Patents

Literature

71 results about "Micro-combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Micro-combustion is the sequence of exothermic chemical reaction between a fuel and an oxidant accompanied by the production of heat and conversion of chemical species at micro level. The release of heat can result in the production of light in the form of either glowing or a flame. Fuels of interest often include organic compounds (especially hydrocarbons) in the gas, liquid or solid phase. The major problem of micro-combustion is the high surface to volume ratio. As the surface to volume ratio increases heat loss to walls of combustor increases which leads to flame quenching.

Method and combustor for combusting hydrogen

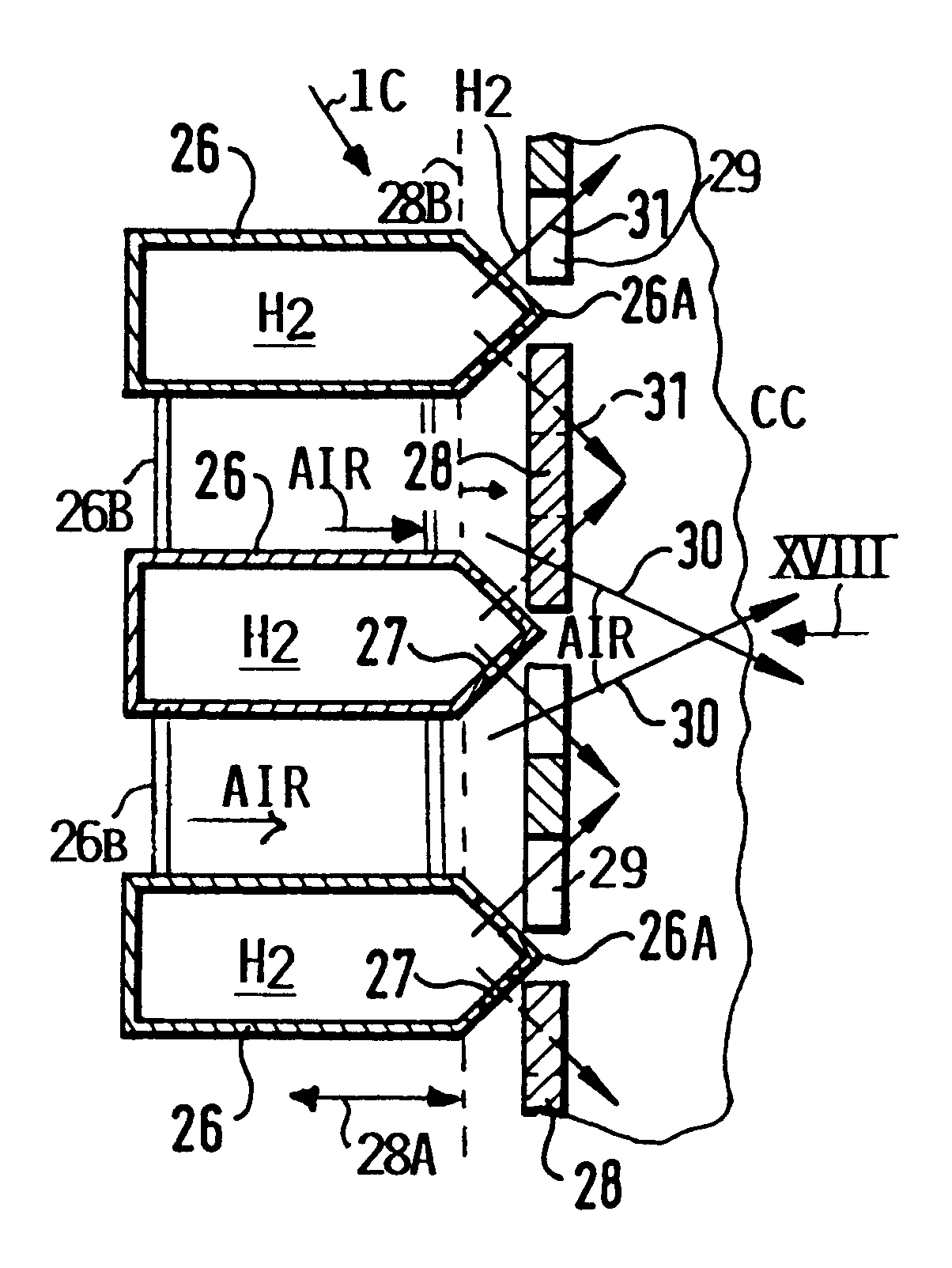

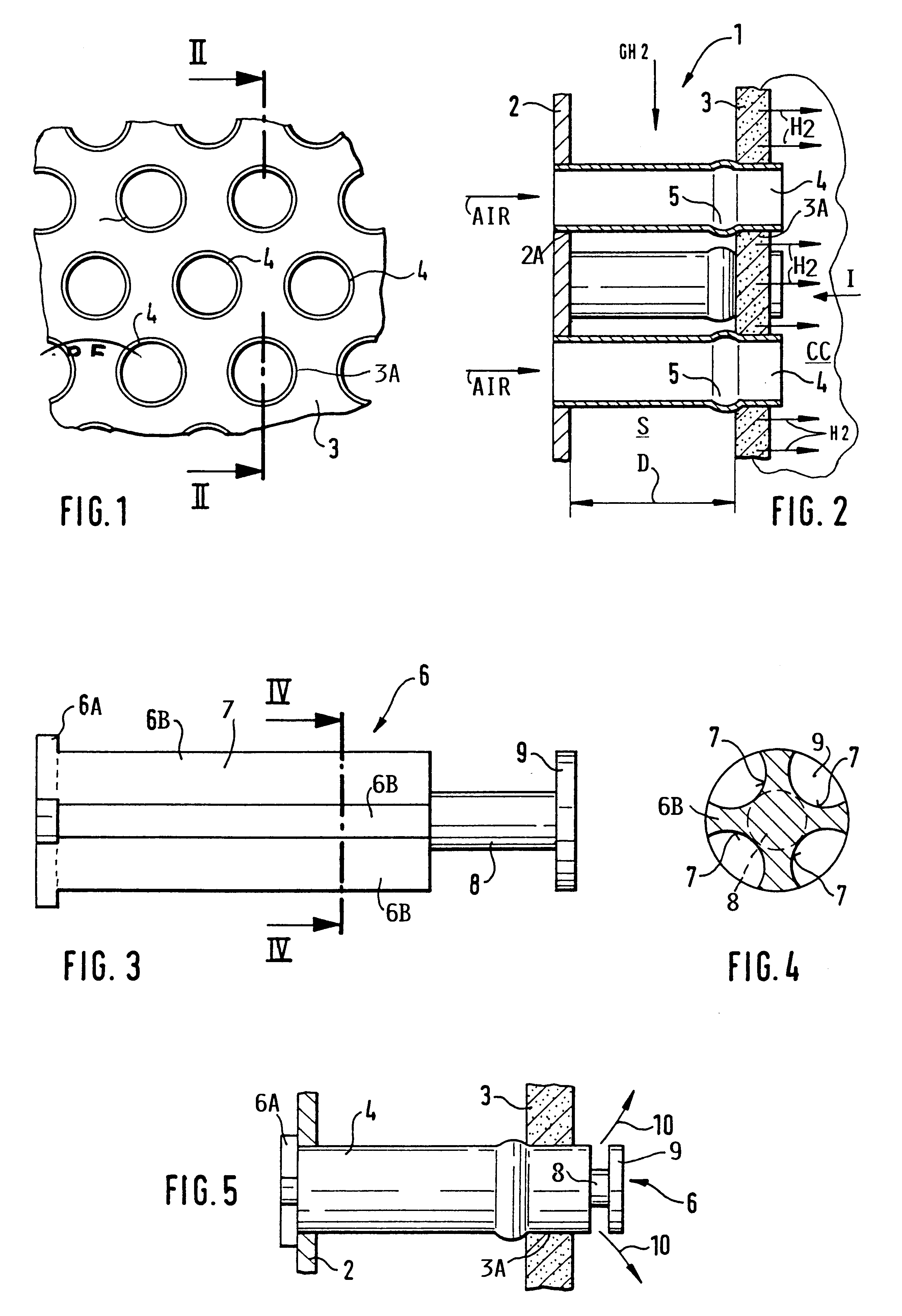

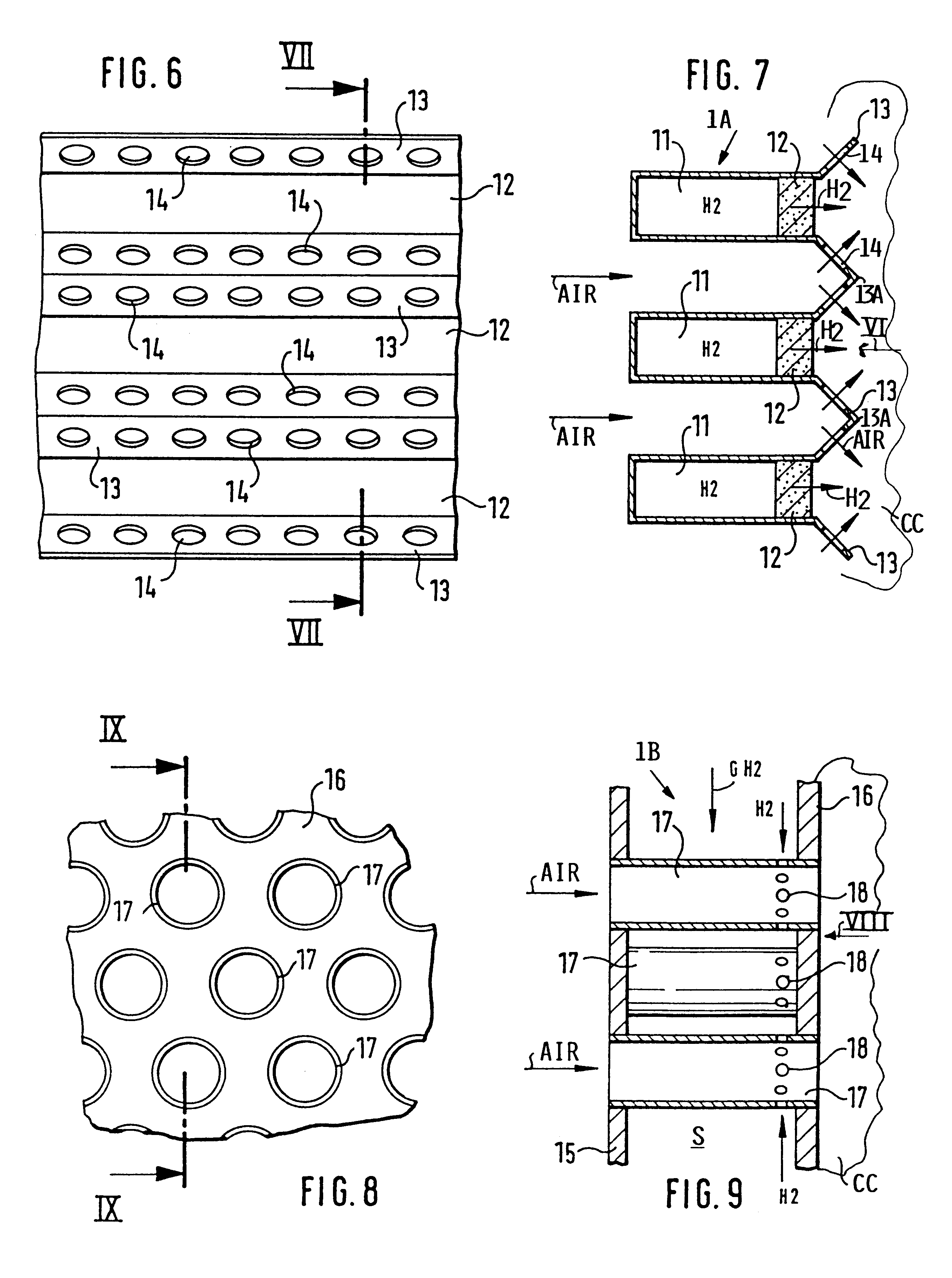

InactiveUS6267585B1Inhibit combustionSmall mixing scaleCombustion using gaseous and pulverulent fuelBurner safety arrangementsExhaust gasGas turbines

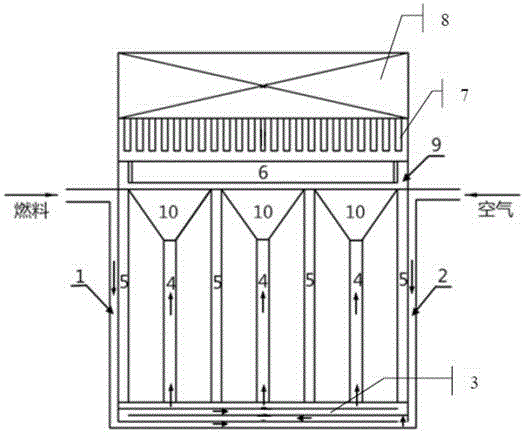

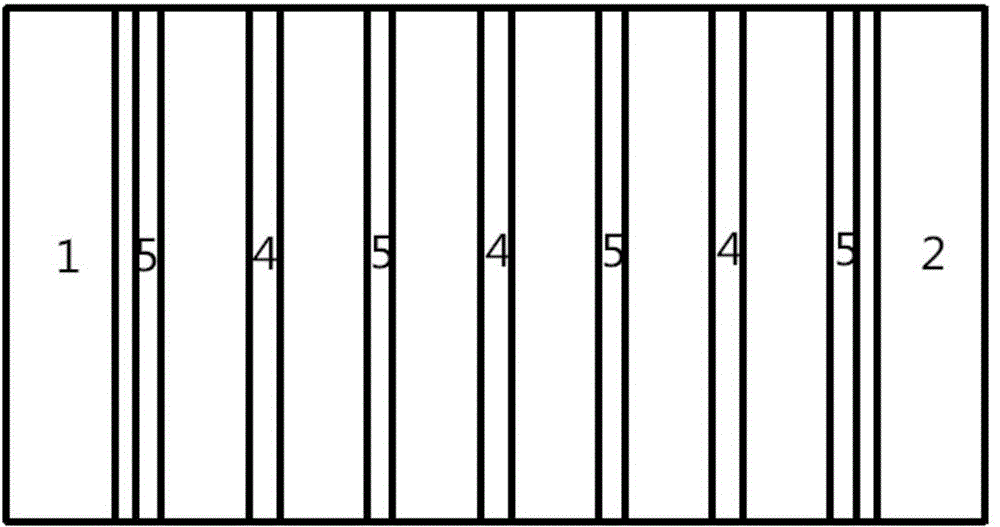

A plate burner for combusting hydrogen with air as an oxidizer forms a wall portion of a combustion chamber for example of a gas turbine. The plate burner is so constructed that air and hydrogen are separately guided to the downstream surface area facing into the combustion chamber for forming a large number of diffusive microcombustion flames, thus achieving a very low mixing scale simultaneously with a high nixing intensity. The number of diffusive micorcombustion flames is so selected that the NOx content in the exhaust gas from the combustion chamber is at the most 10x10-6 cubic foot per cubic foot of exhaust gas. The hydrogen enters the entrance area into the combustion chamber either through a porous wall, and air is injected into the hydrogen environment to form inverse diffusive microcombustion flames or the hydrogen is injected through a multitude of fine holes into high velocity air jets forming regular diffusion flames. In both instances, the formation of NOx in the exhaust gas during combustion is reduced to the above level or below.

Owner:DAIMLER CHRYSLER AEROSPACE AIRBUS

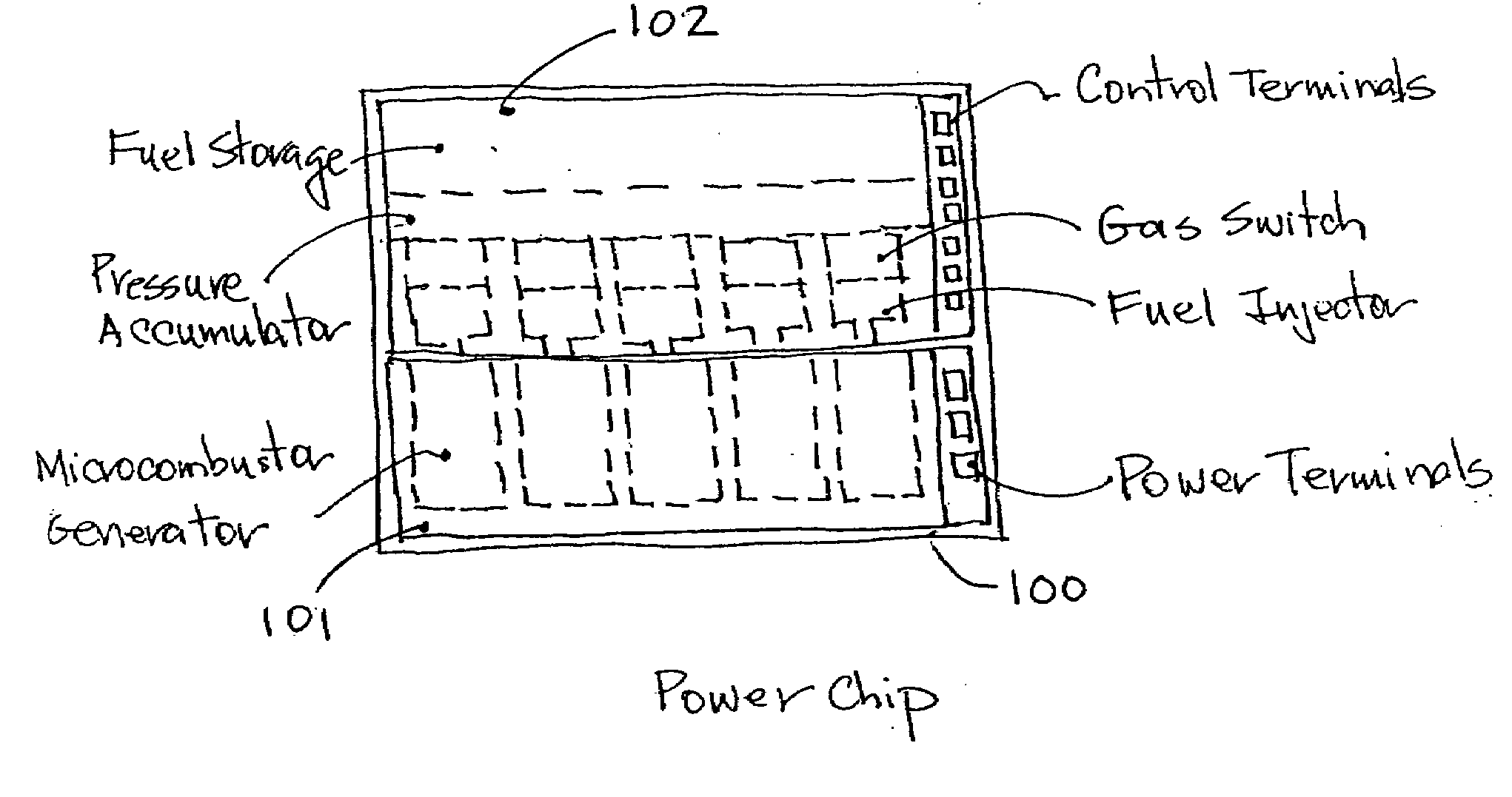

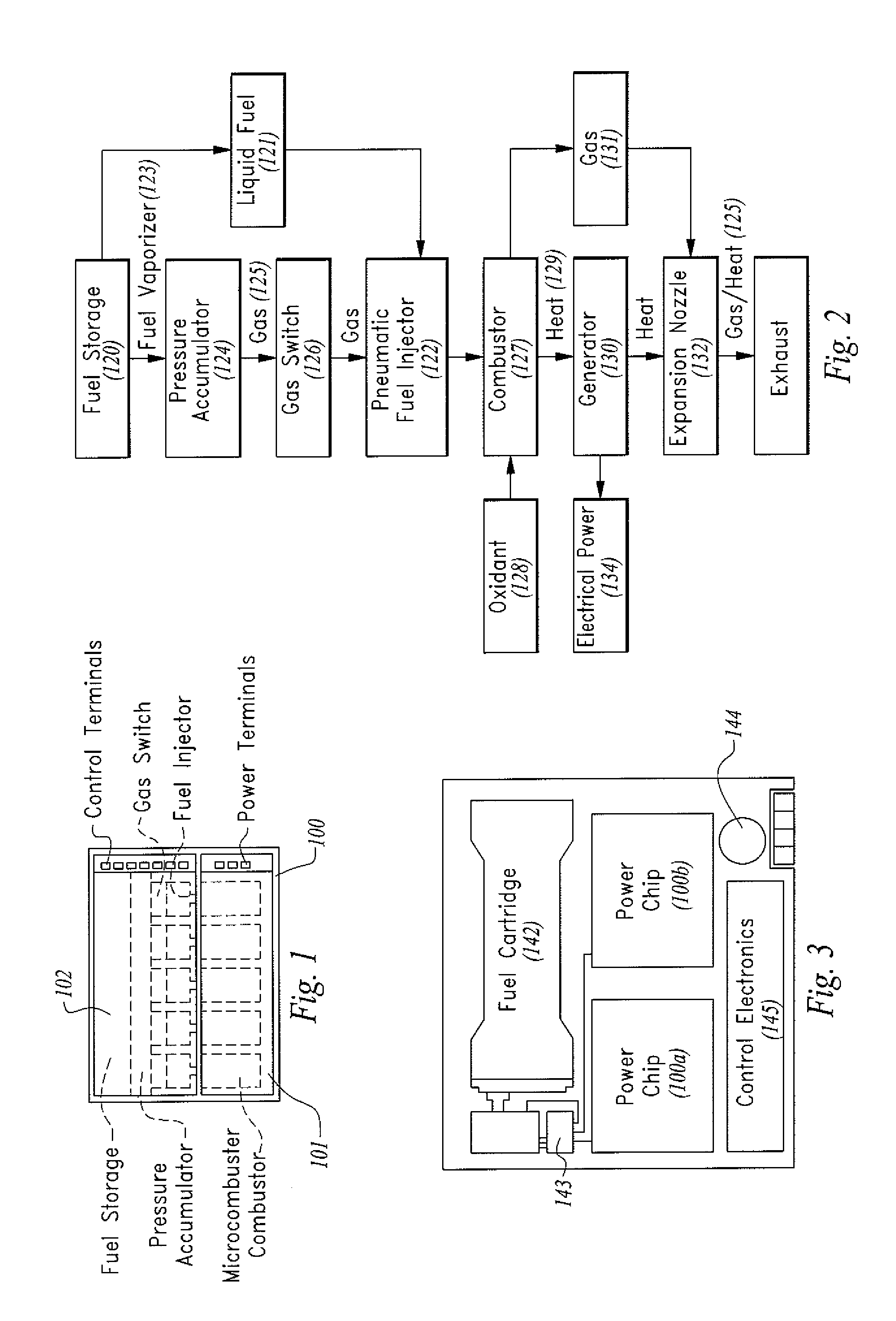

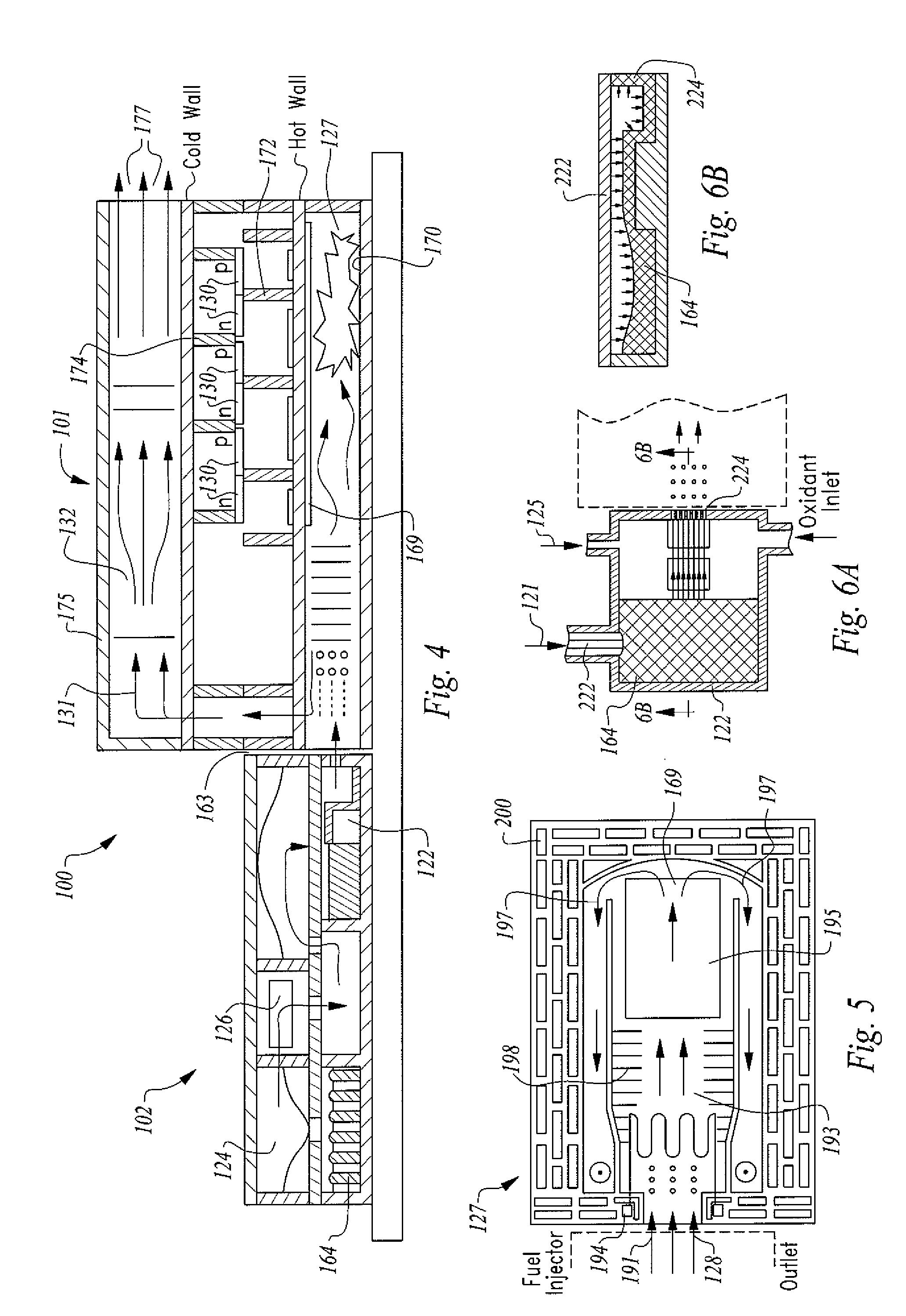

Energy efficient micro combustion system for power generation and fuel processing

