve the problems that cannot meet the requirements of flame retardant materials, and achieve the effects of easy production, improved flame retardant efficiency, and easy charcoal formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

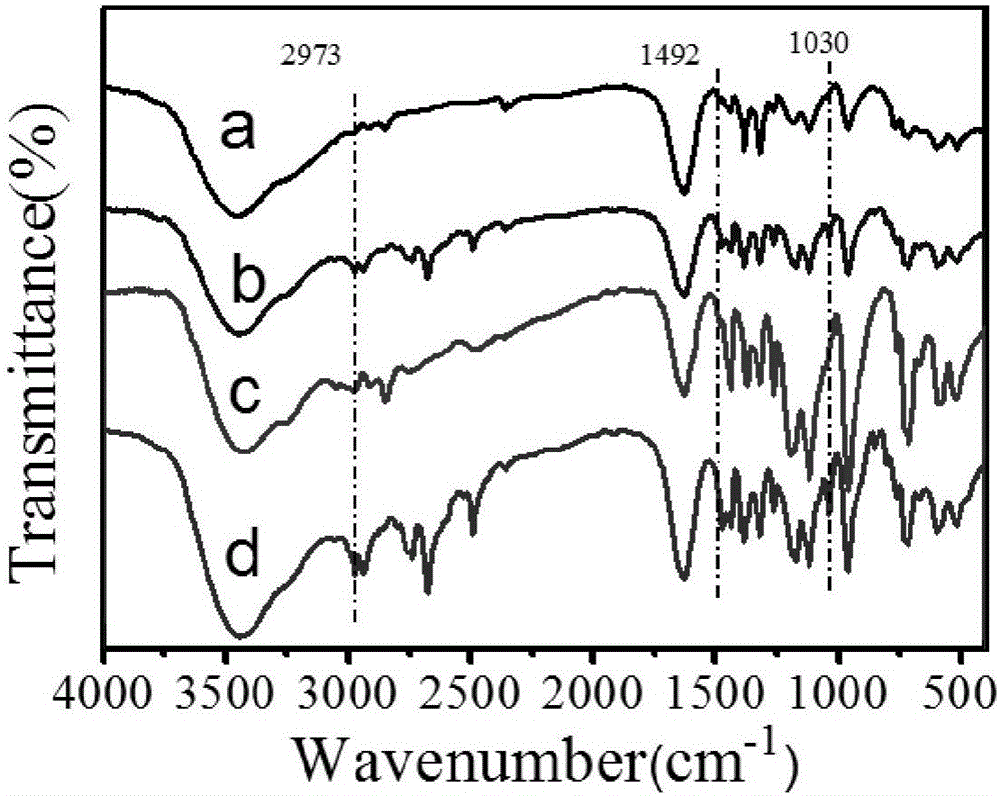

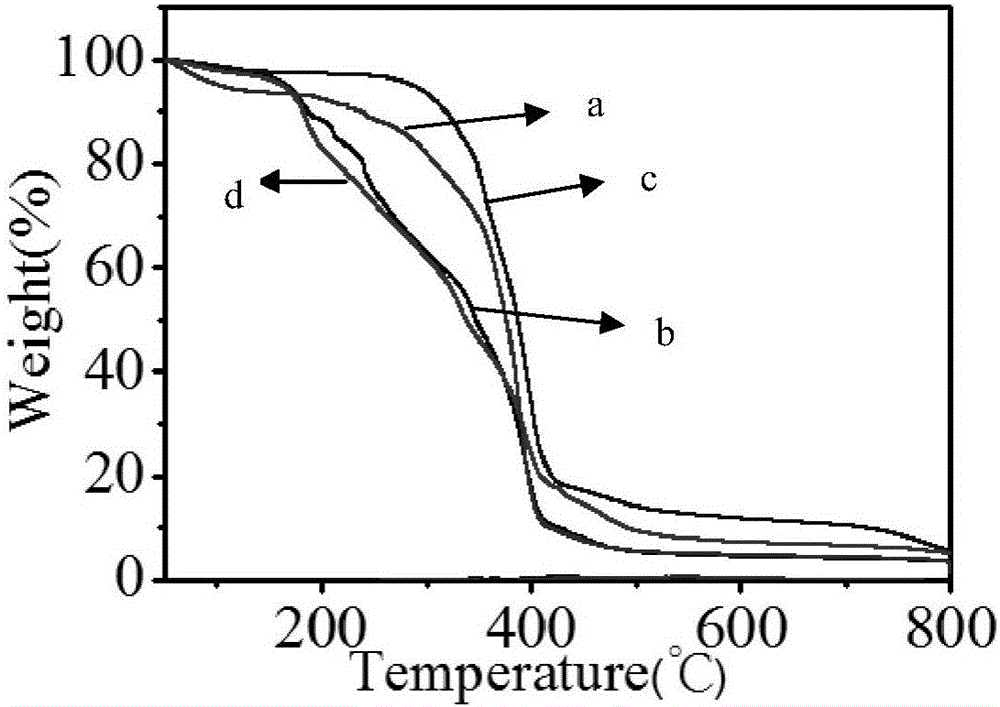

[0028] Take piperazine 2.58g (0.03mol) and dissolve it in 20ml CH at 30°C 2 Cl 2 , add acid-binding agent triethylamine 6.07g (0.06mol) simultaneously, stir in the there-necked flask with the rotating speed of 200r / min until uniform, system passes N 2 protection, and connected to the exhaust absorption device. Take 4.87g (0.025mol) of phenylphosphonic dichloride and dissolve it in 20ml of dichloromethane and place it in a constant pressure dropping funnel, drop it into the piperazine solution at a rate of 1-2 drops / s to react for 1 hour, and a white Precipitation occurs. Then take POCl 3 Dissolve 0.51g (0.0033mol) in 20ml of dichloromethane, put it in a constant pressure dropping funnel, drop the above solution, control the temperature at 40°C and continue the reaction for 1h, and finally add 0.11g (0.0005mol) of coupling agent KH550 to continue the reaction for 2h, Suction filtration and fully washed with ethanol to obtain a viscous substance. The product was dried in a ...

Embodiment 2

[0031] Change the first stage reaction time of embodiment 1 into 2h, all the other conditions are constant, can obtain product P2, infrared spectrum is as follows figure 1 As shown in the middle b curve, the thermogravimetric curve is as figure 2 Shown in the b curve.

Embodiment 3

[0033] Take piperazine 3.27g (0.038mol) and dissolve it in 25ml CH at 30°C 2 Cl 2 At the same time, add 10.34g (0.08mol) of acid-binding agent N,N-diisopropylethylamine, stir in the three-necked flask at a speed of 300r / min until uniform, and the system passes N 2 protection, and connected to the exhaust absorption device. Take 4.87g (0.024mol) of phenylphosphonic dichloride and dissolve it in 20ml of dichloromethane, place it in a constant pressure dropping funnel, add it dropwise to the piperazine solution at a rate of 1-2 drops / s, and react for 1 hour, a white precipitate appears produce. Then take POCl 3 1.42g (0.0093mol) was dissolved in 20ml of dichloromethane, placed in a constant pressure dropping funnel and dripped into the above solution, the temperature was controlled at 30°C to continue the reaction for 1h, and 0.09g (0.0004mol) of coupling agent KH550 was added to continue the reaction for 3h. Filter and fully wash with methanol to obtain a viscous substance, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com