Oxidized graphene/waterborne polyurethane acrylate composite emulsion and preparation method and application thereof

A polyurethane acrylate and composite emulsion technology, which is applied in coatings, anti-corrosion coatings, fire-retardant coatings, etc., can solve the problem of no anti-corrosion performance, and achieve the effects of enhancing anti-corrosion performance, improving compactness and improving adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

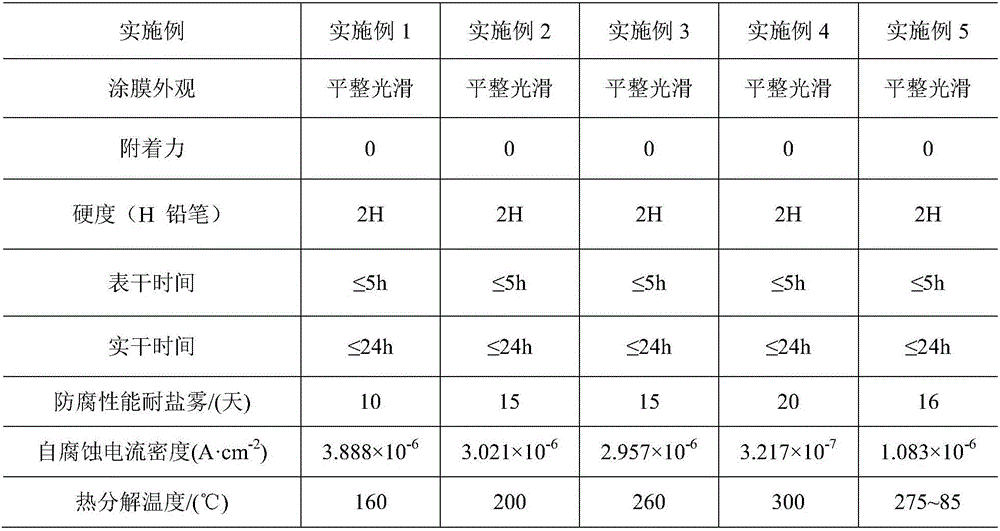

Examples

Embodiment 1

[0038] 1) Preparation of graphite oxide by improved Hummers method

[0039] The synthesis process of graphene oxide is as follows: First, prepare graphite oxide by the improved Hummers method, take 2g of natural flake graphite, 1g of sodium nitrate and 96g of concentrated sulfuric acid and slowly add them in sequence to a 500ml three-necked flask, and stir in an ice-water bath After reacting for 30 minutes, 6 g of oxidant (potassium permanganate) was gradually added, and the reaction was continued for 2 hours with stirring in an ice-water bath. Then slowly move the flask into a constant temperature water bath at 30-35°C, stir for another 3 hours, keep stirring and slowly add 190 g of deionized water dropwise, continue stirring for 1 hour, then cool to room temperature, and then add an appropriate amount of 30% H 2 o 2 , the solution turned bright yellow. Stand still, filter, and wash the filter cake fully with 5% HCl solution until there is no SO in the filtrate 4 2- (with...

Embodiment 2

[0046] 1) First, add 19 parts of a mixture of methyl methacrylate (MMA) and butyl acrylate (BA) (the mass ratio of MMA to BA is 4:1), 7 parts of isofor Alone diisocyanate, 10 parts of polycaprolactone diol, 2 parts of dimethylolpropionic acid, 1 part of trimethylolpropane, the reaction temperature is constant at 75-85°C, and the reaction time is 3 hours.

[0047] 2) Next, add 1.5 parts of hydroxyethyl methacrylate to the system for capping, stir and react for 0.5 hours, keep the temperature of the system at 75-85°C, then add 1.5 parts of triethylamine, and neutralize for 0.5 hours , add 65 parts of an aqueous dispersion containing 0.03 parts of sodium α-olefin sulfonate and 1 part of graphene oxide, stir and disperse at high speed for 5-10 minutes, and keep the constant temperature at 75-85°C.

[0048] 3) Finally, at a constant temperature of 75 to 85°C, continue to drop 20 parts of an aqueous solution containing 0.5 parts of ammonium persulfate, and after 1.5 hours of reactio...

Embodiment 3

[0050] 1) First, add 19 parts of a mixture of methyl methacrylate (MMA) and butyl acrylate (BA) (the mass ratio of MMA to BA is 4:1), 7 parts of isofor Alone diisocyanate, 10 parts of polycaprolactone diol, 2 parts of dimethylolpropionic acid, 1 part of trimethylolpropane, the reaction temperature is constant at 75-85°C, and the reaction time is 3 hours.

[0051] 2) Next, add 1.5 parts of hydroxyethyl methacrylate to the system for capping, stir and react for 0.5 hours, keep the temperature of the system at 75-85°C, then add 1.5 parts of triethylamine, and neutralize for 0.5 hours , add 65 parts of an aqueous dispersion containing 0.03 parts of sodium α-olefin sulfonate and 3 parts of graphene oxide, stir and disperse at high speed for 5-10 minutes, and keep the constant temperature at 75-85°C.

[0052] 3) Finally, at a constant temperature of 75 to 85°C, continue to drop 20 parts of an aqueous solution containing 0.5 parts of ammonium persulfate, and after 1.5 hours of reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com