InactiveUS20090007953A1Efficient managementThermoelectric device with peltier/seeback effectServomotor componentsThermal energyAutomotive thermoelectric generator

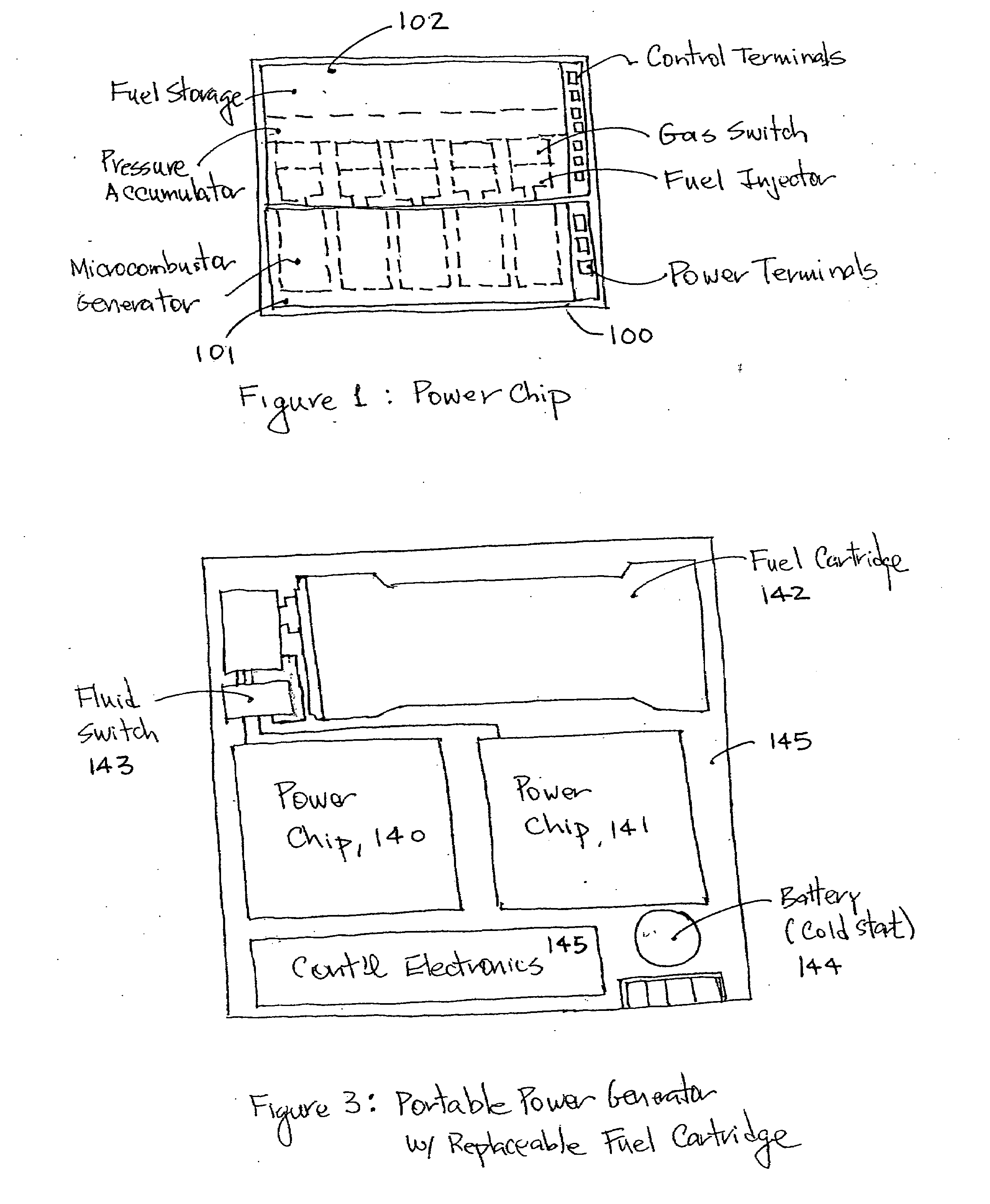

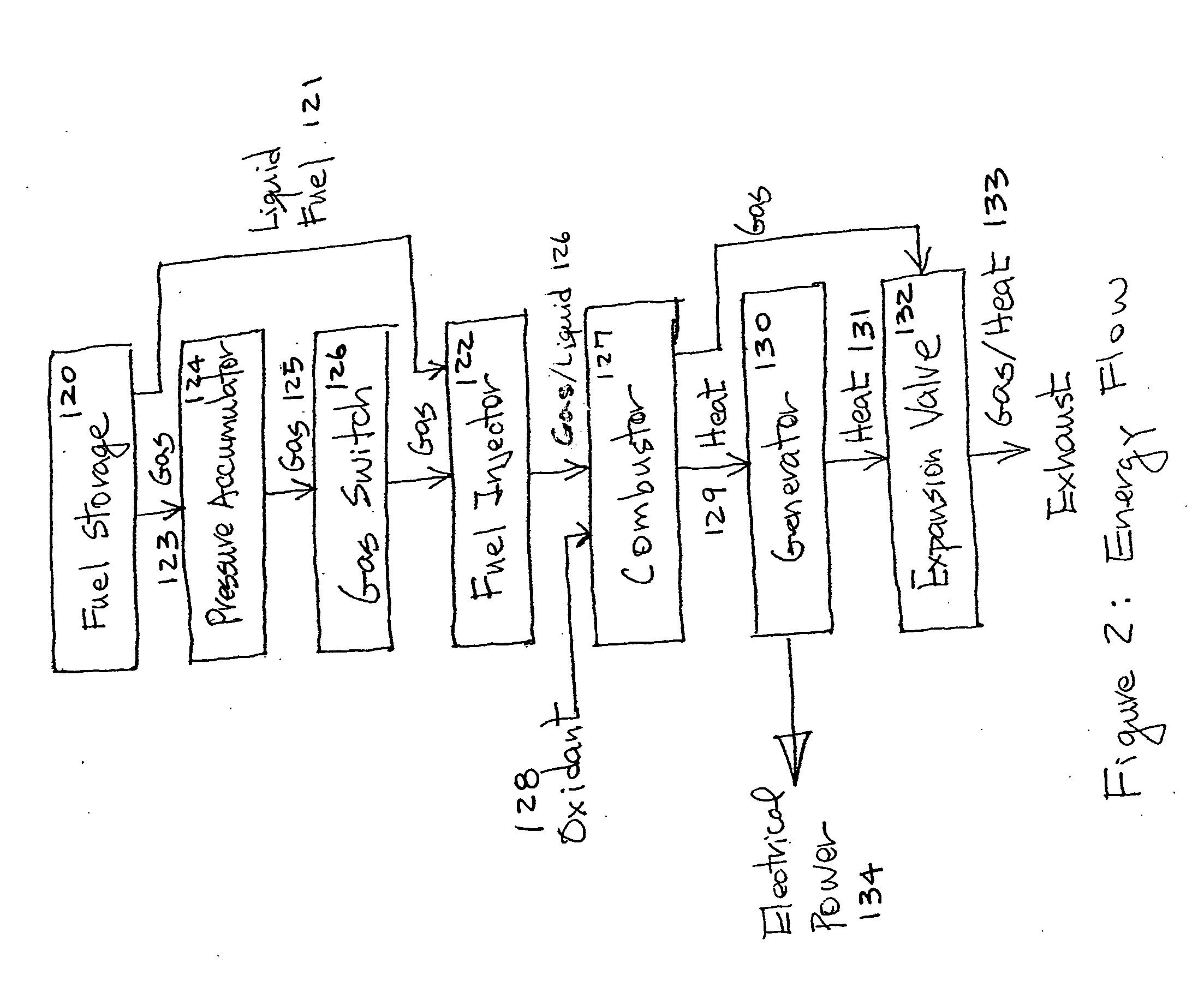

An integrated micro-scale power converter converts hydrocarbon fuel into electricity. The integrated micro-scale power converter includes a micromachined combustor adapted to convert hydrocarbon fuel into thermal energy and a micromachined thermoelectric generator adapted to convert the thermal energy into electrical energy. The combustion reaction in the combustor flows in a path in a first plane while the thermal energy flows in a second plane in the generator the second plane being nearly orthogonal or orthogonal to the first plane. The fuel handler in the combustor is adjacent and thermally isolated from the thermoelectric generator. The fuel handler may include a nozzle and gas flow switch, where the frequency of activation of the gas flow switch controls the amount of the fuel ejected from the nozzle.

Owner:HSU YING WEN

Optimal scheduling model of micro-energy grid with multi-energy storage under multi-time scales

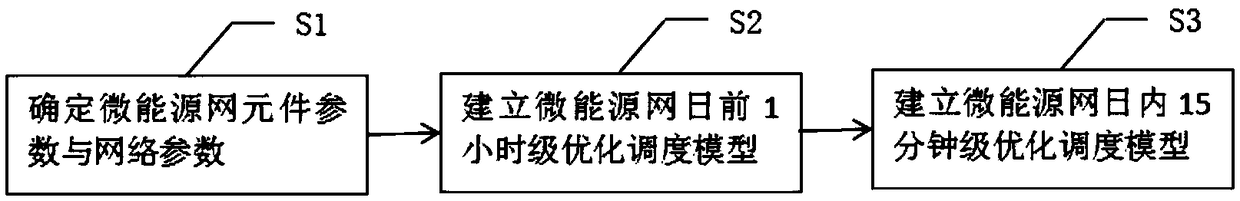

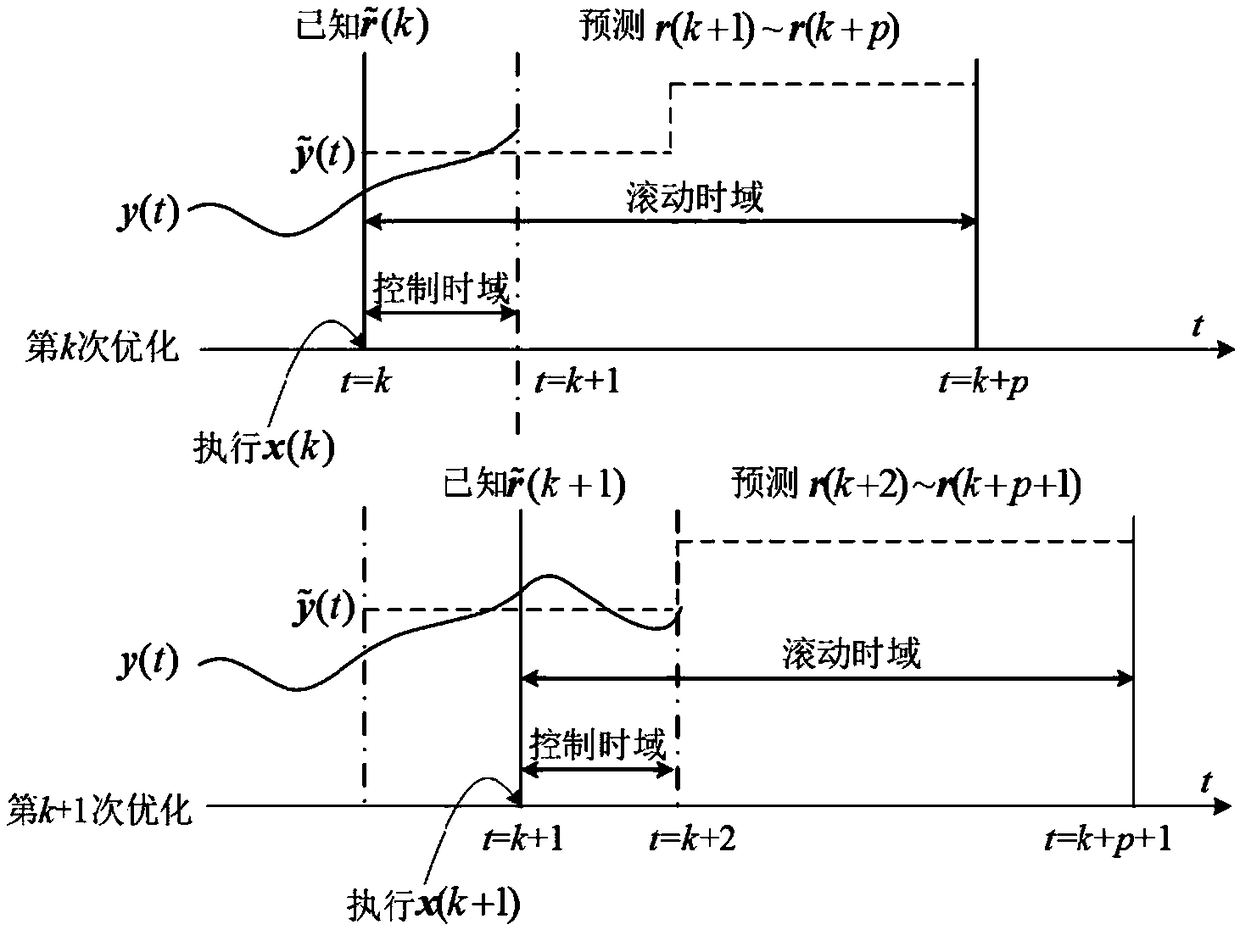

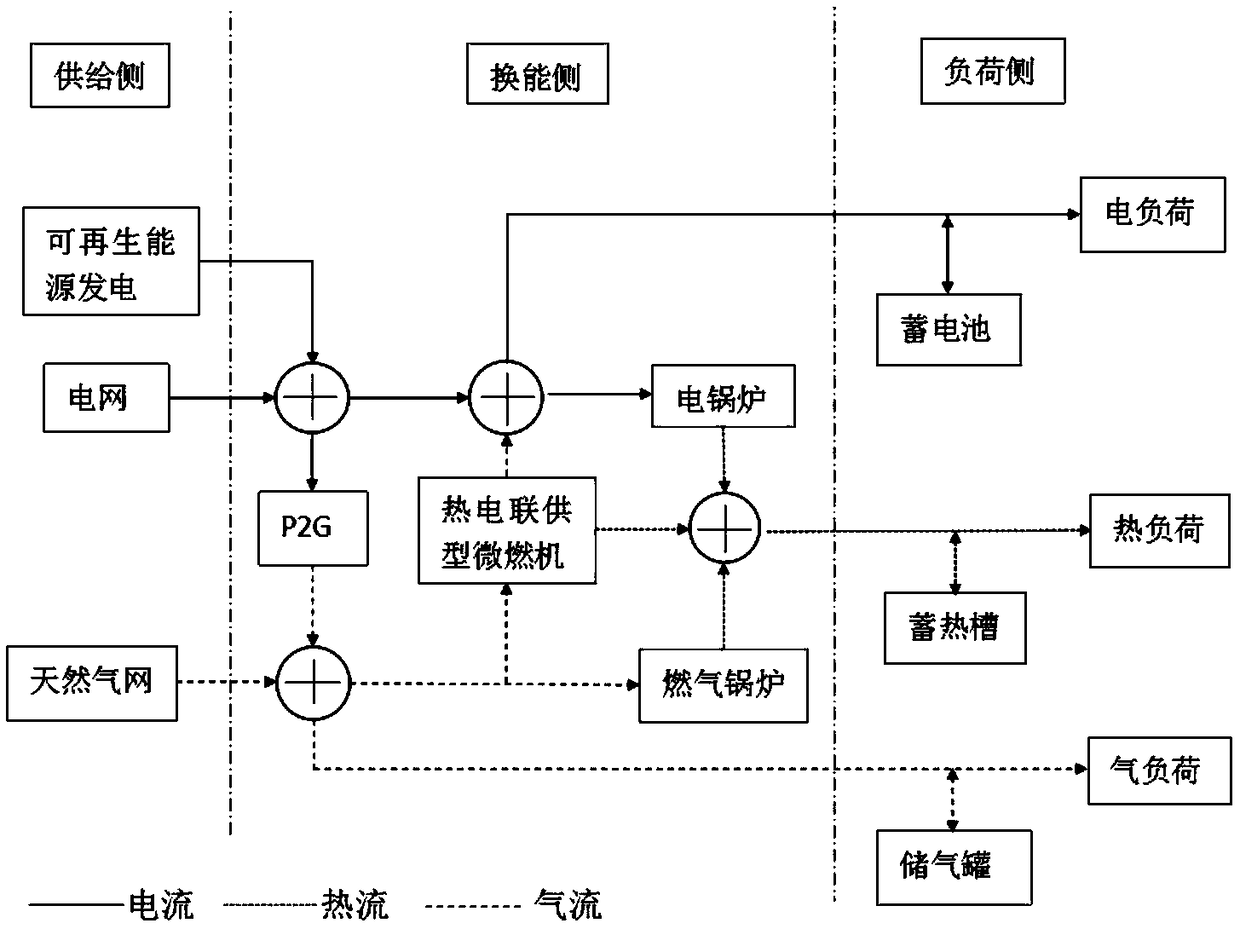

ActiveCN109088442AEffective response powerDealing with Errors EffectivelySingle network parallel feeding arrangementsEnergy storageEnergy balancingDaily operation

The invention discloses an optimal scheduling model of a micro-energy grid with multi-energy storage under multi-time scales, which relates to the field of energy internet optimization operation. Themicro-energy network comprises three energy forms of electricity, heat and gas, including P2G equipment, a heat and power co-generation micro-combustion engine, an electric boiler, a gas boiler, an accumulator, a heat storage tank and a gas storage tank. The multi-time scale considers two time scales, one hour before the day and 15 minutes within the day. The process of establishing the optimal scheduling model of the micro-energy grid comprises the following steps: 1, determining the component parameters and the network parameters of the micro-energy network; 2, establishing an hour-level optimized dispatch model before that day of the micro-energy grid; 3, establishing a micro-energy grid intra-day 15-minute level optimal scheduling model. The invention effectively deals with the power fluctuation of the renewable energy and the load prediction error on the premise of ensuring the daily operation energy balance of each energy storage device, and improves the absorbing capacity of themicro-energy grid to the wind power and the photovoltaic.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY RIZHAOPOWER SUPPLY +1

Data sampling monitoring control device and method for micro combustion steam turbine

