Micro thermal optoelectronic system cooled based on loop heat pipe principle

A micro-thermal photoelectric, loop heat pipe technology, applied in photovoltaic power generation, photovoltaic modules, electrical components, etc., can solve the problem of not adapting to the increasing energy density of the system, and achieve the expansion of stable combustion limits, reduction of heat loss, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

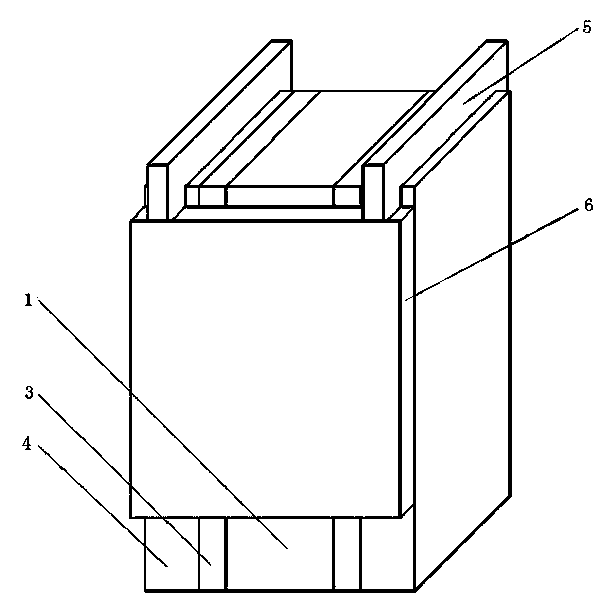

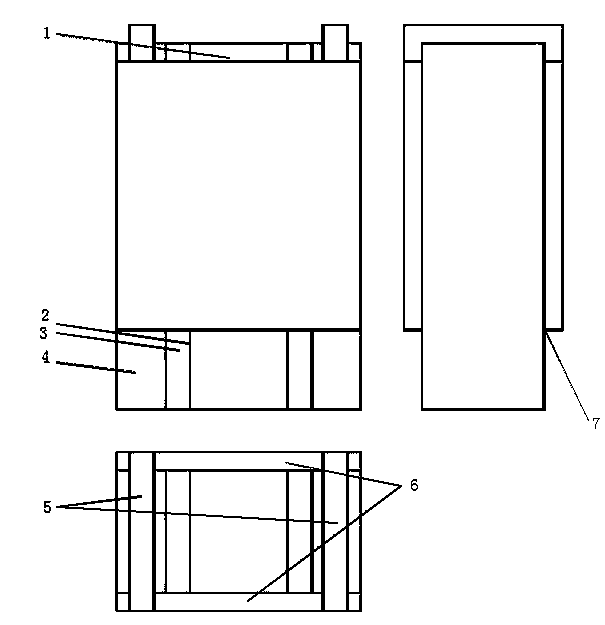

[0017] figure 1 , figure 2 Shown are a perspective view and a three-view view of the present invention respectively. The present invention is made up of micro burner 1, photoelectric conversion system and photovoltaic cell cooling system, and photoelectric conversion system is positioned at the both sides of micro burner 1, is made up of photovoltaic cell 3, and photovoltaic cell cooling system is positioned at the outside of photoelectric conversion system, consists of micro evaporator 4, Composed of steam pipeline 5, micro condenser 6 and liquid pipeline.

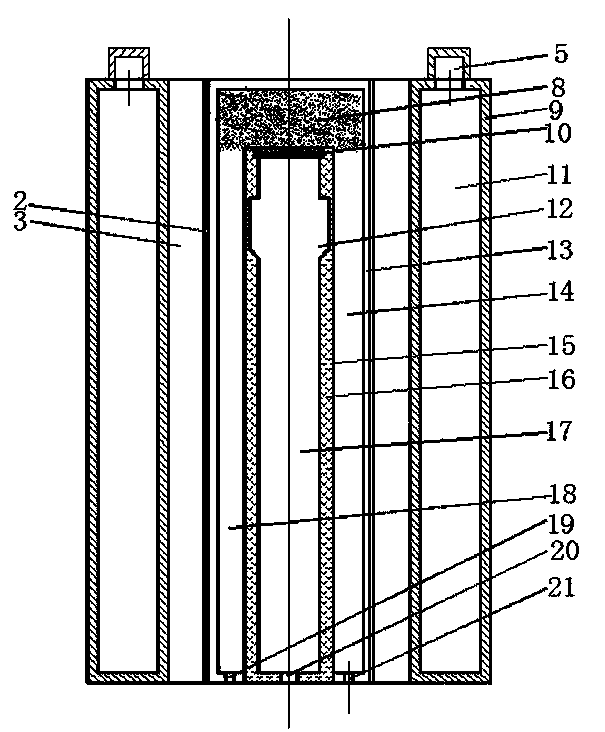

[0018] figure 2 It is a plane structure diagram of a micro burner 1, a glass heat insulating layer 2, a photovoltaic cell 3, and a micro evaporator 4. The micro burner 1 is made of a glass cover 13 sealingly wrapping a micro combustion chamber 17 . The micro-combustion chamber 17 is composed of a micro-combustion chamber shell 16 and a top plate porous medium panel 10 . The glass cover 13 bottom plates are flat wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com