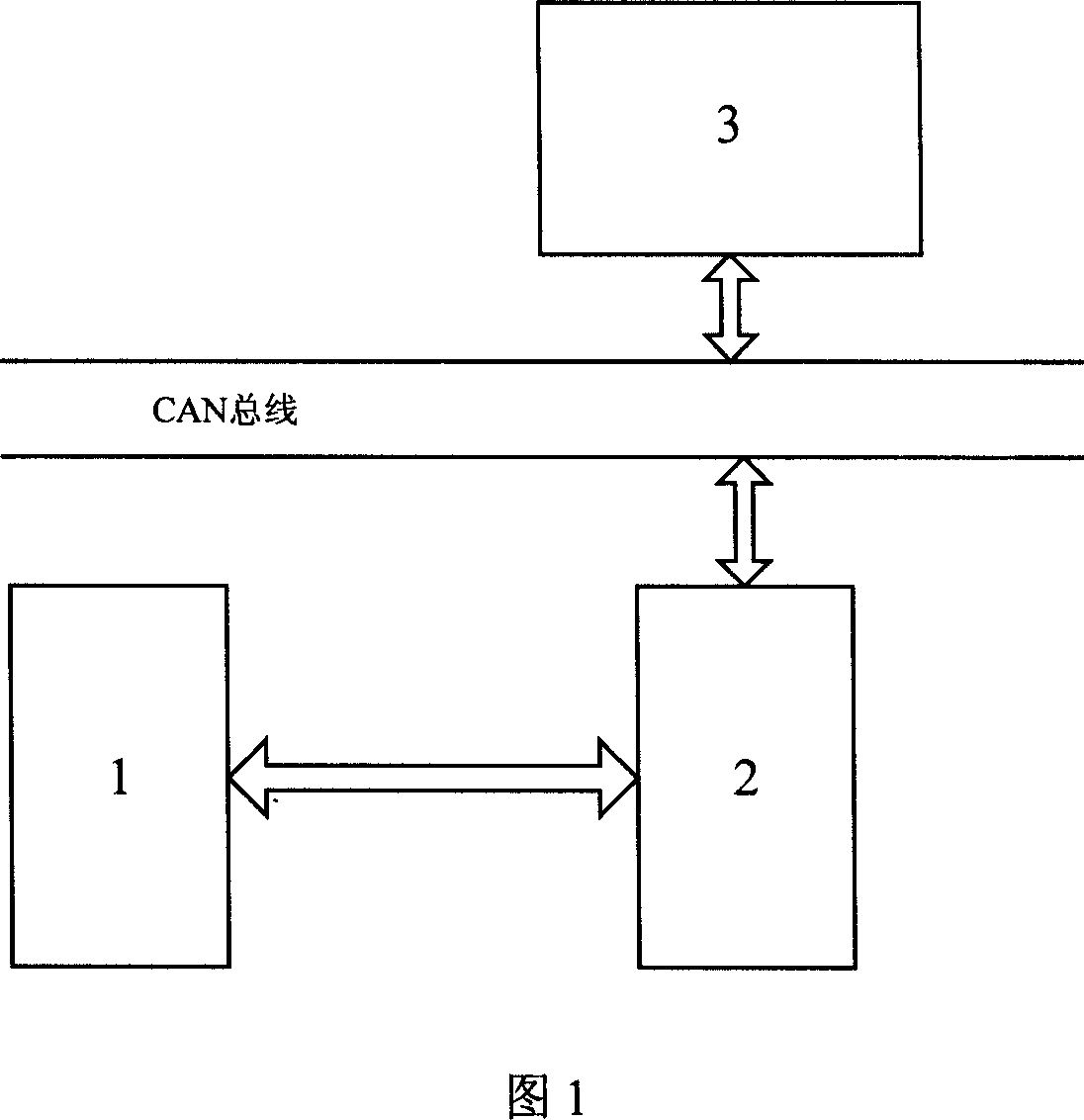

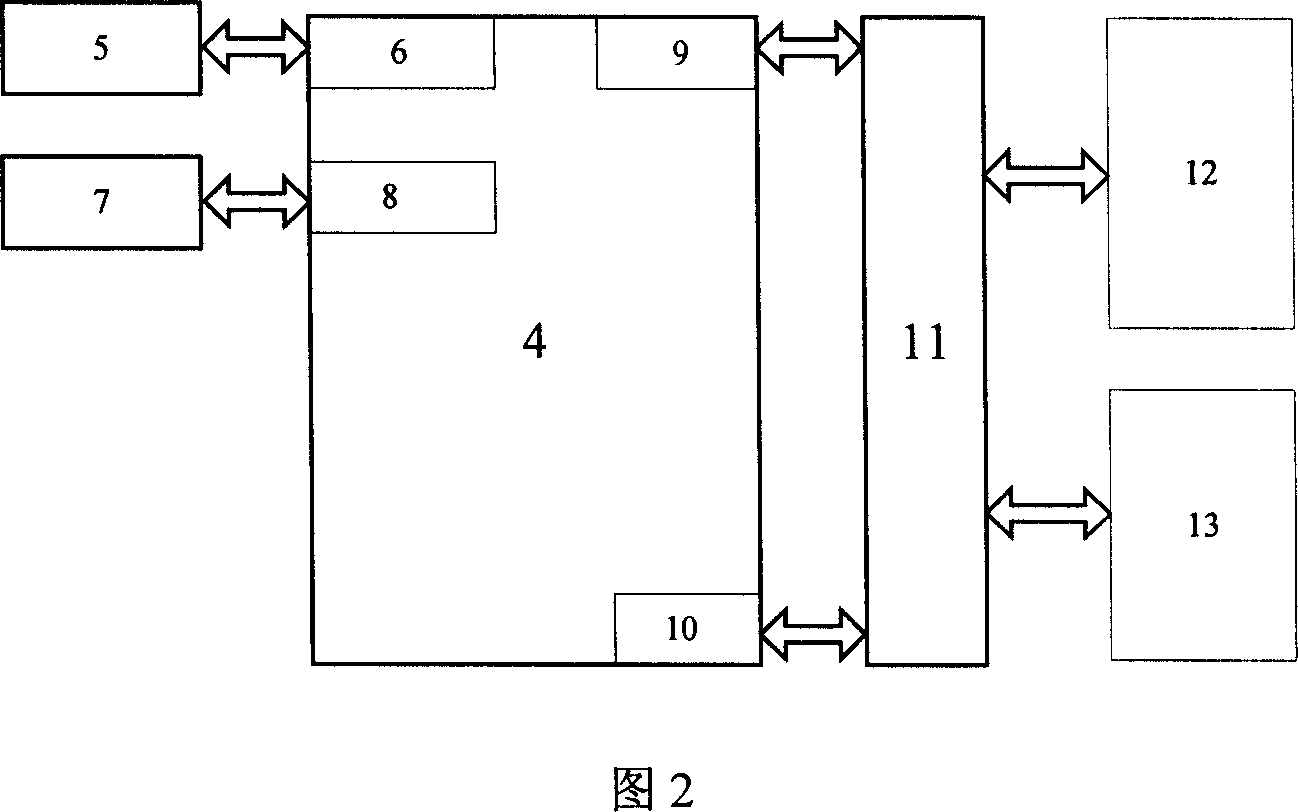

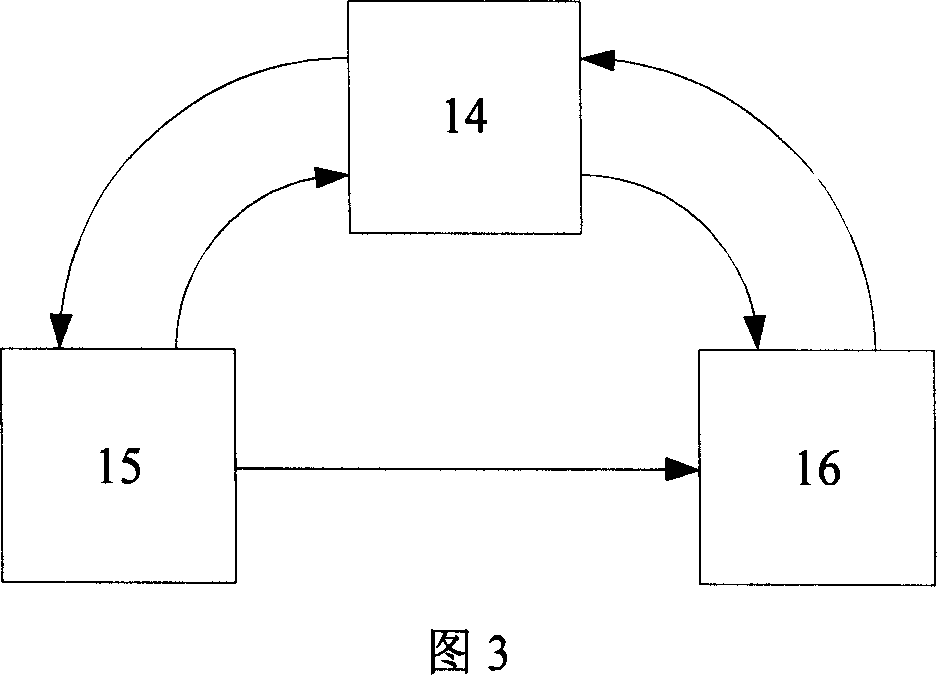

InactiveCN1924746AReal-timeEasy to masterGas turbine plantsTotal factory controlMicro-combustionControl system

This invention relates to micro gas machine data collection monitor and control device and method, which comprises communication connection unit and upper machine, wherein, the connection unit is connected to the upper machine through CAN bus and gas control system; upper machine gas system control is to send order to memory data through communication and through CAN bus to each unit of the gas control system; the upper machine sends order and memory data to the communication module and function module.

Owner:NORTHEASTERN UNIV

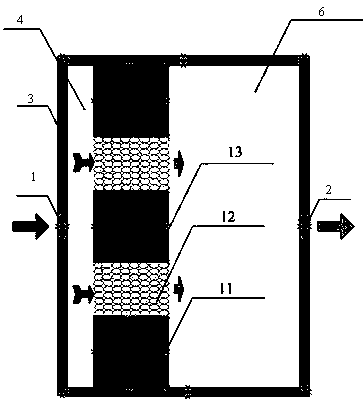

Methanol/ethanol trapped vortex micro-combustor pre-heating intaking method and device for automobile cold-starting

InactiveCN101205866AUniform intake air temperatureIncrease intake air temperatureMachines/enginesEngine startersCombustorEvaporation

The invention provides an auxiliary ignition method which is used for automobile cold start and in which air is preheated by standing vortex micro combustor and a device thereof, relating to the internal combustion engine technology. The method is that: a little carbinol / ethanol fuel is combusted in the micro combustor, generating high temperature fumes, and then the fumes mix with the combustion engine intake air, thereby improving the temperature of the air entering the combustion engine and resolving the problem of the cold start existing in the carbinol / ethanol automobile. The device is arranged behind an air cleaner and in front of an air intake manifold and comprises a standing vortex micro combustor and a carbinol / ethanol preheating evaporator. The carbinol / ethanol liquid make a mixed firing with the air in the micro combustor after the preheating evaporation of a preheater, and generates the high temperature fumes which mix with the main air flow of the automobile intake air. The invention resolves the problem of the cold start by increasing the temperature of the intake air; moreover, the device is simple and convenient in operation.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

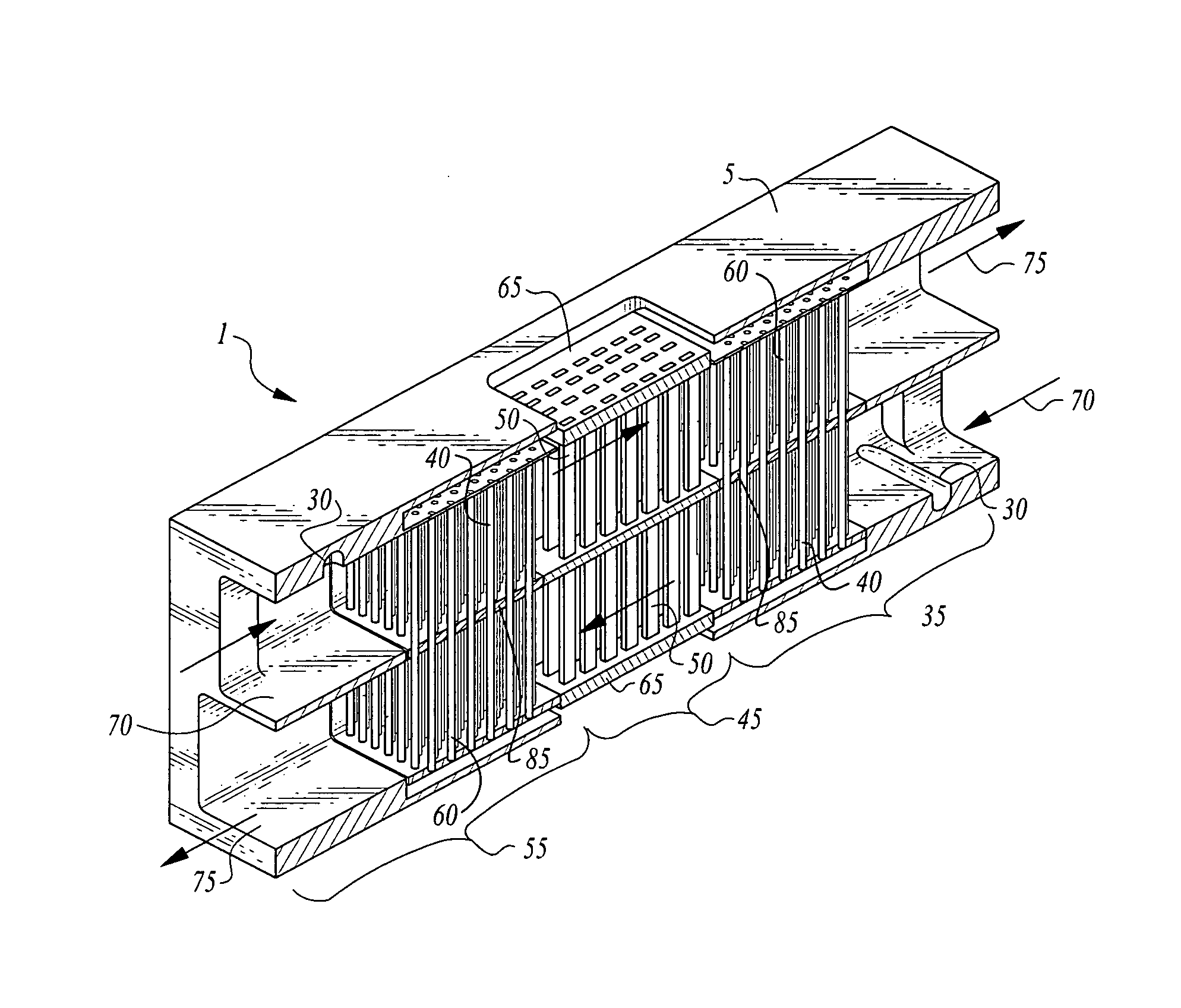

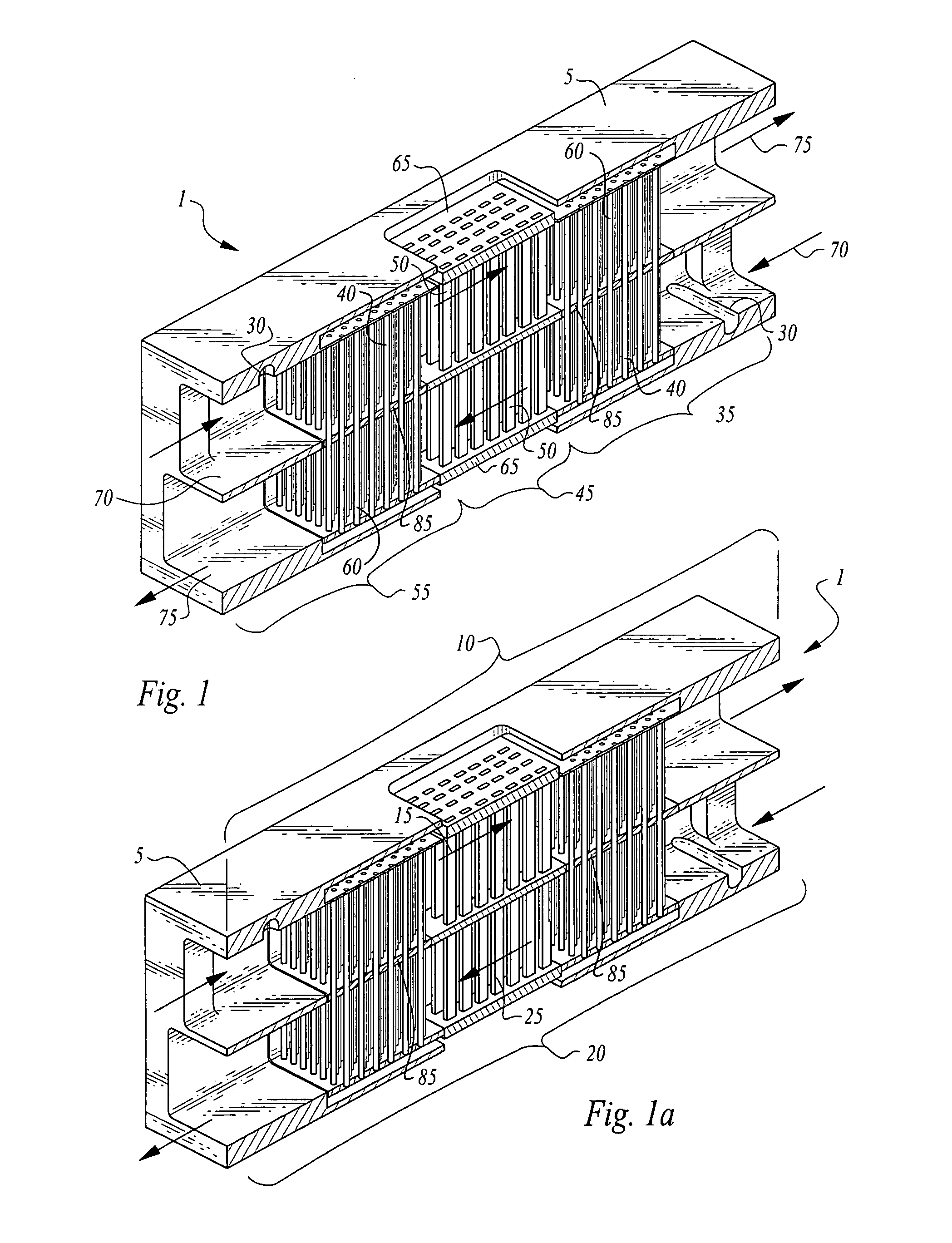

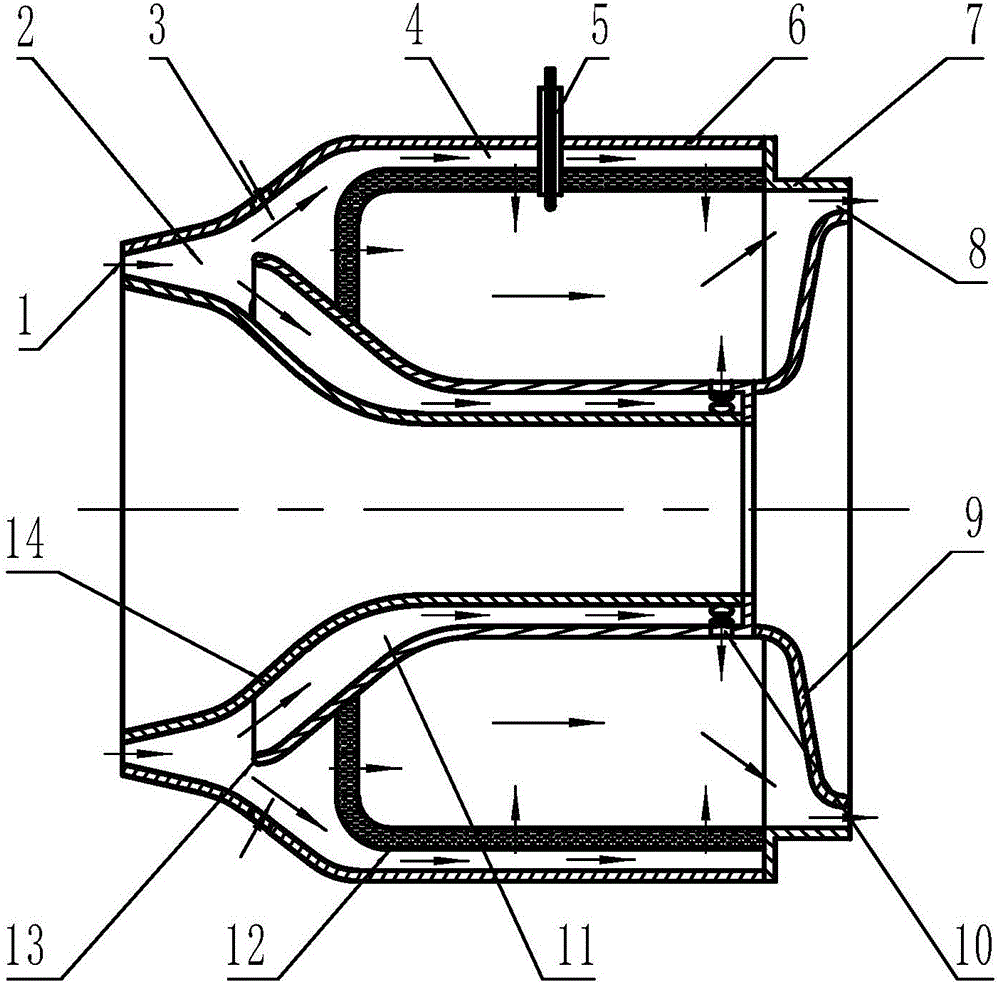

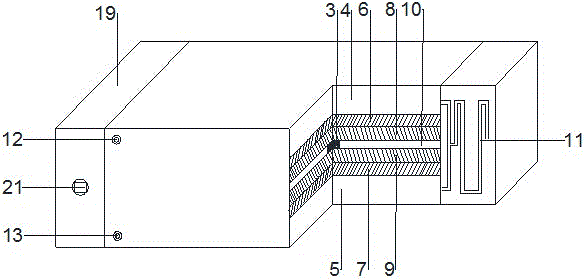

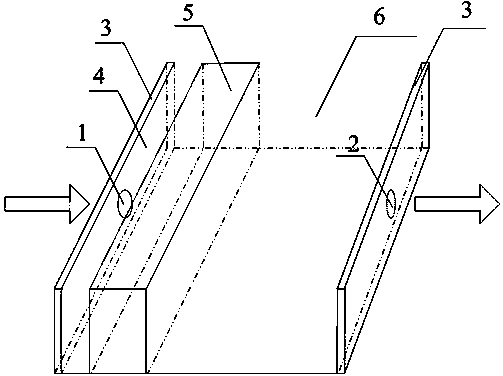

Micro-combustion power system with dual path counter-flow system

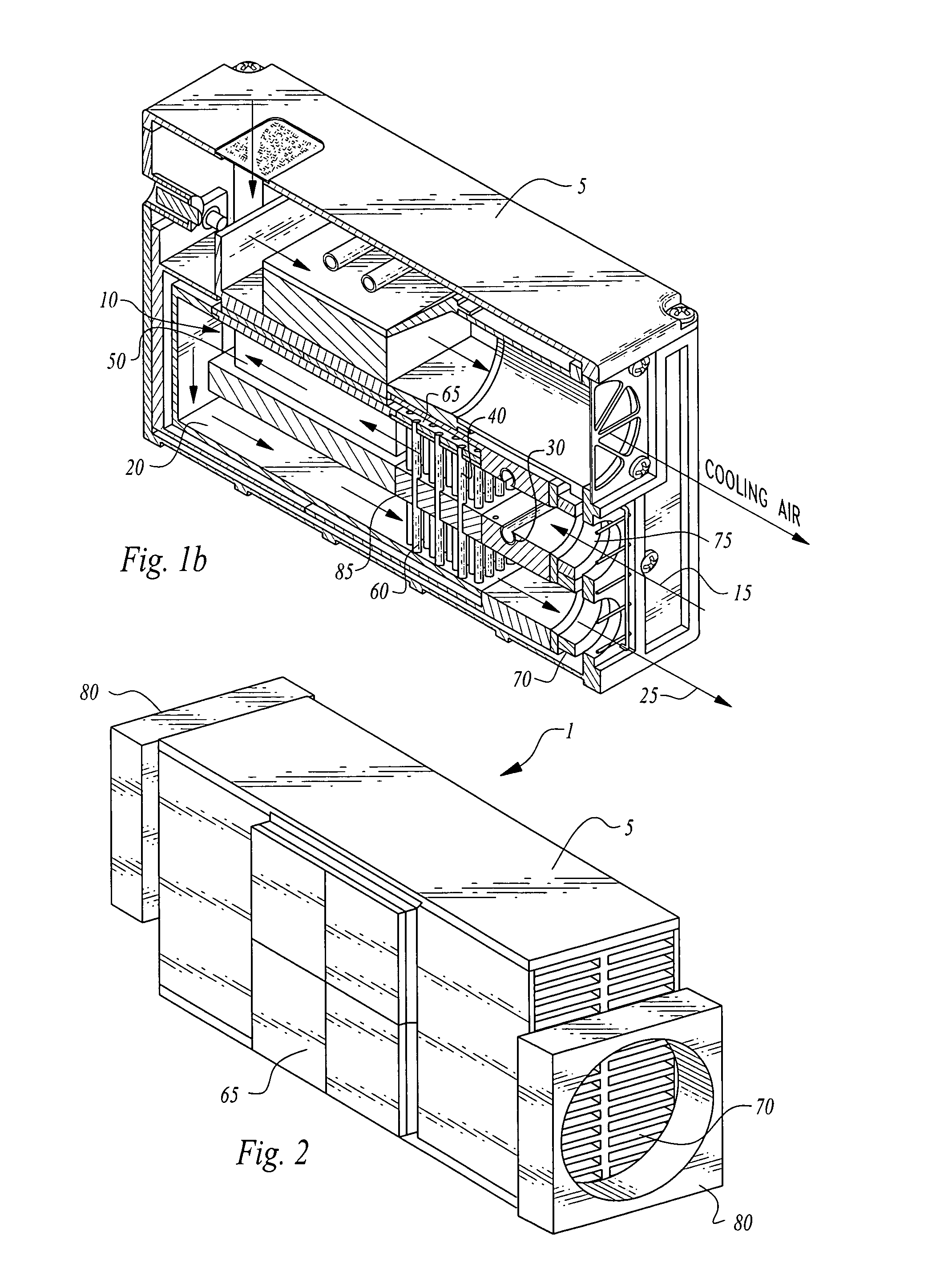

InactiveUS8614392B1Easy to manageThermoelectric device with peltier/seeback effectMachines/enginesThermal energyCounter flow

A micro-combustion power system is disclosed. The invention is comprised of a housing that further comprises two flow path volumes, each having generally opposing flow path directions and each generally having opposing configurations.Each flow path volume comprises a pre-heating volume having at least one pre-heating heat exchange structure. Each flow path volume further comprises a combustion volume having a combustion means or structure such as a catalytic material disposed therein Further, each flow path volume comprise a post-combustion volume having at least one post-combustion heat exchange structure.One or more thermoelectric generator means is in thermal communication with at least one of the combustion volumes whereby thermal energy generated by an air / fuel catalytic reaction in the combustion volume is transferred to the thermoelectric generator to convert same to electrical energy for use by an external circuit.A novel element of the invention relates to the opposing configuration and opposing flow path directions of the respective flow path volumes. The pre-heating heat exchange structure in the first flow path volume and the opposing post-combustion heat exchange structure are comprised of a shared, thermally conductive structure and material. In this embodiment, waste heat from the exhaust gas in the post-combustion chamber is thermally transferred to the opposing pre-heating volume to heat the air / fuel mixture therein to a suitable pre-combustion temperature to take advantage of waste heat while better managing thermal / cooling issues of the device during operation.

Owner:IRVINE SENSORS +1

Single particle fuel micro-combustion, gasification suspension, ignition, imaging and detection system

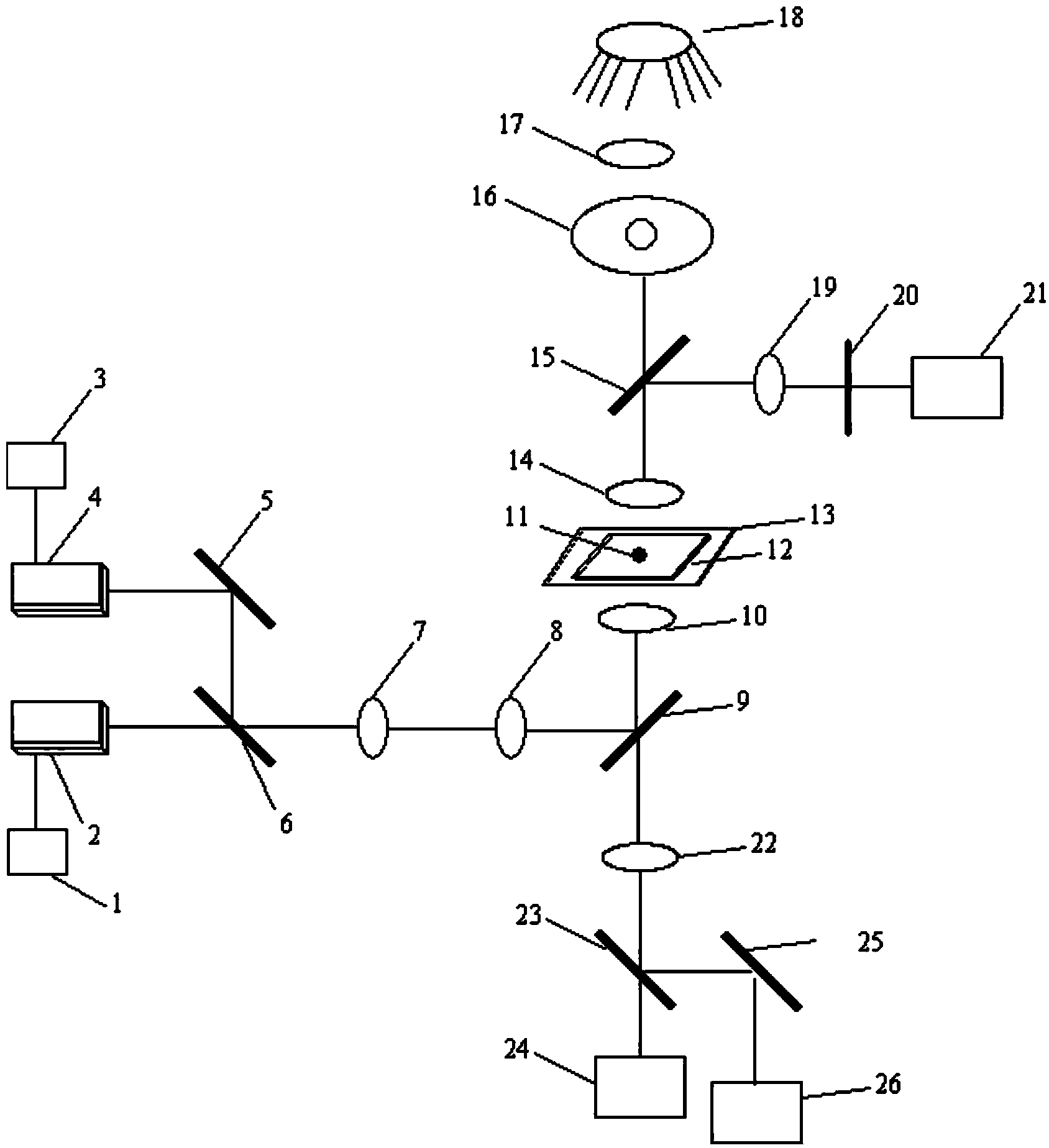

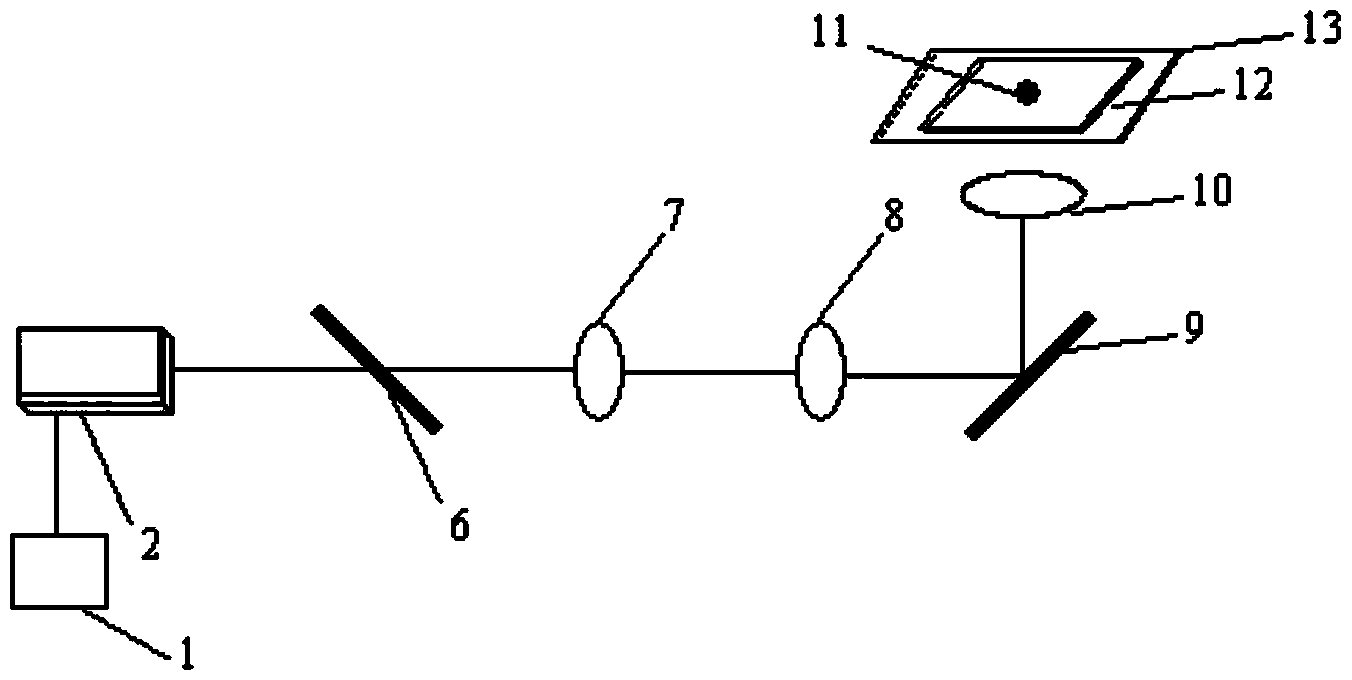

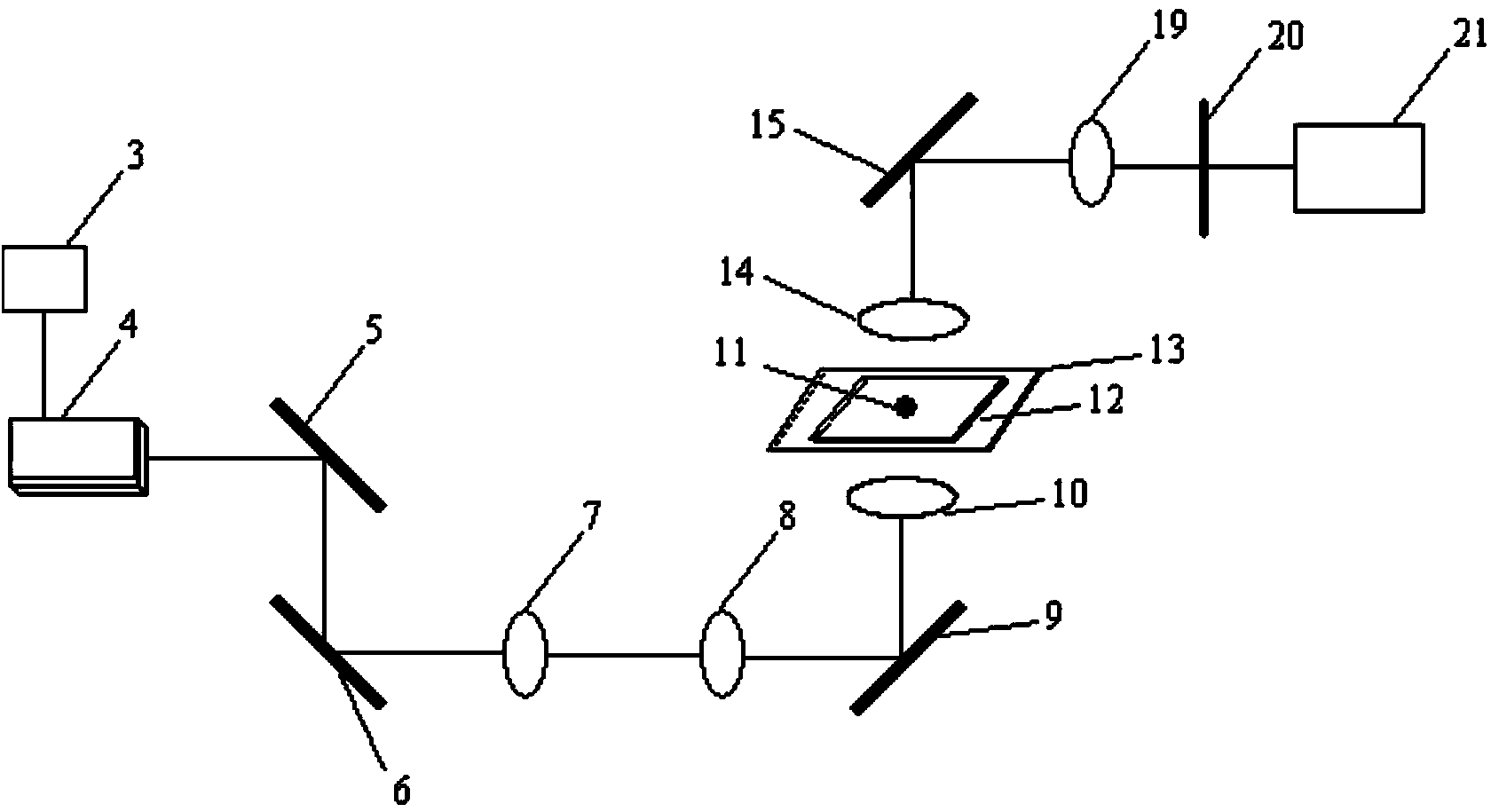

ActiveCN103454185AOvercoming micro burnsOvercoming the Difficulties in the Study of Gasification MechanismRadiation pyrometryParticle size analysisMicroparticleCcd camera

The invention relates to a single particle fuel micro-combustion, gasification suspension, ignition, imaging and detection system. At present, common fuels used for microenergy systems based on micro-combustion are gas fuels which are difficult to store and carry. The system provided by the invention comprises a first laser driver, a first laser, a second laser driver, a second laser, a first reflection lens, a first spectroscope, an inverted telescope, a second spectroscope, a high-power objective lens, microparticle fuels, a micro-combustion chip, a three-dimensional electric displacement platform, a condensing lens, a third spectroscope, an iris diaphragm, a collecting lens, an optical source, a first lens, an optical filter, a four-quadrant detector, a second lens, a third spectroscope, a CCD (Charge Coupled Device) camera, a second reflection lens and an infrared camera. The all-optical particle suspension positioning, igniting and testing method is utilized to test the micro-combustion and the gasification of particles in a non-interference manner, so that the facticity of the micro-combustion and the gasification can be best reflected, the essence of the particles is restored and the mechanism of the particles is effectively revealed.

Owner:HANGZHOU DIANZI UNIV

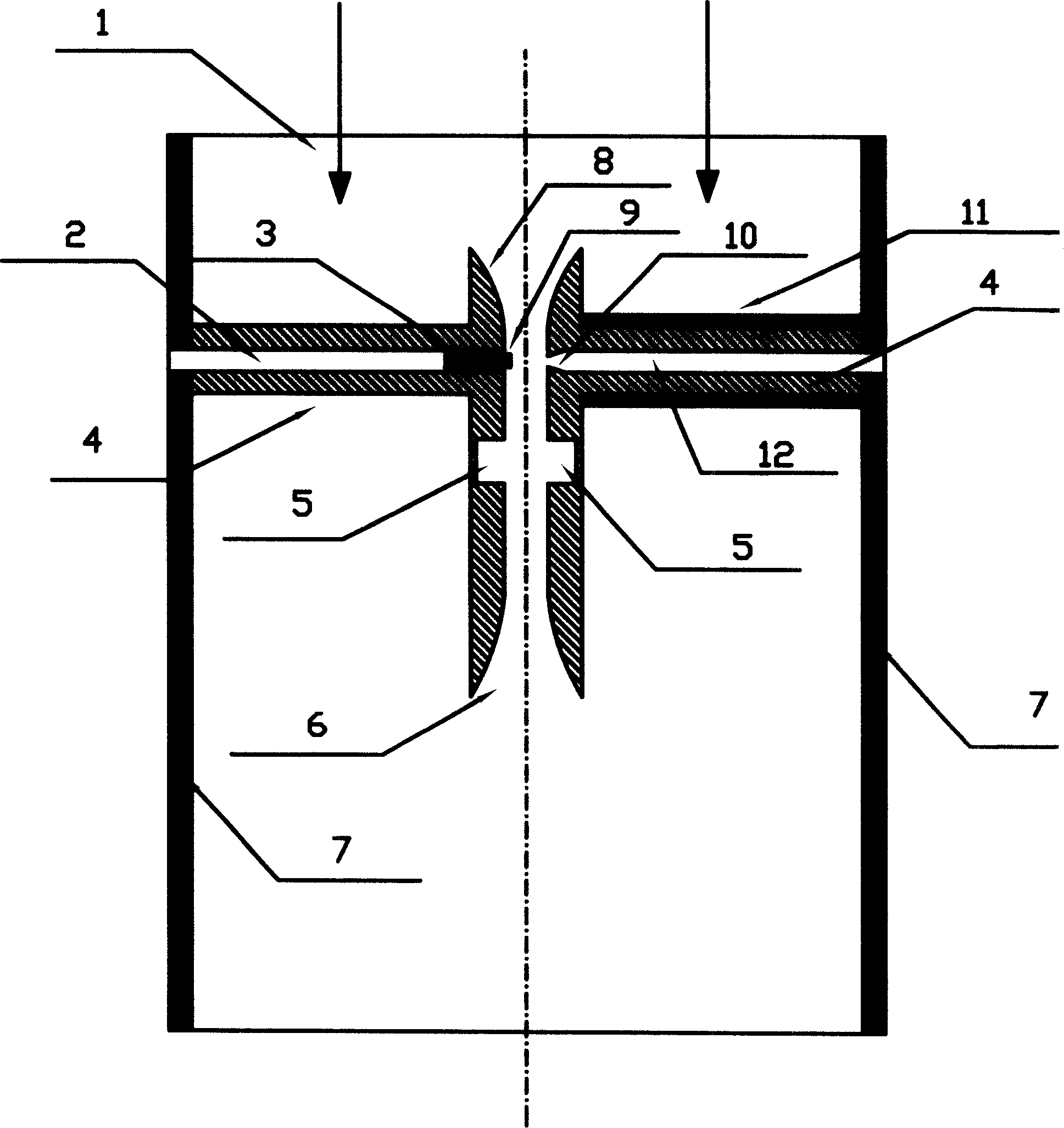

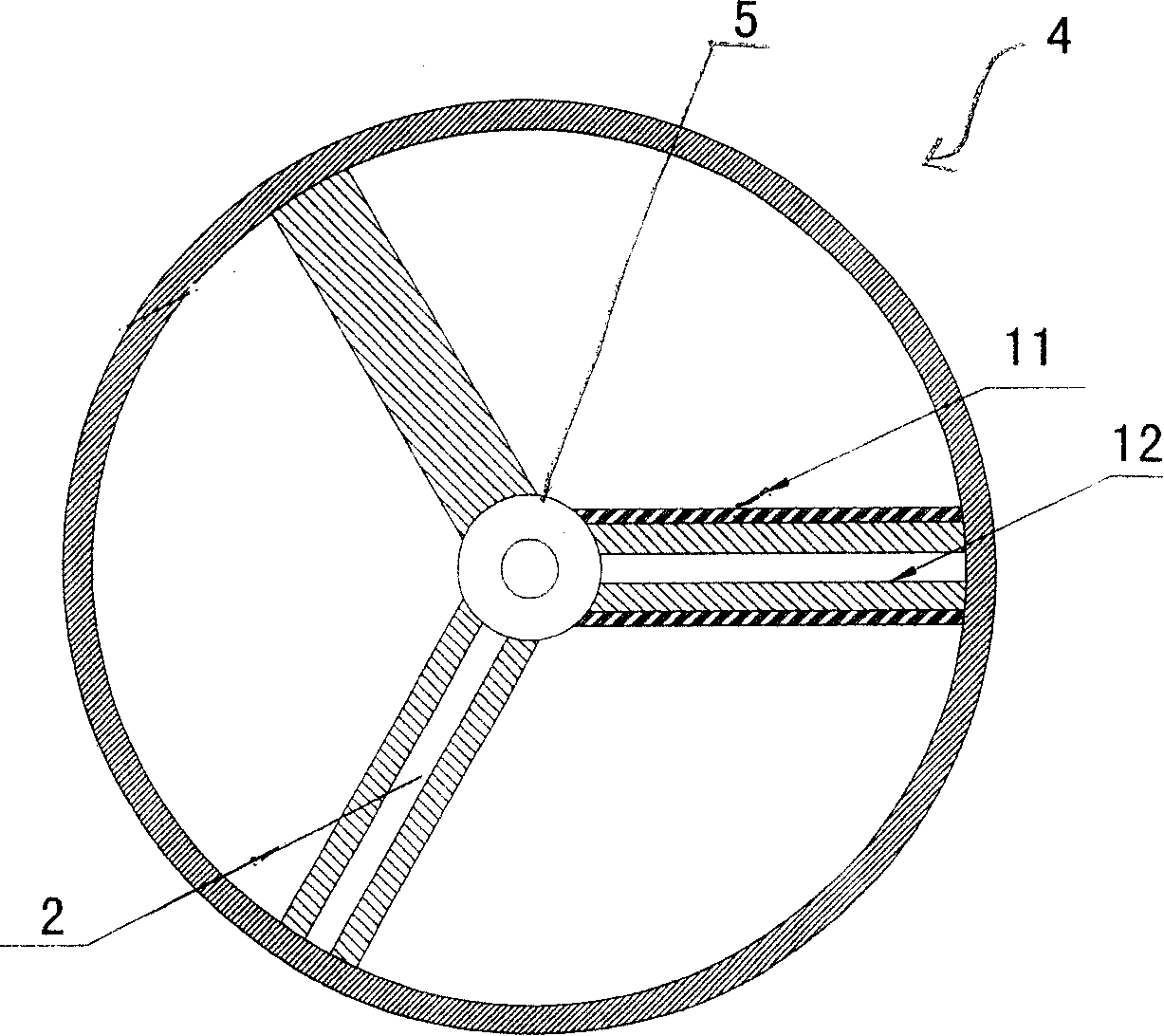

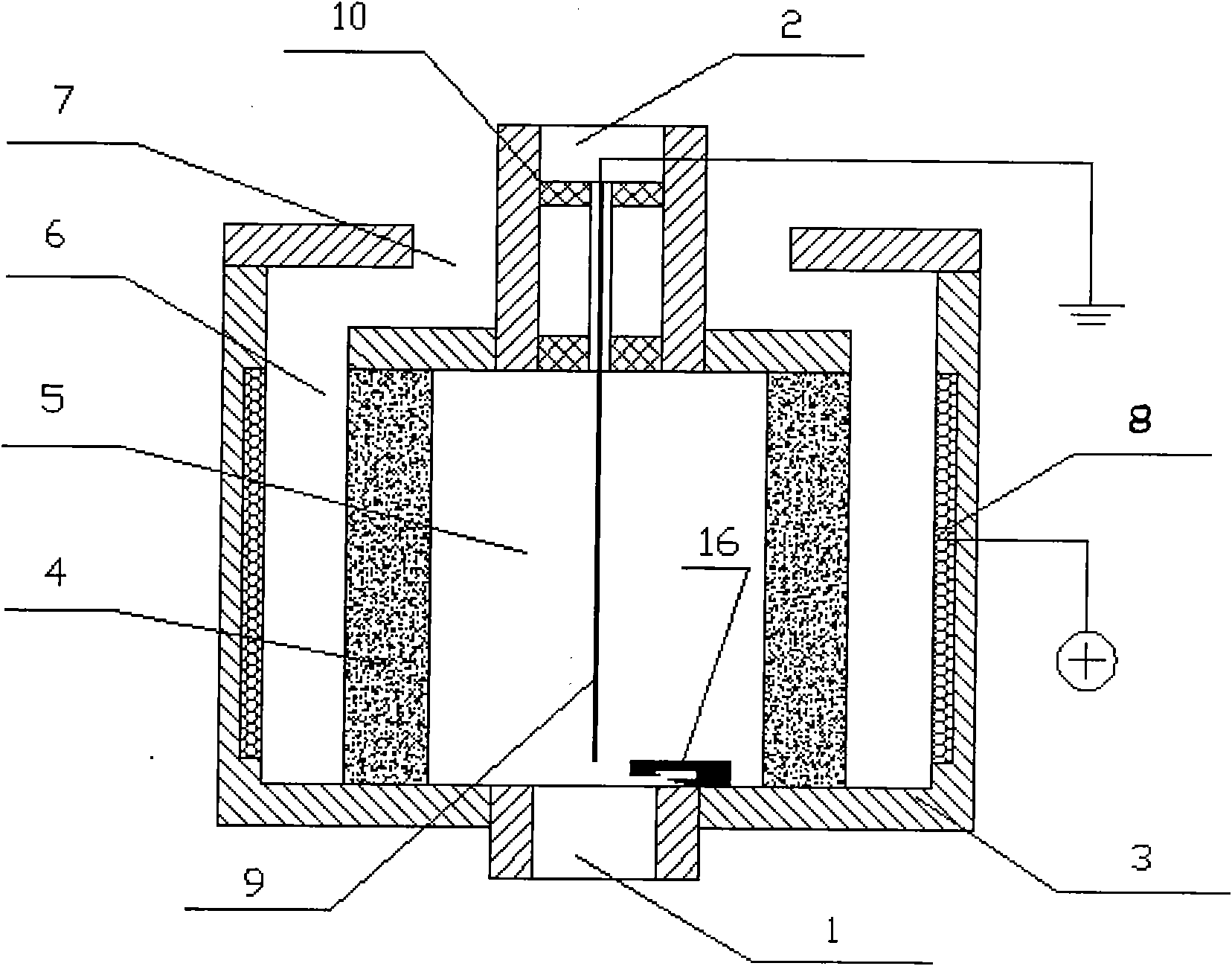

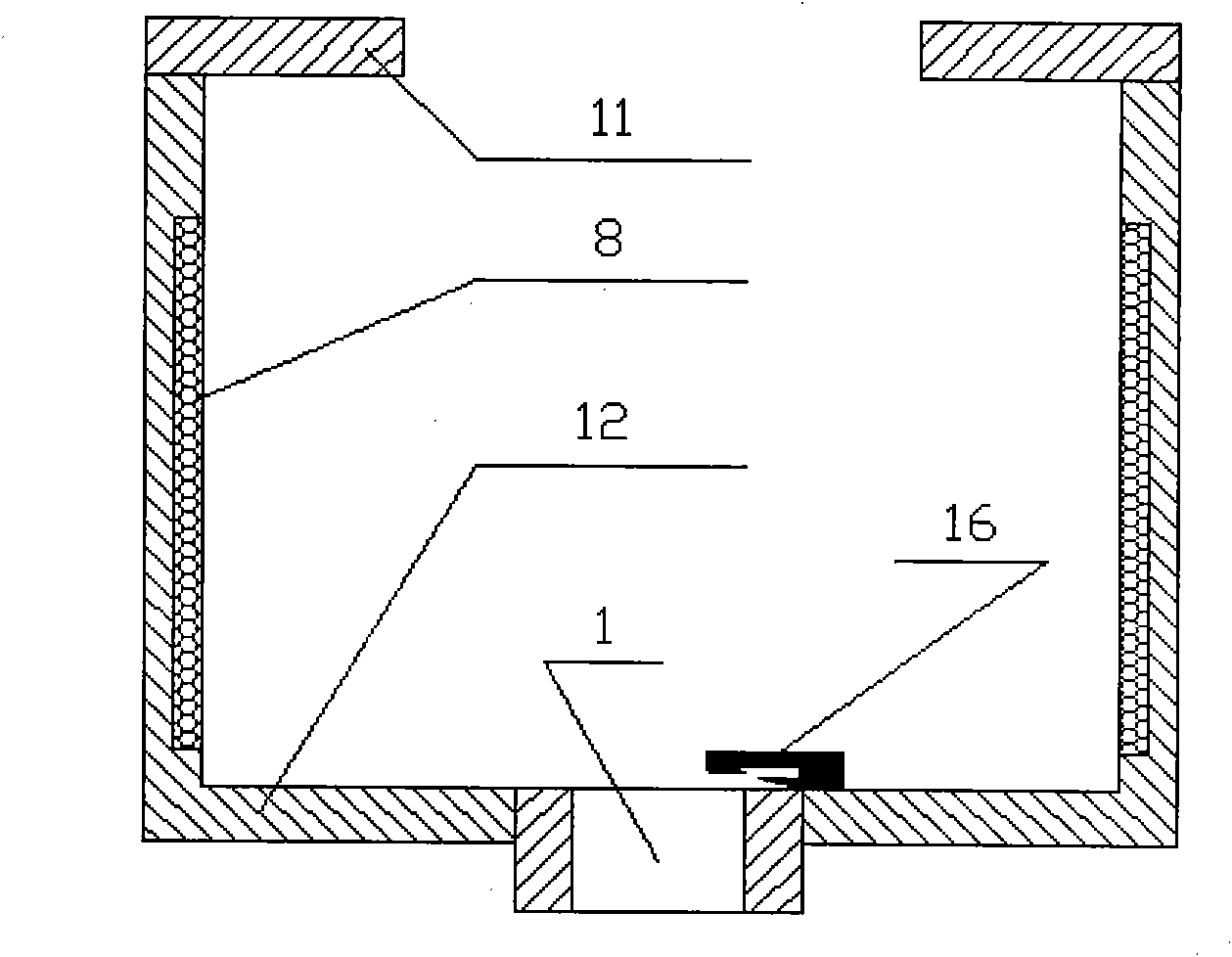

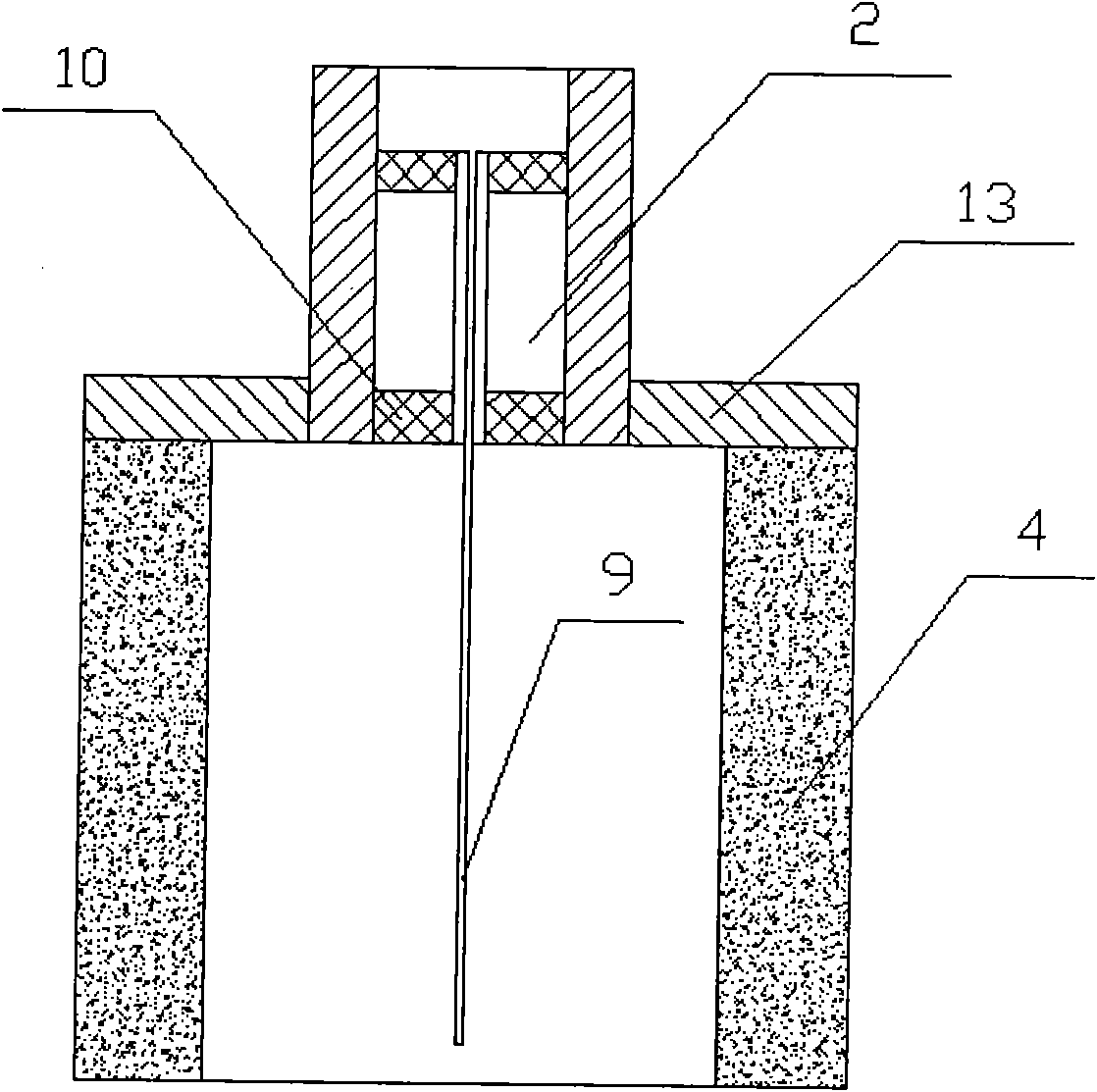

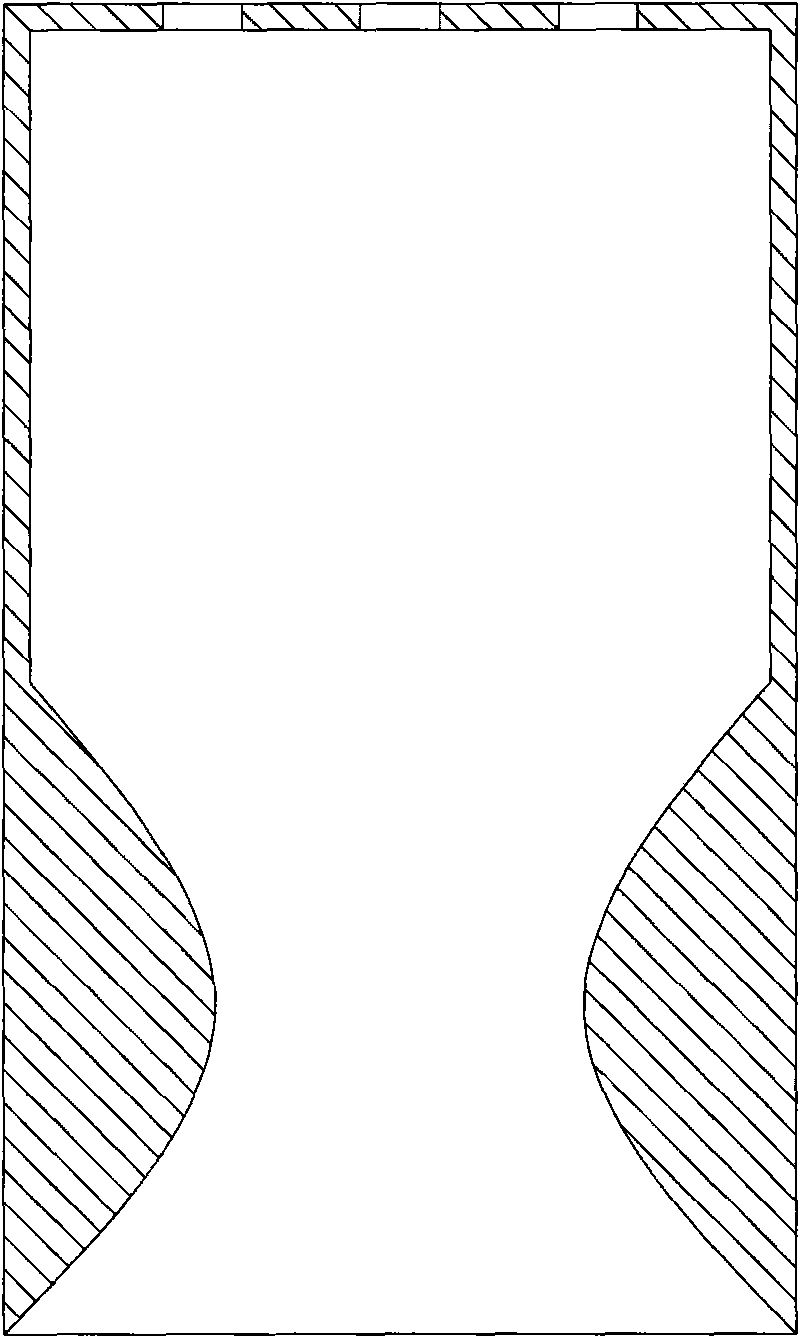

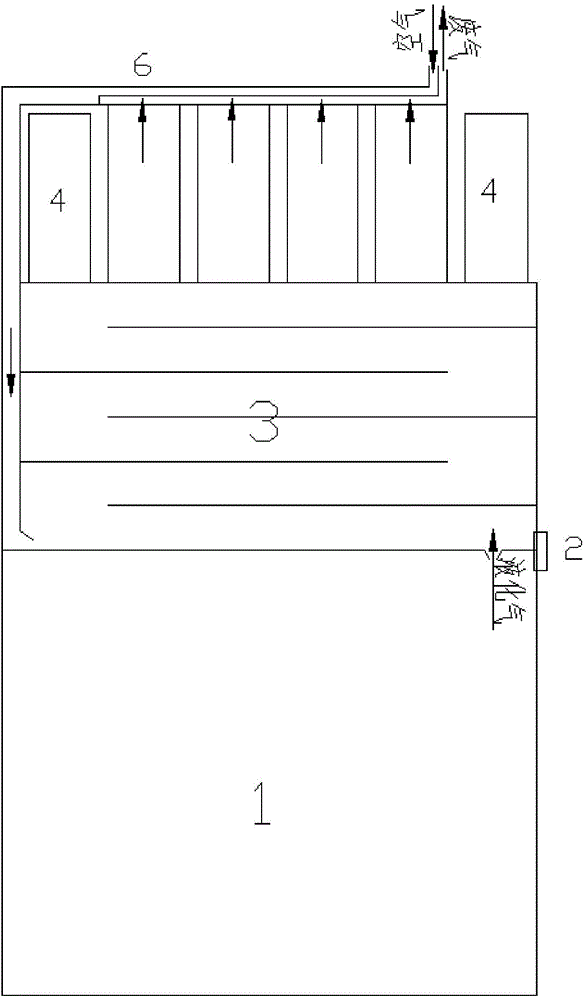

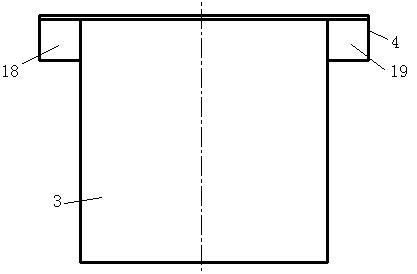

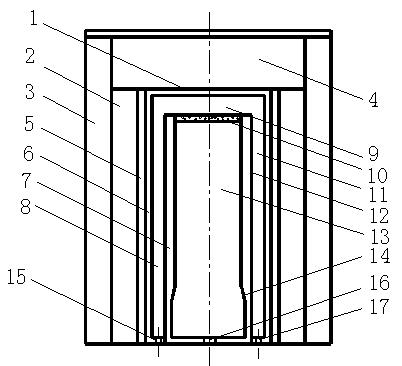

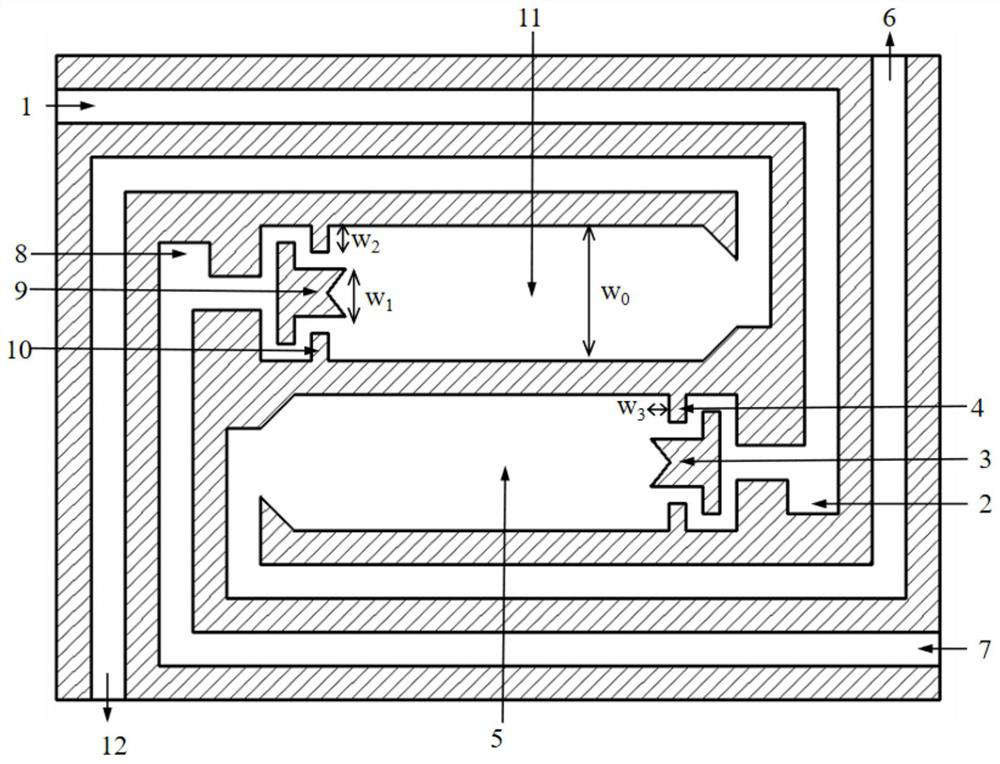

Micro-combustion equipment controlling air flow by using ionic wind

The invention discloses a micro-combustion equipment controlling air flow by using ionic wind, which comprises a fuel inlet (1), an air vent (2), an air inlet (7), an outer sheath wall (3), an inner sheath wall (4), an anode (8), a cathode (9) and an electronic lighter (16), wherein the cathode is a good needle-type high-temperature refractory conductor and the side surface of the inner sheath wall is made from a porous sintered material. A laminated space (6) is formed between the inner sheath wall and the outer sheath wall; the outer sheath wall and the air vent form the air inlet (7); the inner sheath wall is internally provided with a combustion chamber (5); and the anode is embedded or plated on the inner side of the outer sheath wall and the cathode is fixed on the central axial lineof the air vent by a cathode fixing plate (10). By the ionic wind produced by an external electric field, air is forced to flow so as to be in full contact with the fuel in the combustion chamber andensure full combustion; and simultaneously, the structure can effectively reduce heat loss and improve the combustion stability and combustion efficiency.

Owner:SOUTH CHINA UNIV OF TECH

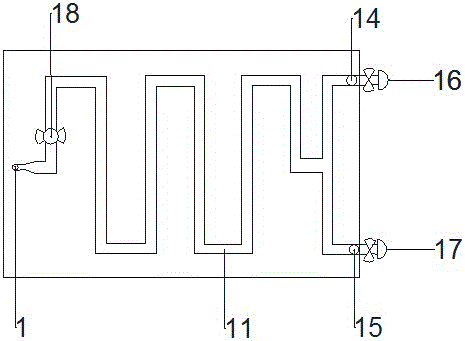

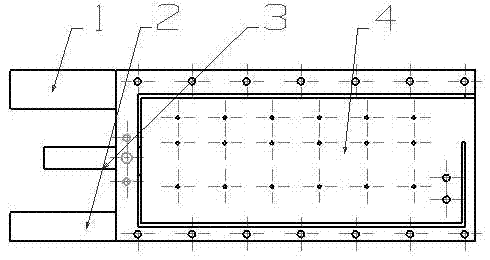

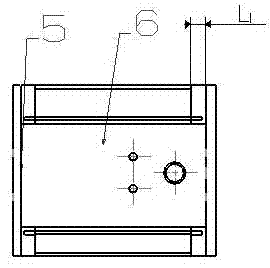

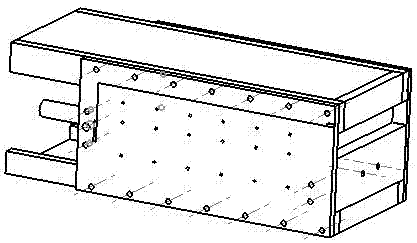

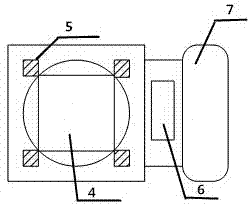

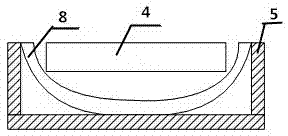

Portable power supply device based on micro-combustion

The invention relates to a portable power supply device based on micro-combustion. The device comprises preheating channels 1 and 2, a mixed chamber 3, a micro-combustor 4 and a thermal photovoltaic power generation module 5 and further comprises a temperature difference power generation module 6, wherein combustion exhaust gas discharged from the micro-combustor 4 impacts the lower end face of the temperature difference power generation module. Compared with the prior art, the device provided by the invention has the advantages that the device combines the advantages of heat energy utilization modes of thermal photovoltaic power generation and temperature difference power generation, and the utilization efficiency of energy resources is greatly improved.

Owner:TIANJIN UNIV

Energy-Efficient Micro-Combustion System for Power Generation and Fuel Processing

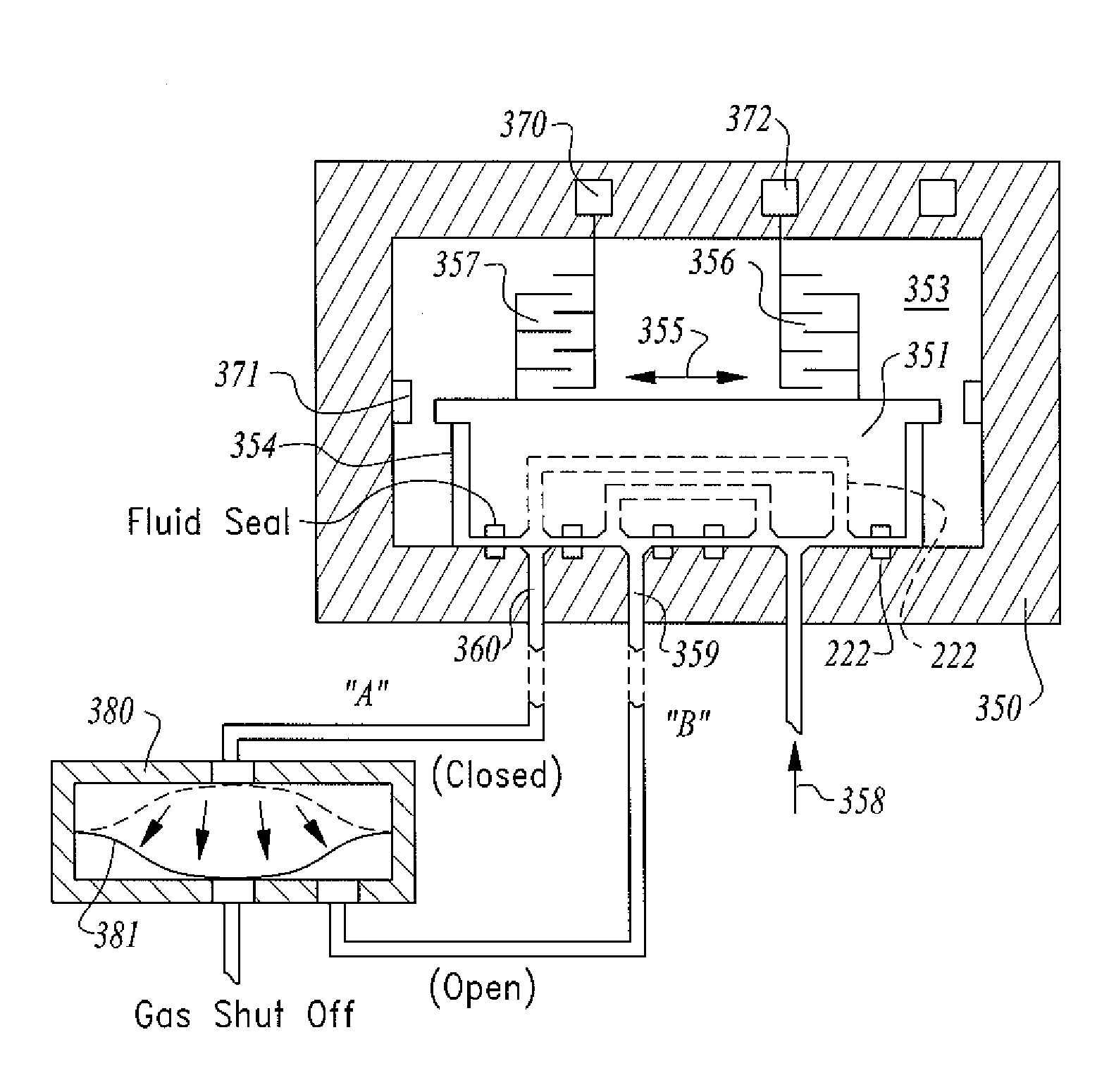

InactiveUS20110083710A1Thermoelectric device with peltier/seeback effectCombustion using catalytic materialThermal energyNuclear engineering

An integrated micro-combustion power generator converts hydrocarbon fuel into electricity. The integrated micro-scale power generator includes a micro-machined combustor adapted to convert hydrocarbon fuel into thermal energy and a micro-machined thermoelectric generator adapted to convert the thermal energy into electrical energy. The combustion reaction in the combustor flows in a path in a first plane while the thermal energy flows in a second plane in the generator; the second plane being nearly orthogonal or orthogonal to the first plane. The fuel handler in the combustor is adjacent and thermally isolated from the thermoelectric generator. The fuel handler may include a nozzle and gas flow switch, where the frequency of activation of the gas flow switch controls the amount of the fuel ejected from the nozzle.

Owner:HSU YING

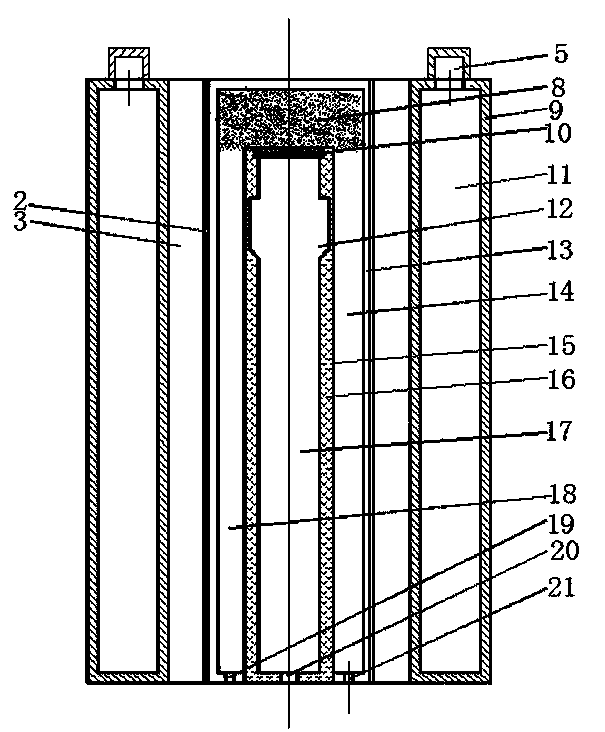

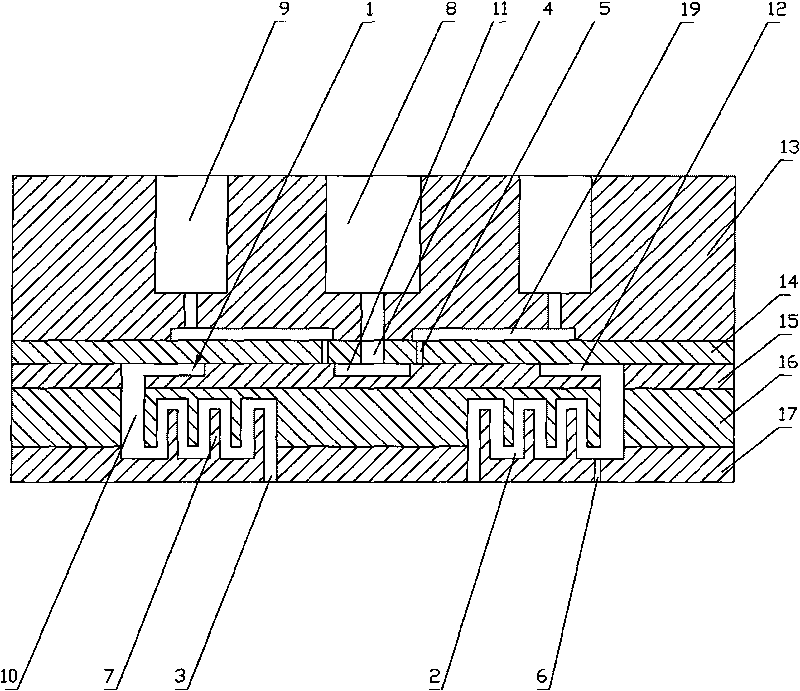

Micro combustion chamber with double-walled structure of combustion gas turbine

ActiveCN106247403AReduce wall temperatureReduce heat lossContinuous combustion chamberCombustion chamberPorous medium

The invention discloses a micro combustion chamber with a double-walled structure of a combustion gas turbine. The micro combustion chamber consists of a combustion chamber outer case, a flame barrel outer ring, a flame barrel inner ring, a combustion chamber inner case and the like. The flame barrel outer ring is made of a porous sintered material; the flame barrel inner ring is made of a high-temperature alloy material; and the inner case and the outer case are made of a stainless steel material. After being subjected to diffusion by a diffusion section, high-pressure air enters the combustion chamber in two streams, wherein one stream flows to an outer ring cavity between the flame barrel outer ring and the combustion chamber outer case, and is fixed with fuels to participate in combustion; and the other stream flows to an inner ring cavity between the flame barrel inner ring and the combustion chamber inner case, flows into the flame barrel through mixing holes, and is mixed with head high-temperature fuel gas. The air is divided into streams, so that a working condition close to a stoichiometric ratio is kept in a combustion area of the flame barrel, and therefore, combustion efficiency is improved, and stable working range of the combustion chamber is improved. A flame stabilization way adopting porous medium plane flames is adopted, so that remarkable effect on reducing wall temperature, strengthening stability of the combustion chamber and improving efficiency of the combustion chamber is achieved.

Owner:BEIHANG UNIV

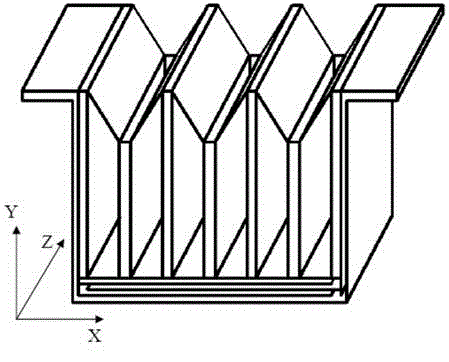

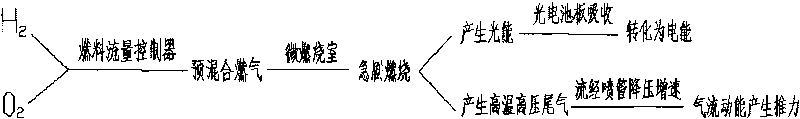

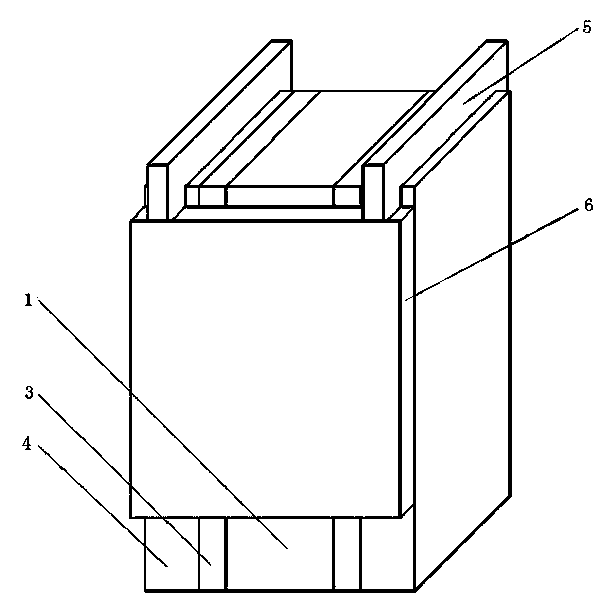

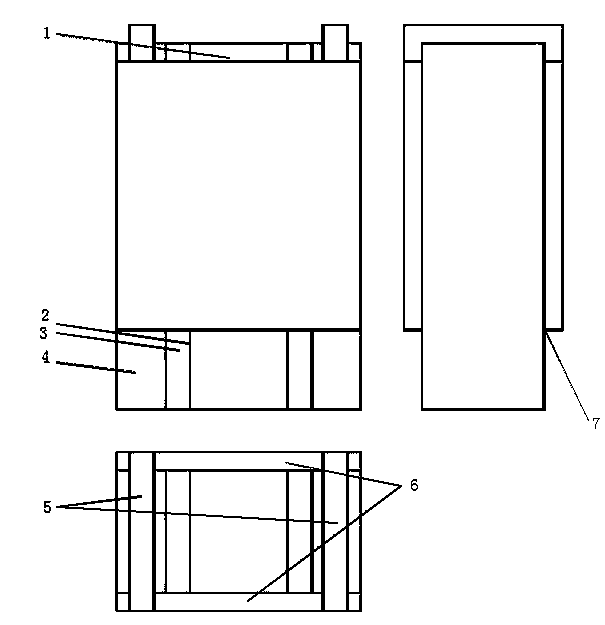

Novel power device for generating electric energy and thrust based on micro-combustion

InactiveCN101691201ATake advantage ofTelevision system detailsImpedence networksCombustion chamberMicro-combustion

The invention relates to a novel micro-combustion based power device for generating electric energy and thrust based on micro-combustion, which belongs to the field of micro-power electromechanical systems. The power device consists of a micro-parallel plate combustion chamber (1), an electric ignition electrode (2), a gas mixer (3), a vacuum transmitting and heat isolation layer (4), a photovoltaic panel (5) and a nozzle (6), wherein the micro-parallel plate combustion chamber (1) is connected with the gas mixer (3) through a guide pipe, the electric ignition electrode (2) is arranged in the micro-parallel plate combustion chamber (1), a fuel inlet on the parallel plate is used for ignition; the lower part of the micro-parallel plate combustion chamber (1) is made into the embedded nozzle (6); two sides of the micro-parallel plate combustion chamber (1) are provided with the vacuum transmitting and heat isolation layers (4), and the outside of the heat isolation layer is provided with a photocell (5). The power device can make full use of energy to generate large power output, simplify structural design of power machine and reduce the discharge of pollutants.

Owner:JIANGSU UNIV

Micro thermal optoelectronic system cooled based on loop heat pipe principle

InactiveCN103595349ANo pollution in the processSimple structurePhotovoltaicsIndirect carbon-dioxide mitigationCombustion chamberMicro-loop heat pipe

The invention discloses a micro thermal optoelectronic system cooled based on a loop heat pipe principle. The micro thermal optoelectronic system cooled based on the loop heat pipe principle is composed of a micro burner, a photoelectric converting system and a photocell cooling system. The photoelectric converting system is located on the two sides of the micro burner and is formed by photocells, and the photocell cooling system is located on the outer side of the photoelectric converting system and is formed by a micro evaporator, a steam pipeline, a micro condenser and liquid pipelines. According to the micro thermal optoelectronic system cooled based on the loop heat pipe principle, foamy copper is arranged between a porous medium top plate on the top of the micro combustion chamber and a glass shade top plate, a cavity structure is formed in the inner side of the vertical wall of the outer shell of the micro combustion chamber, a loop heat pipe system is adopted by the photocell cooling system, the evaporator is divided into a boiling chamber and a liquid suction chamber, a rhombus staggered columnar structure is designed inside the cavity of the condenser, a multiscale surface heat functional structure is adopted on the inner wall surface of the evaporator and the inner wall surface of the condenser, and the thermal performance of the system is improved. Compared with a normal heat pipe, the micro thermal optoelectronic system cooled based on the loop heat pipe principle structurally has the advantages that vapor pipelines and liquid pipelines are separated, and the evaporator and the condenser are integrated.

Owner:JIANGSU UNIV +1

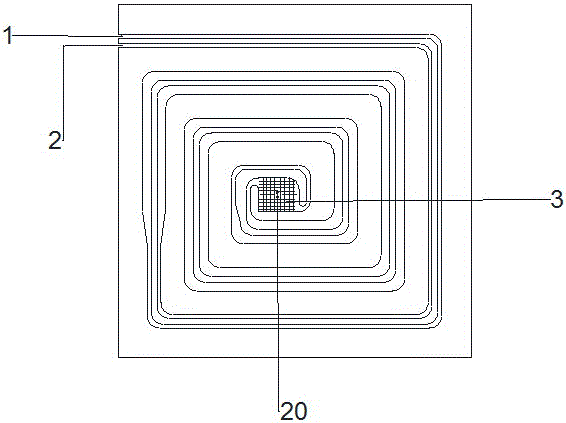

Micro-combustion thermoelectric generator based on porous medium micro-combustion

ActiveCN105827152AReduce volumeFix ignition problemsIndirect carbon-dioxide mitigationGenerators/motorsCombustion chamberPorous medium

The invention discloses a micro-combustion thermoelectric generator based on porous medium micro-combustion. The structure of the micro-combustion thermoelectric generator is displayed in a flake-shape, and is successively formed from top to bottom by a fuel storage layer, an upper thermoelectric generation sheet, an upper thermal insulation layer, a combustion module, a lower thermal insulation layer, a lower thermoelectric generation sheet, and an oxidant storage layer, wherein a combustion chamber is arranged at a hot end of each thermoelectric generation sheet; a gas preheating layer is arranged at a cold end of each thermoelectric generation sheet; the combustion module comprises an inlet channel, an outlet channel and a combustion chamber; the inlet channel is a square double helix parallel structure; the center combustion chamber is filled with porous mediums; and the upper and lower thermal insulation layers are filled by mixture of conduction oil and trace inert gas. The micro-combustion thermoelectric generator based on porous medium micro-combustion has the advantages of being high in energy, being small in volume, being light in weight, having no noise, being continuously stable and being low in discharge, and mainly aims at the mini electronic equipment field, and is suitable for the field and for power supply of mini precision portable equipment of the military and aerospace field.

Owner:HANGZHOU DIANZI UNIV

Miniature premix catalytic reforming combustor

InactiveCN101737780AIncrease catalytic combustion areaExtended burn timeIndirect carbon-dioxide mitigationGaseous fuel burnerCatalytic reformingCombustion chamber

The invention discloses a miniature premix catalytic reforming combustor. A combustor body is provided with air inlets, a premix chamber, a combustion chamber and an air outlet from top to bottom; the air inlets comprise an air inlet and gas inlets uniformly distributed around the air inlet; the air inlet and the gas inlets are respectively communicated with the premix chamber which is communicated with the combustion chamber; the combustion chamber is communicated with the air outlet; the bottom of the combustor body is provided with an ignition hole communicated with the combustion chamber; the top and the bottom of the combustion chamber are respectively provided with annular rib plates which are staggered; and the surfaces of the combustion chamber and the rib plates are coated with a Pt / gamma-Al2O3 catalyst. The inside of the combustion chamber is provided with staggered annular rib plates, the gas combusting time in the combustion chamber is prolonged, and the catalytic combustion area in the combustion chamber is increased; and the micro-space heat exchange is fully utilized to realize cyclic utilization of heat, the radiating loss is reduced, the ignition of fuel is improved, and the combustion stability is improved, so that the micro combustion is more full; therefore, the high-efficiency combustion and low-pollution emission are realized.

Owner:CHONGQING UNIV

Micro-combustion thermal-photovoltaic generating device with regeneration function

InactiveCN104132346ALow priceExtended shelf lifePV power plantsIndirect carbon-dioxide mitigationControl flowMicro-combustion

The invention relates to a micro-combustion thermal-photovoltaic generating device with a regeneration function and aims to provide an electrical power generating system taking a micro-combustor as a heat resource and capable of converting thermal radiation into electric energy. The generating device comprises a shell, a fuel bin, a fuel flow regulator, a mix chamber, igniters, parallel N micro-combustors, thermal photovoltaic panels and a composite two-way airway, wherein the fuel bin is arranged in the shell and used for storing fuel, and the fuel flow regulator is used for controlling flow of the gasified fuel. Compared with the prior art, the micro-combustion thermal-photovoltaic generating device has the advantages that energy density is large by taking liquefied gas as the fuel, and sustainable working time of a system is long; part of waste heat is recycled by the adoption of the composite two-way airway, and thermal efficiency and stability of the system are improved.

Owner:TIANJIN UNIV

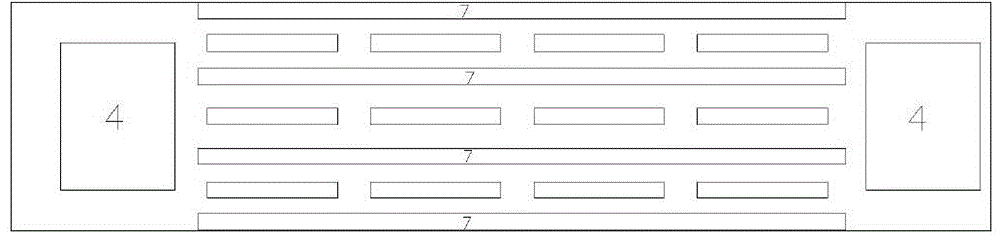

Micro combustion chamber punching type evaporation pipe

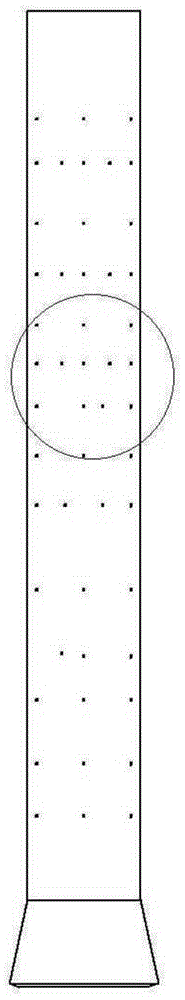

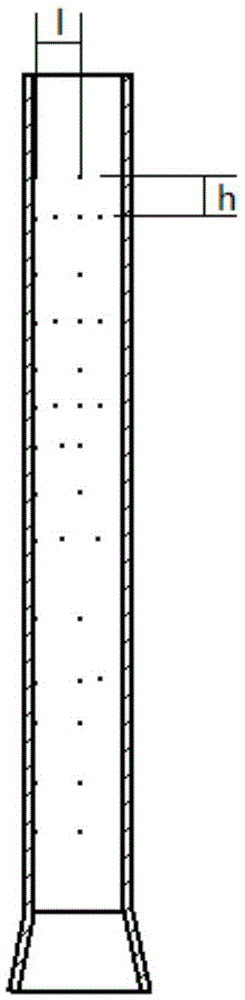

InactiveCN105627365AEnhanced blendingImprove atomization effectContinuous combustion chamberCombustion chamberPunching

The invention provides a micro combustion chamber punching type evaporation pipe. The micro combustion chamber punching type evaporation pipe can effectively improve fuel oil atomization and evaporation effects; through punching in the wall surface, flow perturbation in the micro combustion chamber punching type evaporation pipe is strengthen obviously, mixing of oil and gas is strengthened, and the fuel oil atomization effect is improved. Secondly, the improvement of the atomization effect of fuel oil liquid drop can generate favorable influence on the evaporation effect the fuel oil liquid drop; the particle size of the fuel oil liquid drop is reduced, and an evaporation rate can be increased, so that the evaporation of the fuel oil liquid drop is strengthened. Holes are distributed densely at a place close to an inlet of the micro combustion chamber punching type evaporation pipe, and are distributed sparsely at a place close to an outlet of the micro combustion chamber punching type evaporation pipe, in this way, the atomization and evaporation effects of at the front end of the micro combustion chamber punching type evaporation pipe are ensured, and the collision merging probability of the fuel oil liquid drop at the rear end of the micro combustion chamber punching type evaporation pipe is reduced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

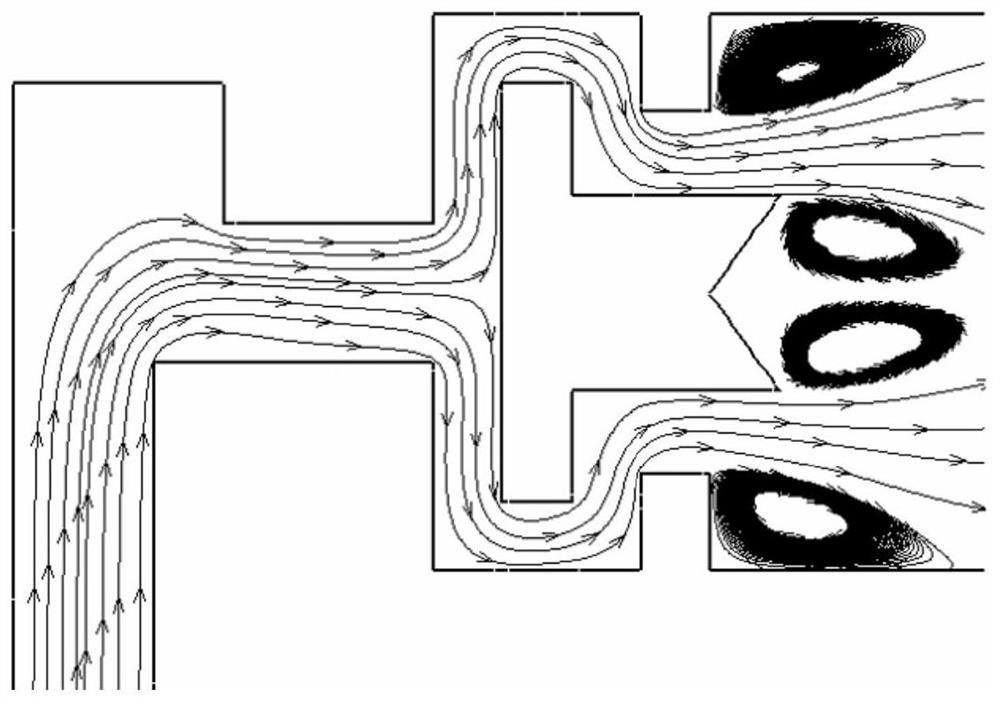

Turbulent micro burner preheated by exhaust gas

InactiveCN103411219ACompact structureShorten the propagation distanceIndirect carbon-dioxide mitigationGaseous fuel burnerCombustion chamberMicro-combustion

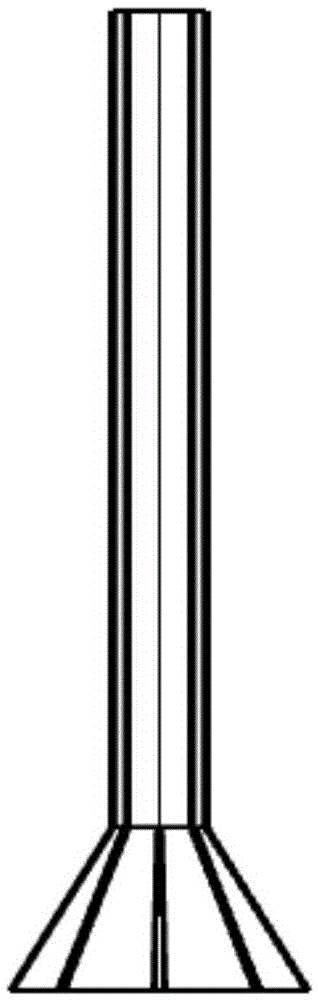

The invention relates to a turbulent micro burner preheated by exhaust gas. The turbulent micro burner comprises a combustion chamber, a gas inlet chamber, an exhaust chamber, a gas inlet pipe and an exhaust pipe, wherein the combustion chamber, the gas inlet chamber and the exhaust chamber are all flat cylinders; the gas inlet pipe and the exhaust pipe are cylinders; the combustion chamber is arranged in the gas inlet chamber; the top of the combustion chamber is communicated with the inner surface of the top of the gas inlet chamber; the combustion chamber is provided with three combustion chamber inlets which are formed in the side surfaces of the combustion chamber respectively; every two adjacent combustion chamber inlets are spaced at an interval of one third of an arc; an included angle formed between an axis of each combustion chamber inlet and a round edge tangent line of the combustion chamber is 30 degrees; a combustion chamber exhaust port is formed in the center of a top section of the combustion chamber and is round, and a circle center of the combustion chamber exhaust port is located in an axis of the combustion chamber; the gas inlet pipe is arranged in a center of the lower surface of the gas inlet chamber, and a section area is equal to that of the combustion chamber exhaust port; the gas inlet chamber is arranged in the exhaust chamber; the gas inlet chamber and the exhaust chamber are connected through fixing supporting columns; the exhaust pipe is arranged in the center of the lower surface of the exhaust chamber, and the section area is larger than that of the gas inlet pipe; and a layer of a heat insulation material is arranged on the outer layer of the exhaust chamber and the outer layer of the exhaust pipe.

Owner:JIANGSU UNIV

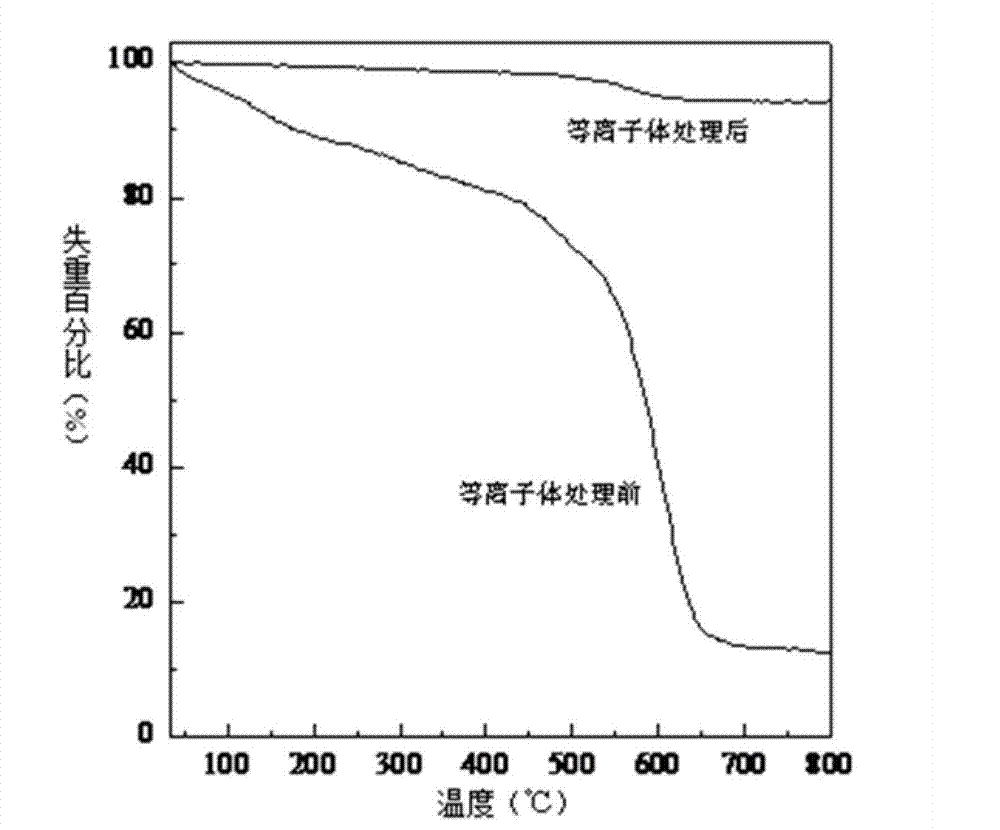

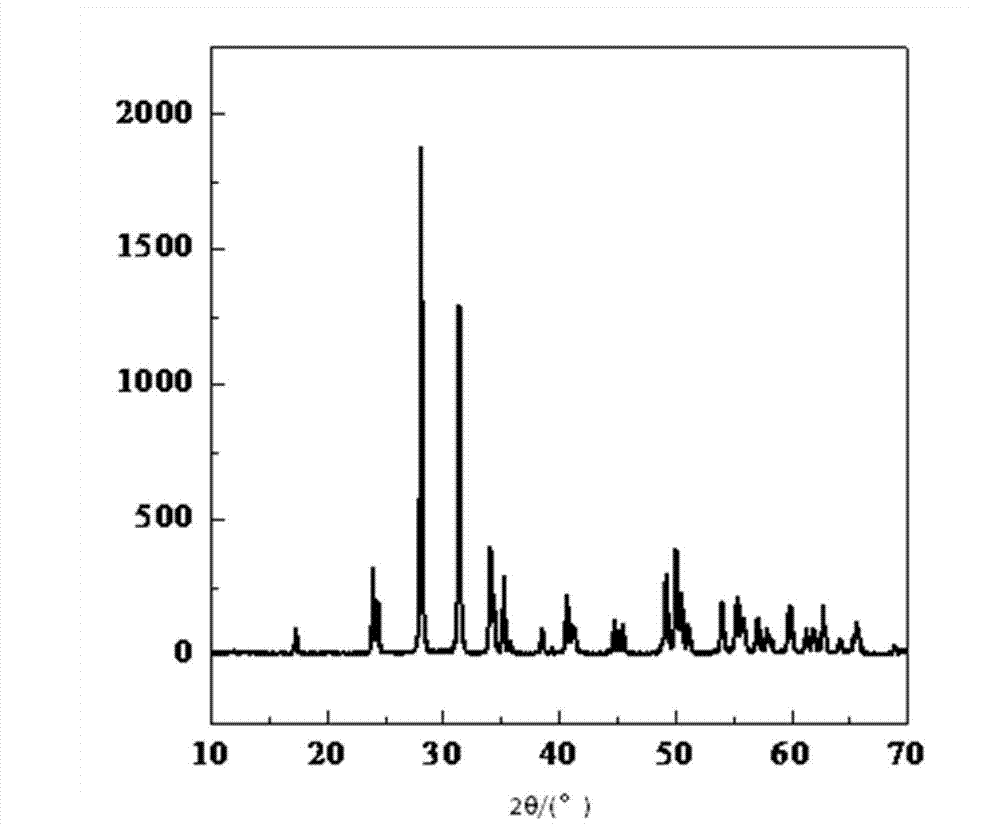

Method for preparing porous metal oxide by cold plasma-induced combustion

InactiveCN103170293AEasy to prepareSave energyEnergy based chemical/physical/physico-chemical processesOxygenHigh pressure

The invention relates to a method for preparing a porous metal oxide by using cold plasma-induced micro-combustion. The method comprises the following steps of: mixing a metal salt or metal oxide with a carbon framework material or soaking the metal salt or metal oxide into the carbon framework material, and putting the mixture loaded with metal ions into a plasma reaction chamber; introducing air or oxygen or oxygen-containing gas mixture into the reaction cavity; and applying 6000-20000V alternating current to two ends of an electrode by using a high-voltage power supply under the atmospheric pressure, and enabling the gas to discharge by using 0.3-2.0A of current to form plasma-induced carbon-containing substance micro-combustion, wherein the micro-combustion time is 8-60 minutes. The cold plasma-induced micro-combustion technology is used for inducing micro-combustion by using particles, such as electrons, excited atoms or molecules, ions and free radicals generated by a plasma device to be reacted with the carbon-containing substances, and preparing the porous metal oxide by sufficiently utilizing the micro-combustion.

Owner:TIANJIN UNIV

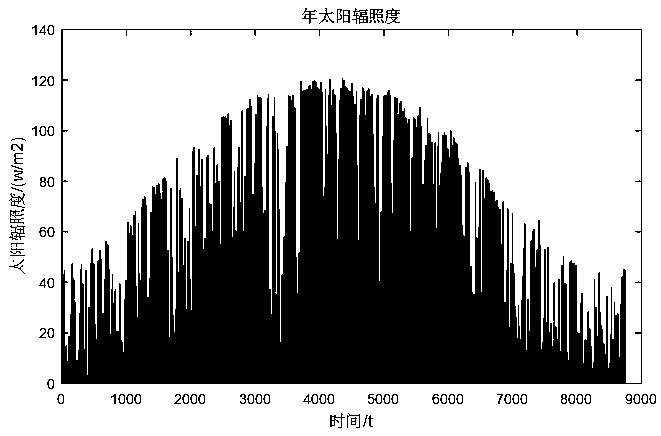

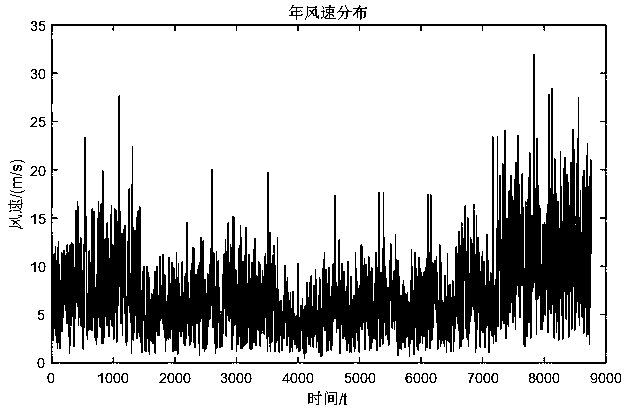

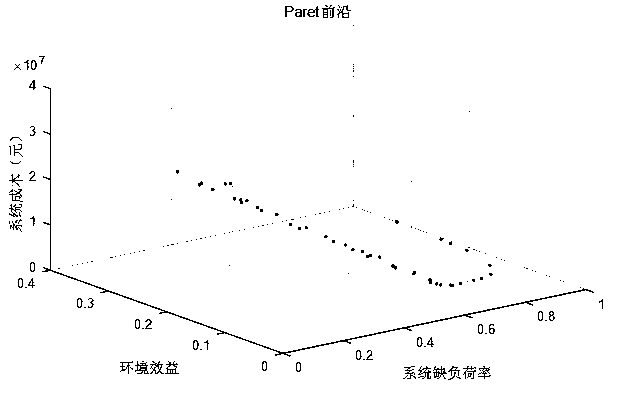

Chaos partial searching-based direct current distribution network power supply energy storage dual-layer planning method

InactiveCN107846007AImplement capacity provisioningDc network circuit arrangementsData processing applicationsMicro gas turbineEngineering

The invention discloses a chaos partial searching-based direct current distribution network power supply energy storage dual-layer planning method. The method comprises the steps of S1, taking distributed power supply capacity as an independent variable and establishing a first layer of multi-target optimization model; S2, specific to the first layer of multi-target optimization model, solving themodel by chaos partial searching-based NSGA-2 to obtain a Pareto result of photovoltaic, wind generator and micro combustion gas turbine; S3, by taking system shortage load rate as a target function,and by taking energy storage capacity as an independent variable, establishing a second layer of optimization model; and S4, solving the second layer of model by a chaos partial searching-based Cuckoo algorithm to obtain an energy storage configuration scheme. By virtue of the dual-layer planning method, the distributed type power supply and energy storage capacity configuration of the complex direct current power distribution network can be realized, so that theoretical foundation is provided for development of the direct current distribution network in the future.

Owner:SOUTHEAST UNIV +1

Micro-combustion chamber heat engine

A combustion engine is provided having a rotating drive shaft and planetary gear sets that are linked to a rotating chamber, keyed to the drive shaft, to turbomachinery within the chamber. Fluid is fed to the chamber through an axial passage in the drive shaft and is compressed by a number of mechanisms, including set of pump blades, turbine and reaction blades initially driven by the drive shaft and its starter motor. Bubbles within the fluid are subjected to high pressures causing combustion to occur within the bubbles. Additional pressure created by the combustion of the bubbles drives the fluid to exert a net torque on the drive shaft through the gearing mechanism, thereby generating power.

Owner:RAY JAMES T

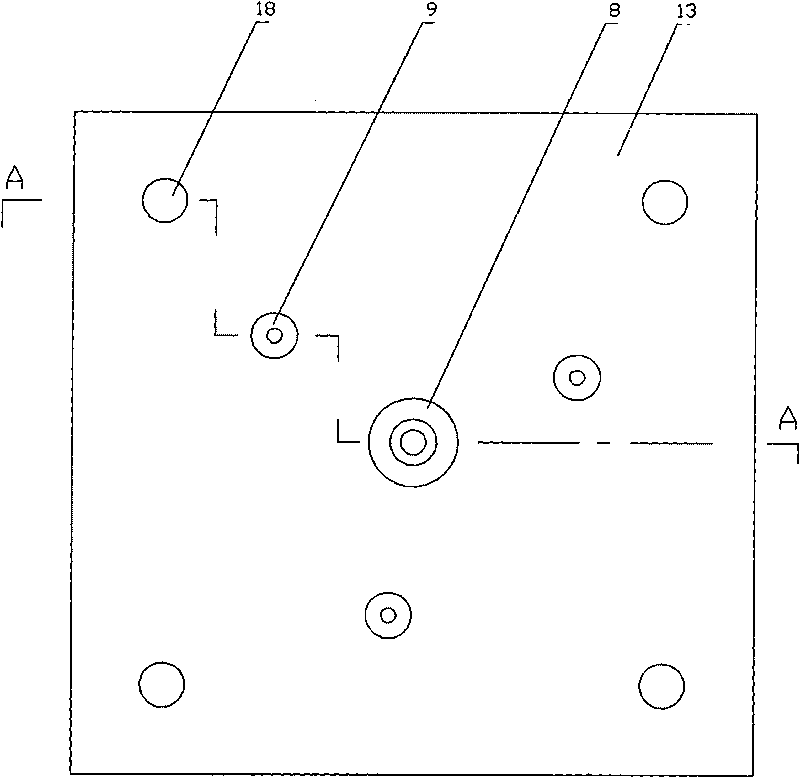

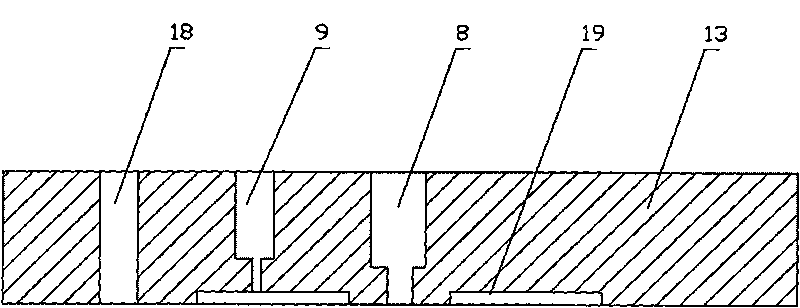

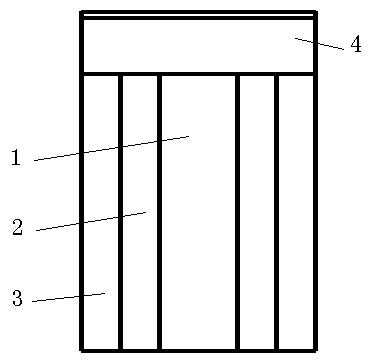

Micro-space combustion test measuring table based on modular design

InactiveCN102507191AImprove general performanceEasy to adjustEngine testingCombustion chamberJet flow

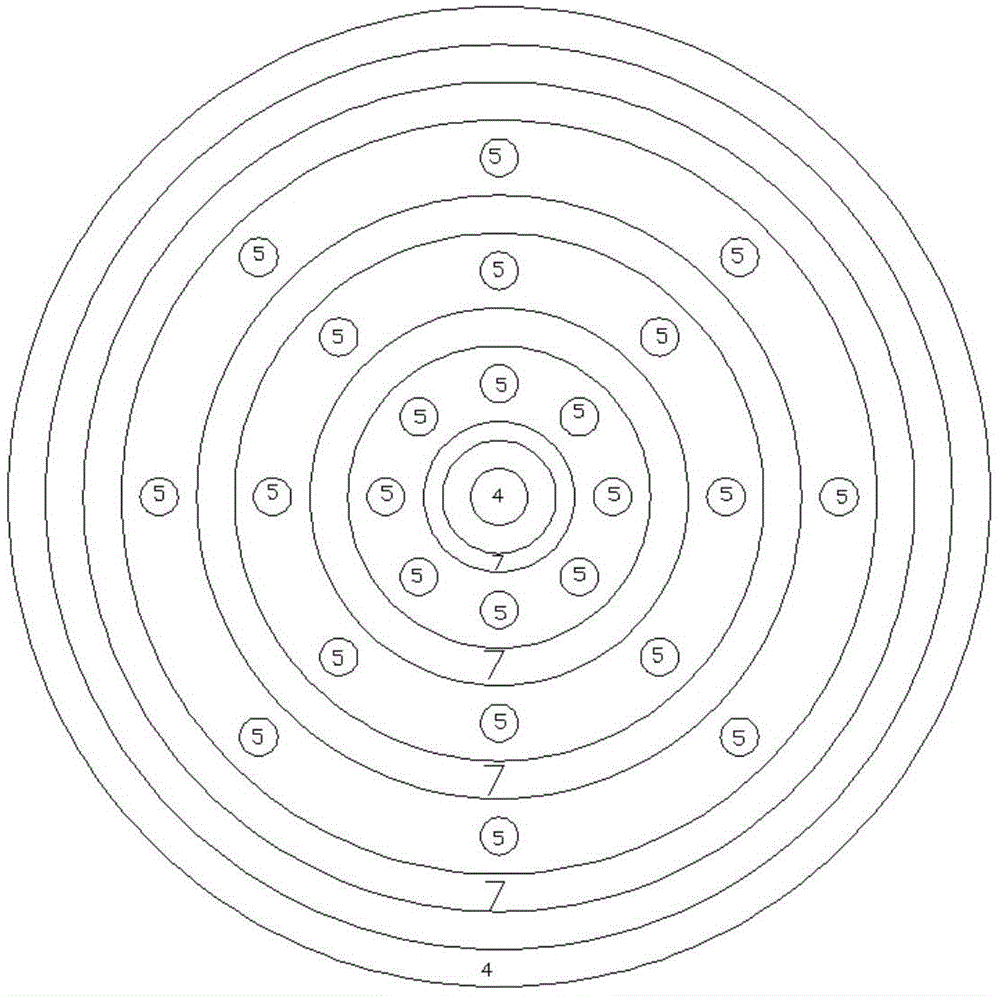

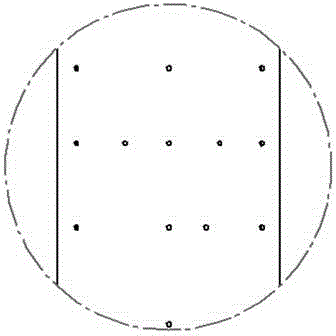

The invention provides a micro-space combustion test measuring table based on a modular design. The micro-space combustion test measuring table based on the modular design is characterized by comprising four mutually independent substance transport passage modules, wherein three of the mutually independent substance transport passageway modules are air supply passage modules and one of the mutually independent substance transport passageway modules is a fuel passage module; the three air supply passage modules respectively are upper and lower air supply passage modules designed at the upper and lower parts of the combustion test measuring table, and an air supply passage module which directly enters into an evaporating pipe; the one fuel passage module ensures that fuels enter into the evaporating pipe through a fuel passage; and partition parts at two sides of the combustion test measuring table respectively adopt high-temperature resistant glass or adopt optical glass and metal plates with measuring holes at low temperature. The measuring table provided by the invention has the advantages of carrying out corresponding adjustment along with a complete micro combustion chamber geometric structure and a pneumatic layout and being favorable for measuring internal flow field parameters of combustion chambers by virtue of most of existing measuring means. The measuring table provided by the invention is applicable to jet flow related basic theory research, performance detection of micro combustion chambers with diameter of 60mm-200mm or design verification of the primary internal flow field of the combustion chambers.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

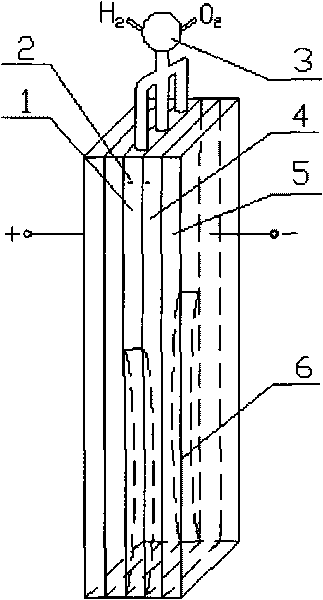

Micro-thermal photovoltaic system for cooling based on heat pipe principle

InactiveCN102638198AReduce flameout distanceIncrease enthalpyPhotovoltaicsIndirect heat exchangersThermodynamicsThermal break

The invention discloses a micro-thermal photovoltaic system for cooling based on a heat pipe principle. A micro burner comprises a glass shielding cover and a micro burning chamber arranged in an inner cavity of the glass shielding cover; gaps are reversed among two sides and the tops of the glass shielding cover and the micro burning chamber; a top board of a shell of the micro burning chamber is a porous medium panel; the inner side wall of the shell of the micro burning chamber at the position of a bottom board of the shell of the micro burning chamber is thinned to form a sudden expansion structure; a glass insulating layer is tightly connected with one side of a photo cell, and the other side of the photo cell is in seamless connection with a panel heat pipe; a hydrogen inlet and an oxygen inlet which are communicated with the gap between the glass shielding cover and the micro burning chamber are formed on a bottom board of the glass shielding cover; an air cooling system is arranged above the micro burning chamber; the bottom surface of a cooling channel is formed by combining the glass shielding layer, the glass insulating layer and the top surface of the photo cell; and the left side surface and the right side surface of the cooling channel are the internal side surface of the panel heat pipe. Therefore, the burning reaction speed and the burning efficiency can be improved, the uniform temperature field distribution is obtained, and the heat loss of the burner is reduced.

Owner:JIANGSU UNIV

Novel portable gas stove based on Swiss roll structure micro-combustor

InactiveCN104728871AIncrease energy densityExtended energy supply timeDomestic stoves or rangesLighting and heating apparatusCombustion chamberMicro-combustion

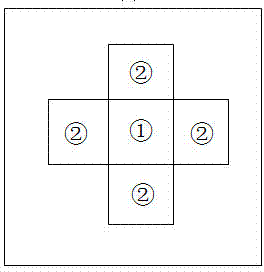

The invention belongs to the field of advanced combustion techniques, and particularly relates to a novel portable gas stove based on a Swiss roll structure micro-combustor. According to the portable gas stove, an ordinary portable gas stove is improved and designed on the basis of the micro-combustion principle; the portable gas stove comprises a combustion chamber, a bracket and a fuel storage bottle, wherein a fuel pipeline is used for controlling an electronic valve; square rotary micro-combustors or round rotary micro-combustors are distributed in the combustion chamber in a matrix; and the micro-combustors are designed into rotary channels with rectangular sections, so that convection heat transfer is increased; reactants are preheated; the overall combustion chamber is relatively small in temperature difference; combustion is full; the quenching phenomenon of the micro-combustion chamber is prevented; by virtue of a rotating parabolic heat mirror arranged between the bracket and the combustion chamber, the heat loss on the lower part of the combustion chamber can be reduced; and the bottom of the upper pot is relatively efficiently heated. The novel portable gas stove provided by the invention is high in energy density, long in function time and small in heat loss; energy resources can be saved; and emission can be effectively reduced.

Owner:JIANGSU UNIV

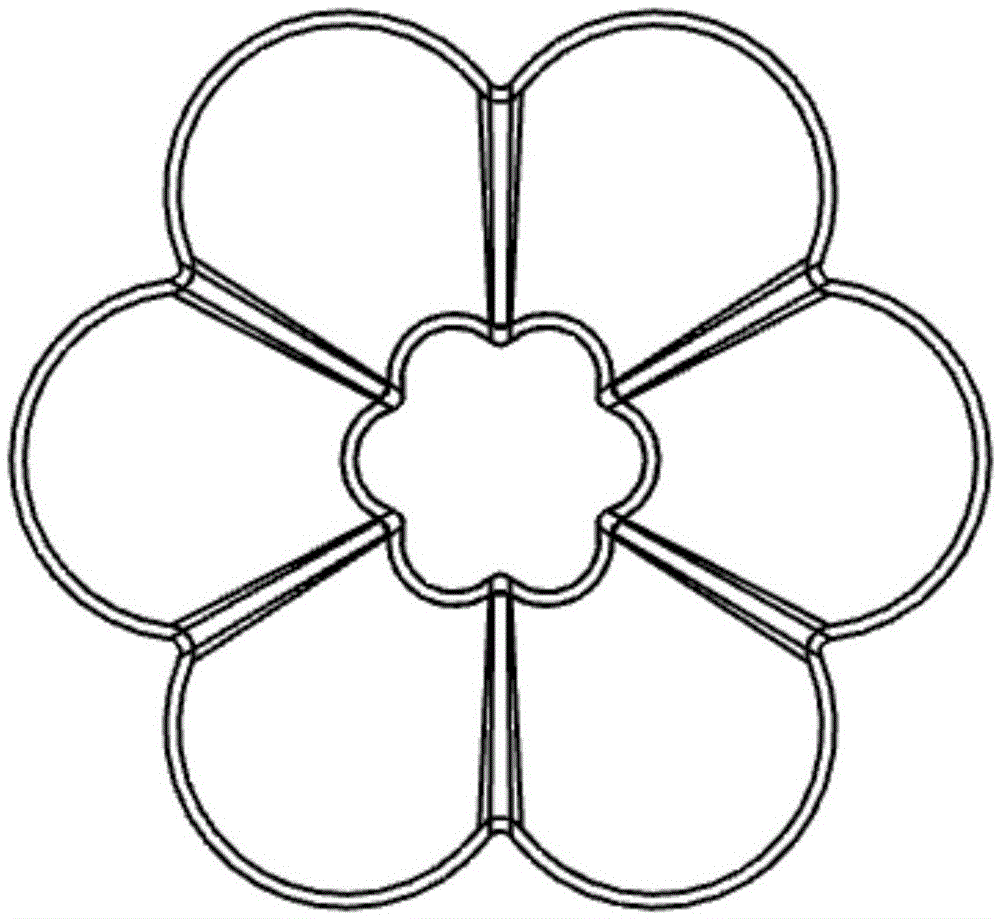

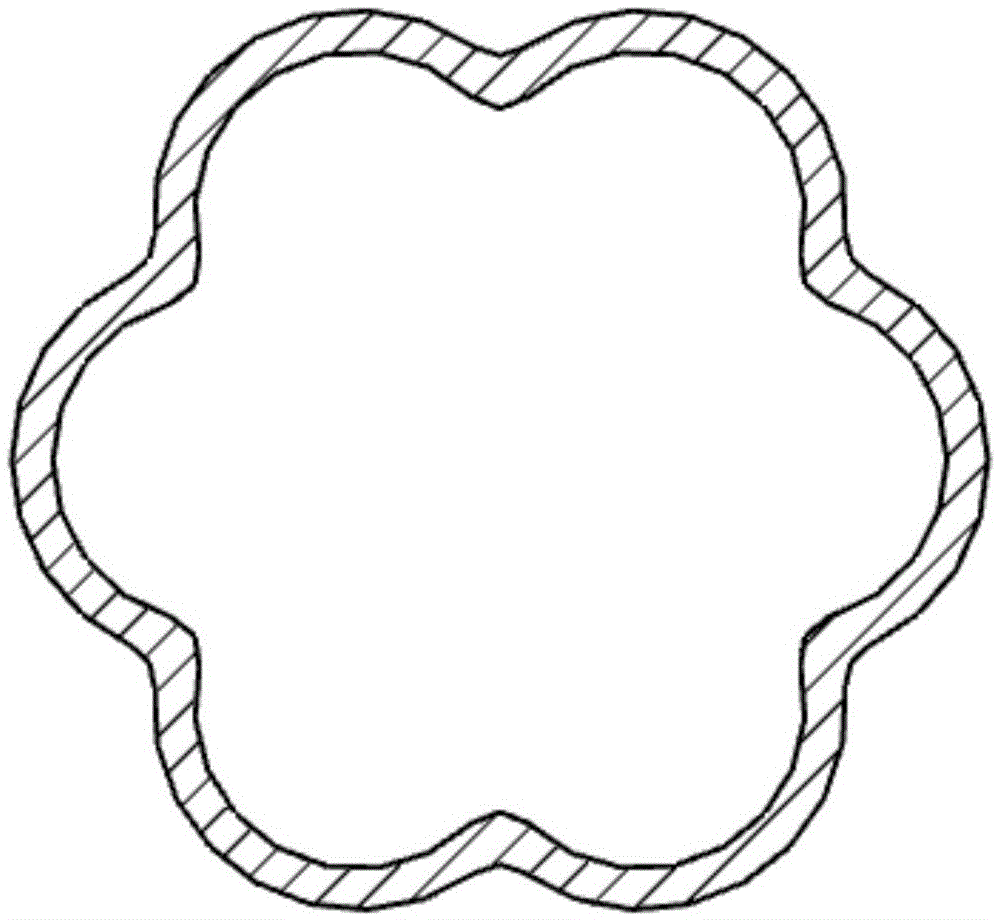

Petal-shaped wall surface evaporating pipe for micro combustion chamber

InactiveCN105546581AThorough atomizationIncreased wall areaContinuous combustion chamberCombustion chamberMicro-combustion

The invention provides a petal-shaped wall surface evaporating pipe for a micro combustion chamber. According to the pipe, the atomization quality of fuel in the micro combustion chamber can be improved, and distribution of temperature in the combustion chamber can be effectively improved. By changing the shape of the wall surface of the evaporating pipe, the contact area between the pipe wall and high-temperature gas in the combustion chamber is enlarged, the heat exchange effect is improved, and the atomization effect of the fuel in the evaporating pipe is improved. By reasonably designing the arc-shaped transitional curved surface, the heat stress exerted on the evaporating pipe in high temperature can be effectively reduced. The evaporating pipe has the advantages that simple improvements are carried out on the design basis of traditional evaporating pipe structures, the problem that atomization in the micro combustion chamber is insufficient is solved, and the shortcoming that distribution of the heat stress is not uniform is overcome.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

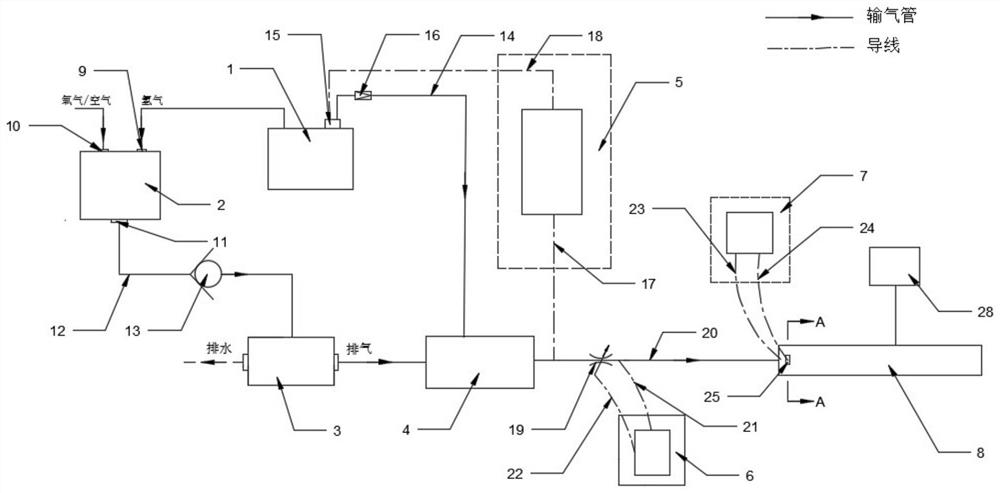

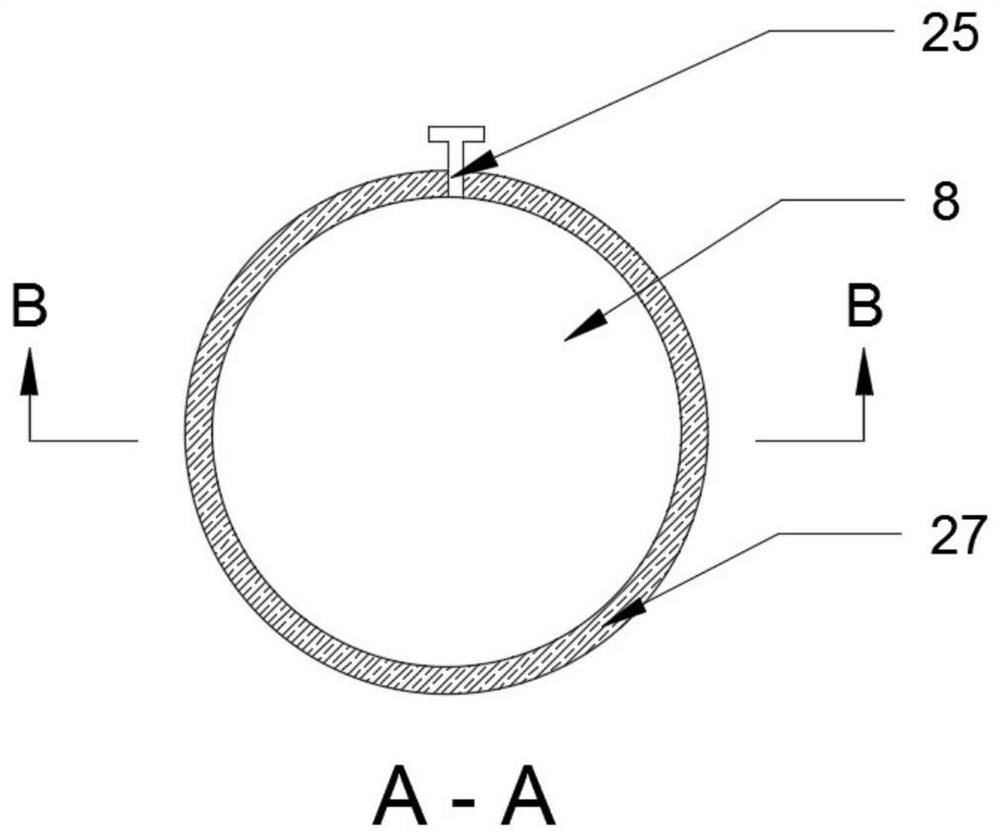

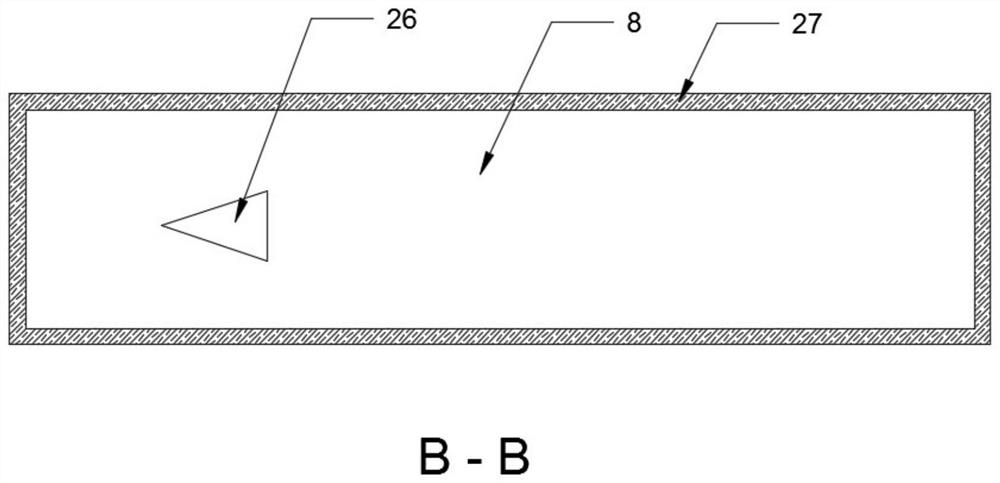

Hydrogen fuel cell tail gas aftertreatment device based on catalysis and micro-combustion

The invention provides a hydrogen fuel cell tail gas aftertreatment device based on catalysis and micro-combustion. The hydrogen fuel cell tail gas aftertreatment device comprises a hydrogen production device, a hydrogen fuel cell, a tail gas filtering device, a gas premixing chamber, a gas concentration monitoring control system, an automatic ignition system and a micro-combustion chamber. A tailgas outlet of the hydrogen fuel cell is sequentially connected with a tail gas filtering device, a gas premixing chamber and a micro-combustion chamber in series through pipelines, and the tail gas filtering device is used for gas-liquid separation; the gas premixing chamber is connected with the hydrogen production device, and the gas concentration monitoring control system controls the hydrogenproduction device to supplement hydrogen to the gas premixing chamber according to the hydrogen concentration of an outlet of the gas premixing chamber. An ignition device is arranged in the micro-combustion chamber, and the automatic ignition system controls the ignition device to ignite according to the temperature in the micro-combustion chamber; and the micro combustion chamber is externallyconnected with power equipment or a power generation system. According to the invention, the efficient utilization of hydrogen, oxygen and heat in tail gas can be realized.

Owner:JIANGSU UNIV

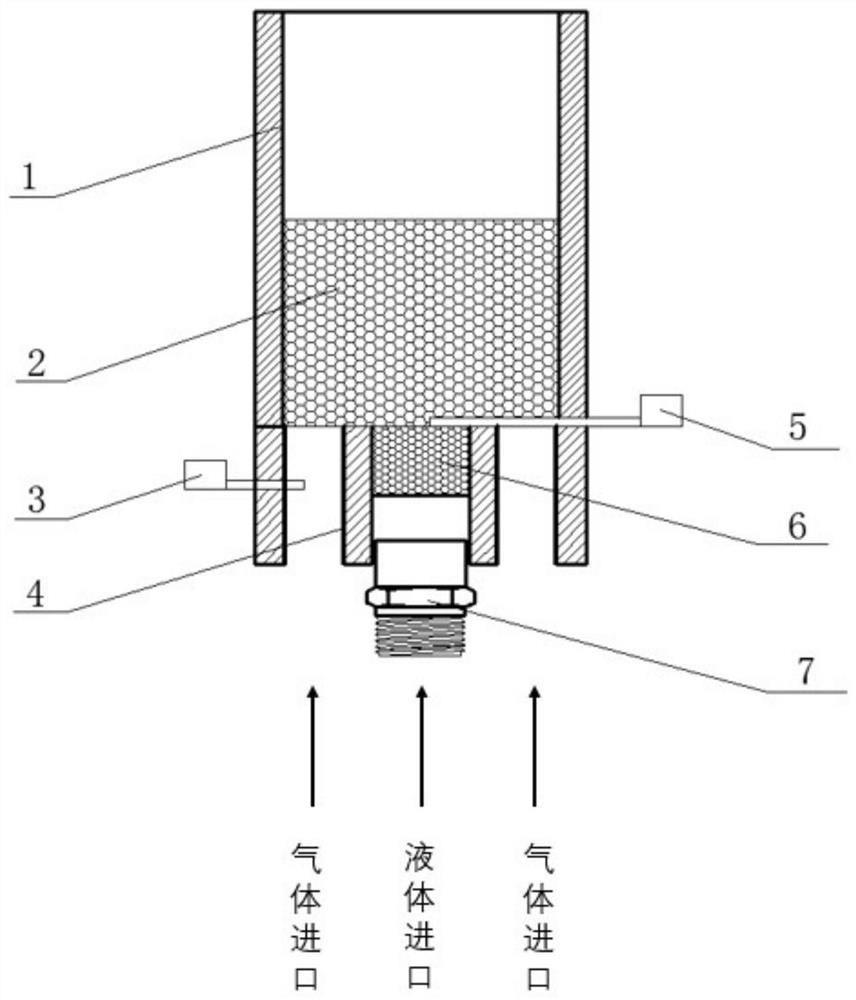

Liquid fuel burning micro-combustor applied to micro-thermal photoelectric system

PendingCN112555818AImprove conversion rateImprove combustion efficiencyCombustion using catalytic materialCombustion apparatusCombustion chamberMicro-combustion

The invention provides a liquid fuel burning micro-combustor applied to a micro-thermal photoelectric system. The micro-combustor comprises feeding channels and a combustion chamber, wherein the feeding channels are positioned at inlets of the combustion chamber and comprise a gas fuel channel and a liquid fuel channel, the gas fuel channel surrounds the liquid fuel channel, a first igniter is arranged in the middle of the gas fuel channel, a second igniter is arranged at the junction of the liquid fuel channel and the combustion chamber, and the gas fuel channel is ignited through the first igniter for preheating the liquid fuel channel. By using the gas and liquid dual fuel inlets, two fuels are effectively and fully premixed, so that the combustion is more stable, by using the gas and liquid dual fuels, the energy conversion efficiency is improved, so that the combustion is more sufficient, and meanwhile, the emission of pollutants such as NOX in the combustion product is reduced.

Owner:JIANGSU UNIV

Pre-mixing micro-catalysis combustion chamber with low heat loss

InactiveCN103712211AReduce convective heat lossImprove photoelectric conversion efficiencyIndirect carbon-dioxide mitigationGaseous fuel burnerCombustion chamberHeat conducting

The invention relates to a micro power system, in particular to a pre-mixing micro-catalysis combustion chamber with low heat loss. A clapboard which is excellent in heat-conducting performance is placed in the micro combustion chamber; the combustion chamber is partitioned into a preheating region and a combustion region; the clapboard is made by bonding a thin copper sheet, a platinum catalyst and a porous copper sheet. Mixed gas is preheated before being ignited, thereby reducing outward heat loss due to radiation, enhancing the flame stability and raising the average temperature of a wall surface.

Owner:JIANGSU UNIV

Dual-cavity annular micro burner based on Swiss roll structure

ActiveCN111623349AExtended flame stability limitImprove combustion efficiencyIndirect carbon-dioxide mitigationGaseous fuel burnerCombustion chamberMicro-combustion

The invention belongs to the technical field of micro scale power generation, and particularly discloses a dual-cavity annular micro burner based on a Swiss roll structure. The micro burner comprisesa first burning structure and a second burning structure; the first burning structure comprises a first air inlet passage, a first rectification cavity, a first burning chamber and a first air outletpassage which communicate with each other in sequence; the second burning structure comprises a second air inlet passage, a second rectification cavity, a second burning chamber and a second air outlet passage which communicate with each other in sequence; the first burning chamber and the second burning chamber are inversely and symmetrically arranged on the upper side and the lower side of the center of the micro burner, so an inlet end of the first burning chamber is adjacent to an outlet end of the second burning chamber and an outlet end of the first burning chamber is adjacent to an inlet end of the second burning chamber; and the first air inlet passage is adjacent to the second air outlet passage and the first air outlet passage is adjacent to the second air inlet passage. Throughthe arrangement of dual burning cavities which are inversely and symmetrically arranged and an annular pre-heating passage, energy required for ignition can be lowered, ignition delay duration is shortened, and the inlet speed is increased.

Owner:HUAZHONG UNIV OF SCI & TECH

Device and method for sectional type thermal remediation of organic contaminated soil

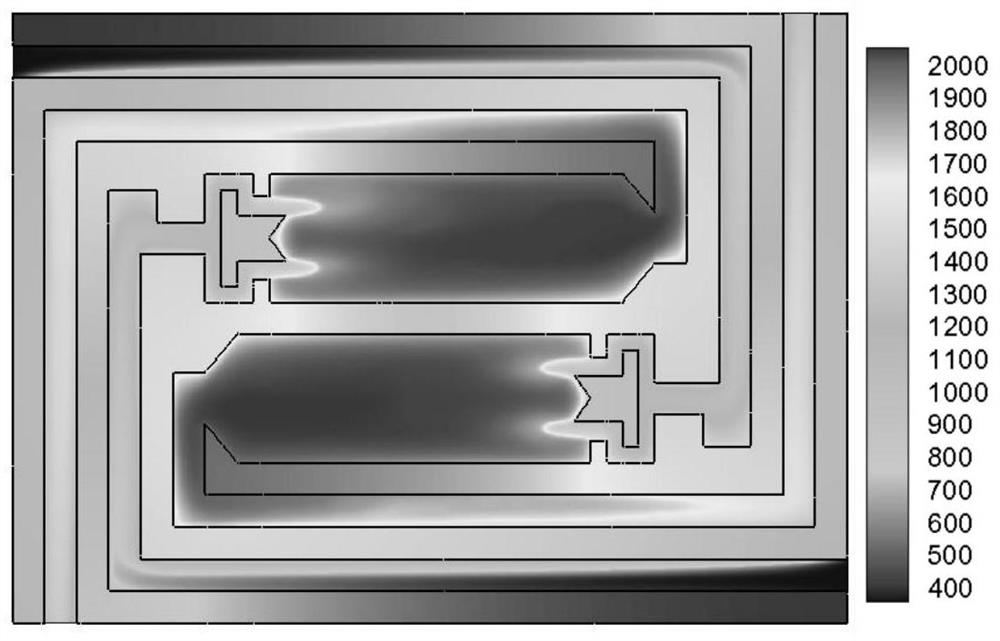

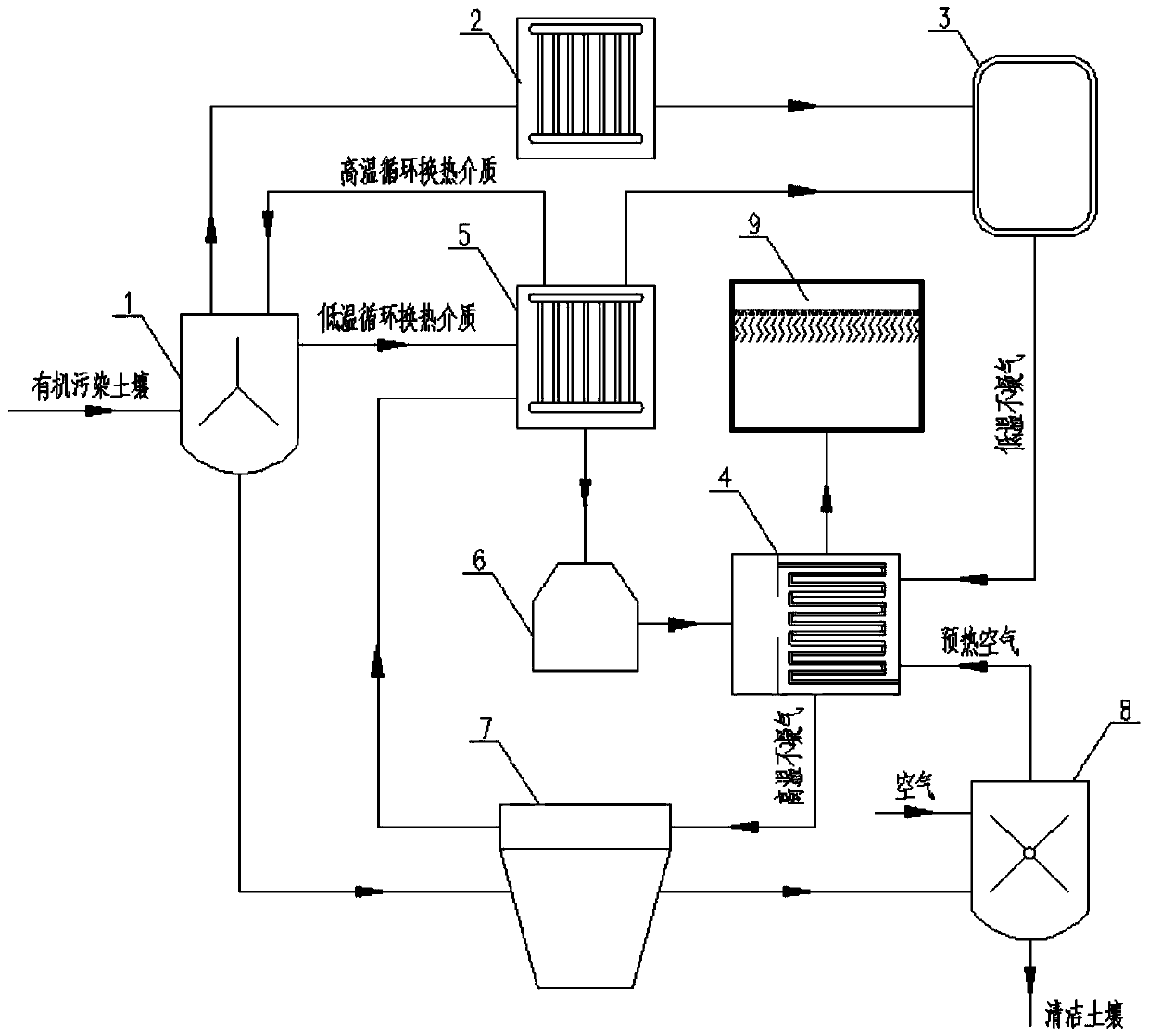

ActiveCN111346908AIncrease moisture contentHigh viscosityContaminated soil reclamationEdaphicThermal desorption

The invention relates to a device and method for sectional type thermal remediation of organic contaminated soil, and belongs to the field of soil remediation. Organic contaminated soil is fed into astirring type preheating device and indirectly exchanges heat with a circulating heat exchange medium in the device, the organic contaminated soil is continuously stirred and heated, moisture and light organic pollutants in the soil are separated out in the heating process and are condensed by a condensing device A and then fed into a non-condensable gas storage tank to be stored; the preheated soil is fed into a thermal desorption device and is subjected to direct contact type heat exchange with high-temperature non-condensable gas from a combustion heat exchanger; the preheated soil is heated to a higher temperature; residual organic pollutants in the soil are subjected to a thermal desorption reaction; a desorbed gas product is fed into a condensing device B to be condensed, condensateenters a condensate storage tank, high-temperature soil obtained after thermal desorption is fed into a granular bed air cooling device, residual trace organic matter in the high-temperature soil andoxygen in the air are subjected to a micro-combustion reaction and cooled by the air, and finally the soil is discharged in a low-temperature clean soil mode.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com